Ashland I-175XL2 User Manual ver 811

I-175XL2

PARTS MANUAL

ver 811

Ashland Industries Inc.

1115 Rail Drive

P.O. Box 717

Ashland, WI. 54806

Ph: 877-634-4622 Toll Free

Ph: 715-682-4622

Fx: 715-682-9717

www.ashlandind.com

T

g

g

T

g

g

T

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Serial Number

WELCOME TO OUR NEW CUSTOMERS!

hank you for your purchase of an Ashland scraper and the confidence you have place d in us to

handle your earthmoving projects. Years of research, testing and successful application have

been spent to ensure quality and m axim um perf ormance for ou r customers. Please read and

understand this manual be f ore attempting to attach or operate this scrap er. This ma nual should

always rema in with the machine. Be sure and fill out and send in the owners re

the beginning of this ma nual, or you may fill out the form on-line by

cli ck on “Regis ter your M achine” at the bot t om of the p age.

oing to ashlandind.com an d

istr atio n form at

SCRAPER ID NUMBER

he serial nu m ber pla t e for the sc raper is located on the right rear area of t he scr aper. The

lette r and numbers sta mped id en tify the serial number, model numb er and ca pacity of the

sc raper. Ple ase r ecord this se rial number for use in ord erin

your equipment if it is ever stolen.

R eferences to serial n umber breaks on part s are located in t he manual with a referen ce seque nce

of XXXXX-XXXXX. Th e be

he ending number is the final serial number use o f the part within this machine.

inning number records the se rial numb er start of the use of that part .

part s, warrantee issue s and to t race

Page #1

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

ASHLAND SCRAPERS

How to Order Parts

PHONE : 715-682-4622 Fax: 715-682-9717

HOW TO OR D ER PARTS:

IMPORTANT

Parts must be ordered through your local authorized ASHLAND dealer.

Be sure to s t at e MODEL and SER IAL NUMBER of y our mach ine, PART NUMBER , DES CRIPTION

and QUANTITY needed.

Unless this is done, we can not provide prompt servi ce or assure sh ip m ent of the co rrect parts.

Ashland Industries weldable replacement parts are available to rebuild, modify o r update yo ur

s craper to current fact ory s pecificat ions .

Page #2

P.O. Box 717

1115 Rail Dr

shland , WI 54806

T

g

p

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Operators and Maintenance

his scr a per i s a durab le piece of equipment and wi th prop er care will yield m any years of t rouble f ree

operat ion. The scrape r requires a power source wi t h TWO 4 way (do uble act ing) hyd raul ic c ontrol

valves.

The scraper should be grease d at all points where

the tractor hydraulic system and add to maintain the proper level. Care should be used when adding oil

or when disconnecting any oil line to ke ep all dirt out of the oil as dirt is a major factor in the failure of

hydraul i c component s .

When the scraper is placed into operation, the operator will have to “feel out” the amount of depth of

cut to obtain maximum lo ading efficiency. This is usually accomplished by taking a lesser and more

uniform cut; however, s ome soil conditions such as loose sand may require a “pumping action” ob tained

by taking successive deep cuts and lifting out of cut as the tractor begins to lose power or traction.

1. After 10 hours wor k, all bolts should be checked and tightened if necessary.

2. Ev ery 10 hours al l g r ease fitt ings s hould be lubricated.

3. After 50 hours work, all bolts should be rechecked and tightened if necessary. Check wheel

bearings and adjust if necess ary.

4. After 300 hours work, clean and repack wheel bearings and replac e, if ne cessary, cutting edges,

worn

ins, etc.

rease fittings are prov id ed. Chec k the oil levels in

Page #3

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

ASHLAND SCRAPERS

XL Assembly

PHONE : 715-682-4622 Fax: 715-682-9717

Page #4

P.O. Box 717

1115 Rail Dr

shland , WI 54806

T

T

j

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Safety Guidelines

GEN ER AL SAFE TY GUIDELIN ES

Safety of t he op erat or is one of t he main con cerns in de signing and dev eloping a new pi ece of

equipment. Designe rs and manufacturers build in as many safety features as po ssible. However, every

year many accidents o ccur which could have been avoided by a few seconds of thought and a more

car eful approach to hand ling equipment. You, t he ope rator, can av o id many accident s by o bserv ing the

follow ing preca uti ons in this s ection. To a voi d personal injury , s tu dy the foll owing p r ecautions and insist

those working with you, or for you, follow them.

