Ashland I-155-TS2 User Manual ver 1111

EARTHMOVERS

I-155-TS2

PARTS MANUAL

ver 1111

Ashland Industries Inc.

1115 Rail Drive

P.O. Box 717

Ashland, WI. 54806

877-634-4622 Toll Free - phone

715-682-4622 phone

715-682-9717 fax

www.ashlandind.com

T

g

g

T

g

g

T

A

PHONE : 715-682-4622 F ax: 715-682-9717

ASHLAND SCRAPERS

Serial Number

WELCOME TO OUR NEW CUSTOMERS!

hank you for your purchase of an Ashland scraper and the c onfidence you have place d in us to

handle your e arthmoving projects. Years of research, testing and succes sful application have

been spent to ensure quality and m axim um perf ormance for ou r customers. Please read and

understand this manual be f ore attempting to attach or operate this scrap er. This ma nual should

always rema in with the machine. Be sure and fill out and send in the owners re

the beginning of this manual, or you may fill out the form on-line by

cli ck on “Regis ter your M achine” at the bott om of the p age.

oing to ashlandind.com an d

istr atio n form at

SCRAPER ID NUMBER

he serial nu m ber pla t e for the sc raper is loca ted on the right rear area of t he scr aper. The

lette r and numbers sta mped id en tify the serial number, model numb er and capacity of the

sc raper. Ple ase record this se rial nu mbe r for u se in orderin

your equipment if it is ever stolen.

R eferences to serial n umber breaks on part s are located in t he manual with a referen ce seque nce

of XXXXX-XXXXX. The be

he ending number is the final seria l number use of the part within this machine.

inning number records the se rial numb er start of the use of that part .

part s, warrantee issue s and to t race

Page #1

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

ASHLAND SCRAPERS

How to Order Parts

IMPORTANT

Parts must be ordered through your local autho rized ASHLAND dealer.

Be sure to state MODEL and SERIAL NUMBER of your machine, PART NUMBER,

DESCRIPTION and QUANTITY ne eded.

Unless this is done, we canno t provid e prompt service or assure shipment of the correct

parts.

PHONE : 715-682-4622 F ax: 715-682-9717

Ashland Industries weldable replacement parts are available to rebuild, modify or update

your scraper to c urrent fa ctory specifications.

Page #2

P.O. Box 717

1115 Rail Dr

shland , WI 54806

T

g

p

A

PHONE : 715-682-4622 F ax: 715-682-9717

ASHLAND SCRAPERS

Operators and Maintenance

his scr a per i s a durab le piece of equipment and wit h proper care will yield m any years of t rouble f ree

operat ion. The scrape r requires a power source w ith TWO 4 way (do uble act ing) hyd raul ic c ontrol

valves.

The scr aper should be grease d at all points where

the tractor hydraulic system and add to maintain the proper level. Care should be used when adding oil

or when dis connecting any oil line to keep all dirt out of the oil as dirt is a ma jor factor in the failure of

hydrau l ic com pon ent s .

When the scraper is placed into operation, the operator will have to “feel out” the amount of depth of

cut to obtain maximum loading efficiency . This is usually accomplished by taking a lesser and more

uniform cut; however, s ome soil conditions such as loose sand may require a “pumping ac tion” obtained

by taking successive deep cuts and lifting out of cut as the tractor begins to lose power or traction.

1. After 10 hours work, all bolts should be checked and tightened if nece ssa ry.

2. Every 10 ho urs all grease fit t ing s should be lubricated.

3. After 50 ho urs work, all bolts should be re checked and tightene d if necessary. Check wheel

bearings and adjust if necessary.

