ARRI LOCPRO 35 User Manual

LOCPRO 35

Instruction Manual

As of: March 1999

ALL ARTWORK, PICTURES AND TEXTS ARE COVERED BY OUR COPY-RIGHT.

HEY MUST NOT BE COPIED FOR REPRODUCTION (E.G. ON CD-ROM DISKS OR INTERNET-SITES) OR USED IN THEIR ENTIRE FORM OR IN EXCERPTS WITHOUT OUR PREVIOUS WRITTEN AGREEMENT.

T

F YOU ARE DOWNLOADING PDF-FILES FROM OUR INTERNET HOME-PAGE FOR YOUR PERSONAL USE, MAKE SURE TO CHECK FOR UPDATED VERSIONS.

I

E CANNOT TAKE ANY LIABILITY WHATSOEVER FOR DOWNLOADED FILES, AS TECHNICAL DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE.

W

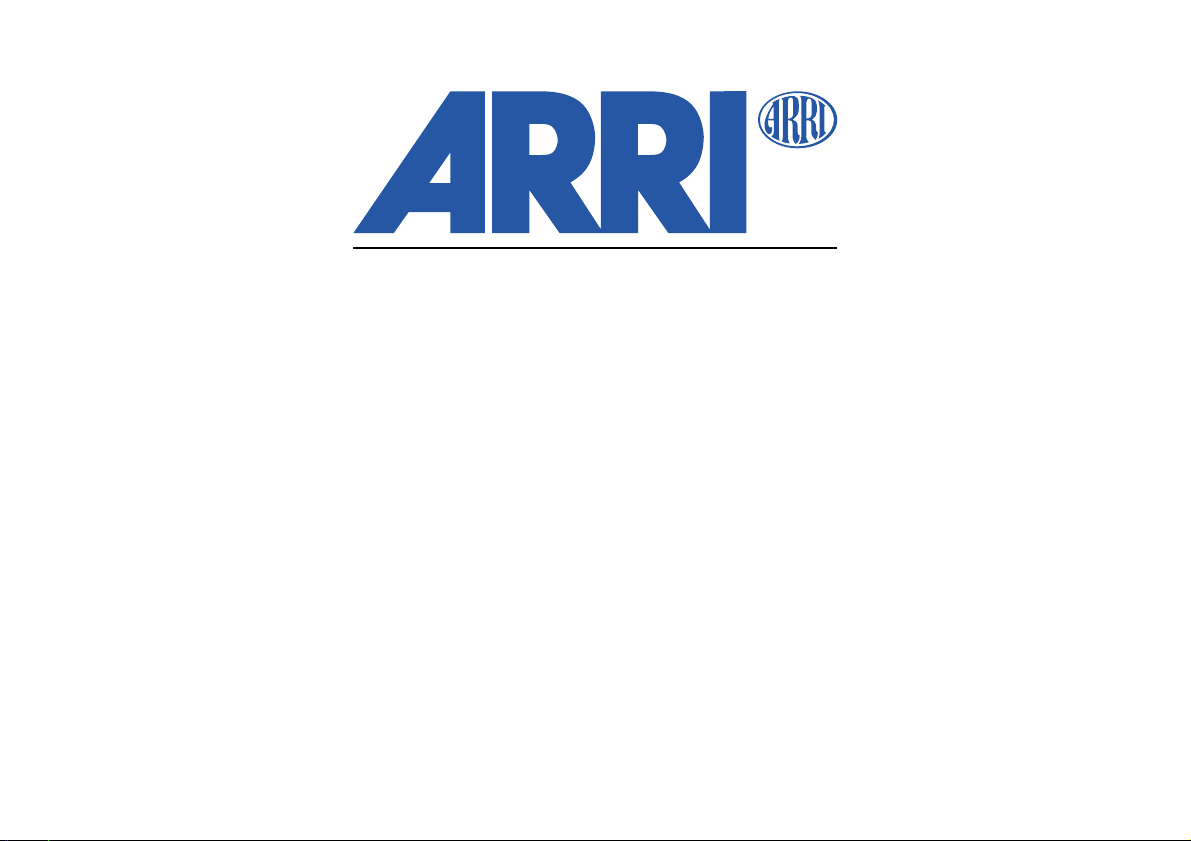

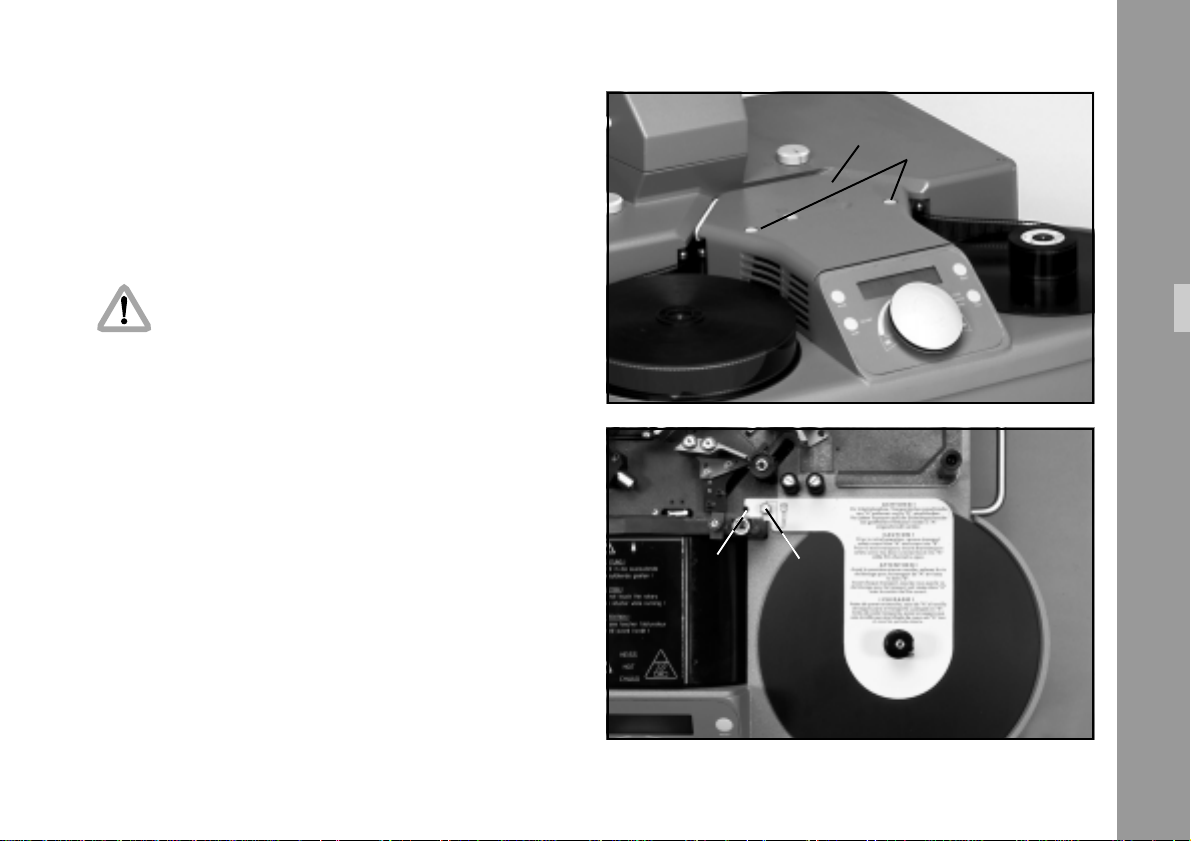

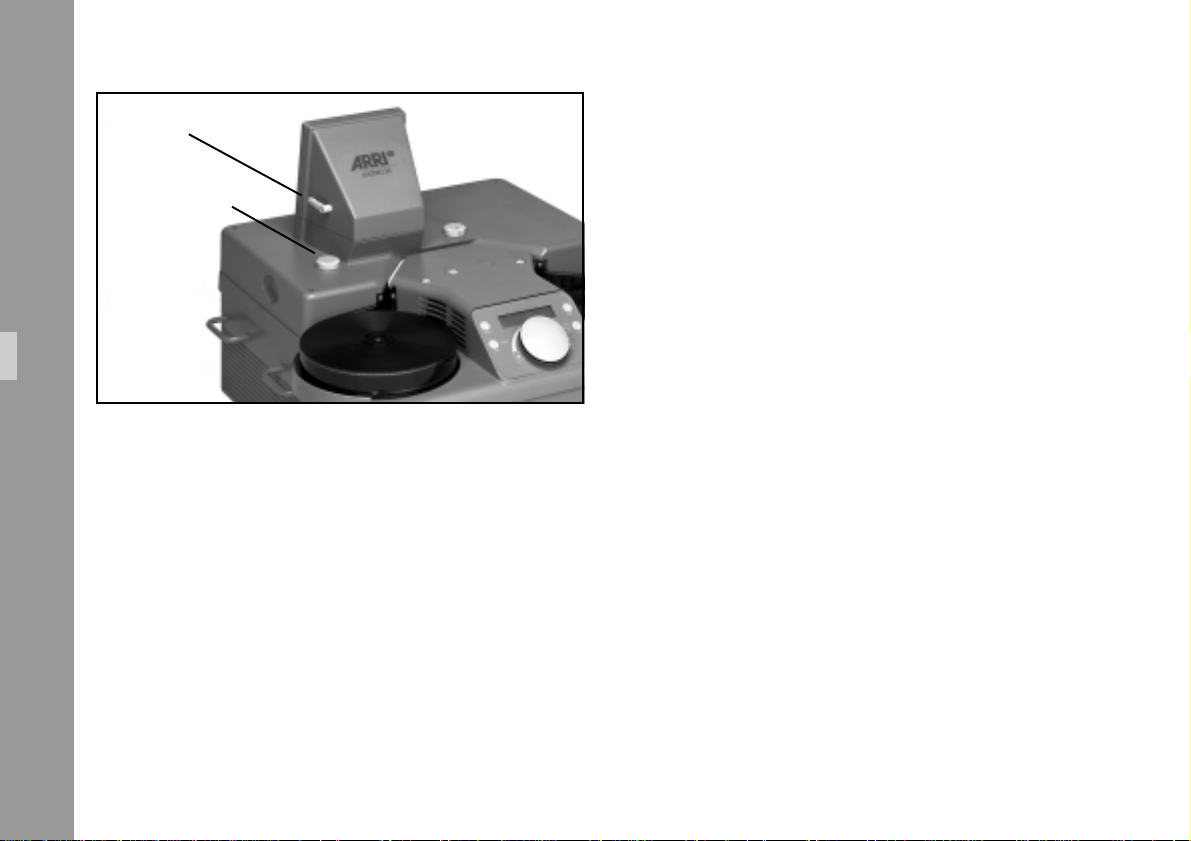

video setting knobadjusting lever

optics‘ cover

focus knob

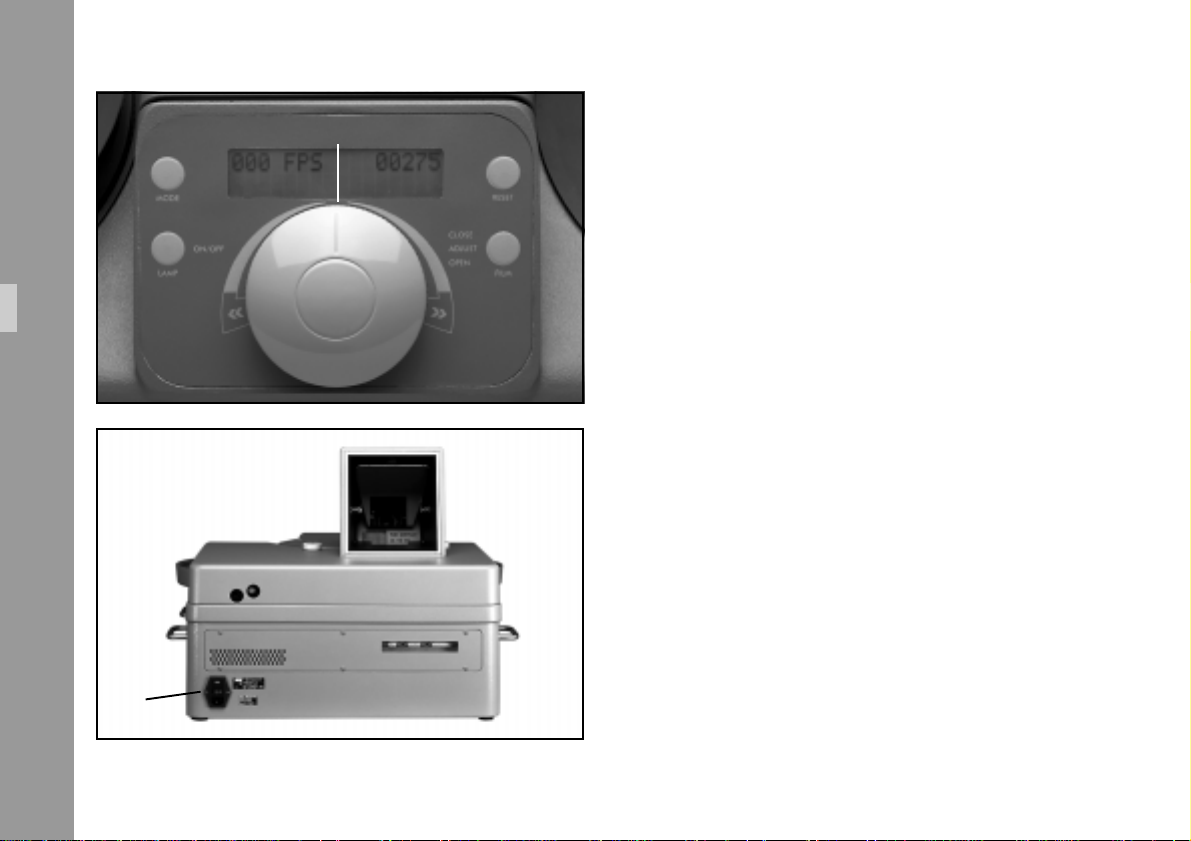

“Mode“ key

“Lamp“ key

Master Control

Knob

sliding switch

lamp cover

display

IR-Receiver

“Reset“ key

“Film“ key

1. Contents

1. Contents 3

2. Safety 5

3. General Product Information 7

4. Unpacking and Installation 9

5. Initial Operation 11

5.1 Precautions for Shipping .................... 11

5.2 Video-Option ....................................12

5.3 Format masks....................................13

5.4 IR-Remote Control .............................. 15

5.5 Switching on the LOCPRO 35 ............. 16

5.6 Switching on the HTI lamp .................. 17

5.7 Film loading ..................................... 18

5.8 Video...............................................19

6. Functions 21

6.1 Wall Projection ................................. 21

6.2 Highspeed Shuttle/Rewinding............. 25

6.3 Sprocket Projection ............................ 26

6.4 Loop Forming Position A/B ................. 27

6.5 Video...............................................29

6.6 ”Mode” Key (Unit Configuration) ........ 33

6.7 Controls ........................................... 36

6.8 Infrared Remote Control ..................... 41

6.9 Interfaces ......................................... 43

7. Service and Maintenance 45

7.1 Cleaning the Film Track...................... 45

7.2 Cleaning Mirror and Lens................... 47

7.3 Shipping and Storage ........................ 48

7.4 Replacing the Fuses ........................... 48

8. Technical Data 51

Serial Interface (X1) .................................... 53

Contents

3

9. Trouble-Shooting Table 55

10. ARRI Service 68

11. Index 69

Contents

Annex Interfaces 79

Service Instructions 80

4

2. Safety

The functions and workmanship quality of this unit were

tested at the factory. It complies strictly to the following

European Guidelines:

• Guideline 89/336 EEC of 3. May 1989

”Guideline of the Council of 3. May 1989 for bringing

into line the statutory regulations of the member

countries about electromagnetic side-effects.”

