Page 1

Installation instructions

Gas hobs

The fitting of the appliance should only be carried out by a authorised person/licensed gasfitter. Please read the safety regulations.

See the data plate for information regarding the total gas consumption, gas type and gas pressure.

Preparations for installation

Pictograms used

Important information

Gas connection

Electrical connection

05

1/2” ISO 228 / 1/2" ISO 7-1

The gas connection must comply with national and local regulations.

The hotplate can be connected with rigid pipe as specified in

AS/NZS 5601.1current edition.

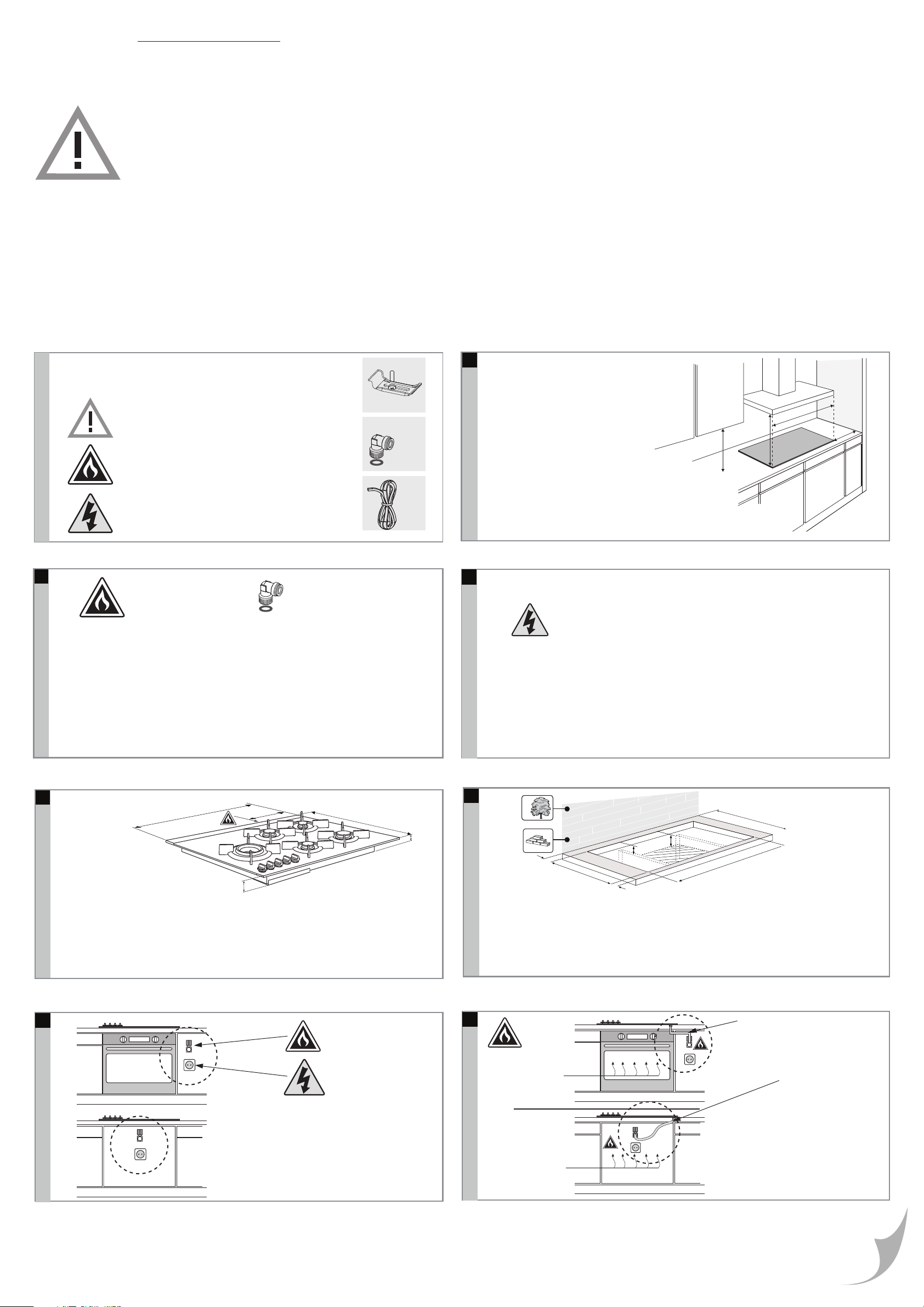

Free space around appliance

Rangehoods and exhaust fans shall be

installed in accordance with

manufacturers instructions.

For an overhead exhaust fan A>750 mm!

C

A (mm) B (mm) C (mm) D (mm)

HG11 min. 650 min. 900 min. 450 min. 120

HG13 min. 650 min. 600 min. 450 min. 120

HG16 min. 650 min. 600 min. 450 min. 120

HG18 min. 650 min. 750 min. 450 min. 120

HG19 min. 650 min. 900 min. 450 min. 120

240 V - 50 Hz - max. 20 W

This appliance must be earthed

The electrical connection must comply with national and local regulations.

B

A

D

When the appliance is connected with a hose assembly,

the supply point shall be accessible with the appliance installed.

