Page 1

Owner's Manual & Assembly Instructions

AK01

Model No.

TSCYS47H4

YS47

A

A

697.68601

YS47EU

YS47Z

A

A

A

Missing Parts, Questions on Assembly?

Call: 1-800-851-1085 or assist@arrow-

sheds.com

Do not return to dealer, they are not

equipped to handle your requests.

723030817

CAUTION: SOME PARTS HAVE SHARP EDGES. CARE

Storage Area: 26 Sq. Ft. 154 Cu. Ft.

2,4 m

BUILDING DIMENSIONS

Exterior Dimensions Interior Dimensions Door

*Approx. Base (Roof Edge to Roof Edge) (Wall to Wall) Opening

Size Size Width Depth Height Width Depth Height Width Height

4' x 7' 50 1/2" x 80 1/4" 49" 79 3/4" 82" 47 3/4" 77 1/2" 81 1/4" 38 1/2" 60 1/4"

1,2 m x 2,0 m 128,3 cm x 203,8 cm 124,5 cm 202,6 cm 208,3 cm 121,3 cm 196,9 cm 206,4 cm 97,8 cm 153,0 cm

2

4,4 m3

* Size rounded o to the nearest foot

MUST BE TAKEN WHEN HANDLING THE VARIOUS PIECES

TO AVOID A MISHAP. FOR SAFETY SAKE, PLEASE READ

SAFETY INFORMATION PROVIDED IN THIS MANUAL

BEFORE BEGINNING CONSTRUCTION. WEAR GLOVES

WHEN HANDLING METAL PARTS.

Page 2

GB: Assembly manual in additional languages available online.

Scan QR code below to access.

FR: Manuel de montage disponible en ligne dans d’autres langues.

Pour y accéder, scannez le code QR ci-dessous.

SP: Manual de montaje en idiomas adicionales disponible online.

Escanee el código QR a continuación para acceder.

DE: Montageanleitung in zusätzlichen Sprachen online verfügbar.

Scannen Sie den QR-Code unten, um darauf zuzugreifen.

I T: Manuale dell’assemblea in altre lingue disponibile online.

Per accedere effettua la scansione del codice QR in basso.

P T: Manual de montagem disponível em outros idiomas online.

Digitalize o código QR abaixo para obter acesso.

D T: Samlingshåndbog i yderligere sprog til rådighed online.

Scan QR kode nedenunder for at få adgang.

SK:Nainternetejekdispozíciinávodnazostavenievďalšíchjazykoch.

Dostanete sa k nemu naskenovaním kódu QR.

CZ:Návodkmontáživdalšíchjazycíchjekdispozicivonlineverzi.

PřístupzískáteponaskenováníQRkóduníže.

HU: Azösszeszerelésiútmutatótovábbinyelvekeniselérhetőonline.

A hozzáféréshez olvassa be az alábbi QR-kódot.

GR: Υπάρχειδιαθέσιμοστοδιαδίκτυοτοεγχειρίδιοσυναρμολόγησης

σεπερισσότερεςγλώσσες.Σαρώστετονπαρακάτωκώδικα

QRγιανααποκτήσετεπρόσβαση.

P/N 6PP722621216

Page 3

A03

BEFORE YOU BEGIN....

Owner's Manual

Before beginning construction, check local building codes regarding footings, location

and other requirements. Study and understand this owner's manual.

Important information and helpful tips will make your construction easier and more

enjoyable.

Assembly Instructions: Instructions are supplied in this manual and contain all

appropriate information for your building model. Review all instructions before you begin,

and during assembly, follow the step sequence carefully for successful results.

Flooring and Anchoring: Your storage building must be anchored to prevent wind

damage. A base is necessary to construct a square and level building. Anchoring and

base materials are not included with your building. We recommend the combined use

of an Arrow Floor Frame Kit and an Arrow Anchoring Kit as an effective method of

securing your building to the ground (Available at your local dealer, Arrow's website

arrowsheds.com or call Arrow's Customer Service department 1-800-851-1085) or you

may construct a base and anchoring system of your choice. Your assembly instructions

provide information on a few methods commonly used to secure and level a storage

building.

Parts and Parts List: Check to be sure that you have all the necessary parts for

your building.

•All part numbers can be found on the parts. All of these numbers (before the -) must agree with the

numbers on the Parts List page.

•If you nd that a part is missing, include the model number of your building and contact:

Arrow Shed, LLC Customer Service Department

1101 North 4th Street Breese, Illinois 62230

•Separate contents of the carton by the part number while reviewing parts list. The rst few steps

show how to join related parts to make larger sub assemblies which will be used later.

•Familiarize yourself with the hardware and fasteners for easier use during construction. These are

packaged within the carton. Note that extra fasteners have been supplied for your convenience.

1-800-851-1085 or assist@arrowsheds.com

Page 4

A04

PLAN AHEAD....

Watch the Weather: Be sure the day you select to install your building is dry and calm.

Do not attempt to assemble your building on a windy day. Be careful on wet or muddy ground.

Teamwork: Whenever possible, two or more people should work together to assemble

your building. One person can position parts or panels while the other is able to handle the

fasteners and the tools.

