Ashland I-180 User Manual

I-180TS

Narrow Rear Frame

PARTS MANUAL

Version 5-05

Ashland Industries Inc.

1115 Rail Drive

P.O. Box 717

Ashland, WI. 54806

877-634-4622 Toll Free - phone

715-682-4622 phone

715-682-9717 fax

www.ashlandind.com

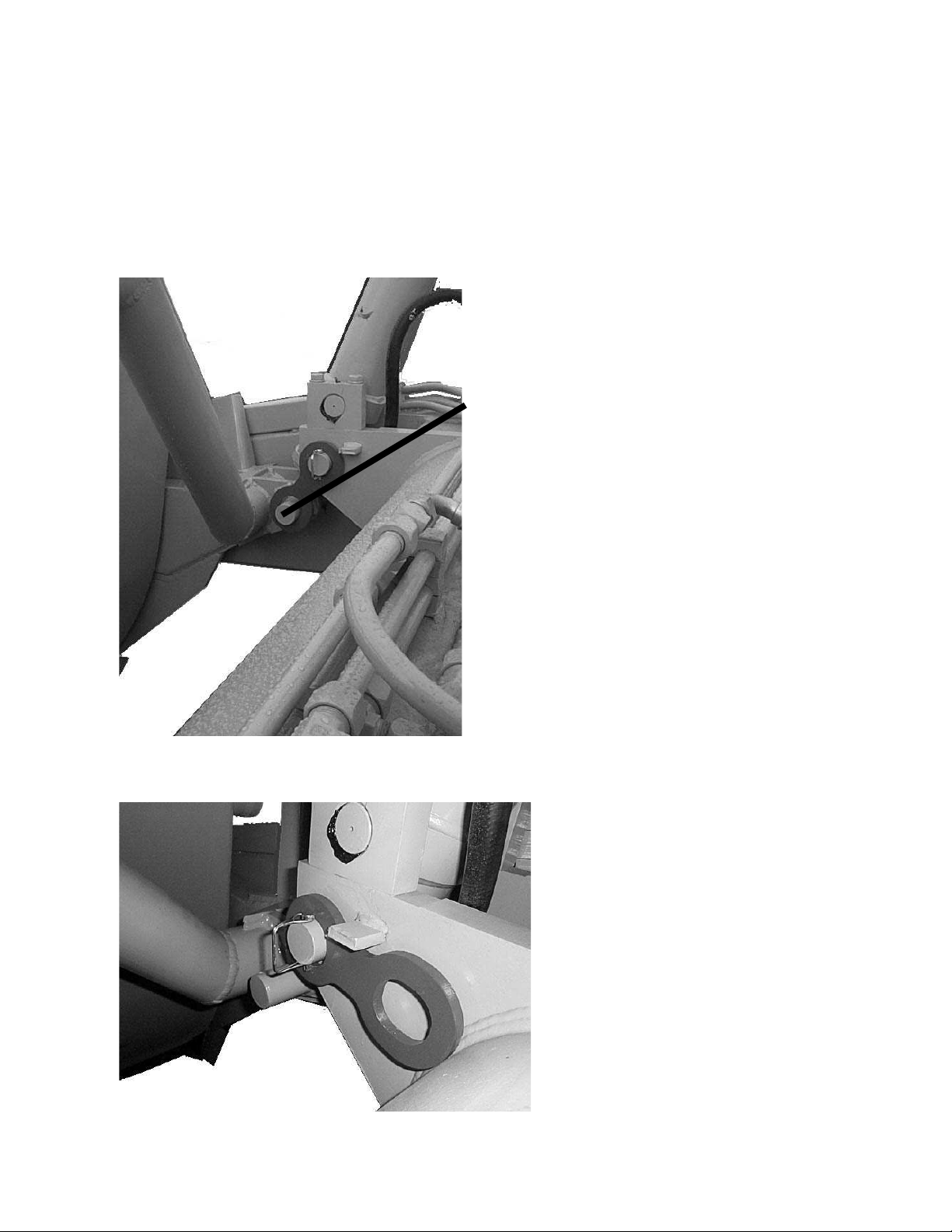

IMPORTANT

Please locate red

Transport Links and

remove prior to operation. Retract

Lift Cylinder Circuit,

Remove Safety

Snap Pin, Remove

link and replace

into storage

position as shown

in figure 2.

Reinstall Safety

Snap Pins.

2

I-180TS Narrow Rear

HOW TO ORDER PARTS:

IMPORTANT

Parts must be ordered through your local authorized ASHLAND dealer.

Be sure to state MODEL and SERIAL NUMBER of your machine, PART NUMBER, DESCRIPTION

and QUANTITY needed.

