Ashley AW3200E User Manual

MODEL: AW3200E

This product can expose you to chemicals including carbon monoxide, which

Ce produit peut vous exposer à des agents chimiques, y compris au monoxyde de

carbone, lesquels sont reconnus dans l’État de la Californie comme causant le cancer et

des malformations congénitales ou autres dommages au fœtus. Pour obtenir plus de

renseignements, veuillez consulter le site www.P65warnings.ca.gov

Save These Instructions. This manual will help you to obtain efcient,

dependable service from the heater, and enable you to order repair

parts correctly. Keep in a safe place for future reference.

R

SAFETY NOTICE: If this heater is not properly installed, a house re

may result. For your safety, follow the installation instructions. Never

use make-shift compromises during the installation of this heater.

Contact local building or re ofcials about permits, restrictions

and installation requirements in your area.

CAUTION! Please read this entire manual before you install or use

your new room heater. Failure to follow instructions may result in

property damage, bodily injury, or even death. Improper Installation

Could Void Your Warranty!

ALL PICTURES SHOWN ARE FOR ILLUSTRATIVE PURPOSES ONLY.

ACTUAL PRODUCT MAY VARY DUE TO PRODUCT ENHANCEMENT.

This manual is subject to change without notice.

Report Number: F20-586

Tested Per EPA Methods ALT-125, ASTM

E2515, ASTM E3053 and CSA B415

Certied to UL 1482-2011 (R2015) and

ULC-S627-00 (R2016)

Approved for mobile home installation

in (USA ONLY)

U.S. Environmental Protection Agency

Certied to comply with 2020

particulate emissions standards.

CALIFORNIA PROPOSITION 65 WARNING:

is known to the State of California to cause cancer, birth defects and/or other

reproductive harm. For more information, go to www.P65warnings.ca.gov

United States Stove Company

227

Industrial Park Rd.,

South Pittsburg, TN 37380

PH: (800) 750-2723

www.usstove.com

853748-0705J

The instructions pertaining to the installation of your wood stove comply with UL-1482 (R2015) and ULC-S627

standards. This manual describes the installation and operation of the Ashley, AW3200E wood heater. This heater

meets the 2020 U.S. Environmental Protection Agency’s cordwood emission limits for wood heaters sold after May

15, 2020. Under specic test conditions this heater has been shown to deliver heat at rates ranging from 19,778

to 67,992 Btu/hr with 1.3 g/hr and 71% efciency. Note: The BTU ratings mentioned above are based on the EPA

test protocol under specic test conditions. Our advertised BTU’s are based on the rst hour of operation at high

burn rate burning cordwood.

Combustible: Wood

Colors: Metallic Black

Flue Pipe Diameter: 6” (153 mm)

Flue Pipe Type: (Standard Single Wall or Double Wall): Black or Blued Steel 2100°F (650°C)

Minimum Chimney Height: 12’ (3.7 m)

Maximum Log Length: 18” (458 mm)

Electrical: 120VAC, 0.55A, 60Hz

Dimensions

DEPTH WIDTH HEIGHT

Overall: Depth x Width x Height: 39” (995 mm) 24” (612 mm) 32-1/2” (826 mm)

Combustion Chamber: Width x Depth: 18-5/16” X 22-1/4” (466 mm X 565 mm)

Door Opening: Width x Height: 14-3/4” 9-7/16” (375 mm X 241 mm)

Pyroceramic Glass Door: (Viewing) Width x Height: 14-9/16” X 9-5/16” (369 mm X 237 mm)

CAUTIONS:

• HOT WHILE IN OPERATION. KEEP CHILDREN, CLOTHING AND FURNITURE AWAY. CONTACT MAY CAUSE SKIN

BURNS.

• DO NOT USE CHEMICALS OR FLUIDS TO IGNITE THE FIRE.

• DO NOT LEAVE THE STOVE UNATTENDED WHEN THE DOOR IS SLIGHTLY OPENED.

• DO NOT BURN GARBAGE, FLAMMABLE FLUID SUCH AS GASOLINE, NAPHTHA OR MOTOR OIL.

• DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

• ALWAYS CLOSE THE DOOR AFTER THE IGNITION.

Note: Register your product on line at www.usstove.com. Save your receipt with your records for any claims.

-2-

Assembly

83172 x 2

r

UNPACK AND INSPECT

Remove the packing from the appliance and inspect for any damage. Your appliance is packed with the door

handle spring not installed. Ensure that the bricks are positioned correctly and not broken (see illustration for

proper brick arrangement). Make sure that the bafe board, above the air tubes, is in place and undamaged.

(DO NOT REMOVE).

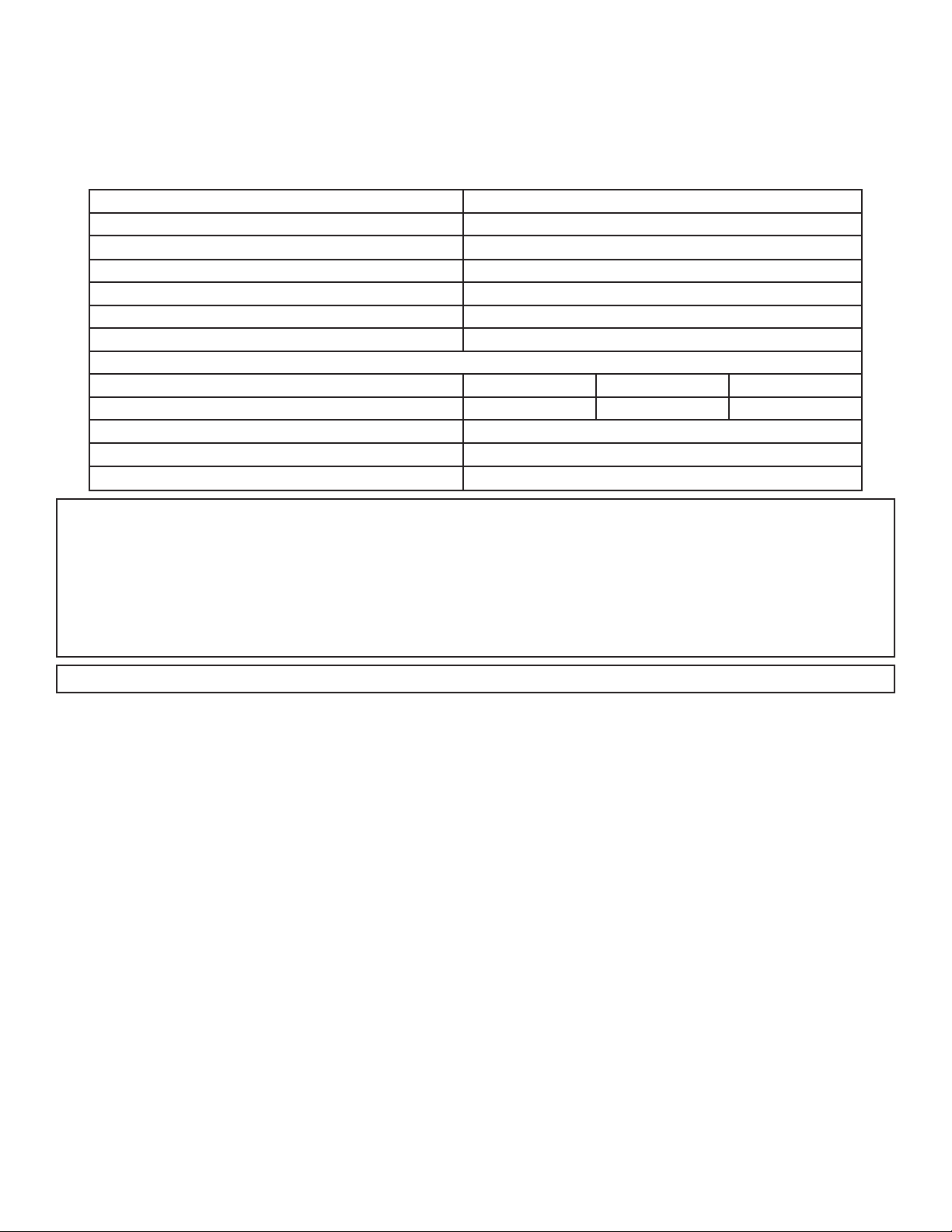

BLOWER ASSEMBLY

The blower assembly must be disconnected from

the source of electrical supply before attempting the

installation. The blower assembly is intended for use only

with a stove that is marked to indicate such use. Do

not route the supply cord near or across hot surfaces!

