Ashland I-180TS2 User Manual ver 1011

I-180TS2

PARTS MANUAL

Ver. 1011

Ashland Industries Inc.

1115 Rail Drive

P.O. Box 717

Ashland, WI. 54806

877-634-4622 Toll Free - phone

715-682-4622 phone

715-682-9717 fax

www.ashlandind.com

1

T

g

g

T

g

g

T

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Serial Number

WELCOME TO OUR NEW CUSTOMERS!

hank you for your purchas e of an Ashland scraper and the confidence you have placed in us to

handle yo ur earthmoving projects . Years of research, testing and succ essful application have

been spent to ensure quality and m axim um perf ormance for ou r customers. Please read and

understand this manual be f ore attempting to attach or operate this scrap er. This ma nual should

always rema in with the machine. Be sure and fill out and send in the owners re

the beginning of this ma nual, or you ma y fill out the for m on-li ne by

cli ck on “Regis ter your M achine” at the bot t om of the p age.

oing to ashlandind.com an d

istr atio n form at

SCRAPER ID NUMBER

he serial nu m ber pla t e for the sc raper is located on the right rear area of t he scr aper. The

lette r and numbers sta mped id en tify the serial number, model numb er and ca pacity of the

sc raper. Ple ase rec ord this se rial number f or use in orderi n

your equipment if it is ever stolen.

R eferences to serial n umber breaks on part s are located in t he manual with a referen ce seque nce

of XXXXX-XXXXX. The be

he ending number is the final serial number use of the part within this machine .

inning number records the se rial numb er start of the use of that part .

part s, warrantee issue s and to t race

Page #1

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

ASHLAND SCRAPERS

How to Order Parts

IMPORTANT

Parts must be ordered through your local authorized ASHL AND dealer.

Be sure to state MODEL and SERIAL NUMBER of your machine, PART NUMBER,

DESCRIPTION and QUANTITY n eeded.

Unless this is done, we canno t provid e prompt service or assu re shipment of the correct

parts.

PHONE : 715-682-4622 Fax: 715-682-9717

Ashland Industries weldable replacement parts are available to rebuild, modify or update

your scraper to current factory specifications.

