Page 1

How to use

7003

Page 2

Before using,the mach.ne

%r the first time-

pea.™«

The rnachine must n leaned at

containing res

Contents Page

Instructions for use................................ 2

¡Instructions for use

Follow the figures in the strip

through these instructions for a

brief summary of how to use the

I machine. Further details and

hints are given below the strip.

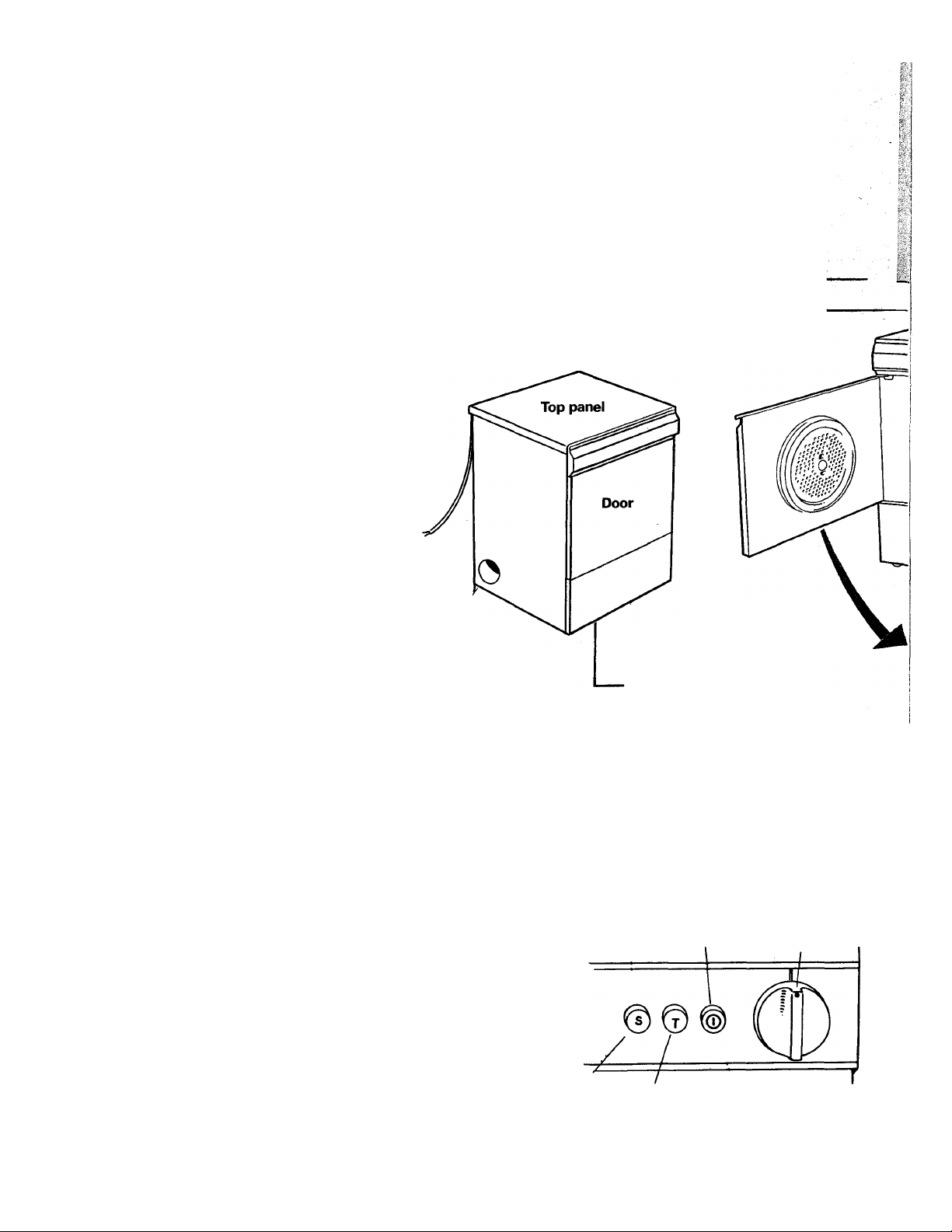

Parts of the tumble dryer

Parts of the tumble dryer

Sorting fabrics........................................ 3

Which program to use

If the machine will not work

Cleaning the lint filter

How the dryer works.............................. 6

Safety....................................................... 6

Accessories............................................ 7

Service and warranty............................. 7

Specifications......................................... 7

Drying times

and energy consumption

Installation

Positioning the tumble dryer. . . . 8-9

Changing the door hingeing

Electrical installation

Instructions summary

.....................................

