Page 1

Owner's Manual & Assembly Instructions

YU01

Model No. EPA104

716450510

Storage Area: 35 Sq. Ft. 188 Cu. Ft.

BUILDING DIMENSIONS

Exterior Dimensions Interior Dimensions Door

*Approx. Foundation (Roof Edge to Roof Edge) (Wall to Wall) Opening

Size Size Width Depth Height Width Depth Height Width Height

10' x 4' 121" x 45 1/4" 123 1/2" 47" 67 3/4" 118 1/4" 42 1/2" 66 9/16" 55 1/2" 60"

3,0 m x 1,1 m 307,3 cm x 114,9 cm 313,1 cm 119,4 cm 172,1 cm 300,4 cm 108,0 cm 169,1 cm 141,0 cm 152,4 cm

3,3 m

2

* Size rounded off to the nearest foot

5,3 m

3

CAUTION: SOME PARTS HAVE SHARP EDGES. CARE

MUST BE TAKEN WHEN HANDLING THE VARIOUS PIECES

TO AVOID A MISHAP. FOR SAFETY SAKE, PLEASE READ

SAFETY INFORMATION PROVIDED IN THIS MANUAL

BEFORE BEGINNING CONSTRUCTION. WEAR GLOVES

WHEN HANDLING METAL PARTS.

Page 2

BEFORE YOU BEGIN....

XA02

Owner's Manual

Before beginning construction, check local building codes regarding footings, location

and other requirements. Study and understand this owner's manual.

Important information and helpful tips will make your construction easier and more

enjoyable.

Assembly Instructions: Instructions are supplied in this manual and contain all

appropriate information for your building model. Review all instructions before you begin,

and during assembly, follow the step sequence carefully for successful results.

Flooring and Anchoring: Your storage building must be anchored to prevent wind

damage. A base is necessary to construct a square and level building. Anchoring and

base materials are not included with your building. Your assembly instructions provide

information on a few methods commonly used to secure and level a storage building.

Parts and Parts List: Check to be sure that you have all the necessary parts for your

building.

•All part numbers can be found on the parts. All of these numbers (before the -) must agree with the

numbers on the parts list. The parts list is located on page 9.

•If you find that a part is missing, include the model number of your building

and contact the retailer where you purchased your shed.

•Separate contents of the carton by the part number while reviewing parts list. The first few steps

show how to join related parts to make larger sub assemblies which will be used later.

•Familiarize yourself with the hardware and fasteners for easier use during construction. These are

packaged within the carton. Note that extra fasteners have been supplied for your convenience.

2

Page 3

PLAN AHEAD....

XA03

Watch the Weather: Be sure the day you select to install your building is dry and calm.

Do not attempt to assemble your building on a windy day. Be careful on wet or muddy ground.

Teamwork: Whenever possible, two or more people should work together to assemble

your building. One person can position parts or panels while the other is able to handle the

fasteners and the tools.

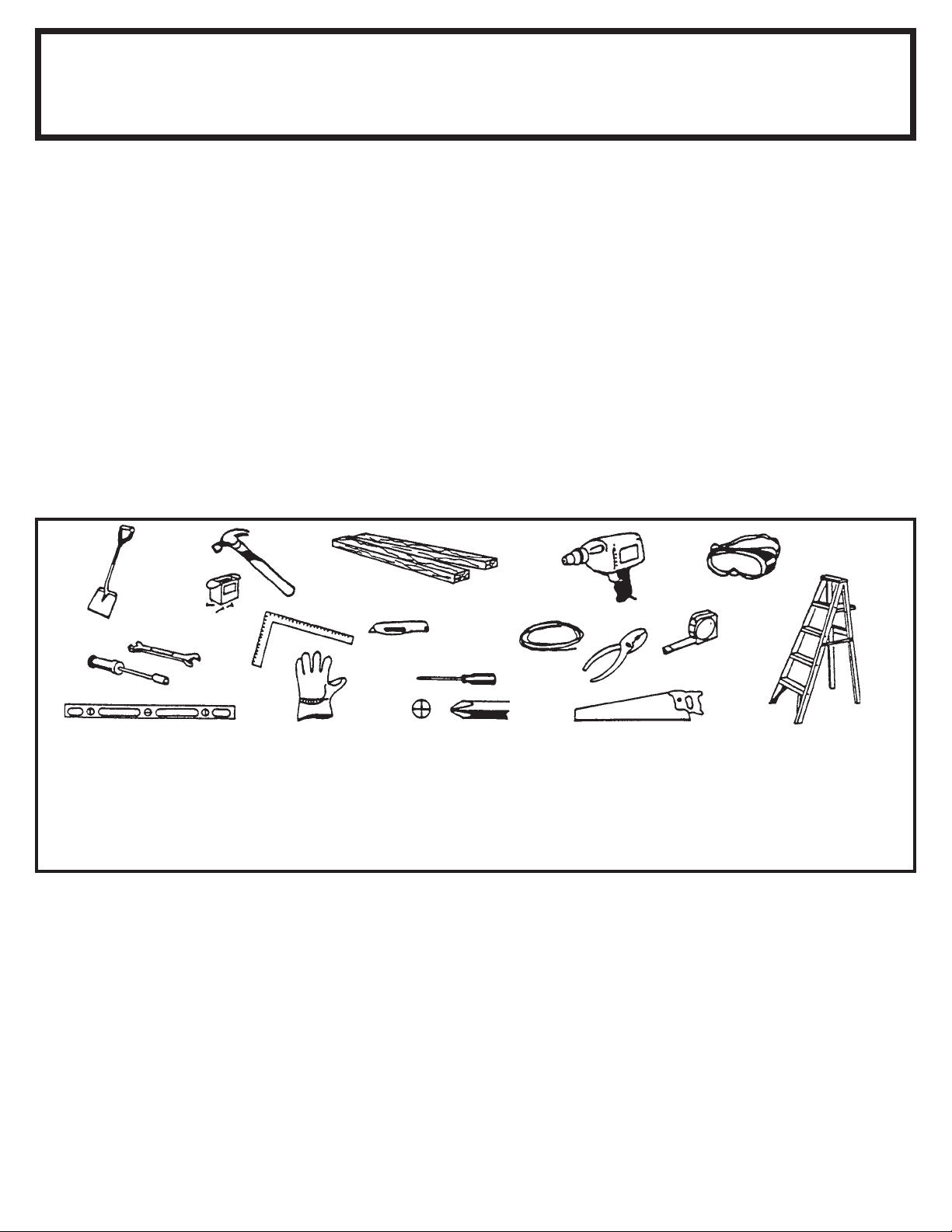

Tools and Materials: These are some basic tools and materials you will need for the

construction of your building. Decide which method of anchoring and the type of base you

wish to use in order to form a complete list of the materials you will need.

