Page 1

WR-5e NE Product Remote Control

1. Introduction

The WR-5e is a microprocessor based remote control unit for most Ashly NE products. Compatible products currently include Pema ampliers, ne8800 and ne4800 system processors, the

ne24.24M matrix processor, and all models of the NE multichannel (four or eight channel) power

ampliers. Additional products may become available in the future. Using Protea NE software,

six function select buttons and two parameter adjust buttons are available to control a limited range

of assigned functions within their host product. Up to four WR-5e units can be daisy-chained and

phantom powered from one NE product, and even more can be added using an in-line power supply

adapter such as the Ashly RPS-18. Note: If a WR-5e is used with a NE host product, no other serial

communications devices, including the Ashly RD-8C, may be used with that product.

The WR-5e is designed

to t into a European electrical

wall box, but functionally is

the same as the WR-5. Electrical connections to the host

unit are made using a four

conductor low gauge wire

terminated with euroblock

connectors. There is also a

two pin jumper labelled “J6”

which requires the provided

female jumper to be installed

in specic situations (see section 2). A standard decora

plate (not included) can be

purchased separately to cover

the WR-5e electrical box and

satisfy the aesthetic needs of

the installation.

Note: Avoid static shock disruptions to connected devices by mounting the WR-5e to an earthgrounded metal wall box, or by earth-grounding a metal decora plate. This prevents any static

discharge from owing through the data lines.

Each of six buttons on the WR-5e can be programmed through Protea NE Software to engage

one of the following functions (if available): preset recall, preset scroll, gain control, channel engage/mute, zone source selection, logic output active high, logic output active low, and matrix mixer,

with a green LED next to each button to display active status. To the right of each button is a pocket

in the mylar overlay for a paper function label to be inserted. The two other buttons are used to adjust function parameters, indicated by the LED display.

Page 2

Operating Manual - WR-5e Remote Control for NE Products

2. Wiring a WR-5e

The WR-5 uses a four conductor

phantom powered serial bus to connect to its host unit or to subsequent

WR-5 units. Up to four WR-5 remotes can be powered from one host

unit. Ashly makes an Inline Power

Booster for use in applications that require more than four WR-5 remotes.

Four conductor telephone wire is

suitable for all wiring, as well as

CAT5, but if shielded wiring is used

be sure to ground the source end of

the shield. Under no circumstances

should shielding be left unconnected

to ground, as the added line capacitance will degrade the data signal.

