Page 1

Owner’s Manual

Refrigerated

Compressed Air Dryers

Model F-20

Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information.

Failure to comply with instructions could result in personal injury and/or property

damage. Retain instructions for future reference.

WARNING: Air treated by this equipment is not suitable for breathing without

further purifi cation. Refer to O.S.H.A. standards for the requirements for breathing

quality air.

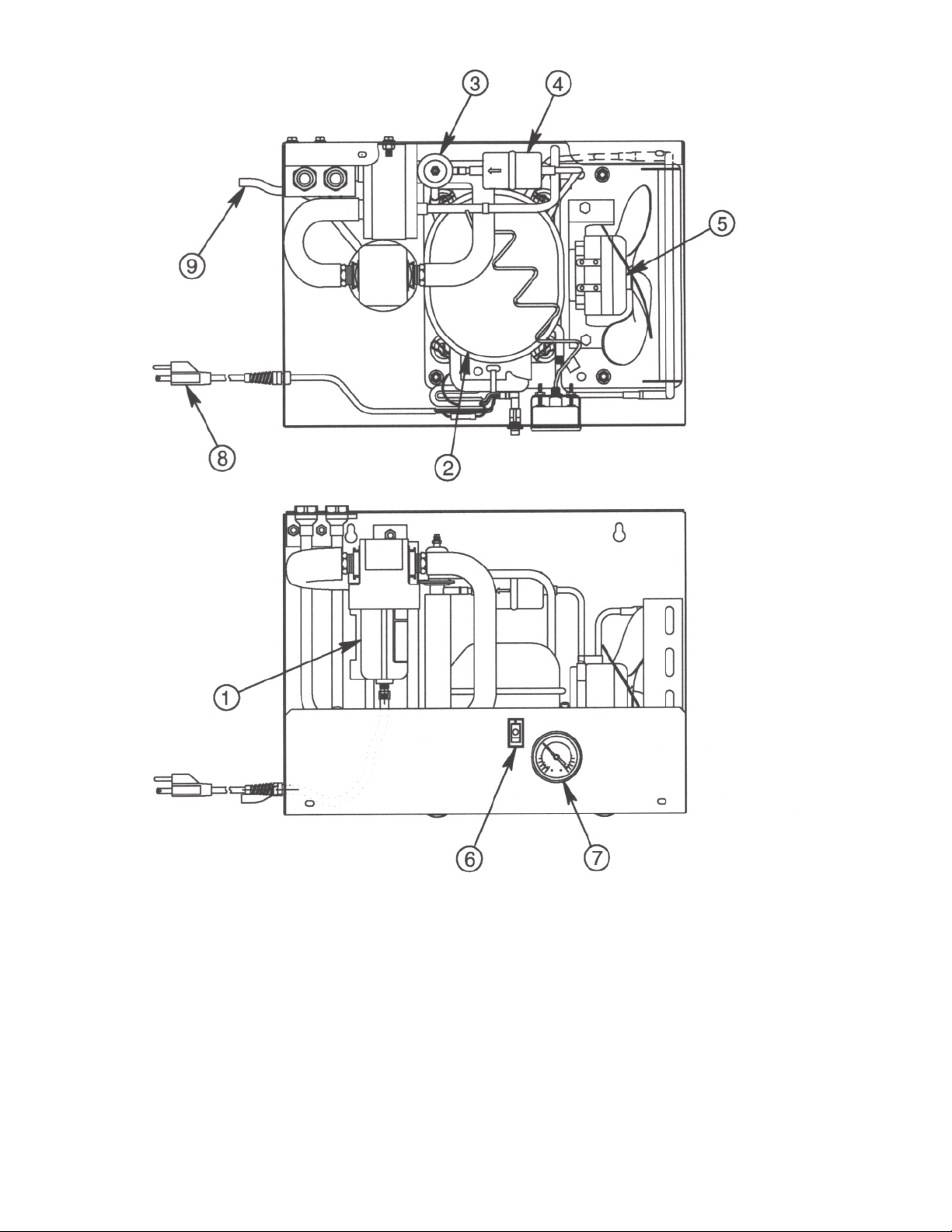

Figure 1 - F-20

ARROW DRYERS 745 CLARK AVE. BRISTOL, CT 06010 TOLL FREE: (877) 640-8300

Form F-0031A

Revised 10/04

Page 2

1) Separator

2) Compressor

3) Expansion/Control Valve

4) Refrigerant Filter

5) Fan Motor

6) Power On Light/Switch

7) Dew Point Indicator

8) Power Cord

9) Drain Line

1

Page 3

Receiving and inspection

Arrow Dryers are carefully prepared for shipment at the

factory to protect them from damage in transit. Dryers

are shipped F.O.B. factory. Immediately upon arrival,

check the dryer for possible damage. If

damage is found, report it to the carrier and file

a damage claim.

Check the suction pressure gauge. If the suction pressure

gauge reads zero, it indicates a possible refrigerant leak.

Notify your dealer immediately.

