Arrow LW82 Owner's Manual & Assembly Manual

729240519

Owner’s Manual

& Assembly Guide

01HG

www.arrowsheds.com

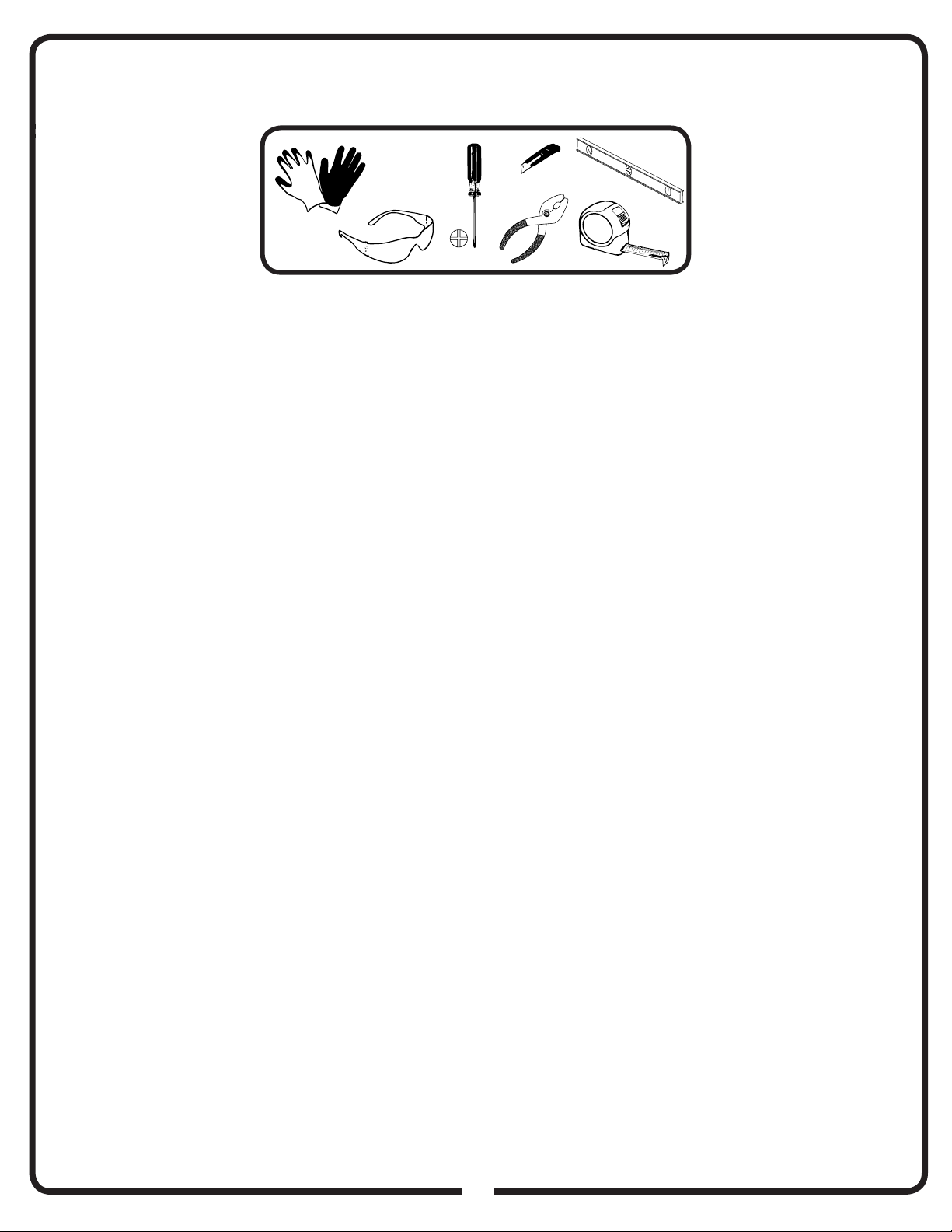

Gloves must be worn

at all times to reduce

risk of injury!

Model No. LW82

8’ x 2’

Nominal Size

Customer Service:

1-800-851-1085 or

assist@arrowsheds.com

BUILDING DIMENSIONS

Approx.

2,4 m x 0,6 m 1,6 m2 2,8 m

* See Inside for Detailed Safety Information.

†

Size

8’ x 2’ 17 Sq. Ft. 100 Cu. Ft. 99 3/4” 30 3/4” 82 1/8” 94 3/4” 25 1/2” 80 1/8” 43 1/2” 60”

Storage

Area

†

Size rounded off to the nearest foot

Exterior Dimensions

(Roof Edge to Roof Edge)

Width Depth Height

3

253,4 cm 78,1 cm 208,6 cm 240,7 cm 64,8 cm 203,5 cm 110,5 cm 152,4 cm

Base

Size

For proper base construction see page 8

Interior Dimensions

(Wall to Wall)

Width Depth Height

247,7 cm x 71,8 cm

97 1/2” x 28 1/4”

Door

Opening

Width Height

03HN

CAUTION

• Care must be taken when handling various pieces of your building since many contain sharp edges.