• Guideline 73/23 EEC of 19.02.73

”Guideline of the Council of 19. Feb. 1973 for

bringing into line the statutory

regulations of the member countries with respect to

electrical operating material for use within particular

voltage limitations.

The electric installation of the room in which the LOCPRO 35

is being used must comply with the demands of the IEC

commitments.

Warnings

For your own safety, please adhere to the following warnings:

Caution! – stands for danger of injury.

Attention!– equipment damage possible.

Note: Operational error possible!

General Safety Specifications

Caution: Danger of Injury!

Never reach into the film channel

while the LOCPRO 35 is running

or remove the covers!!

• In order to ensure safe and proper operation it is

essential that you acquaint yourself with this user

manual.

• Assembly and initial operation are to be carried out

only by persons familiar with the equipment.

Safety

5

• Make sure the LOCPRO 35 stands securely and do not

block the air vents of the HTI lamp cooling fan on the

bottom side! See ➪ photo page 9.

• Keep all inflammable material away from the air vents

Safety

of the HTI lamp cooling fan.

see ➪ photo page 9.

• For sufficient air cooling, it is essential that the air

supply and escape vents on the sides are not blocked.

see ➪ photo page 9.

• Disconnect the unit from the mains before starting

maintenance or service!

Important Notes

• In humid weather please take the usual and customary

safety measures.

• In case of poor picture steadiness check the film guide for

possible contamination, such as e.g. splicing residues

or emulsion deposits.Clean if necessary! (see chapter 7.1)

• Optical surfaces should only be cleaned with an optic

cleaning brush. To remove sticky emulsion deposits, please

use an optic tissue, moistened with pure alcohol.

• Do not use solvents for cleaning!

• The unit is to be opened only by a qualified electrical

specialist. If fuses need to be replaced, ensure that

only the values indicated are used. See chapter 7.4.

• Repairs should be made by authorized service technicians only!

• Use only original replacement parts and accessories!

• Do not loosen the paint-secured screws!

Product Identification

Please always refer to the model type and unit serial number

when ordering spare parts or requesting information.

Explanation of the Symbols

• Follow the maintenance instructions in this user manual.

➪ photo refers to objects identified by pictures, photos

• Follow the shipping and storing instructions.

6

or graphs.

3. General Product Information

The LOCPRO 35 is a lightweight mobile projector for onlocation use. A switch-over mirror system allows either wall

projection or the use of a 1/3” CCD Color High Resolution

video camera. The LOCPRO 35 can synchronize DAT-recorders or perfotape players for picture/sound synchronization.

The following sync signals are available for output: For

synchronization with DAT recorders a timecode LTC signal,

for synchronization with perfotape players in connection

with ASU-accessory (Audio Sync Unit) a biphase signal

with a programmable number of pulses per picture.

•

Fast film transport and simple operation:

The film is transported by a motor with a directly-driven

double-sided sprocket wheel. This patented intermittent

film drive system is acute to less than 0.01 seconds at

any projection speed. Constant film tension and safe

film transport are ensured by computer-controlled drive

motors for both film carriers. The ”auto-stop” feature

stops the film automatically 6 ft (2 m) before the end

of the film.

Automatic detection of the winding direction makes it

unnecessary to manually switch over from winding

direction A to B.

The open film channel facilitates film loading once the

film has been placed onto the winding plate. All steps

from the formation of loop sizes to standby operation

are carried out fully automatically. In addition, a film

can be removed at any time even in the middle of a

film roll.

•

Direct high speed rewinding:

High speed rewinding and quick location of certain film

scenes is easily possible with the gentle high speed

shuttle/rewinding system. By simply turning the Master

Control Knob this system allows you to switch directly to

high speed winding at 200 fps and back to the chosen

projection speed. The frame counter remains active so

that after switching back from high speed winding to

projection speed, the frame line is automatically

repositioned to the correct setting.

General Product Information

7

•

Excellent image quality with flicker-free projection:

Best possible image brightness, excellent picture steadiness and image quality are the outstanding features of

the LOCPRO 35. The 400 W HTI lamp allows optimum

projection of more than 6 ft (2 m) image width and an

average color temperature of 5.400°K.

The built-in video camera (optional) can be connected

to a monitor, video recorder or video printer. Two video

outputs are available, FBAS (BNC) and Y/C. In addition,

it is possible to mask the video image electronically to

match the different film formats as required.

•

Telecine Mode (Pulldown Mode):

Flicker-free transfer onto video tape at 24, 25 or 30 fps

is possible depending on the integrated video system 50 Hz PAL or 60 Hz NTSC. In both cases, the integrated

video camera synchronizes frame transport.

•

Sound Synchronization:

To synchronize DAT-players an LTC signal (timecode)

output is available. In connection with an ASU, a

biphase signal (synchronized picture change signal with

forward/reverse recognition) allows for synchronization

of perfotape players. For the adaption to different

perfotape players it is possible to program on the ASU

General Product Information

the pulses per picture and the max. acceleration.

The LOCPRO 35 is available in the following versions:

• LOCPRO 35 St 230V/50Hz. ...... Id.No. M1.83000.0

• LOCPRO 35 St 115V/60Hz. ......Id.No. M1.83000.A

• LOCPRO 35 TV 230V/50Hz. ..... Id.No. M1.83000.B

with integrated CCD video camera (PAL)

• LOCPRO 35 TV 115V/60Hz. ..... Id.No. M1.83000.C

with integrated CCD video camera (NTSC)

8

4. Unpacking and Installation

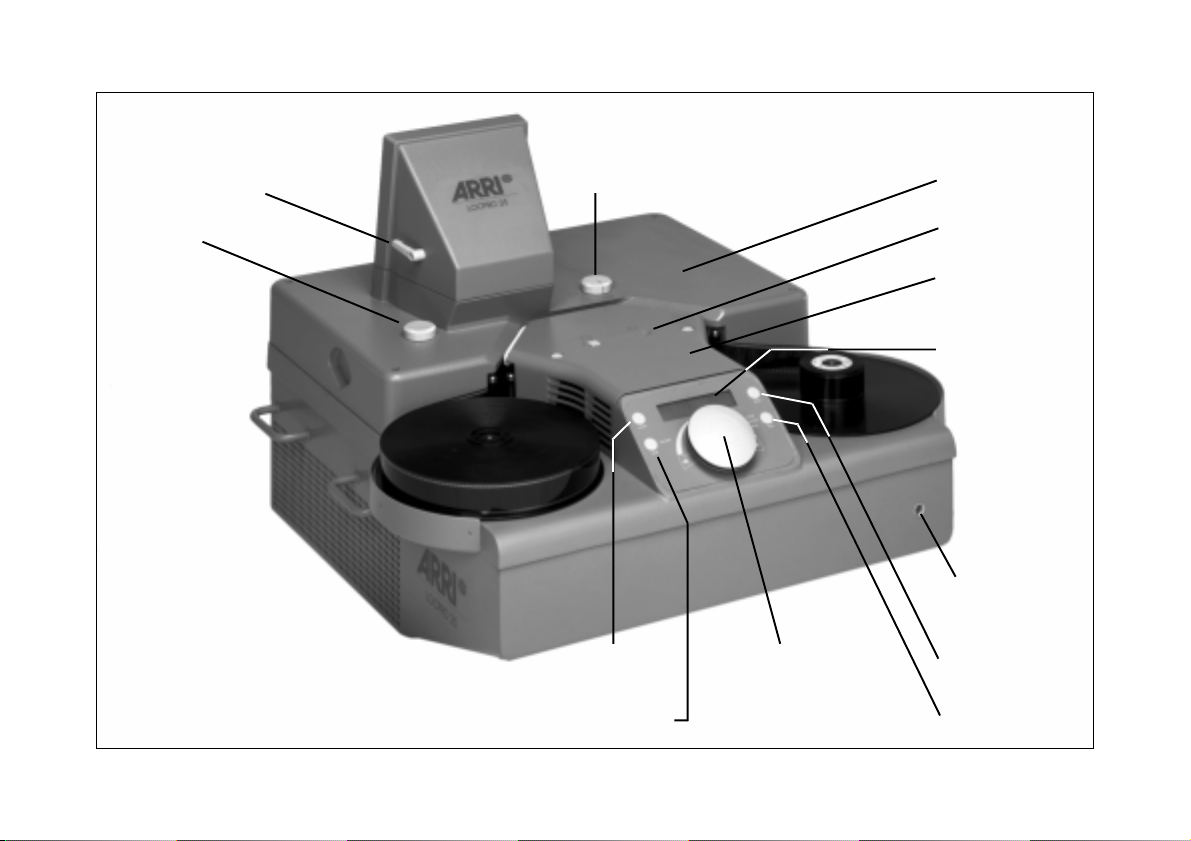

min. 100 mm min. 3.9"

