Ashland CS18-HD User Manual

CS18-HD

PARTS MANUAL

Version 03-09

Ashland Industries Inc.

1115 Rail Drive

P.O. Box 717

Ashland, WI. 54806

877-634-4622 Toll Free - phone

715-682-4622 phone

715-682-9717 fax

www.ashlandind.com

1

CS18HD

A

HOW TO O RDER PARTS:

IMPO RTANT

Parts must be o rdered through your local authorized ASH LAN D deale r.

Be sure to state MODEL and SERIAL NUMBER of your machine, PART N U MBER, DESCRIPTIO N and

QUANTITY neede d .

Unless this is done, we cannot provi de prompt se rvice o r assure shipment o f the c orrect parts .

shland Industries weldable replacement parts are avail abl e to rebuild, modify or update your

s crap e r to curr ent fac t or y spe ci fi cat io ns.

Page 2-5. Safety Guidelines

Page 6-12. Operator and Maintenance Instructions

Page 13. Assembly-Illustration

Page 14. Hitch-Illustration and parts

Page 15. Front S ection Frame-Illustration and parts

Page 16. Lift Cylinder 5 ½ X 20 – Illustration and parts

Page 17. Apron As sembly – Illustration and parts

Page 18. Apron Cylinder – Illustration and parts

Page 19. Bowl and Frame Assembly – Illustration and parts

Page 20. Dump Cylinder – Illustration and parts

Page 21. Wheel Assembly – Illustration and parts

Page 22. Wheel and Hub – Illustration and parts

Page 23. Pins – Illustration

Page 24. Hydraulic Valve – Identification, Illustration, Parts, and Adjustment

Page 25. Hydraulic Schema tic

Page 26-27. Maintenance Checklist and Lubrication

Page 28. Troubleshooting

Page 29. Warranty Statement

Index

Ashland Industries Toll Free: 877-634-4622 Fax: 715-682-9717

Page #1

CS18HD

k

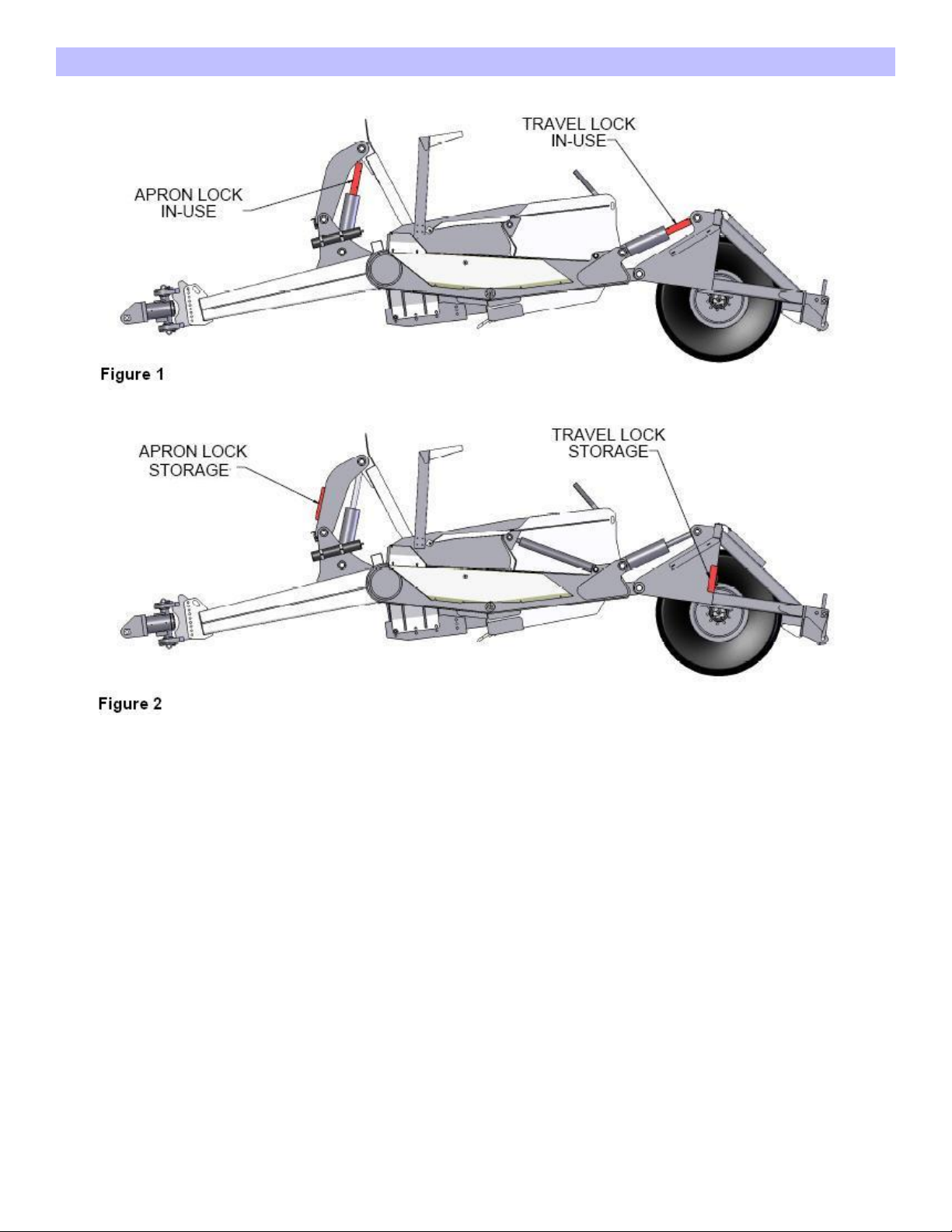

Transport Links

IMPORTANT

Please locate red Transport Links and remove

prior to operation. Retract Lift Cylinder

Circuit, Remove Safety Snap Pin, Remove lin

and replace into storage position as shown in

figure 2.

Re in s ta l l S a fe ty Sn a p P i ns .

Ashland Industries Toll Free: 877-634-4622 Fax: 715-682-9717

Page #2

CS18HD

Safety Guidelines

SA F ETY SIG NAL WORDS

Not e the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The appropriat e signal

wo r d for each has been selected u si ng the following guidelines:

DANGER:

This s ignal word is to be lim ited to the most extrem e s ituations typically for m ac hine com ponen ts which, for functional