Be sure you have the right dryer. Check the nameplate for

voltage and amperage

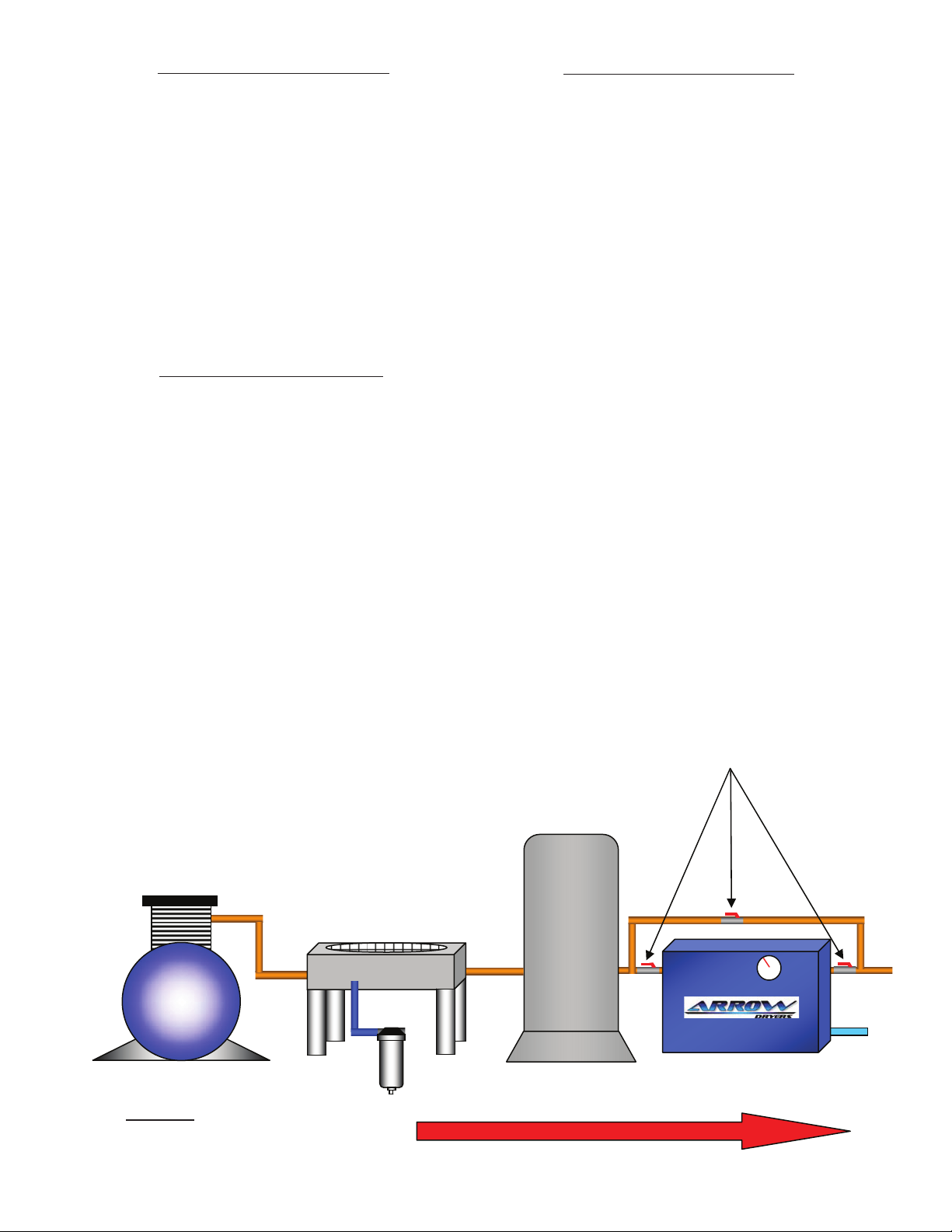

Location and Installation

Locate the dryer indoors in a protected area where ambient temperature will range between 45ºF and 100ºF. Dryers

are usually located near the compressor. Do not cycle the

dryer with the compressor. If an aftercooler is used after the

compressor, install the dryer downstream of the aftercooler

and receiver (see figure 2). Install the dryer so that there is

sufficient room around it to permit circulation of air through

the refrigeration condensing unit. Allow for easy access into

the dryer through the cover panel.

Check the nameplate for voltage and amperage. The dryer

is furnished with a 6 foot electrical cord for connection to a

grounded outlet.

How the Air Dryer Works

Compressed air enters the inlet and passes through the

air-to-air heat exchanger where the air is partially cooled

by the exiting cold air. Next, the air passes through a refrigerant-to-air heat exchanger where it is cooled to near

the freezing point of water. As the air is cooled, it loses the

capacity to hold water vapor. The water vapor condenses

into water droplets and drains to the separator. Passing

through the separator, air flow slows down and causes

more water to condense and collect in the bottom of the

separator bowl. The water is exhausted by the float drain

(see figure 4).

The compressed air, now at a pressure dew point of 35ºF,

leaves the dryer through the air-to-air heat exchanger

where it is heated by the incoming air.

Typical Compressed Air Systems

The dryer can be mounted on a wall with the key hole slots

provided or on a floor stand.