In order to prevent condensation from forming on individual

components, the LOCPRO 35 should be kept in its packing

an additional day (before unpacking), if the temperatures

during shipping (cold) vary extremely from those temperatures in the installation area (warm).

1) Cut off the packing straps.

2) Lift off the packing in an upward direction.

3) Take out the additional items (User Manual, projection

lamp, accessories, maintenance kit).

4) Remove the plastic foil.

5) Always transport the projector to its destination in its

shipping or projection case and lock caster lock levers.

Note: Optimum wall projection of 2300 mm (6.6ft) is

reached when the LOCPRO 35 is installed in such

a way that there is a distance of 4 m (12 ft) between the back of the unit and the projection wall.

min. 100 mm

min. 3.9"

RESET

MODE

CLOSE

ON/OFF

ADJUST

OPEN

LAMP

FILM

min. 300 mm min. 11.8"

LOCPRO 35

min. 300 mm

min. 11.8"

min. 500 mm

min. 19.7"

Unpacking and Installation

9

The LOCPRO 35 must stand on a solid flat

surface and should be disconnected from the

mains before it is moved.

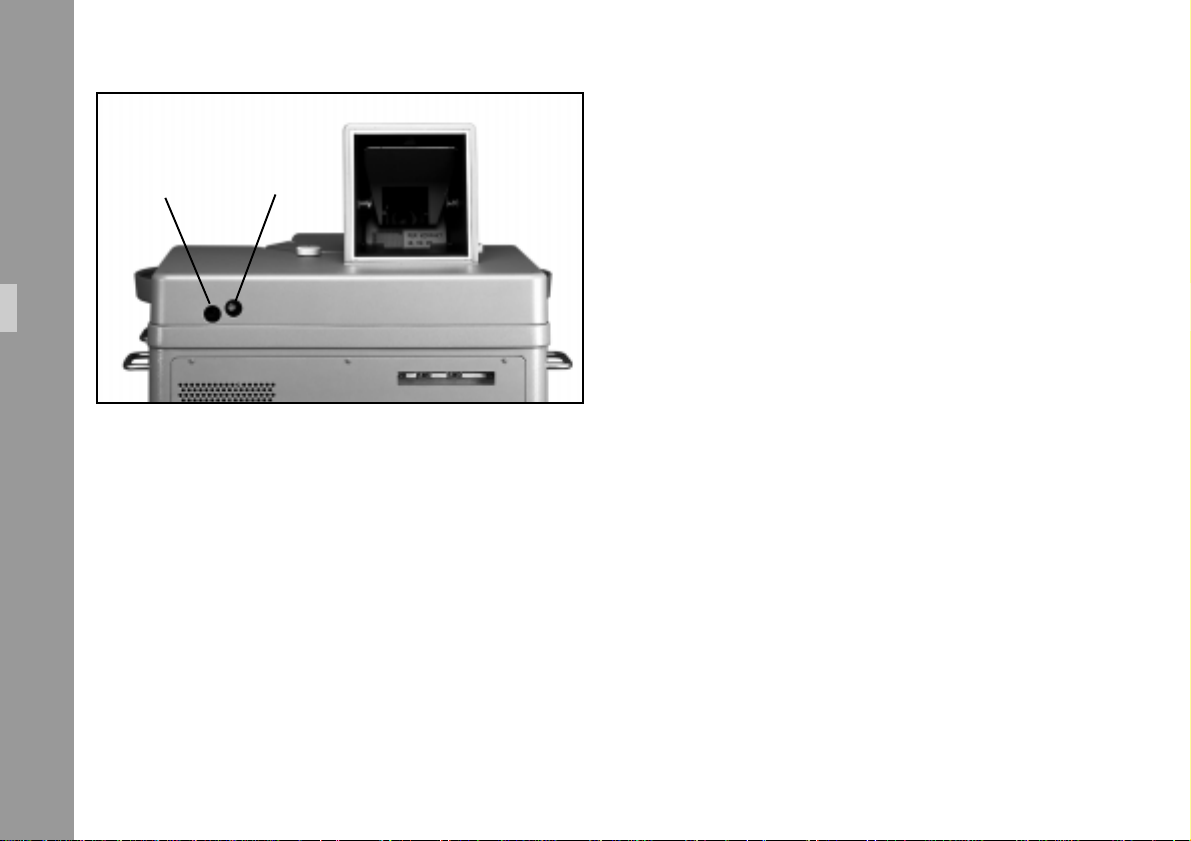

Lift the LOCPRO 35 out off its shipping case and set it up

in such a way that the air vents on the bottom of the lamp

cooling fan ➪ photo are not obstructed. Observe the

clearances on the top and sides, see ➪ photo page 9.

Keep all flammable materials away from the

exit vents of the lamp fan.

Do not cover up the HTI ventilation ducts.

Unpacking and Installation

10

5. Initial Operation

5.1 Precautions for

Shipping

In order to avoid shipping damage the safety

screw must always be screwed in each time the

unit is transported..

1) Depress spring-loaded latches on lamp cover

➪ photo and lift off lamp cover.