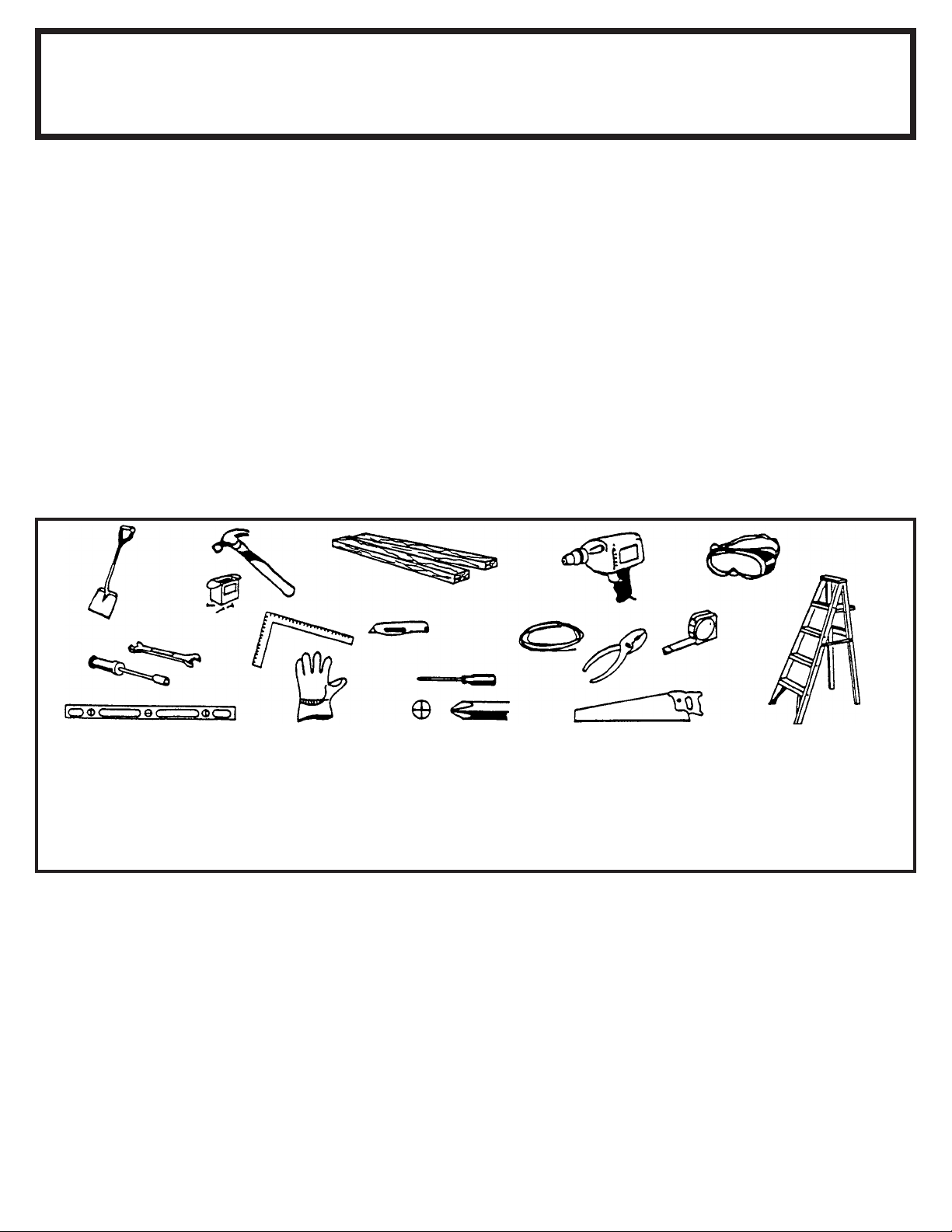

Tools and Materials: These are some basic tools and materials you will need for the

construction of your building. Decide which method of anchoring and the type of base you

wish to use in order to form a complete list of the materials you will need.

Required

• Eye Goggles

• No. 2 Phillips Screwdriver

(With Hardened Magnetic Tip)

Note: A power screwdriver or variable speed drill with Phillips-tip

attachment can speed assembly by

as much as 40%.

• Work Gloves

• Step Ladder

• Utility Knife / Scissors

• Pliers

• Carpenter's Level

• Tape Measure

Required

Optional Time-Savers

• Wrench / Nut Driver

• Electric / Cordless Drill

• Square

• String (for squaring frame)

Base Preparation

• Hammer and Nails

• Spade or Shovel

• Hand Saw / Power Saw

• Lumber and/or Concrete

Selecting and Preparing Your Site: Before assembly, you will want to decide on a

location for your building. The best location is a level area with good drainage.

•Allow enough working space for ease of moving parts into position during assembly. Be sure there

will be enough space at entrance for doors to open fully and enough space around the building to

be able to fasten the panel screws from the outside.

•Before you begin the rst steps in assembling your parts, a base should be constructed and

an anchoring system should be ready to use.