Page #2

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

ASHLAND SCRAPERS

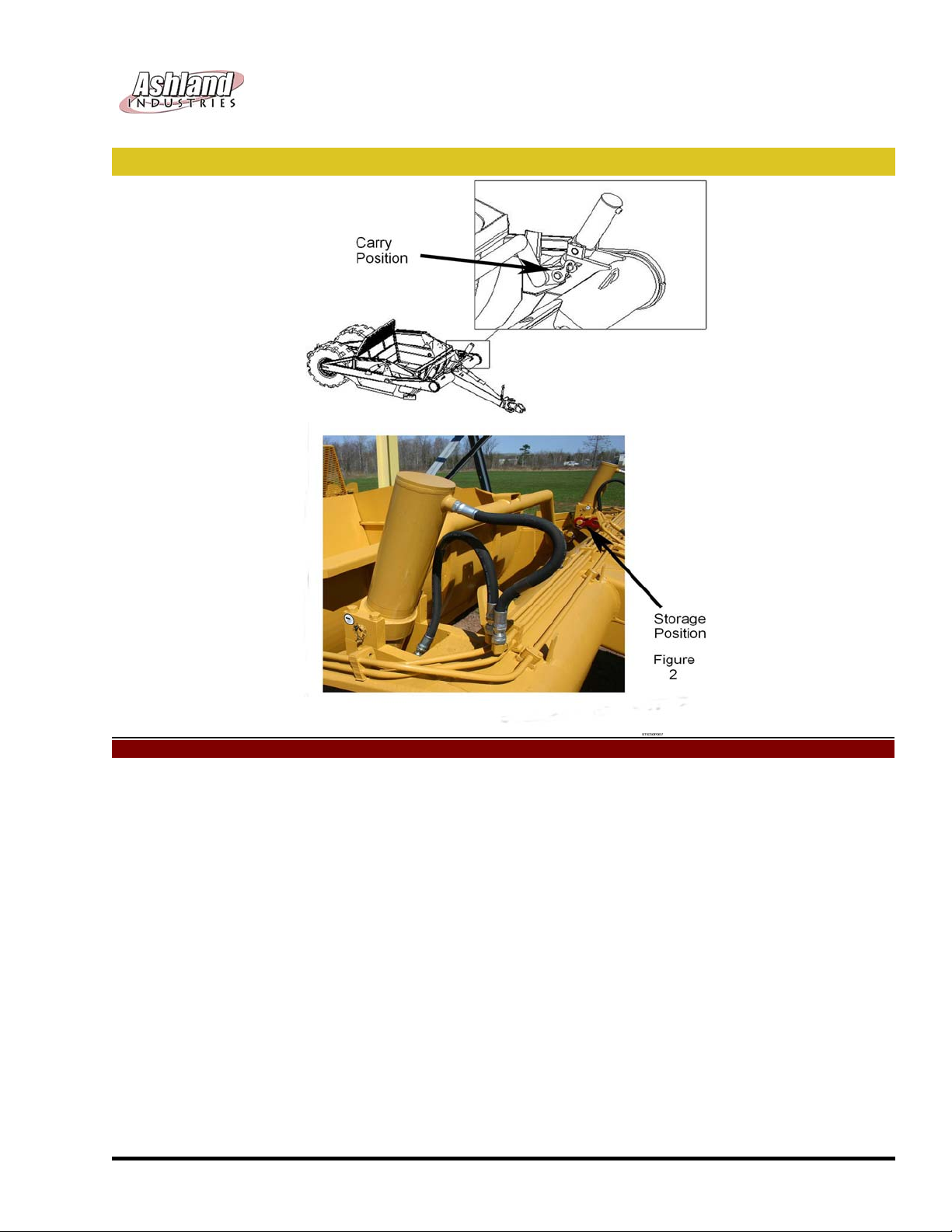

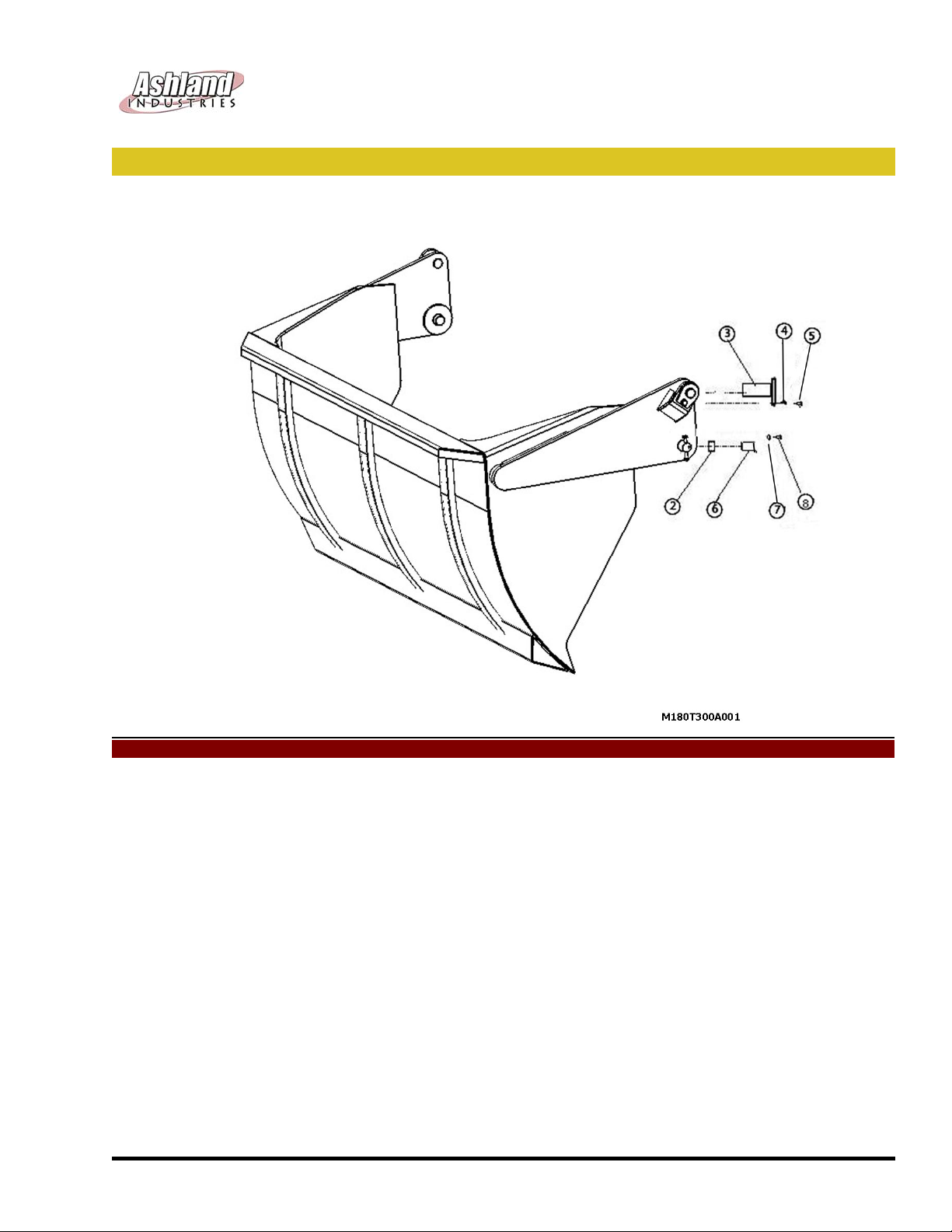

Parts - Transport Locks (TS) 155-180

PHONE : 715-682-4622 Fax: 715-682-9717

KEY PART DESCRIPTION

2 A123309-83 Transport Lock (155TS2-180TS2)

IM PORTA NT

Please locate red Transport Links and

remove prior to operation. Retract Lift

Cylinder Circuit, Rem ove Safe ty Snap Pin,

Remove link and replace into storage

positi on as shown in figure 2.

Reinstall Safety Snap Pins.

Page #3

P.O. Box 717

1115 Rail Dr

shland , WI 54806

T

g

p

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Operation and Maintenance

his scr a per i s a durab le piece of equipment and wi t h proper care will yield m any y ears of troub le free

operat ion. The scrape r requires a power source wi t h TWO 4 way (do uble act ing) hydrauli c cont rol

valves.

The scraper should be greased at all points where

the tractor hydrauli c system and add to maintain the proper level. Care sho uld be used when adding oil

or whe n dis connecting any oil line to keep all dir t out of the oil as dirt is a major factor in the failure of

hydraulic com p onents .

When the scraper is placed into operation, the operator will have to “feel out” the amount of depth of

cut to obtain maximum loading efficien cy. This is usually accomplished by taking a lesser an d more

uniform cut; however, some soil conditions such as loo se sand may require a “pumping action” obtained

by taking successive deep cuts and lifting out of cut as the tractor begins to lose power or traction.

1. Afte r 10 hours work, all bolts should be checked and tightened if necessary.

2. Ev ery 10 hours all grea se fi ttings should be lubricated.

3. After 50 hours work, all bolts should be rechecked and tighte ned if necessary. Check wheel

bearings and adjust if necessary.

4. Afte r 300 hours work, clean and repack wheel bearings and replace, if necessary, cutting edges,

worn

ins, etc.

rease fittings are prov id ed. Chec k the oil levels in

Page #4

P.O. Box 717

1115 Rail Dr

shland , WI 54806

g