Unless this is done, we cannot provide prompt service or assure shipment of the correct parts.

Ashland Industries weldable replacement parts are availabe to rebuild, modify or

update your scraper to current factory specifications.

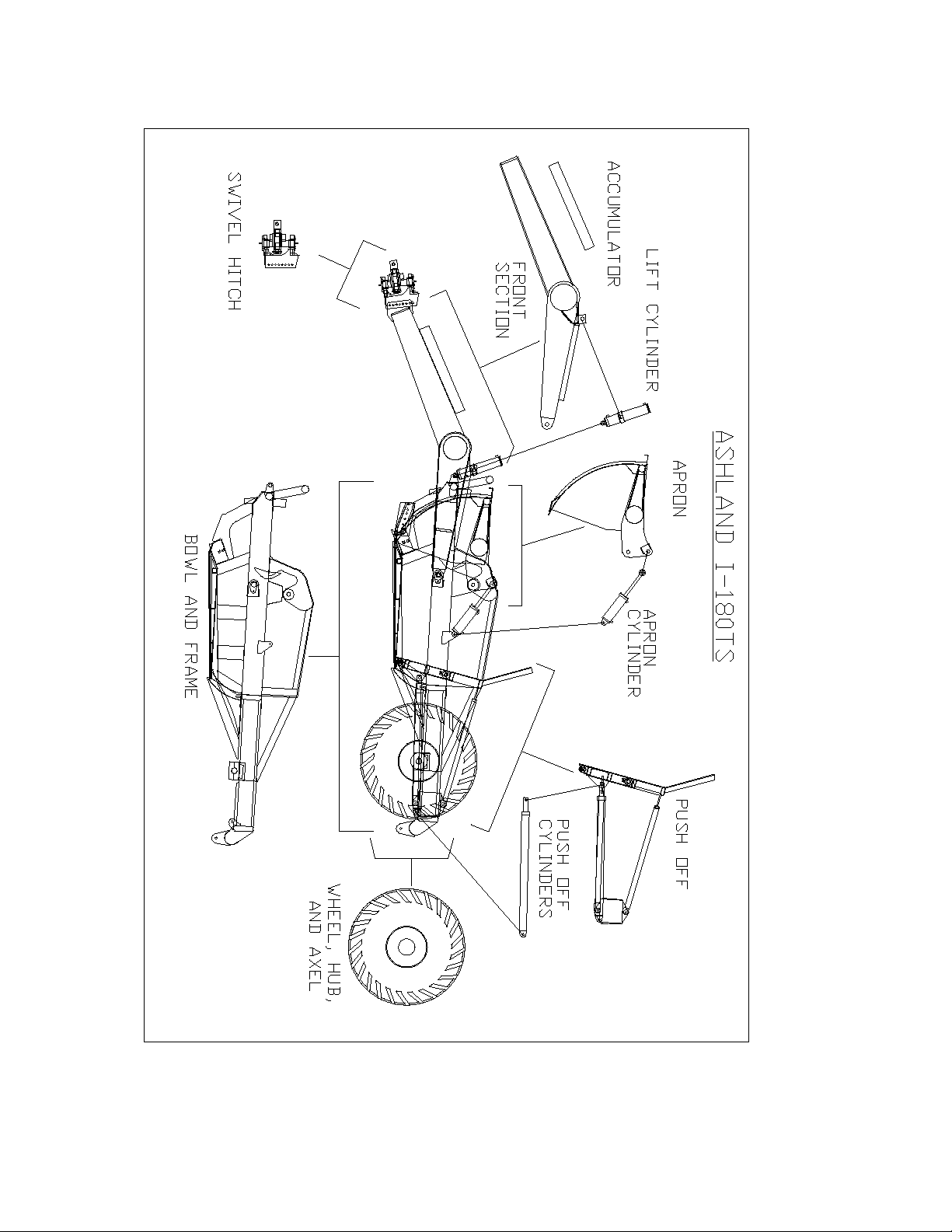

INDEX

Page 4. Operators and Maintenance Instructions

Page 5. Safety Guidelines

Page 6. Illustration - Assembly

Page 7. Complete Yoke Type Hitch

Page 8. Swivel Hitch Assembly

Page 9. Front Section Frame

Page 10. Lift Cylinder 5-1/2 x 20

Page 11. Lift Cylinder 5 x 20

Page 12. Apron Assembly

Page 13. Apron Cylinder old style

Page 14. Apron Cylinder new style

Page 15-16 Bowl and Frame Assembly

Page 17. Push Off Gate Assembly

Page 18. Push Off Cylinder

Page 19. Wheel Assembly

Page 20-27 Hydraulic Plumbing

Page 28-29 Identification, Illustration, Parts List and Adjustment - Hydraulic Valve

Page 30. Hydraulic Schmetic

Page 31-32 Grease Locations

Page 33-36 Service Manual Appendix

Page 37. Warranty Statement

3

OPERATORS AND MAINTENANCE INSTRUCTIONS

This scraper is a durable piece of equipment and with proper care will yield many

years of trouble free operation. The scraper requires a power source with TWO 4 way

(double acting) hydraulic control valves.

