Page 1

Howto

Use

fumble

dryer

Important:

Read all Instructions before using the appliance.

The machine must be installed by a qualified

electrician.

WARNING-To reduce the risk of fire, electric shock, or

injury to persons, read the IMPORTANT SAFETY

INSTRUCTIONS before operaUng this appliance.

SAVE THESE INSTRUCTIONS!

your

Page 2

af®'*'

ided-

,»n««.s;:f„SS

been

aasofine. janees a®

aXp\os'''ef“° e^od®

Contents

Instructions for use 2

Parts of the tumble dryer 2

Sorting fabrics 3

Which program to use? 4

If the machine does not work 5

Cleaning the fluff filter 5

How the dryer works 6

Instructions for use

Follow the figures in the strip

through these instructions for a

brief summary of how to use the

machine. Further details and

hints are given below the strip.

Parts of the tumble dryer

Safety 6

Electrical installation 7

Specifications 7

Drying times

and energy consumption 7

Installation 8-10

Positioning the tumble dryer 8-9

Changing the door hingeing 10

Electrical installation 10

Warranty 11

instructions summary 12

NOTE!

Items to be tumble-dried must first

have been spin-dried, preferably at

800 rpm or more.

Control panel

Main On/Off switch

Adjustable feet

Filter holder

Lint filter

indication lamp which Illuminates

when the main switch is on.

Program knob

T

s

7^

---

Start pushbutton, Pushbutton for selecting drying

spring return temperature.