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Operation and Maintenance

This scraper is a durable piece of equipment and with proper care will yield many years of trouble free

operation. The life of your scraper can be severely shortened by poor m aintenance. Follow consistent

maintenance practices and use good quality grease and hydraulic oil (compatible with the power unit’s

hydraul ic syst em ) to ins ure the l onge st , most prod uctive use from yo ur equipment.

Before startin

be en properly located (ele ctric, phone and pipe lines ). Have a cle ar understanding of all local, OSHA and

MSHA rules that apply to the job . Beware of your environment and keep others a safe distance from the

mac hi ne whi le f am il iari zin g your self w ith the machine’s co ntrol s. The sc raper requires a power sourc e

wit h TWO 4 way (doub le acting) hydraulic control valves.

The scraper should be gre ased a t all points where grease fittings are provided. Co nnec t hydraulic hoses

to the tractor and retract lift cylinders to RE MOVE TR A NS P OR T L OC K P IN S, then extend and retract

all c y li nde rs several t imes to fo rce ou t any air from the h y draulic cy linders an d l ines. Check the oil levels

in the tractor hydraulic system a nd add to maintain the proper level. Care sh ould be used when addin g

oil or when disconnecting any oil line to keep all dirt out of the oil as d irt is a major factor in the failure of

hydraulic components. Eac h time the scraper is hook ed to a power unit , t he sequ encing valve need s t o

be c he cked for prope r tim ing. T his will insure opti mum performa nce from t he s cr a pe r.

When the scr aper is p lace d i nto op erat ion , the o perat or wil l h av e t o “feel o ut” th e am ount o f dept h of

cut to obtain maximum loading efficiency. This is usually accomplished by taking a lesser and more

un ifo r m cut; how e ve r, so me s o il condit ions s uch as loose sand ma y re quire a “pumping action” obtaine d

by taking successive deep cuts and lifting out of cut as the tractor begins to lose power or traction. The

op eration of the scraper will var y depending upon soil type, moisture content, power -unit and jobsite.