Required

• Eye Goggles

• No. 2 Phillips Screwdriver

(With Hardened Magnetic Tip)

Note: A power screwdriver or variable speed drill with Phillips-tip attachment can speed assembly by

as much as 40%.

• Work Gloves

• Step Ladder

• Utility Knife / Scissors

• Pliers

• Carpenter's Level

• Tape Measure

Required

Optional Time-Savers

• Wrench / Nut Driver

• Electric / Cordless Drill

• Square

• String (for squaring frame)

Base Preparation

• Hammer and Nails

• Spade or Shovel

• Hand Saw / Power Saw

• Lumber and/or Concrete

Selecting and Preparing Your Site: Before assembly, you will want to decide on

a location for your building. The best location is a level area with good drainage.

•Allow enough working space for ease of moving parts into position during assembly. Be sure there

will be enough space at entrance for doors to open fully and enough space around the building to

be able to fasten the panel screws from the outside.

•Before you begin the first steps in assembling your parts, a base should be constructed and

an anchoring system should be ready to use.

3

Page 4

SAFETY FIRST....

XA04

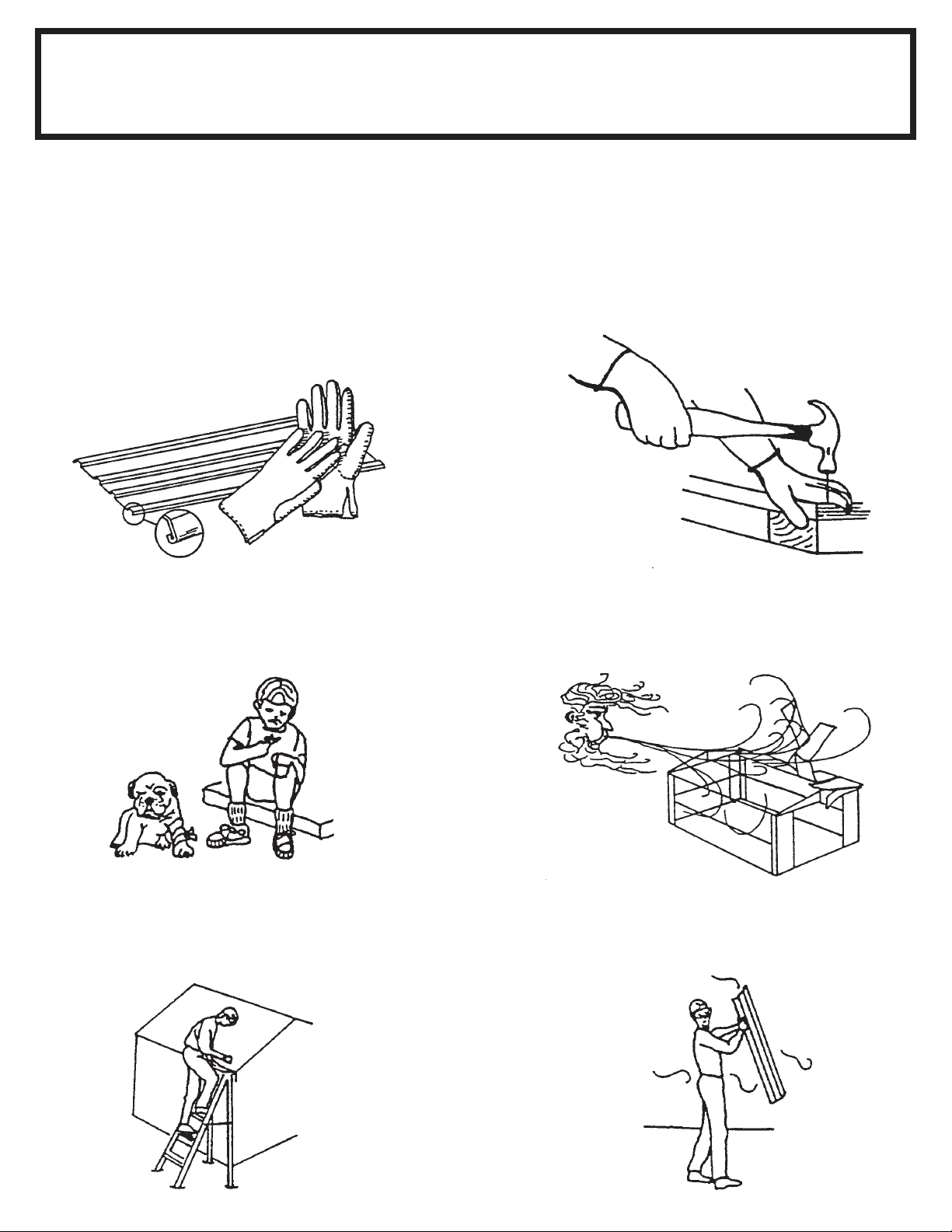

Safety precautions are important to follow throughout the construction of your building.

•Care must be taken when handling various

pieces of your building since some contain

sharp edges. Please wear work gloves, eye

protection and long sleeves when assembling

or performing any maintenance on your building.

safety edge

sharp edge

sharp edge

safety edge

•Keep children and pets away from worksite to

avoid distractions and any accidents which

may occur.