0

V

• button pressed in s Low temperature

• button released & Normal temperature

Page 3

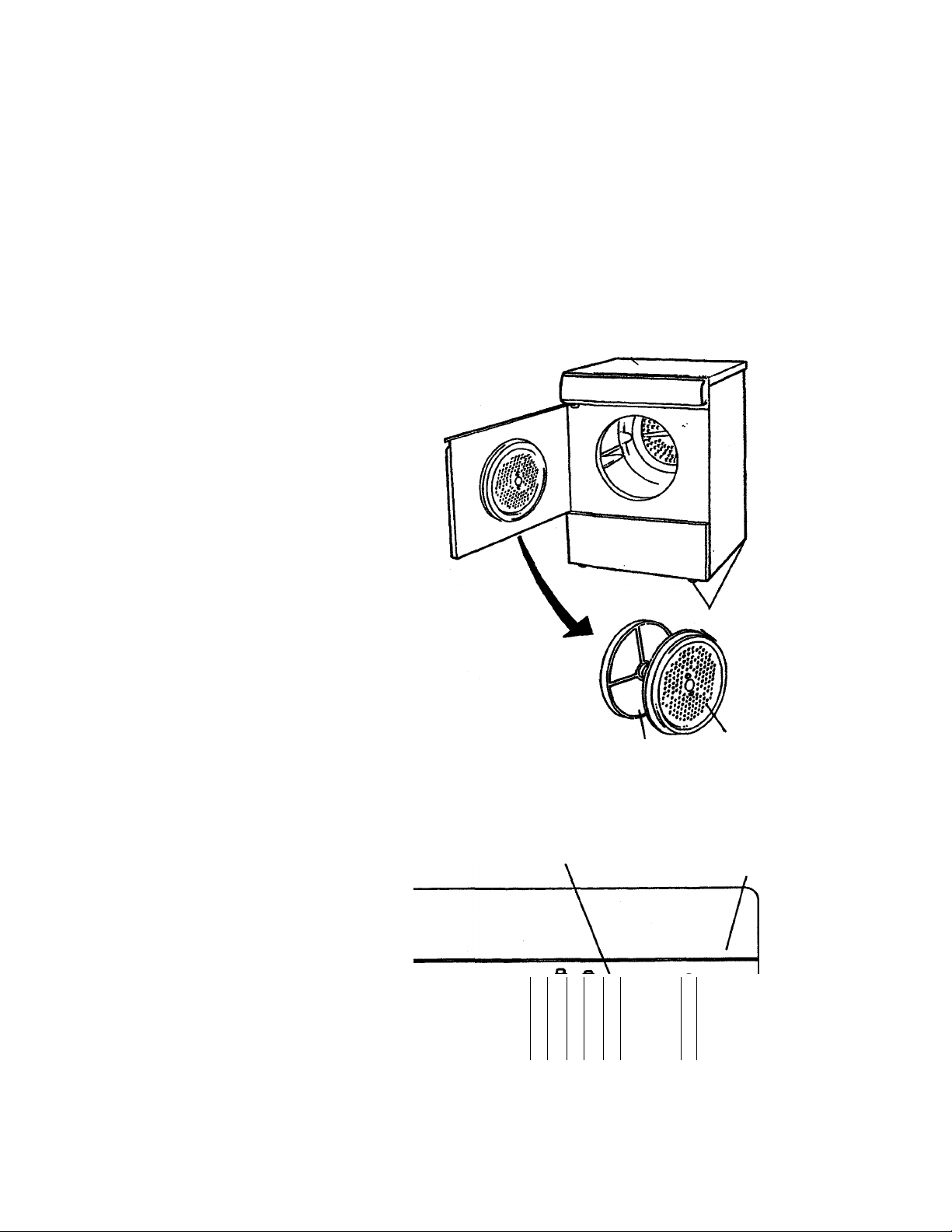

^ Load the washing to be

tumble-dried and

©

Sorting fabrics

Select the drying temperature:

pushbutton pressed in = Low temperature

pushbutton released = Normal temperature

Rear panel, overheating

protection (see page 5)

Hole for exhaust air.

Connect the flexible

exhaust hose

supplied with the

dryer here,

see page 7.

|CZ)I Materials suitable for tumble drying

For the best drying results, clothes should be sorted properly. Separate the lint

shedders (chenille and terry cloth) from the lint collectors (synthetics, flannel

and fabrics with a nap, such as velveteen and corduroy). Separate non*

coiorfast from light colored items, heavy fabrics from light weight fabrics and

permanent press from heavy, bulky items.

Do not tumble dry

Read all permanent care labels carefully. If a garment's care label says "Drip

dry", "Line Dry" or "Dry Flat", do not dry in the dryer. Certain matenals will melt

or become dangerously flammable if heated, while others may lose their shape.

Other items that should not be tumble dried are:

• Items that have been dry-cleaned at home.

• Wool (unless the garment's manufacturer recommends it)

• Fiberglass

• Laminated or rubber coated items

• Vinyl or plastic

• Do not use fabric softeners or products to eliminate static unless

recommended by the manufacturer of the fabric softener or product.

Note: SAFETY

Do not allow children to play on or In the appliance. Close supervision of

children is necessary when the appliance is used near children.

Type of washing

White wash,

colored wash

(cotton, linen)

Temperature

Normal

Synthetics

permanent press

(polyester, cotton)

Delicate wash. Mild

delicate wash.

Temperature-sensitive

materials such as

acrylics, rayon and

acetate

Use the T button to set the machine for tumbling at low temperature.

Otherwise the temperature will automatically go up to normal temperature

(i. e. the T button is released).