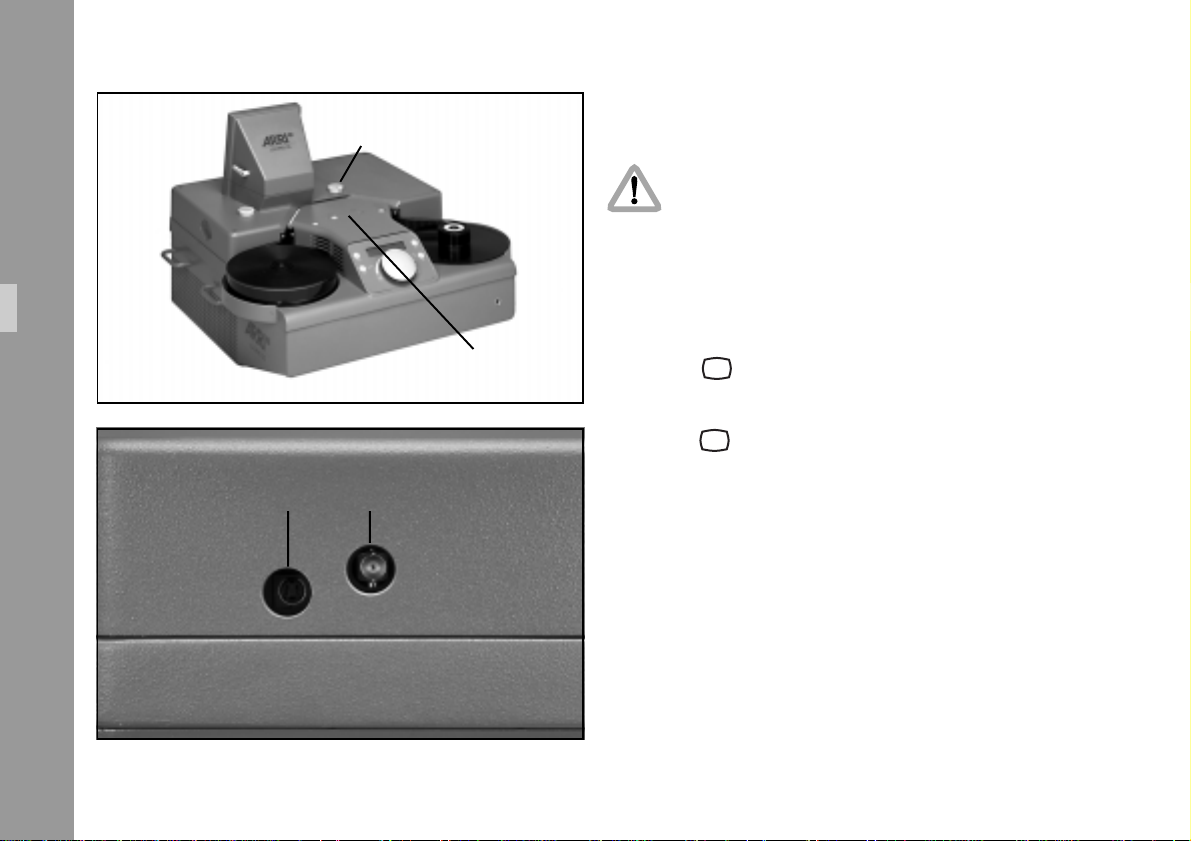

lamp cover

spring loaded latches

2) Remove the shipping safety screw ➪ photo.

To store the screw for subsequent use, screw it into the

bore-hole ➪ photo.

Initial Operation

bore hole safety screw

11

setting knob

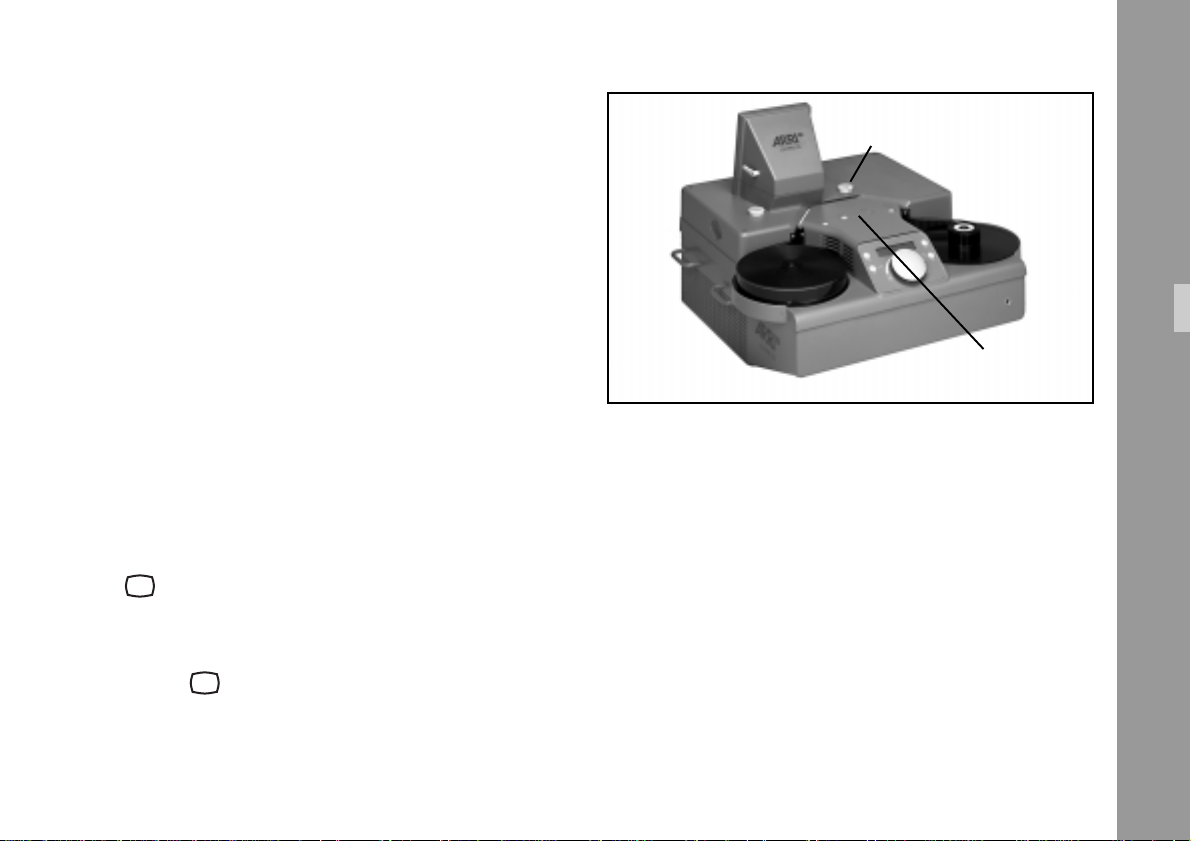

5.2 Video-Option

The LOCPRO 35 must be switched off before

connecting it to an interface cable or DATrecorder or perfotape player.

1) Connect the monitor via BNC-or Y/C-cable to the

appropriate socket ➪ photo on the LOCPRO 35.

Initial Operation

Y/C-socket

12

BNC-socket

slide switch

2) Set mirror with selection knob ➪ photo to the TV

symbol.

3) Shift slide switch on lamp cover ➪ photo to the TV

symbol.

Note: Video ”on/off” is only possible when the

Master Control Knob is in the ”0” position, i.e.

when the film is not being transported.

4) Switch on TV monitor.

5) Adjust monitor for optimum image quality.

5.3 Format masks

The standard aperture size of 18.6 x 24 mm can be

adapted to the various projection formats by using format

masks.

The following masks are available:

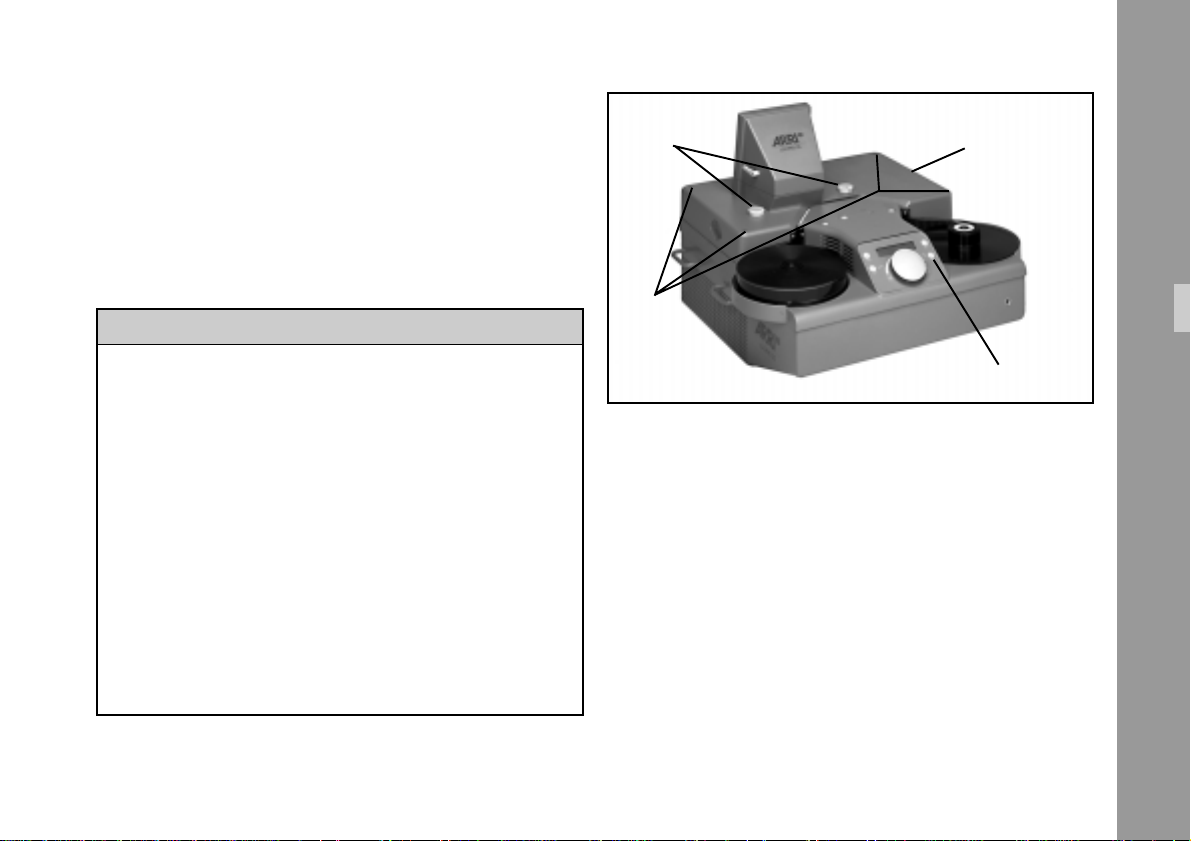

hoodcontrol knobs

Type ........................................................... Ident No.

