Page 1

How

tumble

to

use your

dryer

Page 2

Instructions for use

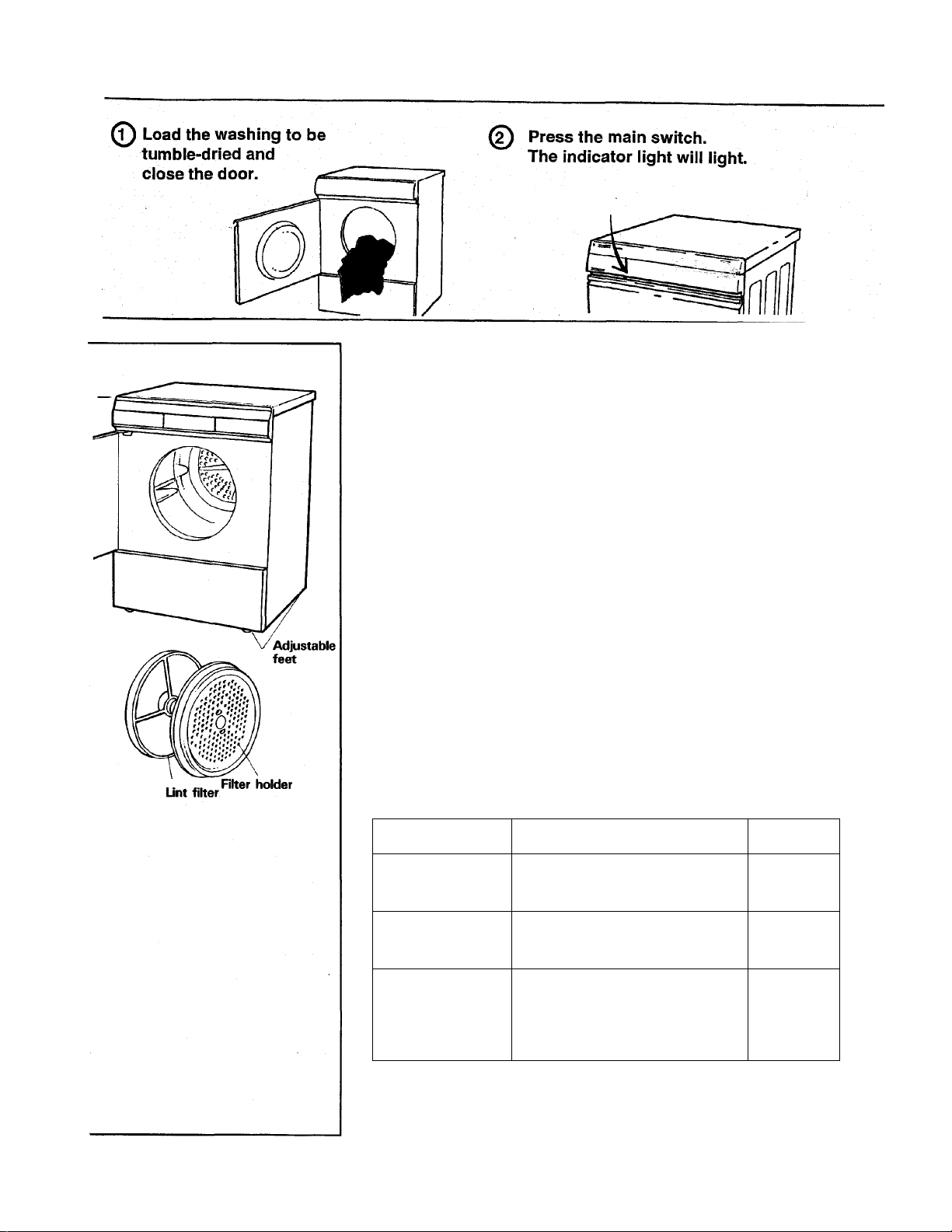

Follow the figures In the strip

through these instructions for a

brief summary of how to use the

machine. Further details and

hints are given below the strip.

Page

Instructions for use....................................... 2

Parts of the tumble dryer

Sorting fabrics

Which program to use?

What the control buttons do

Cleaning the lint filter.................................... 6

If the machine does not work .... 6

Specifications

Electrical Installation

Installation

To change the door opening

Safety

...........................................................

Warranty....................................................... 11

Instructions summary................................. 12

...............................................

................................................