Fix the assembly to the back of the stove with the four

screws provided.

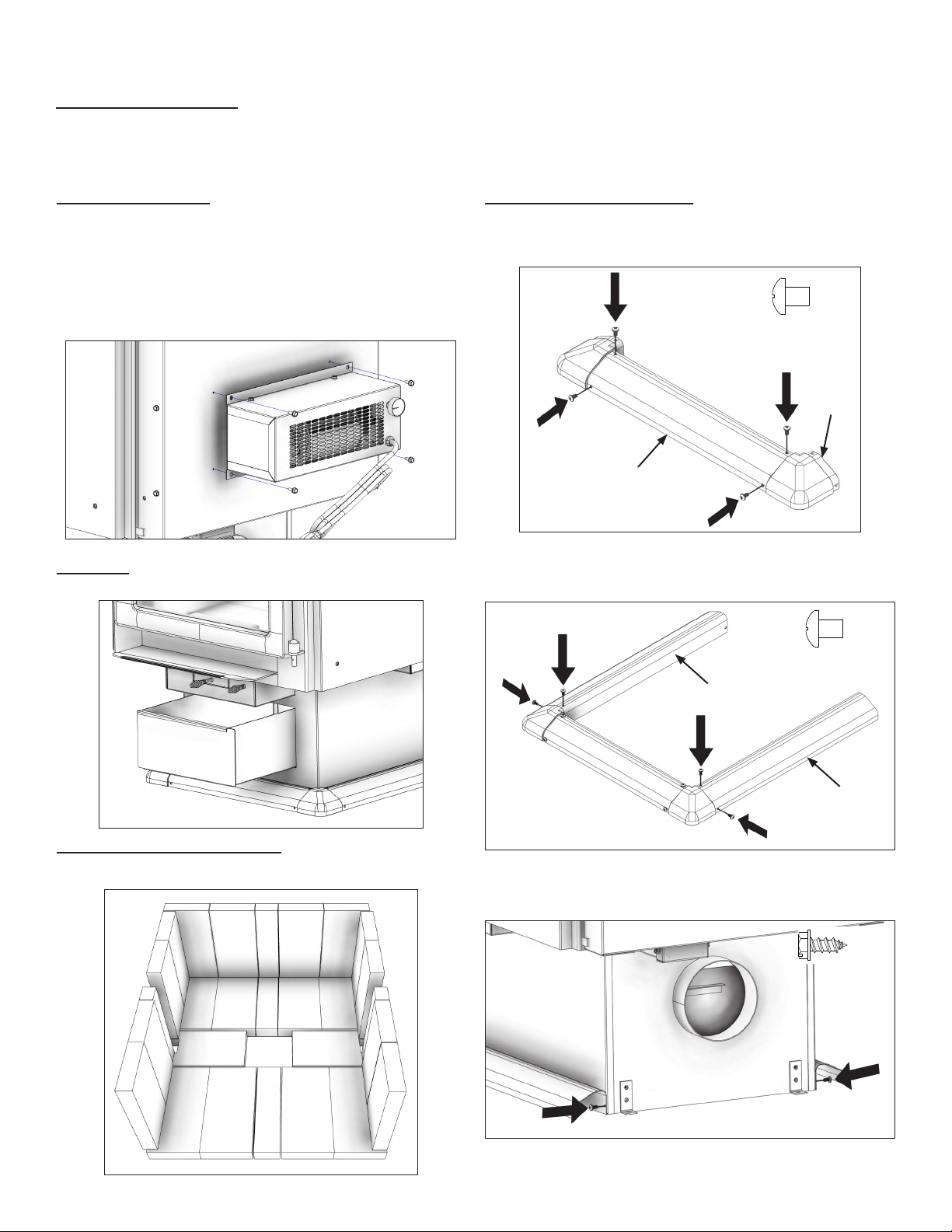

PEDESTAL BASE ASSEMBLY

1. Assemble the pedestal base skirting. Attach two

corner pieces (A) to the center section (B) of

skirting and secure with four (4) truss head screws.

X 4

A

B

ASH PAN

The ash pan is located below the rebox.

FIREBRICK CONFIGURATION

Replace the Firebrick as shown in the illustration.

2. Attach the side skirting sections (C & D) to the

corner pieces and secure with four (4) truss head

screws.

X 4

C

D

3. Slide the U-shaped skirting assembly around the

pedestal base and secure with two 1/4” long pan

head sheet metal screws at the rear corners.

