Page 1

ne 8800

ne 4800

ne 4400

Network Enabled

DSP Processor

ASHLY AUDIO INC.

847 Holt Road Webster, NY 14580-9103 Phone: (585) 872-0010

Toll-Free: (800) 828-6308 Fax: (585) 872-0739 ashly.com

Page 2

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

Important Safety Instructions

Consignes de sécurité à lire attentivement

The lightning ash with arrowhead symbol, within an equilateral triangle, is intended to alert the

user to the presence of uninsulated “dangerous voltage” within the product’s enclosure that may

be of sufcient magnitude to constitute a risk of electric shock to persons. The exclamation point

within an equilateral triangle is intended to alert the user to the presence of important operating

and maintenance instructions in the literature accompanying the device

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. To reduce the risk of re or electric shock, do not expose

this apparatus to rain or moisture.

6. Do not use this apparatus near water.

7. Clean only with dry cloth.

8. Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

9. Do not install near any heat sources such as radiators, heat

registers, stoves, or other apparatus (including ampliers)

that produce heat.

10. Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding type plug has

two blades and a third grounding prong. The wide blade

or the third prong are provided for your safety. If the

provided plug does not t into your outlet, consult an

electrician for replacement of the obsolete outlet.

11. Protect the power cord from being walked on or pinched

particularly at plugs, convenience receptacles, and the

point where they exit from the apparatus.

12. Only use attachments/accessories specied by the

manufacturer.

13. Use only with the cart, stand, tripod, bracket, or table

specied by the manufacturer, or sold with the

apparatus. When a cart is used, use caution when

moving the cart/apparatus combination to avoid injury

from tip-over.

14. Unplug this apparatus during lightning storms or when

unused for long periods of time.

15. Refer all servicing to qualied service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug

is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed to

rain or moisture, does not operate normally, or has been

dropped.

FCC Compliance

Le symbole de la èche dans un triangle équilateral symbolisant la foudre est prévu pour sensibiliser l’utilisateur à la présence de tension de voltage non isolée à l’intérieur de l’appareil.

Elle pourrait constituer un danger de risque de décharge électrique pour les utilisateurs. Le

point d’exclamation dans le triangle équilatérale alerte l’utilisateur de la présence de consignes

qu’il doit d’abord consulter avant d’utiliser l’appareil.

1. Lisez ces instructions.

2. Conservez ces instructions.

3. Observez les avertissements.

4. Suivez ces instructions.

5. Pour réduire le risque de feu ou la décharge électrique,

ne pas exposer cet appareil pour pleuvoir ou l’humidité.

6. Ne pas utiliser l’appareil près de l’eau.

7. Le nettoyer à l’aide d’un tissus sec.

8. Ne pas bloquer les ouvertures de ventilation, installer

selon les consignes du fabricant.

9. Eloigner des sources de chaleur tel: radiateurs,

fourneaux ou autres appareils qui produisent de la

chaleur.

10. Ne pas modier ou amputer le système de la mise à

terre. Une prise avec mise à terre comprend deux lames

dont une plus large ainsi qu’une mise à terre: ne pas la

couper ou la modier. Si la prise murale n’accepte pas

la che, consulter un électricien pour qu’il remplace la

prise désuète.

11. Protéger le cordon de secteur contre tous bris ou

pincement qui pourraient l’endommager, soit à la che

murale ou à l’appareil.

12. N’employer que les accessoires recommandés par le

fabricant.

13. N’utiliser qu’avec les systèmes de xation,chariots,

trépied ou autres, approuvés par le fabricant ou vendus

avec l’appareil.

14. Débrancher l’appareil lors des orages électriques ou si

inutilisé pendant une longue période de temps.

15. Un entretient effectué par un centre de service accrédité

est exigé si l’appareil a été endommagé de quelque

façon: si il a été exposé à la pluie,, l’humidité ou s’il ne

fonctionne pas normalement ou qu’il a été échappé.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference

2. This device must accept any interference received, including interference that may cause undesired operation

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in both a commercial and residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

2

Page 3

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

Table Of Contents

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 THE NE PROCESSOR SERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4 AC POWER AND MECHANICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . .5

5 GETTING STARTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6 FRONT PANEL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7 STANDARD BACK PANEL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

8 OPTIONAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.1 Mic Input Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.2 AES3 Input Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.3 AES3 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

8.4 Network Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

9 PROTEA NE SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9.1 Device Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9.2 Preset Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

9.3 NE Processor Control Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

10 REMOTE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

10.1 WR-5 Programmable Zone Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

10.2 RD-8C or RW-8C Fader Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

10.3 WR-1, WR-1.5, and WR-2 Remote Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . .12

10.4 FR-8 and FR-16 Networked Fader Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

10.5 NE WR-5 Networked Programmable Controller . . . . . . . . . . . . . . . . . . . . . . . . . .13

11 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

12 TROUBLESHOOTING TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

13 BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

14 FACTORY INSTALLED INPUT/OUTPUT OPTIONS . . . . . . . . . . . . . . . . . . . . .18

15 WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

WARNING: THIS APPARATUS MUST BE EARTH GROUNDED THROUGH THE

SUPPLIED POWER LINE CORD

3

Page 4

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

1. INTRODUCTION

Thank you for your purchase of this NE (network enabled) processor. The ne8800, ne4800, and ne4400 combine state of

the art DSP processing with Ethernet control, and use optional factory installed expansion cards to provide mic inputs, AES3

digital audio input/output, and full integration with Dante® or CobraNet® networked audio. Please read the entire manual to

fully understand the features and capabilities of this product.

About Ashly

Ashly Audio was founded in 1974 by a group of recording engineers, concert sound professionals, and electronics design-

ers. The rst products were elaborate custom consoles for friends and associates, but business quickly spread to new clients and

the business grew. The philosophy we established from the very beginning holds true today: to offer only the highest quality

audio tools at an affordable cost to the professional user – ensuring reliability and long life. Many years later, Ashly remains

committed to these principles.

Ashly’s exclusive Five Year, Worry- Free Warranty remains one of the most liberal policies available on any commercial-

grade product. The warranty covers every product with the Ashly brand name, and is offered at no extra cost.

2. UNPACKING

As a part of our system of quality control, every Ashly product is carefully inspected before leaving the factory to ensure

awless appearance. After unpacking, please inspect for any physical damage. Save the shipping carton and all packing ma-

terials , as they were carefully designed to reduce to minimum the possibility of transportation damage should the unit again

require packing and shipping. In the event that damage has occurred, immediately notify your dealer so that a written claim

to cover the damages can be initiated.

The right to any claim against a public carrier can be forfeited if the carrier is not notied promptly and if the shipping carton

and packing materials are not available for inspection by the carrier. Save all packing materials until the claim has been settled.

3. THE NE PROCESSOR SERIES

There are three processor models, each with line level inputs and outputs, a full suite of DSP processing functions, 10/100

Ethernet control, eight assignable 12V Digital Logic I/O ports, eight DC level control ports assignable to input or output levels,

a RS-232 control port, and a remote data port for programmable controllers such as the Ashly WR-5 and RD-8C.

Base Models:

ne4400 - Four line inputs, four line outputs

ne4800 - Four line inputs, eight line outputs

ne8800 - Eight line inputs, eight line outputs

In addition to the base model features, models can be custom ordered with various combinations of mic preamp inputs,

AES3 inputs and outputs, plus Dante or CobraNet network audio.

4

Page 5

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

4. AC POWER AND MECHANICAL REQUIREMENTS

The AC mains requirement for the NE Processor is 90VAC to 240VAC, 50-60Hz, 70W maximum, and requires a properly

grounded AC connection. The unit mounts to a standard 19 inch equipment rack. A cooling fan draws air in from the right side

and blows air out the left side when viewed from the front.