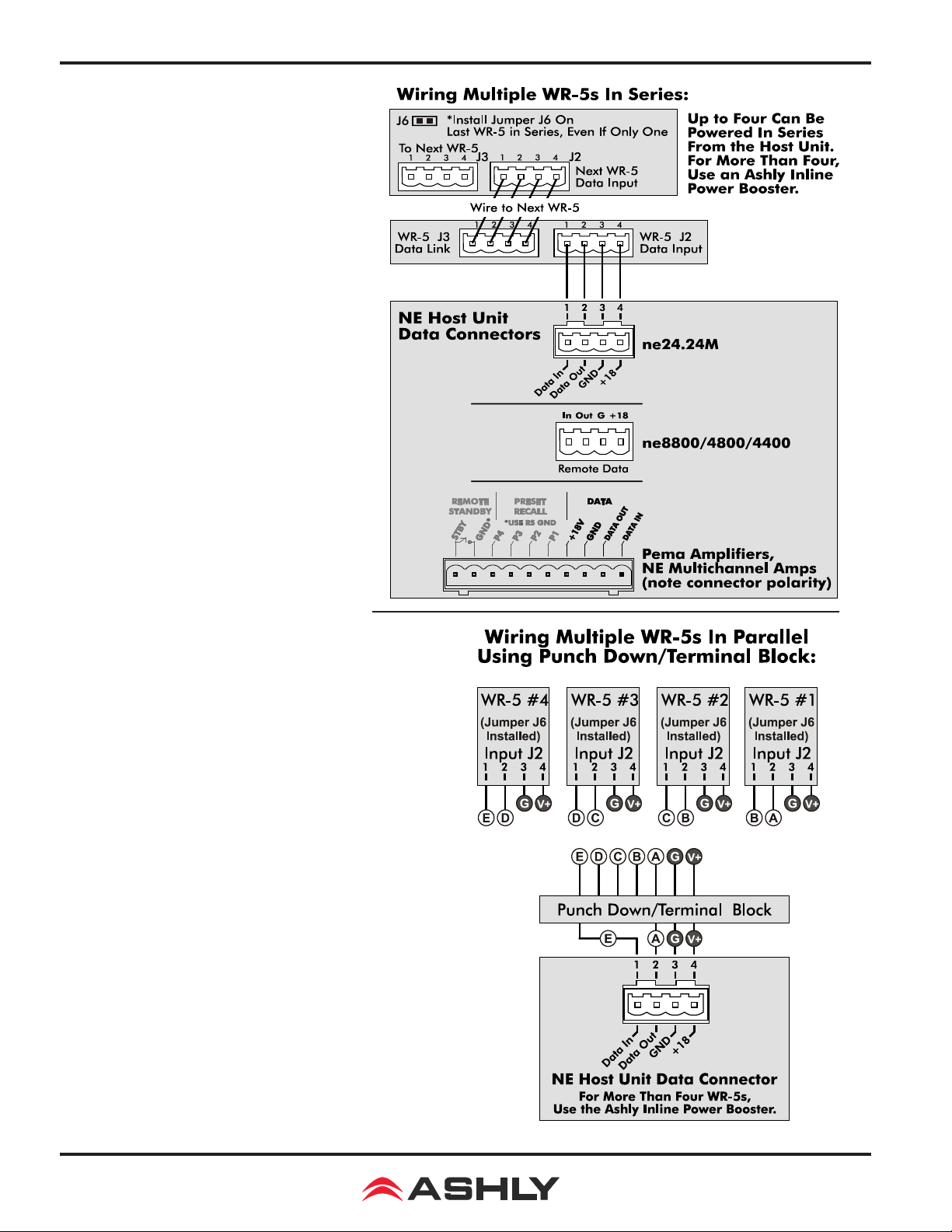

Wiring in Series: If more

than one WR-5 is being wired in

series, connect the next length of

four conductor bus wire from the rst

WR-5’s “LINK” connector to the

following WR-5 “INPUT” connector,

and so on, until the last WR-5 is wired. On the last

WR-5 in series wiring, and even if there is only one

WR-5, install the female jumper J6 on the back of

the pcb to terminate the serial data bus, and make

sure all prior WR-5 units have that jumper removed.

Maximum cable length for data integrity is 1,000 ft

between the host unit and the rst WR-5, and 1,000

ft between each subsequent WR-5.

Wiring in parallel from a central

location: Some installations are more suited to

wiring multiple WR-5 units from one central location rather than daisy-chaining one WR-5 to the

next. Using a punch down block wired to the host

unit’s data connector, each WR-5 uses one four

conductor cable terminated with a single euroblock

connector originating from the punch down block.

The +18 and Ground connections get parallel wired

to each WR-5 (up to four), but the data signal still

gets wired in series In the following manner: Wire

the host unit’s Data Out (pin 2) to the punch down

block, then out from there to the rst WR-5 Data Input (J2 pin 2), out J2 pin 1 back to an isolated punch

2

Page 3

Operating Manual - WR-5e Remote Control for NE Products

down block connection, then back out from there to the next WR-5 data input (J2 pin 2), out J2 pin

1 of that WR-5 back to yet another isolated punch down block connection, and so on, with the last

WR-5 Data Output (J2 pin 1) wired back to the host unit’s Data In connection. In this type of cen-

tralized wiring scheme, every WR-5 that returns its data signal back to the punch down block using

J2 pin 1 must have its J6 jumper installed. Without the J6 jumper installed, the data input signal on

J2 pin 2 is routed to J3 pin 2 for WR-5 series wiring as illustrated above. Maximum cable length for

data integrity is 1,000 combined feet between any two active units.

When more than four WR-5s are being used, an external DC power supply is re-

quired. The power supply must provide at least 13VDC and no more than 35VDC. In addition, each

WR-5 requires 30mA of current, (or 0.03 Amperes). To determine the minimum current rating of the

power supply in mA, multiply 30 times the number of WR-5 remotes to be used (Note: 1000mA =

1A).

Ashly offers an Inline Power Booster called the RPS-18 that provides 24VDC and 625mA

maximum current. It has common, euroblock-style terminals for easy insertion between the host

data port and WR-5 Input jack. Alternatively, it can be inserted between the J3-LINK jack of any

of the rst four WR-5 remotes, and the J2-INPUT jack of the next WR-5 in the chain. This latter

application can be useful to overcome voltage losses, caused by long cable runs to multiple remotes.