Film Gate Mask Set (13 masks incl. case) . M2.81853.0

Mask 1:1.37 ACAD ............................... M2.81876.0

Mask 1:1.66 WIDE SCREEN ................... M2.81877.0

Mask 1:1.85 WIDE SCREEN ................... M2.81878.0

Mask 1:2.35 SUPER 35 .......................... M2.81885.0

Mask 1:1.85 SUPER 35 ......................... M2.81882.0

Mask 1:1.78 HDTV S35......................... M2.81881.0

Mask 1:1,78 HDTV ................................ M2.81879.0

Mask 1:1.66 SUPER 35 .......................... M2.81880.0

Mask 1:1.33 TV-ISO .............................. M2.81875.0

Mask 1:2.35 S 35 ABOVE ...................... M2.81886.0

Mask 1:1.85 S 35 5 VERS ...................... M2.81883.0

Mask 1:1.8 S 35 5.7 VERS. .................... M2.81884.0

Mask 1:1.78 SUPER 35 HDTV –3-PERF: ... M2.81908.0

4 screws

“Film“-key

5.3.1 Exchanging the film gate

format mask:

Insert format mask:

• Open the film channel with ”Film” – key

• Switch off the main power supply.

• Remove optics cover.

Remove the control knobs and the 4 screws with an

Allen key SW3. See Chapter 7.2 (# 2)

Initial Operation

13

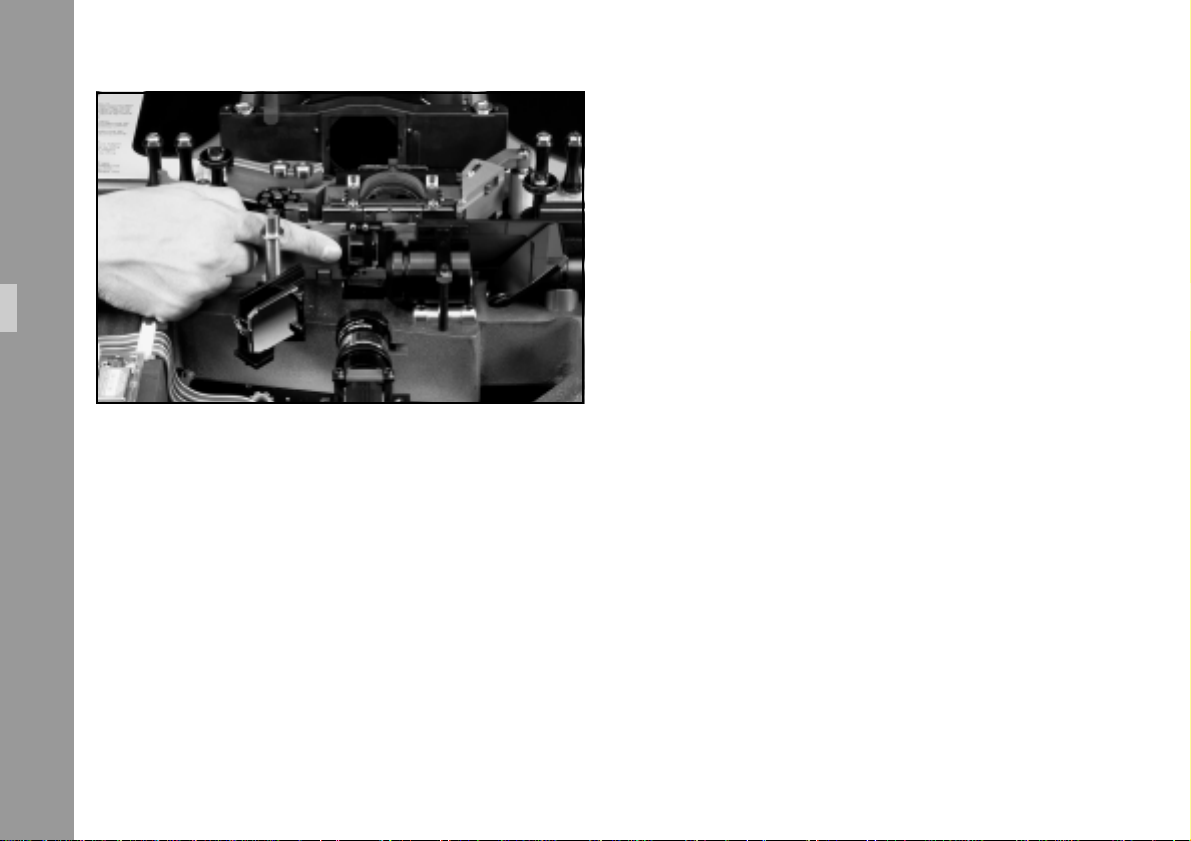

• Remove lens. See Chapter 7.2 (# 4)

Initial Operation

• Check that the film gate frame and the surface of the

film track are clean.

• Replace lens.

• Replace optics cover.

Remove format mask:

• Open film channel with ”Film” – key

• Switch off main power supply.

• Remove optics cover. See Chapter 7.2 (# 2)

• Remove lens. See Chapter 7.2 (# 4)

• Remove the mask from the film gate by gently pressing

back the mask and then sliding it back out to the right

➪ photo.

14

• Insert the format mask with the film gate frame facing

the film gate (frameless side facing upward) by sliding

the mask in from the right side into the spring-loaded

support of the film track until the mask engages with

the film gate.

• Check the film gate mask for correct positioning.

• Replace lens.

• Replace optics cover.

5.4 IR-Remote Control

The IR-Remote Control (an accessory) consists of a handheld transmitter ➪ photo and a receiver ➪ photo

mounted on the front of the LOCPRO 35.

In order to guarantee trouble-free operation, there should

be no partition walls or other obstacles between transmitter

and receiver.

• Unpack the remote control and insert the batteries

making sure to observe the correct polarity.