Normal

Low

Page 4

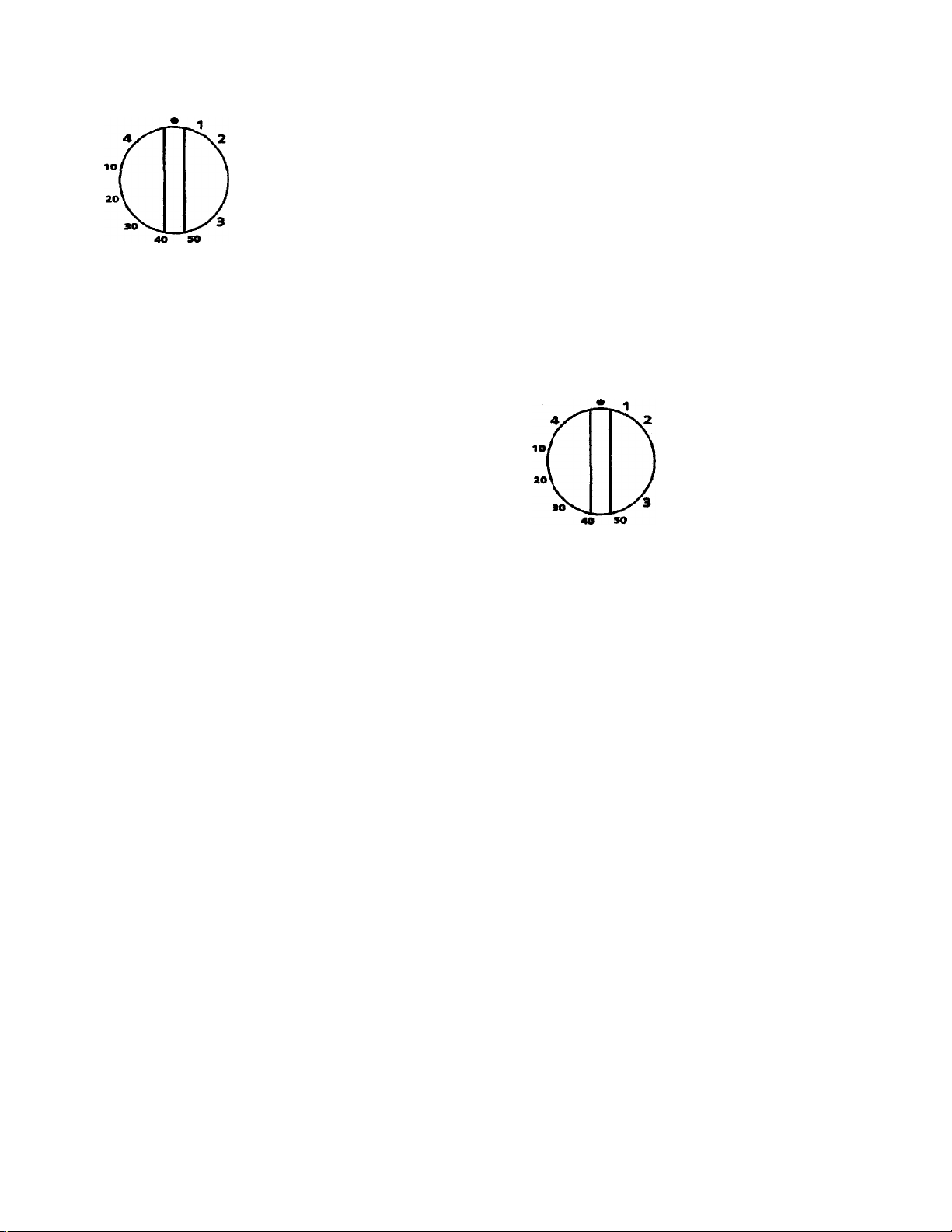

Set the required program using the program knob

Which program to use

Q Press the main On/

Off switch...

... and the Start pushbutton

The indicating iamp wili iight

W

The start pushbutton springs out again

after use.

The program to be used depends on what is to be

done with the washing after tumble-drying. Two

automatic programs are provided: Extra dry and

Dry. if washing is not to be dried completely, e.g.

because it is to be ironed, it is a good idea to use

the time program instead.

Either of the operating temperatures (Low or

Normal) is available with either of the automatic

programs or with the time program.

When you want extra dry

fabrics

1. Extra dry

This automatic program is

intended for use with

washing that is extremeiy

difficult to dry, e.g. jeans

with very thick seams. The

heat is turned off when the

washing is completely dry,

and is followed by a cooling

period of about 15 minutes.

When you want dry

fabrics

2. Dry

This program turns off the

heat when the washing is

dry, but not absolutely

bone-dry. It is then cooled

for about 15 minutes.

When you want to Iron

3. Timed program

The timed program can be

set for any desired heating

time up to one hour. At the

end of the preset time, the

washing is cooled for

about 15 minutes.

Drying time depends on

Turn the program knob

clockwise to the

required program.

A program can be

stopped at any time by

turning the knob to the

0 position.

When you want to air

fabfabrics

4. Airing program cold

This program cannot be

combing with heating. It is

used to shake the dust out

of garment, air them or

soften them up.

If the washing is not dry

When using the automatic

programs, it can happen that

not all of the washing is

properly dry. This may be due

to such reasons as very

heavy fabrics or thick seams.

To dry these items, give a

further period of drying in the

timed program for aboutIO

minutes. Also do not overload

the dryer. If a dryer is

overloaded, its efficiency is

lessened and clothes may not

dry evenly.

Do not over-dry

When using the timed

program, it is possible to

over-dry fabrics, if too long

a time has been set. This

can cause the fabrics to

wrinkle, shrink, or feel

harsh. Synthetic materials

can also become charged

with static electricity.

