Page 1

ASKO

INSTALLATION

INSTRUCTIONS

IMPORTANT!

Read all of these instructions

before installing the dishwasher .

AA

UTUT

OMAOMA

A

UT

OMA

AA

UTUT

OMAOMA

TT

he drhe dr

T

he dr

TT

he drhe dr

back of the machine at the bestback of the machine at the best

back of the machine at the best

back of the machine at the bestback of the machine at the best

high loop height.high loop height.

high loop height.

high loop height.high loop height.

potential drpotential dr

potential dr

potential drpotential dr

this hose in place.this hose in place.

this hose in place.

this hose in place.this hose in place.

TIC HIGH LTIC HIGH L

TIC HIGH L

TIC HIGH LTIC HIGH L

ain hose is fain hose is f

ain hose is f

ain hose is fain hose is f

TT

T

TT

ain prain pr

ain pr

ain prain pr

obob

ob

obob

OOPOOP

OOP

OOPOOP

astened to theastened to the

astened to the

astened to theastened to the

o eliminao elimina

o elimina

o eliminao elimina

lemslems

lems

lemslems

,,

lea lea

,

lea

,,

lea lea

tete

te

tete

vv

ee

v

e

vv

ee

DISHWASHER

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

Introduction 2

What You Need 2

Dimensions 3

Preparing the Location 3

Hot Water Supply 4

Drain Supply 5

Electrical Connections 6

Preparing the Dishwasher for Installation 6

Moving the Machine into Place 7

Connecting the Electric Cable 7

Connecting the Water Supply 8

Adjusting the Leveling Legs 8

Fastening the Dishwasher to the Cabinet 8

Replacing the Toe Kick Brackets 9

Installing the T oe Kick 9

Changing the Front Panels 9

Fitting the 1805FI Custom Door Panel 10

Fitting the Semi-integrated Custom Door Panel on Model 1895 12

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

Page 1

Page 2

INTRODUCTIONINTRODUCTION

INTRODUCTION

INTRODUCTIONINTRODUCTION

Read these instructions carefully and completely before

you install the machine. The installation should be

carried out by a qualified person who is familiar with all

local codes and ordinances for electrical and plumbing

connections.

If a dishwasher is being installed in this area for the

first time, most of the cabinet work, plumbing, and

electrical has to be done before you move the machine

into place.

WHAWHA

WHA

WHAWHA

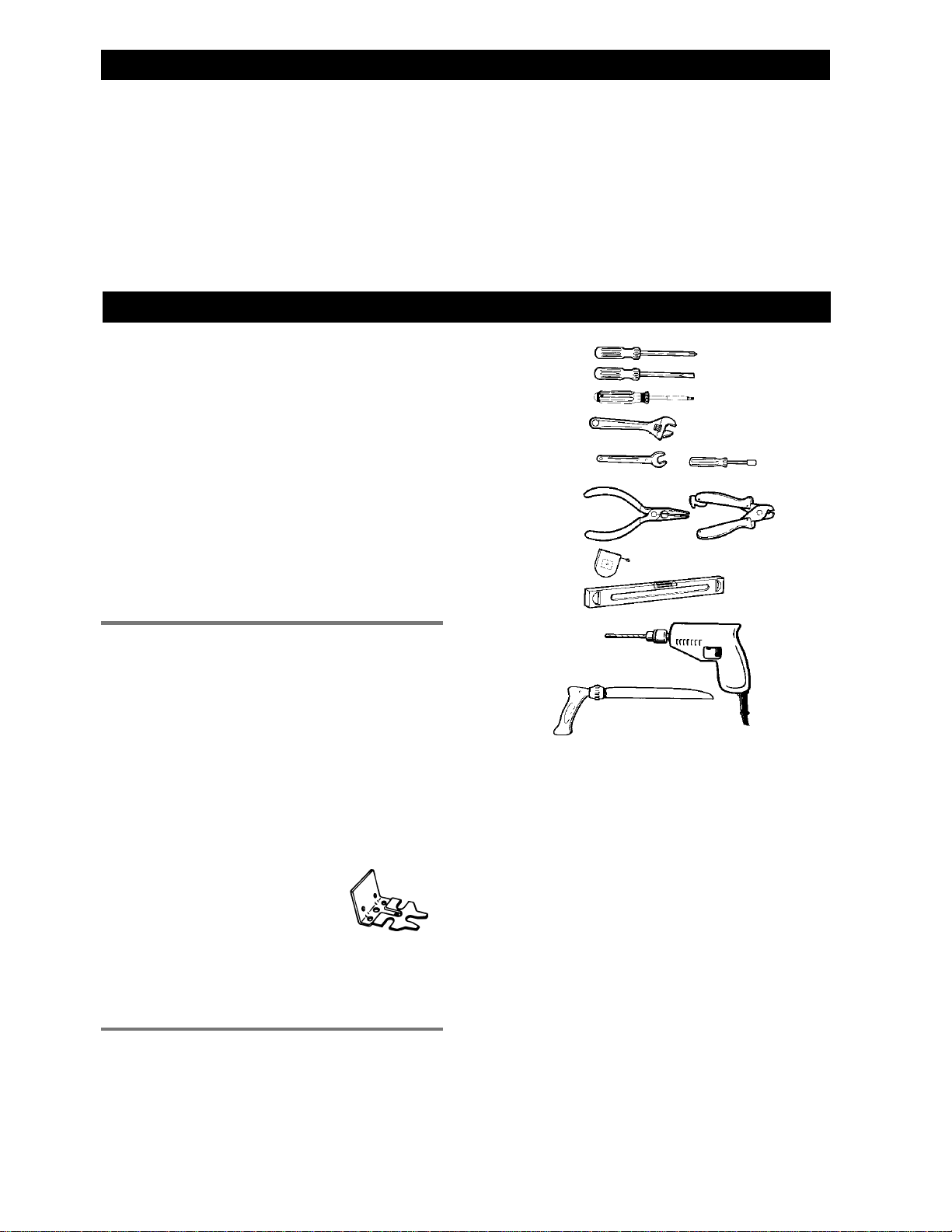

TOOLSTOOLS

TOOLS

TOOLSTOOLS

1) Phillips No. 2 screwdriver

2) Flat blade screwdriver

3) Torx screwdriver size T 20

4) Adjustable wrenches (if you use copper fittings)

5) Open-ended wrench (1/2" [12 mm] or 5/8" [16 mm])

6) Wire cutters and strippers

7) Tape measure

8) Spirit level

9) Electric drill with 1” drill bit

10) Keyhole saw

T T

YY

OU NEEDOU NEED

T

Y

OU NEED

T T

YY

OU NEEDOU NEED

If you are replacing an old dishwasher, you must check

the plumbing connection and wiring before you move

the new dishwasher into place.