Results will vary.

1. Aft er 10 hour s work, al l bo lts shou ld be chec ked a nd tig htened i f nece ssary.

2. Every 1 0 hours all grease f itt ing s sho ul d be l ubr ic a t ed.

3. After 50 hours work, all bolts should be rechecked and tightened if necessary.

Check whee l bearings an d adjust if necessary.

4. After 300 hours work, clean and r epack whee l bearings and replace, if necessary,

cutting edges, wor n pins, etc.

the job , m a ke sure Diggers Hot Line has be en co ntacted and all underground utilities have

Page #5

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Operation and Maintenance

SCRAPER DAM AG E CA N OCCUR IF

1. The scraper is running over t he haul road with the bow l f ully raise d.

2. A pow er un it t hat is abo v e the horsep ow er rat in g is pul li ng the s craper.

3. The scrape r is being used to le vel haul roads with the apron closed.

4. The scrape r is being top loaded with the bowl is a raised position.

5. Th e scraper is bei ng u sed to lo ad rock.

These types of damage are not cove red by warranty. Warranty only covers defects in material o r

workmanship and not abuse bec ause o f improper use.

KNOW THE JOB:

1. Know the weight of the material to be moved.

:

2. Lay t he job out t o take ad v antage of grad es wh en loadi ng , if possibl e.

3. Keep hauls as shor t as possi bl e.

4. Keep haul roads smooth.

5. If more than one unit is on the job, make sure the haul roads are one way and that the

op erat ors unde rsta nd the direction .

6. Brief the operator s as to what the job consists of so there is not misunderstanding.

7. Know the moisture content in the material to be moved.

8. Will wa ter be need ed f or pro per co m pactio n?

9. Will drainage be a pr obl e m?

10. How many unit s wi ll be need ed t o ef fi ci ently complete the job?

TRANSPORT SCRAPER SAFELY:

1. Always empty scraper.

2. Clean all mat erial from ext erior of scraper.

3.

4. Use proper lighting and fla gging.

Make sure all road rules are followed

.

5. Lower scraper bowls to provide just enough clearance over obstacles.

6.

7. R ed uc e sp eed on cur v e s and when going down hil l.

Page #6

Tran sport at a safe s peed to avoid roll ov er

P.O. Box 717

1115 Rail Dr

.

shland , WI 54806

g

g

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Operation and Maintenance

APRON OPENING GUIDELINES:

You will need to determine the ideal opening for your soil condition. It is important to have the apron

opened prior to loading To receive the highest productio n possible, it is important to know the general

characteristics of the material that you will be loading. In heavier soils like clay or gumbo, the soil will

slab up and and remai n together after being cut by the blades. In li

soil , the matieral will pile u p or push af t er being cut by th e bl ade. Use th e suggest ions lis t ed below:

Topsoil wi th heavy vegetation (1 2” to 24” op eni n g):

When cutting undisturbed soils, you will need to open the apron high enough to allow debris to easily

enter the scraper bowl. If the apron is opened too high, the rolling up sod will fall out past the apron

and h in der the incoming material. If the apr on is no t ad justed quic k enough, the material will bunch or

push ahead of the machine. If this h a ppens, you should clos e t he apro n and pu ll out the cut quickly. If

you wai t too long, you may develop too large a pile to clear the scraper w hile rising out of the cut. This

can cause the po wer unit to lose tr action and poss ibly cause you to get stuck.

Clay or loa m y material (6” to 12” opening):

To cut clay or loam soils, lower the apron to approximately 6” to 12” between the blades and the bottom

of the apron. When you first lower the bowl, you’ll see the material bei ng cut by the blades and

enterin

small pile ah ead of the apron. B y limi ting this apron op eni ng, the small p ile will “b lad e of f” any loo se

material ahead of the machine. Ad justments should be made if large objects su c h as rocks or deep

gouges are within the cut.

Sand or loose t op s oil (15” to 30” opening):

Load ing sand or loose top so il is the most di ff ic ult t y pe of soil t o load. In co m bina t ion wi th th e larger

apron open in g, y ou ’l l want to op erat e at a fas t er ground spe ed. By tr av eling faster and lowering the

blad e deeper than normal, it forc es t he material i nto the scraper b ow l.