4. Afte r 300 hours work, clean and repack wheel bearings and replace, if necessary, cutting edge s,

worn

ins, etc.

rease fittings are prov id ed. Chec k the oil levels in

Page #3

P.O. Box 717

1115 Rail Dr

shland , WI 54806

j

A

PHONE : 715-682-4622 F ax: 715-682-9717

ASHLAND SCRAPERS

Safety Guidelines

SAFETY SIGNAL WORDS

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The

appropriate signal word for each has been selected using the following guidelines:

DANGER: Indicates an imminent ly hazardous situation that, if not avoided, will result in death

o r seriou s inj ury. T hi s signal w ord i s t o be l imited to the m ost extrem e situations t ypically for

machine components which, for functional purposes, cannot be quarded.

WARNING: Indicates a pote ntially hazar dous situation that, if not avoided, could result in

death or serious injury, and includes hazards that a re exposed whe n guards are removed. It

may also be used to alert against unsafe practices.

CAUTION: I n dicates a potentially hazardous situation that, if not avoided, may result in minor

o r m oderate injury . It m ay also be used to alert agai nst un safe pr act ices.

GENERAL SAFETY GUIDELINES

Sa fety of the operator is one of the main concerns in designing and developing a new piece of

equi pment. Designers and manu fac tur ers build in as many safety features as po ssib le. However, every

year many accidents occur which could have been avoided by a few sec onds of thought and a more

ca reful approach to handling e quipment. You, the opera tor, can avoid many accidents by observing the

following precautions in this section. To avoid personal injury, study the following precautions and insist

tho se working with you, or for you, follow them.

Re place any CAUTION, WA RN ING, D ANGE R or inst ructi on safet y decal that is n ot readable or is mi ssing.

Location of such decals is ind i cated in thi s booklet.

Do not attempt to op erate thi s equipment under t he inf lu ence of drug s or al cohol.

Review the sa fety instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should

be a responsible adult familiar with farm machiner y and trained in this equipment ’s operations. Do not

allow per sons t o operat e or assemb l e this unit unti l they have read this man u al and have

dev e lope d a th o rou gh un de rst a n ding of th e s afe t y pr e cautio n s a n d o f how it wor k s.

To prevent injury or d eath, use a tractor equipped with a Roll Over Protective System (ROPS). Do n ot

paint over, re mov e o r deface any s afet y signs or w a rning deca ls on your e quipment. Observe a ll sa fe ty

sign s and pr act ic e t he i nstructions on them.

Nev e r excee d t he lim its o f a piec e o f m achi n ery . If it s ab i l it y t o d o a

- D ON’T TRY IT.