5. GETTING STARTED

Download the software

Ashly Protea NE software is no longer included on a CD with each unit. Check the Ashly web site at www.ashly.com

to download the latest software release. Autorun will launch the application<ProteaSystemSoftwareNE> to install the Protea

software. A note about rewalls: When running Protea NE software on a PC for the rst time, Windows will prompt the user to

allow the software through any active rewalls. Allow this. Once the software is properly installed, Windows must be congured

to permanently allow a rewall exemption for Protea NE software.

Connect to Ethernet

The Ethernet control connection is made using an RJ-45 terminated eight conductor cable connected directly to a computer

or indirectly over a standard 10/100M Ethernet network. Maximum cable distance for Ethernet is 100 meters from the nearest

hub or switch for copper twisted pair CAT5 cable. For more detailed information about the proper implementation of an ethernet

network, review one of the many comprehensive Ethernet networking guides available on the internet.

Identify the processor in software

Once the software is loaded to the computer and an Ethernet connection has been made to the NE processor, all Ashly NE

products installed on that network will be automatically detected and shown in the active device listing on the left side of the

Protea software startup canvas. In addition to detecting which models are currently online, any factory installed options (mic

preamps, AES3, CobraNet) are auto-detected and the software control surface for the new NE product automatically displays

available controls for the options present. Note: In the event of multiple processors of the same model on the network, the user

can nd a single physical unit by right clicking over the unit’s name in the drop down menu or picture on the canvas, and then

click <Identify>, which will ash the Com LED on that unit’s face panel for two seconds.

The software scans for active NE devices on power-up, but the user can manually scan at any time as well with <Scan For

Devices> at the bottom of the network NE device listing. NE devices continuously broadcast their availability to the software.

All currently connected and active NE devices are highlighted in green, while NE products which may be or have been formerly

installed but are currently off-line or unavailable show up in red. Individual NE products can be dragged onto the project canvas

to simulate physical rack installation groups, but editing each product can be done from either the product list or the canvas.

The NE system project canvas

The project canvas is used to visually represent and control a xed physical sound system installation, and can display any

of the Ashly NE processors, ampliers, and remotes used in that system. The user can also place individual control objects such

as level faders, single LEDs, meter bars, etc, and assign them to specic product functions within that project. Once a control

object is placed, right click on it to bring up its properties. Lines, rectangles, text, even image les can be added to create a

custom virtual control screen along with the NE products and individual control objects. To see all available canvas tools, right

click anywhere over open canvas. Checking <Design Mode> allows placed objects to be moved around, while unchecking

<Design Mode> locks objects in place.

5

Page 6

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

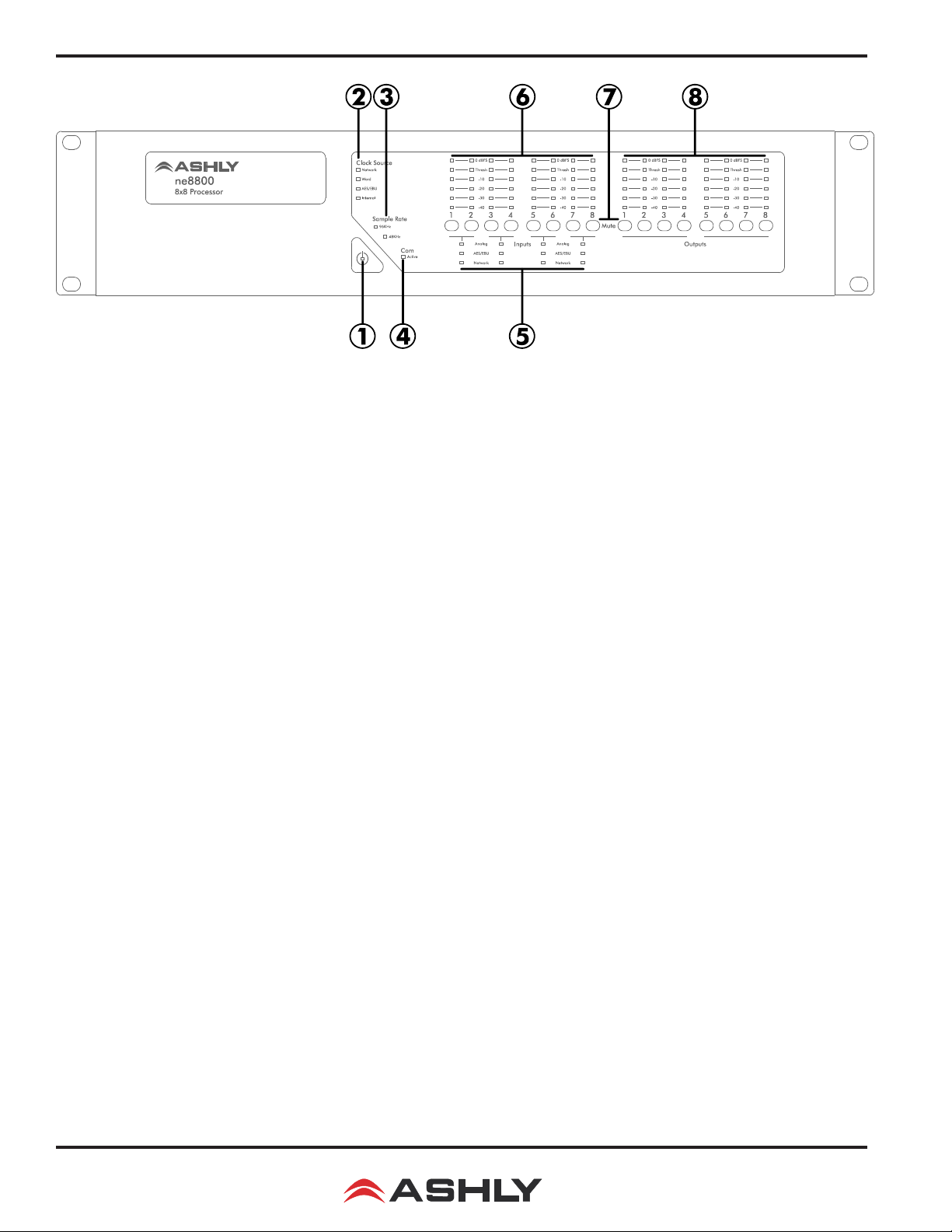

6. FRONT PANEL FEATURES

1. Power LED – Indicates the unit is turned on.

2. Clock Source – The Network clock, Word clock, AES3 clock, or Internal clock are indicated according to the master

clock source selected in the control software. The Network clock LED turns orange when Net Matrix Mode is enabled.

3. Sample Rate – 48KHz or 96KHz sampling rate may be selected from software. Also during ash reprogramming, both

sampling rate LEDs will light amber for the duration of the procedure.

4. Com LED – The Com LED indicates that data is being sent or received via the Ethernet control port. The Com LED

can also be made to ash on for two seconds to visually identify a physical unit from within the software.

5. Input Source – If more than one type of input is available for a given channel pair, an input source selection tab is

available in software. The user can select an input pair source as analog (line input), analog (mic preamp), AES3 input, network

audio, as well as set the input source selection to auto detect digital audio sources while automatically switching back to analog

input when no AES3 or network audio signals are present. Green LED color = “Selected”, Red = “Not Valid”, and Off = “Not

Being Used”.

6. Input Level Meters – Input LED level meters display the signal level at the A/D converter before the DSP section.

Levels displayed on the front panel are measured in dBFS (Decibels Full Scale), where 0dBFS is the maximum level possible,

or true clipping. Software meter displays can be assigned as dBFS, dBu, or VU, but the front panel meters are always dBFS.

The Threshold LED is used for dynamics functions congured in the DSP Controls section of the software.

7. Input/Output Mute– This button is pressed to mute the input or output channel, and will additionally update that channel’s mute status as shown in software. Green means the channel is unmuted, while red means the channel is muted and will

not pass audio. For security, all front panel mute controls can be disabled from within software under <Device Options>, then

<Disable Front Panel Mutes>. If a mic input channel is set up for the push to talk function using logic I/O pins, that channel’s

mute button will illuminate orange to indicate push to talk status, and turn green whenever the mic button is pressed.