We enco urag e you t o ex perimen t wi t h different apron open in gs to determ ine t he best condi tion for y our

jobsite.

the bowl. As you continue to move forward, small clumps will fall past the apron and develop a

ht er soils, li ke san d or dry loos e top

The Apr on is designed to capture material inside of the scr aper bowl and s hould not be used as a la rge

bl ade. O bs truc tions like la rge r o cks or dens e piles may c ause the apro n to ben d inward after prolonge d

exposure to these conditions.

Page #7

P.O. Box 717

1115 Rail Dr

shland , WI 54806

j

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Safety Guidelines

SAFETY SIGNAL WORDS

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The

appropriate signal word for each has been selected using the following guidelines:

DANGER: Indicates an imminent ly hazardous situation that, if not avoided, will result in death

o r seriou s inj ury. T hi s signal w ord i s t o be l imited to the m ost extrem e situations t ypically for

machine components which, for functional purpos es, cannot be qua rded.

WARNING: Indicates a potentially haz ardous situation tha t, if not avoided, could result in

death or serious injury, and includes hazar ds that are exposed when guards are removed. I t

may also be used to alert against unsafe practices.

CAUTION: I n dicates a potentially hazardous situation that, if not avoided, may result in minor

o r m oderate injury . It m ay also be used to alert agai nst un safe pr act ices.

GENERAL SAFETY GUIDELINES

Sa fety of the operator is one of the main concerns in designing and developing a new piece of

equi pment. Designers and manu fac tur ers build in as many safety features as po ssib le. However, every

year many accidents occur which could have bee n avoided by a fe w sec onds of thought and a more

careful approac h to handling e quipment. You, t he o perator, can avoid many accidents by observing the

following precautions in this section. To avoid personal injury, study the following precautions and insist

those working with you, or for you , follow them.

Re place any CAUTION, WA RN ING, D ANGE R or inst ructi on safet y decal that is n ot readable or is mi ssing.

Location of such decals is in d i cated in this booklet.

Do not attempt to op erate thi s equipment under t he inf lu ence of drug s or al cohol.

Review the safety instruc tions with a ll users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should

be a responsible adult famili ar with farm machinery and trained in this equipment’s operations. Do not

allow per sons t o operat e or assemb l e this unit unti l they have read this man u al and have

dev e lope d a th o rou gh un de rst a n ding of th e s afe t y pr e cautio n s a n d o f how it wor k s.

To prevent injury or death, use a tractor equipped with a Roll Over Protective System (ROPS). Do not

paint over, re mov e o r deface any s afet y signs or w a rning deca ls on your e quipment. Observe a ll sa fe ty

sign s and pr act ic e t he i nstructions on them.

Never excee d t h e limits of a pi ec e of m ac h i n er y . If i t s ab i li t y to d o a

- D ON’T TRY IT.