.................................................

..............................

................................

.....................

....................................

...................

10

4

8-10

11

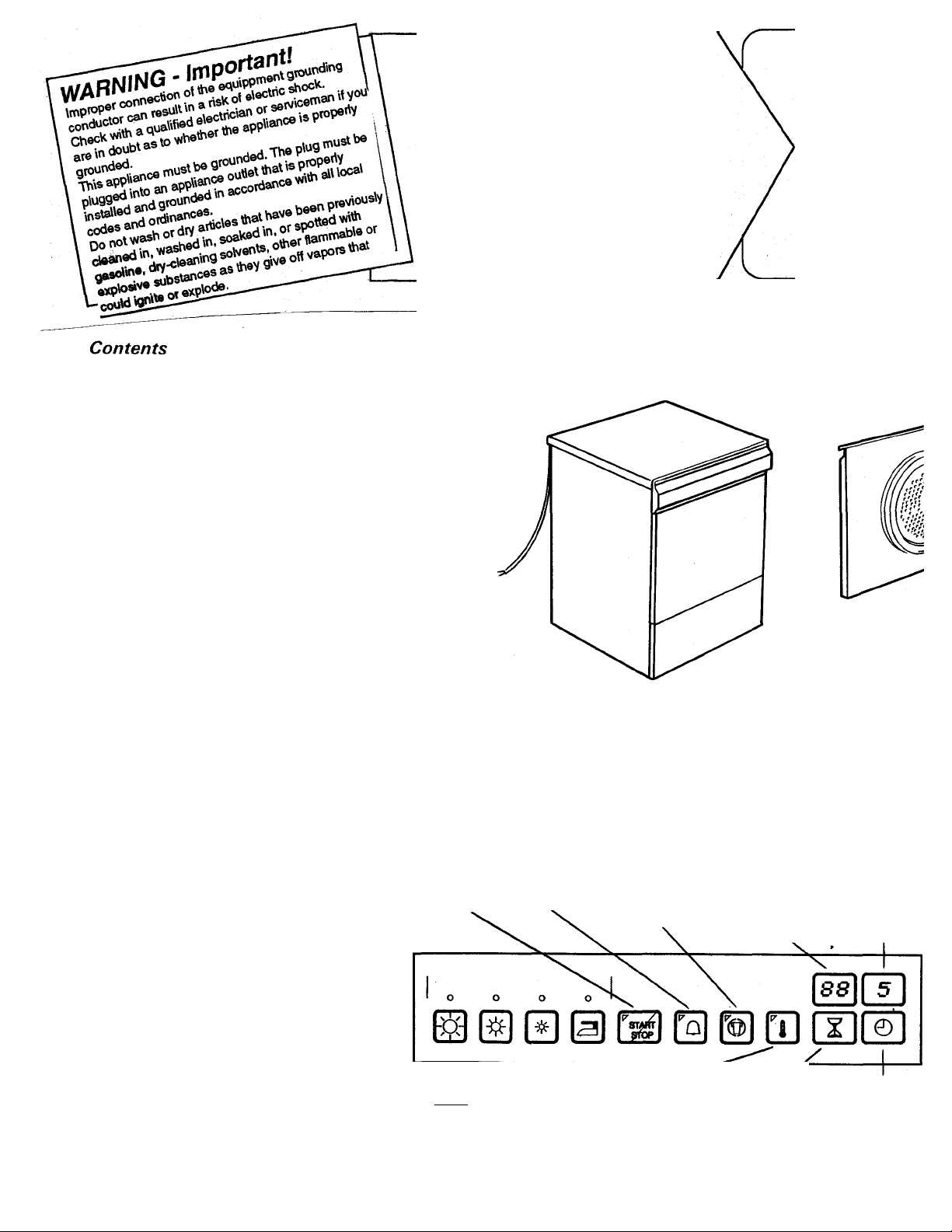

Parts of the tumble

dryer

2

3

4

7

7

Main electric

supply cable

Isee P. 11)

Indicator light

which illuminates

when the main

switch is on.

NOTE!

Items to be tumble-dried must first

have been spin-dried, preferably at

800 rpm or more.