NOTE:

ASKO dealer within five days from the date of purchase.

After unpacking the dishwasher, thoroughly check the

unit for cosmetic damage.

Cosmetic damage must be reported to the

1)

2)

3)

4)

5)

6)

7)

8)

MAMA

TERIALSTERIALS

MA

TERIALS

MAMA

TERIALSTERIALS

♦ Minimum 3/8" OD copper tubing of sufficient length

for your installation

♦ Shut-off valve and fittings for water supply line

♦ 1 compression nut

♦ 1 compression sleeve

♦ 1 90° street elbow

♦ 1 90° compression elbow, 3/8" (10 mm) OD

Tip Guards (optional)Tip Guards (optional)

Tip Guards (optional)

Tip Guards (optional)Tip Guards (optional)

When it is not possible to attach the

dishwasher to the cabinet, you

should install tip guards to prevent

the machine from tipping when you

open the door.

Refer to page 3 for installation

instructions.

TECHNICAL DTECHNICAL D

TECHNICAL D

TECHNICAL DTECHNICAL D

Water pressure 18-176 psi

Power 120 v, 60 Hz, 15 amp.

Heating element 1400 w

Max loading 1650 w

AA

A

AA

TT

T

TT

AA

A

AA

Tip Guards

(P/N 8070851)

9)

10)

Page 2

Page 3

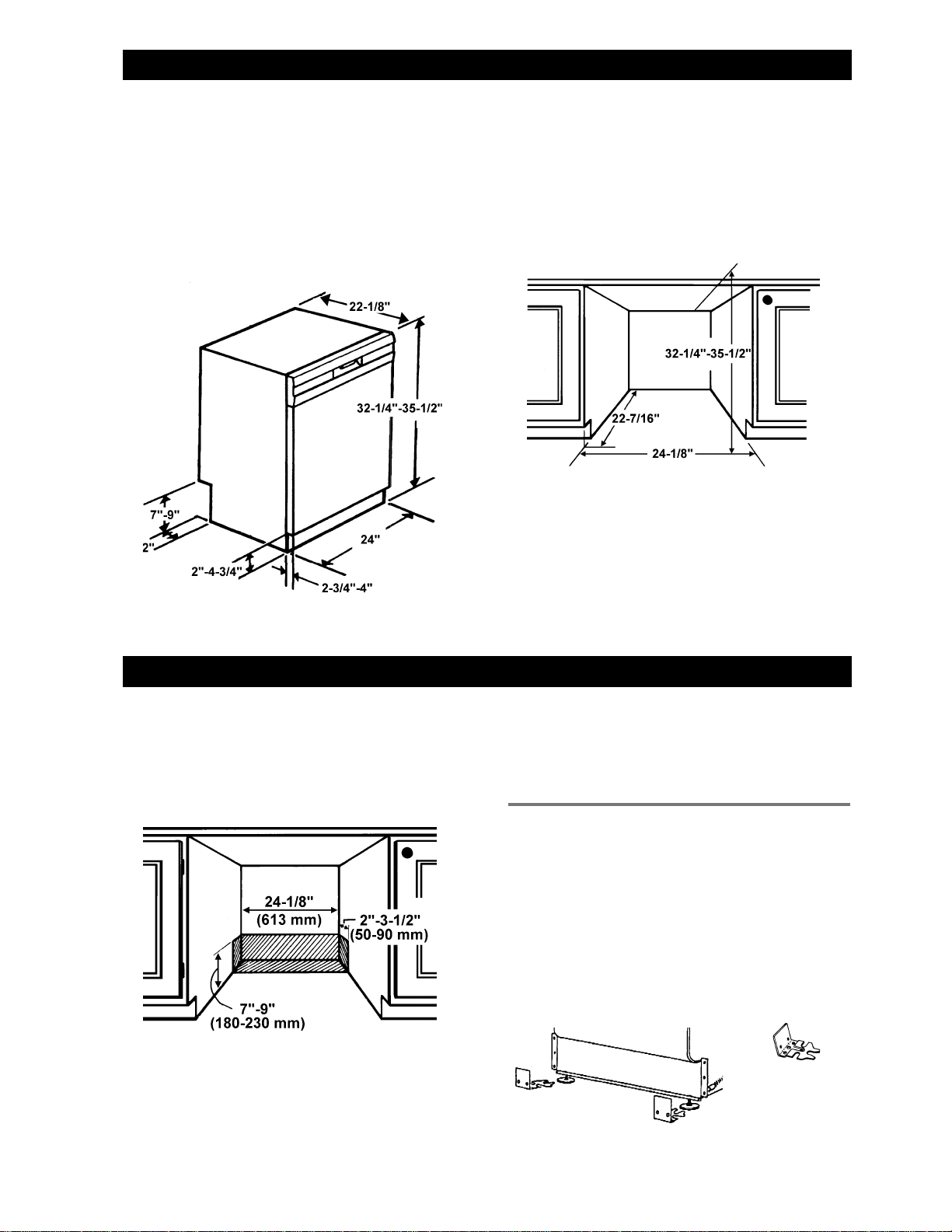

DIMENSIONSDIMENSIONS

DIMENSIONS

DIMENSIONSDIMENSIONS

UNIT DIMENSIONSUNIT DIMENSIONS

UNIT DIMENSIONS

UNIT DIMENSIONSUNIT DIMENSIONS

US European

Measure Measure

Height 32-1/4"–35-1/2" 825–900 mm

Width 24" 610 mm

Depth 22-7/16" 570 mm

Weight 104 lb 48 kg

CABINET OPENINGCABINET OPENING

CABINET OPENING

CABINET OPENINGCABINET OPENING

US European

Measure Measure

Height 32-1/4"–35-1/2" 825–900 mm

Width* 24" 610 mm

Depth 22-7/16" 570 mm

*

Models 1805 FI and 1895 do not have fill strips. The

width for these models is 23-1/2” (596 mm).