8. Output Level Meters – Like the input meters, output meters reference 0dBFS, meaning 0dBFS is the true clipping

point, and are measured from the D/A converter point after the DSP section.

6

Page 7

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

7 STANDARD BACK PANEL FEATURES

1. Line Inputs – Depending on the model, there are either four or eight line inputs available. Line inputs are active bal-

anced with euroblock connectors. If an unbalanced signal is used, connect the unused input pin to ground. Maximum input level

is +20dBu = FS (full scale).

2. Line Outputs - Depending on the model, there are either four or eight line outputs available. Line outputs are servo-

balanced with euroblock connectors, and may be wire balanced or unbalanced, with a maximum output level of +20dBu FS.

3. 12V Digital Logic I/O - All models have a nine pin euroblock connector for logic inputs or outputs. The Logic I/O tab

in software allows logic pins to be assigned as either logic inputs or logic outputs. Logic input “high” range is from +2.3VDC

to +25VDC (do not exceed +25VDC). Logic inputs can be assigned to trigger a preset recall or push-to-talk mic function from

contact closure. Logic pins can also be assigned as current-limited 12V logic outputs, triggered by a preset recall or WR-5 button

for control of 12V or 5V external devices. See page 11 for more logic pin details.

4. 5VDC Remote Level Control - All models have a 10 pin euroblock connector for accommodating up to eight user

dened remote DC level controls. Use an Ashly WR-1 remote attenuator (or equivalent 10K potentiometer), along with a remote

gain block placed within the software DSP section to assign remote level control to any channel’s input or output section. Wire

the 5VDC Remote Control ground to the CCW pin of the remote control potentiometer, wire +5 to the CW pin, and wire the

control pin (1-8) to the potentiometer wiper.

5. Ethernet Jack - This is the RJ-45 connector used for 10/100 ethernet control. Maximum cable distance to the nearest

computer, hub, or switch using CAT5 twisted pair copper cable is 100 meters.

6. RS-232 Jack - This connector is for remote control by non-Ethernet based hardware that uses RS-232 control data

protocol. A complete NE RS-232 protocol document is available on the Ashly website.

7. Remote Data - This is used to connect a remote WR-5 programmable button controller or RD-8C fader controller.

8. Word Clock - If two pieces of digital audio gear need to be synchronized, i.e. their sample rates are very slightly

different and must be made to match exactly, word clock synchronization is necessary to avoid sample skipping. Additionally,

when several pieces of gear are cascaded in an AES3 digital audio chain, each digital audio input adds some small amount of

clocking jitter and perhaps sample delay. After several units, the cumulative jitter could cause a loss of lock (and hence loss

of audio), increased distortion due to large amounts of jitter, or even a small delay. By connecting a master word clock to each

device, they all become precisely synchronized.

7

Page 8

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

The NE processor defaults to “Auto Selection” which automatically detects a Network, Word Clock, AES3, or Internal

master clock source and automatically switches, in this order of priority. Therefore, in most system congurations, the user

doesn’t need to worry about the master clock source, the processor will automatically pick the best master clock from the highest priority available. The processor will mute all audio outputs for about one second when it switches master clock sources.

This Auto Selection mode can be over-ridden in the control software by clicking on <Device Options, Sample Rate & Master

Clock Selection>.

The word clock switch on Ashly equipment provides two functions. First, it routes the word clock input signal hard-wired

looped-through to the word clock output jack when in the OUT (Loop) position, but breaks the signal and generates an internal

word clock source in the IN (Term) position. Secondly, the OUT position does not apply any load to the looped-through word

clock signal, but the IN position applies a 75 ohm termination to the word clock input and supplies a 75 ohm source impedance

to the word clock output. Therefore, the word clock switch should be in the IN “term” position whenever the unit is at either

end of the word clock line, and in the OUT “loop” position when placed anywhere else along the line. No external terminations

are needed.

9. Factory Reset - To reset the NE processor to original factory settings and permanently erase all stored preset data from

the unit, use a paper clip or similar object to depress the recessed switch and hold for six seconds during power up. Factory reset

is complete when all channel LEDs on the face panel are lit.

10. AC Inlet - 90-240 VAC, 50-60Hz, 70W, detachable AC cord. Do not remove or lift the mains connector ground.

11. Power Switch - This switch applies and removes power to the unit.

8 OPTIONAL BACK PANEL FEATURES

12. Mic Input Channels - High performance mic inputs are available as factory installed options for channels 1-4, and/

or 5-8. Mic input connections are balanced euroblock, with switchable +48V phantom power. When a mic preamp option is

installed, the <Input Source> tab appears in the software and represents the mic preamps as available input sources with an icon

labelled <Pre>. Mic preamp gain of 0dB, +20dB, +40dB, or +60dB is set in the input source menu by clicking on the preamp

icon for a given channel and checking the appropriate gain.

Some microphones in paging applications have a button/switch which the user must push in order to use the microphone.

This button acts as a contact closure which is wired to a logic input and used to control mute and ducking functionality. When

the <Push To Talk Mic> box is checked in the input preamp section, that channel’s mic will only be unmuted when the assigned

logic pin’s contact is closed (the button is pressed). Note: the push to talk mic feature mutes the mic channel and indicates its

status by turning the mute button orange. Manual mute will still override the push-to-talk unmuting of that channel. Also, if that

mic is also a ducking trigger, it will trigger the ducked channel level reduction immediately, regardless of the mic input level.

13. AES3 Input Channels - AES3 (AES/EBU) is a digital audio format where two channels of digital audio are transmitted over a standard mic cable. Depending on the option installed, the AES3 input expansion card receives four or eight channels

of audio which can then be routed, processed, and distributed. When an AES3 input is installed, the input source select tab

allows for exclusive selection of AES3 input, as well as selection of AES3 with analog backup in the event there is no digital

input signal. AES3 has a cable length limitation of about 100 meters depending on cable type and impedance ratings. Refer to

the AES3 specications for detailed line impedance and impedance matching information.

14. AES3 Outputs - AES3 outputs, if installed, always carry the exact same audio signals as the line outputs, except in

AES3 format. There is no access to AES3 outputs in software.

15. Network Audio Card - Ashly currently supports Dante and CobraNet network audio options, offering a full featured

audio interface portal into or out of the larger audio network. See the NE software section on network audio for further implementation details.

8

Page 9

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

9. PROTEAne SOFTWARE

Device Options Menu

Flash Reprogram

The NE processor rmware (the internal program that runs the unit) can be updated/reprogrammed via the Ethernet control

connection. The latest rmware le can be downloaded from our web site, and installed according to the <Flash Programmer>

dialogue box. During reprogramming process, all channels are muted and both sampling rate LEDs will be lit amber.

Link Conguration

Linking allows multiple DSP processing blocks on different channels or even different Ashly NE devices to track each

other. For example - if two graphic equalizers on different channels are linked, any change made to one of the equalizers will

result in an identical change to the other. Most DSP blocks can be linked to one of eight link groups. When a DSP function is

assigned to a link group, both a colored tab and the link group number appear beneath the DSP block icon. The link group’s tab

color, group name, and local/network (link across devices) status is assigned in the link conguration dialogue box. Note: If a

WR-5 or RD-8C is connected to a NE device, and a DSP function that can be controlled by the WR-5 or RD-8C (such as gain)

is linked across multiple devices, changes made by that WR-5 or RD-8C will only affect it’s host NE device. Linked changes

across devices must come from the NE software, not remotes.

Meter Display

Software meter displays can be set to VU, dBu, or dBFS (dB Full Scale). dBFS is typically used when all or most of

the gain/level adjustments occur in the DSP domain. The front panel LEDs on the NE processor are dBFS only and cannot be

changed to dBu or VU. For comparison, 0 dBFS is the same as +20dBu on a product which clips at +20dBu. Therefore, -20dBFS

is typically the desired operating range, while still allowing 20dB headroom for transient signals.