X 2

-3-

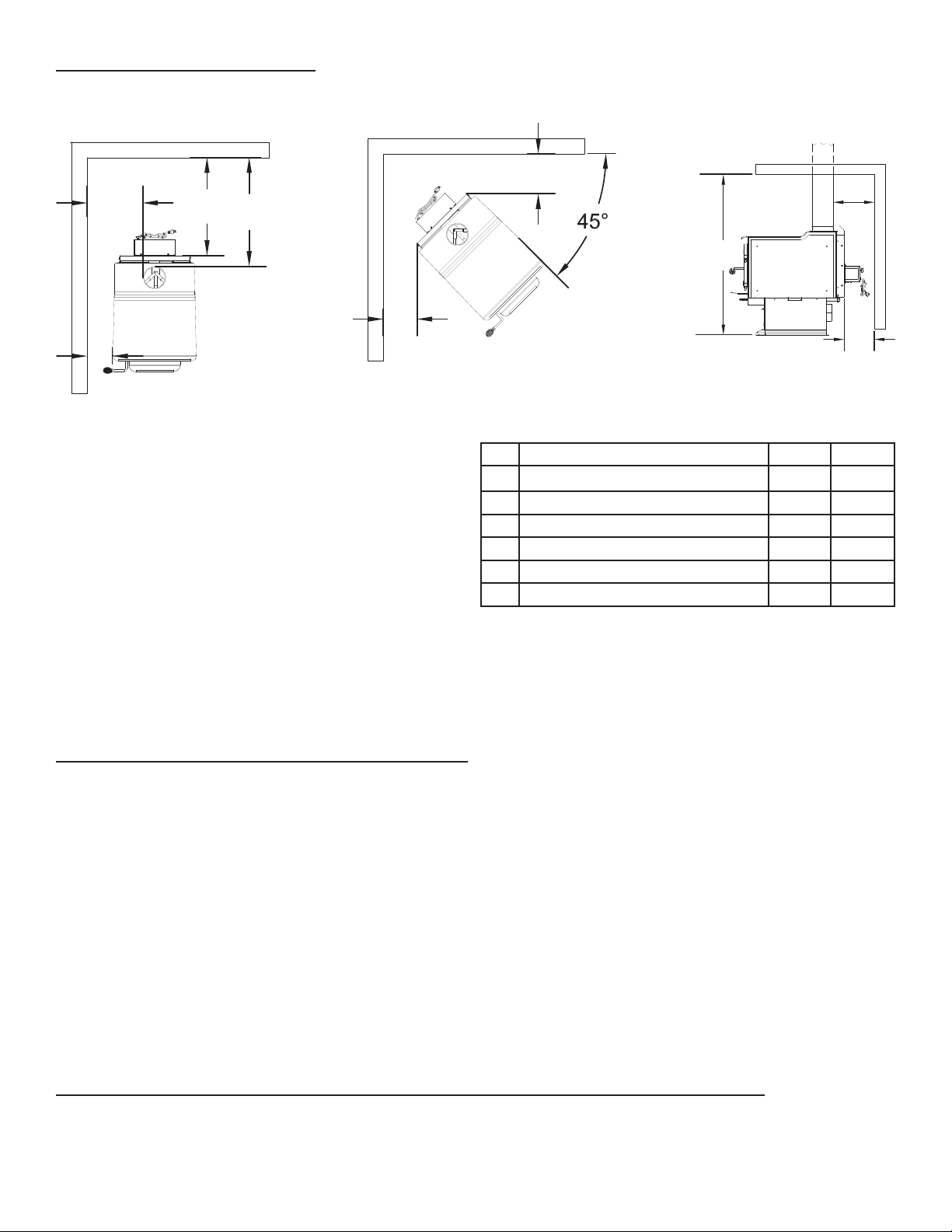

FLOOR PROTECTOR DIMENSIONS

Installation

SAFETY NOTICE

• IF THIS STOVE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. TO REDUCE THE RISK OF FIRE, FOLLOW

THE INSTALLATION INSTRUCTIONS.

• CONSULT YOUR MUNICIPAL BUILDING DEPARTMENT OR FIRE OFFICIALS ABOUT PERMITS, RESTRICTIONS AND

INSTALLATIONS REQUIREMENTS IN YOUR AREA.

• USE SMOKE DETECTORS IN THE ROOM WHERE YOUR STOVE IS INSTALLED.

• KEEP FURNITURE AND DRAPES WELL AWAY FROM THE STOVE.

• NEVER USE GASOLINE, GASOLINE-TYPE LANTERN FUEL, KEROSENE, CHARCOAL LIGHTER FLUID, OR SIMILAR

LIQUIDS TO START OR “FRESHEN UP” A FIRE IN THIS HEATER. KEEP ALL SUCH LIQUIDS WELL AWAY FROM THE

HEATER WHILE IT IS IN USE.

• IN THE EVENT OF A CHIMNEY FIRE, PUSH THE AIR CONTROL FULL CLOSED TO DEPRIVE THE FIRE OF OXYGEN.

CALL THE FIRE DEPARTMENT.

• DO NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

• A SOURCE OF FRESH AIR INTO THE ROOM OR SPACE HEATED SHALL BE PROVIDED WHEN REQUIRED.

POSITIONING THE STOVE

It is very important to position the wood stove as close as possible to the chimney, and in an area that will favor

the most efcient heat distribution possible throughout the house. The stove must therefore be installed in the

room where the most time is spent, and in the most spacious room possible. Recall that wood stoves produce

radiating heat, the heat we feel when we are close to a wood stove. A wood stove also functions by convection,

that is through the displacement of hot air accelerated upwards and its replacement with cooler air. If necessary,

the hot air distribution from the stove may be facilitated by the installation of a blower. The wood stove must not

be hooked up to a hot air distribution system since an excessive accumulation of heat may occur. A wood stove

must never be installed in a hallway or near a staircase, since it may block the way in case of re or fail to respect

required clearances.

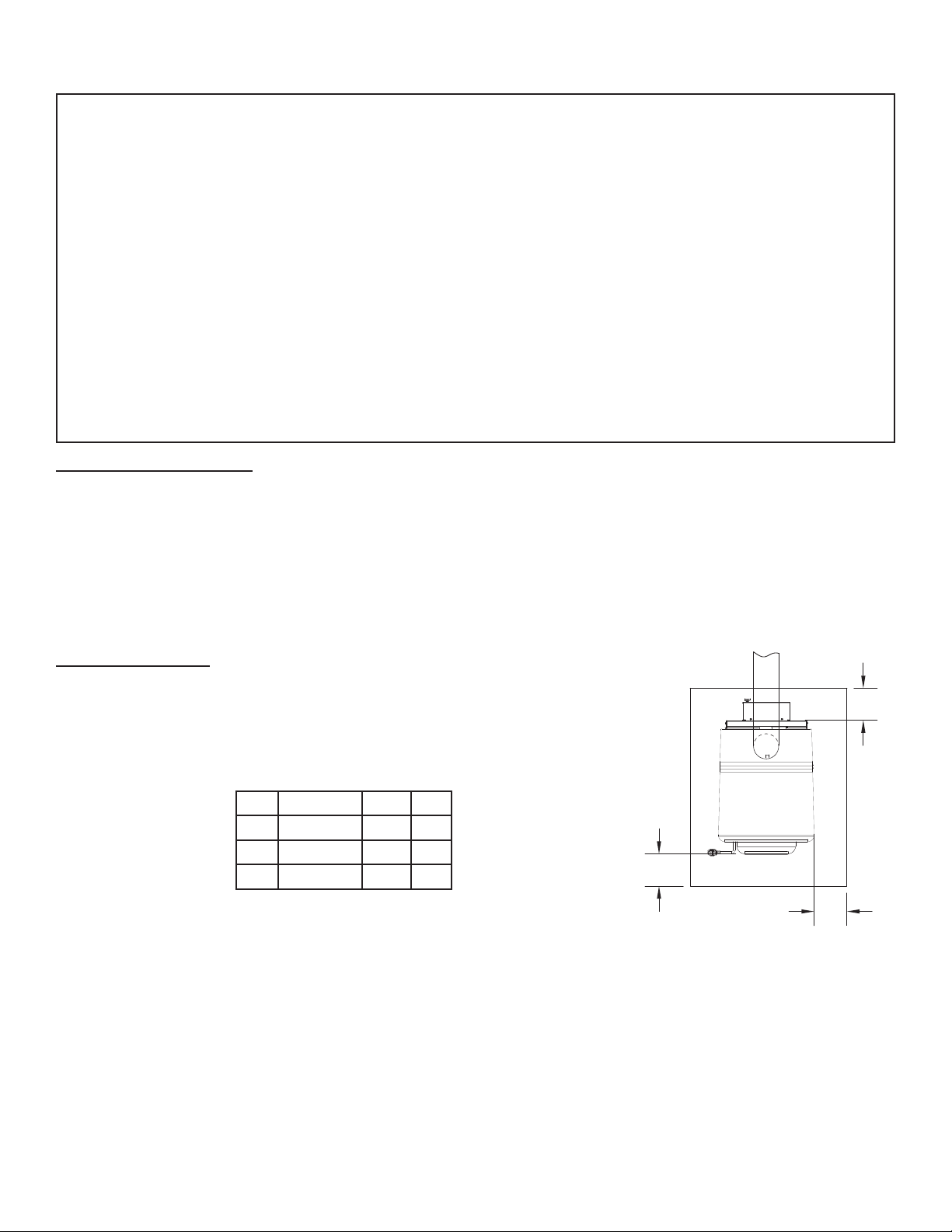

FLOOR PROTECTOR

This heater must have a non-combustible oor protector with an R-Value of at

least 1.2 installed beneath it if the oor is constructed of combustible material.

