Armstrong World Industries HWC PREMIER 302, HWC PREMIER 123, HWC PREMIER 183, HWC PREMIER 243, HWC PREMIER 203 User Manual

...

Service Reference Manual

HWC Thru-the-Wall Units

Models:

HWC Premier 122, 182, 242, 302 123, 183, 243, 303

Copyright © 1998

Armstrong Air Conditioning Inc.

All rights reserved.

Disclaimer

This manual presents information and guidelines for proper installation, adjustment, operation and maintenance of Armstrong Magic-Pak HW/HWC Thru-the-Wall units. Read this manual before attempting assembly, installation, start-up, adjustment or operation of the unit. If you have any questions about the operation of the unit or a particular safety device, call or write Armstrong Air Conditioning Inc., 421 Monroe Street, Bellevue, Ohio USA 44811. Telephone: 419- 483-4840 Fax: 419-483-3557

The documentation and drawings contained in this manual are intended as a general guide, and may not reflect exactly the current designs, or all of the options available to our customers.

Please call or write Armstrong Air Conditioning Inc. regarding specific details of a particular furnace model, configuration or installation.

The information and specifications contained in this manual are subject to change without notice. Armstrong Air Conditioning Inc. reserves the right to change such specifications at any time without incurring obligation. Every effort has been made to ensure the accuracy of the information in this manual. For the most current information, please contact the Armstrong Customer Service Department.

This document is confidential. All information within is the sole property of Armstrong Air Conditioning Inc. and is loaned for mutual assistance. It may not be used for any purpose other than originally intended, without prior written consent of Armstrong. It is not intended for use by homeowners or as a guide for do-it-yourself projects. It provides specialized information for use by qualified service personnel, who have the proper equipment, training and experience necessary to safely install, repair, adjust and maintain the Magic-Pak units and components described within.

SRM-HW/HWC 8/99

|

Service Reference Manual |

TABLE OF CONTENTS |

|

|

||

|

|

TABLE OF CONTENTS |

|

|||

|

|

|

||||

|

|

1 |

- Specifications |

|

||

|

|

2 |

- Sequence of Operations |

|

||

|

|

3 |

- Unit Tear Down |

|

||

|

|

4 |

- Component Location Illustrations |

|

||

|

|

5 |

- Unit Components |

|

||

|

|

6 |

- Installation |

|

||

|

|

7 |

- Accessories |

|

||

|

|

8 |

- Parts Lists |

|

||

|

|

9 |

- Troubleshooting/Performance/ |

|

||

|

|

|

Charge Weights |

|

||

|

Go to: |

If you need information on: |

|

|||

|

|

|

|

|

||

|

Section 1 |

Performance, electrical data and cabinet dimensions. |

|

|||

|

Section 2 |

Sequence of operation descriptions with accompanying schematics. |

|

|||

|

Section 3 |

Complete description of unit disassembly. |

|

|||

|

Section 4 |

Locations of major components of HW/HWC models. |

|

|||

|

Section 5 |

Illustrations and specifications for individual components including valves, |

|

|||

|

|

blowers, ignition controls and blower control boards. |

|

|||

|

Section 6 |

Installation requirements and startup guidelines. |

|

|||

|

Section 7 |

Complete listing of all Armstrong accessories available, including wall |

|

|||

|

|

sleeves, louvers and gas conversion kits. |

|

|||

|

Section 8 |

Complete service parts lists for all HW and HWC models. |

|

|||

|

Section 9 |

System check and troubleshooting procedures. |

|

|||

SRM-HW/HWC 8/99

Service Reference Manual |

SPECIFICATIONS |

1-1

Section 1 - Specifications

Models Covered By This Manual ............ |

1-2 |

Model Number Guide ............................ |

1-2 |

Product Serial Numbers |

|

(Beginning 1993) ................................. |

1-2 |

Summary of Model Revisions/Variations 1-3 |

|

Heating Configuration Table ........................ |

1-3 |

Cooling Configuration Table ......................... |

1-3 |

HW/HWC ............................................ |

1-4 |

Physical and Electrical ................................ |

1-4 |

Performance Ratings .................................. |

1-4 |

Blower Performance ................................... |

1-6 |

Dimensions ................................................ |

1-6 |

Wall Sleeve................................................ |

1-7 |

SRM-HW/HWC 8/99

SPECIFICATIONS |

Magic-Pak: HW/HWC |

1-2

Models Covered By This Manual

HWC Gas Heating/Electric Cooling Units

HW122, 123

HW182,183

HW242, 243

HW302, 303

HW Gas Heating Only Units

26HW

38HW

51HW

64HW

Model Number Guide

HW/HWC Models |

26 H W C 12 2 -- 2A |

|

|

26 = Rated Input BTU/Hr x 1000

H = Gas Heat

W = Thru-the-Wall

C = Cooling

12 = Nominal Cooling BTU/Hr x 1000

2 = Cooling Efficiency 2 - 9.7 SEER

2A = Revision Code

Product Serial Numbers, Beginning 1993

84 |

95 |

A |

12345 |

84 = Armstrong Factory Number

95 = Year (ex: 1995)