pu r poses, c annot be guar ded.

WARNING: Indicates a pot entially hazardous situation that, if not avoided, could result in death or serious injury,

and inc ludes hazar ds that ar e ex posed when guar ds ar e r emov e d. It ma y als o be used to aler t a gainst uns afe

practices.

CAUTION: Indic ates a potentially hazardous situation that, if not avoided, may result in minor or m oderate

inj ur y . It ma y als o be used to aler t again s t un s afe practices.

Saf ety of the operator is one o f the main concerns in desi gning and dev elopin g a n ew piece of equipment . Designe r s

an d ma nufactur er s build in as many s afety feat ur es as possible. Howev er , e ve r y ye ar many ac c idents oc c ur whic h could

ha v e been avoid e d by a few seconds of thought and a mor e c aref ul approach t o handli ng e quipment. You, the operator ,

can avoid many acc iden ts by obs erving the followin g pr ec autions in this section. To avoid per sonal injury, stu dy the

followi ng pr ec autions and insist those work ing with y ou, or for yo u, follow them .

Re place any CA UTION, WARNING, DA NGER or instruction safety decal that is not r eadable o r i s missing. Loc ation of

such decals is indicated i n this b ooklet.

Do not a tt em pt to operat e this equ ipm ent under the influence of dr ugs or alc ohol.

Re v iew the safety inst r uctions with all us ers annually.

This equipment is dangerous to childr en and persons unfamil iar with its operation. The operator should be a responsi ble

ad ult familiar wit h farm mac hinery and trai ned in this equipment ’s operat ions. Do not allo w p ersons to o perate or

assemble this unit until they have read this manual and have developed a thorough understanding of the safety

precautions and of how it works.

To pr ev ent injur y or death, use a tract or equipped with a Roll O v er P rotectiv e S y s tem (ROPS). Do not paint ov er,

remov e or deface any s afety si gns or war ning decals on y our equipment. Obs er v e all safe ty si gns and pract ic e t he

in s tr ucti ons on them.

Ne v e r ex c eed t he limit s of a piece of machinery. If i ts abili ty to do a job, or to do so safely, is in questi on - DON’T TR Y

IT.

Indicates an imminently haz ar dous situation t hat, if not av oided, will res ult in death o r serious injury.