ob, or to do so safely, is in question

Page #8

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

ASHLAND SCRAPERS

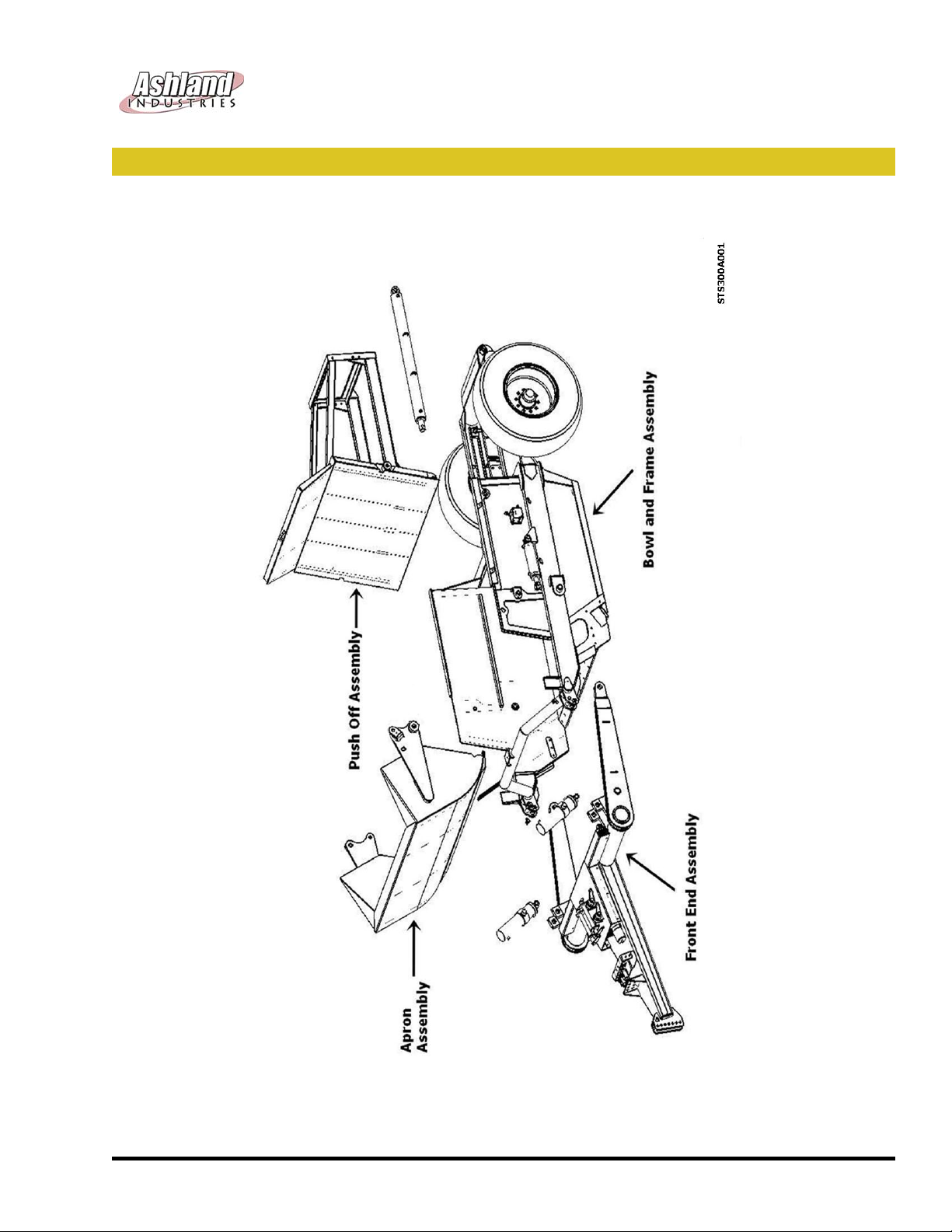

TS Assembly

PHONE : 715-682-4622 Fax: 715-682-9717

Page #9

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

PHONE : 715-682-4622 Fax: 715-682-9717

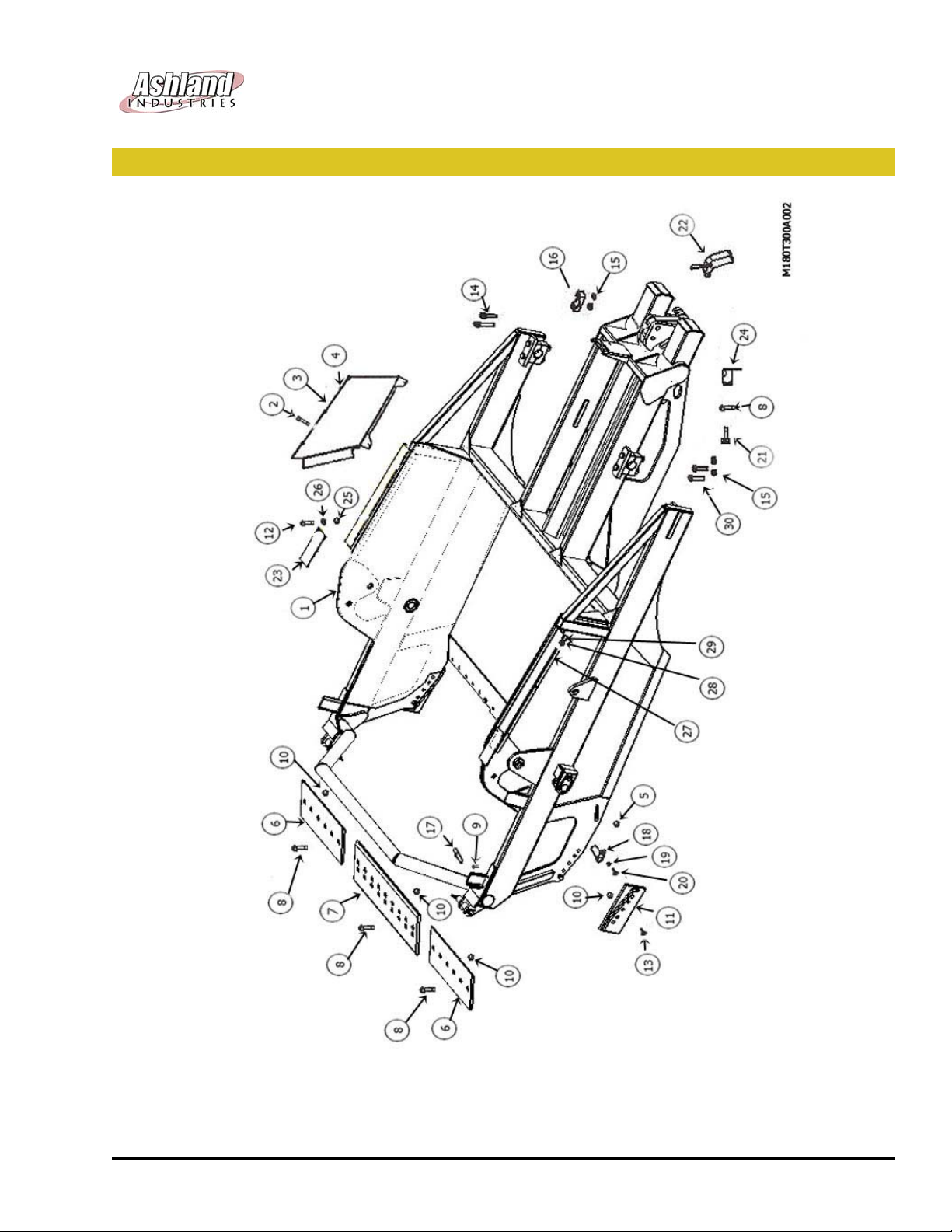

ASHLAND SCRAPERS

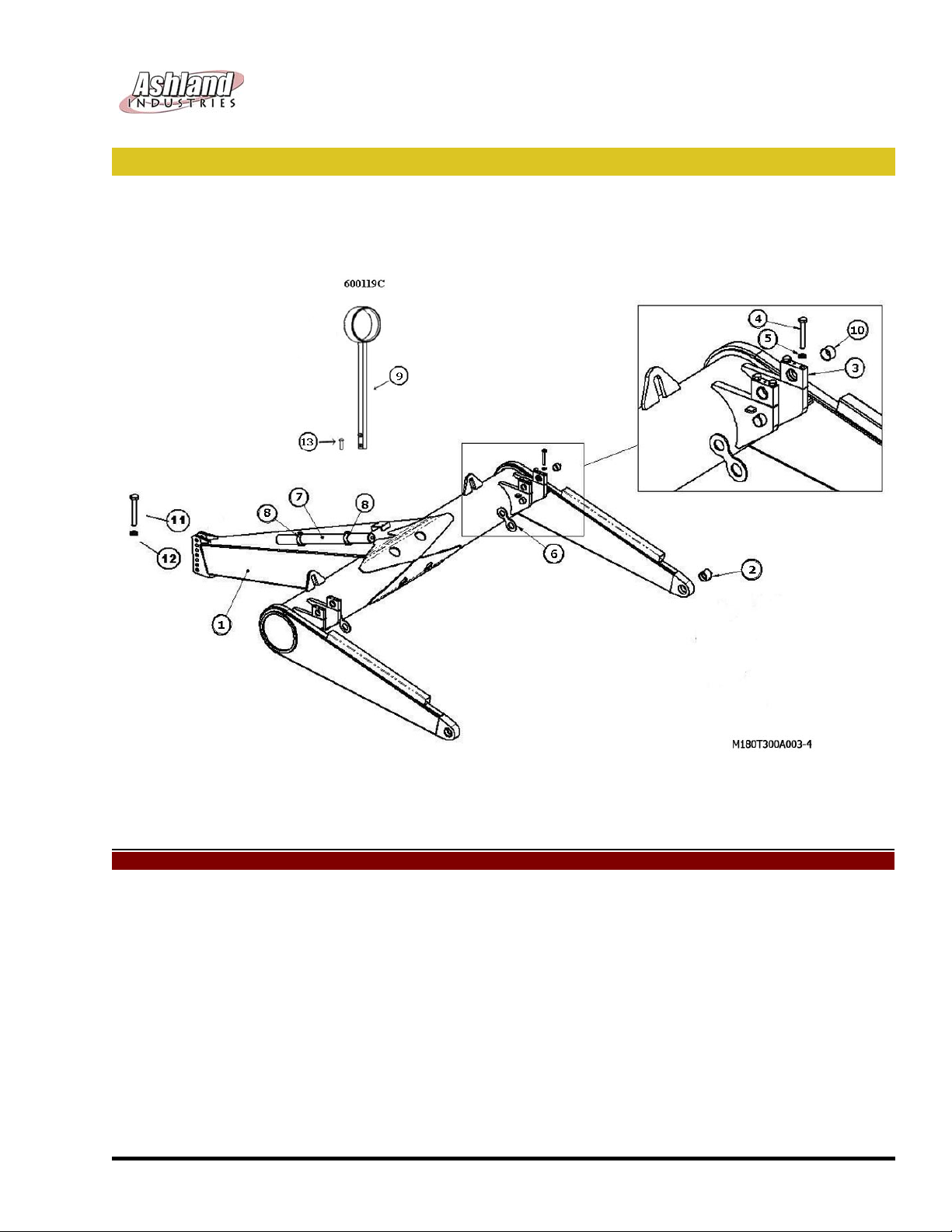

Front Frame Assembly (180)

KEY PART DESCRIPTION SN 180TS2

1 A123320 Front Section

2 A123320-08 3” ID x 3-1/2” OD x 3” long bronze bushing

3 A123456 Trunion mount block

4 AFB-00039 "Bolt, 3/4” NC x 5-1/2” long, gr. 8"

5 AFW-00002 3/4” lock washer

6 A123320-20 Travel Lock

7 A125005 Accumulator

8 A125009 Mounting brackets

9 600119C Hose Holder 22375-XXXXX

10 A125179 Trunion Bushing

11 AFB-00021 Hitch Bolt:1x5-1/2 NC Gr 8

12 AFN-00037 1” NC Locknut

13 AFB-00033 Bolt: 1/2 NC X 2 1/2" Gr. 8

Page #10