•Practice caution with the tools being used in the

assembly of this building. Be familiar with the

operation of all power tools.

•Do not attempt to assemble the building if parts

are missing because any building left partially

assembled may be seriously damaged by light

winds.

•Never concentrate your total weight on the

roof of the building. When using a step ladder

make sure that it is fully open and on even

ground before climbing on it.

•Do not attempt to assemble the building on a

windy day, because the large panels acting as a

"sail", can be whipped about by the wind making

construction difficult and unsafe.

4

Page 5

CARE & MAINTENANCE....

XA05

Finish: For long lasting finish, periodically clean and wax the exterior surface. Touch-

up scratches as soon as you notice them on your unit. Immediately clean the area with

a wire brush; wash it and apply touch-up paint per manufacturer's recommendation.

Roof: Keep roof clear of leaves and snow with long handled, soft-bristled broom. Heavy

amounts of snow on roof can damage building making it unsafe to enter.

Doors: Always keep the door tracks clear of dirt and other debris that prevent them from

sliding easily. Lubricate door track annually with furniture polish or silicone spray. Keep

doors closed and locked to prevent wind damage.

Fasteners: Use all washers supplied to protect against weather infiltration and to protect

the metal from being scratched by screws. Regularly check your building for loose

screws, bolts, nuts, etc. and retighten them as necessary.

Moisture: A plastic sheet (vapor barrier) placed under the entire floor area with good

ventilation will reduce condensation.

Other Tips....

• Wash off inked part numbers on coated panels with soap and water.

• Silicone caulking may be used for watertight seals throughout the building.

Do not store swimming pool chemicals in your building. Combustibles and

corrosives must be stored in air tight approved containers.

Keep this Owner's Manual and Assembly Instructions for future reference.

5

Page 6

Base

YU06

The Base For Your Building

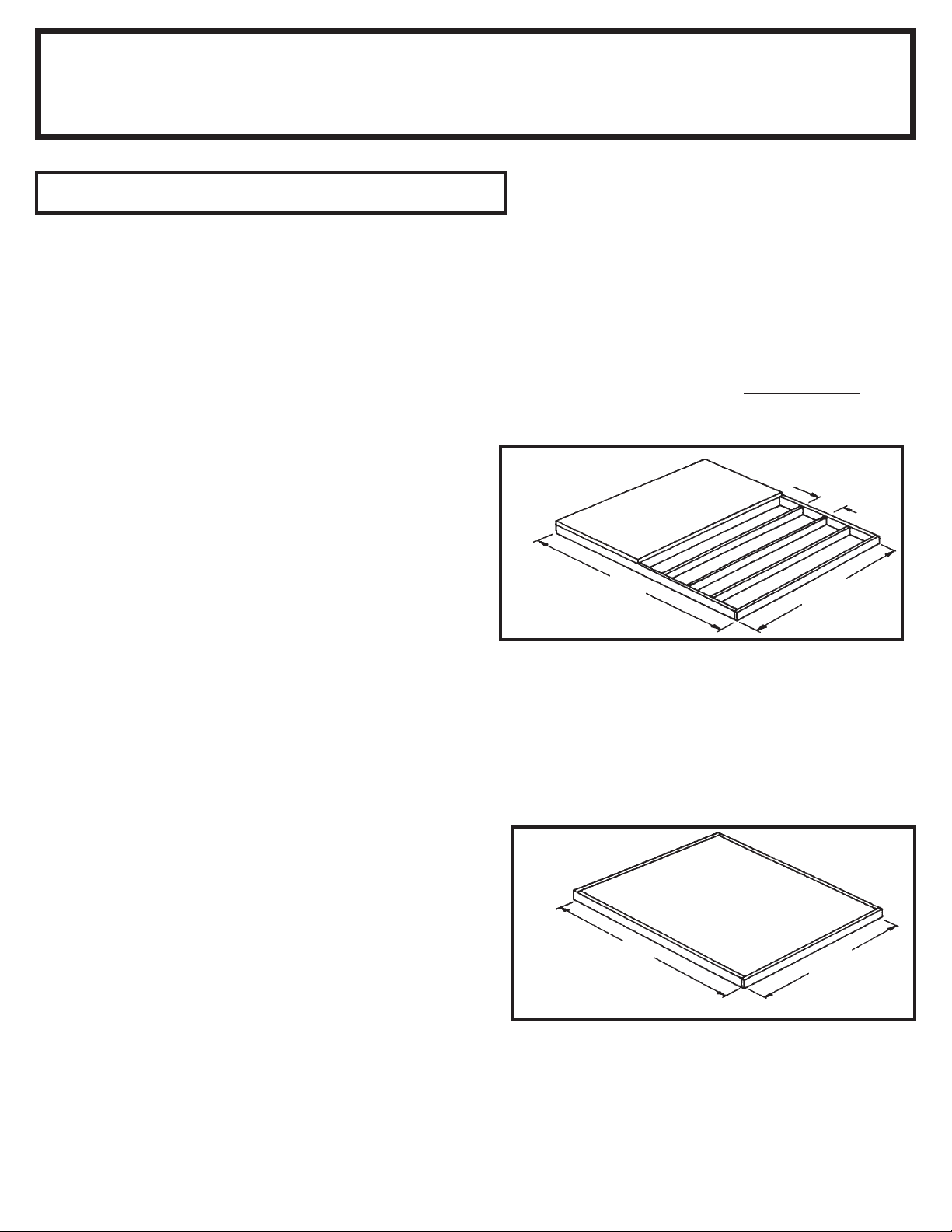

OPTION 1: Wood Platform

If you decide to build your own base, be sure to select the appropriate materials.

These are the recommended materials for your base:

● 2 x 4's (38 mm x 89 mm) Pressure Treated Lumber

● 5/8" (15,5 mm) 4 x 8 (1220 mm x 2440 mm) Plywood-exterior grade NOTE: Pressure Treated Lumber must not be used where it

will make contact with your storage building. The properties of Pressure Treated Lumber will cause accelerated corrosion.