GENERAL SAFETY GUIDELINES

Ashland Industries Toll Free: 877-634-4622 Fax: 715-682-9717

Page #3

CS18HD

g

g

g

Operator Instruction

OPERATORS AND MAINTENANCE INSTRUCTIONS

This scraper is a durable piece of equipment and with proper care will yield many years of trouble

free operation. The life of your scraper can be severely shortened by poor maintenance. Follow

consistent maintenance practices and use

power u nit’s hydraulic system) to insure the longest, most pr oductive use from y our eq uipmen t.

ood quality grease and hydraulic oil (co mpati ble with the

Before starting the j ob, make sure Di ggers Hot Line has been co ntacted and all under

have been properly located (electric, phone and pipelines). Have a clear understanding of all local,

OSHA and MSHA rules that apply to the job. Beware of your environment and keep others a safe

distance from the machine while familiarizing y ourself with the machine’s controls. The scraper

requires a power source with TWO 4 way (double acting) hydraulic control valves.

The scraper should be greased at all points where gr ease fittings are provided. Connect hydraulic

h oses to th e trac tor and retract lift cylinders to RE MOVE TRANSPORT LOCK PINS (point A), then

extend and retract all cylinders several times to f orce out any air from the hydraulic c ylinders and

lines. Check the oil levels in the tractor hydraulic system and add to maintain the proper level.

Care should be used when addin

as dir t is a major factor in the failure of hydraulic components. Each time the scraper is holed to a

power unit, the sequencin g valve needs to be checked for proper timing . This will insure optimum

perfo rman ce from th e scraper.

When the scraper is placed into oper ation, th e operator will have to “feel out” the amount of

depth of cut to obtain max i mum load ing efficiency. This is usually accomplished by taking a lesser

and more uniform cut; however, some soil co nditions such as loose san d may require a “pumping

action” obtained by taking succ essive deep cuts and lifting out of cut as the tractor begins to los e

power or traction. The operation of the scraper will vary dependin g upon soil type, moisture

content, power -unit and jobsite. Results will vary.

1. After 10 hours work, all bolts should be checked and tightened if necessary.

2. Every 10 hours all grease fittings should be lubricated.

3 . After 50 hours work, all bo lts s ho uld be rechecked and tightened if nec essary.

Check wheel bearings and adjust if necessary.

4. After 300 hours work, clean and repack wheel bearings and replace, if necessary,

cutting edges, worn pins, etc .

oil or when d isconn ecting any oil line to keep all dirt out of the oil

round utilities

Ashland Industries Toll Free: 877-634-4622 Fax: 715-682-9717

Page #4

CS18HD

Operator Instruction

OPERATORS AND MAINTENANCE INSTRUCTIONS

SCRAPER DAMAGE CAN OCCUR IF:

1. The scraper is running over the haul road with the bowl fully raised.

2. A po wer unit that is above the horsepower rating is pulli ng t he scraper.

3. The scraper is being used to level haul roads with the apron closed.

4. The scra per is being top lo aded w ith the bow l is a r ais ed pos it ion.

5. The scraper is being used to load rock.

These types of damage are not covered by warranty. Warranty only covers defects in material or

workmanship and not abuse because of improper use.

KNOW THE JOB:

1. Know the weight of the material to be moved.

2. Lay the job out to take advantage of grades when loading, if possi ble.

3. Keep hauls as short as possible.

4. Keep haul roads smooth.

5. If more than one unit is on the job, make sure the haul roads are one way and that the

o perators unders ta nd the direction.

6. Brief the operators as to what the job consists of so there is not misunderstanding.

7. Know the moisture content in the material to be moved.

8. Will water be needed for proper compaction?

9. Will drainage be a problem?

10. How many units will be needed to effici entl y co mplete the job?

TRANSPORT SCRAPER SAFELY:

1. Always empty scraper.

2. Clean all material from exterior of scr aper.

3. Make sure all road rules are followed.

4. Use proper lighting and flagging.

5. Lower scraper bowls to provide just enough cl earance over obstacles.

6. Transport at a safe speed to avoid roll over.

7.

Ashland Industries Toll Free: 877-634-4622 Fax: 715-682-9717

Reduce speed on curves and wh en goin g down hill.

Page #5

Loading...

Loading...