If a oor pad is used, it should be UL listed or equal. The oor protector should be

large enough to extend under the stove and beyond each side as indicated.

If there is a horizontal run of ue pipe, there needs to be oor protection under

it that extends two inches beyond either side of the pipe.

Key Dimension Inch mm

A Front 18 458

B Back 8 204

C Sides 8 204

B

A

C

-4-

CLEARANCE TO WALLS

Side wall

Side wall

Backwall

CLEARANCE TO WALLS

WALLS & CELING

CLEARANCES TO COMBUSTIBLES

It is of utmost importance that the clearances to combustible materials be strictly adhered to during installation

of the stove. Refer to the provided tables:

Backwall

Ceiling

F

J

D

H

G

H

F

E

CORNER INSTALLATION

CLEARANCE TO

CORNER INSTALLATION

D

• Do not place any combustible material within 4’

(1.2 m) of the front of the unit.

• The clearance between the ue pipe and a wall

are valid only for vertical walls and for vertical ue

pipe.

• The chimney connector must not pass through an

attic or roof space, closet or similar concealed

space, a oor, or a ceiling.

• For Canadian installations, where passage through

a wall, or partition of combustible construction

is desired, the installation must conform to CAN/

CSA-B365.

• A ue pipe crossing a combustible wall must have a

minimum clearance of 18” (457.2 mm).

• To reduce ue clearances from combustible

materials, contact your local safety department.

Key Dimensions Inch mm

D Backwall to Stove 17 432

E Sidewall to Stove 26 661

F Wall to corner (Angled Installation) 18 458

G Ceiling Height 84 2134

H Backwall to Flue 19 483

J Sidewall to Flue 35 889

SPECIAL MOBILE HOME REQUIREMENTS (USA ONLY)

WARNING! - Do not install in a sleeping room.

CAUTION! - The structural integrity of the mobile home oor, wall, and ceiling/roof must be maintained.

In addition to the previously detailed installation requirements, mobile home installations must meet the following

requirements:

• The space heater is to be connected to a factory-built chimney conforming to CAN/ULC-S629, Standard for

650°C Factory-Built Chimneys.

• The heater must be permanently attached to the oor (see “Securing Appliance’s On A Pedestal To The Floor”

section of this manual.

• The heater must be electrically grounded to the steel chassis of the mobile home with 8 GA copper wire using

• When moving your mobile home, all exterior venting must be removed while the mobile home is being

• Outside air is mandatory for mobile home installation. See your dealer for purchasing.

• Check with your local building ofcials as other codes may apply.

• Only use the specied components listed in this manual for this unit. The use of components that are not meant

a serrated or star washer to penetrate paint or protective coating to ensure grounding.

relocated. After relocation, all venting must be reinstalled and securely fastened.

for this unit can cause unsafe conditions.

COMBUSTION AIR ASSEMBLY INSTRUCTIONS (MOBILE HOME INSTALLATIONS - REQUIRED)

This appliance requires a source of combustion air. If your home is of tight construction or has negative pressure

problems, you will need an outside source of air. Below is a list of possible indicators that a source of outside

combustion air may be required.

-5-

• Your stove does not draw steadily, smoke rollout occurs, wood burns poorly, or back-drafts occur whether or

not there is combustion present.

• Existing fuel-red equipment in the house, such as replaces or other heating appliances, smell, do not operate

properly, suffer smoke roll-out when opened, or back-drafts occur whether or not there is combustion present.

• Opening a window slightly on a calm (windless) day alleviates any of the above symptoms.

• The house is equipped with a well-sealed vapor barrier and tight tting windows and/or has any powered

devices that exhaust house air.

• There is excessive condensation on windows in the winter.

• A ventilation system is installed in the house.

If an outside air intake is required, you may purchase a FAK-07 vent kit from your local stove dealer and install

it on the rear of the appliance.

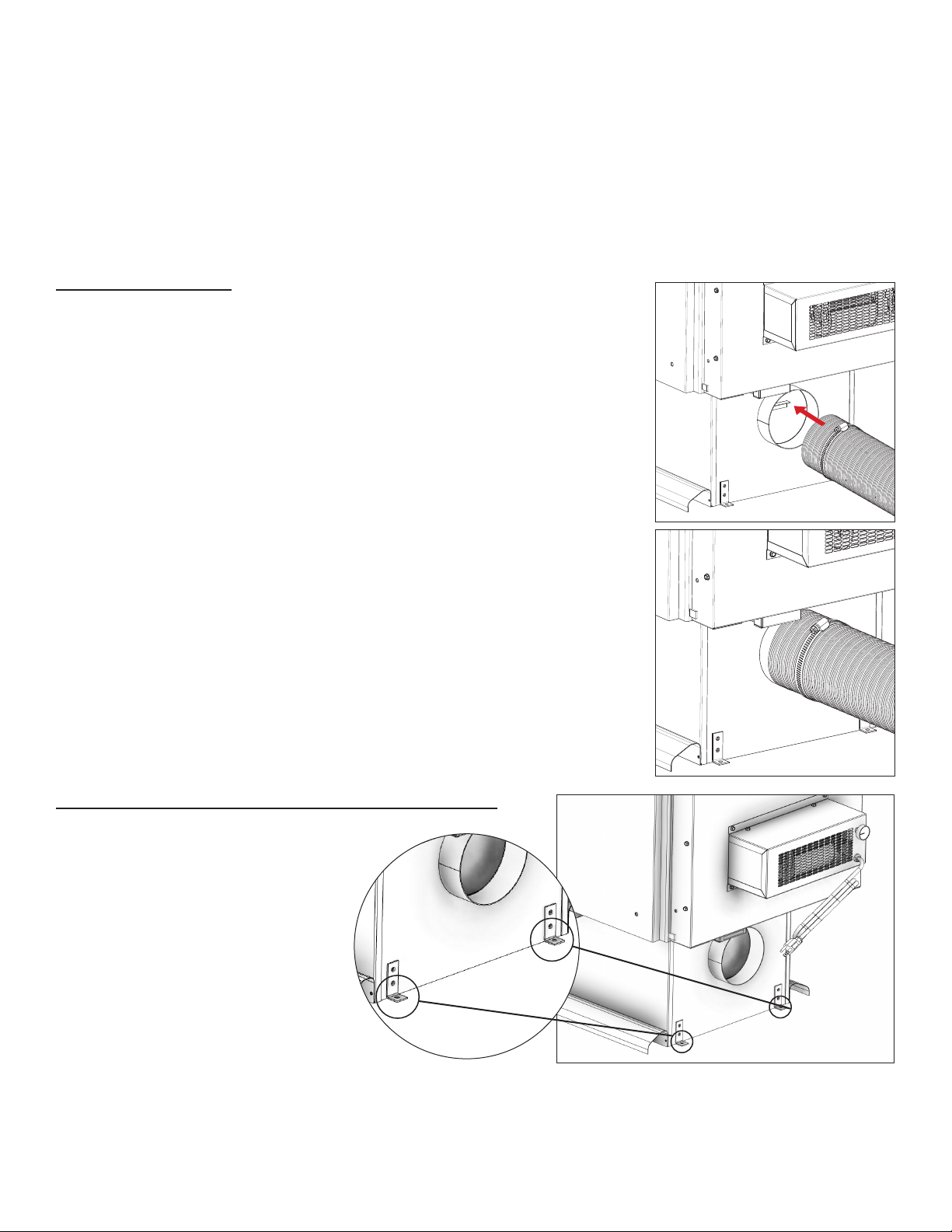

FAK-07 INSTALLATION

Installation must adhere to all local codes. If after reading these instructions

you have any doubt about your ability to complete the installation properly,

you must obtain the services of a licensed heating and cooling contractor or

certied wood stove installer.