PREPPREP

PREP

PREPPREP

The best place for your dishwasher is in the kitchen

near the sink. This makes it easier to connect the water

and drain supply lines.

A built-in dishwasher must be enclosed on the top,

both sides and the back.

The kick plate supplied with your dishwasher will fit a 24"

opening. When using European standard installation, a

kick plate is available from your ASKO dealer. (Part

Numbers: White=8057528-0; Black=8057528-29)

The electrical and water supplies should enter through

the area indicated by the shading on the illustration

above. They should come through the right side of the

ARING ARING

ARING

ARING ARING

Under-Counter Space Needed

THE LTHE L

THE L

THE LTHE L

OCAOCA

OCA

OCAOCA

TIONTION

TION

TIONTION

machine, a maximum of 2” from the back wall and 7” to

9” from the floor, depending on the underneath cabinet

height.

Access holes must be round and smooth, and they

must be no bigger than 1-1/2" in diameter.

INSTINST

INST

INSTINST

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

(OPTIONAL)(OPTIONAL)

When it is not possible to fasten the dishwasher to the

cabinet, you should install tip guards to prevent the

machine from tipping when the door is opened. The tip

guards can be attached either to the floor or the wall.

The tip guards should be mounted behind the machine,

19” apart (measuring center to center) and 18-1/2” from

the front of the machine. (Note: This measurement

could vary, depending on the thickness of the custom

panel, if any.)

ALLING ALLING

ALLING

ALLING ALLING

We recommend that you install tip

guards when it isn’t possible to fasten

the dishwasher to the cabinet.

Rear

THE THE

THE

THE THE

TIP GUTIP GU

TIP GU

TIP GUTIP GU

Tip Guards

(P/N 8070851)

ARDSARDS

ARDS

ARDSARDS

Page 3

Page 4

CORNER INSTCORNER INST

CORNER INST

CORNER INSTCORNER INST

If the dishwasher is installed in a corner, there must be

a minimum clearance of 2 inches (50 mm) from the

side wall so the door can open.

HOHO

T T

WW

AA

HO

HOHO

T

T T

TER SUPPLTER SUPPL

W

A

TER SUPPL

WW

AA

TER SUPPLTER SUPPL

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

YY

Y

YY

2” clearance

WARNING!

applicable sanitary, safety and plumbing codes in your

area.

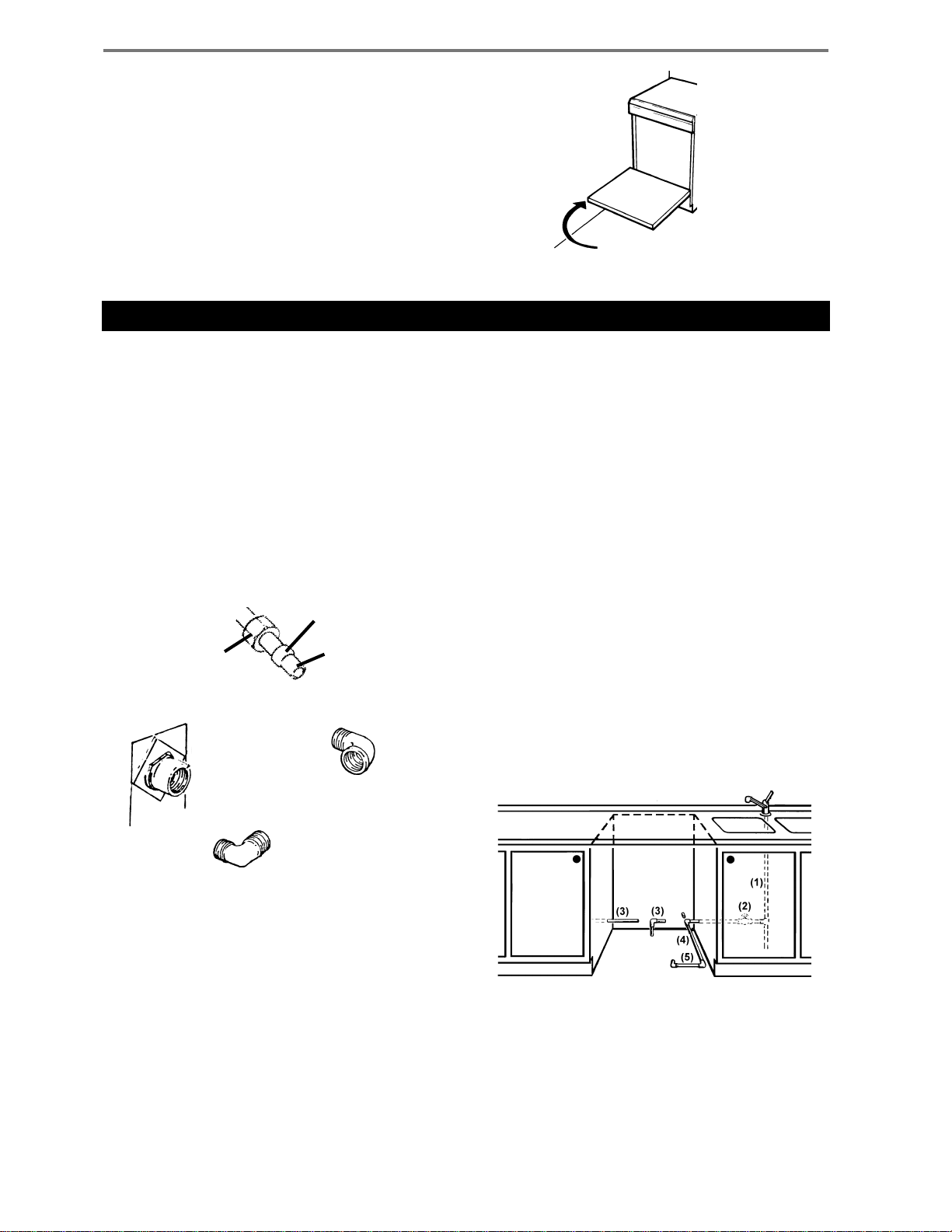

The machine should preferably be connected to a hot

water supply. If a cold water supply is used, the washing

times will be longer but the performance will not be

affected.