The scraper should be greased at all points where grease fittings are provided. Connect

hydraulic hoses to the tractor and retract lift cylinders to REMOVE TRANSPORT LOCK

PINS (point A), then extend and retract all cylinders several times to force out any air from

the hydraulic cylinders and lines. Check the oil levels in the tractor hydraulic system and

add to maintain the proper level. Care should be used when adding oil or when disconnecting any oil line to keep all dirt out of the oil as dirt is a major factor in the failure of

hydraulic components.

When the scraper is placed into operation, the operator will have to “feel out” the

amount of depth of cut to obtain maximum loading efficiency. This is usually accomplished

by taking a lesser and more uniform cut; however, some soil conditions such as loose sand

may require a “pumping action” obtained by taking successive deep cuts and lifting out of

cut as the tractor begins to lose power or traction.

1. After 10 hours work, all bolts should be checked and tightened if necessary.

2. Every 10 hours all grease fittings should be lubricated.

3. After 50 hours work, all bolts should be rechecked and tightened if necessary.

Check wheel bearings and adjust if necessary.

4. After 300 hours work, clean and repack wheel bearings and replace, if necessary,

cutting edges, worn pins, etc.

5. Maintain tire pressure at 45 to 50 psi.

4

SAFETY SIGNAL WORDS

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The appropriate signal word for each has been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in

death or serious injury. This signal word is to be limited to the most extreme situations typically for machine components which, for functional purposes, cannot be

guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury, and includes hazards that are exposed when guards are

removed. It may also be used to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

GENERAL SAFETY GUIDELINES

Safety of the operator is one of the main concerns in designing and developing a new piece

of equipment. Designers and manufacturers build in as many safety features as possible.

However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. You, the operator,

can avoid many accidents by observing the following precautions in this section. To avoid

personal injury, study the following precautions and insist those working with you, or for

you, follow them.

Replace any CAUTION, WARNING, DANGER or instruction safety decal that is not readable

or is missing. Location of such decals is indicated in this booklet.

Do not attempt to operate this equipment under the influence of drugs or alcohol.

Review the safety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The

operator should be a responsible adult familiar with farm machinery and trained in this

equipment’s operations. Do not allow persons to operate or assemble this unit

until they have read this manual and have developed a thorough understanding

of the safety precautions and of how it works.

To prevent injury or death, use a tractor equipped with a Roll Over Protective System

(ROPS). Do not paint over, remove or deface any safety signs or warning decals on your

equipment. Observe all safety signs and practice the instructions on them.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely,

is in question - DON’T TRY IT.