• Drill a 5” hole through the wall at the desired point of entry. The point of

entry should be at or below the level of the intake air tube on the wood

stove. Slide the tail portion of the weather hood through the hole. Secure

the weather hood with fasteners at each of the four corners. This task should

be done after the stove has been installed and the exhaust piping routed.

Try to position the hole for the air intake as near as possible to the stove.

• Slide both hose clamps over the 5” aluminum ex pipe not included). Then

slide the ex pipe over the air intake tube of the stove. Apply the rst hose

clamp over this end of the aluminum ex hose and tighten.

• Route the ex pipe to the “through wall connection” and slid the ex pipe

over the tail piece. Apply the second hose clamp over the tail piece and

tighten.

NOTE: Fasteners are not provided with this kit. Please obtain fasteners (size

8 x 1-1/2” pan head) that are made for your home’s exterior wall type (i.e.

masonry, wood, ect.).

FAK-07 Kit consists of the following parts: Weather Hood with 5” connector

pipe attached and hose clamps.

SECURING APPLIANCE’S ON A PEDESTAL TO THE FLOOR

Use the designated holes to secure the unit to the oor.

-6-

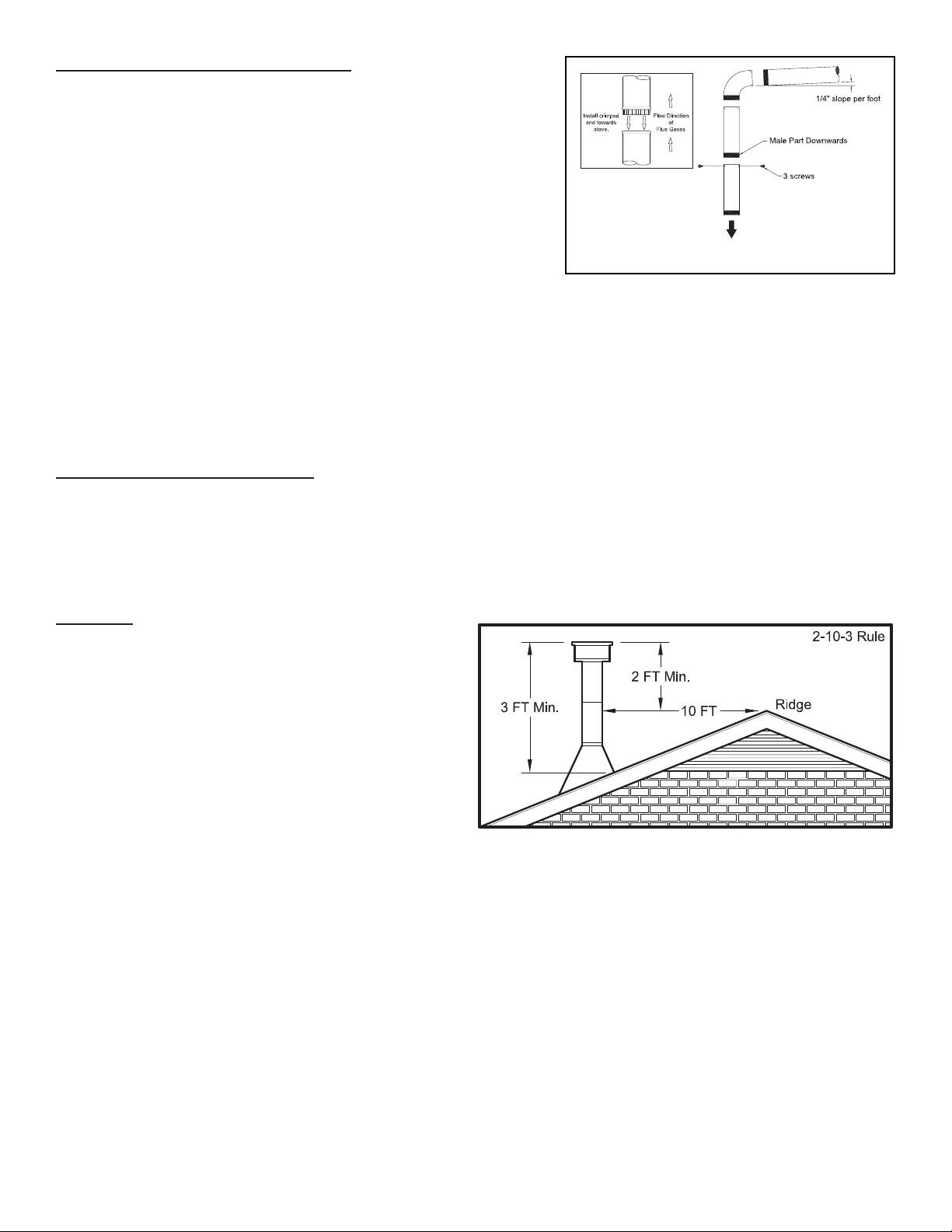

CHIMNEY CONNECTOR (STOVE PIPE)

To

Appliance

The chimney connector and chimney must have the same

diameter as the stove outlet (6”). If this is not the case, we

recommend you contact your dealer to ensure there will be no

problem with the draft. The stovepipe must be made of aluminized

or cold roll steel and have a minimum thickness of 0.021” or

0.53mm. It is strictly forbidden to use galvanized steel. The smoke

pipe should be assembled to promote the male section (crimped

end) of the pipe to be faced down. Attach each section to

another with three equidistant metal screws. The pipe must be

short and straight. All sections installed horizontally must slope at

least 1/4 inch per foot, with the upper end of the section toward

the chimney. Any installation with a horizontal run of chimney pipe

must conform to NFPA 211. Contact NFPA (National Fire Protection Association) and request the latest edition of

the NFPA Standard 211. To ensure a good draft, the total length of the coupling pipe should never exceed 8’ to

10’ (2.4m to 3.04m). Except for cases of vertical installation, in a cathedral-roof style where the smoke exhaust

system can be much longer and connected without problem to the chimney at the ceiling of the room. There

should never be more than two 90 degrees elbows in the smoke exhaust system. The installation of a “barometric

draft stabilizer” (replace register) on a smoke exhaust system is prohibited. Furthermore, the installation of a draft

damper is not recommended. With a controlled combustion wood stove, the draft is regulated upon intake of

the combustion air in the stove and not at the exhaust.

IMPORTANCE OF PROPER DRAFT

Draft is a force that moves air from the appliance up through the chimney. The amount of draft in your chimney

depends on the length of the chimney, local geography, nearby obstructions and other factors. Too much draft

may cause excessive temperatures in the appliance. An inadequate draft may cause back-pufng into the

room and “plugging” of the chimney. An inadequate draft will cause the appliance to leak smoke into the room

through appliance and chimney connector joints. An uncontrollable burn or excessive temperature indicates an

excessive draft.