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

ASHLAND SCRAPERS

Apron Assembly (180)

PHONE : 715-682-4622 Fax: 715-682-9717

KEY PART DESCRIPTION SN 180TS2

1 A123322 Apron Model 180

2 A125257-35 Bushing 2" ID Ball Swivel 22656-XXXXX

2 A125249 Bushing 2" ID Ball Swivel w/Graph. Plugs XXXXX-22655

3 A123322-14 "Pin: 2” x 4 1/4” L, (for apron cyl rod end)

4 A123358 Flanged Bolt Bushing

5 AFB-00079 Bolt: 5/8" X 1 1/2"

6 A123321-113 Apron Pivot Pin w/grease zerk

7 AFN-00018 1/2” lock nut

8 AFB-00012 1/2” Bolt 1/2 X 4 1/2"

Page #11

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Bowl & Frame Assembly (180)

KEY PART DESCRIPTION

1 A123321 Bowl and Frame Assembly 180

2 AFB-00094 Flanged Bolt: 3/8" NC X 1" L

3 A123369-1L Dirt Shield - Left Side

4 A123369-1R Dirt Shield - Right Side

5 A125018 Bushing: 2 3/8" OD X 2" ID X 1 1/4"L

6 A125103 Left & Right Straight Corner Blade

7 A125072 Center Blade, 18" Straight, Reversible