IR-receiver

Initial Operation

15

master control knob

Initial Operation

mains switch

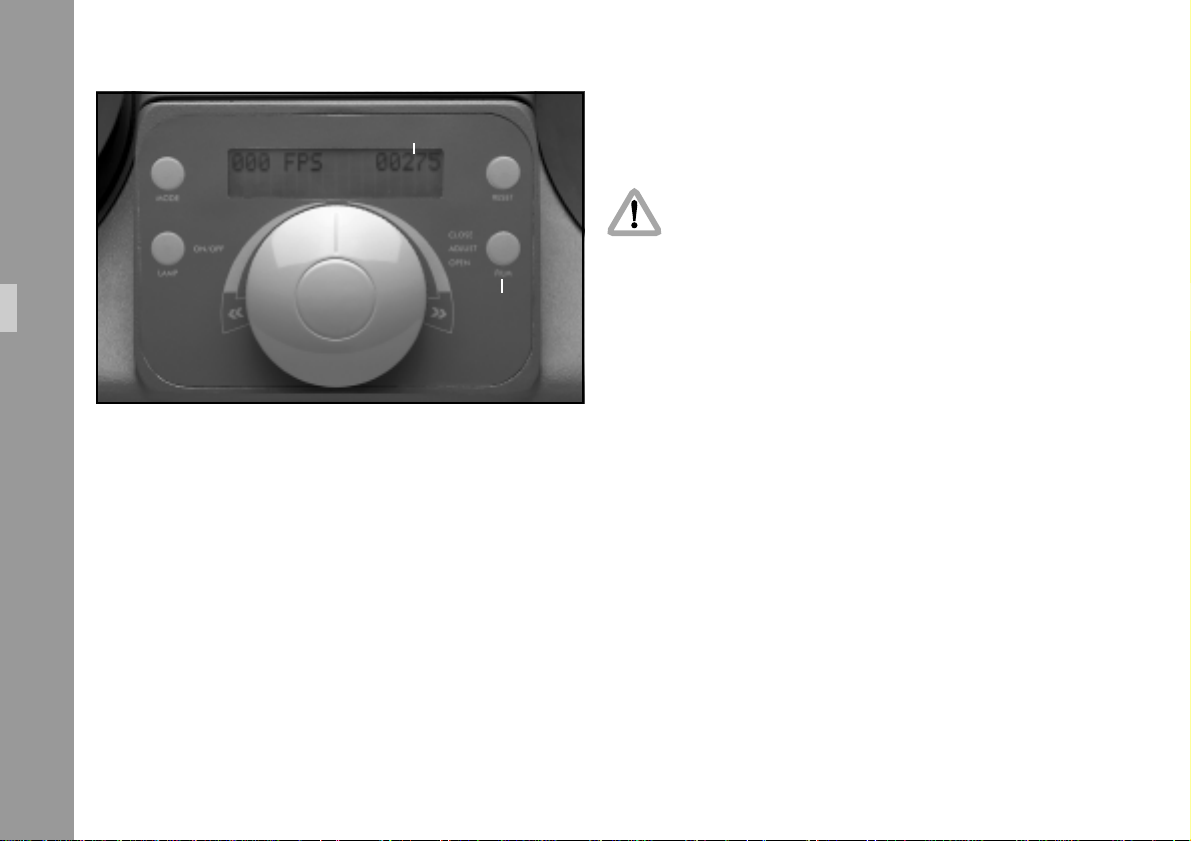

5.5 Switching on the LOCPRO 35

1) Set the Master Control Knob ➪ photo to ”0” position.

2) Switch on the mains switch ➪ photo on the back of

the unit.

16

5.6 Switching on the HTI lamp

Before switching on the HTI lamp, please ensure that

• The Master Control Knob ➪ photo is in the ”0” position.

• Film is not running in the projector.

1) Depress ”lamp” key for approx. 1 second to ignite the

lamp. During this ignition phase, which lasts approx.

5 seconds, all key functions are disabled.

master control knob

“lamp“-key

2) The HTI lamp can be switched off after a reset time of

5 seconds by depressing the ”lamp” key again.

Note: Run-up time to full light power is approx. 40

seconds. Working temperature of the lamp is

reached in three minutes. During this period the

lamp should never be switched off, because this

gradually reduces the life of the lamp and

results in poor ignition behavior.

Initial Operation

Note: The average life of an HTI lamp

is approx. 750 hours.

Spare lamps can be ordered under

Id.No. 05.09873.0.

17

frame counter

3) Insert film into the film channel and fix end of the film

in the film core of the right winding plate. Then wind

up approx. three turns.

Ensure same winding direction on both plates!

To avoid damage of film track do not use

stapled film.

Initial Operation

5.7 Film loading

1) Place the film roll with the neg. film on the left film

plate so that the emulsion side is facing the operator.

If a print film is projected, the emulsion side must be

on the opposite side.

2) Open the film channel by depressing ”film” key ➪ photo

for some time (>1s).

18

“film“- key

4) Tighten both film rolls.

5) Press ”film” key briefly.

The feed carriage closes the film channel.

The film loop is formed automatically and the frame

counter ➪ photo is reset to ”0”.

Note: Inside or outside winding direction (A/B) are

recognized by the projector.

5.8 Video

As an option, the LOCPRO 35 can be equipped with a

video system.

5.8.1 Video camera

The LOCPRO 35 TV is available with two video camera

versions.

50 Hz unit:

50 Hz shutter (open sector 79°) with PAL video camera.

60 Hz unit:

60 Hz shutter (open sector 71°)with NTSC video camera.

Starting video camera operation

setting knob

slide switch

Initial Operation

1) Swing the mirror out of the optical path to the TV symbol

with selection knob ”video” ➪ photo.

2) Shift the slide switch ➪ photo to the right to the TV

symbol .

Note: Switch-over to video operation is only possible

during still projection and when film is not being

transported (sync phase of revolving shutter

from internal quartz to video synchronization).

19

FBAS (BNC)S-VHS (Y/C)

Initial Operation

5.8.2 Video outputs TV

Video output sockets provide FBAS (BNC) ➪ photo and

S-VHS (Y/C) ➪ photo signals from the color CCD video

camera.

A monitor, video recorder, video printer can be connected

to the LOCPRO.In addition the video images can be

transferred to an image processing computer.

20

6. Functions

6.1 Wall Projection

The LOCPRO 35 must stand on a solid, flat

surface and should be completely disconnected

from the mains before it is moved.

See also notes in chapter 4.

Optimum wall projection of approx. 2.3 m (7 ft) width is

reached at a distance of 4 m (12 ft), measured from the

back of the unit to the projection wall.

6.1.1 Frame line

master control knob

“film“- key

Functions

After closing the film channel (see chapter 5.7), adjust the

frame line, if necessary.

Note: Frame line adjustment is only possible during

still projection.

1) Master control knob is in ”0” position (no film transport).

2) The frame line (horizontal line in the projected picture)

can be shifted out of the visible picture by briefly

depressing the ”film” key ➪ photo.

Each keystroke shifts the frame line by 1/4 frame.

21

adjusting lever

focus knob

Functions

6.1.2 Image Position and Focus

• The projected image can be tilted upward up by 15°

with the projection height adjusting lever ➪ photo.

• Focus is adjusted with the rotary focus knob ➪ photo.