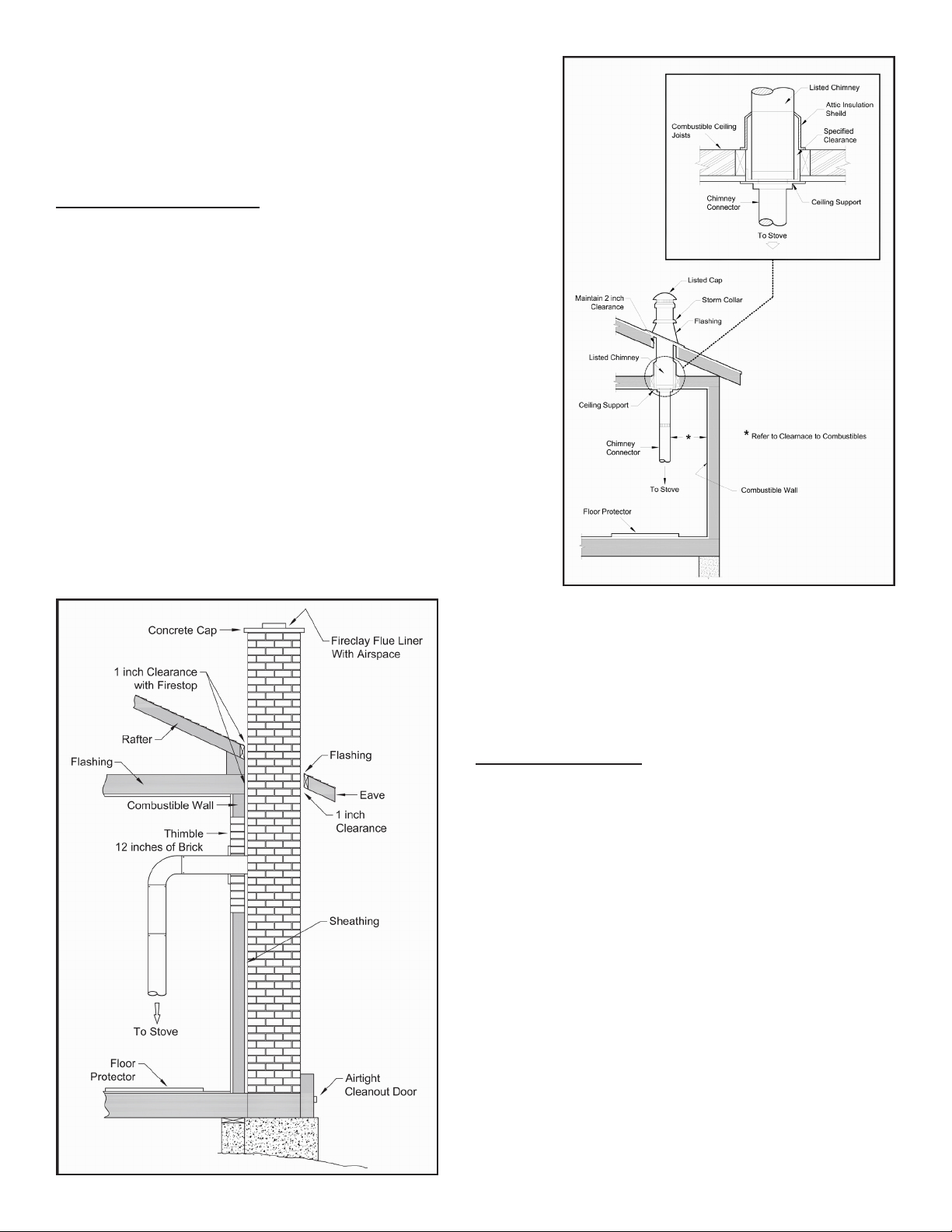

CHIMNEY

Your wood stove may be hooked up with a 6” factorybuilt or masonry chimney. If you are using a factory-

built chimney, it must comply with UL 103 or CSA-B365

standard; therefore it must be a Type HT (2100°F). It

must be installed according to the manufacturer’s

specications. Take into account the chimney’s

location to ensure it is not too close to neighbors or

in a valley which may cause unhealthy or nuisance

conditions. If you are using a masonry chimney, it

must be built in compliance with the specications of

the National Building Code. It must be lined with re

clay bricks, metal or clay tiles sealed together with re

cement. Round ues are the most efcient. The interior diameter of the chimney ue must be identical to the

stove smoke exhaust. A ue which is too small may cause draft problems, while a large ue favors rapid cooling

of the gas, and hence the build-up of creosote and the risk of chimney res. Note that it is the chimney and not

the stove which creates the draft effect; your stove’s performance is directly dependent on an adequate draft

from your chimney. Do not connect this unit to a chimney ue serving another appliance.

The following recommendations may be useful for the installation of your chimney:

1. It must rise above the roof at least 3’ (0.9m) from the uppermost point of contact.

2. The chimney must exceed any part of the building or other obstruction within a 10’ (3.04m) distance by a

height of 2’ (0.6m).

3. The installation of an interior chimney is always preferable to an exterior chimney. Indeed, the interior

chimney will, by denition, be hotter than an exterior chimney, being heated up by the ambient air in the

house. Therefore the gas which circulates will cool more slowly, thus reducing the build-up of creosote and

the risk of chimney res.

4. The draft caused by the tendency for hot air to rise will be increased with an interior chimney.

5. Using a re screen at the extremity of the chimney requires regular inspection to ensure that it is not obstructed

thus blocking the draft, and it should be cleaned when used regularly.

-7-

FACTORY BUILT CHIMNEY

When a metal prefabricated chimney is used, the

manufacturer’s installation instructions must be followed. You

must also purchase (from the same manufacturer) and install

the ceiling support package or wall pass-through and “T”

section package, restops (where needed), insulation shield,

roof ashing, chimney cap, etc. Maintain proper clearance

to the structure as recommended by the manufacturer. The

chimney must be the required height above the roof or other

obstructions for safety and proper draft operation.

MASONRY CHIMNEY

Ensure that a masonry chimney meets the minimum

standards of the National Fire Protection Association

(NFPA) by having it inspected by a professional. Make

sure there are no cracks, loose mortar or other signs of

deterioration and blockage. Be sure to the chimney

cleaned before the stove is installed and operated.

When connecting the stove through a combustible wall

to a masonry chimney, special methods are needed.