Page 5

A05

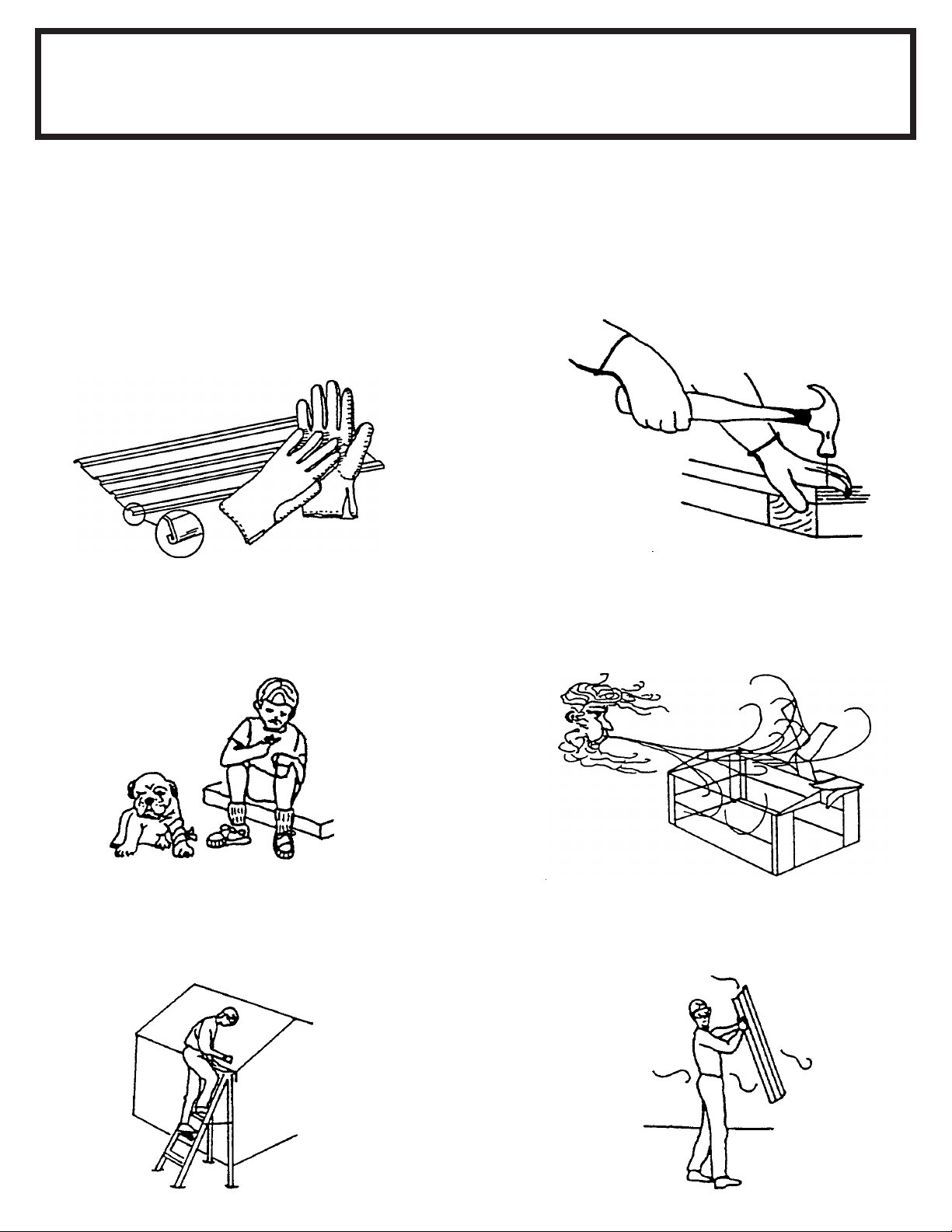

Safety precautions are important to follow throughout the construction of your building.

SAFETY FIRST....

•Care must be taken when handling various

pieces of your building since some contain

sharp edges. Please wear work gloves, eye

protection and long sleeves when assembling

or performing any maintenance on your

building.

safety edge

sharp edge

sharp edge

safety edge

•Keep children and pets away from worksite

to avoid distractions and any accidents which

may occur.

•Practice caution with the tools being used in

the assembly of this building. Be familiar with

the operation of all power tools.

•Do not attempt to assemble the building if

parts are missing because any building left

partially assembled may be seriously damaged

by light winds. Call 1-800-851-1085 or assist@

arrowsheds.com

•Never concentrate your total weight on the

roof of the building. When using a step ladder

make sure that it is fully open and on even

ground before climbing on it.

•Do not attempt to assemble the building on a

windy day, because the large panels acting as a

"sail", can be whipped about by the wind making

construction di cult and unsafe.

Page 6

A06

CARE & MAINTENANCE....

Finish: For long lasting nish, periodically clean and wax the exterior surface. Touch-up

scratches as soon as you notice them on your unit. Immediately clean the area with a wire

brush; wash it and apply touch-up paint per manufacturer's recommendation.

Roof: Keep roof clear of leaves and snow with long handled, soft-bristled broom. Heavy

amounts of snow on roof can damage building making it unsafe to enter. In snow country,

Roof Strengthening Kits are available for most Arrow Buildings for added protection against

heavy snow accumulation. Contact Arrow as outlined on the Ordering Accessories page

to place an order.

Doors: Always keep the door tracks clear of dirt and other debris that prevent them from

sliding easily. Lubricate door track annually with furniture polish or silicone spray. Keep

doors closed and locked to prevent wind damage.

Fasteners: Use all washers supplied to protect against weather in ltration and to protect

the metal from being scratched by screws. Regularly check your building for loose screws,

bolts, nuts, etc. and retighten them as necessary.

Moisture: A plastic sheet (vapor barrier) placed under the entire oor area with good

ventilation will reduce condensation.

Other Tips....

• Wash o inked part numbers on coated panels with soap and water.

• Silicone caulking may be used for watertight seals throughout the building.

Do not store swimming pool chemicals in your building. Combustibles and

corrosives must be stored in air tight approved containers.

Keep this Owner's Manual and Assembly Instructions for future reference.