AES3 Receiver Status

With a four or eight channel AES3 input option installed, each stereo AES3 input can be monitored for detected sample

rate error and other data errors that may occur between the AES3 source and the NE processor input. This can be useful for

diagnosing problems in either communication setup or wiring. Any errors detected by the NE processor are latched, meaning

even an intermittent error will be detected and remain highlighted until the <Reset Errors> button is clicked.

Sample Rate and Master Clock Selection

This screen displays the current master clock source, current sample rate, and word clock status. Click on <Show Advanced

Control> to change master clock or sampling rate. The factory defaults are auto selection of the master clock and 48kHz sampling rate. Note: Network audio may not necessarily run at 96kHz. Also, network audio has the highest master clock priority,

because most network audio formats are unable to synchronize to a word clock master.

Disable Front Panel Mutes

This control prevents the NE processor mute buttons from functioning. Mute status can still be controlled from software.

DVCA Control

One of the DSP Gain block functions is called <Gain w/VCA>. With this function a channel can be assigned to one of

four virtual subgroups, each with a master fader within software.

DSP Enable/Disable Control

The user can disable DSP functions on selected inputs, outputs, or the entire mixer to free up DSP processing power.

Network Audio Matrix

The network matrix input/output functions allow the NE processor to be integrated into a larger digital audio network. With CobraNet,

the NE processor can selectively route incoming line, mic, or AES3 signals, including DSP processing, out to the CobraNet network using

the network matrix. Likewise, individual CobraNet network channels can be selected and routed (through DSP) to the analog or AES3

outputs of the NE processor. With Dante, the net matrix input does not offer selective matrix routing, that job is performed using the Dante

Controller. Dante net matrix output channels can be assigned in the software using the DSP output mixer, or by using Dante Controller

.

9

Page 10

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

Preset Options

Presets and Sub Presets

The NE processor will store up to 30 device presets or sub presets. A device preset takes a “snapshot” of the most common

audio settings and stores control data for all channels and all audio functions. A sub preset, although in the same format as the

full preset le, scans for and only stores the DSP parameters individually tagged as sub presets within each DSP tool box, within

one channel or across multiple channels. Sub Presets are thus used to change only the selected functions. When naming presets

or sub presets, indicate in the preset name if it is a sub preset, this will help later when assigning the sub preset to a recall event

such as contact closure or WR-5 control. Individual presets (or sub presets) can be saved to the processor by using <Preset Options/Save Preset (Sub Preset) To Device>, or saved to a PC using <Preset Options/Save (Sub Preset) To File>. Preset and sub

preset les for Ashly NE products use the extension (*.pne). A sub preset report can be generated to see what specic actions

will be taken when loading a sub preset.

A preset or sub preset le can be recalled from either a computer or from the processor’s internal memory. An installation can be set up so that an Ashly WR-5 active programmable remote, or a contact closure, triggers the recall of presets or sub

presets stored in the NE processor. For contact closure preset recall, use the software Logic I/O tab to assign one of 30 presets

or sub presets to one of the eight digital logic input pins on the processor’s back panel. For Ashly WR-5 preset management,

connect the WR-5 to the NE processor and use the WR-5 device in software to assign device and preset (or sub preset) controls.

Caution: A new preset may have dramatically different settings capable of damaging sound system components, so be careful

not to recall the wrong preset while the system is on.

The NE Processor Control Surface

Input Source

The input source tab displays all available inputs to the NE processor per channel pair, and allows the user to select which

input type and in what priority those inputs are to be used. Also shown is the current master clock and sampling rate.

Net Matrix Mode: If a network audio card is installed, and <Net Matrix> is selected under the device options menu, the

network audio input is removed from the primary input source tab and instead placed in the resulting <Net Matrix Inputs> tab,

along with the input DSP controls, allowing analog or AES3 inputs to be routed through the input DSP section and on out to the

external digital audio network. Likewise, the <Net Matrix Outputs> tab allows extraction of network digital audio channels for

routing to the output DSP section and out to the NE processor’s analog output channels.

DSP Controls

All of the DSP control is done in the DSP tab. If additional network audio is available to the DSP processor, select the <Net

Matrix> item under the device options menu, and the DSP controls will be split into input and output sections for interfacing

with the external Dante or CobraNet audio network. Complete explanation of each DSP function is available in the software

help. Open a placed DSP tool and press F1 for help with that tool. DSP controls include the following functions:

Dynamics: Brick Wall Limiter, Compressor, AutoLeveler, Ducker, Gate, Ambient Noise Compensation (outputs only)

Gain: Gain, Gain with VCA, Remote Gain, and WR-5 Remote Gain

Equalization:

Crossover: HPF and LPF on both inputs and outputs, 4 Way, 3 Way, or 2 Way Crossover on outputs only

Graphic 31 band, Parametric EQ with 10, 6, 4, or 2 band, Feedback Suppressor (inputs), FIR lter (outputs)

Delay: Speaker Delay (0-58mS), Delay (0-1.365mS)

Tools: Audio Meter (0 to -80dBFS), Signal Generator (pink noise, white noise, sinewave)

10

Page 11

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

Metering

Three separate metering tabs are available for viewing the autoleveler, compressor/gate actions, or overall input and output

signal levels across all channels. Note: In addition to the xed meter tabs, individual meter control objects can be placed on the

main software canvas and assigned to an input or output for a custom meter display.

Logic I/O

This tab is where the 12V digital logic I/O pins on the NE processor’s back panel are assigned function. Pins designated as

logic inputs, upon contact closure with the logic ground, can recall a preset, utilize ‘push to talk’ to unmute a mic input and trigger

a ducker, or be assigned no function. Do not wire contact closure switches to any external ground. If a logic input pin is unconnected, it will be internally pulled high. If a logic input pin is driven from an external source, any voltage from +2.3V to +25V

will be detected as logic high. Do not exceed +25V or damage may occur to the internal circuitry.

Pins designated as logic outputs will issue either a logic high level (+12V source at 10mA) or logic low level (0V sink

at 100mA) when the GPO function (general purpose output) is selected. The high or low output state is a function of the currently loaded preset, or can be the result of a WR-5 button programmed to set the logic output to active high or active low. The

logic outputs are current limited to sourcing no more than 10mA so that these outputs can be directly wired to LED indicators.

Security

The security tab allows several levels of user ID/password protected access. The default user ID is Admin, with no password until the principle operator enters one. Up to six additional users can be added, each with their own password and access

rights assigned by the Admin.

Network Properties

This is where to nd the current hardware and rmware conguration of a specic NE processor, as well as network

details. Also found here is an <Identify Device> button which will ash the Com LED on the face panel.

10. REMOTE CONTROL (check the Ashly website for updated or additional remote control models)

10.1 WR-5 Programmable Zone Controller

The WR-5 is a microprocessor based programmable remote control unit which can be used with the NE processor. The

WR-5 is designed to t into a standard US electrical wall box. Up to four WR-5 remotes can be phantom powered from one

NE processor. Additional remotes can be powered by using the Ashly RPS-18 remote power supply. Each of six buttons on the

WR-5 can be programmed to engage one of the following functions listed below. The up/down buttons are used to adjust the

function property.

1) Preset Recall

2) Preset Scroll Mode

3) Gain Control

4) Channel Engage/Mute

5) Zone Source Selection

6) Logic Output Active High

7) Logic Output Active Low

8) Matrix Mixer

Ashly WR-5 Programmable Controller

11

Page 12

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

(10.1 WR-5 continued)

Programming of each WR-5 button is done after the WR-5 is wired to its host NE processor through the remote data connector

and the NE processor is networked to a PC running Proteane software. Each WR-5 has its own identifying property and is uniquely

represented with its own software control surface. Click the <Identify Remote> button to nd a physical WR-5. For more than four

WR-5 remotes, the Ashly RPS-18 power supply must be used. Note that a jumper (J3) must be placed on the last and only the last

WR-5 in series, even if there is only one WR-5 being used (see previous drawing).