The hot water supply line should be minimum 3/8" OD

copper tubing. The inlet valve has a 3/8" NPT female

connection.

Compression nut

Inlet valve, 3/8” OD

Plumbing connections must comply with

CONNECTIONSCONNECTIONS

CONNECTIONS

CONNECTIONSCONNECTIONS

Compression sleeve

3/8” OD copper

water line

90° compression elbow

3/8” NPT one end

After determining where the water supply line will enter

the dishwasher, drill a 1" access hole and run the line

to the approximate inlet valve location shown in the figure

below. The inlet valve is on the right front of the machine,

so the water line should be placed on the right side.

If you use soft copper line, leave the tube straight out in

the opening to slide the dishwasher in. Bend the tube

into position after the dishwasher is slid into the cabinet

opening.

For service convenience, a shut-off valve (not supplied)

should be installed in the supply line in an easily

accessible location (such as, beneath the sink) or in

the supply line near the dishwasher fill valve.

It is important that the water supply line and the shut-off

valve have a sufficient flow volume. At last 3 gallons (12

liters) per minute must be able to pass through the

line. The water pressure should be 18-176 psi.

WARNING!

In order to prevent heat damage to the inlet valve, all

solder connections must be made before the water

line is connected to the dishwasher.

INSTINST

INST

INSTINST

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

Page 4

90° street elbow

(1) Hot water supply

(2) Shut-off valve

(not supplied)

NOTE:

You should only install the number 4 tubing

before you push the machine into position.

Tubing number 5 is to be fitted when the

machine is in position.

(3) Alternate locations

(4) & (5) Tubing

Page 5

DRAIN SUPPLDRAIN SUPPL

DRAIN SUPPL

DRAIN SUPPLDRAIN SUPPL

YY

Y

YY

ASKO provides a 7/8” drain hose which is connected to

the back of the unit to form a high loop. If additional

drain hose is needed, please purchase an additional

ASKO drain hose and joint it to the provided hose with a

7/8” copper tube.

NOTE:

The access hole for the drain line should be 1-1/2".

The end of the drain line is 1/2”, but it is adjustable to

7/8”, 3/4”, 5/8”. If the drain connection is larger than

1/2”, you can easily cut the drain line to fit the connection.

The illustrations to the right show three ways to connect

the drain supply line.

THE HIGH LTHE HIGH L

THE HIGH L

THE HIGH LTHE HIGH L

All ASKO dishwashers have drain hoses attached to

the drain pump and fastened to the top back of the unit.

This gives the drain hose an

is necessary for proper draining. The drain hose is

fastened at the best high loop height with a plastic zip

tie. T o eliminate potential drain problems, simply leave

this hose in place

IMPORIMPOR

IMPOR

IMPORIMPOR

REMEMBER:REMEMBER:

REMEMBER:

REMEMBER:REMEMBER:

♦ Failure to provide the proper drain connection height

♦ No part of the drain hose should be higher than 35"

♦ The hose must not be drawn straight to a floor well

♦ The drain hose can be extended to a maximum

♦ If the drain line is going to be connected to a waste

♦ Do not use fittings smaller than 7/8”; otherwise the

Do not use any fittings anywhere in the drain

line that are less than 7/8" ID.

OOPOOP

OOP

OOPOOP

automatic high loop

.

TT

ANT ANT

T

ANT

TT

ANT ANT

(minimum of 20" above the bottom of the dishwasher

base) or a 20" high loop will result in improper

drainage, which will damage the machine.

from the bottom of the dishwasher.

or its equivalent because it might function as a

siphon and empty the machine.

length of 10 feet. Joints and jointed tubes, if any,

must have a minimum 7/8" ID.

disposer, be sure to remove the knockout or plug

from the fitting on the disposer before connecting

the drain line.

water may not drain properly.

THINGS THINGS

THINGS

THINGS THINGS

TT

T

TT

OO

O

OO

, which

THREE THREE

THREE

THREE THREE

DRAIN CONNECTIONSDRAIN CONNECTIONS

DRAIN CONNECTIONS

DRAIN CONNECTIONSDRAIN CONNECTIONS

A.)T ypical connection to sink plumbing before

trap (high loop drain)

B.)Connection to air gap then to the trap

C.)Connection to waste disposer with air gap

WW

W

WW

AA

A

AA

YY

Y

YY

S S

S

S S

TT

T

TT

O INSTO INST

O INST

O INSTO INST

ALLALL

ALL

ALLALL

When the installation is ready, open the supply valve

and let the pressure act for a while. Then check that all

connections are tight and there are no leaks.

NOTE:

Don’t forget to remove the knockout

or plug from the disposer fitting.

Page 5

Page 6

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

WARNING!

electrical appliance, be sure the electrical power

has been turned off at the breaker/fuse box.

WARNING!

supply and place a tag at the disconnect switch

indicating that you are working on the circuit.

WARNING!

connections must comply with the applicable

portions of the national electrical code and/or

other local electrical codes.

The electrical supply must be a 110–120 volts, 15 or 20

amp properly grounded circuit. No other appliance or

outlets should be on this circuit.

GRGR

OUNDING INSTROUNDING INSTR

GR

OUNDING INSTR

GRGR

OUNDING INSTROUNDING INSTR

This unit must be grounded to operate properly. It must

be connected to a grounded metal, permanent wiring

system, or an equipment-grounding conductor must

be run with the circuit conductors and connected to the

equipment-grounding terminal or lead of the appliance.