Replace any CAUTION, WARNING, DANGER or instruction safety decal that is not readable or is missing.

Location of such decals is indicated in this boo klet.

Do not attempt to operate this equipment under the inf luence of drugs or alcohol.

Review the safety instructio ns in the operator ’s manual with all users annually.

hi s equi pme nt is dangero us to childr en and persons unfa mili ar with its operation . The op erator shoul d

be a responsible adult familiar with farm or constructio n machi nery and trai ned in this equipment’ s

op e rations. Do not allow persons to operate or assemble this unit until they have read this

manual and the owner’s manual and have developed a thorough understanding of the safety

precautions an d how the m achi ne works.

o prevent injury or death, use a tractor equipped with a Roll O ver Protective System (ROPS). Do not

paint over, remove o r deface any safety signs or warning decals on your equipment. Observe all safety

signs and practice the instructions on them.

Never exc eed the limits of a piec e of m achinery. If its ability to do a

- DON’T TRY IT.

o b, or to do so safel y , is in qu est ion

Page #5

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

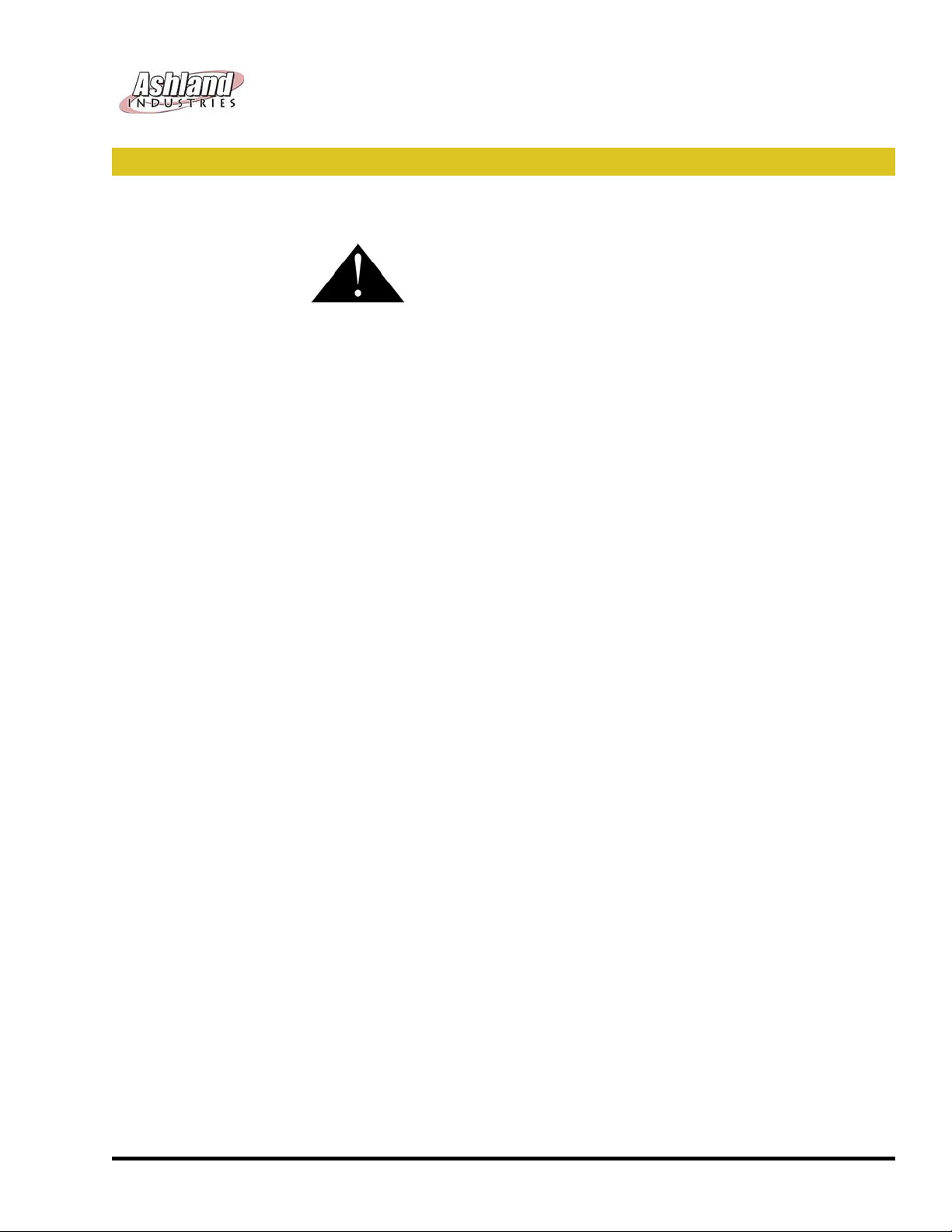

Gooseneck Frame Assembly (175)

KEY PART DESCRIPTION

1 A17507 Gooseneck Frame

1 AFB-00080 Bolt 5/16” NC x 1/2” Lg.

2 AFB-00079 Bolt, 5/8 NC X 1 1/2" Gr. 8

3 14505 Grease Zerk - Straight

4 A123321-09 Main Frame Pin

5 A123358 Bushing Pin Keeper

6 A123230-20 Travel Lock

7 AFB-00081 "Bolt, 7/8”NF x 5” Lg. Grade 5"

8 7597 "Nut, 7/8”NF"

9 8125 Lockwasher 7/8”