Page 7

A07

BEFORE

AFTER

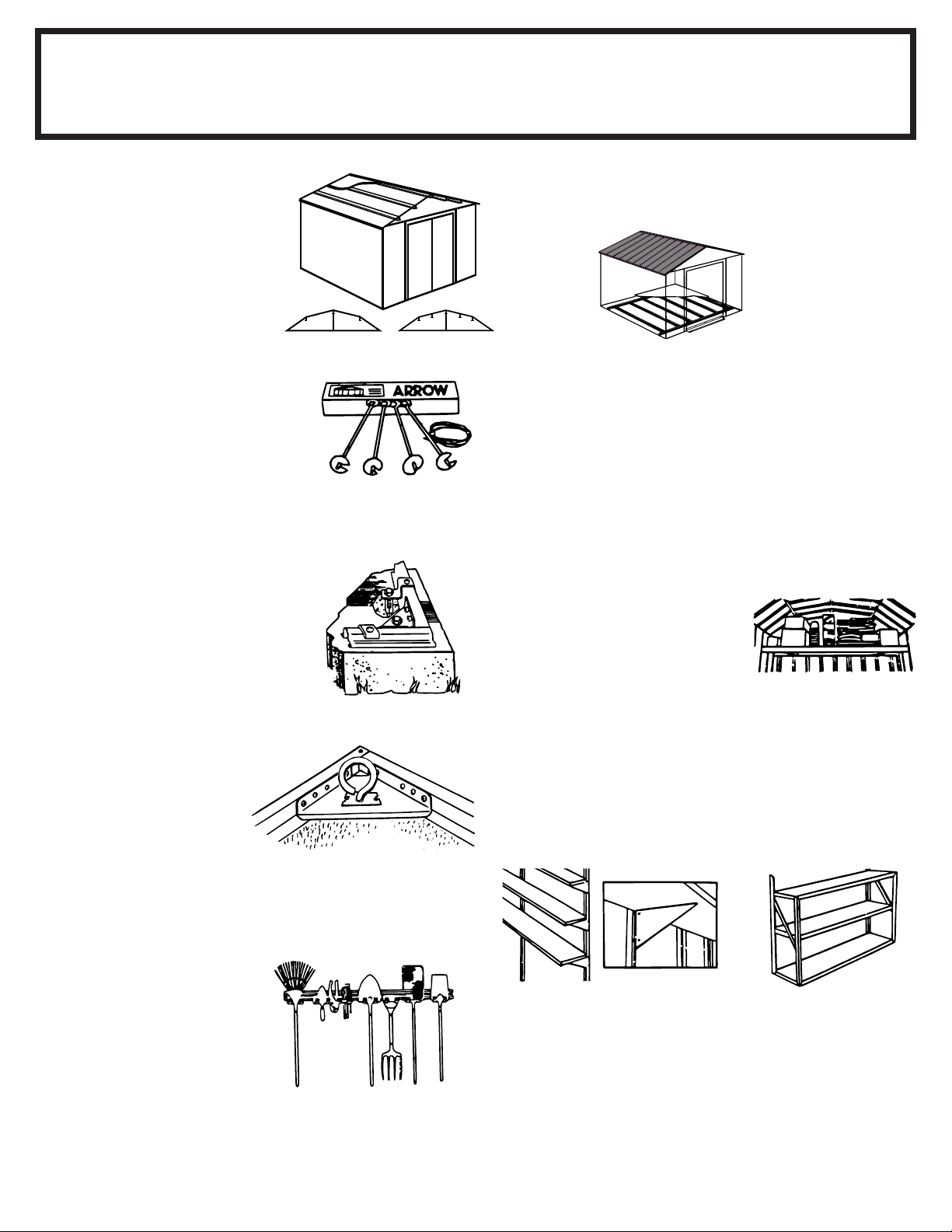

ACCESSORIES....

ROOF STRENGTHENING

(heavy snow load) KITS

Extra roof beams and gable braces

designed for added protection against

heavy snow accumulation. Increases

the strength of your roof.

ANCHOR KITS

Model No. AK4

Anchor Kit contains heavy-duty steel

augers, 60' (18 m) of steel cable and

4 cable clamps. No digging or concrete

pouring, just insert cable under roof,

over roof beams, into augers and twist

augers into the ground. For buildings

larger than 10'x9' (3,0 m x 2,6 m), use 2 kits.

Model No. AK100

New concrete anchor system permits

anchoring any size Arrow building

directly to a concrete slab. Each kit

contains heavy-duty, hot-dipped

galvanized steel corner gussets and

perimeter clips which t over the oor

frame and lag bolt into a concrete slab.

Full assembly instructions and a 1/4"

masonary drill bit are included.

FLOOR FRAME KITS

MODELS FB47410, FB5465, FB106-A

FB109-A and FB1014-A

A simple new oor frame system made of heavy-duty, hot-dipped

galvanized steel. Use as base for plywood, sand or stone.

ATTIC KIT / WORKBENCH KIT

Model No. AT101

Heavy-duty galvanized steel bars that

t all 10' (3,0 m) wide Arrow buildings.

They install quickly and easily to

help organize space and create

more useable space as an attic or

workbench. Will hold up to 250 lbs.

(113 kg) evenly distributed.

Some drilling required to t buildings without mid-wall bracing.

Model No. AK600

Earth Anchor Kit anchors any size

Arrow building to the ground.

Each kit contains heavy duty,

hot-dipped galvanized steel

corner gussets and 4 earth anchors.

TOOL HANGING RACK

Model No. TH100

The perfect tool organizer. Twin

25 1/2" (64,8 cm) steel channels

plus ve heavy-duty snap-in

hangers and a small tool holder for

screwdrivers, pliers, etc. Holders

slide along channel for fully

adjustable spacing. Great for

garage, basement, or the back

of any door. Fits all Arrow

storage buildings.

SHELF UNITS

Heavy-duty, galvanized steel shelf units help organize storage

space. They easily mount on the wall or sit on the oor. Fits all

Arrow buildings.*

Model No. SS404

• Makes 8" to 12" (20,3-30,5 cm)

wide shelves in any length.

• Brackets, braces,

hardware included.

Lumber is not included.

* Some drilling required to t buildings without mid-wall bracing.

Model No. SS900-B

• Grey color

• 3 shelves

• Holds up to 85 lbs. (38 kg)

(even weight distribution)

Page 8

A08 02/13

We recommend that you purchase accessory items from your local storage building dealer whenever possible;

however, because the full line of accessories is not always available from all dealers, Arrow is o ering them

to you on a direct basis.

There are two ways to order Arrow Storage Building Accessories:

ORDERING ACCESSORIES....

Option 1

Accessories can be purchased

through

arrowsheds.com

SPECIAL NOTE:

If your accessory is shipped via truck line a day time phone number is required to arrange delivery. If no

one is available to sign for the delivery, you may be subject to a re-delivery charge assessed by the carrier.