Control panel

Start/Stop Buzzer

Select dryness

Cycle

Extra Dry

Dry (normal program)

Damp Dry

Iron Dry

Intermittent

action

AntICrease

Temperature

selection

Low temp. 50°C

Number of

minutes left

of timed

program

Setting

of timed

program

Number <

hours

delayed

start

Selecta

delayed

start

Page 3

Sorting fabrics

For the best drying results, clothes should be sorted properly. Separate the

lint shredders (chenille and terry cloth) from the lint collectors (synthetics,

flannel and fabrics with a nap, such as velveteen and corduroy). Separate

non-colorfast from light colored items, heavy fabrics from light weight

fabrics and permanent press from heavy, bulky items.

Do not tumble dry

Read all permanent care labels carefully. If a garment's care label

says "Drip Dry", "Line Dry" or "Dry Flat", do not dry in the dryer. Certain

materials will melt or become dangerously flammable if heated, while others

may lose their shape. Other items that should not be tumble dried are;

• Items that have been dry-cleaned at home

• Wool (unless the garment's manufacturer recommends it)

• Fiberglass

• Laminated or rubber coated items

• Vinyl and plastic

• Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

Do not allow children to play on or in the appliance. Close supervision of

children is necessary when the appliance is used near children.

Type of wasing

White wash and

coloreds

(cotton, linen)

Synthetics

Permanent press

(polyester, cotton)

Delicate fabrics,

hand-washed items

Temperature-sensitive

materials such as

acrylic, rayon, acetate

Recommended Load Size

Suitable for washing equivalent to a

FULL load from an Asko

washing machine

Suitable for washing equivalent to a

HALF load from an Asko

washing machine

Suitable for washing equivalent to a

HALF load from an Asko

washing machine

Temp

Normal

Normal

Low

Page 4

3 Select

or

4 Select dryness

Automatic program

Timed program

4 Press the hour-glass button until

QQ

oo

you can see the required time in

the window.

I

Which program should I use?

The program to use depends on what you want to do with the washing after tumble-drying. There are four automatic programs

- Extra Dry, Dry, Damp Dry and Iron Dry - and a timed program, allowing you to determine the drying time yourself.

The pushbutton controls

Extra dry: When you want extra dry fabrics: This automatic program is intended for use with washing that

is extremely difficult to dry, i.e. jeans with very thick seams. The heat is turned off when the washing is

completely dry, and is followed by a cooling period of about 15 minutes.

Dry: For "ready-to-wear" dryness: This program turns off the heat when the washing is dry but not absolutely

bone-dry. It is then cooled for about 15 minutes. This is the program to use when you want dry fabrics.

Damp Dry: This program is intended to leave a small amount of moisture in the clothes to allow small wrinkles

to fall out when hung-up.

Iron Dry: For fabrics to be ironed: This program turns off the heat when the washing is just damp enough

for ironing.

Program Start/Stop: You can stop any program at any point by pressing the Stop pushbutton for three seconds.

End of Cycle Signal: Press this button for a warning buzzer to sound when the program is finished. One hour

after the end of the program the buzzer will sound once a minute. At the same time the cylinder will rotate

to prevent wrinkling.

Anti-Crease: To help prevent wrinkles, this cycle enables the machine to tumble for three seconds every minute

for one hour, or will stop if the clothes are removed before the hour has ended.

Low Temp: Use this button if low temperature is required.

m

Setting the time for the timed program; Press the TIME pushbutton. The machine responds by displaying

5 minutes in the window. By pressing the time pushbutton, you can increase the time in 5-minute intervals

10-15-20. After 20 minutes, the time increase is by 10 minute-intervals 30-40-50-60-70-80-90. All timed

programs are followed by an automatic 15 minute cool down period.

The timed program is automatically set for low temperature. However, normal can be used by pushing the

low temperature button one time. The light in the button will go out signifying normal temperature.

To air fabrics; Use the unheated program, which you obtain by pressing the time pushbutton until C appears

in the display. This program can not be combined with any other program. Use this program to shake the dust

out of garments, or to fluff them up.

Time-delayed start: Press thel ^ Ipushbutton to set a starting time delay of 1-12 hours. Each time you press

the button, a further hour’s delay will be added and displayed.