5

page_02-icon.eps

6

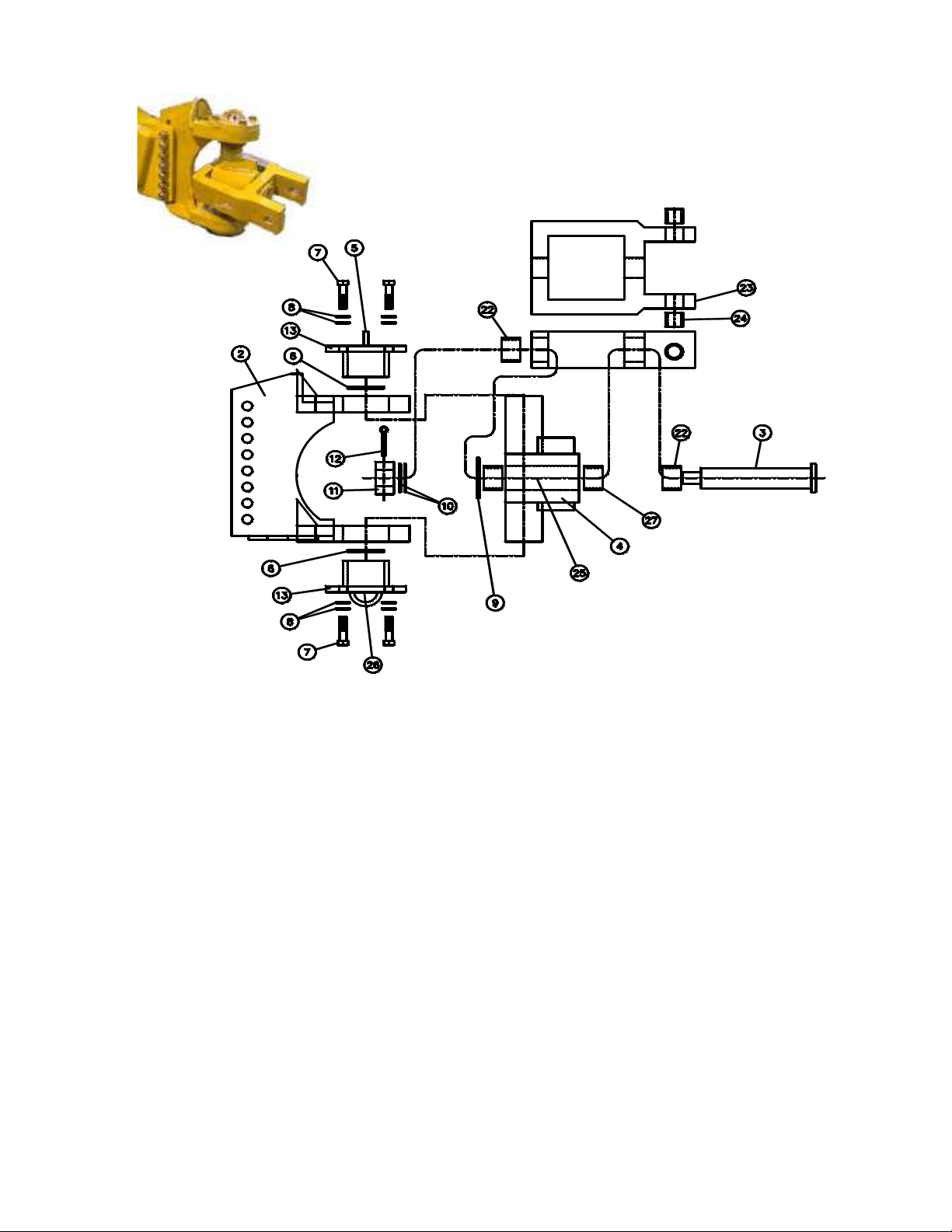

A125056

Complete Yoke Type Hitch

Implemented April 2003

KEY NO. PART NO. DESCRIPTION

2. A125056-02 UTIL HITCH BRKT

3. A125056-03 MDU HITCH PIN

4. A125056-04 MDU HITCH SWIVEL

5. A125056-05 19C 18D HITCH CAP

6. A125056-06 19C 18D WASHER SWIVEL HITCH

7. A125056-07 BOLT: 3/4 X 3 HEX GR 8

8. A125056-08 WASHER: FLAT - 3/4 HARD F-436

9. A125056-09 WASHER: FKAT-2-1/2 HARD F-436

10. A125056-10 WASHER: FLAT-1-1/2 HARD F-436

11. A125056-11 NUT: SLOTTED 1-1/2 COARSE

12. A125056-12 PIN: COTTER 5/16 X 2-1/2