ob, or to do so s afely, is in question

Page #4

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

ASHLAND SCRAPERS

TS Assembly

PHONE : 715-682-4622 F ax: 715-682-9717

Page #5

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

PHONE : 715-682-4622 F ax: 715-682-9717

ASHLAND SCRAPERS

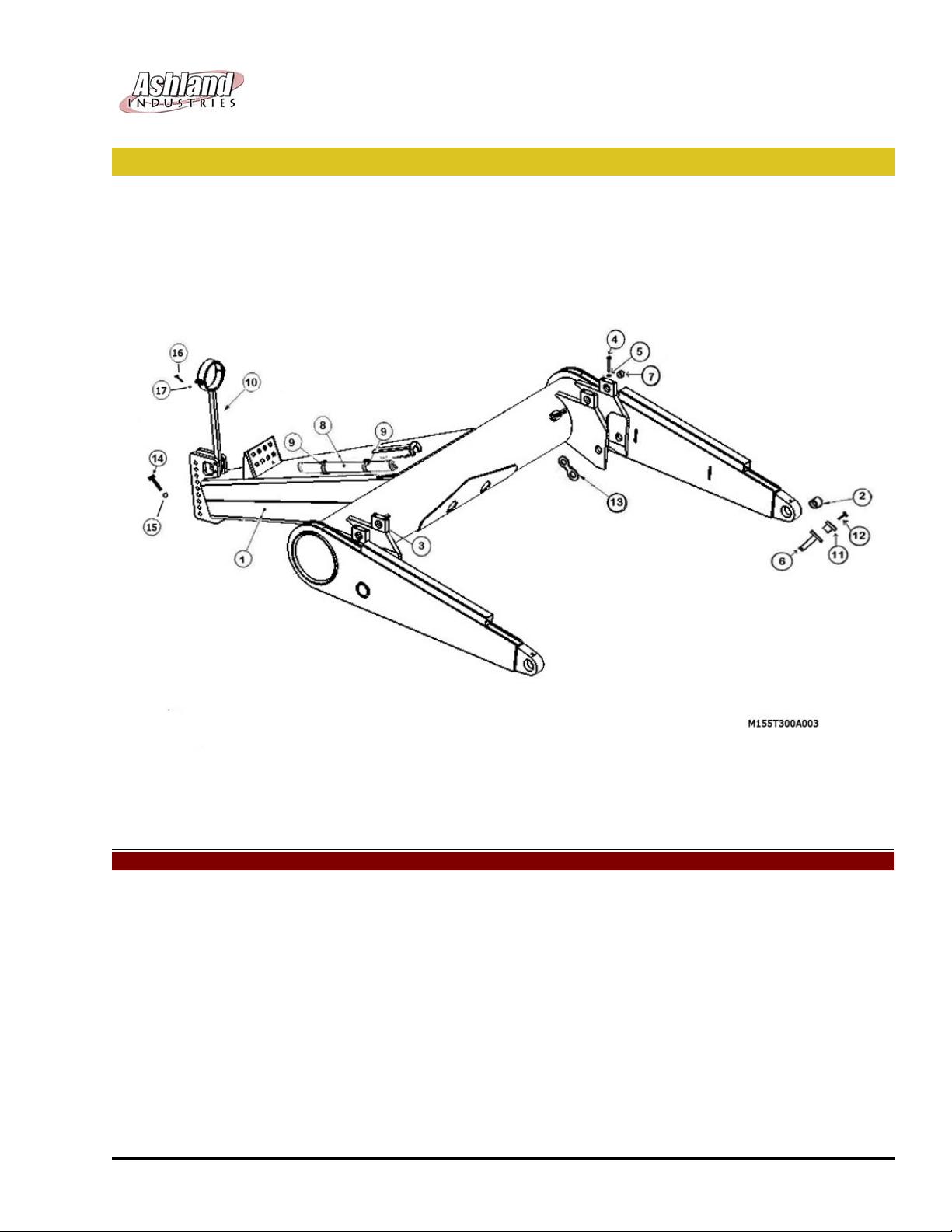

Front Frame Assembly (155-1200)