Be sure that the compressor air passes through the dryer

in the proper direction. Connect the compressed air lines to

the inlet and outlet connection as marked on the cabinet.

Connect the air lines with standard pipe fittings.

The mechanical separator has an automatic float drain with

a ⅜” plastic drain line connection that exits through the

dryer cabinet.

It is recommended that a bypass line is piped around the

dryer. Shutoff valves should be installed at both inlet and

outlet, with another valve in the bypass line. This complies

with O.S.H.A. lockout regulations and permits the dryer to

be removed from the system or serviced without turning off

the air supply.

3 Valve Dryer By-Pass

Air Receiver

Compressor

Figure 2

Aftercooler

Air Flow

Separator w/ Auto Drain

2

Air Dryer

Condensate

Drain

Page 4

Dimensions

F-20 Air Dryer

F-20 Wiring Diagram

115/220V CSIR

Specifi cations

Model Power Capacity Dimensions Air Line Drain Net Max. Full L.R.

No. Supply SCFM (Inches) Conn. Line H.P. Refrig Wt. Press. Load AMP

@ 100 PSIG Length Height Width FPT Conn. Charge* Lbs. PSI AMP

O.D.

F-20-1 115/1/60 20 18 14.0 13 1/2” 3/8” 1/6 10 OZ. 50 250 3.3 18

F-20-2 230/1/60 20 18 14.0 13 1/2” 3/8” 1/6 10 OZ. 50 250 1.6 9.3

F20-250 220/1/50 20 18 14.0 13 1/2” 3/8” 1/6 10 OZ. 50 250 1.7 10.5

*Refrigerant R-134A

3

Page 5

Design Conditions

The Dryer must not be cycled with the air compressor. The dryer is non-cycling and is designed to run

continuously (even under light loads). If the compressed

air system remains pressurized and the air compressor cycles off and on to maintain line pressure, the dryer should

remain in operation to keep the air lines dry.