• Do NOT attempt to assemble your building before double checking that you have all the parts indicated in the parts lists.

Any building left partially assembled may be seriously damaged by even light winds.

• Do NOT attempt to assemble your building on a windy day. The large panels can catch the wind like a “sail”, making

construction diffi cult and unsafe.

• Keep children and pets away from the worksite during construction and until the building is completely assembled. This will

help avoid distractions and any accidents which may occur.

• NEVER concentrate your weight on the roof of the building.

Watch the Weather Closely

• Before assembling any parts, your base should be constructed and an anchoring system should be ready to use.

Your building MUST be anchored to prevent wind damage.

ASSEMBLY

• The best location is a level area with good drainage.

• Allow enough space outside the building to be able to access the roof with a ladder.

• Use Teamwork: Two or more people are required to assemble your building.

For missing or damaged parts contact Customer Service. Do not return to store.

1-800-851-1085 or assist@arrowsheds.com

CARE & MAINTENANCE

• DO NOT use power washing to clean your shed.

• Combustibles and corrosives must be stored in air tight containers designed for chemical and/or combustible storage.

Corrosive chemicals such as fertilizers, pesticides and herbicides should be cleaned off the interior and exterior surfaces

immediately. Rust caused by chemical damage is not covered by the warranty.

RUST PROTECTION PRECAUTIONS

• Avoid nicking or scraping the coating surface, inside and out.

• Keep roof, base perimeter and door free of debris.

• Touch up scrapes or nicks and any area of visible rust as soon as possible.