Single items

Use the timed program

when there is only one item

to be dried. This is because

the autcxnatic program may

turn off the heating too

early, so that the item is not

properly dried.

Dryer added fabric softeners

Because some dryer added fabric softeners may cause

damage to automatic dryers, use only ones that the

manufacturers give a written assurance that their

softener can safely be used in your dryer.

Permanent press hints

For the most wrinkle free

permanent press drying, only

dry one half load at a time to

assure errough room for items t|>

tumble freely. Do not combine

permanent press items with

other very heavy clothes in the

dryer. Remove clothes

immediately after the drying

cycle is completed and either

hang them up or lay them flat.

Page 5

© If you want to check how

© When the dryer has stopped:

dry the washing is:

Open the door.

The drum stops automatically

and will not restart until you close

the door and press the Start

pushbutton. dryer signals when washing is ready

When the program that has been used has finished,

the dryer stops and two signals sound.

When drying permanent press fabrics, best results will

be obtained if they are removed as soon as possibie

after the program has stopped.

• Remove the washing

• Clean the lint fiiter

• Turn off the power at the main

On/Off pushbutton switch

If the machine does not work

The machine wili not start

Check that:

* the door is properly closed.

* the On/Off pushbutton is pressed in.

* you have set the required program or the

required time correctly.

* the electric plug is firmly inserted in its socket (if

the machine is not permanetty wired in).

* all fuses are intact.

NOTE! if the machine still fails to ^rt, it is

prdiable that the overheating cutout has

^•'«^rated. It switches off the tunrMer if the

\ dmperatureistoohi£^, forexan^sleif dusthas

blocked the lint filter. Cleem the filter and reset the

overheating protection switch by pressing the

rubber disc on the back of the machine.

Fluff filter

Filter holder

Cleaning the lint filter

The lint filter must be cleaned after

each time the machine has been

used. If this is not done, drying

performance wilt suffer, as in

sufficient air will pass through the

drum. The machine may also

overheat: this will cause it to stop

automatically.

Clean the filter as follows:

1. Grasp the filter holder by the two

holes near the center and pull it off

the peg on which it is supported in

the front door.

2. Take the filter out of the holder

and brush away the lint in it by

hand.

NOTE! Wear and tear of fabrics in a

tumble dryer is insignificant. The lint

caught in the lint filter is dust and

fiber residue that has been formed

when the garments have been used.

The machine starts, but will not continue to run

If the machine starts when the Start button is

pressed, but stops as soon as the button is

released, it indicates that the overheating

cutout has operated. Clean the lint filter and

allow the machie to cool down.

Excessive drying time

Check that the lint filter is not blocked. Do not

overload the dryer. Items to be tumble-dried

lUst first have been spin-dried, preferable at

' t

00 r/min or more.

NOTE: When you start the dryer for the first

time, a slight rumbling may be heard during a

short warming-up period. When the dryer is runin, this sound will disappear.

3. Replace the filter in the holder

and refit the holder in position on the

peg in the door.

NOTEI Clean lint collecting near the

tumble dryer as it can be sucked

into the air intake.

Other user service

About once a year, remove the

exhaust air hose and clean it and the

outlet from the machine.

Page 6

How the dryer works

1 Air is drawn from the room through

the bottom of the machine.

An electric heater heats the air

passing into the drum.

Warm air enters the drum through

holes in the back and dries the

washing. The drum rotates, and the

two paddles prevent garments from

becoming tangled.

The air passes through the tint filter

and the front of the drum and enters

the fan.

Air is forced out through the outlet

through a fixed duct (see page 10)

The temperature remains at

approximately 40° C (104° F)

as long as the clothes are

moist. When the clothes dry,

the temperature rises and the

heater element is automatically

switched off at the preset

temperature. The air that is not

heated is then drawn through

the drum and coots the clothes

for about 15 minutes.

The thermostats which switch

off the heating at normal and

low temperature 60° C (140°

F), 45° C(113° F) are fitted

next to the fan. There are

atso two thermostats next to

the heater eiement. One

switches off the heater

element if the temperature

becomes too high and the

other switches off the

compiete tumbie dryer if a

fauit occurs. This overheating

protection, which is fitted at

the rear of the machine, can

be reset when the

temperature has faiien. Refer

to the section entitled "If the

machine does not work"

(page 5).