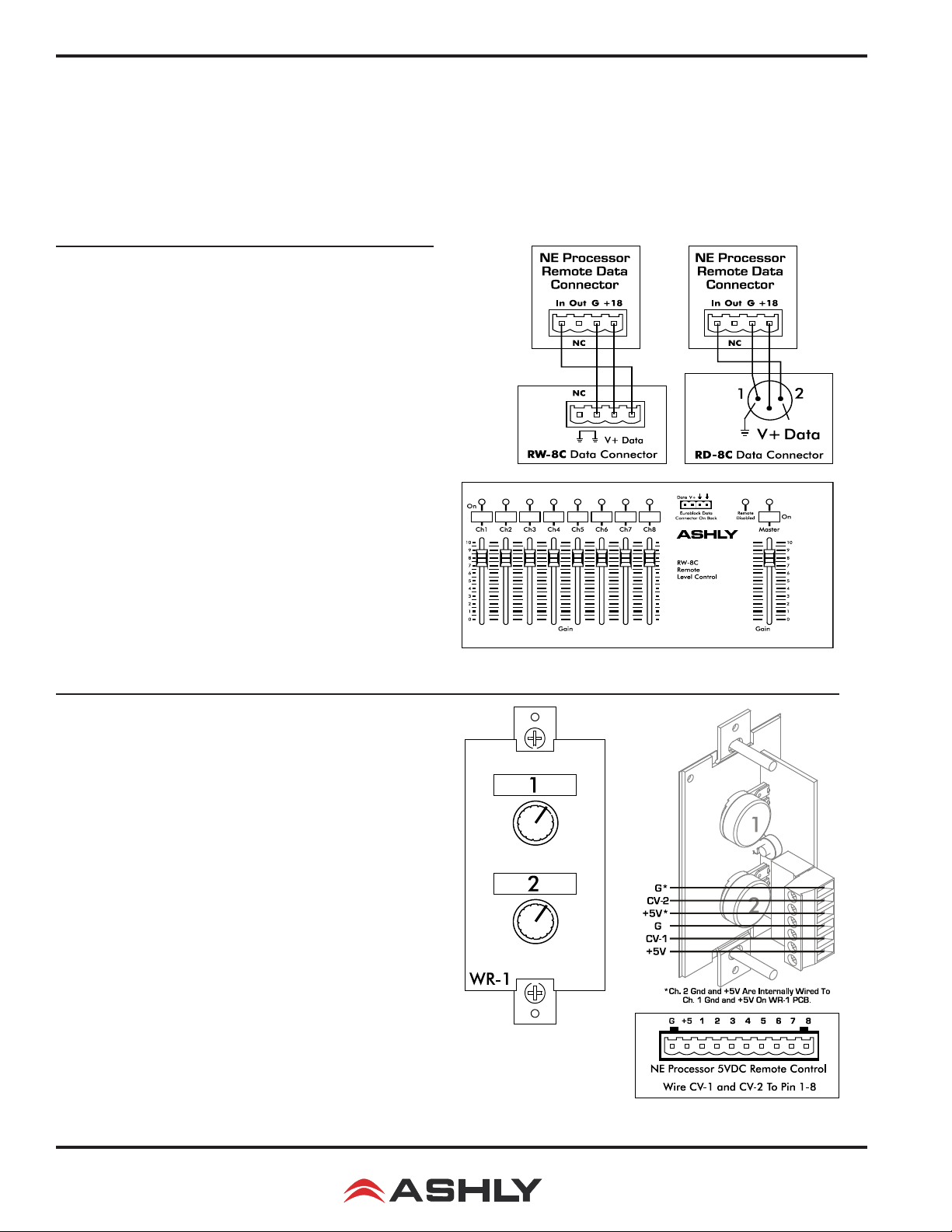

10.2 RD-8C or RW-8C Remote Fader Control

A second microprocessor based desktop controller, the

Ashly RD-8C (or RW-8C wall mount), is an eight channel level

controller that uses slide faders for individual channel and master

level control and mute. The RD-8C is wired to the four pin Data

Input euroblock connector on the back panel. Only one RD-8C

can be wired to a NE processor. NOTE: When an RD-8C is used,

no other serial data type remotes can be used.

In the software DSP section, a remote gain function must

be placed in any input or output and then assigned to one of the

RD-8C slide faders for remote level control of that channel. The

RD-8C uses an XLR jack, while the RW-8C uses a euroblock

connector to wire to the NE processor (see wiring diagram).

10.3 WR-1 Remote DC Level Control

Individual input or output channels can have remote level

control using a potentiometer assembly such as the Ashly WR-1

and four conductor bell wire. The WR-1 is a dual potentiometer

remote volume control designed to t in a standard US electrical

wall box. Each volume control is connected to a terminal block

on the WR-1 circuit board, which is then wired to the processor

back panel euroblock connector labeled “5VDC Remote Control” as shown. Do not connect the WR-1 remote level control

ground to any other external grounds.

10.4 WR-1.5 Level and Preset Recall (not shown)

The WR-1.5 offers a four position rotary switch for preset

recall along with a single potentiometer for DC level control.

See our website for further details.

10.5 WR-2 Pushbutton Preset Recall (not shown)

The WR-2 offers four pushbutton switches for recalling device presets by wiring to the NE processor logic inputs and assigning them preset recall function. See our website for WR-2 details.