13. A125056-13 19C 18D SWIVEL HITCH CAP SEAL

22. A125056-22 BUSHING: 275250187

23. A125056-23 REYNOLDS UTILITY HITCH YOKE

24. A125056-24 BUSHING: 175150150

25. A125056-25 ZERK - STRAIGHT

26. A125056-26 ZERK - 90 DEGREE

27. A125056-27 BUSHING: 300251200

7

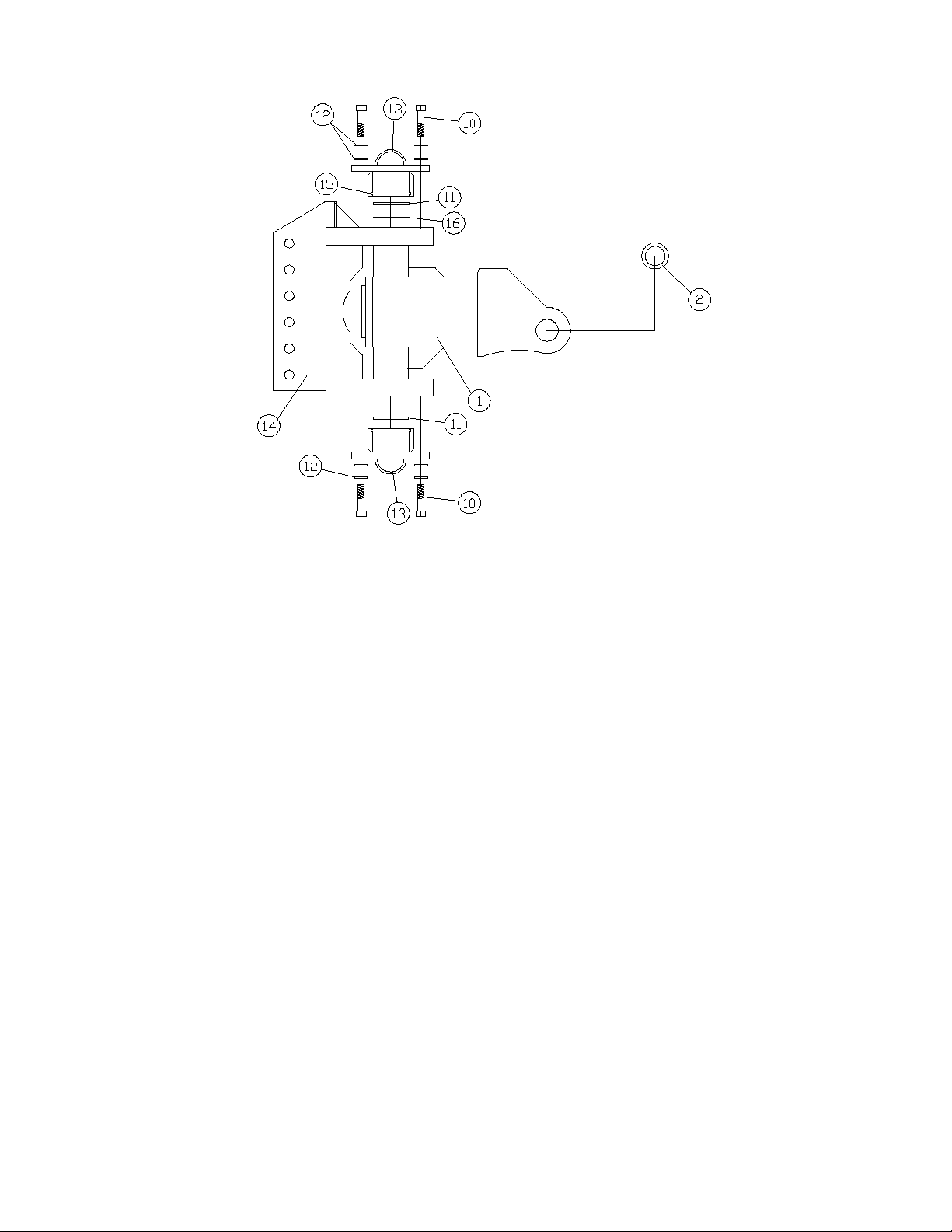

SUPER CAPACITY SWIVEL HITCH ASSEMBLY

A125057

COMPLETE HITCH: H.D. ICON 360 DEG. SWIVEL

ITEM QTY PART NUMBER DESCRIPTION

1 1 A125057-01 Swivel Hitch Yoke

2 2 A125057-02A Bushing, 2-1/2” OD, Reynolds Spec.

A125057-02JD Bushing, 60 mm ID, John Deere Spec.