Important Safety Instructions

WARNING - To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow

basic precautions, including the foltowing;

1. Read all Instructions before using the

appliance.

2. Do not wash or dry articles that hav

been previously cleaned in, washed in,

soaked in, or spotted with gasoline, dry-

cleaning solvents, other flammable or

explosive substances as they give off

vapors that could ignite or explode.

3. Do not allow children to play on or in

the appliance. Close supervision of

children is necessary when the

appliance is used near children.

4. Before the appliance is removed from

service or discarded, remove №e door

to the washing or drying compartment.

5. Do not reach into appliance if the tidb,

agitator, or drum is moving.

6. Do not install or store this appliance

where it will be exposed to the weather.

7. Do not tamper with controls.

8. Do not repair or replace any part of the

appliance or attempt any seiMceing unless

specificaily reccxnmended in the usermaintenance instructions or in published

user-repair instmctions that you

understand £ui have the skMs to cany out.

9. Do not use fabric softeners or products to

eliminate static unless recommended by

the manufacturer of the fabric softener or

product.

10. Do not use heat to dry articles containing

foam rubber or similarly textured rubberiika

materials.

11. Clean lint screen before or after each

load.

12. Keep area around the exhaust opening

and rejacent surrounding areas free from

the accumulation of lint, dust, and dirt.

13. The interior of the machine and exhaust

duct should be cleaned periodically byu

qualified service personnel.

14. The dryer door has a magnetic

lock, wt^ means that it can be

opened from the inside. A door

switch automatically stops the dryer

if the door is opened. The machine

does not start automaticaily if the

door is closed, e.g. if a child should

get into the dnmn and close the door

from the inside. In order to restart

the machine, the Start pushbutton

must be pressed.

15. The machine is protected by a

thermostat fitted by the heating

element, which turns the machine

off if the temperature is too high.

Page 7

Specification

Height

Width

Depth

Depth - Door open

Weight

Speed

Drum materiai

Outer casing

Instaiiation

32 1/4" (820 mm)

23 1/2" (595 mm) +

exhaust hose

connection

23 1/2" (595 mm),

including controi

panel and program

knob

46“ (1170 mm)

86 lbs. (39 kg)

52 rpm

Stainless steel

Galvanised steel

sheet

Free-standing, buiidin or on top of a

washing machine

Drying times and energy consumption

Drying times and energy

consumption

The table below shows drying times

and energy consumption in

accordance with the following

conditions:

• Program 2 has been used (the

normal "Dry" automatic program).

• Drying temperature Normal

• Fabrics dried are of cotton,

previously spun at 800 r/min.

• The dryer is in a room with a

temperature of 20° C (68° F), and

the exhaust hose supplied with the

machine is in use.

Drying times

many factors, such as the

amount of washing, moisture

content, type of fabric, air

temperature and humidity.

Performance can also be

affected by how the machine

has been installed. Drying

time is also naturally affected

by how dry the washing is to

be when removed from the

machine.

Power requirement

For connection Doubie-phase,

Internai fuse

Power requirement

3150 W

208-240 V,30A

15A

3150 W

Air evacuation

The air evacuation can be connected at the

rear. When the machine is belvered, one

the rear is open.

T rio tumble dryer is supplied with a stub

pipe, A UL-CSA hose must be supplied by

the consumer or installer.

Fit the air evacuation as foiiows:

• Push the hose onto the stub pipe and

fasten a clamp.

• Insert the stub pipe with the hose into the

hole.

WARNING - To reduce the risk of fire, this

appliarwe MUST BE EXHAUSTED

OUTDOORS or the equivalent.

Connection to a ventiiation duct

Connect the exhaust hose to a ventilation

exhaust fitting or to a discharge through

the wall.

Secure the hose joint to the outlet stub on

the machine.

Run the hose with as few bends as

possible to the point of discharge. If

necessary, it can be extended to a

maximum of 22 feet erf 4" diameter hose.

Make any bends as gentle as possible. A

maximum of four 90° bends may be fitted

in the hose. The more bends and the

longer the hose, the less will be the

amount of air passing through the

machine.

If more than 22 feet of hose is needed,

diameter must be increased to 6* or 8".