In either application, do not connect the +18V pin from the host unit’s Data connector to the exter-

nal supply +18V. It is possible to use the host unit’s +18V for the rst four WR-5 remotes and then

supplement any remaining WR-5 remotes with the inline power booster. Always connect the exter-

nal power supply ground to the host unit’s Data connector ground.

Cable Length - Two things to consider when running cable to the WR-5 are data integrity

& power supply voltage. Active buffers (line drivers) in the WR-5 maintain data integrity, allowing

up to 1,000ft (304m) of cable between devices. Thus, a maximum cable length up to 1,000ft may be

used between the Remote Data Port and WR-5 remote, and another cable up to 1,000ft may be used

from the WR-5 Link jack to an additional WR-5 remote, and so on. Hence each WR-5 functions as a

data repeater.

However, long cable runs act as resistors, which reduce the DC power supply voltage delivered

to the WR-5. Each WR-5 requires a minimum of 13VDC measured across J2-INPUT jack terminals

3 & 4. It is vital to keep track of the power supply voltage drop across each successive cable run to

those pins. For example, typical CAT5 (24AWG) wire has a DC resistance of 0.026 ohms per foot.

Since there are two conductors, (V+ and GND), the resistance is doubled to 0.052 ohms per foot.

Therefore, voltage drop across CAT5 wire can be computed as:

Voltage drop = current (in Amps) * 0.052 (ohms) * cable length in feet

Where current is computed at 30mA (0.03A) per WR-5. If the supply voltage at the WR-5 falls

below 13VDC, the WR-5 will not power up. TIP: To minimize voltage loss over cable length, use

multiple conductors for V+ and GND, (WR-5 terminals 3 & 4). For example, CAT5 wire has a total

of eight 24AWG conductors. Use one pair for wiring up the two data terminals. Use three conductors in parallel for V+, and use the three remaining conductors for GND. This effectively reduces

the power supply voltage drop by a factor of three.

3

Page 4

Operating Manual - WR-5e Remote Control for NE Products

3. Getting Started

The WR-5e comes with all function buttons set to “Off”. To program from a PC running Protea

NE Software, follow these steps:

1) Connect a PC running Protea NE Software to the host NE product using a standard ethernet

RJ-45 cable.

2) Connect the rst WR-5e to the NE product’s data connector as shown, installing the jumper

on J6 if it is the only WR-5.

Upon connecting and powering up the system, the WR-5e will have a “heartbeat”, meaning an

internal small green LED on the PCB will be ashing. As a WR-5 powers up, the LCD rst shows

the two digit rmware revision, then once communication with the host is established the WR-5e

displays “- -” in the LCD window. If there is a two-digit number showing in the LCD, that means

the WR-5 has been previously programmed to control a zone and that number is the gain level for

that zone.

In the Protea NE software window, the WR-5e will appear in an expaned menu of its host unit

in the left side listing on the screen. Individual NE products and their remote control units can be

dragged onto the project canvas to simulate physical rack and room installation groups, but editing

each product can be done from either the product list or the canvas. Once an image has been placed

on the canvas, it must be deleted by hand if that device is no longer available to the software. Scanning for devices does not automatically remove images which may have been installed at one time

but are now off line. However, in the NE system menu at the left side of the screen, an ofine host

unit will appear in red text while an online unit appears in green. Further WR-5 help is available

by opening the WR-5 device and pressing F1, or by navigating through the software Help menu.

The project canvas is used to visually represent and control a xed physical sound system

installation, and can display all Ashly NE processors, ampliers, and remotes used in that system.

Lines, rectangles, text, and image les can be added to create a custom virtual control screen along

with the NE products and individual control objects. To see all available canvas tools, right click

anywhere over open canvas. Checking <Design Mode> allows placed objects to be moved around,

while unchecking <Design Mode> locks objects in place.

4. Programming the WR-5e

Protea NE software is able to determine from the host product which functions are available for

WR-5 control, as not all functions listed below are available on all NE products.

1) Off - No function assigned and the button’s LED remains unlit

2) Preset Recall - A single preset number is assigned to a button. When the button is pressed,

the recalled preset number and the letters “PC” are alternately ashed on the WR-5 for seven seconds, also locking out any other WR-5 action for that time.

3) Preset Scroll Mode - A range of presets can be assigned to a button and selected by pressing and holding the up/down buttons. Upon release of the up/down button, the displayed preset will

load. The button’s LED will ash for the duration of the preset scroll operation.