......................

...........................

.......................

............................

......................

8-11

......................

..........................

.........................

11

12

2

4

5

5

Main electric

supply cable

(see Page 11

Hole for exhaust

air. Connect the

flexible exhaust

hose supplied with

the dryer here

7

10

(see Pages 10-11).

Pull off removable front cover

for access to the resetting

switch for the overheating

protection located behind it

(see page 5)

Control panel

Indicator light

—

NOTE!

Items to be tumble-dried must first

have been spin-dried, and preferably

at 800 r/min or more.

Main On/Off

switch

Start Pushbutton for selecting

pushbutton, drying temperature,

spring return »button pressed in = Low temperature

•button released = Normal Temperature

Program knob

(see Page 4)

Page 3

Sorting fabrics

Materials suitable for tumble drying

For the best drying results, clothes should be sorted properly. Separate

the lint shedders (cheniile and terry cloth) from the lint collectors

(synthetics, flannei and fabrics with a nap, such as veiveteen and

corduroy). Separate non-colorfast from light colored items, heavy fabrics

from iight weight fabrics and permanent press from heavy, buiky items.

Do not tumble dry

Read ail permanent care labels carefully. If a garment's care label

says "Drip Dry", "Line Dry" or "Dry Fiat", do not dry in the dryer.

Certain materials will melt or become dangerously flammable if heated,

while others may lose their shape. Other items that should not be tumble

dried are:

• Items that have been dry-cleaned at home

• Wool (unless the garment's manufacturer recommends it)