3

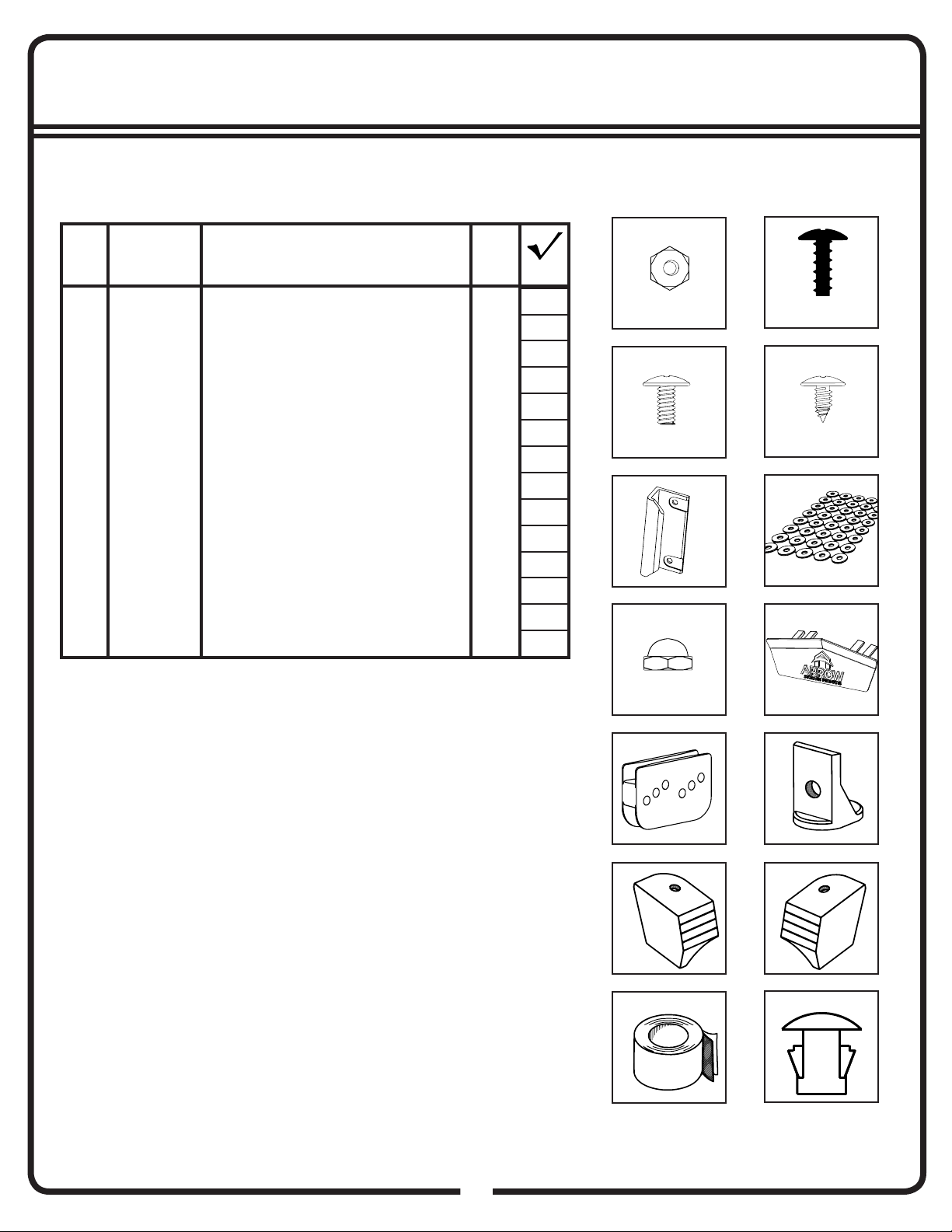

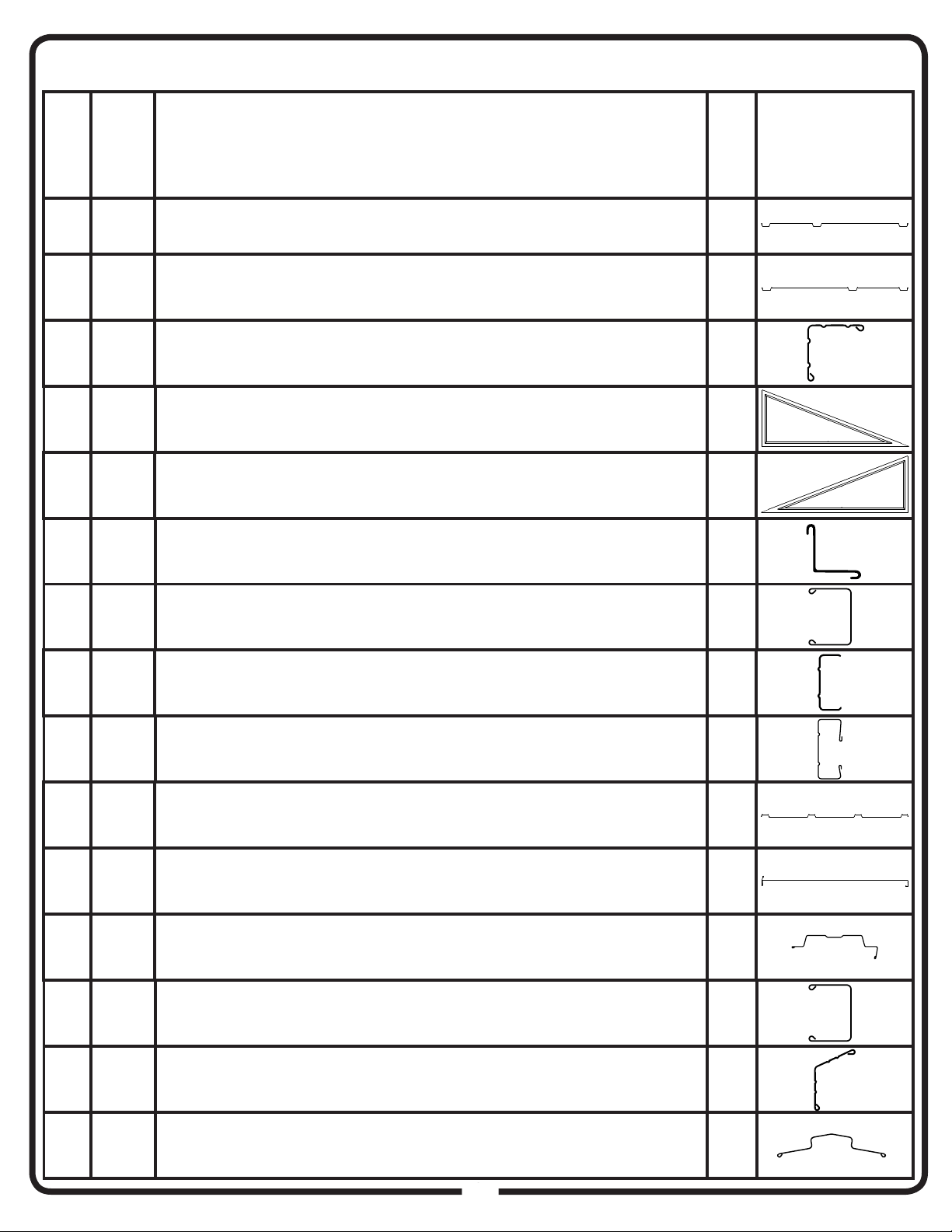

HARDWARE LIST...

Hardware Views by Key No.

04HG

Key Part Part Qty.

No. No. Description List

1 65103 Hex Nut (#8-32) 64

2 65900A Black Screw (#10B x 1/2) (13 mm) 8

3 65923 Bolt (#8-32 x 3/8) (10 mm) 64

4 65004 Screw (#8AB x 5/16) (8 mm) 200

5 66045 Door Handle 2

6 66646 Washer Sheet 4

7 65109 Acorn Nut 6

8 67468 Peak Cap 2

9 66769 Door Slide 4

10 66382 Lower Door Guide 4

11 66183L Left Roof Trim Cap 2

12 66183R Right Roof Trim Cap 2

13 67293B Weather Stripping 1

14 66775 Plug 2

1

11/32 Hex.