Page 5

5 Select other options:

6 Select a delayed

start

7 Press START

Warning

buzzer

Û

Program deh

Automatic

programs

Timed

program

Airing

program

Intermittent

action

ills

Load**

Full load

Half load of

temperaturesensitive

fabrics

Low tempera

ture (50°C)

m

Program

Extra Dry

Hmn"' Dry/Damp Dry

Ironing Dry

Extra Dry 1.3 1.4

tamo. Dry/Damp Dry

Ironing Dry

&-90mln

C

Energy

Conaumptlon*

2850 W 1900 W

3,1

2,9 / 2,8 3,2/3,0

2,S

1.2 1.3

1.1

0.3-4.5 0.2-3.0 50°C

0.05 0.05

3.4

2,8

1.2

Max. temp.

60°C

50“C

STJ

’ Times and energy consumptions are as obtained by the methods specified by the Swedish National Board for Consumer

Policies, i.e. the washing has been spin-dried at 800 r/min and the tumble diyer is in a ventilated room at a temperature

of 20°C (68°F).

’* Refers to full and half loads from the Asko washer.

Drying time

Drying time depends on many factors, such as

the amount of washing, how damp it is, the type

of fabrics, rated power of the machine and the

temperature of the room. It also, of course,

depends on how dry you want the washing when

you take it out of the machine.

Shrinkage

Knitted fabrics in particular are liable to shrink.

Do not use Extra Dry program for these materials,

and always stretch them out directly after drying.

Dryer Added Fabric Softeners

Because some dryer added fabric softners may

cause damage to automatic dryers, use only ones

that the manufacturers give a written assurance

that their softener can safely be used in

your dryer.

Single items

Use the timed program when there is only one

item to be dried. This is because the automatic

program may turn off the heating too early, so

that the item is not properly dried.

If the washing is not dry after tumble-drying

When using the automatic programs, it can happen that not

all of the washing is properly dry. This may be due to such

reasons as very heavy fabrics or thick seams. To dry these

items, give a further 10 minutes or so in the timed program.

Also, do not overload the dryer. If a dryer is overloaded, its

efficiency is lessened and clothes may not dry evenly.

Do not over-dry

When using the timed program, it is possible to over-dry

fabrics, if too long a time has been set. This can cause the

fabrics to wrinkle, shrink or feel harsh. Synthetic materials

can also become charged with static electricity.

Permanent press hints

For the most wrinkle-free permanent press drying, only dry

one half load at a time to assure enough room for items to

tumble freely. Do not combine permanent press items with

other very heavy clothes in the dryer. Remove clothes

immediately after the dryer cycle is completed and either

hang them up or lay them flat.

Page 6

8 If you want to load

more washing:

(If the door is open for

more than three minutes,

the machine will "forget"

the preset program, and

you must re-enter the

program you want.)

Open the door.

The drum will stop auto

matically. Close the door

to restart and press

the START

pushbutton. ^

____

START

STOP .

If you want to alter the program:

*Press START for three seconds.

This stops and cancels the program

that is running and you can then

set the new program that you want.

9 When the machine has

stopped:

• Remove the washing

• Clean the lint filter

• Turn off the main switch

Cleaning the lint filter

The lint filter must be cleaned

after each time the machine has

been used. If this is not dona

drying performance will suffer, as

insufficient air will pass through

the drum. The machine may also

overheat: this will cause it to stop

utomatically.

Clean the filter as follows;

1. Grasp the filter holder by the

two holes near the center and

pull it off the peg on which it is

supported in the front door.

2. Take the filter out of the holdei

and brush away the lint in it by

hand.

NOTE; Wear and tear of fabrics

in a tumble dryer is insignificant.

The lint caught in the lint filter is

dust and fiber residue that has

been formed when the garments

have been used.

3. Replace the filter in the holder

and refit the holder in position on

the peg in the door.

Note! Clean lint collecting near the tumble

dryer as it can be sucked into the

air intake.

NOTE:

When you start the dryer for the first

time, a slight rumbling may be heard

during a short warming-up period. When

the dryer is run-in, this sound will

disappear.

If the machine

does not work

The machine will not start

Check that:

* The front door is properly closed.

* The main On/Off pushbutton is pressed in.

* You have set the required program or the required time

correctly.

* The electric plug is firmly inserted in its socket.

* All fuses are intact.

H the machine still fails to start, it is probable that the

automatic safety cutout has operated, h disconnects the

power supply to the machine if the internal temperature

rises excessively, i.e. if the lint filter is blocked by dust.

Start by cleaning the filter, emptying the water container

and cleaning the condenser. Reset the cutout by pressing

the button on the back of the machine.