• Fiberglass

• Laminated or rubber coated items

• Vinyl and plastic

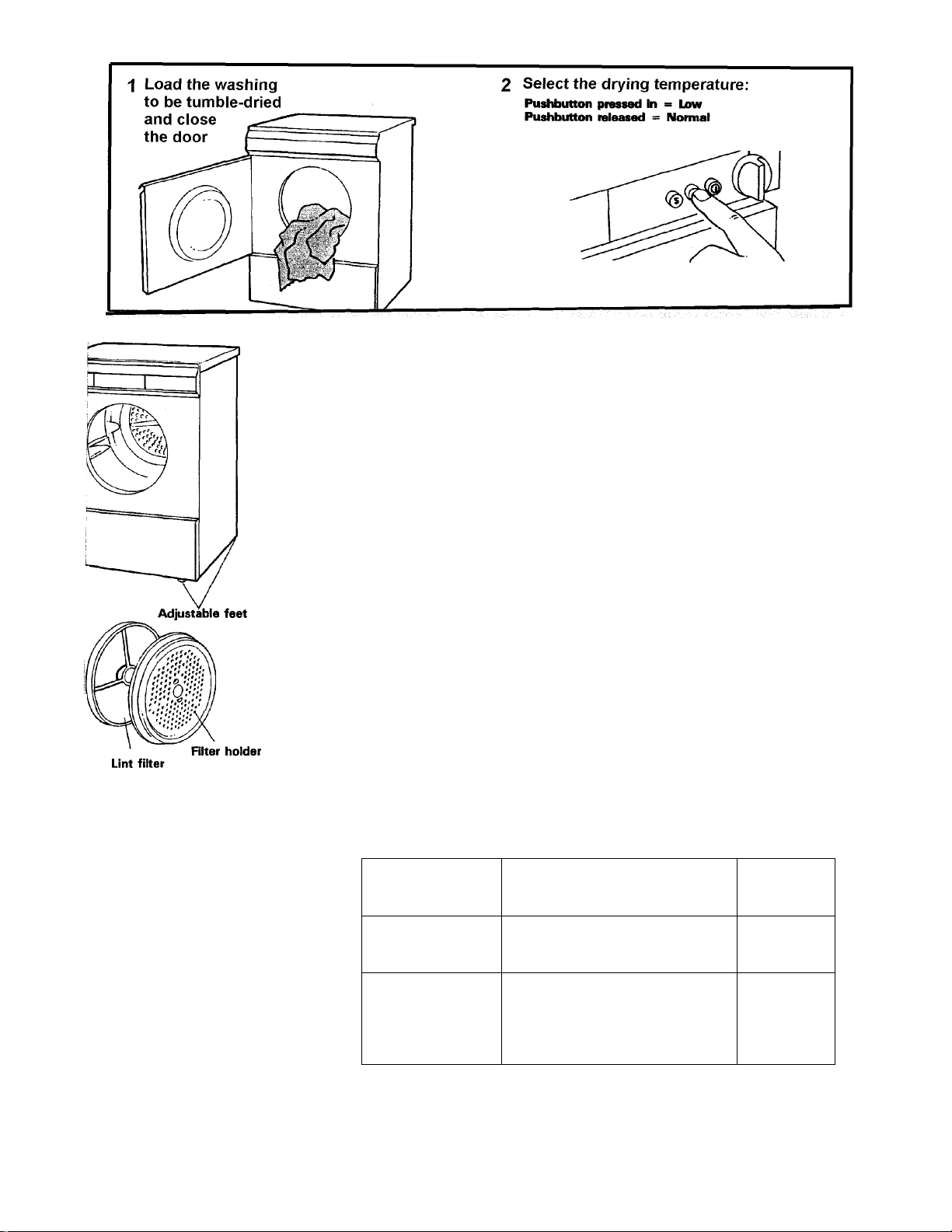

Type of washing Recommended size of load

White wash,

colored wash

(cotton, linen)

Synthetics

Permanent press

(Polyester, cotton)

Delicate wash.

Mild delicate wash.

Temperature-sensitive

materials such as acry

lics, rayon and acetate

Use the T button to set the machine for tumbling at low temperatura Otherwise the

temperature will automatically go up to normal temperature (ie. the T button is released).

Corresponds to the wash

from a FULL drum in an Asko

washing machine

Corresponds to the wash

from a HALF-FULL drum in an

Asko washing machine

Corresponds to the wash

from a HALF-FULL drum in an

Asko washing machine.