PREPPREP

PREP

PREPPREP

Before working on wiring for any

Disconnect electrical power

Electrical and grounding

UCTIONSUCTIONS

UCTIONS

UCTIONSUCTIONS

ARING ARING

ARING

ARING ARING

THE DISHWTHE DISHW

THE DISHW

THE DISHWTHE DISHW

ASHER FOR INSTASHER FOR INST

ASHER FOR INST

ASHER FOR INSTASHER FOR INST

NOTE:

Damage to the dishwasher could occur if it is not

properly grounded.

WARNING!

drain line and branch circuit wiring do not touch

any exposed terminals of dishwasher wiring.

Access holes must not be larger

than 1-1/2” in diameter with no sharp

edges.

Make sure the water supply line,

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

At this point the styrofoam, plastic wrap, and the wood

pallet (base) should be removed from the dishwasher.

Now is an excellent time to inspect for any shipping

damage. Should you find any damage, you should

report it to your dealer or builder

Be sure to remove the toe kick and toe kick insulation

which are wrapped in heavy brown paper and packed

inside the dishwasher.

THE FILL STRIPSTHE FILL STRIPS

THE FILL STRIPS

THE FILL STRIPSTHE FILL STRIPS

All ASKO dishwashers (except Models 1805FI and 1895)

have color-coded fill strips to finish off the installation.

To prevent damage to the machine, be sure to remove

the shipping screws that secure the fill strips to the

access panel. These screws are to be thrown away . Do

not replace them into the access panel.

immediately

WARNING!

Do not screw the fill

strips back to the

lower access panel;

otherwise, the

machine will have to

be uninstalled if

service is necessary.

.

SLIDES FOR REAR LEGSSLIDES FOR REAR LEGS

SLIDES FOR REAR LEGS

SLIDES FOR REAR LEGSSLIDES FOR REAR LEGS

The unit comes with two white plastic slides for the rear

legs to protect the kitchen floor from being damaged

when you slide the unit into place. The slides simply

snap onto the bottom of the rear legs.

Protective slides for rear

legs simply snap onto the

bottom of the legs.

REMOREMO

REMO

REMOREMO

T o remove the access panel, first remove the two screws

on each side of the access panel. There are two tabs at

the top of the access panel that hold the panel in place

against the guard plate. To remove the panel, you must

slide it down below these tabs.

REMOREMO

REMO

REMOREMO

BRABRA

BRA

BRABRA

To remove the toe kick brackets, hold the small metal

spring tab on the outer edge of the base pan toward the

outside of the machine. Continue holding the tab as

you pull straight out on the bracket. (

stubborn because it’s in guide slots on the base pan.)

VING VING

VING

VING VING

VING VING

VING

VING VING

CKETSCKETS

CKETS

CKETSCKETS

THE THE

THE

THE THE

THE THE

THE

THE THE

AA

CCESS PCCESS P

A

CCESS P

AA

CCESS PCCESS P

TT

OE KICKOE KICK

T

OE KICK

TT

OE KICKOE KICK

Note:

ANELANEL

ANEL

ANELANEL

It may be

Access

Panel

NOTE:

Page 6

Fill

Strip

Toe kick bracket

If the cabinet opening is European measurement

(23-1/2 inches [600 mm]), remove the fill strips

to fit the dishwasher into the opening.

Page 7

REMOREMO

REMO

REMOREMO

There are four screws that hold the guard plate in place,

two on the upper/underneath side and two on the front.

To remove the guard plate, first remove the toe kick

brackets (see page 6). Then remove the two screws on

the upper/underneath side of the guard plate. Next,

remove the two screws from the front side of the guard

plate.

VING VING

VING

VING VING

Guard plate

THE GUTHE GU

THE GU

THE GUTHE GU

ARD PLAARD PLA

ARD PLA

ARD PLAARD PLA

TETE

TE

TETE

After the screws are removed, grip the bottom of the

guard plate and pull it toward you to remove it. You can

now access the inlet valve, electrical connection, and

drain pump and hose, as illustrated below.

Remove the two

screws on each

side of the guard

plate.

MOMO

VING VING

MO

VING

MOMO

VING VING

1. Position the machine in front of the cabinet

opening.

2. Make the height adjustment while the dishwasher

is in front of the opening.

3. Pull out the drain hose to ensure there are no sharp

bends.

4. On the bottom rear of the dishwasher there is a

black ziptie around the rubber buffer that holds the

circulation pump in place. Cut the ziptie and remove

it.

5. Start to feed water, electric, and drain lines into

position.

6. Make sure you’ve put the protective slides on the

rear legs to prevent damaging the floor when you

slide the unit into place (see page 6).

7. Gently slide the unit into the dishwasher opening.

As you do this, feed the drain line into the drain line

hole. Also, feed the electrical and water lines to the

THE MATHE MA

THE MA

THE MATHE MA

CHINE INTCHINE INT

CHINE INT

CHINE INTCHINE INT

Remove the two

screws on each

side of the guard

plate.

O PLAO PLA

O PLA

O PLAO PLA

As you slide the unit into place, feed the drain line into

the drain line hole and the electrical and water lines to

the right front of the dishwasher.

CECE

CE

CECE

WARNING!

CONNECTING THE ELECTRIC CABLECONNECTING THE ELECTRIC CABLE

CONNECTING THE ELECTRIC CABLE

CONNECTING THE ELECTRIC CABLECONNECTING THE ELECTRIC CABLE

WARNING!

1. Connect supply cable with

a UL-listed strain relief

bushing (if nonmetallic

cable is to be used).

2. Connect branch circuit

white lead to white lead on

main terminal block.

Before starting this procedure, be sure

3. Connect branch circuit black lead to brown lead on

main terminal block.

4. Connect ground wire to ground on terminal block.

Be careful of sharp edges.

Page 7

Page 8

CONNECTING CONNECTING

CONNECTING

CONNECTING CONNECTING

In order to prevent heat damage to the inlet valve, all

solder connections must be made before the water

line is connected to the dishwasher.

Flush the water supply line prior to connecting it to the

inlet valve of the machine.

The unit has a float switch in the base pan to protect

against flooding. If the inlet valve connection is not

seated properly, water may leak into the base pan and

activate the float switch. Make sure the connection is

seated and not leaking before completing the installation.