If Pressure Treated Lumber comes in contact with your storage building your warranty will be voided.

● 10 & 4 penny Galvanized Nails ● Concrete Blocks (optional)

16"/24"

The platform should be level and flat (free of bumps, ridges etc.)

to provide good support for the building. The necessary materials

may be obtained from your local lumber yard.

40,6 cm/61,0 cm

To construct the base follow instructions and diagram.

Construct frame (using 10 penny galvanized nails)

Measure 16"/24" (40,6 cm/61,0 cm) sections to construct

inside frame (see diagram)

Secure plywood to frame (using 4 penny galvanized nails)

Allow 6 - 7 hours for construction.

FRONT

(DOOR)

Note: Platform/Slab will extend 9/16" (1,4 cm) beyond

floor frame on all four sides. Seal this 9/16" (1,4 cm) of

wood with a roofing cement (not included), or bevel

this 9/16" (1,4 cm) of concrete when pouring,

121"

307,3 cm

for good water drainage.

OPTION 2: Concrete Slab

The slab should be at least 4" (10,2 cm) thick. It must be level and flat to provide good support for the frame.

The following are the recommended materials for your base.

● 1 x 4's (19 mm x 89 mm) (will be removed once the concrete cures)

● Concrete ● Sheet of 6 mil plastic

● We recommend for a proper strength concrete to use a mix of:

1 part cement ● 3 parts pea sized gravel ● 2 1/2 parts clean sand

Prepare the Site/Construct a Base

1. Dig a square, 6" (15,2 cm) deep into the ground (remove grass).

2. Fill up to 4" (10,2 cm) in the square with gravel and tamp firm.

3. Cover gravel with a sheet of 6 mil plastic.

4. Construct a wood frame using four planks of 1x4 (19 mm x 89 mm)

lumber.

5. Pour in concrete to fill in the hole and the frame giving a

total of 4" (10,2 cm) thick concrete. Be sure surface is level.

FRONT

(DOOR)

Note: Finished Slab dimensions, with lumber removed.

121"

307,3 cm

45 1/4"

114,9 cm

45 1/4"

114,9 cm

Allow 3 - 5 hours for construction and a week for concrete curing time.

6

Page 7

Anchoring

XA07

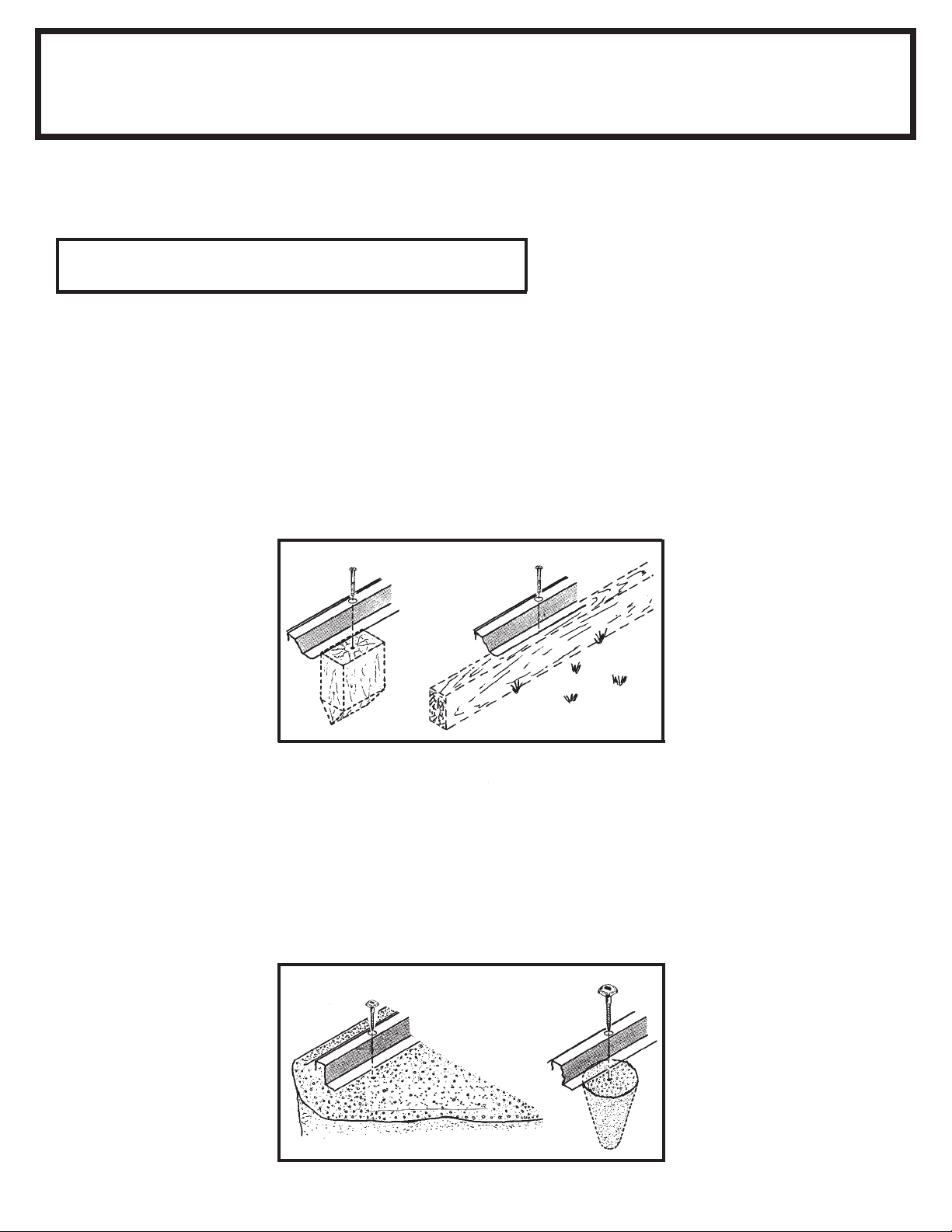

Anchoring Down The Building

It is important that the entire floor frame be anchored after the building is erected.