10 8 AFB-00064 HHCS: 3/4 NC X 3" GR. 8 ZINC

11 2 A125056-06 WASHER: FOR ICON HITCH CAP

12 16 AFW-00007 WASHER: FLAT 3/4" ZINC USS

13 2 A125057-13 HITCH CAP, ICON

14 1 A125057-14 SWIVEL HITCH BRACKET, 7 HOLE

15 2 A125057-15 SEAL, HITCH CAP

16 1 A125057-16 SHIM, HITCH CAP

8

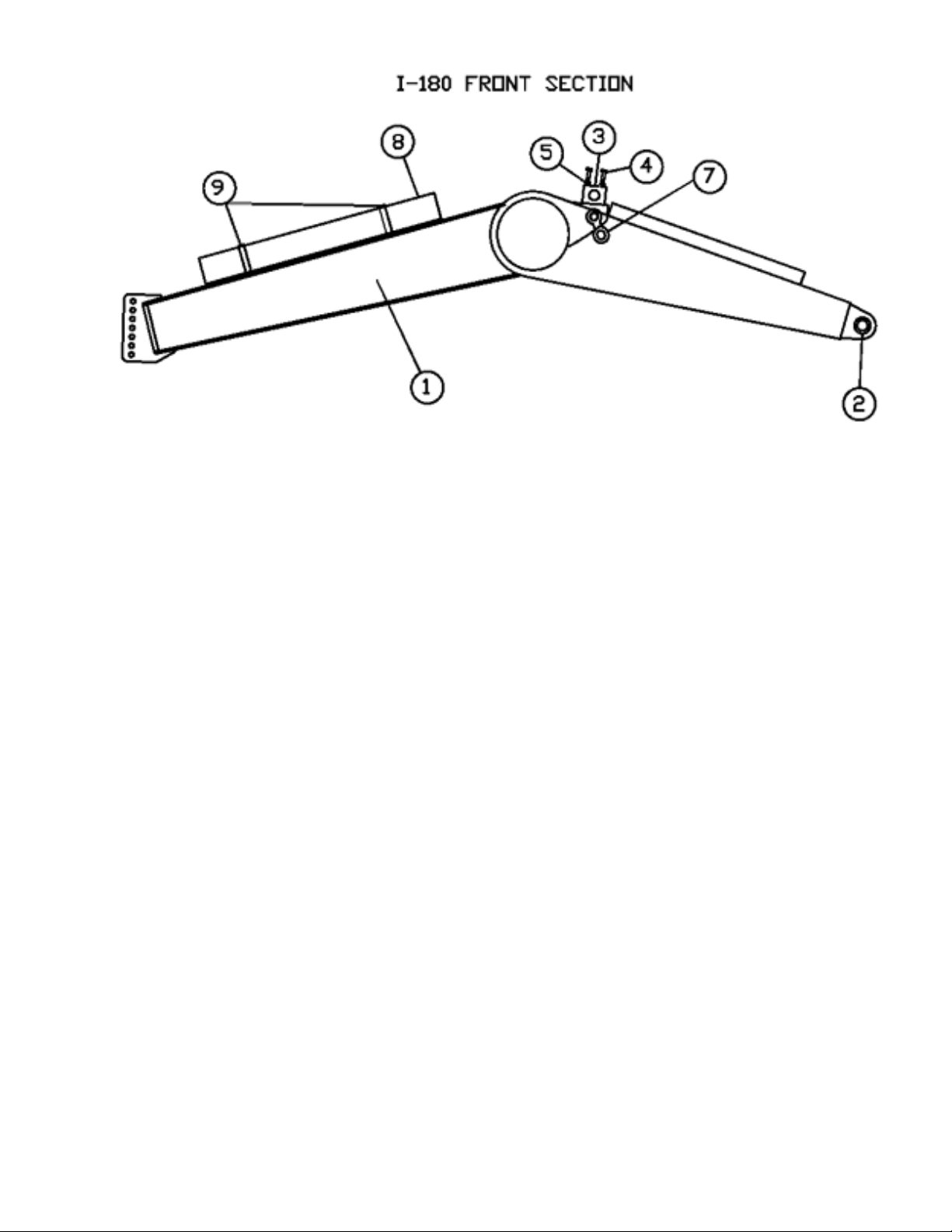

I-180TS Front Section Frame

A123320

ITEM QTY PART NUMBER DESCRIPTION

1 1 A123320 Front Section

2 2 A123320-8 2” ID x 3-1/2” OD x 3” long bronze

bushing

3 4 A123293A Trunion mount block

4 8 AFB-00039 Bolt, 3/4" NC x 5-1/2" long, gr. 8

5 8 AFW-00002 3/4" lock washer

7 2 A123320-20 Travel Lock

8 1 A125005 Accumulator

9 2 A125009 Mounting brackets

9

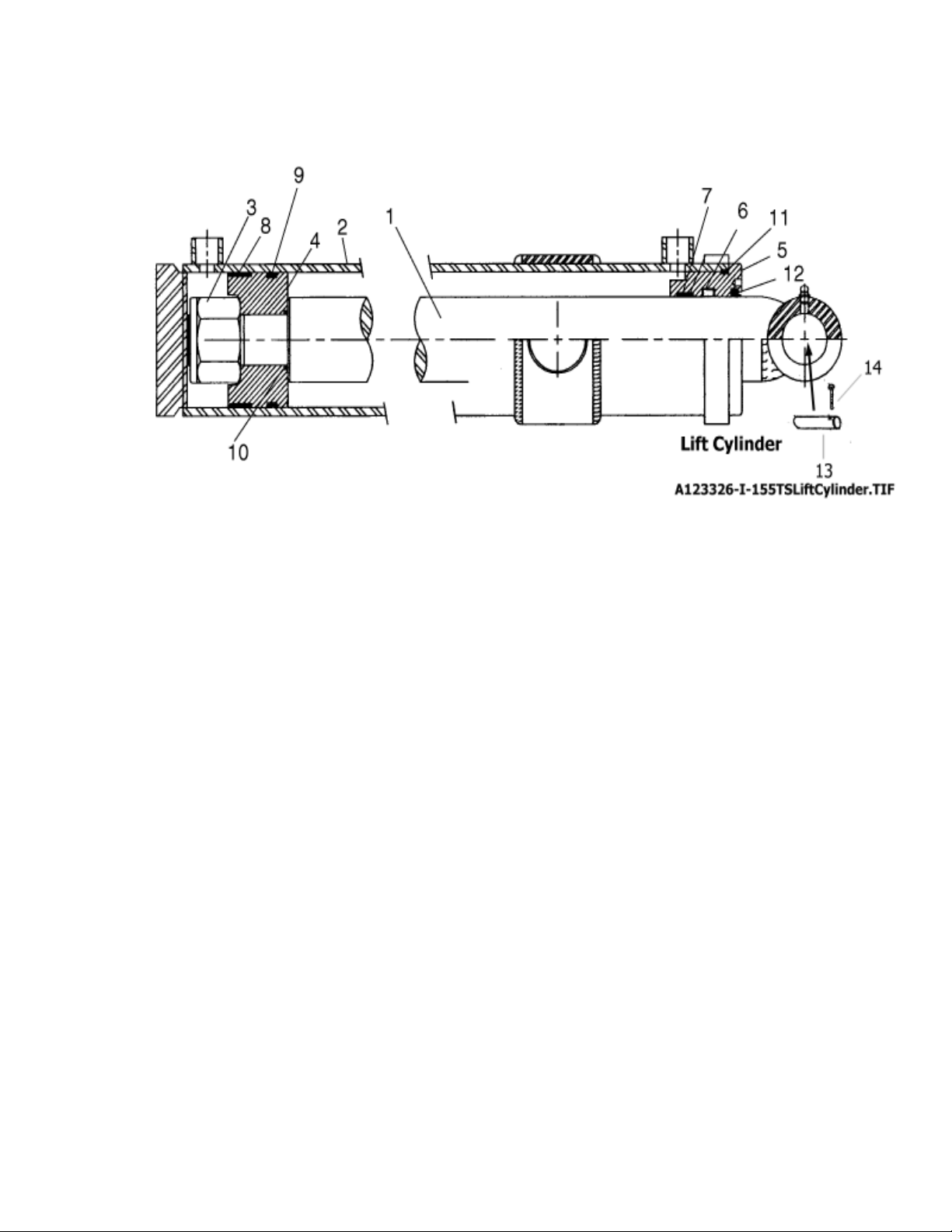

*** Dealer Note ***

MODEL I-180

LIFT CYLINDER 5 1/2 X 20

PART NO. A125044

KEY NO. PART NO. DESCRIPTION

1. A123326-1 Piston Rod: 2-1/2”

2. A125044-02 Barrel Weldment, 5-1/2”

3. AFN-00018 Nut: Lock 1-1/2-12

4. A125044-04 Piston, 5-1/2”

5. A125044-05 Gland, 5-1/2”

6. A123324-6 Rod Seal

7. A123324-5 Wear Band ID for Gland

8. A125044-10 Wear Ring, 5-1/2”

9. A125044-15 Piston Seal, 5-1/2”