Ashly RW-8C Remote Level Controller

Ashly WR-1 Remote DC Level Controller

12

Page 13

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

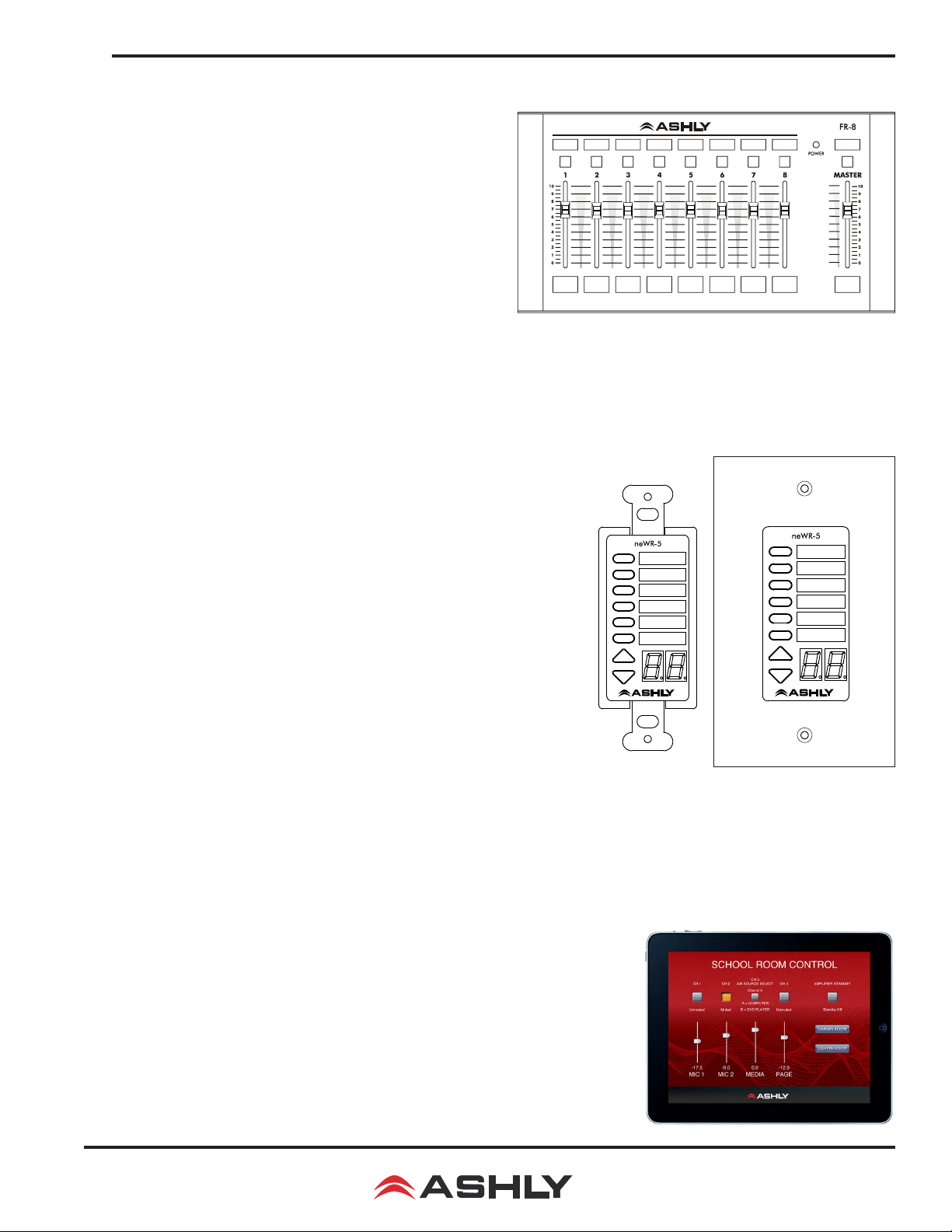

10.6 FR-8 and FR-16 Networked Fader Controller

The FR-8 (shown) and FR-16 (not shown) are eight and

16 channel programmable fader remote control devices which

connect to the NE processor over an Ethernet network. Each

fader can be assigned in Proteane software to control level in

one or more channels. A pushbutton LED switch associated

with each fader shows signal level/clip for audio signals

controlled by that fader and can be assigned mute function or

A/B source select for that fader. The FR-8 and FR-16 devices

can mount to a wall box, panel cutout, or remain freestanding.

Power is from an IEEE 802.3af Power over Ethernet

(PoE) switch, hub, or in-line PoE injector. A back panel

lockout connection is available to disable all controls using a

key switch.

The FR-8 or FR-16 appears in the Proteane software device network tree and must be assigned to the NE processor under

control. Labels can be inserted behind the mylar overlay to properly identify custom programmed fader and button functions.

10.7 neWR-5 Networked Programmable Button Controller

Ashly FR-8 Networked

Programmable Fader Controller

The neWR-5 remote control is a networked version of the WR5, using Ethernet instead of the Data Port to communicate with the NE

processor. Connecting and powering the neWR-5 is done using Cat-5

Ethernet cable and an IEEE 802.3af Power over Ethernet (PoE) switch,

hub, or in-line PoE injector. If PoE is unavailable, the Ashly RPS-18 (sold

separately) is a 15-48VDC power supply capable of at least 2 watts per

neWR-5 and can be hard wired to the back of the neWR-5. PoE current

draw is 38mA @48VDC and 80mA@15VDC. A decora cover plate

(not included) can be purchased at hardware stores to cover the neWR-5

electrical box and satisfy the aesthetic needs of the installation.

The neWR-5 appears in the Proteane software device menu tree and

must be assigned to the NE processor under control. The neWR-5 has six

programmable function buttons which can light up green, red, or amber to

display status. Further information on LED status is found in the neWR-5

owner’s manual available on the Ashly website. To the right of the function

buttons is a pocket in the mylar overlay for a printed function label

(template available on website) to be inserted. The two other buttons are

used to adjust function parameters such as gain or preset number, and are

indicated by the LED display.

There is also a hard-wired Lock-Out feature on the neWR-5, where the closing of a switch wired to the lockout

Euroblock renders all buttons inactive.

Ashly neWR-5Networked

Programmable Button Controller

10.8 Ashly Remote App for iPad

A custom and secure touch-screen control surface for the iPad® can be designed

using the <Ashly Remote> application, available free on iTunes® or via the Ashly website.

Controls, labels, and images are combined to manage key processor functions over a wireless network connection.

®

13

Page 14

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

11. SPECIFICATIONS Note: 0dBu = 0.775Vrms, 0dBFS (dB full scale) = +20dBu

Overall Sonic Performance . . . . . . . . . . . . . . . . Analog in, digital out Digital in, analog out Analog in, analog out2 Digital in, digital out

Frequency Response, 20 Hz – 20 kHz: . . . . . . . . . . . . . .+/- 0.1 dB +/-0.25 dB +/- 0.25 dB NA

Dynamic Range, 20Hz-20kHz, unweighted: . . . . . . . . . .> 115 dB > 114 dB > 114 dB NA

THD+N, 1kHz, +20dBu analog (-1dBFS digital): . . . . .< 0.001 % < 0.002 % < 0.002 % < 0.00001 %

Latency at 48 kHz (96 kHz)4: . . . . . . . . . . . . . . . . . . . . . .1.42 ms (0.71 ms) 0.90 ms (0.45 ms) 2.21 ms (1.11 ms) 0.10 ms (0.05 ms)

Notes: 1) Measured 20 Hz – 20 kHz unweighted using AES17 LPF at 48 kHz sample rate.

2) Analog in to analog out measured using internal master clock.

3) Zero noise or signal amplitude variation introducted in digital domain.

4) Latency of network audio link is additional to latency of digital audio processor.

Audio Inputs . . . . . . . . . . . . . . . . . . . Analog Line/Mic AES3 Digital

Input Type:. . . . . . . . . . . . . . . . . . . . . . Active balanced Euroblock Transformer balanced female XLR

Input Impedance: . . . . . . . . . . . . . . . . . 20k ohms 110 ohms

Max Input Level: . . . . . . . . . . . . . . . . . +20 dBu 7.0 Vpp

Audio Outputs

Output Type:. . . . . . . . . . . . . . . . . . . . . Servo-balanced Euroblock AES3 Transformer balanced male XLR

Output Impedance:. . . . . . . . . . . . . . . . 20 ohms 110 ohms

Max Output Level: . . . . . . . . . . . . . . . . +20dBu 5.0 Vpp

Word Clock

Input/output Type: . . . . . . . . . . . . . . . . 75 ohm BNC

Lock Range: . . . . . . . . . . . . . . . . . . . . . 48 kHz +/- 4%, 96 kHz +/- 4%

Input Impedance: . . . . . . . . . . . . . . . . . Selectable 75 ohm or high-impedance

Input Voltage Range: . . . . . . . . . . . . . . 1.0 Vpp – 7.0 Vpp

Output Impedance:. . . . . . . . . . . . . . . . 75 ohm

Output Level: . . . . . . . . . . . . . . . . . . . . 5.0 Vpp nominal, unterminated

Master Clock

Sources: . . . . . . . . . . . . . . . . . . . . . . . . Audio network, Word clock, AES3, Internal crystal clock

Modes: . . . . . . . . . . . . . . . . . . . . . . . . . Prioritized auto switching or manual

Digital Audio Hardware

Samples Rates:. . . . . . . . . . . . . . . . . . . 48 kHz, 96 kHz

DSP Processing: . . . . . . . . . . . . . . . . . 32-bit oating-point Sharc® processor array

Audio Input Source Selection: . . . . . . . Selectable in adjacent channel pairs from analog, digital, or network inputs

Network Audio Routing:. . . . . . . . . . . . Selectable between input/output or internal to matrix mixer

Digital Audio Output Jitter:. . . . . . . . . 0.5 ns average, 1.0 ns peak

Remote Control

Ethernet Control . . . . . . . . . . . . . . . . . Standard RJ45 10/100 Ethernet with auto-conguration

RS-232 Control . . . . . . . . . . . . . . . . . . Standard female Dsub9 jack (RS-232 control protocol document for Ashly NE products available on Ashly website)

4-pin active remote. . . . . . . . . . . . . . . . 4-pin Euroblock for phantom-powered bi-directional remotes

Logic Inputs (up to eight). . . . . . . . . . . 9-pin Euroblock for assignable logic inputs. Detected logic high range is from +2.3V to +25V. Do not exceed +25V.

Logic Outputs (up to eight) . . . . . . . . . Shared pins with logic inputs. Source: +12V at 10mA for logic output high. Sink: 0V at 100mA for logic output low.