A

E

C

A (mm) B (mm) C (mm) D (mm) E (mm)

HG11 1114 412 48 48 387

HG13 330 522 48 48 75

HG16 644 522 45 45 69

HG18 794 522 45 31 440

HG19 904 522 45 45 517

B

D

F

E

E/F

C

D

H

G

A

B

A (mm) B (mm) C (mm) D (mm) E (>mm) F (>mm) G H

HG11 600 1070 380 60 30 50 55 100

HG13 600 290 490 60 30 50 55 100

HG16 600 560 490 60 30 50 50 100

HG18 600 750 490 60 30 50 50 100

HG19 600 860 490 60 30 50 50 100

oven

Accessibility!

y

>60º C

<60º C

x

oven

Y:

metal

y

Gas supply valve

shall be accessible

x

X:

safety hose

Gas supply valve

shall be accessible

Page 2

Placing sealing tape

For stainless steel drip tray

Gas connection

05

05

C

Worktop

For glass drip tray

C

hob

C

1/2“ ISO 228

1/2“ ISO 7-1

PTFE tape

1/2“ ISO 7-1

PTFE tape

HG13/HG16/HG18/HG19

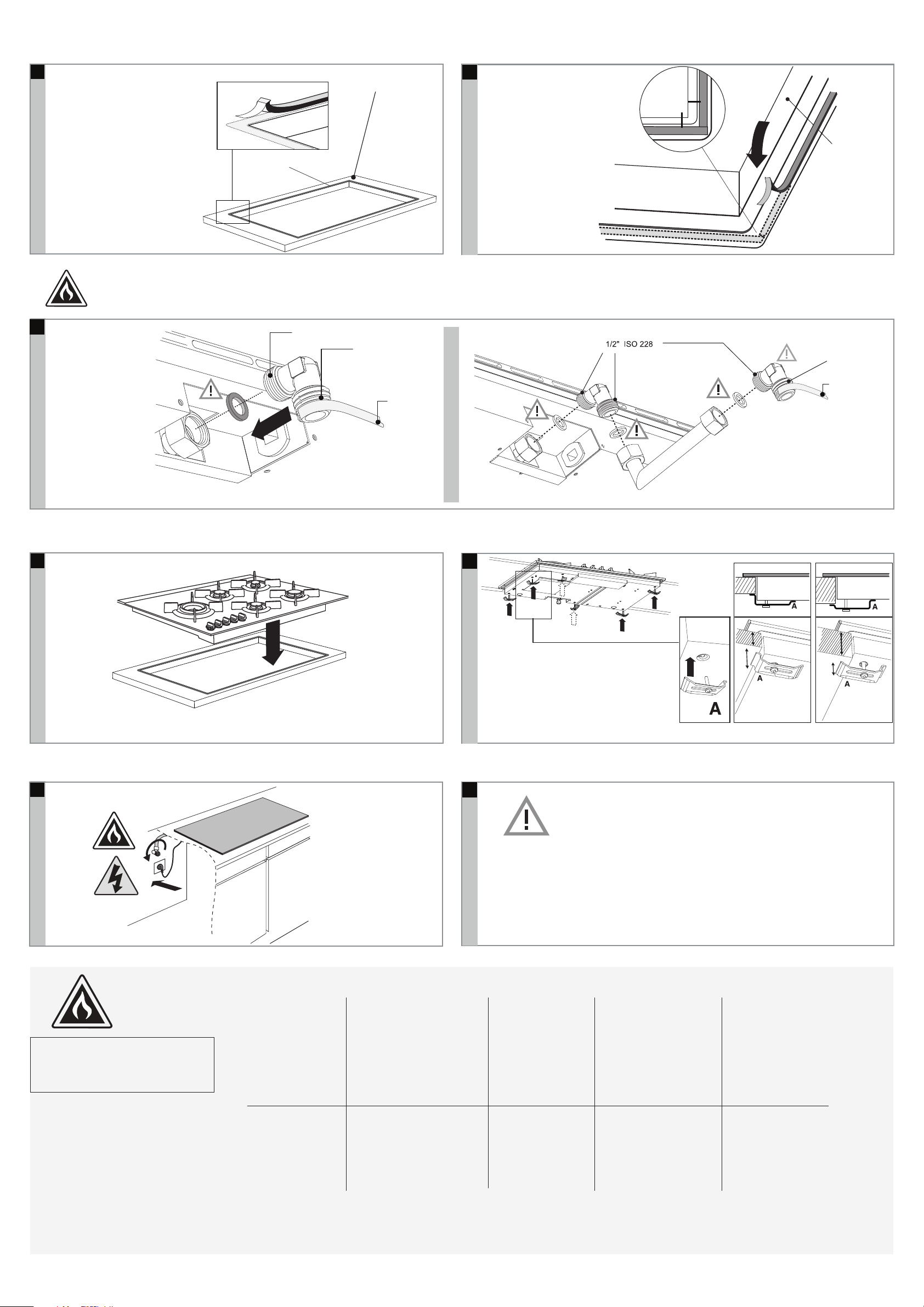

Building in

Connecting and testing

05

Fitting of appliance regulator

for Natural gas or test point

adaptor for LPG. Check and set

the gas pressure with appliance

operating!

HG11

Fitting of appliance regulator

for Natural gas or test point

adaptor for LPG. Check and set

the gas pressure with appliance

operating!

05

Simmer Normal Large Wok

HG11 - 2 - 2

HG13 - - - 1

HG18 1 1 1 1

HG19 1 2 1 1

Check that the connections are gastight.

Test the working of the appliance!

GAS BURNER INJECTOR BURNER (MM) ADJ. SCREW (MM) BURNER RATE (MJ/h) GAS PRESSURE (kPa)

N.G. Small 0.90 0.45 3.60

Medium 1.20 0.60 6.70

Large 1.35 0.65 8.50 1.0

Wok (inner) 1.20 + 0.66 0.60 8.80

Wok (outer) 2.10 + 0.66 0.60 19.70

ULPG Small 0.48 0.26 3.05

Medium 0.66 0.30 5.80

Large 0.77 0.36 7.30 2.75

Wok (inner) 0.63 + 0.40 0.34 7.50

Wok (outer) 1.00 + 0.40 0.34 14.80

700005540100

Loading...

Loading...