3

#2 Phillips #2 Phillips

5

7

2

#2 Phillips

4

6

8

The fasteners used in each step are shown actual size at the top

of each page. If you are unsure which fastener to use, hold it up

to the picture and use the one that matches.

5/16 Hex.

9

11

13

10

12

14

4

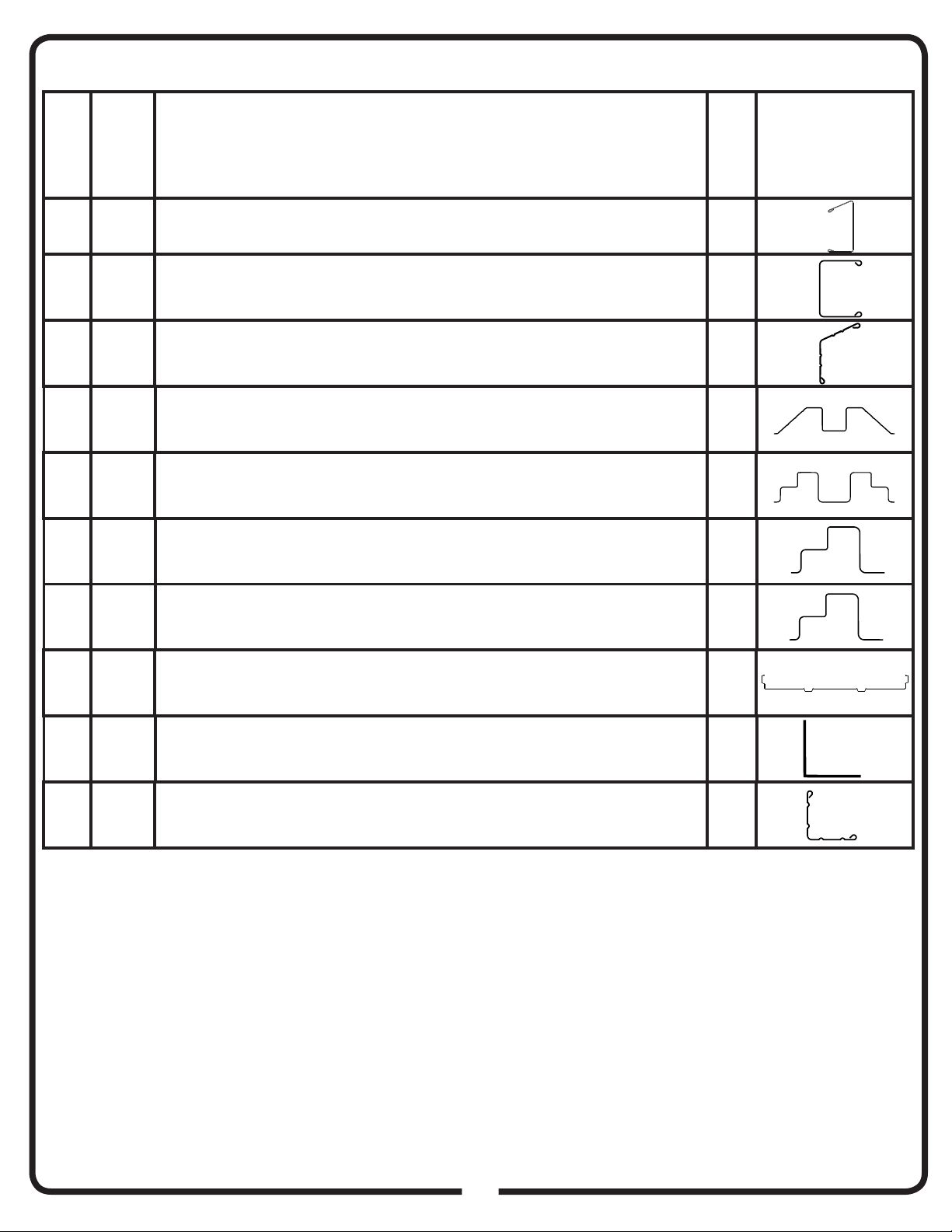

PARTS LIST

05HG

Key

Part No.

No.

6243 Wall Panel

15

11297 Front Wall Panel

16

11294 Rear Wall Angle

17

8700

18

8701 Left Gable

19

10498 Horizontal Door Brace

20

Part

Description

Right Gable

Qty.

4

2

2

2

2

4

Part Views

6278 Vertical Door Brace

21

11295

22

11296 Door Track

23

10828 Roof Panel

24

10478

25

9369 Door Jamb

26

9924 Rear Wall Channel

27

Door Track Splice

Door

2

1

2

2

2

2

2

6014 Side Roof Trim

28

6868 Ridge Cap

29

2

1

6

5

PARTS LIST

06HG

Key

Part No.

No.

10829 Roof Beam

30

9916 Side Wall Channel

31

6646 Side Wall Angle

32

8941

33

9379 Front Floor Frame

34

9377 Rear Floor Frame

35

Part

Description

Ramp

Qty.