Analog Control

Remote attenuators . . . . . . . . . . . . . . . 10-pin Euroblock for (8) assignable 0-5 VDC passive remote attenuators

3

3

Compatible Ashly Remotes

DC level control. . . . . . . . . . . . . . . . . . WR-1, WR-1.5

Preset recall. . . . . . . . . . . . . . . . . . . . . WR-1.5, WR-2, WR-5, neWR-5, Ashly Remote iPad® app

Remote serial data control. . . . . . . . . . WR-5, RD-8C

Remote Ethernet control . . . . . . . . . . . Proteane Software, neWR-5, FR-8, FR-16, Ashly Remote iPad® app

Microphone Input Option

Mic Input Connectors . . . . . . . . . . . . . Euroblock (5.08mm)

Phantom Power . . . . . . . . . . . . . . . . . . On/Off Switch, +48V @ 14mA per mic (balanced)

Preamp Gain (software select). . . . . . . . . 0dB, +20dB, +40dB, +60dB

Equivalent Input Noise. . . . . . . . . . . . . -128dBu, 20Hz-20kHz, 150 Ohm source

AES3 Digital Audio Option

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . Four or Eight channel, 110 ohm transformer balanced XLR, AES3 Outputs are pass-through only (no DSP)

Sample Rates . . . . . . . . . . . . . . . . . . . . 48kHz, 96kHz

Max Cable Length . . . . . . . . . . . . . . . . 100 meters

Network Audio Option

Available Types . . . . . . . . . . . . . . . . . . Dante, CobraNet

Power Requirements: . . . . . . . . . . . . . 90-240 VAC, 50-60 Hz, 70W maximum

Weight:. . . . . . . . . . . . . . . . . . . . . . . . . .Unit weight 10.5 lbs (4.77kg), Shipping weight 12.7 lbs. (5.78 kg)

Dimensions:. . . . . . . . . . . . . . . . . . . . . 19.0” L x 3.5” H x 8.5” D (48.26 cm x 8.89 cm x 21.59 cm)

Environmental: . . . . . . . . . . . . . . . . . . 40-120° F, (4-49° C), noncondensing

14

Page 15

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

DSP Specications

Dynamics

Brick Wall Limiter

Threshold: . . . . . . . . . . . . . . . . . . . . . . -20dBu to +20dBu

Ratio: . . . . . . . . . . . . . . . . . . . . . . . . . . innite

Attack: . . . . . . . . . . . . . . . . . . . . . . . . . 0.2ms/dB to 50 ms/dB

Release: . . . . . . . . . . . . . . . . . . . . . . . . 5ms/dB to 1000ms/dB

Compressor

Threshold: . . . . . . . . . . . . . . . . . . . . . . -20dBu to +20dBu

Ratio: . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2:1 to innite

Attack: . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 to 50ms

Release: . . . . . . . . . . . . . . . . . . . . . . . . 5ms/dB to 1000ms/dB

Detector: . . . . . . . . . . . . . . . . . . . . . . . Peak/Average

Autoleveler

Target Level: . . . . . . . . . . . . . . . . . . . . -40dBu to +20dBu

Action: . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Gain: . . . . . . . . . . . . . . . . . . 0dB to +22dB

Ratio: . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2:1 to 10:1

Threshold Below Target: . . . . . . . . . . . -30dB to 0dB

Gain Increase/Decrease Rate:. . . . . . . 5ms/dB to 1000ms/dB

Hold Time: . . . . . . . . . . . . . . . . . . . . . . 0-6 sec

Ambient Noise Compensator (outputs only)

Maximum Gain: . . . . . . . . . . . . . . . . . . -20dB to +20dB

Min/Base Gain: . . . . . . . . . . . . . . . . . . -40dB to +20dB

Gain Change Rate: . . . . . . . . . . . . . . . 0.2s/dB to 20s/dB

Mixer Input Sensing Channel: . . . . . . . Input 1-4 or Input 1-8

Ambient Noise Threshold: . . . . . . . . . . -60dBFS to 0dBFS

Program/Ambient Gain Ratio:. . . . . . . 0.3 : 1 to 3 : 1

Ducker

Ducking Type: . . . . . . . . . . . . . . . . . . . high/low priority, trigger,

libuster, ducked at input,

ducked at mixer

Trigger Threshold: . . . . . . . . . . . . . . . -80dBu to +20 dBu

Ducking Release: . . . . . . . . . . . . . . . . . 5ms/dB to 1000ms/dB

Ducking Depth: . . . . . . . . . . . . . . . . . . 0dB to -30dB, -inf.

Gate

Modes: . . . . . . . . . . . . . . . . . . . . . . . . . Normal, lock-out,

Selectable frequency key

Frequency Key Filter: . . . . . . . . . . . . . Band-pass lter

Key Filter Range:. . . . . . . . . . . . . . . . . 20 Hz – 20 kHz, 1/64 oct. to 4 oct.

Threshold: . . . . . . . . . . . . . . . . . . . . . . -80dBu to +20dBu

Range: . . . . . . . . . . . . . . . . . . . . . . . . . off, 100dB to 0dB

Attack: . . . . . . . . . . . . . . . . . . . . . . . . . 0.2ms/dB to 50 ms/dB

Release: . . . . . . . . . . . . . . . . . . . . . . . . 5ms/dB to 1000ms/dB

Gain

Normal Gain Control: . . . . . . . . . . . . . -50dB (mute) to +12 dB in 0.5 dB

increments, polarity invert

Gain with Digital VCA: . . . . . . . . . . . 4 assignable groups, -50dB (mute) to

+12dB, polarity invert

Remote Gain Control: . . . . . . . . . . . . . 8 assignable 0–5V DC level controls

or Assignable RD-8C level control

(ne)WR-5 Remote Gain:. . . . . . . . . . . . Remote Gain -50dB (mute) to 0dB

Equalization

Feedback Suppressor (inputs only, 48kHz only)

(output FIR lter is disabled on channel using input feedback suppressor)

Filters: . . . . . . . . . . . . . . . . . . . . . . . . . 12

Filter Modes: . . . . . . . . . . . . . . . . . . . . Floating, restricted, manual, locked

Filter Types:. . . . . . . . . . . . . . . . . . . . . Notch, Parametric

Feedback detection freq. range: . . . . . 20 Hz – 20 kHz

Bandwidth Range. . . . . . . . . . . . . . . . . 0.016 to 3.995 Oct.

Sensitivity Control: . . . . . . . . . . . . . . . 5 levels

Floating Filter Reset:. . . . . . . . . . . . . . 5 seconds to 24 hours

FIR Filter (output only, 48kHz only, 2-384 taps)

(input feedback suppressor is disabled on channel using output FIR lter)

File types:. . . . . . . . . . . . . . . . . . . . . . . *.csv, *.r

gentle, normal, aggressive, user dened

Graphic EQ

Bands: . . . . . . . . . . . . . . . . . . . . . . . . . 31

Filter Types:. . . . . . . . . . . . . . . . . . . . . Constant Q, Proportional Q

Bandwidth Range: . . . . . . . . . . . . . . . . 0.499 Octave to 0.25 octave

Parametric EQ

Filter Type:. . . . . . . . . . . . . . . . . . . . . . 10-band, 6-band, 4-band, or 2-band

available on every input and output

Parametric Filters

Frequency Range: . . . . . . . . . . . . . . . . 20Hz to 20kHz

Level Range: . . . . . . . . . . . . . . . . . . . . +15dB to -30dB

Bandwidth Range: . . . . . . . . . . . . . . . . 0.016 Octave to 3.995 octave

6/12dB Hi/Low Shelf Filters

Frequency Range: . . . . . . . . . . . . . . . . 20Hz to 20kHz

Level Range: . . . . . . . . . . . . . . . . . . . . +15dB to -15dB

All Pass Filter

Frequency Range: . . . . . . . . . . . . . . . . 20Hz to 20kHz

Variable Q HP/LP Filters

Frequency Range: . . . . . . . . . . . . . . . . 20Hz to 20kHz

Q Range: . . . . . . . . . . . . . . . . . . . . . . . 0.267 to 3.047

Notch Filter

Frequency Range: . . . . . . . . . . . . . . . . 20Hz to 20kHz

Bandwidth Range: . . . . . . . . . . . . . . . . 0.016 to 3.995 octave

Bandpass Filter

Frequency Range: . . . . . . . . . . . . . . . . 20Hz to 20kHz

Bandwidth Range: . . . . . . . . . . . . . . . . 0.016 to 3.995 octave

Crossover

4 Way, 3 Way, 2 Way on Outputs Only,

Low-Pass and High Pass Filters on Inputs and Outputs

Type:. . . . . . . . . . . . . . . . . . . . . . . . . . . Bessel, Butterworth, Linkwitz-Riley,