KEY PART DESCRIPTION SN 155TS2

1 A123329 Front Frame Assembly

2 A123320-08 Bronze Bushing: 3"ID X 3 1/2 OD X 3"L

3 A123456 Trunion Mount Block

4 AFB-00039 Bolts, 3/4" X 5 1/2"

5 AFW-00002 Lockwasher, 3/4"

6 A123321-09 Pin: Main Frame Attachment

7 A125179 Bushing for Trunion Mount Block

8 A125005 Accumulator

9 A125009 Mounting Brackets

10 600119C Hose Support 22397-XXXXX

11 A123358 Flanged Bolt Bushing

12 AFB-00079 Bolt: 5/8" X 1 1/2" Gr 8

13 A123320-20 Travel Lock

14 AFB-00021 Bolt: 1" X 5 1/2" NC Gr. 8

15 AFN-00037 Nut: 1" NC Locknut

Page #6

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 F ax: 715-682-9717

ASHLAND SCRAPERS

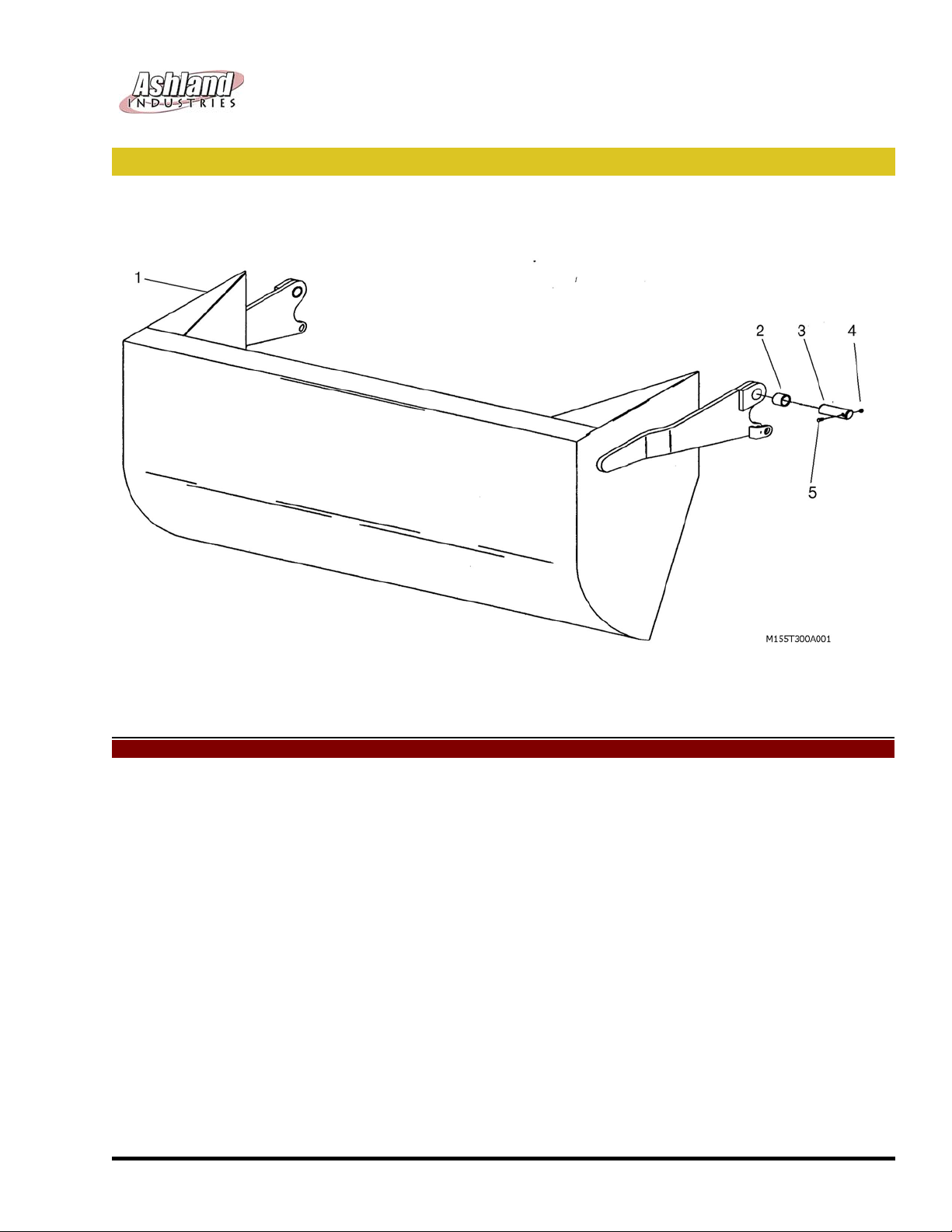

Apron Assembly (155-1200)