Excessive drying time

Check that the lint filter is not blocked. Excessive drying

times can also be caused by the machine being installed in

a very small space and by the air in the room (which cools

the machine) becoming too warm. Make sure that the

machine has a plentiful supply of cool air. Do not overload

the dryer. Hems to be tumble-dried must first have been

spin-dried, preferably at 800 r/min or more.

Fauit indication

The display window that shows the number of hours of

delayed start can also display fault message:

F2 - When the machine has run lor a maximum time of 3

hours, it will stop automatically. Check that the fuse

is intact. This fault indication can be indicating when

running a small terry load. Always use Timed

Program or Automatic Program Damp Dry by this

type of load.

F3 - This indicates an electric fauH. Phone for service.

F4 - Indicates a clogged fluff fiHer. This code will appear

after the program has finished. Be sure to remove

fluff fiHer and clean before running the next load of

clothes.

F5 - Indicates a fauH whh the moisture sensor. Call for an

Authorized Asko Service Agent.

Page 7

Specifications

Height 32 1/4" (820 mm)

Width 23 1/2" (595 mm)

Depth

Weight

Drum volume 29.3 gallons (111 1)

Speed

Power

requirement

For connection

as supplied

Heater power Single-phase,

Air flow

Drum material Stainless steel

Outer casting Galvanized steel

Installation Free-standing, built-

plus exhaust

connection

23 1/2" (595 mm),

including control

panel and program

knob

86 lbs. (39 kg)

52 r/min

3150 W

Single-phase, 15 A

2850 w

65-78

cubic yds./hr.

(50-60 m^/h)

sheet

in or on top of a

washing machine

Electrical

Installation

Electrical installation must be

carried out by a skilled electri

cian. As supplied, the machine is

arranged for single-phase.

Connection as delivered:

1-phase, 208/230 V,

heater power 2850 W,

15 A fuse required.

NOTE: Follow all state and

local codes.

To install washer/dryer into a single

30A 208/240V wall receptical:

1. Remove top of washer - by

removing three 25 torx screws.

2. Using power cord attached to

dryer, thread through power cord

restraint on washer. Attach to

terminal block on bulk head.

NOTE: This should be at the top of

the terminal block.

3. Remove knock-out plug on bulk

head of washer. Install dryer cord

30A 250V AWG 10/3 through

knock-out to terminal block.

4. Replace top to washer and

test units.

Drying times and energy consumption

Drying times and

energy consumption

The table on the right shows drying

times and energy consumption in

accordance with the following

conditions:

• Program 2 has been used

(the normal, 'Dry' automatic

program).

• Drying temperature: Normal.

• Fabrics dried are of cotton,

previously spun at 800 r/min.

• The dryer is in a room with a

temperature of 20°C (68°F), and

the exhaust hose supplied with

the machine is in use.

Drying times

Drying time depends on many factors,

such as the amount of washing,

moisture content, type of fabric,

incoming air temperature and

humidity. Performance can also be

affected by how the machine has

been installed. Drying time is also

naturally affected by how dry the

washing is to be when removed from

the machine.

Connection to a ventilation duct

Connect the exhaust hose from

the tumble dryer to a ventilation

exhaust fitting or to a discharge

through the wall.

Secure the hose joint to the Outlet

stub on the machina

Run the hose with as few bends as

possible to the point of discharge. If

necessary, it can be extended to a

maximum of 8.75 yards of 4"

diameter hose.

Make any bends as gentle as possi

ble. A maximum of four 90° bends

may be fitted in the hose. The more

bends and the longer the hose, the

less will be the amount of air pass

ing through the machina

If more than 8.75 yards of hose is

needed, diameter must be increased.

If the hose is taken to a wall outlet,

a ventilation grille should be fitted to

prevent reverse flow of cold air.

IMPORTANT:

The appliance should

not be exhausted into

a chimney, a wall, a

ceiling, or a concealed

space of a building.

The only rigid of flexible metal duct should be

used for exhausting, unless the appliance has

been investigated for use with nonmetallic duct.

Ventilation

grille

Fit the

ventilation

grille to

the inside

or outside

of the wall

Page 8

Installation

Positioning the tumble dryer

B Built in

The dryer can be built in beneath a

countertop with a height of 33 1/2

- 35 1/2”. At least 23 5/8" width

is needed. Space must also be

available for the exhaust hose on

the left, right or rear of the

machine. See tlte diagram for

hole sizes and positions.