Notched Linkwitz-Riley

Bessel: . . . . . . . . . . . . . . . . . . . . . . . . . 12/18/24/48 dB/octave

Butterworth:. . . . . . . . . . . . . . . . . . . . . 12/18/24/48 dB/octave

Linkwitz-Riley: . . . . . . . . . . . . . . . . . . . 12/24/48 dB/octave

Notched Linkwitz-Riley:. . . . . . . . . . . . 4th, 8th order

Frequency: . . . . . . . . . . . . . . . . . . . . . . off, 20Hz-20kHz

Delay

Speaker Delay

At 48 kHz: . . . . . . . . . . . . . . . . . . . . . . 58.65 ms in 20 µS increments

At 96 kHz: . . . . . . . . . . . . . . . . . . . . . . 29.32 ms in 10 µs increments

Long Delay

At 48 kHz: . . . . . . . . . . . . . . . . . . . . . . 1365.31 ms in 20 µS increments

At 96 kHz: . . . . . . . . . . . . . . . . . . . . . . 682.65 ms in 10 µS increments

Air Temperature Compensation . . . . . . Fahrenheit (-22°F to +122°F)

Celsius (-30°C to -50°C)

Tools

Signal Generator

Signal Types. . . . . . . . . . . . . . . . . . . . . Pink Noise, White Noise

Sine Wave (20Hz to 12kHz)

Level Range . . . . . . . . . . . . . . . . . . . . . Off, -50dBu to +20dBu

Individual Channel Level Meters

Range . . . . . . . . . . . . . . . . . . . . . . . . . . -80dBFS to 0dBFS

Matrix Mixer

Gain range: . . . . . . . . . . . . . . . . . . . . . +12 dB to –50dB in

0.5 dB increments, then OFF

Mute: . . . . . . . . . . . . . . . . . . . . . . . . . . Per input, On/Off

Auto:. . . . . . . . . . . . . . . . . . . . . . . . . . . Automix assign per input

Global Auto Mixer Response Time. . . . 0.01s to 2.00s

Linking

All functions can be linked to 1 of 8 link groups

15

Page 16

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

12. TROUBLESHOOTING TIPS

No Ethernet Communications

Is there LED activity on the back panel RJ-45 Ethernet connector? Is the ethernet cable good? Is good ethernet signal

getting to the point of application? (test by plugging in a laptop) Is your rewall blocking Proteane software? Do you have a

local area connection enabled? Do you have a secondary WiFi connection enabled? Ashly provides a comprehensive Ethernet

use guide and other topics in our website’s technical support section.

No Audio Meter Activity

Is the input wiring correct? Is the proper input source selected? Is the channel muted, gated, or ducked? Are all gain

stages properly set? Is the matrix mixer section properly routed? Do you have signal if you disconnect all WR-1 and/or RD-8C

units?

No Audio Output

Is the output muted? Are the DSP meters showing input or output signal? Are your inputs routed to, turned up, and

unmuted in the matrix mixer section of the DSP outputs? Are crossover lters mistakenly set to eliminate any pass band?

Distorted Sound

Do you see clip indicator lights in the audio chain? If the meter scales are set to dBFS, 0dBFS is the clipping point.

WR-5 Doesn’t Work

Is the wiring correct? Is the two pin jumper installed on J3 on the back side of the last WR-5 in series, even if there is

only one WR-5? If there are more than four WR-5 units in series, an external power supply must be used capable of providing

+18V at 25mA per WR-5. Does the WR-5 appear in the Protea Software network drop down menu underneath the host NE

processor? Are WR-5 functions properly dened in the WR-5 and/or NE Processor?

RD-8C or RW-8C Doesn’t Work

Is the wiring correct? Are proper RD8-C fader assignments made in the DSP Gain > Remote Gain > RD8C Controls

tool boxes for each applicable input or output channel requirement? No other serial data remote control units can be used when

using an RD-8C.

WR-1 Doesn’t Work

Is the wiring correct? Are proper control assignments made in the DSP Gain > Remote Gain > Rear Panel Remote

Level Controls tool boxes for each applicable input or output channel requirement?

How Do I Use RS-232?

RS-232 is available on the NE processor as a means for non-ethernet third party equipment to communicate control

information to the NE processor. An RS-232 implementation reference for the NE processor is available on the Ashly web site.

You cannot program any serial data remotes using RS-232. Only the data port connection on NE processors can be used to

program the WR-5 or RD-8C using Proteane software.

16

Page 17

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

13. BLOCK DIAGRAM

17

Page 18

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

14.

18

(See page 8 for further option details)

Page 19

Operating Manual - ne8800, ne4800, ne4400 DSP Processor

15. Ashly Audio Inc. LIMITED WARRANTY (USA ONLY)

(Other countries please contact your respective distributor or dealer.)

For units purchased in the USA, warranty service for this unit shall be provided by ASHLY AUDIO,

INC. in accordance with the following warranty statement.

ASHLY AUDIO, INC. warrants to the owner of this product that it will be free from defects in workmanship and materials for a period of FIVE years from the original-date-of-purchase. ASHLY AUDIO INC.

will without charge, repair or replace at its discretion, any defective product or component parts upon

prepaid delivery of the product to the ASHLY AUDIO, INC. factory service department, accompanied

with a proof of original-date-of-purchase in the form of a valid sales receipt. This warranty gives you

specic legal rights, and you may also have other rights, which vary from state to state.

EXCLUSIONS: This warranty does not apply in the event of misuse, neglect, or as a result of unauthorized alterations or repairs made to the product. This warranty is void if the serial number is

altered, defaced, or removed. ASHLY AUDIO, INC. reserves the right to make changes in design, or

make additions to, or improvements upon, this product without any obligation to install the same on

products previously manufactured.

Any implied warranties, which may arise under the operation of state law, shall be effective only for

FIVE years from the original-date-of-purchase of the product. ASHLY AUDIO, INC. shall be obligated

to only correct defects in the product itself. ASHLY AUDIO, INC. is not liable for any damage or injury,

which may result from, or be incidental to, or a consequence of, such defects. Some states do not

allow limitations on how long an implied warranty lasts, or the exclusion, or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you.

OBTAINING WARRANTY SERVICE:

For warranty service in the United States, please follow this procedure:

1) Return the product to ASHLY AUDIO, INC. freight prepaid, with a written statement describing the

defect and application that the product is used in. ASHLY AUDIO, INC. will examine the product and

perform any necessary service, including replacement of defective parts, at no further cost to you.

2) Ship your product to:

ASHLY AUDIO, INC.

Attention: Service Department

847 Holt Road

Webster, NY 14580-9103

19

Page 20

Operating Manual - ne8800, ne4800, ne4400

ASHLY AUDIO INC. 847 Holt Road Webster, NY 14580-9103, USA

Phone: (585) 872-0010 Fax: (585) 872-0739

Toll Free (800) 828-6308 ashly.com

©2015-2018 by Ashly Audio Corporation, a division of Jam Industries Ltd. All rights reserved worldwide.

All features, specications, and graphical representations are subject to change or improvement without notice.

Printed in USA R-10 01/18 v30m00460

Loading...

Loading...