A125072-SER Center Blade, 18" Double Serrated, Reversible

8 PB1P-NC-100-0275 Plow Bolt: 1" NC X 2 3/4" L

9 AFP-00001 Cotter Pin

10 AFN-00012 Nut: 1" NC

11 A123357 Bank Shaver/Router Bit, Reversible, L & R

12 AFB-00027 Bolt: 3/8 X 1 1/2"

13 AFB-00018 Bolt: 1" NC X 3" L

14 AFB-00109 Bolt: 1 1/4" NF X 9" L

15 AFN-00032 Nut: 1 1/4" NF

16 A123321-65 Axle Mount

17 A123335 Lift Cylinder Pin

18 A23321-09 Main Frame Pin

19 A123358 Flanged Bolt Bushing

20 AFB-00079 Bolt: 5/8" X 1 1/2" L

21 A123321-98 Pins

22 A123321-89 Pin Keeper

23 A123369-13 Dirt Shield Flap

24 A125006 Safety Snap Pin 1/4 X 2 1/4

25 7450 3/8 NC Nut

26 AFW-00010 3/8 Flat Washer

27 A125020 32" Grease Line

28 A125026 3/8 NF Bulkhead Nut

29 A125019 Grease Fitting 1/4 - 28 x 54" L

30 AFB-00122 Bolt: 1 1/4 NF X 10" Gr. 8

Page #12

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Bowl & Frame Assembly I-180TS2

Page #13

P.O. Box 717

1115 Rail Dr

shland , WI 54806