If the hose is taken to a wall outlet, a

ventiiation grille should be fitted to prevent

reverse ftow of cold air.

IMPORTANTI

The appliance should not be exhausted

into a chimney, a wall, a ceiling, or a

concealed space of a buildirvg.

The only rigid of flexible metal duct should

be used for exhausting, unless the

appliance has been investigated for use

with nonmetallic duct.

Fit the ventilation

grille to the inside

or outside of the

wall

Ventilation

grille

Page 8

Installation

(It is essential that the machine is

leveled and the locknuts are tight.)

Positioning of the tumbie dryer:

r

-------------—1

A Free-standing instailation

The dryer can be placed next to a |

washing machine.

Locknut

B Built in

The dryer can be built in beneath a

countertop with a height of 331/2-35 1/2'

least 23 5/8" width is needed.

Space must also be available for the exhaust

hose on the left, right or rear of the machine.

NOTE:

Height Adjustment: 321/4-33 1/2".

Do not Raise Higher than 331/22.

At

V ]

4 23/32"

5 1/2" iy

4 1/8"

HQ

5 5/16" 5 1/2" V'

---------

y

I 4 23/32"

i r Diameter of holft

5/16'

How much air does the dryer

need?

The dryer needs about 196 cubic yards of

fresh air per hour. The room in which it is

installed must therefore have a sufficient air

change rate to ensure that the machine

receives enough fresh air.

Energy saving hints

• Dry consecutive loads to avoid reheating the dryer.

• Do not overload the dryer.

• Do not put unspun, very wet items in the dryer.

• Clean the lint filter after each load.

• Do not over dry clothes when using the timed program.

• If you plan on ironing items, remove them while still slightly damp.

• Leave the door closed while the dryer is in operation.

n

Page 9

C. stacked Installation

The dryer can be mounted on top of

any ASKO matching washing

machine. Use the mounts supplied

with the machine.

^^ese parts are supplied with the tumble dryer:

2 metal brackets for

securing ttie tumble

dryer

2 plastic cups

How to install the tumble dryer on top of a washing machine

1. Remove the screws shown

from the back of the washing

machine, and use them to

secure the two brackets.

2. Fix the plastic cups which locate front feet of the tumble

dryer on top of the washing machine. This is important,

as they ensure that the machine is safely positioned on

top of the washing machine. Break off tab A on the

plastic cup to be fitted on the right-hand side of the

machine, and tab B from the cup to be fitted on the lefthand side of the machine. Remove the protective paper

from the self-adhesive surface beneath the cups.

Taking care not to press the exposed adhesive surface

3. Lift the tumble dryer Into position,

raise the front edge and push the

machine backwards until it engages

with the brackets.

Lower the front of the dryer,

making sure that its feet drop

into the plastic cups.

The edge of the

detergent compartment

against the top of the washing machine, so that

the cups fasten before being properly located,

position the cups so that the tabs indicated by the

arrows (see right-hand drawing) locate the cup

exactly with respect to the front and sides of the

machine. When the cups are properly positioned

as shown, press them firmly down on to the top of

the washing machine. Finish by breaking off the

plastic tabs, which have now served their purpose.

Side of the top imnel

Tumble

dryer

Washing

machine

1

Page 10

Changing the door hinging...

Switch off the main power supply first!

Tools: Phillips screwdriver, 10 mm wrench.

1. Remove the lower panel A.

2. Unscrew the upper screw B + C.

3. The upper hinge is now loose. Raise the door a little

so that it comes away from the bottom hinge. Remove

the top hinge.

4. Move the hinge pin J to the other hole in the hinge

using 10 mm wrench.

5. Push out the hinge bearings from the old holes in the

door.

6. Take the door apart by removing all screws which are

around the edge of the door.

7. Undo magnet cap D.

8. Remove the cover washer from the magnet position E

on the other side.

9. Screw the magnet tight at E (spring plus washer plus

screw) and insert cover washer in the hole at D.

10. Screw the door together.

11. Remove the plug from the new hole for the hinge at

the upper edge of the door at H. Insert this plug in the

old hinge hole.