Temperature

Normal

Normal

Low

Page 4

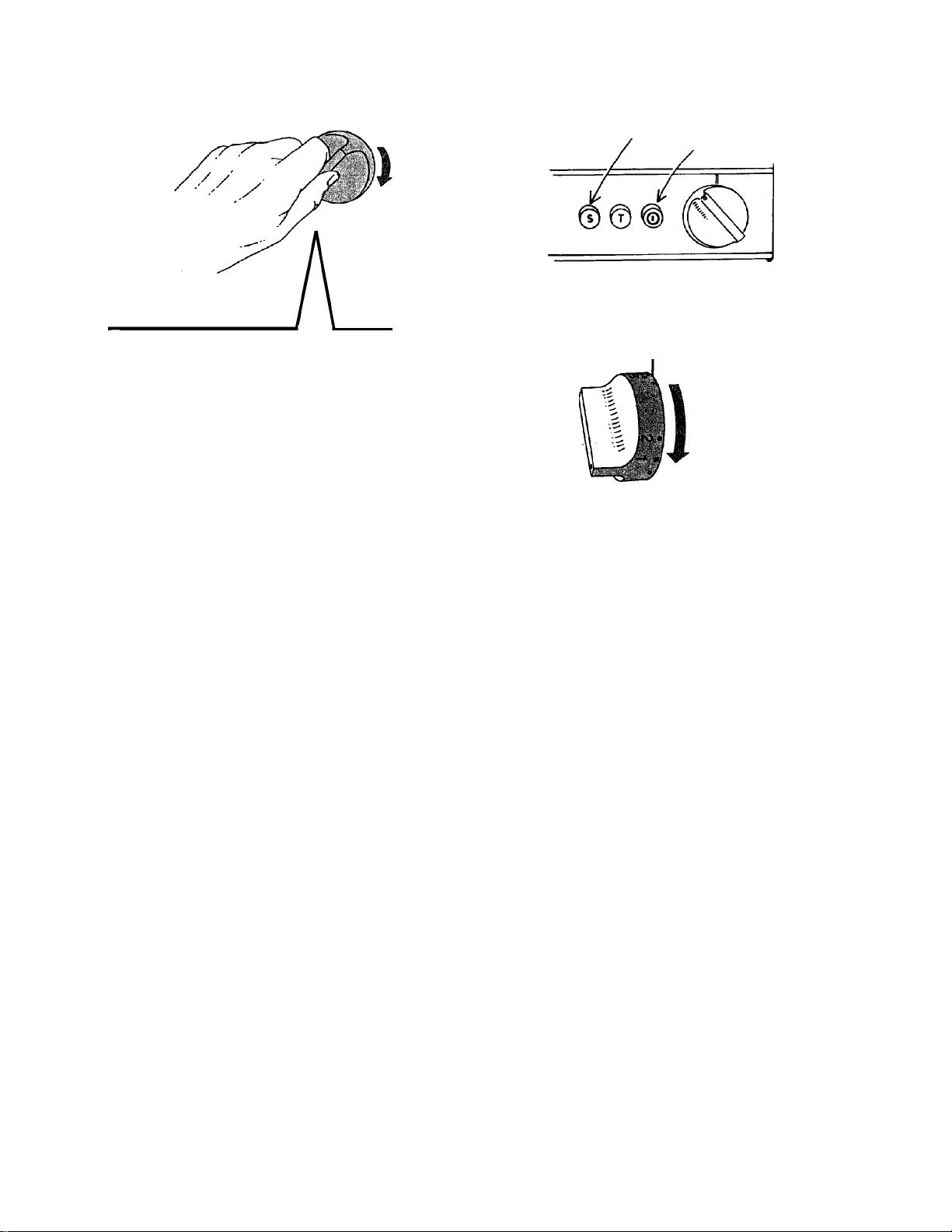

Set the required program

using the program knob

Which program to use

The program to be used depends on what is to be

done with the washing after tumble-drying. Two

automatic programs are provided: ‘Extra Dry' and

‘Dry', if washing is not to be dried completely,

i.e. because it is to be ironed, it is a good idea to

use the time program instead. Either of the

operating temperatures (Low or Normal) is available

with either of the automatic programs or with the

time program.

4 Press the main On/Off switch

and the Start pushbutton

(The indicating lamp will light)

The Start pushbutton springs out

again after use.

Turn the program

knob clockwise to

the required pro

gram. A program

can be stopped at

any time by turn

ing the knob to

the 0 position

When you want

dry fabrics:

2) Dry

This program turns off the heat

when the washing is dry but not

absolutely bone-dry. It Is then

cooled for about 15 minutes. This

Is the program to use when you

want dry fabrics.

1) Extra dry

This automatic program Is Intended

for use with washing that Is ex

tremely difficult to dry, I.e. jeans

with very thick seams. The heat

Is turned off when the washing Is

completely dry, and Is followed

by a cooling period of about

15 minutes.

If washing is not dry

after tumble-drying

When using the automatic pro

grams, it can happen that not all of

the washing is properly dry. This

may be due to such reasons as

very heavy fabrics or thick seams.

To dry these items, give them a

further period of drying in the

timed program for about 10

minutes. Also, do not overload the

dryer. If a dryer is overloaded, its

efficiency is lessened and clothes

may not dry evenly.

When you want

to iron:

3) Timed program

The timed program can be set for

any desired heating time up to one

hour. At the end of the preset time,

the washing Is cooled for

about a further 15 minutes.

Permanent press hints

For the most wrinkle free perma

nent press drying, only dry one

half load at a time to assure

enough room for Items to tumble

freely. Do not combine perma

nent press Items with other very

heavy clothes In the dryer.

Remove clothes Immediately

after the drying cycle Is complete

and either hang them up or lay

them flat.

Do not over-dry

When using the timed program, it

is possible to over-dry fabrics, if

too long a time has been set. This

can cause the fabrics to wrinkle,

shrink, or feel harsh. Synthetic

materials can also become charged

with static electricity.

When you want

to air fabrics:

4) Airing program, cold

This program cannot be combined

with heating. It Is used to shake

the dust out of garments, air them

or soften them up.

Dryer added fabric softeners

Because some dryer added fabric

softeners may cause damage to

automatic dryers, use only one

that the manufactures give a

written assurance that their

softener can safely be used In

your dryer.

Single items

Use the timed program when there

is only one item to be dried. This

is because the automatic program

may turn off the heating too early,

so that the item is not properly

dried.

Page 5

If you want to check how

dry washing is:

Open the door.

The drum stops automatically

and will not restart until you

close the door and press

the Start pushbutton.

When the dryer has stopped:

• Remove the washing

• Clean the lint filter

• Turn off the power at the main On/Off pushbutton switch

If the machine

does not work

The machine will not start

Check that:

•The front door is properly closed.