4

2

2

1

2

2

Part Views

8984 Side Floor Frame

36

6668

37

7905 Roof Beam Bracket

38

9204 Roof Beam Brace

39

Corner Panel

2

2

4

2

6

6

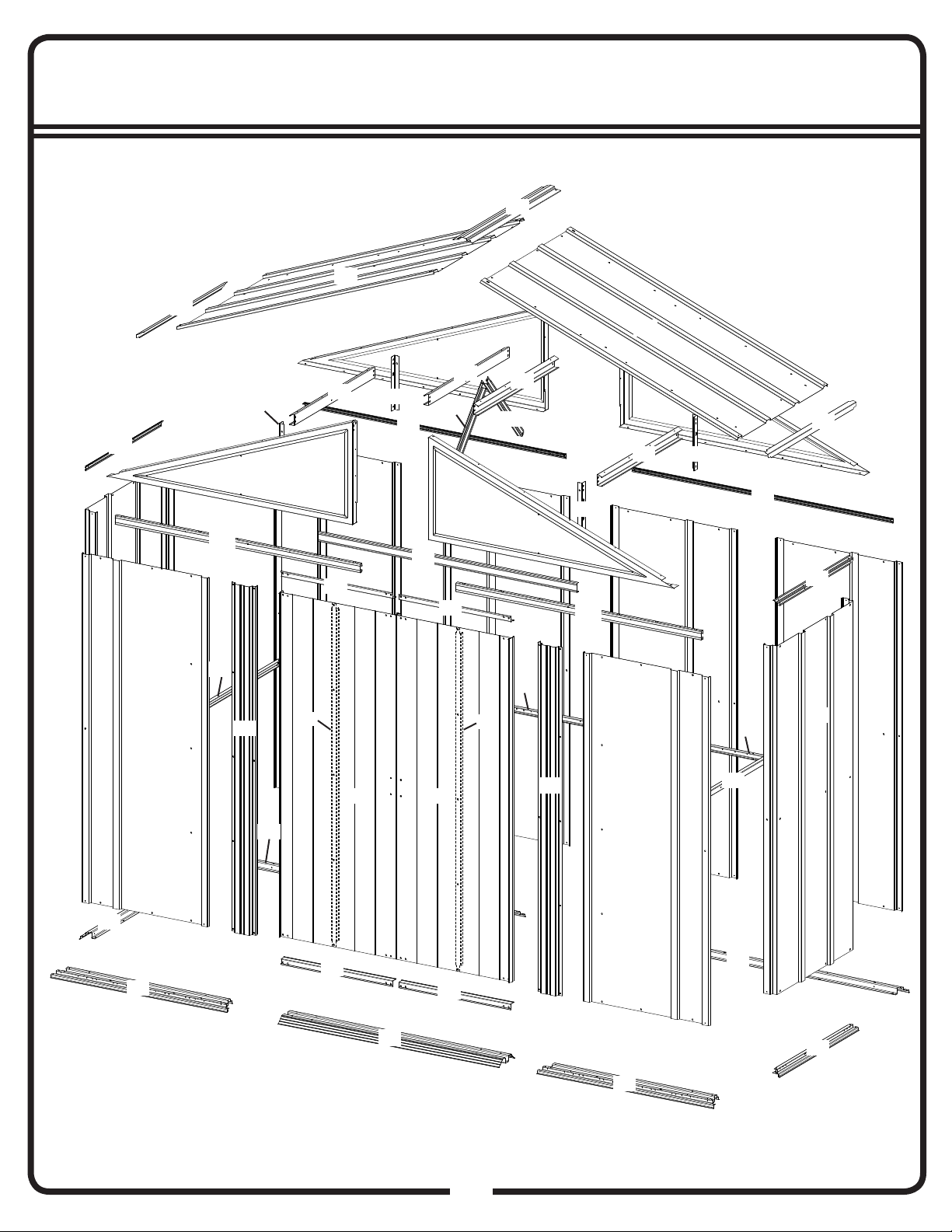

ASSEMBLY BY KEY NO.