-8-

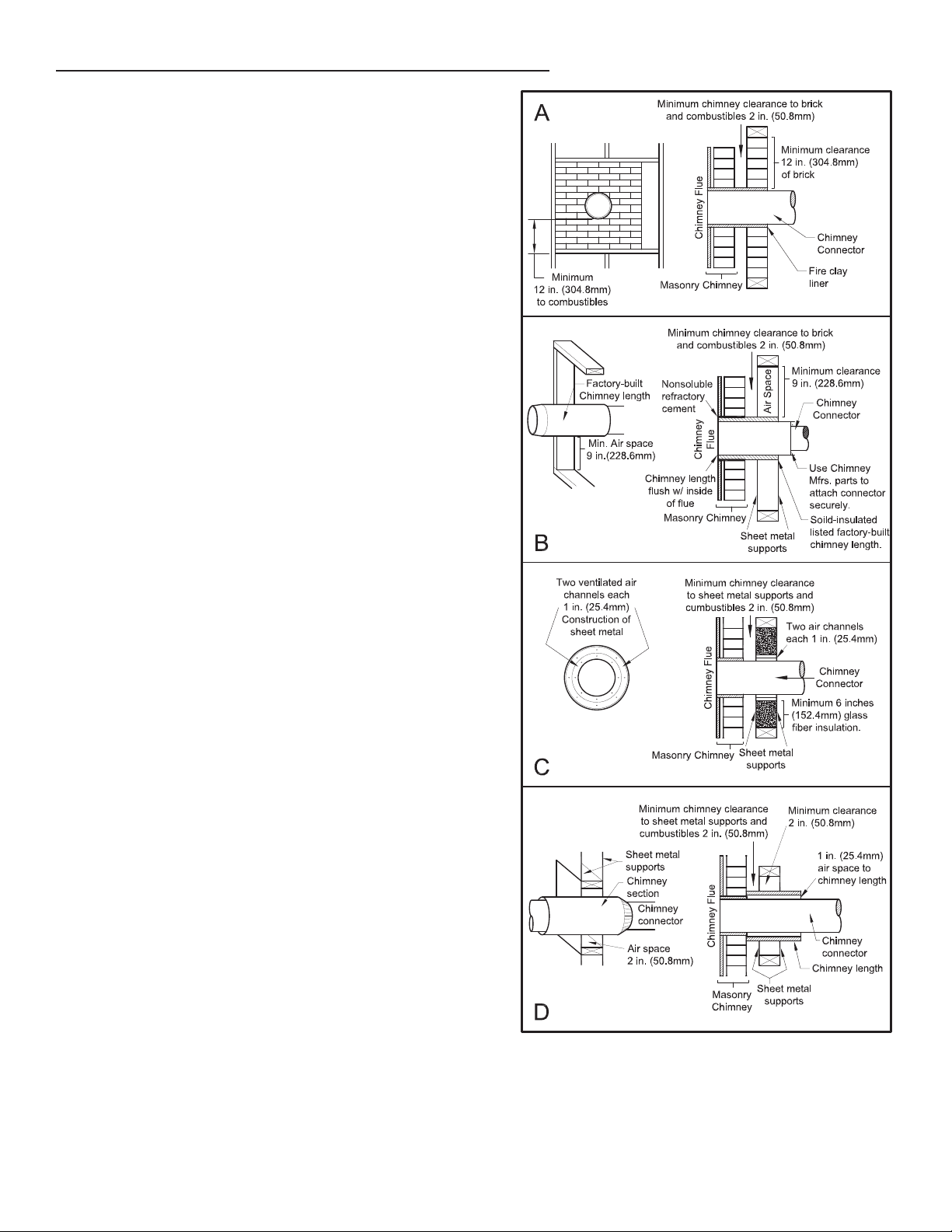

COMBUSTIBLE WALL CHIMNEY CONNECTOR PASS-THROUGHS

METHOD A - 12” (304.8 mm) Clearance to Combustible

Wall Member: Using a minimum thickness 3.5” (89 mm) brick

and a 5/8” (15.9 mm) minimum wall thickness clay liner,

construct a wall pass-through. The clay liner must conform

to ASTM C315 (Standard Specication for Clay Fire Linings)

or its equivalent. Keep a minimum of 12” (304.8 mm) of brick

masonry between the clay liner and wall combustibles. The

clay liner shall run from the brick masonry outer surface to

the inner surface of the chimney ue liner but not past the

inner surface. Firmly grout or cement the clay liner in place

to the chimney ue liner.

METHOD B - 9” (228.6 mm) Clearance to Combustible

Wall Member: Using a 6” (152.4 mm) inside diameter, listed,

factory-built Solid-Pak chimney section with insulation

of 1” (25.4 mm) or more, build a wall pass-through with a

minimum 9” (228.6 mm) air space between the outer wall of

the chimney length and wall combustibles. Use sheet metal

supports fastened securely to wall surfaces on all sides,

to maintain the 9” (228.6 mm) air space. When fastening

supports to chimney length, do not penetrate the chimney

liner (the inside wall of the Solid-Pak chimney). The inner end

of the Solid-Pak chimney section shall be ush with the inside

of the masonry chimney ue, and sealed with a non-water

soluble refractory cement. Use this cement to also seal to

the brick masonry penetration.

METHOD C - 6” (152.4 mm) Clearance to Combustible Wall

Member: Starting with a minimum 24 gage (.024” [.61 mm])

6” (152.4 mm) metal chimney connector, and a minimum

24 gage ventilated wall thimble which has two air channels

of 1” (25.4 mm) each, construct a wall pass-through.

There shall be a minimum 6” (152.4 mm) separation area

containing berglass insulation, from the outer surface of the

wall thimble to wall combustibles. Support the wall thimble,

and cover its opening with a 24-gage minimum sheet metal

support. Maintain the 6” (152.4 mm) space. There should

also be a support sized to t and hold the metal chimney

connector. See that the supports are fastened securely to

wall surfaces on all sides. Make sure fasteners used to secure

the metal chimney connector do not penetrate chimney

ue liner.

METHOD D - 2” (50.8 mm) Clearance to Combustible Wall

Member: Start with a solid-pak listed factory built chimney

section at least 12” (304 mm) long, with insulation of 1” (25.4

mm) or more, and an inside diameter of 8” (2 inches [51 mm]

larger than the 6” [152.4 mm] chimney connector). Use this

as a pass-through for a minimum 24-gauge single wall steel

chimney connector. Keep solid-pak section concentric with

and spaced 1” (25.4 mm) off the chimney connector by

way of sheet metal support plates at both ends of chimney

section. Cover opening with and support chimney section

on both sides with 24 gage minimum sheet metal supports.

See that the supports are fastened securely to wall surfaces

on all sides. Make sure fasteners used to secure chimney ue line do not penetrate the inner liner.

NOTES:

1. Connectors to a masonry chimney, excepting method B, shall extend in one continuous section through the

wall pass-through system and the chimney wall, to but not past the inner ue liner face.

2. A chimney connector shall not pass through an attic or roof space, closet or similar concealed space, or a

oor, or ceiling.

-9-

Fuel Recommendations

WOODSTOVE UTILIZATION

Your heating appliance was designed to burn wood only; no other materials should be burned. Waste and

other ammable materials should not be burned in your stove. Any type of wood may be used in your stove, but

specic varieties have better energy yields than others. Please consult the following table in order to make the

best possible choice.

TYPE

Hickory 63 4500 1.0 Well 31.5

White Oak 48 4100 .9 Fair 28.6

Red Oak 46 3900 .8 Fair 27.4

Beech 45 3800 .7 Hard 26.8

Sugar Maple 44 3700 .6 Fair 26.2

Black Oak 43 3700 .6 Fair 25.6

Ash 42 3600 .5 Well 25.0

Yellow Birch 40 3400 .4 Hard 23.8

Red Maple 38 3200 .3 Fair 22.6

Paper Birch 37 3100 .3 Easy 22.1

Elm/Sycamore 34 2900 .2 Very Difcult 20.1

Red Spruce 29 1800 .1 Easy 16.1

WEIGHT

(LBS. CU. FT., DRY)

PER CORD

EFFICIENCY

RANKING

SPLITS

MILLIONS BTU’s/

CORD

It is EXTREMELY IMPORTANT that you use DRY WOOD only in your wood stove. The wood should have dried for

9 to 15 months, such that the humidity content (in weight) is reduced below 20% of the weight of the log. It is

very important to keep in mind that even if the wood has been cut for one, two, or even more years, it is not

necessarily dry, if it has been stored in poor conditions. Under extreme conditions it may rot instead of drying.

This point cannot be over stressed; the vast majority of the problems related to the operation of a wood stove is

caused by the fact that the wood used was too damp or had dried in poor conditions. These problems can be:

- ignition problems

- creosote build-up causing chimney res

- low energy yield

- blackened windows

- incomplete log combustion

Smaller pieces of wood will dry faster. All logs exceeding 6” in diameter should be split. The wood should not be

stored directly on the ground. Air should circulate through the cord. A 24” to 48” air space should be left between

each row of logs, which should be placed in the sunniest location possible. The upper layer of wood should be

protected from the element but not the sides.