22

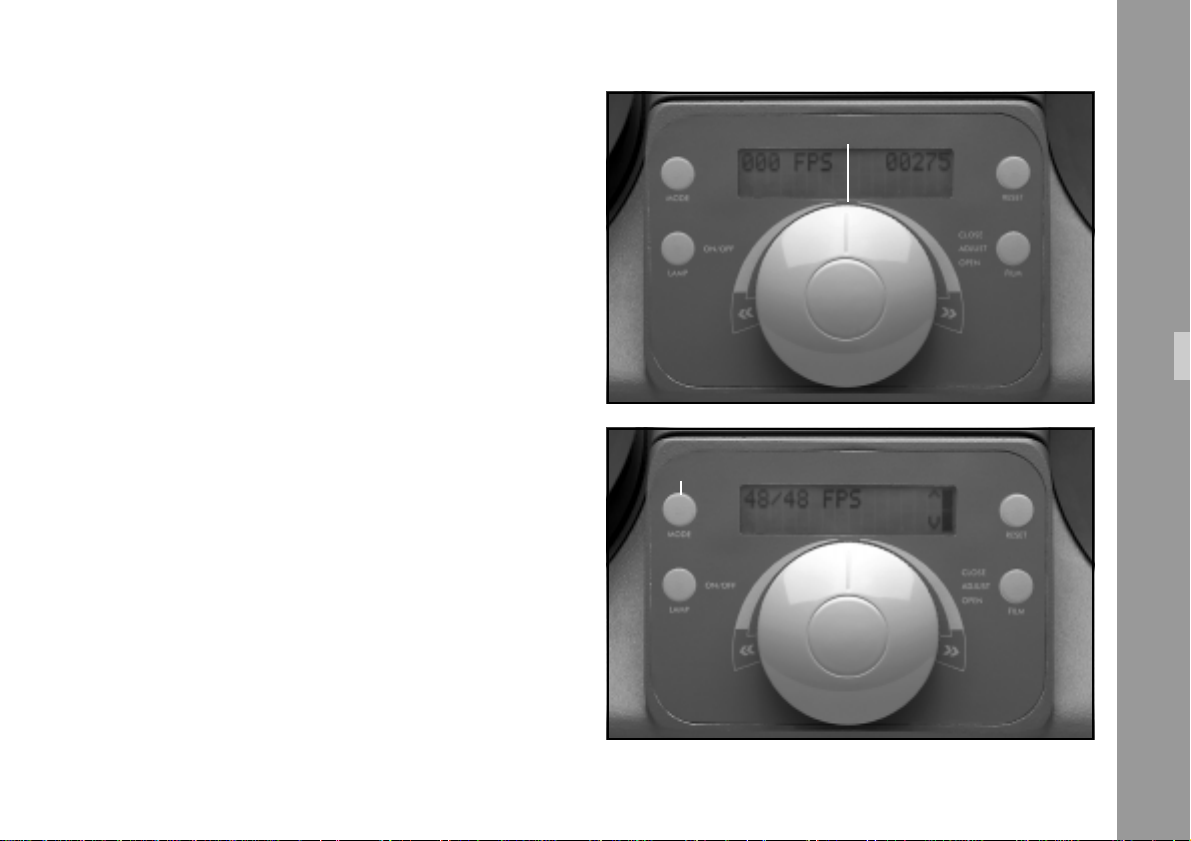

6.1.3 Frame Rate

The frame rate can only be set after the mains has been

switched on and the film channel is closed. Ensure that

the Master Control Knob ➪ photo is reset to ”0” each

time after the film channel has closed.

master control knob

1) Select the requested frame rate (visible on the display)

by turning the Master Control Knob ➪ photo. The

film now runs at the selected speed.

The following frame rates can be chosen for forward and

reverse operation:

• 50 Hz Version

1.56-3.12-6.25-12.5-25-50 fps (standard)

Highspeed shuttle 200 fps

48-24-30 fps can be selected directly via ”Mode” Key

➪ photo (see chapter 6.6).

• 60 Hz Version

1.87-3.75-7.5-15-30-60- fps (standard)

Highspeed shuttle 200 fps

48-24-25 fps can be selected directly via ”Mode” Key

➪ photo.

Functions

“Mode“- key

23

Note: The reduced running speeds (1 per

thousand with switched on NTSC

video operation) are displayed as the

non-reduced speeds, e.g. 59.94 fps is

displayed as 60 fps.

Functions

2) In ”0” position (center position) the film transport is

stopped.

3) The ”autostop” stops the film run approx. 2 m (6 ft)

before the film end.

Attention: Film channel cannot be opened

during film run.

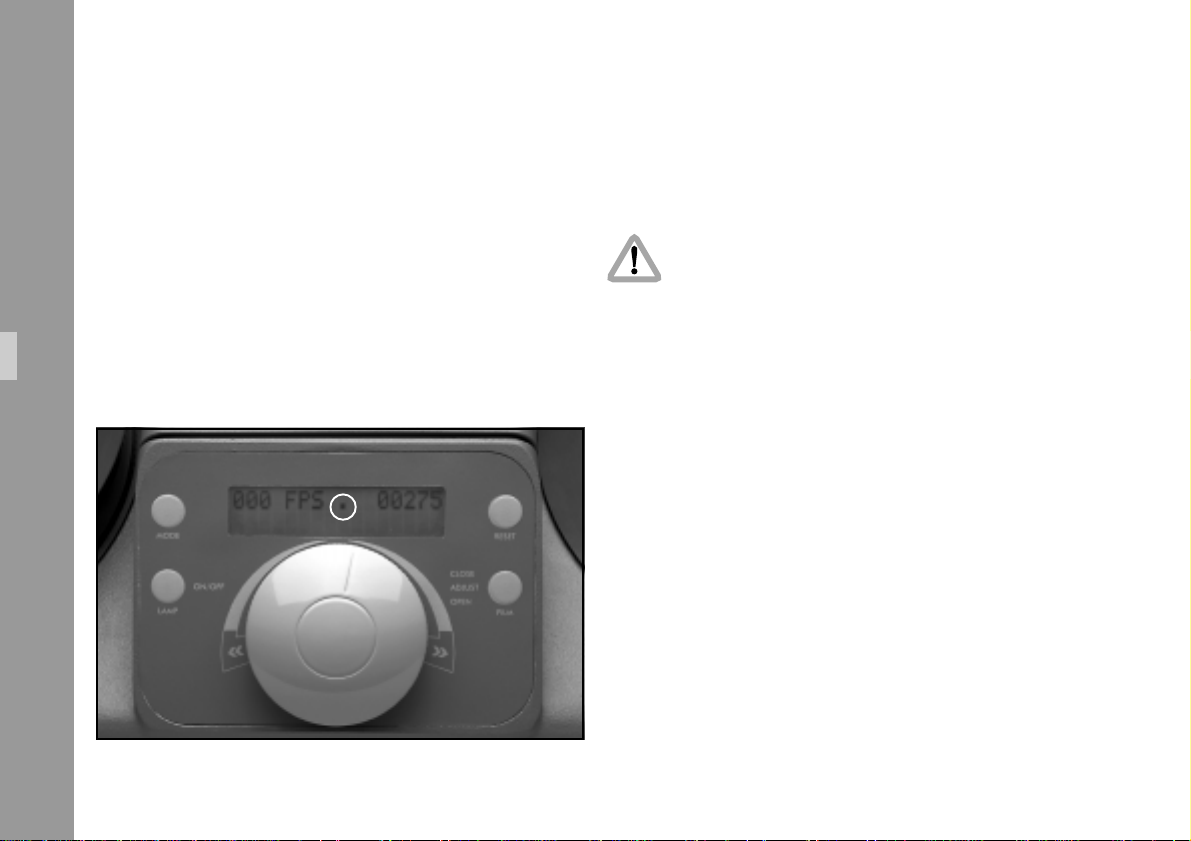

6.1.4 Single Frame Operation

If, during still projection, the Master Control Knob is turned

only slightly to the right or left of the ”0” position so that film

transport has not yet started, single frame release is possible. In

this case, a dot appears in the center of the display ➪ photo.

1) By briefly depressing the ”Film” Key, the film is

advanced by 1 frame.

2) If the Master Control Knob is turned to the left of the

”0” position, then single frame release to the left

becomes active. When turning to the Knob to the

right, single frame to the right is activated.

24

Note: Single frame operation is also possible via IR

remote control.

6.1.5 Autostop Function

In order to prevent the film from unintentionally running

out to the end, the auto-stop feature automatically stops

the film approx. 2 m (6 ft) before the end. This applies to

both film plates.

master control knob

Note: The auto-stop function is only ensured if the film

core used coincides with the value selected in

mode 4 (”more config” ”bobby size”).

Selectable diameters are 50 (2“), 75 (3“) and

100 mm (4“).

Disabling the Auto-stop Function

• To run the film completely through the film channel

without end stop, press the ”Film” Key ➪ photo

during projection or high speed shuttle. The frame

counter display flashes, the auto-stop feature is

disabled and the film runs through the film channel

without stopping.

The auto-stop function is reactivated by changing the

direction of film transport with the Master Control Knob.

Functions

“film“- key

6.2 Highspeed Shuttle/

Rewinding

By turning the Master Control Knob ➪ photo beyond the

highest projection speed to the left or right, the film runs at

a speed of approx. 200 fps in the selected direction.

During this high speed transport mode the film stage is

lifted up by magnets for safer film transport. When

releasing the Master Control Knob, film transport is

reduced to fastest projection speed.

25

Loading...

Loading...