10 A14002 Cast Socket Half - Rear

11 A14003 Cast Socket Half - Front w/Zerk Hole

12 A2206 Grease Zerk - Long Shank

13 A123320-08 "Bushing, 3 ID X 3.5 OD X 3"

14 OPT-00001 Hitch Jack

14 OPT-00001 Hitch Jack

15 A123321-89 Bushing Pin Keeper

15 A125006 Safety Link Pin

Page #6

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

ASHLAND SCRAPERS

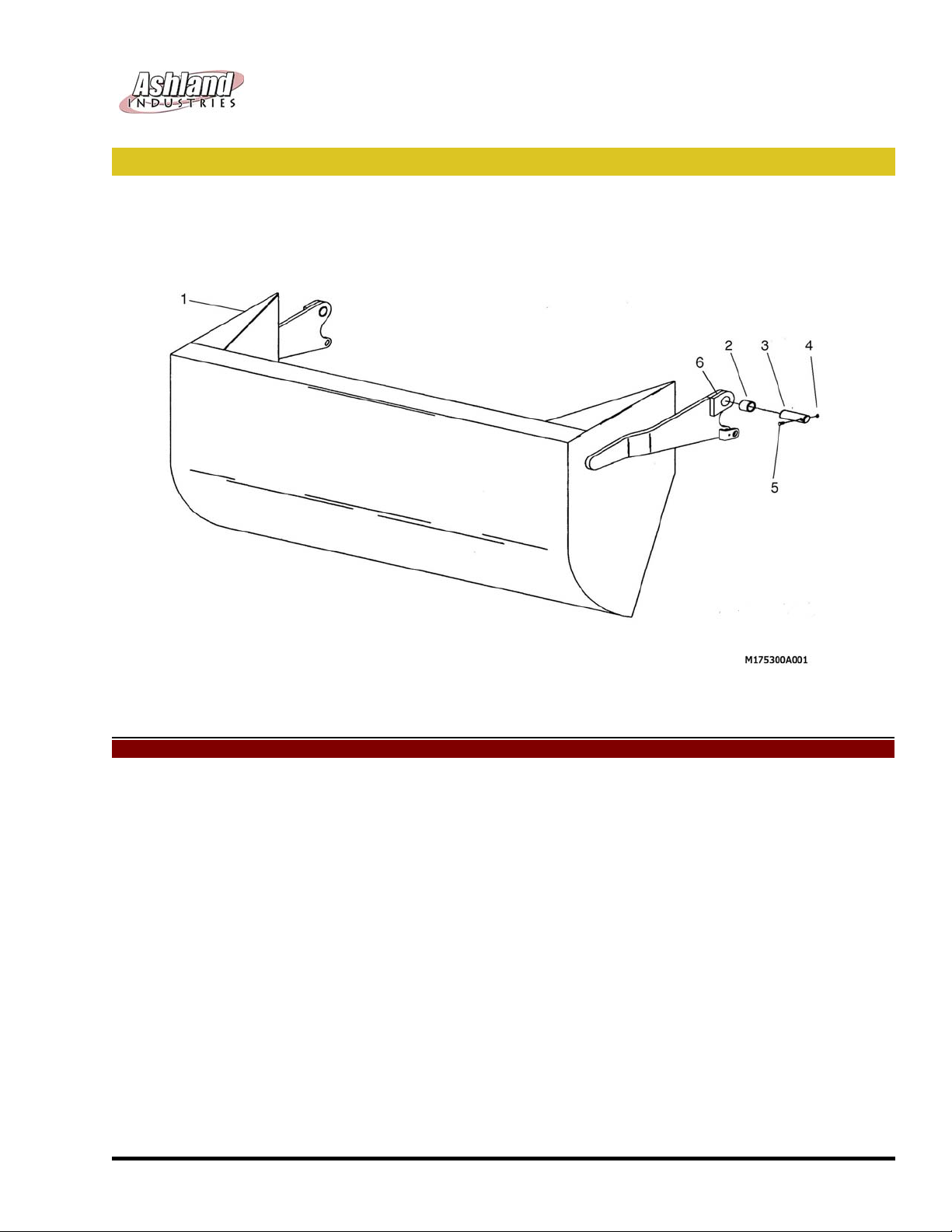

Apron Assembly (175)