•The main On/Off pushbutton is

pressed in.

•The electric plug is firmly inserted in

its socket (if the machine is not

permanently wired in).

•Aii fuses are intact.

NOTEi

If the machine still fails to start, it is

probable that the overheating cutout

has operated. It switches off the

tumbler if the temperature is too high.

For example if dust has blocked the

lint filter. Clean the filter and reset the

overheating protection switch by

pressing the rubber disc on the back

of the machine.

Cleaning

the lint filter

The lint filter must be cleaned after

each time the machine has been

used. If this is not done, drying

performance will suffer, as insuffi

cient air will pass through the drum.

The machine may also overheat: this

will cause it to stop automatically.

Clean the filter as follows:

© Grasp the filter holder by the two

holes near the center and pull it

off the peg on which it is

supported in the front door.

Take the filter out of the holder

and brush away the lint in it by

hand.

NOTE: Wear and tear of fabrics in a

tumble dryer is insignificant.

The lint caught in the lint

filter is dust and fiber

residue that has been

formed when the garments

have been used.

Replace the filter in the holder

and refit the holder in position on

the peg in the door.

The machine starts, but

will not continue to run

If the machine starts when the Start

button is pressed, but stops as soon

as the button is released, it indicates

that the overheating cutout has

operated. Clean the lint filter and

allow the machine to cool down.

Excessive drying times

Check that the lint filter is not block

ed. Do not overload the dryer. Items

to be tumble-dried must first have

been spin-dried, preferably at 800

r/min or more

Note!

Clean lint collecting near the

tumble dryer as it can be sucked

into the air intake.

Other user service

About once a year, remove the

flexible exhaust air hose and clean it

and the outlet from the machina

Page 6

How the dryer works

® Air is drawn in from the

room through the bottom of

the machine.

@ An electric heater heats the

air passing into the drum.

(D Warm air enters the drum

through holes in the back

and dries the washing. The

drum rotates, and the two

paddles prevent garments

from becoming tangled.

@ The air passes through the

lint filter at the front of the

drum and enters the fan.

Air is forced out through the

outlet you have selected

through a fixed duct (see

page 11).

The temperature remains at

approximately 40°C (104°F) as

long as the clothes are moist.

When the clothes dry, the

temperature rises and the heater

element is automatically switch

ed off at the preset temperature.

The air that is not heated is

then drawn through the drum

and cools the clothes for about

15 minutes.

The thermostats which switch

off the heating at normal and

low temperature (60°C (140°F)

Safety

The dryer must not be used to

dry fabrics which may contain

residues of flammable liquids.

The dryer door has a magnetic

lock, which means that it can

be opened from the inside. A

door switch automatically stops

the dryer if the door is opened.

The machine does not start

automatically if the door is

45°C (113°F)) are fitted next to

the fan. There are also two

thermostats next to the heater

element. One switches off the

heater element if the tempera

ture becomes too high and the

other switches off the complete

tumble dryer if a fault occurs.

closed, i.e. if a child should get

into the drum and close the

door from the inside. In order to

restart the machine, the Start

pushbutton must be pressed.

The machine is protected by a

thermostat fitted by the heating

element, which turns the

machine off if the temperature is

too high.

This overheating protection,

which is fitted at the rear of the

machine, can be reset when the

temperature has fallen. Refer to

the section entitled "If the

machine does not work" (pg. 5).

Energy saving hints

• Dry consecutive loads to avoid

reheating the dryer.

• Do not overload the dryer.

• Do not put unspun, very wet items in

the dryer.

• Clean the lint filter after each load.

• Do not over dry clothes when using

the timed program.

• If you plan on ironing items, remove

them while still slightly damp

• Leave the door closed while the dryer

is in operation.

Page 7

Accessories

Service and warranty

The following items are supplied with

the tumble dryer:

• Instructions

•Plug for blocking the exhaust air duct

hole if the discharge is changed from

one side to the other.

•Mounting brackets for standing the

machine on top of a washing machine

• Hose ties for the exhaust air hose

• Jointing piece

•Stacking knob conversion

Specifications

Height

Width

Depth

Weight 84 lbs.