NOTE:

Height Adjustment:

32 1/4" - 33 1/2”

Do not Raise Higher

than 33 1/2”

How much air does

the dryer need?

The dryer needs about 65 cubic yds.

of fresh air per hour. The room in

which it is installed must therefore

have a sufficient air change rate to

ensure that the machine receives

enough fresh air.

-----

5 1/2" K

4 23/32"

, ^ , Diameter of hole,

^

Page 9

C. stacked Installation

The dryer can be mounted on top of

any ASKO matching washing

machine. Use the mounts supplied

with the tumble dryer.

These parts are supplied with the tun^ie dryer:

2 metal brackets for

securing the tumble

dryer

2 plastic cups

How to install the tumble dryer

on top of a washing machine

1. Remove the screws shown

from the back of the washing

machine, and use them to

secure the two brackets.

The edge of the Si^ of the top panel

2. Rx the plastic cups which locate front feet of the turróle

dryer on top of the washing machine. This is important,

as they ensure that the machine is safely positioned on

top of the washing machine. Break off te^ A on the

plagie cup to be fitted on the right-hand side of the

machine, and tab В from the cup to be fitted on the lefthand side of the machine. Remove the |»x^ective paper

from the self-adhesive surface beneath the cups.

Taldng care not to press the exposed acRteshre surface

3. Lift the tumble dryer into position,

raise the front edge and push the

machine backwards until it engages

Lower the front of the dryer,

making sure that its feet drop

into the plastic cups.

with the brackets.

against the top of the washing machine, so that

the cups fasten before being properly located,

posttion the cups so that the tad» indicated by the

arrows (see right-hand drawing) locate the cup

exactly with respect to the front and sides of the

machine. When the c^>s are properly posttbned

as shown, press them firrrdy down on to the top of

the washing nrachine. Finish by breaking off the

plastic tabs, which have now served their purpose.

Tumble

dryer

Washing

machine

\

Page 10

Changing the door hingeing...

Switch off the main power supply first!

Tools: Phillip screwdriver, 10 mm wrench.

1. Remove the lower panel A.

2. Unscrew the upper screw B + C.

3. The upper hinge is now loose. Raise the door a little

so that it comes away from the bottom hinge.

Remove the top hinge.

4. Move the hinge pin J to the other hole in the hinge

using 10 mm wrench.

5. Push out the hinge bearings from the old holes in

the door.

6. Take the door apart by removing all screws which

are around the edge of the door.

7. Undo magnet cap D.

8. Remove the cover washer from the magnet position

E on the other side.

9. Screw the magnet tight at E (spring plus washer plus

screw) and insert cover washer in the hole at D.

10. Screw the door together.

11. Remove the plug from the new hole for the hinge at

the upper edge of the door at H. Insert this plug in

the old hinge hole.

12. Knock out the hole at the lower hinge hole K using a screwdriver. Insert the plug supplied in the old hinge hole.

13. Fit the hinge bearings in the new hinge hole.

14. Unscrew the lower hinge and move the hinge pin as shown in Item 5 above.

15. Remove the plastic protection at F and G and place this where the hinge was previously fitted.

16. Tighten the top hinge.

17. Screw in screw B for the bottom hinge a few turns.

18. Insert the lower hinge pin in the door hole. Place the door's top hinge hole on the upper hinge pin. Place the

door and the! lower hinge in position in screw B that has already been fitted. Screw in screw C.

19. Adjust the lower hinge so that the door hangs straight. Tighten screws B and C.

20. Refit the lower panel.

Air venting

There are three positions where the air evacuation

can be connected: at the rear, on the right hand

side and on the left hand side. When the machine is

supplied, one hole at the rear is open. The other

two are covered.

The tumble dryer is supplied with a stub pipe

and a plastic band. (A flexible hose must be

supplied by consumer.)

Fit the air evacuation as follows:

• Push the hose onto the stub pipe

and fasten with the plastic band.

• Remove the cover as necessary.

• Insert the stub pipe with

the hose into the hole.

• Fit the cover to the open hole.

WARNING — To reduce the risk of fire this appliance

MUST BE EXHAUSTED OUTDOORS or the equivalent.

10

If you want to change

the outlet:

• Remove the cover from

the hole where you wish

to fit the hose.

• Fit the stub pipe with

the hose connected

to it.

• Insert the stub pipe into

the new opening.