Below are recommended ways of anchoring.

Anchoring into Wood/Post:

Use 1/4" (6 mm) Wood Screws. There are 1/4" (6 mm)

dia. holes provided in the frames for proper anchoring.

1. 2.

Anchoring into Concrete:

1. For poured concrete slab or footing or patio blocks:

Use 1/4" x 2" (6 mm x 51 mm) Lag Screws.

2. For Anchor Post of Concrete poured after building is

erected: Use 1/4" x 6" (6 mm x 152 mm) Lag Screws.

1.

2.

7

Page 8

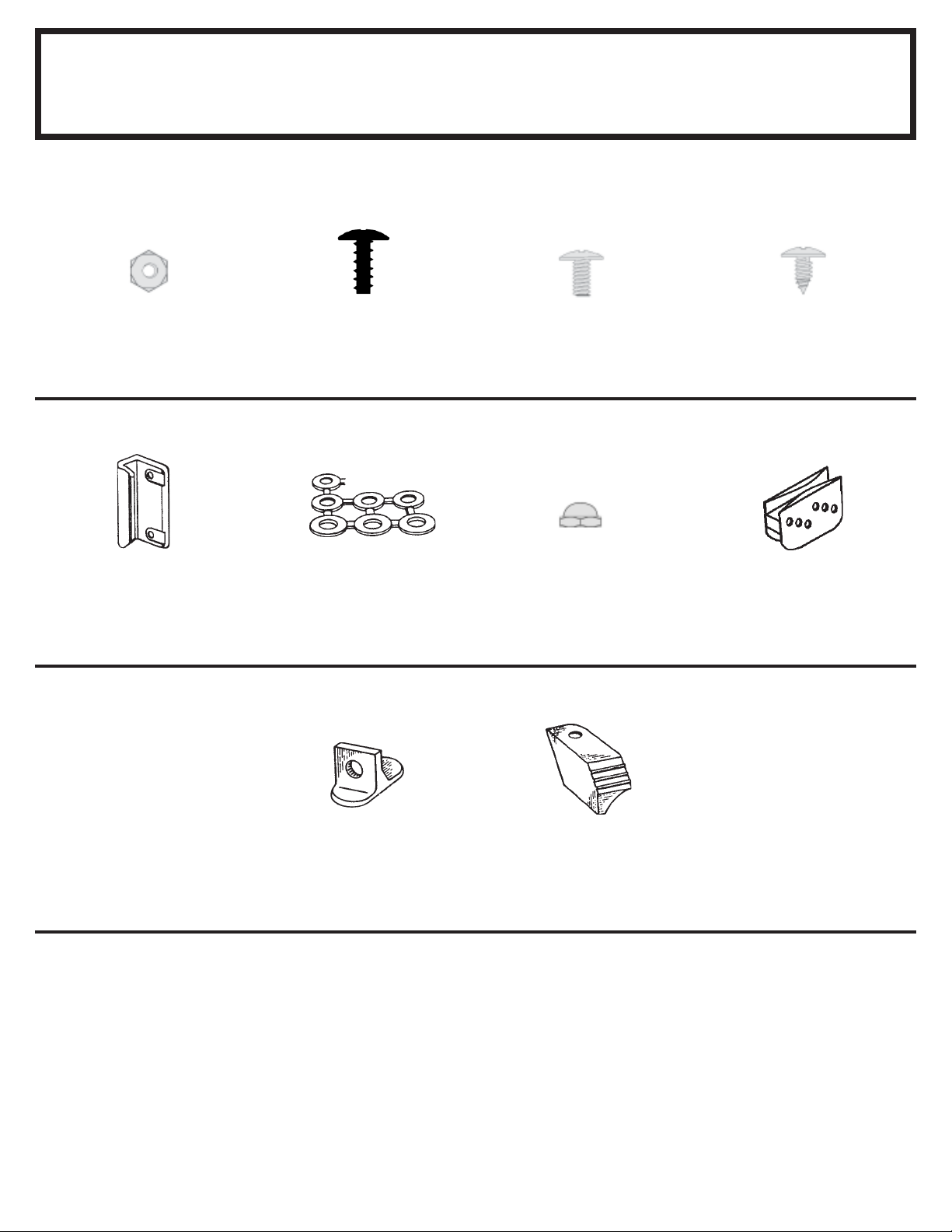

YU08

#8-32 Hex Nut (60)

65103

Hardware

Remove from bag of screws

and save for the last step

65900A

#10Bx1/2" (13 mm)

Black Screw (8)

(Packed with Screws)

65923

#8-32x3/8" (10 mm)

Bolt (60)

65004

#8Ax5/16" (8 mm)

Screw (246)

66045

Handle (2)

66646

Washer (247)

(7 sheets of 40)

66382

Lower Door Guide (4)

65109

#8-32 Acorn Nut (4)

(Packed with Screws)

66183

Roof Trim Cap

(2 right & 2 left)

66769

Door Slide (4)

8

Page 9

YU09

Parts List

Assembly Part Part Quantity Check

Key No. Number Description in CartonList

1 10567 Rear Wall Angle 2

2 6403 Door Track Splice 1

3 10497 Horizontal Door Brace 4

4 10574 Front Header 2

5 10557 Roof Panel 2

6 10562 Right Gable 1

7 80015 Left Gable 1

8 6892 Right Roof Trim 2

9 10558 Right Roof Panel 1

10 80011 Left Roof Panel 1

11 10571 Roof Beam 2

12 10564 Side Wall Angle 2

13 10545 Side Wall Channel 2

14 80019 Left Roof Trim 2

15 8934 Ramp 1

16 10544 Side Floor Frame 2

17 9365 Front Wall Channel 2

18 6278 Vertical Door Brace 2

19 10475 Right and Left Doors 2

20 6515 Wall Panel 4

21 9369 Door Jamb 2

22 9917 Rear Wall Channel 2

23 8936 Rear Floor Frame 2

24 9366 Door Track 2

25 9367 Front Floor Frame 2

26 6020 Corner Panel 4

27 9373 Front Wall Panel 2

28 3719 Door Handle Brace 2

29 10559 Roof Panel 1

9

Page 10

YU10

Assembly by Key No.