12. Knock out the hole at the lower hinge hole K using a screwdriver. Insert the plug supplied in the old hinge hole.

13. Fit the hinge bearings in the new hinge hole.

14. Unscrew the lower hinge and move the hinge pin as shown in item 5 above.

15. Remove the plastic protection at F and G and place this where the hinge was previously fitted.

16. Tighten the top hinge.

17. Screw in screw B for the bottom hinge a few turns.

18. Insert the lower hinge pin in the door hole. Place the door's top hinge hole on the upper hinge pin. Place the door and

the lower hinge in position in screw B that has already been fitted. Screw in screw C.

19. Adjust the lower hinge so that the door hangs straight. Tighten screws B and C.

20. Refit the lower panel.

Eiectricai instaiiation

The machine is delivered ready-fitted with

a plug, and is interKfed for connection to a

single-phase siqiply. The supply must be

earthed. If the machine is to be ised in a

wet area, the supply must be protected by

a residual current device.

Connection to a permanently wired supply

point must be made only by a qualified

electrician.

GROUNDING INSTRUCTiONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric

shock by providing a path of least resistance for electric current This appliance is equipped with a cord having an

equipment-grounding conductor and a grounding piug. The piug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check

with a qualified electrician or serviceman if you are in doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance - if it will not fit the outlet, have a proper outlet installed by a

qualified electrician.

10

As supplied: 1 -phase, 208-240 V, 60 Hz

2850 W heater rating,

30 A fuse required

NOTE: On rear of the machine there is a receptacie oniy

dedicated ASKO washing machines, rated 208-240 V.

in use of this recepUttie, deihrered ready-fitted piug or an equai

must be used. The suppiy connection must be 208-240 V, 30 A.

ASKO washing machines rated 208-240 V have an intemai fuse of

15 A.

Page 11

9

ASKO Product Warranty

Home Clothes Washers and Dryers

For Residential Installations

Length of warranty

ONE YEAR FULL

WARRANTY

From date of purchase

FIVE YEAR LIMITED

WARRANTY

One year fuil plus second through

fifthyear limited from date of purchase.

TWENT-FIVE YEAR UMITED

WARRENTY

One year full plus second through

twentyfive year limited from date of

purchase.

For Non-Residentlal Installations

SIX MONTHS FULL WARRANTY

FROM DATE OF PURCHASE

ASKO will pay for:

ASKO replacement parts and/or repair iabor to correct

defect in materials or workmanship. Service must be

provided by an authorized ASKO sen/ice outlet.

ASKO replacement parts (repair labor costs not included)

for any defective solid state controls, timers,motors,

pumps.

ASKO replacement parts (repair labor costs not included)

for the stainless steel inner and outer dmm/tub if it faiis

to hold water due to a manufacturing defect such as cracking

or rusting.

ASKO replacement parts and/or labor to correct defect In

materials or workmanship. Service to be provided by an

authorized ASKO service outlet.

ASKO will not pay for:

A. Service calls to: 1. Correct the installation of the washer or dryer

2. Instruct how to use the washer or dryer

3. Replace house fuses or correct housing wiring

4. Correct house plumbing

5. Cleaning or senricing of the button trap, outlet pump of the washer

6. Cleaning or serving of the lint filter or condensing unit of the dryer

B. Repair and/or parts for faihite of product if washer or dryer is used in other than normal use.

C. Damage resulting from accident, fire, floods, acts of God, alteration, mteuse abuse, improper

installation or installation not in accordance with local eiectricai or plumbing codes.

D. Any labor or shipping costs for parts during tf№ limited warranty.

E. Replacement parts or repair labor costs for units operated outside the Continetal United States.

F. Pick-up and delivery. ASKO products are designed to be repaired in the home.

IN NO EVENT SHALL ASKO INC. BE RESPONSIBLE FOR ANY

INCIDENTAL OR CONSEQENTIAL DAMAGES.

Some states will not allow the exclusion or limitation of incidental or consequential damages, so this

exclusion or limitation may not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

For wanenty service, contact the dealer from whom you purchased the unit or an authorized ASKO service

outlet. Service wilt be provided during normal business hours. Should you have a service problem that is not

resolved locally write:

ASKO USA INC.

s PO Box 851805

Richardson, TX 75085-1805

11

Page 12

How to use the tumble dryer

2. Select the drying temperature:

Pressed in: Low

Released: Normal

Normal:

Whites

Coloureds

Synthetics

Permanent Press

Low

Acrylics

Delicate items

ASKOCrUNDA 96-12

Loading...

Loading...