Order accessories by telephone

using your MasterCard or Visa credit card.

Call toll free 1-800-851-1085

Allow 2 weeks for delivery.

Option 2

(Customer Service).

Page 9

BR9

Base

The Base For Your Building

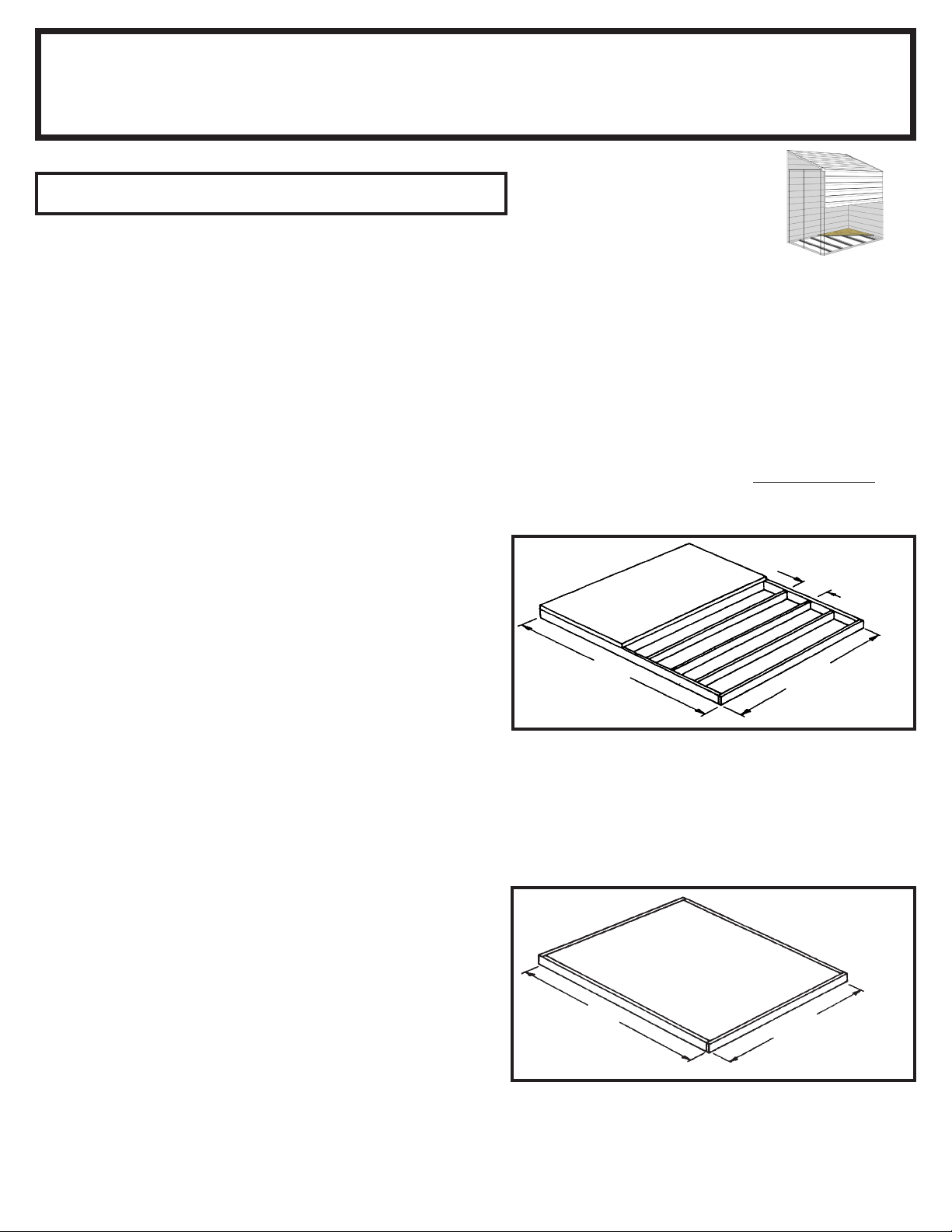

OPTION 1: ARROW FLOOR FRAME KIT: (Order No. FB47410)

Arrow has the best base for your building in this simple kit. It keeps stored items above the ground. This kit should be used with

one of the following:

A. To support a plywood deck B. To be lled with sand. We recommend the combined use of

1. an ARROW FLOOR FRAME KIT and 2. an ARROW ANCHORING KIT as an effective method of securing the building to the

ground. Allow 1 - 2 hours for construction.

OPTION 2: Wood Platform

If you decide to build your own base, be sure to select the appropriate materials.

These are the recommended materials for your base:

2 x 4's (38 mm x 89 mm) Pressure Treated Lumber

5/8" (15,5 mm) 4 x 8 (1220 mm x 2440 mm) Plywood-exterior grade NOTE: Pressure Treated Lumber must not be used where

it will make contact with your storage building. The properties of Pressure Treated Lumber will cause accelerated corrosion.

If Pressure Treated Lumber comes in contact with your storage building your warranty will be voided.

10 & 4 penny Galvanized Nails Concrete Blocks (optional)

16"/24"

The platform should be level and at (free of bumps, ridges etc.)

to provide good support for the building. The necessary materials

may be obtained from your local lumber yard.

40,6 cm/61,0 cm

To construct the base follow instructions and diagram.

Construct frame (using 10 penny galvanized nails)

Measure 16"/24" (40,6 cm/61,0 cm) sections to construct

inside frame (see diagram)

Secure plywood to frame (using 4 penny galvanized nails)

Allow 6 - 7 hours for construction.

Note: Platform/Slab will extend 9/16" (1,4 cm) beyond oor

frame on all four sides. Seal this 9/16" (1,4 cm) of wood with a

roo ng cement (not included), or bevel this 9/16" (1,4 cm) of

80 1/4"

203,8 cm

concrete when pouring, for good water drainage.