8

10

7

14

5

17

24

21

27

26

12

18

3

28

11

4

1

26

13

2

3

18

28

20

20

20

22

22

24

23

26

27

29

5

11

4

1

20

12

26

13

14

9

8

6

16

25

19

19

21

3

15

3

17

16

25

10

23

Page 11

Step 1

YU11

● Parts Needed For ●

Floor Frame Assemblies

●●

● 8934 Ramp (1)

●●

●●

● 9367 Front Floor Frame (2)

●●

●●

● 8936 Rear Floor Frame (2)

●●

(8)

(5)

The front floor frame is made up of

three pieces. The rear floor frame is

made up of two pieces. The holes in

these pieces will align when the

pieces are positioned with correct

amount of overlap. The illustrations

below show the proper overall length

for the front and rear. Proceed as

follows:

1 Place the front floor frames as

shown. Center the ramp, with drain

holes facing outside, on top of the two

front floor frames. Join the frames by

inserting eight screws.

STEP

1

9367

9367

8934

9367

8934

DRAIN HOLES FACE

OUTSIDE

8936

Front Floor

Frame Assembly

119 3/8" 303,2 cm

9367

2 Overlap the rear floor frames as

shown. The holes in these pieces

will align when the pieces are positioned with correct amount of overlap. See the illustrations below for

the proper overall length of the rear

floor frame. Join the frames by inserting five bolts into frame set as shown.

3 Double check the length of each

and set these pieces aside for later

use.

STEP

2

8936

Rear Floor Frame

119 3/8" 303,2 cm

8936

119 3/8" 303,2 cm Rear

STEP

3

119 3/8" 303,2 cm Front

11

Page 12

Step 2

YU12

● Parts Needed For ●

Frame Assemblies

●●

● 10567 Rear Wall Angle (2)

●●

●●

● 9917 Rear Wall Channel (2)

●●

(2)

The main frame pieces reinforce the

walls. These pieces will later be installed in the center and at the top

edge of the rear wall. Proceed as

follows:

1 Overlap the rear wall channel

pieces as shown in the figure and

fasten the two pieces together with

one bolt in the center hole (three

holes will align).

2 Overlap the rear wall angle pieces

as shown in the figure and fasten

them together with one bolt in the

center hole.

9917

10567

Rear Wall Channel

118 1/8" 300,0 cm

9917

STEP

1

Rear Wall Angle

118 1/8" 300,0 cm

10567

3 Double check the length of each

and set these pieces aside for later

use.

STEP

2

Rear Wall Channel

118 1/8" 300,0 cm

Rear Wall Angle

118 1/8" 300,0 cm

STEP

3

12

Page 13

Step 3

YU13

(8)

● Parts Needed For ●

Roof Beam Assemblies

●●

● 10571 Roof Beam (2)

●●

The roof beams support the roof panels. The roof beam is made up of two

pieces overlapped at the center.

Hint: These pieces are force-fitted,

so you may have to press hard to join

them together.

1 Place the end of one roof beam

inside a second roof beam so that the

six holes in each piece align. Do not

insert bolts yet.

2 Fasten the pressed-together roof

beam with eight bolts.

3 Double check the length and set

this piece aside for later use.

10571

STEP

1

STEP

10571

119 7/8"

304,5 cm

2

10571

10571

119 7/8"

304,5 cm

13

Page 14

Step 4

YU14

(14) (2)

The door track/header assembly supports the sliding doors and reinforces

the front wall. It is made up of five

pieces.

● Parts Needed For ●

Door Track / Header

Assembly

NOTE:

Door Track Splice (painted part)

6403

●●

● 6403 Door Track Splice (1)

●●

●●

● 9366 Door Track (2)

●●

●●

● 10574 Header (2)

●●

1 Using the door track splice,

(painted), join the door track

(galvanized) pieces end-to-end as

shown.

2 Insert four screws from the under-

side only.

3 Using this door track assembly,

with small holes on top, join the

header pieces, short leg on top, as

shown using screws.

4 Fasten overlap area of header with

2 bolts and nuts.

5 Position door slides onto the

legs, from the end of door track

assembly, as shown in the end view.

STEP

118 1/8"

300,0 cm

STEP

9366

1

6403

3

10574

STEP

2

66769

9366

Long Leg

on Top

Short Leg

on Bottom

9366

9366

10574

STEP

4

6 Set this piece aside for later use.

END VIEW

119 7/8"

304,5 cm

STEP

5

66769

14

Page 15

Step 5

YU15

(8) (2)

● Parts Needed For ●

Floor Frame

●●

● Front Floor Assembly (1)

●●

●●

● 10544 Side Floor Frame (2)

●●

●●

● Rear Floor Assembly (1)

●●

RIGHT

REAR

10544

1 Assemble the four corners of the

floor frame using two screws at each

corner as shown. At the front corners

fasten bolts through from the bottom

with nuts on top.

2 Measure the floor frame diago-

nally. When the diagonal measurements are equal, the floor frame is

square.

NOTE

If using a wood platform or

concrete slab do not fasten the

floor frames to your base at this

time. You will anchor the building

after it is erected.

STEP

1

10544

FRONT

8936

10544

RIGHT

FRONT

10544

9367

When Diagonal Measurements

are Equal the Floor Frame

is Square.

STEP

2

The floor frame must be square

and level or holes will not align.

Level

15

Page 16

Step 6

YU16

● Parts Needed For ●

Corners

Narrow

Side

●●

● 6515 Wall Panel (2)

●●

●●

● 9373 Front Wall Panel (2)

●●

●●

● 6020 Corner Panel (4)

●●

(38)

The remainder of the building assembly requires many

hours and more than one person. Do not continue

beyond this point if you do not have enough time to

complete the assembly today. A partially assembled

building can be severely damaged by light winds.