Air Flow SCFM: The rated air flow (SCFM) of the dryer

is designed for 100 PSIG. Above the rated air flow, the dew

point will rise and moist air may reappear downstream. The

dryer may cycle off and on under excessive load and cause

compressor damage.

Inlet Air Temperature: The dryer will function normally

up to 100ºF. Above this temperature, the dryer capacity will

fall off. Inlet air temperature should be controlled so that it

does not exceed 100ºF.

Line Pressure: The maximum design pressure is 250

PSIG. The standard internal float drain in the separator will

not rise and water will ejected.

How to Make Minor Refrigerant

Suction Pressure Adjustments

1) Keep the dryer running under no load and turn off or

bypass the compressed air.

2) Remove the dryer cover and locate the control valve

(See Figure 3).

3) Loosen the locknut and turn clockwise to increase or

counterclockwise to decrease the suction pressure (1/4

turn will normally be enough). Tighten lockout securely

and wait 3 to 4 minutes for the suction pressure to

settle. Repeat if needed.

Figure 3

Maintenance and Care

Periodically or as part of a preventative maintenance program, check the following:

Ambient Air Temperature: Locate the dryer indoors in

a protected area where the ambient temperature will range

between 45ºF and 100ºF. Note: Above an ambient temperature of 100ºF the refrigerant will rise until the dryer shuts

down. Several off and on cycles under these conditions will

damage the compressor.

Automatic Expansion Valve: The automatic expansion valve regulates the refrigerant suction pressure. The

expansion valve is factory set between 33 and 36 PSIG.

Always turn the dryer on 5 to 10 minutes before

the air compressor. This will allow the dryer to reach

operating temperature and will prevent moist air downstream of the dryer. After starting the dryer, the dew point

indicator will slowly drop and hold be within the green area

of the gauge.

A lighted on/off switch glows when the power is on. During normal operation, the light will be on and the gauge

will read in the green area. If the gauge reads in lower

red area, the cause is a low refrigerant charge or low expansion valve setting. If the gauge reads in the higher red

area, the compressor could be off. Other causes of a high

gauge reading: a dirty air cooled condenser, high ambient air temperature, high inlet air temperature or an air

flow above the dryer’s capacity. When the dryer is off, the

gauge should read close to room temperature.

Start UP

Be sure that there is a free flow of water from the separator

drain. Check the drain mechanism and bronze element periodically and clean monthly. The drain cock can be opened

manually under pressure by turning the knurled stem.

To clean the drain assembly, bypass the air supply. Remove the bowl and then remove the float assembly and

wash all part in warm soapy water. Clean bronze element

with kerosene. Reassemble in the reverse order.

Be sure that there is a free flow of air over the condenser

coils. Check the condenser fins periodically to prevent a

build up of dust deposit. If fins are coated with dust, blow

compressed air through the fins to clean.

Frosting on refrigerant lines is an indication of too much refrigeration capacity. This results in frozen air passages and

prevents air flow through the dryer. It may be necessary to

increase the refrigerant suction pressure.

Dry Air Exits

Wet Air Enters

Model F-20

Bronze Element

Figure 4

Float Drain

4

Quite Zone to

Eliminate Carryover

Page 6

TROUBLESHOOTING CHART

Symptom Possible Causes(s) Corrective Action

Unit will not run. 1. No Power. 1. Correct power supply, fuses,

circuit breaker.

2. Internal compressor overload. 2. Feel the temperature of the comp-

ressor and allow to cool off if hot.

Observe the fan motor. Have the

motor checked if it does not run.

Clean the condenser.

Dew Point Indicator Red (High) 1. Internal compressor overload. 1. Check for air overload. Check inlet

air temperature. Check operation

of fan motor.

2. High ambient temperature. 2. Check room temperature and hold

between 45°F and 100°F.

Dew Point Indicator Red (Low) 1. High air fl ow. 1. Air fl ow above rated fl ow of dryer.

2. Drain valve not discharging. 2. Manually blow down drain until

water fl ow stops. Clean drain.

3. Freezing moisture in evaporator. 3. Re-adjust hot gas valve to the green

area on the dew point indicator gauge.