OPTION 3: Concrete Slab

The slab should be at least 4" (10,2 cm) thick. It must be level and at to provide good support for the frame.

The following are the recommended materials for your base.

1 x 4's (19 mm x 89 mm) (will be removed once the concrete cures)

Concrete Sheet of 6 mil plastic

We recommend for a proper strength concrete to use a mix of:

1 part cement 3 parts pea sized gravel 2 1/2 parts clean sand

Prepare the Site/Construct a Base

1. Dig a square, 6" (15,2 cm) deep into the ground (remove grass).

2. Fill up to 4" (10,2 cm) in the square with gravel and tamp rm.

3. Cover gravel with a sheet of 6 mil plastic.

4. Construct a wood frame using four planks of 1x4 (19 mm x 89 mm)

lumber.

5. Pour in concrete to ll in the hole and the frame giving a

total of 4" (10,2 cm) thick concrete. Be sure surface is level.

80 1/4"

203,8 cm

Note: Finished Slab dimensions, with lumber removed.

50 1/2"

128,3 cm

50 1/2"

128,3 cm

FRONT

(DOOR)

FRONT

(DOOR)

Allow 3 - 5 hours for construction and a week for concrete curing time.

9

Page 10

BR10

Anchoring

Anchoring Down The Building

It is important that the entire oor frame be anchored after the building is erected.

Below are recommended ways of anchoring.

Anchoring into Wood/Post:

Use 1/4" (6 mm) Wood Screws. There are 1/4" (6 mm)

dia. holes provided in the frames for proper anchoring.

Arrow Anchoring Kit: (Model No. AK100 or 68383)

Recommended for use with the concrete base.

Contains: Corner gussets, perimeter clips, hardware,

1/4" masonary drill bit and installation instruction.

Anchoring into Concrete:

1. For poured concrete slab or footing or patio blocks:

Use 1/4" x 2" (6 mm x 51 mm) Lag Screws.

2. For Anchor Post of Concrete poured after building is

erected: Use 1/4" x 6" (6 mm x 152 mm) Lag Screws.

10

Page 11

AK11

Hardware

65103

#8-32 Hex Nut (10)

66714

#6-32x7/16" (11 mm)

Flat Hd Bolt (23)

(Packed with Screws)

65941

#6-32 Hex Nut (23)

(Packed with Screws)

66692

#10ABx1" (25 mm)

Screw (2)

(Packed with Screws)

65923

#8-32x3/8" (10 mm)

Bolt (10)

66646

Washer (160)

(4 sheets of 40)

65004

#8Ax5/16" (8 mm)

Screw (222)

66022

Gray Foam Tape (1)

66016

66684

Spring Latch (2)

66462

Hasp (1)

66604

Hinge (4)

11

Facia Cap

(1 Right and 1 Left)

67293

Foil Tape (1)

66463

Swivel Staple (1)

Page 12

Parts List

AK12

Assembly Part Part Quantity Check

Key No. Number Description in Carton List

1 9796 Ramp 1

2 8977 Side Floor Frame 2

3 9795 Floor Frame 2

4 9793 Corner Post 4

5 9789 Left Door Jamb 1

6 9791 Front Header 1

7 8070 Side Eave Frame 1

8 8062 Rear Header 1

9 8061 Left Gable 1

10 8060 Right Gable 1

11 8069 Side Peak Frame 1

12 8067 Siding Stud - Short 3

13 8068 Siding Stud - Long 2

14 8066 Roof Frame 2

15 8075 Rear Siding - 6 Board 2

16 8074 Side Siding - 6 Board 6

17 8073 Top Siding - 5 Board 1

18 8080 Peak Trim 1

19 8078 Right Wall Trim 1

20 8079 Left Wall Trim 1

21 8076 Right Roof Trim 1

22 8077 Left Roof Trim 1

23 9792 Door Stop 1

24 9787 Left Door 1

25 9788 Right Door 1

26 11057 Door Latch Brace 2

27 9794 Horizontal Door Brace 4

28 9790 Right Door Jamb 1

29 6481 Gusset 4

30 11058 Diagonal Door Brace 4

31 11059 Diagonal Door Brace 4

12

Page 13

Assembly by Key No.

AK13

16

30

31

27

27

27

25

24

30

30

30

26

2623

31

31

31

27

13

Page 14

Step 1: Right Door Assembly

1

3

2

You will need for this page:

9788

1

9794

2

11057

1

66462

1

11058

2

AK14 New

(QTY: 3)

(QTY: 12)

Right Door

Horizontal

Door Brace

Door Latch

Brace

Attach HASP to FRONT SIDE of RIGHT DOOR

using three (3) bolts and nuts.

9788

66714

66462

65941

9794

Slide the Door Latch Brace into the

11057

middle of the Door and securing it

with four (4) Screws. Then attach the

Horizontal Door Braces to each end

of Door using two (2) Screws on each

brace.

Hasp

11059

Diagonal Door

Brace

Diagonal Door

Brace

2

(QTY: 1)

11058

11058

9788

9794

Place the ends of Diagonal Door Braces

with small holes under Horizontal Door

Braces as shown. Secure all Diagonal Door

Braces to center of Door Handle Brace

using one (1) Tapping Screw. Attach all

Diagonal Door Braces under Horizontal

Door Braces using four (4) Screws at each

corner as shown.

11059

9794

Diagonal Door Braces attach from behind

Horizontal Door Brace.

66692

11059

11059

6

14

Page 15

Step 1: Continued

4

You will need for this page:

AK15

FB

(QTY: 4)

66604

Hinge

Attach Hinges to Door using

four (4) Flat Head Bolts and

Nuts.