PHONE : 715-682-4622 Fax: 715-682-9717

KEY PART DESCRIPTION

1 A17505 Apron Model 175

2 A16027 Bushing: 1 1/2 ID X 2 OD X 2" L

3 A123337 Pin: Apron Pivot 110TS-175XL2

4 7450 Nut: 3/8" NC

5 AFB-00049 Bolt: 3/8" NC X 3"

6 14505 Grease Zerk-straight

Page #7

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 Fax: 715-682-9717

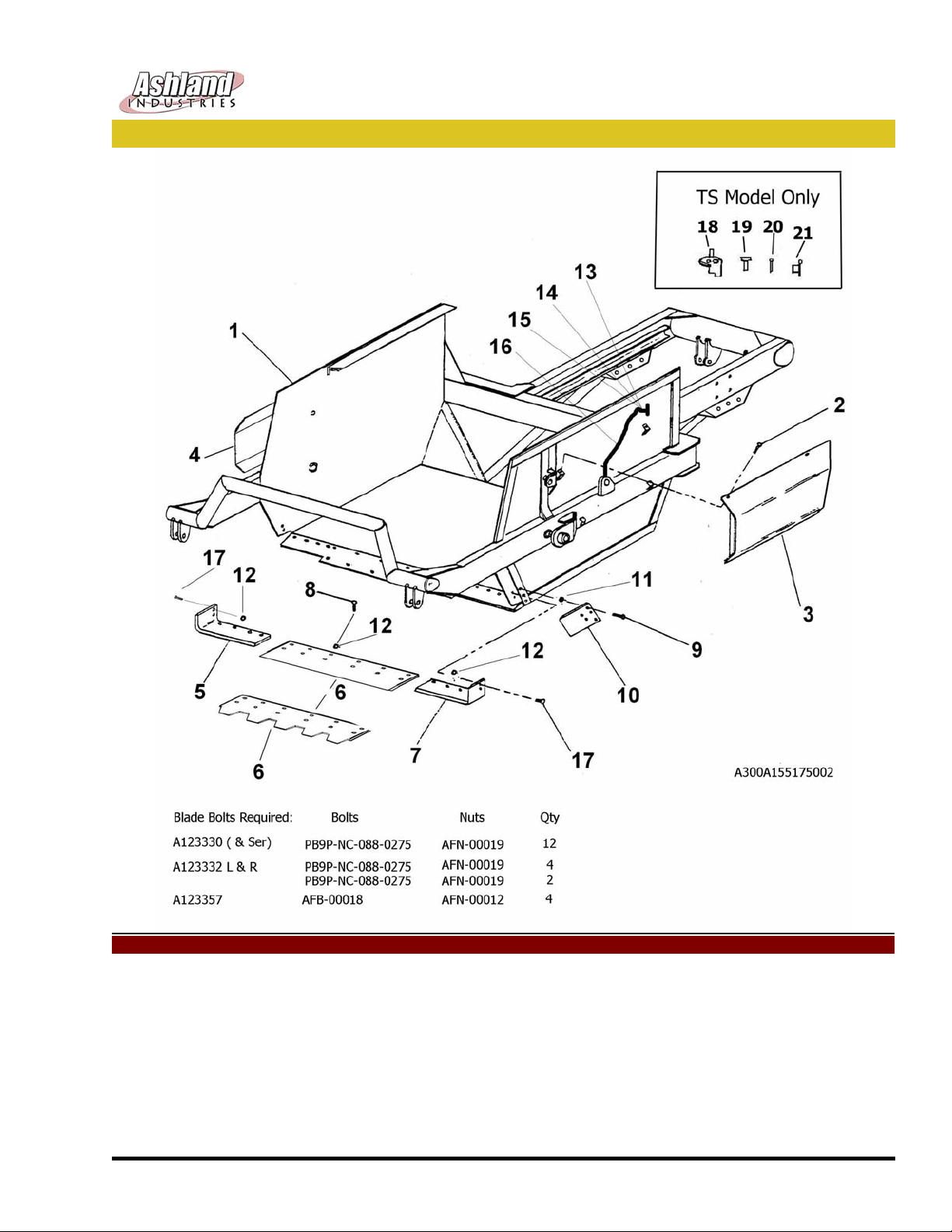

Bowl & Frame Assembly (155-175-1200)

KEY PART DESCRIPTION

1 A17503 Bowl and Frame Model 175

2 AFB-00094 Flanged Bolt: 3/8 NC X 1"

3 A123309-62L Apron Cylinder Guard - Left Side

4 A123309-62R Apron Cylinder Guard - Right Side

5 A123332L Left Cutting Edge-8" X22 1/2" X 7/8" Hardened

6 A123330 Center Cutting Edge, 1 1/8 X 12" X 63"

A123330-SER Center Currint Edge, (Optional) Serrated, 1 1/8 X 12" X 63"

7 A123332R Right Cutting Edge-8" X 22 1/2" X 7/8" Hardened

8 PB9P-NC-088-0275 "Plow bolt, 7/8” NC x 2-3/4”

9 AFB-00018 Bolt: 1" NC X 3" L

Page #8

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 Fax: 715-682-9717

ASHLAND SCRAPERS

Bowl & Frame Assembly (155-175-1200)