10. A123324-10 O-Ring, ID of Piston

11. A125044-20 O-Ring, OD of Gland

12. A123324-7 Rod Wiper

13. A123335 Pin, 2” x 10-1/2” lg.

14. AFP-00001 Cotter Pin, 1-4” x 3”

*** Dealer Note ***

A125044-40 Seal Kit (Items 6-12)

Some 2002 models used a 5" x 20" lift cylinders in lieu of this cylinder. To

ensure correct parts shipment carefully examine the cylinder for size.

5-1/2" x 20" 5" x 20" (p.n. A123326)

Barrel Circumference 19-1/4" 17-1/2"

Barrel Diameter 6" 5-1/2"

10

LIFT CYLINDER 5 X 20”

PART NO. A123326

KEY NO. PART NO. DESCRIPTION

1. A123326-1 Piston Rod: 2-1/2”

2. A123326-2 Barrel Weldment

3. AFN-00018 Nut: Lock 1-1/2-12

4. A123324-4 Piston

5. A123324-3 Gland

6. A123324-6 Rod Seal

7. A123324-5 Wear Band

8. A123324-8 Wear Ring

9. A123324-9 Piston Seal

10. A123324-10 O-Ring

11. A123324-11 O-Ring

12. A123324-7 Rod Wiper

AHS-00140 Seal Kit (Items 6-12)

13. A123335 Pin, 2” x 10-1/2” lg.

14. AFP-00001 Cotter Pin, 1-4” x 3”

*** Dealer Note ***

*** Dealer Note ***

Some 2002 models used a 5" x 20" lift cylinders in lieu of this cylinder. To ensure

correct parts shipment carefully examine the cylinder for size.