2

66604

6

15

Page 16

Step 2: Left Door Assembly

1

3

2

You will need for this page:

9787

1

9794

2

11057

1

66463

1

11058

2

11059

AK16 New

2

(QTY: 4)

Tapered end

up.

Door Latch

Brace

(QTY: 11)

Left Door

Horizontal

Door Brace

Attach SWIVEL STAPLE to FRONT SIDE of

LEFT DOOR using four (4) bolts and nuts.

9787

66714

66463

65941

Slide the Door Latch Brace into the

middle of the Door. Attach the Door

Latch Brace and Door Stop using seven

(7) Screws.

11057

Swivel Staple

Diagonal Door

9792

Door Stop

Brace

1

Diagonal Door

Brace

(QTY: 1)

Place Horizontal Door Braces on

each ewnd of door. Place the ends

of Diagonal Door Braces with small

holes under Horizontal Door Braces

as shown. Secure all Diagonal Door

Braces to center of Door Handle

Brace using one (1) Tapping Screw.

Attach all Diagonal Door Braces

under Horizontal Door Braces using

four (4) Screws at each corner as

shown.

9794

9792

9787

Diagonal Door Braces

attach from behind

Horizontal Door Brace.

66692

6

16

11058

11059

11058

11059

9794

Page 17

Step 2: Continued

4

5

6

You will need for this page:

FB

66604

2

66684

2

AK17

(QTY: 4)

Attach Hinges to Door using

four (4) Flat Head Bolts and

Nuts.

Attach both Top and Bottom

Latch Springs to left side of Door

using six (6) Screws.

Attach both Top and Bottom

Horizontal Door Braces to right

side of Door using one (1) Screw

each.

(QTY: 8)

Hinge

Top Latch

Spring

66684

66604

66684

6

17

Page 18

Step 3

AK18

1 Center the ramp on top of the oor

frame. Note that the door can be

installed on either end. Join the

frames by inserting four screws.

2 Assemble the four corners of the

oor frame using two screws at each

corner as shown.

Parts Needed For

Floor Frame Assembly

STEP

1

9796

9796 Ramp (1)

9795 Floor Frame (2)

8977 Side Floor Frame (2)

RIGHT

REAR

8977

9795

8977

STEP

2

3 Measure the oor frame diagonally.

When the diagonal measurements

are equal, the oor frame is square.

NOTE

If using a wood platform or

concrete slab do not fasten the

oor frames to your base at this

time. You will anchor the

building after it is erected.

FRONT

9795

When Diagonal Measurements

are Equal the Floor Frame

is Square.

STEP

3

Level

The oor frame must be square

and level or holes will not align.

18

Page 19

Step 4

AK19

NOTE

The remainder of the building assembly

requires many hours and more than one

person. Do not continue beyond this

point if you do not have enough time to

complete the assembly today. A partially

assembled building can be severely

damaged by light winds.

1 Fasten two corner posts to the

rear corners of the floor frame assembly using four screws.

2 Position one rear siding, starting

at rear frame, between corner posts

and fasten with six screws. Always

use washers under the heads of

fasteners where they are shown!

Corner Posts/Rear Siding

Parts Needed For

9793

Rear Floor Frame

STEP

9793 Corner Post (2)

8075 Rear Siding (1)

9793

FRONT

CORRECT

INCORRECT

Each siding panel has a bottom edge

and a at edge. The bottom edge

always overlaps the at edge. Keep

the at edge up. Do not fasten at

edge now.

1

8075

STEP

2

Remove &

Replace

19

Page 20

Step 5

AK20

1 Attach a gusset to each end of the

two corner posts using one screw.

Parts Needed For

Corner Posts/Side Siding

TOP VIEW

6481 Gusset (4)

9793 Corner Post (2)

8074 Side Siding (2)

2 Fasten one corner post assembly

to the front corner of the oor frame

assembly using two screws. Caution! Once corner post is attached,

fasten one side siding to the corner

posts with six screws. Do not fasten

at edge now.

IMPORTANT

Always use 2nd set of holes from

end of siding panel when attach-

ing to corner post.

3 Fasten remaining corner post and

one side siding as in previous step.

6481

Corner Post

Side Siding

Trim

(Installed later)

STEP

1

9793

6481

STEP

3

FRONT

9793

8074

6481

6481

8074

Remove &

Replace

STEP

2

20

Page 21

Step 6

AK21

Parts Needed For

Headers/Frame/Jambs

9791 Front Header (1)

8070 Side Eave Frame (1)

8062 Rear Header (1)

9789 Left Door Jamb (1)

9790 Right Door Jamb (1)

1 Fasten side eave frame behind

top of corner posts using two screws,

top leg facing inside building. Note:

For left end door location, fasten

side eave frame as shown.

For right end door location fasten

side eave frame on opposite side

of building.

2 Fasten front header behind top of

corner posts/gussets using one bolt

and nut on each end.

3 Fasten rear header across top of

corner posts using one bolt and nut

on each end. Note that side eave

frame overlaps front & rear headers.

4 Attach right & left door jambs to

the front header using bolts and nuts,

and to the corner posts and front oor

frame using screws.

Front Header

Front

9791

STEP

2

STEP

1

STEP

3

Rear Header

8062

8070

STEP

4

Right Door Jamb

Notched Edge

9789

9790

Front

21

Page 22

Step 7

AK22

Parts Needed For

Side/Rear Siding/Studs

8074 Side Siding (2)

8075 Rear Siding (1)

8067 Siding Stud (3)

8068 Siding Stud (2)

1 Position the side siding (6 board)

to corner posts, at edge of siding

upward and bottom resting on 1st side

siding. See gure. Always follow this

pattern. Fasten siding to corner posts

using six screws. Do not fasten at

edge now. Position 2nd side siding

on opposite side of building and fasten as before. Always use washers

where they are shown!