29

24

28

18

24

07HG

32

37

16

23

31

26

38

19

21

30

20

25

15

38

17

22

25

39

20

30

18

21

39

30

27

15

26

38

23

19

30

16

38

15

28

17

32

15

37

27

31

36

34

35

20

33

35

20

36

34

7

14GQ

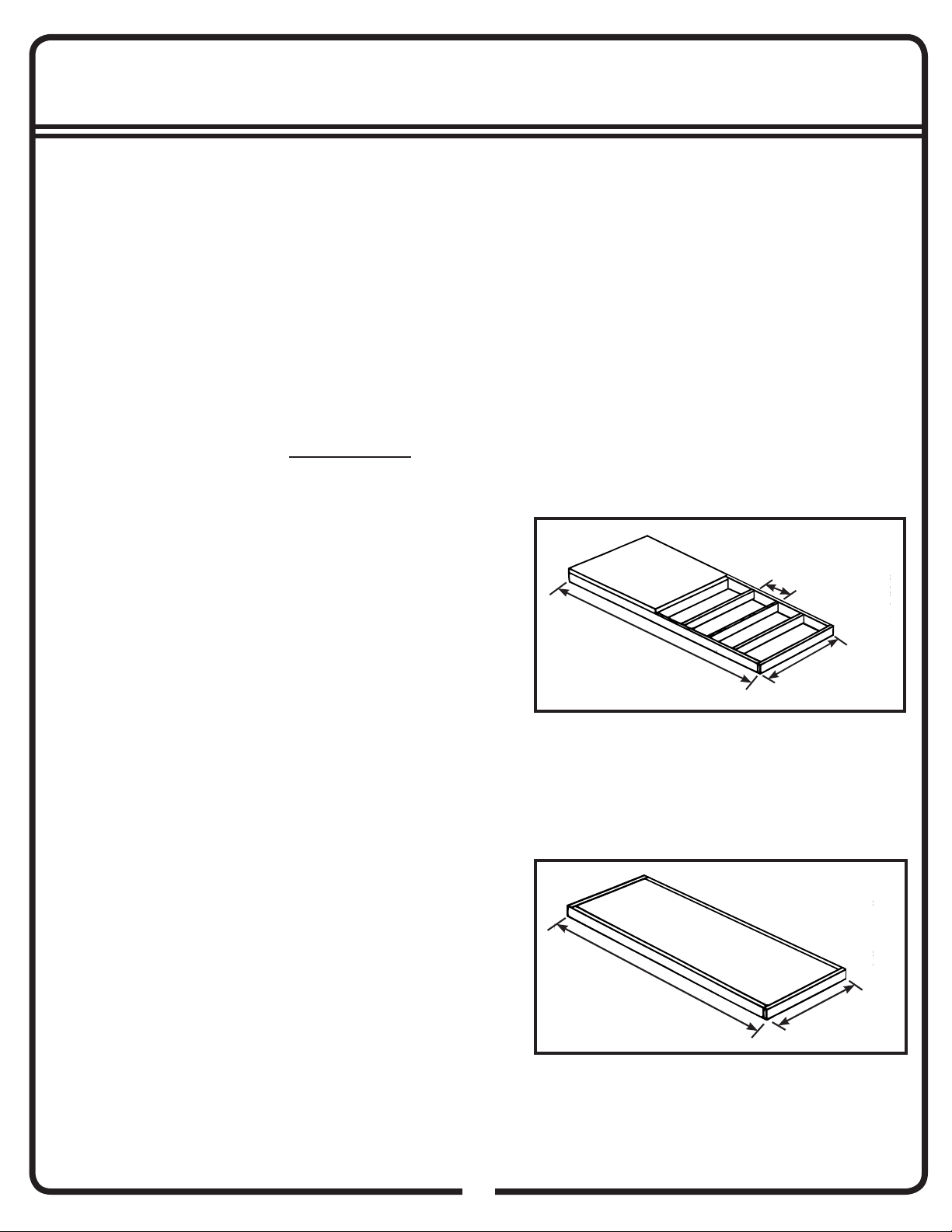

CONSTRUCTING A BASE...

No matter which of the options below you choose for a base, an ARROW ANCHORING KIT is

recommended as an effective method of properly securing your building after assembly is complete.

OPTION 1: Directly on ground (earth)

Assemble your building directly on level ground (grass, dirt, rock, sand, etc.).

OPTION 2: Wood Platform

If you decide to build your own base, be sure to select the appropriate materials.

These are the recommended materials for your base:

• 2 x 4's (38 mm x 89 mm) Pressure Treated Lumber • 5/8" (15,5 mm) 4 x 8 (1220 mm x 2440 mm) Plywood-exterior grade

• 10 & 4 penny Galvanized Nails • Concrete Blocks (optional)

NOTE: Pressure Treated Lumber must not be used where it will make contact with your storage building. The properties of

Pressure Treated Lumber will cause accelerated corrosion.

The platform should be level and fl at (free of bumps, ridges etc.)

to provide good support for the building. The necessary materials

may be obtained from your local lumber yard.

To construct the base follow instructions and diagram.

Construct frame (using 10 penny galvanized nails)

Measure 16"/24" (40,6 cm/61,0 cm) sections to construct

inside frame (see diagram)

Secure plywood to frame (using 4 penny galvanized nails)

OPTION 3: Concrete Slab

The slab should be at least 4" (10,2 cm) thick. It must be level

and fl at to provide good support for the frame.

The following are the recommended materials for your base.

• 1 x 4's (19 mm x 89 mm) (will be removed once the concrete cures)

• Concrete • Sheet of 6 mil plastic

• We recommend for a proper strength concrete to use a mix of:

1 part cement • 3 parts pea sized gravel • 2 1/2 parts clean sand

Prepare the Site/Construct a Base

1. Dig a square, 6" (15,2 cm) deep into the ground (remove grass).

2. Fill up to 4" (10,2 cm) in the square with gravel and tamp fi rm.

3. Cover gravel with a sheet of 6 mil plastic.

4. Construct a wood frame using four planks of 1x4 (19 mm x 89 mm)

lumber.