4) Gain Control - Ashly NE products with Hot-Plug DSP processing must have an (ne)WR5

Remote Gain block placed in software on the channel(s) whose gain is to be under WR-5 control.

4

Page 5

Operating Manual - WR-5e Remote Control for NE Products

Since there are many possible gain adjustment points within the various NE products, the

WR-5 displayed gain level is only a relative adjustment for that WR-5. In other words, gain could

be changed elsewhere in the host unit, independent from WR-5 control. The WR-5 can adjust gain

from a relative 0 to 99, and an upper and lower number limit can be set in the function range section

to limit the maximum and minimum reach of that control.

When a gain control button is pressed, its LED ashes and the up/down buttons determine gain.

If the up/down buttons remain idle for ve seconds, the gain button becomes inactive until being

pressed again.

If a Zone Output is active for that WR-5, meaning one or more output checkboxes are selected

within the Zone Setup area, the WR-5 up/down buttons and numeric display will revert (after ve

seconds of inactivity) from the individual button gain mode to the overall output gain adjust mode

for that zone. If no output is selected for that zone, the display shows “--” as the default.

5) Channel Engage/Mute - A button can be congured to engage or mute a channel or group

of channels. The button LED is on when the channel(s) are engaged on.

6) Zone Source Selection - This is used to select one or more inputs for the zone under WR-5

control. When multiple zone source select buttons are assigned uniquely different or overlapping

inputs, each button will simply add to or subtract from the other’s input selections, unless the Exclusive Source Selection box is checked in the zone setup, in which case only the current button’s

selected inputs will be used.

The Disable Zone Level Control software checkbox allows input source selections to be

changed from the WR-5, but not the output gain. The output gain can still be adjusted from software, but the WR-5 user is locked out from making zone output gain changes.

7) Logic Output Active High - This allows the user to toggle the Logic Output assigned pin to

the button. The LED is on when the output is High.

8) Logic Output Active Low- The LED is on when the output is Low.

9) Matrix Mixer - This is used to select one or more inputs for the zone under WR-5 control,

and allows level control of that group at the dsp matrix mixer point.

5

Page 6

Operating Manual - WR-5e Remote Control for NE Products

Ashly Audio Inc. LIMITED WARRANTY (USA ONLY)

(Other countries please contact your respective distributor or dealer.)

For units purchased in the USA, warranty service for this unit shall be provided by ASHLY

AUDIO, INC. in accordance with the following warranty statement.

ASHLY AUDIO, INC. warrants to the owner of this product that it will be free from defects in

workmanship and materials for a period of FIVE years from the original-date-of-purchase. ASHLY

AUDIO INC. will without charge, repair or replace at its discretion, any defective product or component parts upon prepaid delivery of the product to the ASHLY AUDIO, INC. factory service department, accompanied with a proof of original-date-of-purchase in the form of a valid sales receipt.

This warranty gives you specic legal rights, and you may also have other rights, which vary from

state to state.

EXCLUSIONS: This warranty does not apply in the event of misuse, neglect, or as a result of

unauthorized alterations or repairs made to the product. This warranty is void if the serial number is

altered, defaced, or removed. ASHLY AUDIO, INC. reserves the right to make changes in design, or

make additions to, or improvements upon, this product without any obligation to install the same on

products previously manufactured.

Any implied warranties, which may arise under the operation of state law, shall be effective

only for FIVE years from the original-date-of-purchase of the product. ASHLY AUDIO, INC. shall

be obligated to only correct defects in the product itself. ASHLY AUDIO, INC. is not liable for any

damage or injury, which may result from, or be incidental to, or a consequence of, such defects.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion, or

limitation of incidental or consequential damages, so the above limitations or exclusions may not

apply to you.

OBTAINING WARRANTY SERVICE:

For warranty service in the United States, please follow this procedure:

1) Return the product to ASHLY AUDIO, INC. freight prepaid, with a written statement describing the defect and application that the product is used in. ASHLY AUDIO, INC. will examine

the product and perform any necessary service, including replacement of defective parts, at no further cost to you.

2) Ship your product to:

ASHLY AUDIO, INC.

Attention: Service Department

847 Holt Road

Webster, NY 14580-9103

2011 by Ashly Audio Corporation. All rights reserved worldwide.

6

Printed in USA 0111 R0

Loading...

Loading...