(6)

NOTE

Each screw and bolt in the wall

requires a washer.

CORRECT

INCORRECT

1 Position a corner panel at the

corner of the floor frame as shown.

The widest part of each corner panel

must be placed along the side of the

building for all four corners. Fasten

the corner panel to the floor frame

with three screws. Fasten overlapping rib using two screws and a bolt

with nut.

Support the corner panel with a step

ladder until a wall panel is attached.

2 Attach the front wall panels to the

6020

front corner panels, as shown. A small

gap will exist between front wall panel

and ramp.

3 Attach the wall panels to the rear

corner panels, as shown.

NOTE

Be careful to install the correct

panel in each position as shown

STEP

1

9373

SIDE

6020

6020

Wide Side

6515

6515

6020

REAR

TOP VIEW

FRONT

6515

STEP

2

9373 9373

6515

6020

SIDE

6020

STEP

3

STEP

4

6020

4 Double-check the part numbers of

the wall panels, before proceeding.

The floor frame must be square

and level or holes will not align.

Panels rest on

frame as shown

16

9373

Washer

6020

Page 17

Step 7

YU17

● Parts Needed For ●

Frames

●●

● Rear Wall Angle Assembly (1)

●●

●●

● Rear Wall Channel Assembly (1)

●●

●●

● 10545 Side Wall Channel (2)

●●

●●

● 10564 Side Wall Angle (2)

●●

●●

● Door Track/Header Assembly (1)

●●

(46)

(2)

The main frame pieces give rigidity to

the side walls and provide a surface

for attaching the gables which support the roof.

1 Fasten the rear wall angle across

the inside top of the rear wall using

screws.

2 Fasten the rear wall channel

across the middle of the rear wall

using screws.

NOTE

The upper leg of the side wall

angles must face the outside

of the building.

Gap

13/16"

(2,1 cm)

STEP

3

STEP

5

Side Wall Angles

Must Face

Outside Building

10564

DOOR TRACK/HEADER ASSEMBLY

10545

Rear Wall

Angle Must

Face Inside

Building

9917

STEP

1

STEP

10567

2

3 Fasten the side wall angles across

the inside top of the side panels using screws.

4 Fasten the side wall channels

across the middle of the side panels

using screws. Fasten overlaps in rear

corners with screws.

5 Fasten the door track/header

assembly across the top of the front

wall panels using screws. See the

figure.

FRONT

STEP

4

17

Page 18

Step 8

YU18

● Parts Needed For ●

Wall Panels

3 Fasten the wall panels at the top

and bottom with screws.

●●

● 6515 Wall Panel (2)

●●

(30)

Each wall panel has a crimped rib on

one side. The crimped rib should go

under the rib of the panel that follows

it.

(3)

1 Locate all of the wall panels and

set each one alongside the building.

2 Be sure that you have the correct

panels in each position. Do this by

overlapping the panels and determining if the holes line up with the

holes in the frame.

4 Fasten the center of each panel to

the wall channel with screws.

Fasten overlapping ribs as before.

STEP

1

STEP

2

6515

Crimped Rib

Underneath

STEP

3

Panels rest on

frame as shown

18

STEP

4

Detail Showing

Center of Panel

Screwed to Wall

Channel

Bolt and nut

does not go thru

wall channel

at overlap

Page 19

Step 9

YU19

(18) (4)

● Parts Needed For ●

Front Channel/Door Jamb

9365

●●

● 9369 Door Jamb (2)

●●

●●

● 9365 Front Wall Channel (2)

●●

The door jambs reinforce the door

opening and provide an attractive

trim. Follow these steps for both

door jambs.

1 Fasten the front wall channels

in their positions between the end of

the side wall channel and the corner panel using screws. Do not put

a screw in the hole at the end behind the door opening at this time.

2 Fasten a door jamb to the front

panel with two bolts, nuts and acorn

nuts, as shown.

3 Fasten the center of the door

jamb to the front wall panel and the

front wall channel with two screws.

Acorn Nut

Hex Nut

Acorn Nut

STEP

1

STEP

2

9369

FRONT

FRONT

INSIDE OF

BUILDING

(2) bolts

Bolt

Screw

TOP VIEW

Door Track

9369

TOP VIEW

Front Wall Channel

STEP

Front Wall Channel

Cross-Section

Top View

Screw

3

4 Fasten the top of the door jamb to

the door track with two screws. Do

the same for the bottom into frame.

Repeat steps 2 through 4 for the

opposite door jamb.

STEP

4

19

Screw

TOP VIEW

Door Track

Screw

Page 20

Step 10

YU20

(2)

1 The dimension stated below mea-

sures from the end of the angle towards the front of the building. Fasten the roof beam assembly, small

holes on top, to the side wall angle

with a bolt and nut.

● Parts Needed For ●

Roof Beam

●●

● Roof Beam Assembly (1)

●●

23 1/2"

59,7 cm

STEP

1

Opening

Facing

Back

20

Page 21

Step 11

YU21

(18)

Installing the roof panels is best done

with a step ladder. Begin installing

roof panels at the right side of the

building. Each screw and bolt in the

roof requires a washer.

NOTE

Measure the building diagonally

again and make adjustments to

make sure the building is square

and level. This will make the roof

panels fit better, and holes will

align.

● Parts Needed For ●

Right/Left Roof Panels

2 Position a right roof panel at the

right side and fasten to the header,

roof beam and rear wall angle using

screws as shown.

3 Install the left roof panel 80011 on

the left side in the position shown

below.

●●

● 10558 Right Roof Panel (1)

●●

●●

● 80011 Left Roof Panel (1)

●●

1 Locate the roof panels and find the

right roof panel part number 10558.