5. Pour in concrete to fi ll in the hole and the frame giving a

total of 4" (10,2 cm) thick concrete. Be sure surface is level.

16"/24"

40,6 cm/61,0 cm

97 1/2"

247,7 cm

FRONT

(DOOR)

Note: Platform/Slab will extend 9/16" (1,4 cm) beyond

fl oor frame on all four sides. Seal this 9/16" (1,4 cm)

of wood with a roofi ng cement (not included), or bevel

this 9/16" (1,4 cm) of concrete when pouring, for good

water drainage.

97 1/2"

247,7 cm

FRONT

(DOOR)

Note: Finished Slab dimensions, with lumber removed.

28 1/4"

71,8 cm

28 1/4"

71,8 cm

12

8

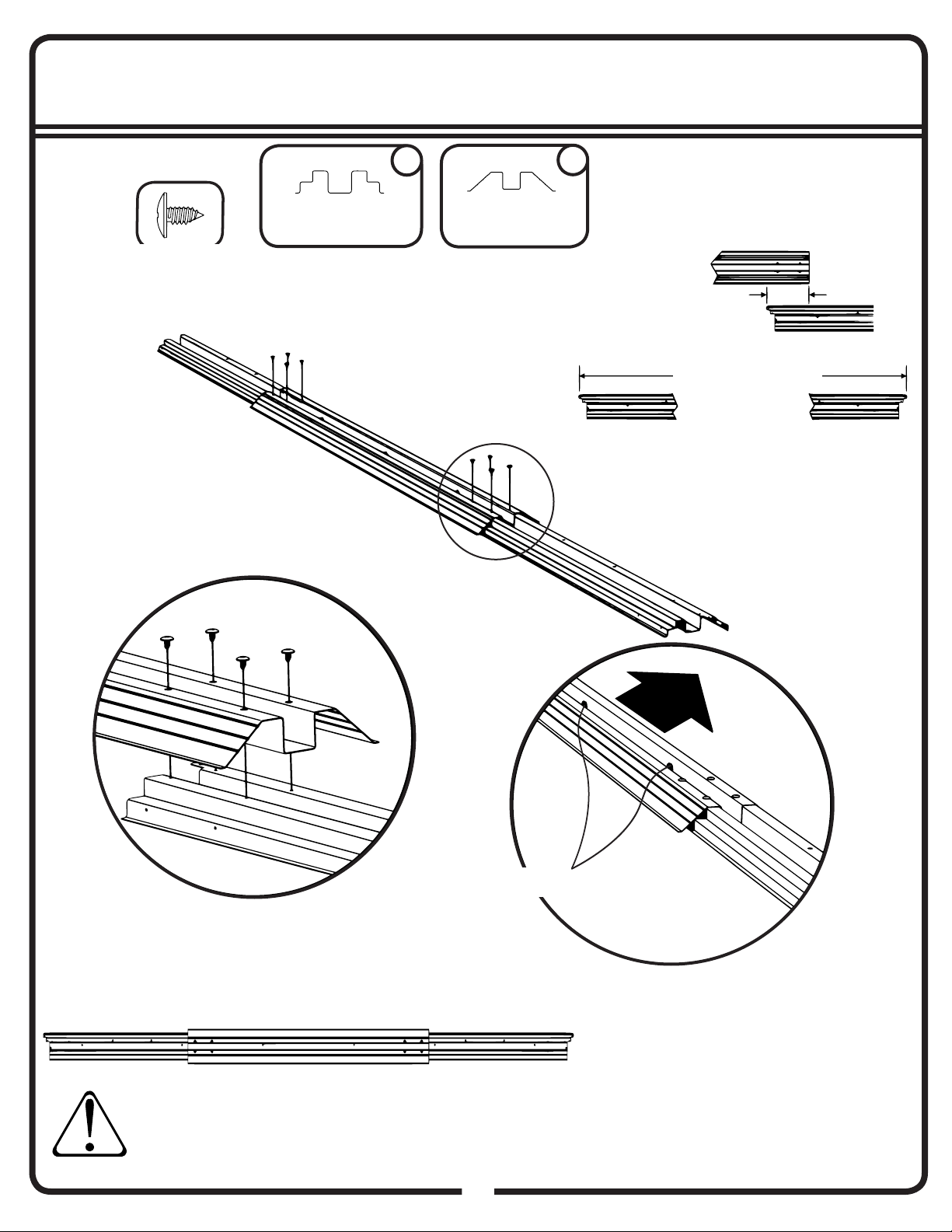

Step 1

09HG

You will need for this page:

9377

(QTY: 5)

9377

Rear Floor Frame

2

9377

Overlap Length

11 7/8” 30,2 cm

95 7/8” 243,5 cm

Finished Length

Bolts thru Top.