Drum volume

Speed

Power

requirement

For connection

as supplied

Heater power Single-phase,

Air flow 196-222 cubic yds./hi

Drum material

Outer casting Galvanised steel

Installation

32 V4"

23 1/2" plus

exhaust connection

23 1/2", including

control panel and

programm knob

29.3 gallons

52 r/min

3100 W

Single-phasa 13A

2850 w

Stainless steel

sheet

Free-standing, built-in

or on top of a

washing machine

Guarantee

For guarantee detaiis, see the

guarantee card.

Part A of the card should be sent to

ASKO Appliances and the other

retained as proof of purchase for

under-warranty repairs.

Service

If you do require service, telephone

your local ASKO retailer or ASKO on

01-568-4666. To avoid needless

service calls, please carry out the

checks as listed on page 5.

Please note: A trip charge will have to

be made even under the following

circumstances:

1. If the fault is not with the machina

2. If a demonstration is required.

3. if the instructions in this handbook

have not been complied with re

sulting in the following: an un

cleared blockage, incorrect installa

tion, poor loading and useaga

cosmetic damage, excessive water

present in drum.

Drying times

and energy consumption

Drying times

Drying time depends on many

factors, such as the amount of

washing, moisture content, type of

fabric, incoming air temperature

and humidity. Performance can aiso

be affected by how the machine

has been instailed.

Drying time is aiso naturaliy affected

by how dry the washing is to be

when removed from the machine.

Drying times and energy consumption

The tabie on the right shows drying

times and energy consumption in

accordance with the foiiowing

conditons:

• Program 2 has been used (the

normai, 'Dry' automatic program).

• Drying temperature: Normal.

• Fabrics dried are of cotton,

previously spun at 800 r/min.

• The dryer is in a room with a

temperature of 20“C (68®F), and

the exhaust hose supplied with

the machine is in use.

Drying times and energy

consumption for single

phase connection

Weight of

washing

10 lb.* 4.0 kWh

g lbs. 3.6 kWh

6.5 lbs.

4.5 lbs.

* Equivalent to a Full load from

an Asko washer

Energy

consumption

2.8 kWh

2.0 kWh

Drying

time

130 min

120 min

95 min

70 min

Page 8

Installation

Positioning the tumble dryer

(It is essential that the machine is leveled

and the locknuts are tight.)

A Free-standing

B Built in

The dryer can be built in beneath a

countertop with a height of 33 1/2

- 35 1/2”. At least 23 5/8" width

is needed. Space must also be

available for the exhaust hose on

the left, right or rear of the

machine. See the diagram for hole

sizes and positions.

How much air does the dryer need?

The dryer needs about 196 cubic yds.

of fresh air per hour. The room in

which it is installed must therefore

have a sufficient air change rate to

ensure that the machine receives

enough fresh air.

5 5/16"

_ 4 23/32"

^Diameter of holft

--------

r

5 1/2"

'V

Page 9

^ Stacked installation

The dryer can be mounted on top of

any ASKO matching washing machine.

Use the mounts supplied with the

machine.

How to install the tumble dryer

on top o f a washing machine

CD Remove the screws shown

from the back of the washing

machine, and use them to

secure the two brackets.

Fix the plastic cups which

locate the front feet of the

tumble dryer on top of the

washing machine. This is

important, as they ensure that

the machine is safely poshioned

on top of the washing

machine

These parts are supplied with the tumble dryer:

Two metal brackets for

securing the tumble dryer Two plastic cups

Break off tab A on the plastic

cup to be fitted on the right-

hand side of the machine, and

tab B from the cup to be fit

ted on the left-hand side of

the machine. Remove the pro

tective paper from the selfadhesive surface beneath the

cups. Taking care not to press

the exposed adhesive surface

against the top of the washing

machine, so that the cups

fasten before being properly

located, position the cups so

Program knob and plastic scaU

for reading off programmer

positions from below

Front edge of the

detergent compartment

that the tabs indicated by the

arrows (see right-hand drawing)

locate the cup exactly with

respect to the front and sides

of the machine When the cups

are properly positioned as

shown, press them firmly down

on to the top of the washing

machine. Finish by breaking off

the plastic tabs, which have

now served their purpose.

Side of the

top panel

It can be difficult to see the

marks on the program knob

when the tumble dryer is

mounted on top of a washing

machine. Replace the knob with

l^a^different knob and scale

supplied with the tumble dryer,

and intended for reading from

below.