2 Repeat procedure with rear siding

panel. Fasten siding to rear header

to complete rear siding.

3 Position two short siding studs

between corner posts, behind side

eave frame, and fasten tab using

a screw. Rest bottom tab of stud

between siding and oor frame and

fasten with a screw. Fasten siding

to studs, as shown.

Bottom

Edge

End View

8074

STEP

8074

8075

STEP

2

STEP

1

4 Fasten one short siding stud to the

rear of building between the corner

posts in the same manner. Fasten

top tab behind rear header.

5 Position two long siding studs to

the left side of building in the same

manner using screws.

Small hole in tab

Side Eave Frame

Flat

Edge

Be certain all Siding

overlaps are fastened

with a single screw

8068

5

Rear Header

STEP

4

8068

8067

8067

8067

STEP

22

3

Large hole in tab

Page 23

Step 8

AK23

NOTE

The gables are packed nested

together and might be mistaken

as one piece. Carefully separate

them before continuing.

1 Lift and fasten a left gable on top

of header, with lower leg under side

eave frame at corner, using screws.

Repeat Step 1 with right gable for

the opposite side of building.

Gables/Peak/Roof Frames

Parts Needed For

Position of

Side Peak Frame

Side Peak Frame

Fasten at Lower Hole

8069

8061 Left Gable (1)

8060 Right Gable (1)

8069 Side Peak Frame (1)

8066 Roof Frame (2)

STEP

2

Gable Fits Under

Side Eave Frame

8060

2 Fasten side peak frame to the

inside top corners of gables using two

screws, top shorter leg facing inside

building. Fasten top tab of the siding

studs to the lower hole in side peak

frame using screws.

3 Position roof frames under side

peak and eave frames. Be sure the

end of frame with the shortest space

between the 1st and 2nd hole is positioned at the lower side eave frame,

and fasten using screws.

8061

8060

8061

STEP

1

Fasten lower hole of

Side Peak Frame

STEP

3

8066

8066

Short space

between 1st

and 2nd hole

Right End

Door Location

23

Page 24

Step 9

AK24

Parts Needed For

Side Siding/Foam Tape

8074 Side Siding (2)

Installing the siding to the roof is

best done with a step ladder.

NOTE

Measure the building diagonally

again and make adjustments to

make sure the building is square.

This will make the siding t better,

and holes will align.

1 After the 3rd side siding is fas-

tened to the 2nd, roll it over on the

roof and fasten as before.

2 Apply gray foam tape along lower

bottom edge of the 4th side siding

by removing protective paper and

pressing on edge of leg. Cut tape

to proper length.

4th Side Siding

STEP

3

Foam

Tape

Apply Gray Foam Tape

STEP

Roll Side Siding over

onto Roof

Protective

Paper

2

STEP

1

3 Fasten 4th side siding to the 3rd

but do not fasten top edge at this time.

Gray

Foam

Tape

End

View

Foam Tape

Do not fasten top

edge at this time

8074

8074

24

Page 25

Step 10

AK25

1 Fasten remaining top siding

(5 board), to the top side of building.

Parts Needed For

Top Siding/Trim

8073 Top Siding (1)

8080 Peak Trim (1)

8078 Right Wall Trim (1)

8079 Left Wall Trim (1)

8076 Right Roof Trim (1)

8077 Left Roof Trim (1)

2 Fasten peak trim to peak of roof

using screws thru siding into frame.

3 Apply foil tape by overlapping sid-

ing by 1/2" (13 mm), pressing rmly

into contour of siding, from top to

bottom of gables. Rub for good adhesion. Do not cut tape, let roll hang

free until ready to use on next panel.

When complete, press opposite side

down to gable. The purpose of this

is to seal out the weather.

4 Fasten right and left wall trim to

side corners of building using screws.

5 Fasten right and left roof trim

to the ends of roof, overlapping wall

trim, using screws.

Foil Tape

STEP

3

STEP

2

8078

8080

8073

FRONT

8076

STEP

1

STEP

6

6 Fasten right and left facia caps

at the breaks in the roof trim, using

screws.

STEP

4

8079

25

Facia Cap

8077

STEP

5

Page 26

Step 11

AK26

1 Position doors in corners of door

opening as shown and fasten hinges

with 7/16" (11 mm) at head bolts

and #6 hex nuts. When spring latch

is engaged with hole in header or

ramp, these will hold left door closed

when not it use. The hasp and staple

can be used to keep doors closed,

or used with a padlock (not supplied)

to lock doors.

Parts Needed For

Door Assembly

Right Door Assembly (1)

Left Door Assembly (1)

26

Page 27

YS47

A

697.68601

A

TSCYS47H4

A

YS47EU

A

AK27

YS47Z

A

Anchoring and Floor Frame

Anchoring

Anchor your building at this time.

Floor Frame

If you have purchased a Floor Frame Kit you need to install it at this time.

SOME FACTS ABOUT RUST

Rusting is a natural oxidizing process that occurs

when bare metal is exposed to moisture. Problem

areas include screw holes, unfinished edges, or

where scrapes and nicks occur in the protective

coating through normal assembly, handling and use.

Identifying these natural rusting problem areas and

taking some simple rust protection precautions can

help to stop rust from developing, or stop it quickly

as soon as it appears.

1. Avoid nicking or scraping the coating surface,

inside and out.

2. Use all the washers supplied. In addition to

protecting against weather in ltration, the washers

protect the metal from being scraped by the screws.

3. Keep roof, base perimeter and door tracks free of

debris and leaves which may accumulate and retain

moisture. These can do double damage since they

give o acid as they decay.

4. Touch up scrapes or nicks and any area of visible

rust as soon as possible. Make sure the surface is

free of moisture, oils, dirt or grime and then apply

an even lm of high quality touch-up paint.

27

723030817

Page 28

Loading...

Loading...