Bolts thru Bottom.

9

Step 1

10HG

You will need for this page:

(QTY: 8)

9379

9379

Front Floor Frame

8941

2

8941

Ramp

1

Overlap Length

7 3/8” 18,7 cm

95 7/8” 243,5 cm

Finished Length

FRONT

9379

FRONT

Drain holes must face outside the building.

CHECK THAT ALL ASSEMBLED PARTS ARE THE CORRECT LENGTH BEFORE CONTINUING

10

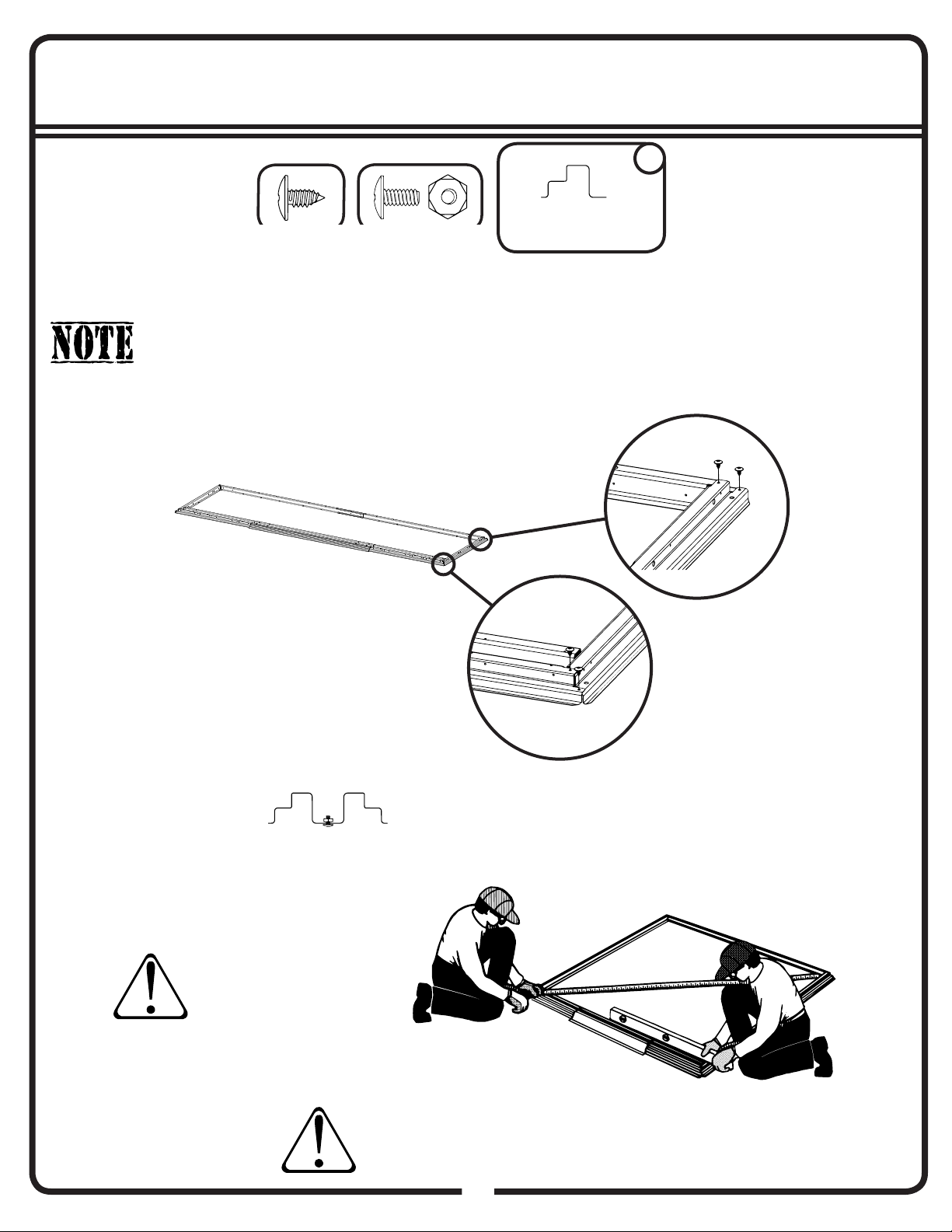

Step 1

11HG

You will need for this page:

Do NOT fasten your Floor Frames to your Base at this time. You will anchor your building after it is erected. If using a Floor Frame Kit, you must wait until after assembly to install it.

8984

(QTY: 8)

FRONT

(QTY: 2)

8984

8984

Side Floor Frame

2

9377

Assemblies from Step 1:

• Front Floor Assembly (1)

• Rear Floor Assembly (1)

8984

Insert a bolt and nut thru bottom of

Front Floor Frame at each front corner

to secure Front Frame to Side Frames.

When diagonal measurements

are equal, the Frame is square.

8984

9379

The Floor Frame must be BOTH square AND

level or the holes will not line up properly.

11

Loading...

Loading...