It is important that the water supply line and the shut-off

valve have a sufficient flow volume. At last 3 gallons (12

liters) per minute must be able to pass through the

line. The water pressure should be 18-176 psi.

If the water line is installed properly, there is no need to

seal the connection with Teflon™ tape.

Bend the tube into position after the dishwasher is in

the cabinet opening. It’s best to use a tube bender to

keep the line from kinking.

TESTING FOR LEAKSTESTING FOR LEAKS

TESTING FOR LEAKS

TESTING FOR LEAKSTESTING FOR LEAKS

1. Turn on the water supply and check for leaks.

2. Turn the power on at breaker/fuse box and test the

dishwasher operation by running a Rinse cycle.

(This should take about four minutes.)

3. Turn off the electrical power and check for leaks

THE THE

THE

THE THE

WW

AA

TER SUPPLTER SUPPL

W

A

TER SUPPL

WW

AA

TER SUPPLTER SUPPL

YY

Y

YY

(1) Hot water supply

(2) Shut-off valve

NOTE:

4. Make sure that no kinks have developed in the drain

If there are no leaks and the dishwasher seems to be

working properly, continue with the installation.

You should only install the number 4 tubing

before you push the machine into position.

Tubing number 5 is to be fitted when the

machine is in position.

under the dishwasher.

lines.

(3) Alternate locations

(4) & (5) Tubing

ADJUSTING THE LEVELING LEGSADJUSTING THE LEVELING LEGS

ADJUSTING THE LEVELING LEGS

ADJUSTING THE LEVELING LEGSADJUSTING THE LEVELING LEGS

Now that all the connections are made and the machine

is in place under the cabinet, you should make the final

height adjustment.

1. Using a 1/2” (12 mm) wrench, adjust the locking

nuts until the machine is level. (The machine may

have an inclination of 2° maximum without affecting

its performance.)

FASTENING THE DISHWASHER TO THE CABINETFASTENING THE DISHWASHER TO THE CABINET

FASTENING THE DISHWASHER TO THE CABINET

FASTENING THE DISHWASHER TO THE CABINETFASTENING THE DISHWASHER TO THE CABINET

It’s necessary to fasten the dishwasher to the cabinet

so it won’t tilt when the door is opened or if something

heavy is placed on the door. Use only the stainless

steel screws provided with the machine.

1. Use option A for U.S. or European standard

installations. Use option B only for European

standard installations.

2. Cover the screw heads with the plastic plugs

provided with the machine.

3. When the machine is properly attached, check that

the feet are tight against the floor and that the

machine is level.

NOTE:

When it is not possible to attach the dishwasher

to the cabinet, you should install tip guards.

(See “Tip Guards” on page 2.)

2. When the feet are properly

adjusted, tighten the locking

nuts to the base pan.

NOTE:

When adjusting the unit lower than 33-1/4” the

toe kick has to be modified; the holes for the

access panel and fill strips need to be

elongated.

NOTE:

Option A can be used for U.S. or European

installations. Use option B for European

standard installations only.

Page 8

Page 9

REPLAREPLA

REPLA

REPLAREPLA

CING CING

CING

CING CING

THE THE

THE

THE THE

TT

OE KICK BRAOE KICK BRA

T

OE KICK BRA

TT

OE KICK BRAOE KICK BRA

CKETSCKETS

CKETS

CKETSCKETS

After you replace the guard plate (see page 7), you need

to replace the toe kick brackets. While holding the spring

tab on the base pan toward the outside of the machine,

slide the bracket into the

slots on the guard plate

and work it between

the guide slots on

the base pan.

INSTINST

INST

INSTINST

Once you have the toe kick bracket in place, you can

install the toe kick, as follows:

1. If you have not done so, remove the toe kick and felt

2. Lay the insulation on the back side of the toe kick to

3. Peel the adhesive protection strip off the insulation

4. Positioning the notches on the toe kick at the edge

5. Screw the toe kick to the toe kick brackets.

ALLING ALLING

ALLING

ALLING ALLING

insulation from the brown paper packaging.

make sure it fits properly.

and press it firmly to the back side of the toe kick,

making sure you don’t cover any slots on the toe

kick.

of the access panel, slide the toe kick up behind

the access panel then let it slide to the floor.

THE THE

THE

THE THE

Guard plate

TT

OE KICKOE KICK

T

OE KICK

TT

OE KICKOE KICK

Adjusting the Bracket DepthAdjusting the Bracket Depth

Adjusting the Bracket Depth

Adjusting the Bracket DepthAdjusting the Bracket Depth

Y ou will have to adjust the bracket depth to allow for the

thickness of the toe kick. To do this, first measure the

thickness of the toe kick. Then press the spring tab on

the sides of the base pan toward the outside of the

machine and carefully pull or push the bracket to the

required depth less the thickness of the toe kick.

NOTE:

Adjusting the Height onAdjusting the Height on

Adjusting the Height on

Adjusting the Height onAdjusting the Height on

Models 1805FI and 1895Models 1805FI and 1895

Models 1805FI and 1895

Models 1805FI and 1895Models 1805FI and 1895

These models come with two toe kicks. Use the

mounted toe kick if the machine will be 32-1/2” to

33-1/2” high. If it will be higher, use the toe kick

packed inside the dishwasher.

The toe kick has extended screw slots that allow you to

adjust the height. Position the toe kick so it touches the

floor and tighten the screws.

Make sure the toe kick bracket is securely

inside the guides on the base pan.

Extended screw slots

CHANGING CHANGING

CHANGING

CHANGING CHANGING

WARNING!

appliance, be sure the electrical power has been

turned off at the breaker/fuse box.

Refer to the illustration at right for instruction references.

1. Remove the lower access panel with standard or

20 torx screwdriver.

2. Using needlenose pliers, remove the plastic plugs

around the edges of the access panel and upper

door panel. You may discard the plugs.

3. Using the screws provided with the trim kit, loosely

secure parts A and C to the upper door panel.

4. Slide the upper panel into the trim kit grooves.

5. Tighten the screws holding parts A and C.

6. Secure part B and tighten screws.

7. Loosely screw part E to the lower access panel.

8. Slide the custom panel into trim kit channels and

tighten the screw to part E.