KEY PART DESCRIPTION

1 A123310A Apron Model 155

2 A16027 Bushing: 2” OD x 1-1/2” ID x 2” Long

3 A123337 Pin: 1-1/2” x 5-3/8”

4 7450 Nut: 3/8” NC

5 AFB-00049 Bolt: 3/8” NC x 3”

Page #7

P.O. Box 717

1115 Rail Dr

shland , WI 54806

A

PHONE : 715-682-4622 F ax: 715-682-9717

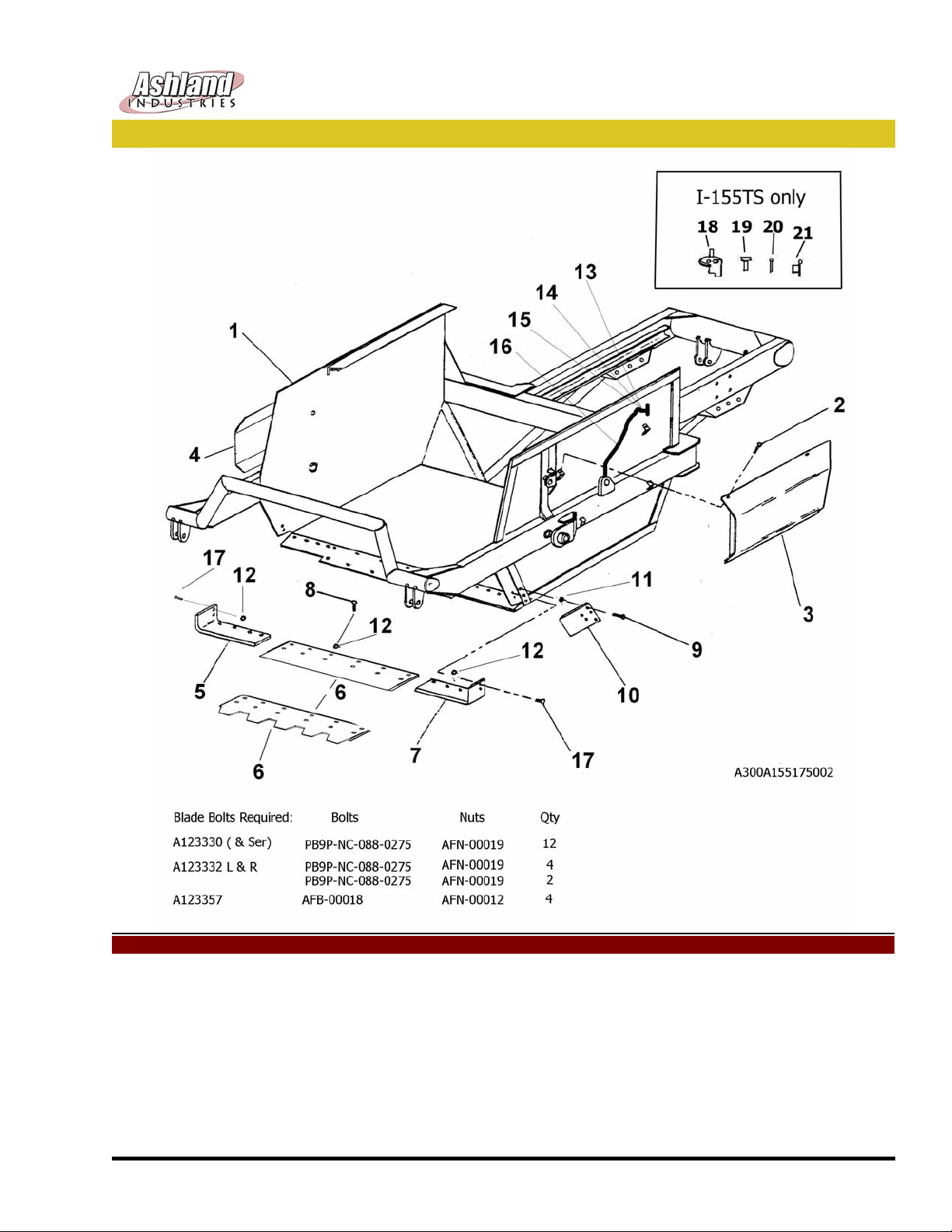

Bowl & Frame Assembly (155-175-1200)