TESTING YOUR WOOD

• When the stove is thoroughly warmed, place one piece of split wood (about ve inches in diameter) parallel

to the door on the bed of red embers.

• Keep the air control full open and close the door. If ignition of the piece is accomplished within 90 seconds

from the time it was placed in the stove, your wood is correctly dried. If ignition takes longer, your wood is

damp.

• If your wood hisses and water or vapor escapes at the ends of the piece, your wood is soaked or freshly cut

(green). Do not use this wood in your stove. Large amounts of creosote could be deposited in your chimney,

creating potential conditions for a chimney re.

-10-

Operating Instructions

CAUTIONS: HOUSE FIRE HAZARDS

• Do not store wood on oor protector, underneath stovepipe(s) if applicable, or anywhere within clearances

to combustible surfaces specied for this appliance.

• Never operate with secondary tubes, ber board, or insulation removed.

OPERATING SAFETY PRECAUTIONS

• Never overre this appliance by building excessively hot res as a house/building re may result. You are

overring the appliance if it begins to glow or turn red.

• Never build excessively large res in this type of appliance as damage to the rebox or smoke leakage may

result.

• Do not build re too close to glass.

• Hot while in operation. Keep children, clothing, and furniture away. Contact may cause skins burns. Do not

touch the appliance until it has cooled.

• Provide adequate air for combustion to the room where the appliance is installed.

• Inspect chimney liner every 60 days. Replace liner immediately if it is rusting or leaking smoke into the room.

• Attempts to achieve heat output rates that exceed heater design specications can result in permanent

damage to the heater.

WARNING: EXPLOSION HAZARD

• Never use chemicals, gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter uid, or similar

ammable liquids to start or “freshen up” a re in the appliance.

• Keep all ammable liquids, especially gasoline, out of the vicinity of the appliance - whether in use or in

storage.

Hardwood, 18” (45cm) should be air dried (seasoned), for a minimum of 6 months. Logs grater than 6” (152mm)

in diameter should be split. Wood should be stored in a dry, well ventilated area. The humidity content for usable

rewood must be less than 20% of the weight of the log. This heater is designed to burn natural wood only. Higher

efciencies and lower emissions generally result when burning air dried seasoned hardwoods, as compared to

softwoods or to green or freshly cut hardwoods.

Attempts to use wet or unseasoned wood will cause:

- ignition problems - rapid creosote build-up resulting in chimney re

- incomplete combustion - low heat yield

- blackened glass

DO NOT BURN:

1. Garbage;

2. Lawn clippings or yard waste;

3. Materials containing rubber, including tires;

4. Materials containing plastic;

5. Waste petroleum products, paints or paint thinners,

or asphalt products;

6. Materials containing asbestos;

7. Construction or demolition debris;

8. Railroad ties or pressure-treated wood;

9. Manure or animal remains;

Burning these materials may result in release of toxic fumes or render the heater ineffective and cause smoke.

Dead wood lying on the forest oor should be considered wet, and requires full seasoning time. Standing dead

wood can usually be considered to be about 2/3 seasoned. Splitting and stacking wood before it is stored

accelerates drying time. Storing wood on an elevated surface from the ground and under a cover or covered

area from rain or snow also accelerates drying time. A good indicator if wood is ready to burn is to check the

piece ends. If there are cracks radiating in all directions from the center then the wood should be dry enough

to burn. If your wood sizzles in the re, even though the surface is dry, it may not be fully cured, and should be

seasoned longer.

10. Salt water driftwood or other previously salt water

saturated materials;

11. Unseasoned wood; or

12. Paper products, cardboard, plywood, or

particleboard. The prohibition against burning

these materials does not prohibit the use of re

starters made from paper, cardboard, saw dust,

wax and similar substances for the purpose of

starting a re in an affected wood heater.

-11-

Do not burn manufactured logs made of wax impregnated sawdust or logs with any

chemical additives. Manufactured logs made of 100% compressed sawdust can be

burned, but be careful burning too much of these logs at the same time. Start with one

manufactured log and see how the stove reacts. You can increase the number of logs

burned at a time to making sure the temperature never rises higher than 475°F (246°C)

on a magnetic thermometer for installation on single wall stove pipes or 900°F (482°C)

on a probe thermometer for installation on double wall stove pipe. The thermometer

should be placed about 18” (457 mm) above the stove. Higher temperatures can

lead to overheat and damage your stove.

TAMPER WARNING

This wood heater has a manufacturer-set minimum low burn rate that must not be altered. It is against federal

regulations to alter this setting or otherwise operate this wood heater in a manner inconsistent with operating

instructions in this manual.

EFFICIENCIES

Efciencies can be based on either the lower heating value (LHV) or the higher heating value (HHV) of the fuel.

The lower heating value is when water leaves the combustion process as a vapor, in the case of woodstoves the

moisture in the wood being burned leaves the stove as a vapor. The higher heating value is when water leaves

the combustion process completely condensed. In the case of woodstoves this would assume the exhaust gases

are room temperature when leaving the system, and therefore calculations using this heating value consider

the heat going up the chimney as lost energy. Therefore, efciency calculated using the lower heating value of

wood will be higher than efciency calculated using the higher heating value. The best way to achieve optimum

efciencies is to learn the burn characteristic of you appliance and burn well-seasoned wood. Higher burn rates

are not always the best heating burn rates; after a good re is established a lower burn rate may be a better

option for efcient heating. A lower burn rate slows the ow of usable heat out of the home through the chimney,

and it also consumes less wood.

NOTICE - INITIAL BURNS TO CURE PAINT

BECAUSE OF THE HIGH OPERATING TEMPERATURES, THIS APPLIANCE IS COATED WITH A SPECIAL HIGH TEMP PAINT

WHICH REQUIRES A SERIES OF LOW TO MEDIUM BURNS TO FULLY CURE FOR DURABILITY AND A LIFETIME OF SERVICE.

Proper curing of the high-temp paint requires a series of three initial burns. The appliance should be allowed to

cool off between each burn. The rst two burns should be small res and low temperatures (250°F) for a duration

of 20 minutes each. The third re should be at a temperature of approximately 500°F for 20 minutes. Provide

adequate cross ventilation to clear any smoke or odor caused by initial rings.

Notice: Use solid wood fuel only! Do not burn garbage , or ammable uids. Do not use coal. This appliance

is not designed to accommodate the air ow (draft) required to properly burn coal or coal products. Do not

elevate the re using grates or irons. Build the re directly on the rebrick.

FUELING INSTRUCTIONS

This wood stove has been certied by the US EPA to meet strict 2020 guidelines. To ensure this unit produces

the optimal minimum emissions it is critical that only well-seasoned cordwood is burned (see the “Fuel

Recommendations” section of this manual). Burning unseasoned wet wood only hurts your stoves efciency and

leads to accelerated creosote buildup in your chimney. Be considerate of the environment and only burn dry

wood.

CAUTION: DO NOT LEAVE APPLIANCE UNATTENDED THE WITH DOOR OPEN.

For a cold start-up, place 4 to 5 pieces of newspaper into the rebox. On top of

the newspaper, lay 5 lbs of kindling in random placement to ensure airow through

the kindling. On top of the kindling, place approximately 6.5 lbs of small pieces of

cordwood. NOTE: Use smaller pieces of wood during start-up and a high burn rate

to increase the stove temperature.

-12-

6.5 lbs

Loading...

Loading...