5-1/2" x 20" 5" x 20" (p.n. A123326)

Barrel Circumference 19-1/4" 17-1/2"

Barrel Diameter 6" 5-1/2"

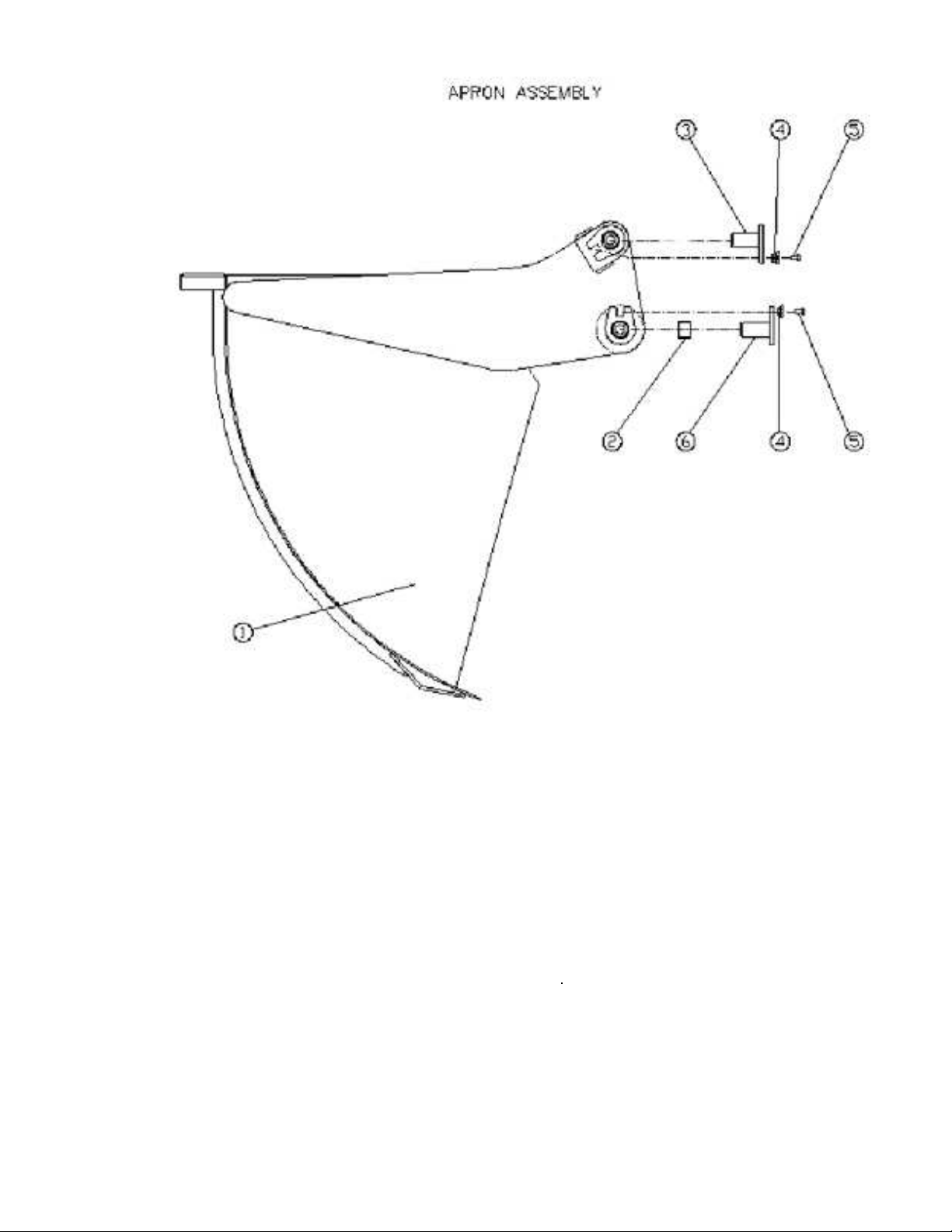

A123322 Apron Model I-180-TS

ITEM QTY PART NUMBER DESCRIPTION

1 1 A123322 Apron Model I-180-TS

2 2 A123299-10 Bushing, 2- 2/8" O.D. x 2" I.D. x 1-1/2" long

with grease groove

3 2 A123322-14 Pin: 2" x 3-3/4" long, For Apron cyl rod end

4 4 A123358 Flanged bolt Bushing

5 4 AFB-00079 Bolt: 5/8" x 1-1/2"

6 2 A123322-08 Apron Pivot Pin w/grease zerk

12

Loading...

Loading...