9. Secure part D of the trim kit and tighten the screws.

10. Secure the lower access panel to the dishwasher.

11. Drop the access panel to line up with the lower

holes on the guard plate.

Before working on any electrical

THE FRTHE FR

THE FR

THE FRTHE FR

ONT PONT P

ONT P

ONT PONT P

ANELSANELS

ANELS

ANELSANELS

NOTE:

After you install the front panels, you should test the

door before you push the dishwasher into the cabinet

opening. If the door doesn’t open properly, you may

need to adjust the door springs (see page 10).

The stainless steel panels do not have holes

for custom trim. You have to drill the holes.

Panel Trim Kit

Page 9

Page 10

FITTING FITTING

FITTING

FITTING FITTING

THE THE

THE

THE THE

1805FI1805FI

1805FI

1805FI1805FI

CUST CUST

CUST

CUST CUST

OM DOOR POM DOOR P

OM DOOR P

OM DOOR POM DOOR P

ANELANEL

ANEL

ANELANEL

The 1805FI can only be installed with a custom door

panel that extends from the toe kick to the counter top.

The unit comes with everything needed to make

installing the door panel easy. The door is predrilled for

the panel’s mounting screws.

The custom panel should be at least 1/4” thick.

ITEMS PRITEMS PR

ITEMS PR

ITEMS PRITEMS PR

♦ Two 3/8” screws (B)

♦ One protective tape (C)

♦ Four adhesive-backed plastic spacer washers (D)

♦ Four 1-3/4” screws (G)

INSTINST

INST

INSTINST

Before fitting the custom panel, the dishwasher must

be installed underneath the cabinet. After you’ve made

the required measurements, pull the machine out again

to install the panel.

Refer to the illustration at right for instruction references.

1. Fit the handle (A) onto the panel according to the

manufacturer’s instructions. (

should be used rather than a knob, because a knob

does not provide enough grip.)

2. Peel the adhesive backing off the washers and place

them in line with the four keyholes (C) on the metal

front of the dishwasher door.

3. Loosen the screws (D) on the outer edges of the

dishwasher door.

4. Pull the turbo fan exhaust frame (E) down until the

lower edge aligns with the lower edge of the cabinets

and tighten the screws. Next, snap the plastic duct

into the turbo fan exhaust vent.

OO

VIDED VIDED

O

VIDED

OO

VIDED VIDED

ALLING ALLING

ALLING

ALLING ALLING

WITH WITH

WITH

WITH WITH

THE CUSTTHE CUST

THE CUST

THE CUSTTHE CUST

THE UNITTHE UNIT

THE UNIT

THE UNITTHE UNIT

NOTE:

OM POM P

OM P

OM POM P

A handle

ANELANEL

ANEL

ANELANEL

CUSTCUST

CUST

CUSTCUST

Width: 23-3/8” (597 mm)

Height: 28-1/8”–30-1/8” (714 mm–765 mm)

Thickness: 1/4” (25 mm)

Weight: Up to 22 lb.

NOTE:

NOTE:

OM POM P

OM P

OM POM P

Specifications subject to change without

notice.

Heavy-duty door springs can be purchased for

wooden door panels weighing over twelve

pounds. (P/N 8071323-77).

Installing the 1805FI Custom Panel

ANEL DIMENSIONSANEL DIMENSIONS

ANEL DIMENSIONS

ANEL DIMENSIONSANEL DIMENSIONS

(Measured from the top of the panel to

the lower edge of the kitchen cabinet.)

WARNING!

The custom panel must not

obstruct the turbo fan exhaust.

See step 4 above for instructions

on how to adjust the fan exhaust.

5. The two short screws (B) go into the back of the

panel, 16-3/16” from the upper edge of the panel

and 5/8” from the outer edges. Insert the short

screws into the panel, leaving 1/8” of space between

the screw head and the panel.

6. Hook the panel screws (F) into the keyholes (C) on

the dishwasher door.

7. Push the panel upwards until the lower edge aligns

with the lower edge of the cabinets.

NOTE:

than 2-15/16” below the bottom of the dishwasher

door. Otherwise, it will strike the toe kick and

damage the machine and/or the panel.

8. Open the door and tighten the screws (F) inside.

9. Remove the backing from the protective tape and

apply it on the bottom edge of the panel, in front of

the exhaust vent.

The custom panel should not extend more

ADJUSTING THE DOOR SPRINGSADJUSTING THE DOOR SPRINGS

ADJUSTING THE DOOR SPRINGS

ADJUSTING THE DOOR SPRINGSADJUSTING THE DOOR SPRINGS

After you install the custom panel,

make sure the door can be

opened at any angle. If it tends to

fall down, pull out the machine

and tension the door springs on

the sides of the machine by

moving them one hole farther

back or by twisting the spring to

make it shorter. If that doesn’t resolve the problem, you

may need to purchase the heavy-duty door springs (Part

Number 8071323-77).

FASTENING THE DISHWASHERFASTENING THE DISHWASHER

FASTENING THE DISHWASHER

FASTENING THE DISHWASHERFASTENING THE DISHWASHER

TO THE CABINETTO THE CABINET

TO THE CABINET

TO THE CABINETTO THE CABINET

Refer to page 8.

Page 10

Page 11

1805FI CUST1805FI CUST

1805FI CUST

1805FI CUST1805FI CUST

OM POM P

OM P

OM POM P

ANEL INSTANEL INST

ANEL INST

ANEL INSTANEL INST

ALLAALLA

ALLA

ALLAALLA

TION OPTIONSTION OPTIONS

TION OPTIONS

TION OPTIONSTION OPTIONS

4-inc4-inc

4-inc

4-inc4-inc

Custom panels the same height as the

dishwasher door

If the custom panel is the same height as the

dishwasher door, a 2” decorative fill strip or pull-out

cutting board must be used to fill the area between the

panel and the counter top (as illustrated below).

h h

TT

oe Kicoe Kic

h

T

oe Kic

h h

TT

oe Kicoe Kic

A 2” decorative fill strip or cutting board is

required when the door panel is the same

height as the dishwasher door.

k Installak Installa

k Installa

k Installak Installa

tionstions

tions

tionstions

If you install the door panel to reach the cabinet top, we

recommend that you install a 2” support strip between

the upper edge of the dishwasher and the counter to

hide the top of the dishwasher and further reduce water

noise.