STEP

3

80011 Left Roof Panel

STEP

1

10558 Right Roof Panel

STEP

2

FRONT

21

Page 22

Step 12

YU22

(36)

1 Install a wide roof panel 10557,

narrow roof panel 10559, and a

wide roof panel 10557 in the posi-

tions shown. Fasten middle of rib

overlap with a bolt and nut.

NOTE

Narrow roof panel crimped rib is

overlapped by wide rib of adjacent

panel where possible.

(4)

● Parts Needed For ●

Roof Panel

STEP

●●

● 10557 Roof Panel (2)

●●

●●

● 10559 Roof Panel (1)

●●

Fasten At

Overlap With

Bolt

Screws To

Roof Beam

Screws To

Rear Wall

Angle

10559 Roof Panel

1

10557 Roof Panel

Screws To

Header

FRONT

22

Page 23

Step 13

YU23

(10)

(6)

● Parts Needed For ●

Gables

2 Fasten to the right roof panel, side

wall angle and front header using

screws, bolts and nuts as shown.

●●

● 10562 Right Gable (1)

●●

●●

● 80015 Left Gable (1)

●●

1 Position the right gable at the right

end of the completed roof by tucking

top edge inside the rib of the right roof

panel and sliding the lower leg in

between the leg of the side wall angle

and top edge of the wall panels.

NOTE

The front leg of the gable must be

positioned inside of the front

header.

3 Repeat steps 1 and 2 for the left

gable.

STEP

1

Gable

Side Wall

Angle

Wall

Panel

Bottom leg of

gable must

slide into

opening

between side

wall angle and

top of panel.

23

10562

STEP

2

Page 24

Step 14

YU24

(8)

1 Attach the right and left roof trim

to the ends of the roof panels on the

front and rear of the building using

screws at each roof panel overlap.

NOTE

A single screw fastens both trim

pieces at the overlap.

(4)

● Parts Needed For ●

Roof T rim

2 Using your thumb and index fin-

ger, overbend the bottom flange of

the roof trim at the corner inward

enough so the right and left roof

trim caps fit onto right and left corners.

3 Fasten the roof trim caps to the

roof trim using a screw.

6892

●●

● 6892 Right Roof Trim (2)

●●

●●

● 80019 Left Roof Trim (2)

●●

80019

STEP

3

Roof Trim Cap

80019

STEP

1

Roof Trim

6892

STEP

2

Tuck Flange

Inward to Fit

Inside of

Roof Trim Cap

24

Page 25

Step 15

YU25

● Parts Needed For ●

Door Assembly

●●

● 3719 Door Handle Brace (2)

●●

●●

● 10475 Right and Left Doors (2)

●●

●●

● 10497 Horizontal Door Brace (4)

●●

●●

● 6278 Vertical Door Brace (2)

●●

(12)

The steps on this page tell how to

assemble the right door. You will

perform exactly the same procedures

for the left door. Each bolt and screw

in the door requires a washer. Proceed as follows:

1 Attach the door handle brace and

handle to the door with 1 bolt as

shown. Don't tighten the bolt yet.

2 Swing the door handle brace up to

the hole on the center of the door and

insert a screw.

3 Hold the vertical door brace

against the center of the inside surface of the door and turn the screw to

hold the vertical door brace and door

handle brace in place. Fasten to

door above and below center

connection using 2 screws.

(4)(6)

10497

6278

6278

66382

66382

3719

3719

10475

Right Door

66045

66045

STEP

1

66045

3719

10475

Left Door

66382

10497

6278

10497

66382

STEP

4 Insert a second bolt in the door

handle and tighten both bolts.

5 Put a horizontal door brace onto

the top edge and bottom edge and

fasten with 1 bolt in the center.

6 Attach the lower door guides and

bolts as shown.

7 Repeat steps 1 through 6 for the

left door.

STEP

66382

25

STEP

2

STEP

4

5

10497

3

END VIEW

SHOWING:

Horizontal

STEP

Door Brace

Guide

Door

Washer

6

Page 26

Step 16

YU26

● Parts Needed For ●

Door Installation & Adjustment

●●

● Right Door Assembly (1)

●●

●●

● Left Door Assembly (1)

●●

(8)

1 From inside the building, put the

bottom of the right door assembly (on

your left when you are inside the

building) behind door jamb into the

front frame track.

2 Position the top of the door so that

the holes in the door line up with the

holes in the door slides.

3 Fasten the door to the door slides

using two #10Bx1/2" (13 mm) screws

per door slide.

Gable

Door Track

Door Slide

Front Floor Frame Assembly

Horizontal Door Brace

Door

STEP

1

STEP

2

Door Slide

NOTE

The holes in the door slides allow

you to adjust the doors. Place the

door in the middle holes.

4 Repeat steps 1 through 3 for the

left door.

Adjustment Holes

Adjustment Holes Allow

Doors to Meet Evenly

Along Their Length

#10Bx1/2" (13 mm)

Screw

STEP

3

Right Door Left Door

STEP

4

Keep this Owner's Manual and Assembly Instructions for future reference.

26

Page 27

YU28

Anchoring

Anchor your building at this time.

EPA104

SOME FACTS ABOUT RUST

Rusting is a natural oxidizing process that occurs

when bare metal is exposed to moisture. Problem

areas include screw holes, unfinished edges, or

where scrapes and nicks occur in the protective

coating through normal assembly, handling and

use. Identifying these natural rusting problem areas

and taking some simple rust protection precautions

can help to stop rust from developing, or stop it

quickly as soon as it appears.

1. Avoid nicking or scraping the coating surface,

inside and out.

2. Use all the washers supplied. In addition to protecting against weather infiltration, the washers protect the metal from being scraped by the screws.

3. Keep roof, base perimeter and door tracks free of

debris and leaves which may accumulate and retain

moisture. These can do double damage since they

give off acid as they decay.

4. Touch up scrapes or nicks and any area of visible

rust as soon as possible. Make sure the surface is

free of moisture, oils, dirt or grime and then apply an

even film of high quality touch-up paint.

716450510

Loading...

Loading...