Lift the tumble dryer into posi-

^ tion, raise the front edge and

push the machine backwards

until it engages with the

brackets.

a) Pull off the

programm knob

Lower the front of the dryer,

making sure that its feet drop

into the_glastic cups.

b) Press the scale ring into

position so that the lugs

/ on the back of it locate

/ in the holes in the panel

c) Press the new program

knob into position

Tumble dryer

Washing machine

Page 10

Changing the door hingeing

Switch off the main power supply first!

Tools: Phillip screwdriver, 10 mm wrench.

1. Remove the lower panel A.

2. Unscrew the upper screw B + C.

3. The upper hinge is now loose. Raise the door a little so that it comes away from the bottom hinge.

Remove the top hinge.

4. Move the hinge pin J to the other hole in the hinge using 10 mm wrench.

5. Push out the hinge bearings from the old holes in the door.

6. Take the door apart by removing all screws which are around the edge of the door.

7. Undo magnet cap D.

8. Remove the cover washer from the magnet position E on the other side.

9. Screw the magnet tight at E (spring plus washer plus screw) and insert cover washer in the hole at D.

10. Screw the door together.

11. Remove the plug from the new hole for the hinge at the upper edge of the door at H. Insert this plug in

the old hinge hole

12. Knock out the hole at the lower hinge hole K using a screwdriver. Insert the plug supplied in the old

hinge hole.

13. Fit the hinge bearings in the new hinge hole.

14. Unscrew the lower hinge and move the hinge pin as shown in Item 5 above.

15. Remove the plastic protection at F and G and place this where the hinge was previously fitted.

16. Tighten the top hinge.

17. Screw in screw B for the bottom hinge a few turns.

18. Insert the lower hinge pin in the door hole. Place the door's top hinge hole on the upper hinge pin. Place

the door and the lower hinge in position in screw B that has already been fitted. Screw in screw C.

19. Adjust the lower hinge so that the door hangs straight. Tighten screws B and C.

20. Refit the lower panel.

10

Page 11

Air venting

There are three positions where the air

evacuation can be connected: at the rear,

on the right hand side and on the left

hand side. When the machine is supplied,

one hole at the rear is open. The other

two are covered.

The tumble dryer is supplied with a stub

pipe and a plastic band. (A flexible hose

must be supplied by consumer.)

Fit the air evacuation as follows:

• Push the hose onto the stub pipe and

fasten with the plastic band.

• Remove the cover as necessary.

• Insert the stub pipe with the hose into

the hole.

• Fit the cover to the open hole.

If you want to change the outlet;

• Remove the cover from the hole

where you wish to fit the hose.

• Fit the stub pipe with the hose

connected to it.

• Insert the stub pipe into the new

opening

• Fit the cover to the hole where the

hose was previously fitted.

Connection to a ventilation duct

Connect the exhaust hose from

the tumble dryer to a ventilation

exhaust fitting or to a discharge

through the wall.

Secure the hose joint to the outlet

stub on the machine.

Run the hose with as few bends

as possible to the point of dis

charge. If necessary, it can be

extended to a maximum of 8.75

yards of 4" diameter hose.

Make any bends as gentle as

possible. A maximum of four 90°

bends may be fitted in the hose.

The more bends and the longer

the hose, the less will be the

amount of air passing through the

machine.

If more than 8.75 yards of hose is

needed, diameter must be in

creased.

Fit the

ventilation

grille to

the inside

or outside

of the wall

Electrical

installation

Electrical installation must be

carried out by a skilled electrician.

As supplied, the machine is

arranged for single-phase.

Connection as

delivered:

1-phase, 240 V,

heater power

2850 W, 13 A

fuse required.

If the hose is taken to a wall

outlet, a ventilation grille

should be fitted to prevent

reverse flow of cold air.

11

Page 12

I Set the required program

using the program knob.

Program key:

® Press the main On/Off switch

and the Start pushbutton.

1 Extra Dry (automatic program).

2 Dry (automatic program).

3 Timed program. Set the

required time (up to one hour)

and the required temperature.

4 Airing program (no heat).

Normal programme

when dry washing

is wanteid.

_____

_

Do not tumble dry hems

labeled"Drip Dry". "Une Dry"

or "Dry Flat".

Art.nr 80 557 88

Clean the lint fiber each time

the machine has been used.

Loading...

Loading...