A 2” support strip

hides the top of the

dishwasher and

further reduces

water noise.

6-inc6-inc

6-inc

6-inc6-inc

For 6” toe kick installations, the decorative fill strips or

support strips are unnecessary.

h h

h

h h

TT

T

TT

oe Kicoe Kic

oe Kic

oe Kicoe Kic

k Installak Installa

k Installa

k Installak Installa

tionstions

tions

tionstions

Custom panels that extend to cabinet top

Another installation option for a 4” toe kick is to extend

the custom panel to the cabinet top (as illustrated

below), which eliminates the need for a decorative fill

strip.

Panel extends from toe kick to cabinet top.

30-1/8"

(765 mm)

23-1/2"

(596 mm)

4"

(100 mm)

23-5/8"

(599 mm)

With this installation, the door

panel extends 2” above the

dishwasher control panel, as

illustrated. This makes setting

the controls slightly less

convenient, but the aesthetic

benefits seem to outweigh this

small disadvantage.

2"

(50 mm)

28-1/8"

(714 mm)

23-1/2"

(596 mm)

6"

(150 mm)

23-5/8"

(599 mm)

No fill strips or support strips are

necessary with a 6” toe kick.

Page 11

Page 12

FITTING FITTING

FITTING

FITTING FITTING

PP

ANEL ON MODEL 1895ANEL ON MODEL 1895

P

ANEL ON MODEL 1895

PP

ANEL ON MODEL 1895ANEL ON MODEL 1895

THE SEMI-INTEGRATHE SEMI-INTEGRA

THE SEMI-INTEGRA

THE SEMI-INTEGRATHE SEMI-INTEGRA

TED CUSTTED CUST

TED CUST

TED CUSTTED CUST

OM DOOROM DOOR

OM DOOR

OM DOOROM DOOR

Model 1895 was designed to easily accommodate

custom panels. If you use the 4” toe kick, a 2” filler strip

or a pullout cutting board above the unit will be

necessary.

The opening width for Model 1895 is 23-5/8” (600 mm),

which is 3/8” narrower than standard domestic

dishwashers.

ITEMS PRITEMS PR

ITEMS PR

ITEMS PRITEMS PR

♦ Two short screws (D)

♦ Four long screws (E)

♦ Four adhesive-backed plastic spacer washers (D)

♦ One protective tape

INSTINST

INST

INSTINST

Before fitting the custom panel, the dishwasher must

be installed underneath the cabinet. After you’ve made

the required measurements, pull the machine out again

to install the panel.

Refer to the illustration at right for instruction references.

1. Loosen the screws (A) on the outer edges of the

dishwasher door.

2. Pull the turbo fan exhaust frame (B) down until the

lower edge aligns with the lower edge of the cabinets

and tighten the screws (A). Next, snap the plastic

duct securely into the turbo fan exhaust vent.

OO

VIDED VIDED

O

VIDED

OO

VIDED VIDED

ALLING ALLING

ALLING

ALLING ALLING

WITH WITH

WITH

WITH WITH

THE PTHE P

THE P

THE PTHE P

THE UNITTHE UNIT

THE UNIT

THE UNITTHE UNIT

ANELANEL

ANEL

ANELANEL

WW

OODEN POODEN P

W

OODEN P

WW

OODEN POODEN P

Width: 23-3/8” (594 mm)

Height: 22-9/16”–24” (573 mm–609 mm)

Thickness: 3/4” (19 mm) (to be flush with the control

Weight: Up to 22 lbs.

NOTE:

NOTE:

Specifications subject to change without

notice.

Heavy-duty door springs can be purchased for

wooden door panels weighing over twelve

pounds. (P/N 8071323-77).

Installing the 1895 Custom Panel

ANEL DIMENSIONSANEL DIMENSIONS

ANEL DIMENSIONS

ANEL DIMENSIONSANEL DIMENSIONS

panel)

WARNING!

The custom panel must not

obstruct the turbo fan exhaust.

See step 2 above for instructions

on how to adjust the fan exhaust.

3. The spacers (C) between the control panel and the

custom door panel allow you to accommodate the height

of the custom panel (from 1” up to 1-7/16”). T o remove a

spacer, loosen the nuts at the bottom of the spacers

and remove as many as necessary. Screw the nuts

back on and cut off any protruding parts of the plastic

screws. (If necessary, you can omit the spacers.)

4. To mark where to put the two short screws (E), hold

the custom panel in place against the front of the

dishwasher door and measure 16-1/8” from the top of

the dishwasher, marking that distance on both sides

of the custom panel. Next, measure 5/8” from the edges

and mark that across the first measurement.

5. Insert the short screws (E) into the back of the

wooden panel where you marked, leaving 1/8” of

space between the screw heads and the panel.

6. Insert the screw heads (E) into the lower part of the

keyholes (D) and push the panel upward until the

door aligns with the cabinets.

7. Holding the custom panel in place, open the

dishwasher door and tighten the four screws (F)

that secure the panel.

ADJUSTING THE DOOR SPRINGSADJUSTING THE DOOR SPRINGS

ADJUSTING THE DOOR SPRINGS

ADJUSTING THE DOOR SPRINGSADJUSTING THE DOOR SPRINGS

After you install the custom

panel, make sure the door can

be opened at any angle. If it

tends to fall down, pull out the

machine and tension the door

springs on the sides of the

machine by moving them one

hole farther back or by twisting

the spring to make it shorter. If

that doesn’t resolve the problem, you may need to

purchase the heavy-duty door springs (Part Number

8071323-77).

FASTENING THE DISHWASHERFASTENING THE DISHWASHER

FASTENING THE DISHWASHER

FASTENING THE DISHWASHERFASTENING THE DISHWASHER

TO THE CABINETTO THE CABINET

TO THE CABINET

TO THE CABINETTO THE CABINET

Refer to page 8.

Page 12

Loading...

Loading...