KEY PART DESCRIPTION

1 A123309 Bowl and Frame Model 155-1200

2 AFB-00094 Flanged Bolt: 3/8 NC X 1"

3 A123309-62L Apron Cylinder Guard - Left Side

4 A123309-62R Apron Cylinder Guard - Right Side

5 A123332L Left Cutting Edge-8" X22 1/2" X 7/8" Hardened

6 A123330 Center Cutting Edge, 1 1/8 X 12" X 63"

A123330-SER Center Currint Edge, (Optional) Serrated, 1 1/8 X 12" X 63"

7 A123332R Right Cutting Edge-8" X 22 1/2" X 7/8" Hardened

8 PB9P-NC-088-0275 "Plow bolt, 7/8” NC x 2-3/4”

9 AFB-00018 Bolt: 1" NC X 3" L

Page #8

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 F ax: 715-682-9717

ASHLAND SCRAPERS

Bowl & Frame Assembly (155-175-1200)

KEY PART DESCRIPTION

10 A123357 Bank Shaver/Router Bit, Reversible, L & R

11 AFN-00012 Nut: 1" NC

12 AFN-00019 Nut: 7/8" NC

13 A125019 Grease Fitting 1/4 x 28.54 Long

14 A125026 Bulkhead nut 1/8 n.p.s.m.

15 A123309-89 Single Hole Tab

16 A125022 18" Grease Line

17 PB9P-NC-088-0225 "Plow bolt, 7/8” NC x 2-1/4”

18 A123309-93 3" Locking Lug for Rear Hitch

19 A123309-96 Pin for Locking Lug

20 AFP-00001 Pin, Cotter, 1/4" X 3"

21 A125006 Safety Snap Pin

Page #9

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 F ax: 715-682-9717

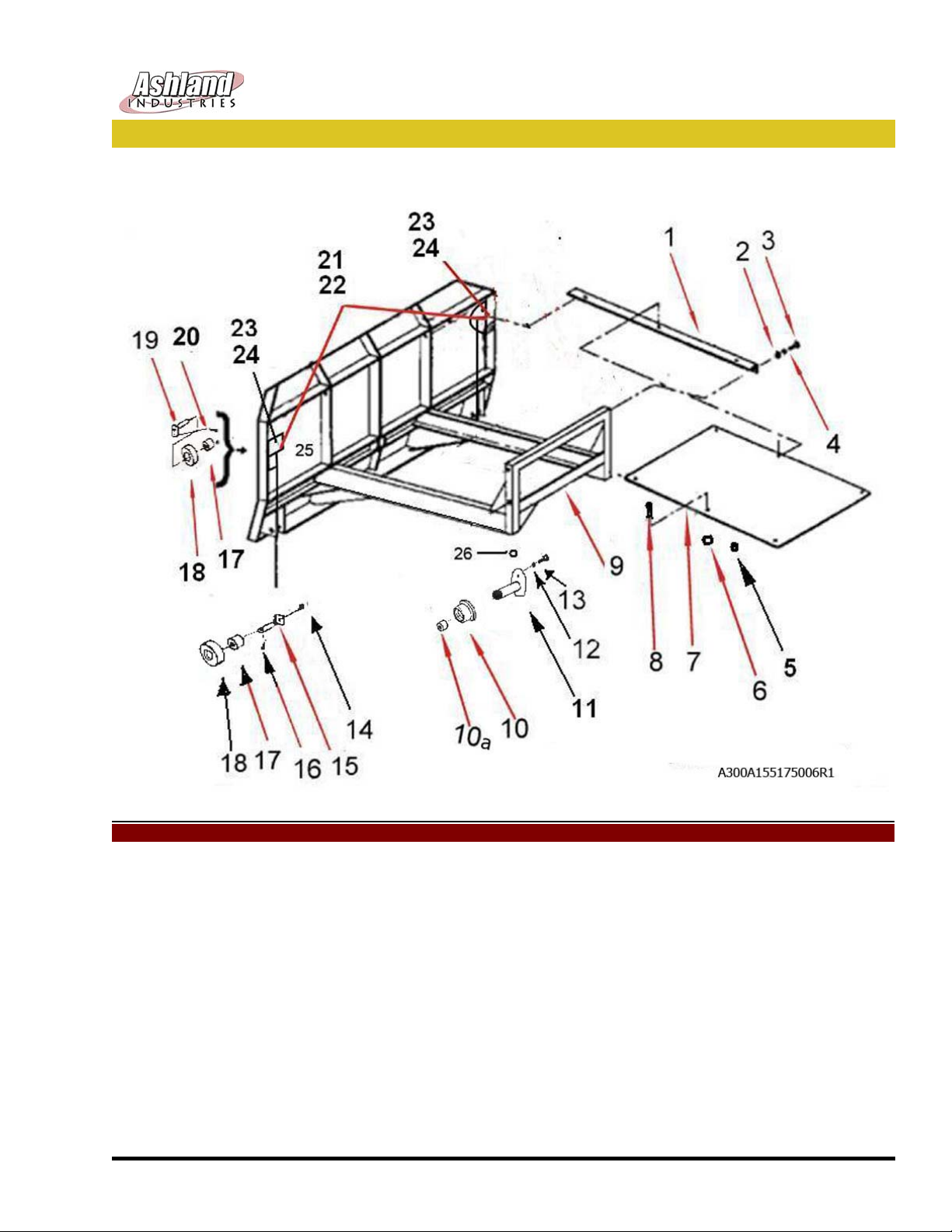

Push Off Assembly(155-175-1200)

KEY PART DESCRIPTION SN 155TS2