KEY PART DESCRIPTION

10 A123357 Bank Shaver/Router Bit, Reversible, L & R

11 AFN-00012 Nut: 1" NC

12 AFN-00019 Nut: 7/8" NC

13 A125019 Grease Fitting 1/4 x 28.54 Long

14 A125026 Bulkhead nut 1/8 n.p.s.m.

15 A123309-89 Single Hole Tab

16 A125022 18" Grease Line

17 PB9P-NC-088-0225 "Plow bolt, 7/8” NC x 2-1/4”

Page #9

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 Fax: 715-682-9717

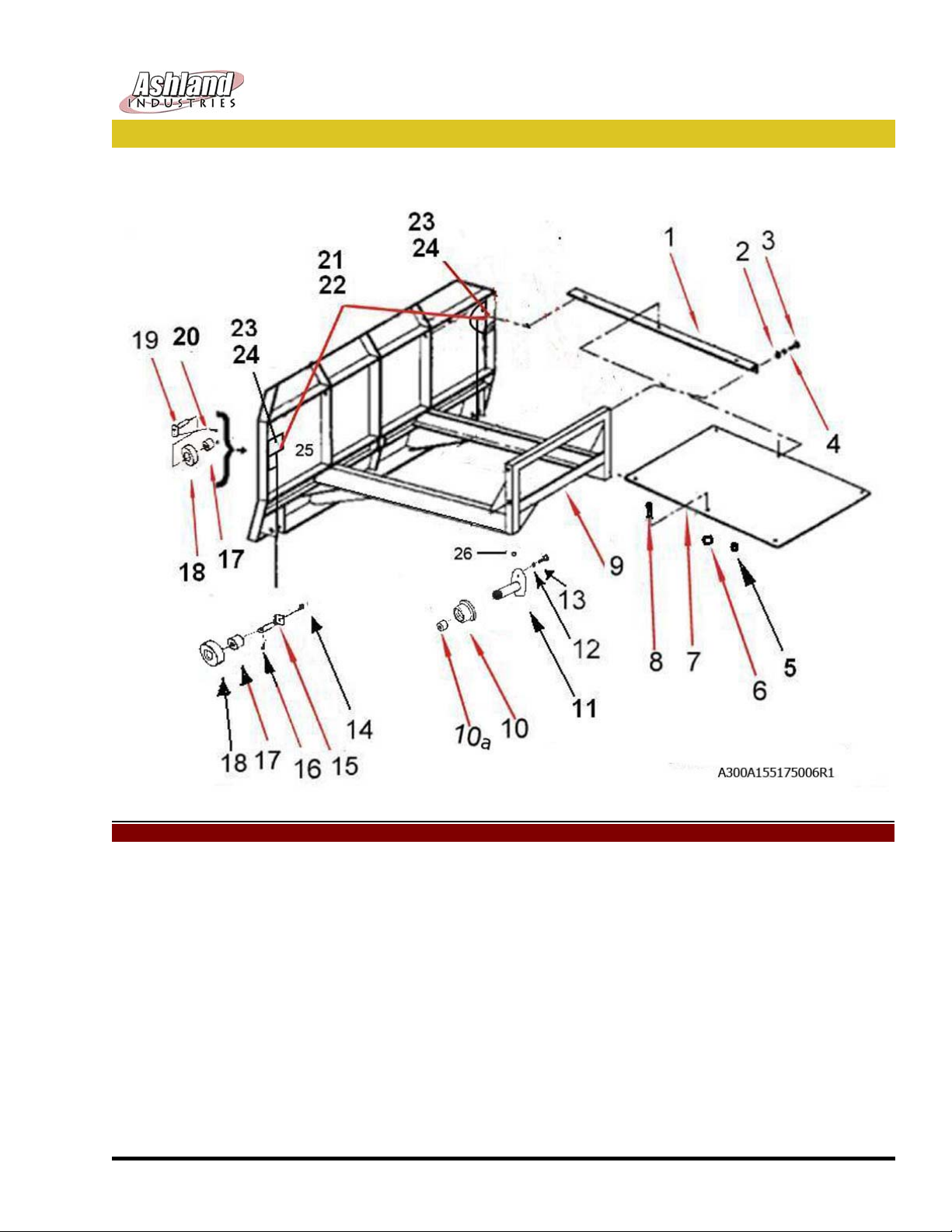

Push Off Assembly(155-175-1200)

KEY PART DESCRIPTION SN 175XL2

1 A14022 Brace

2 AFN-00006 Nut: 3/4” NC

3 AFB-00037 Bolt: 3/4” NC x 2” Lg.

4 AFW-00002 Lockwasher: 3/4”

5 8100 Lockwasher: 1/2”

6 AFN-00015 Nut: 1/2” NC

7 A14023 Dirt Shield

8 AFB-00015 Bolt: 1/2” NC x 1-1/2”

9 A17502 Pushoff Gate: Model 175

10 A123306 Roller: Rear Gate 22684-XXXXX

10a A123307 Bushing 22684-XXXXX

11 A123305 Pin: 1 1/4" X 3 1/2" Tap. Roll w/ Grease fitting 22684-XXXXX

12 8100 Lockwasher: 1/2”

13 AFB-00033 Bolt: 1/2 NC X 2-1/2”

14 AHF-00028 Grease Fitting: 1/8” NPT -90 degree

15 A6007A Pin: 1-1/4” x 4-1/8” Lg.

Page #10

P.O. Box 717

shland , WI 54806

1115 Rail Dr

Loading...

Loading...