(See minor pressure adjustment)

Water downstream of dryer 1. Compressed air is fl owing through 1. Dryer must be operating 5-10

dryer before it is turned on. minutes before compressed air load.

2. Dirty separator element or drain. 2. Disassemble and clean.

3. Overload dryer above air fl ow 3. Reduce air load to dryer

capacity. specifi cations.*

4. High suction pressure. 4. Inlet air temperature too hot.

5. Low outlet air pressure. 5. Freezing of water, adjust suction

pressure.*

6. Low refrigerant charge. 6. Contact service technician to leak

check.

*ALL ADJUSTMENTS MUST BE MADE WITH DRYER RUNNING UNDER NO COMPRESSED AIR LOAD.

5

Page 7

If Trouble Starts

If the dryer cycles off and on for any reason TURN OFF

THE DRYER. Call the factory for instructions, Check or

repairs of the refrigeration systems must be made by

a qualified refrigeration service technician. Before call-

ing the factory for instructions, have the following data to

report.

Model No.

Serial No.

Refrigeration Suction Pressure.

REPLACEMENT PARTS

Model F-20-1 F20-2 F20-250

Voltage 115/1/60 230-220/1/60 240-220/1/50

Compressor Make TECUMSEH R-134A TECUMSEH R-134A TECUMSEH R-134A

Separator/

Drain Assembly PART NUMBER PART NUMBER PART NUMBER

Separator F354F-S2 F354F-S2 F354F-S2

Bowl Separator 75180-S2 75180-S2 75180-S2

Repair Kit RKF35 RKF35 RKF35

Element Kit EK35 EK35 EK35

Float Drain FD06B FD06B FD06B

Refrigeration

System

Condensing Unit 97829 97799 97834

Compressor 97836 97838 97837

Condenser 92950 92950 92950

Expansion Valve 91221 91221 91221

Refrigerant Filter 91235 91235 91235

Heat Exchanger 14100 14100 14100

Electrical

Fan Motor 94930 92933 92933

Fan Blade 92940 92940 92940

Overload 91411 91409 91409

Power On Light/Switch 57300 57300 57300

Gauges

Dew Point Temp. Indicator 14765 14765 14765

Cabinet Panels

Base 14011 14011 14011

Cover 14016 14016 14016

Right Side Vented 92430 92430 92430

Left Side Vented 14121 14121 14121

6

Page 8

ORDER REPLACEMENT PARTS

BY CALLING

(877) 640-8300

Please provide following information:

• Model Number

• Serial Number (if any)

• Part Description and Number

Address parts correspondence to:

ARROW DRYERS

745 Clark Ave.

Bristol, CT 06010

WARRANTY POLICY

When used under the conditions recommended by the manufacturer, Arrow Dryers, this

model is warranted to be free from defects in material and workmanship for a period of

twenty-four (24) months from date of receipt, not to exceed thirty (30) months from the

factory ship date, provided Arrow is furnished the customer’s name, address, and date of

shipment information

These units will utilize either a braze plate or modular type heat exchanger which will be

warranted for five (5) years. This warranty is limited to the replacement of the heat exchangers, F.O.B. Factory, and subject to the same restrictions as outlined below concerning misuse, abuse or accident. The automatic drain carries a 90-day warranty.

This warranty will apply to equipment installed, operated and maintained in accordance

with the procedures and recommendations as outlined in the owner’s manual published

by Arrow Dryers.

During the life of this warranty, Arrow Dryers will repair or replace (at Arrow Dryers’ option) any defective part or assembly, free of charge, F.O.B. its plant if such defect occurred

in normal service and was not due to apparent misuse, abuse or accident.

Any warranty service performed in the field must be authorized by Arrow Dryers, Unauthorized service voids the warranty and any resulting charge will not be paid by Arrow

Dryers.

Arrow Dryers makes no other warranties or guarantees, expressed or implied. The merchantability of the components is expressly excluded. The manufacturer assumes no liability for indirect or consequential damages.

7

Loading...

Loading...