1 A14022 Brace

2 AFN-00006 Nut: 3/4” NC

3 AFB-00037 Bolt: 3/4” NC x 2” Lg.

4 AFW-00002 Lockwasher: 3/4”

5 8100 Lockwasher: 1/2”

6 AFN-00015 Nut: 1/2” NC

7 A14023 Dirt Shield

8 AFB-00015 Bolt: 1/2” NC x 1-1/2”

9 A16024 Pushoff Gate: Model 150-155-1200

10 A123306 Roller: Rear Gate 22684-XXXXX

10 A123353 Wear Pad XXXXX-22683

10a A123307 Bushing 22684-XXXXX

11 A123305 Pin: 1-1/4 X 3 1/2" Tap Roll w/Grease Fitting 22684-XXXXX

11 A123305A Pin: 1-1/4 X 2-3/4” for Wear Pad XXXXX-22683

12 8100 Lockwasher: 1/2”

13 AFB-00033 Bolt: 1/2 NC X 2-1/2”

Page #10

P.O. Box 717

shland , WI 54806

1115 Rail Dr

A

PHONE : 715-682-4622 F ax: 715-682-9717

ASHLAND SCRAPERS

Push Off Assembly(155-175-1200)

KEY PART DESCRIPTION SN 155TS2

14 AHF-00028 Grease Fitting: 1/8” NPT -90 degree

15 A6007A Pin: 1-1/4” x 4-1/8” Lg.

16 AFP-00001 Cotter Pin: 1/4 X 3-1/2”

17 A10163 Bushing: 1-3/4” OD x 1-1/4” ID

18 A10164 Roller: 4-1/4 OD X 1-3/4 ID.

19 A123323-21 Pin: 1-1/4 X 4 1/8” Tab Head

20 7036 Bolt: 1/2 NC X 2”

21 A125020 Remote Grease Lines, 32”

22 A125021 Remote Grease Lines, 54”

23 A125019 Grease Fitting 1/4 x 28.54 Long

24 A125026 BulkHead Nut

25 A123323-40 Double Hole Tab

26 7500 1/2" Nut

Page #11

P.O. Box 717

shland , WI 54806

1115 Rail Dr

Loading...

Loading...