• Fit the cover to the hole

where the hose was

previously fitted.

Page 11

Energy saving hints

•Dry consecutive loads to avoid reheating

the dryer.

•Do not overload the dryer.

•Do not put unspun, very wet items in

the dryer.

•Clean the lint filter after each load.

•Do not over dry clothes when using the

timed program.

•If you plan on ironing items, remove them

while still slightly damp. Use the iron

drying program.

•Leave the door closed while the dryer

is in operation.

ASKO Product Warranty

Home Clothes Washers and Dryers

For Residential Installations

Length of warranty ASKO will pay for:

ONE YEAR FULL WARRANTY

From date of purchase

FIVE YEAR LIMITED WARRANTY

One year full plus second through fifth

year limited from date of purchase.

TWENTY-FIVE YEAR LIMITED

WARRANTY

One year full plus second through twentyfive year limited from date of purchase.

For Non-Residential Installations

SIX MONTHS FULL WARRANTY

FROM DATE OF PURCHASE

ASKO replacement parts and/or repair labor to correct defect in

materials or workmanship. Service must be provided, by an

authorized ASKO service outlet.

ASKO replacement parts (repair labor costs not included) for any

defective solid state controls, timers, motors, pumps.

ASKO replacement parts (repair labor costs not included) for the

stainless steel inner and outer drum/tub if it fails to hold water

due to a manufacturing defect such as cracking or rusting.

ASKO replacement parts and/or labor to correct defect in

materials or workmanship. Service to be provided by an

authorized ASKO service outlet.

The dryer must not be used to dry fabrics

which may contain residues of flammable

liquids.

The dryer door has a magnetic catch, which

means that it can be opened from the inside.

A door switch automatically stops the

dryer if the door is opened. The machine

does not start automatically if the door is

closed, i.e. if a child should get into the

drum and close the door from the inside.

In order to restart the machine, the Start

pushbutton must be pressed.

The machine is protected by a thermostat

fitted by the heating element, which turns the

machine off if the temperature is too high.

ASKO will not pay for:

A. Service calls to: 1.

B. Repair and/or parts for failure of product if washer or dryer is used in other than normal use.

C. Damage resulting from accident, fire, floods, acts of God, alteration, misuse abuse, improper installation

or installation not in accordance with local electrical or plumbing codes.

D. Any labor or shipping costs for parts during the limited warranty.

E. Replacement parts or repair labor costs for units operated outside the Continental United States.

F. Pick-up and delivery. ASKO products are designed to be repaired in the homa

IN NO EVENT SHALL ASKO INC. BE RESPONSIBLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states will not allow the exclusion or limitation of incidental or consequential damages, so this exclusion

or limitation may not apply to you. This warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

For warranty service, contact the dealer from whom you purchased the unit or an authorized ASKO service

outlet. Service will be provided during normal business hours. Should you have a service problem that is not

resolved locally write: ASKO USA INC.

Correct the installation of the washer or dryer

2.

Instruct how to use the washer or dryer

Replace house fuses or. correct housing wiring

3.

4.

Correct house plumbing

Cleaning or servicing of the button trap, outlet pump of the washer

5.

Cleaning or servicing of the lint filter or condensing unit of the dryer

6.

______________ ______

P.O. Box 851805

Richardson, TX 75085-1805

11

Page 12

How to use your tumble dryer

Load the washing to be tumble-dried and close the

door. Press the main switch.

Automatic programs

Choose dryness selection

Extra Dry

Dry (normal program)

Damp Dry

Iron Dry

Do not tumble-dry articles

marked with this symbol.

EXTRA DAMP IRON

DRY DRY DRY DRY

EI0H)

Select other options:

Press START

Warning buzzer

Intermittent action

Low temperature

Delayed start

Timed program

Set the required drying time by pressing the

hour-glass button. The time Is to be seen In

the display.

88

1

■'o

m

Clean the fluff filter

each time you have

used the machine.

[U

STOP

We reserve the right

to make changes.

If you want to load more washing:

* Open the door.

The drum will stop automatically.

* Load the extra washing,

close the door

and press START.

When the machine has stopped:

* Remove the washing

* Clean the lint filter

* Turn off the main switch

It is not permitted to make any

changes to the specifications of

the machine without the written

permission of the manufacturer.

Art nr 80 575 82

TD 73 - 7304

Loading...

Loading...