A = Month (see list below)

12345 = Sequential Number

A = Jan |

B = Feb |

C = Mar |

D = Apr |

E = May |

F = June |

G = July |

H = Aug |

J = Sept |

K = Oct |

L = Nov |

M = Dec |

HW/HWC-SRM

8/99

Service Reference Manual |

SPECIFICATIONS |

1-3

Summary of Model Revisions/Variations

Table 1-1 Heating Configurations of HW/HWC Units

Model |

Configuration |

AFUE |

Ignition/Blower Control |

Ignition |

|

Type |

|||||

|

|

|

|

||

|

|

|

|

|

|

(All) HWC (123, 183, 243, 303) -1 |

Gas Heat/ |

80 |

UTech Combination Ignition/Blower Control 1097 |

DSI |

|

Electric Cool |

|||||

|

|

|

|

||

|

|

|

|

|

|

(All) HW -9 |

Gas Heat Only |

80 |

UTech Combination Ignition/Blower Control 1097 |

DSI |

|

|

|

|

|

|

|

(All) HWC (122, 182, 242, 302) |

Gas Heat/ |

|

Ignition Control: Fenwal Triton 2461D |

|

|

80 |

Blower Control: Heatcraft IBCH4C401, |

DSI |

|||

-11, -10, -9, -8, -7, -6, -5 |

Electric Cool |

||||

|

Tridelta 920B0048 or UTech 1010 |

|

|||

|

|

|

|

||

|

|

|

|

|

|

(All) HWC (122, 182, 242, 302) |

Gas Heat/ |

|

Ignition Control: Fenwal 05-29 |

|

|

80 |

Blower Control: Heatcraft IBCH4C401, |

DSI |

|||

-4, -3, -2, -1 |

Electric Cool |

||||

|

Tridelta 920B0048 or UTech 1010 |

|

|||

|

|

|

|

||

|

|

|

|

|

Table 1-2 Cooling Configurations of HWC Units

Model |

Configuration |

Tonnage |

SEER |

Compressor Type* |

Metering Device |

|

|

|

|

|

|

|

|

(All) HWC 123-1 |

Gas Heat/Electric Cool |

1 |

9.7 |

Tecumseh Rotary |

Capillary Tube/Filter Drier |

|

|

|

|

|

|

|

|

(All) HWC183-1 |

Gas Heat/Electric Cool |

1.5 |

9.7 |

Tecumseh |

Capillary Tube/Filter Drier |

|

Reciprocating |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

(All) HWC 243-1 |

Gas Heat/Electric Cool |

2 |

9.7 |

Copeland Scroll |

Capillary Tube/Filter Drier |

|

|

|

|

|

|

|

|

(All) HWC 303-1 |

Gas HeatElectric Cool |

2.5 |

9.7 |

Copeland Scroll |

Capillary Tube/Filter Drier |

|

|

|

|

|

|

|

|

(All) HWC 182-11, - |

Gas Heat/Electric Cool |

1.5 |

9.7 |

Tecumseh |

Capillary Tube/Filter Drier |

|

9, -7, -6 |

Reciprocating |

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

(All) HWC 242-11, -9 |

Gas Heat/Electric Cool |

2 |

9.7 |

Copeland Scroll |

Capillary Tube/Filter Drier |

|

|

|

|

|

|

|

|

(All) HWC 122-10, - |

Gas Heat/Electric Cool |

1 |

9.7 |

Tecumseh Rotary |

Capillary Tube/Filter Drier |

|

8, -5, -4, -3, -1 |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

(All) HWC 242-10, - |

Gas Heat/Electric Cool |

2 |

9.7 |

Copeland Scroll |

Capillary Tube/Filter Drier |

|

8, -5, -4, -3, -1 |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

(All) HWC 302-9 |

Gas Heat/Electric Cool |

2.5 |

9.5 |

Copeland Scroll |

Capillary Tube/Filter Drier |

|

|

|

|

|

|

|

|

(All) HWC 182-8, -5, |

Gas Heat/Electric Cool |

1.5 |

9.7 |

Tecumseh Rotary |

Capillary Tube/Filter Drier |

|

-4, -3, -2 |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

(All) HWC 302-8, -5, |

Gas Heat/Electric Cool |

2.5 |

9.5 |

Copeland Scroll |

Capillary Tube/Filter Drier |

|

-4, -3, -1 |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

(All) HWC 182-1 |

Gas Heat/Electric Cool |

1.5 |

9.5 |

Copeland Scroll |

Capillary Tube/Filter Drier |

|

|

|

|

|

|

|

* For more information on the compressors used in HWC units, see the Unit Components section, beginning on page 5-28.

SRM-HW/HWC 8/99

SPECIFICATIONS |

Magic-Pak: HW/HWC |

1-4

HW/HWC

Physical and Electrical

Table 1-3 |

Physical and Electrical Specifications - HWC Units |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. |

Comp. |

Comp. |

O.D. |

|

Outside |

|

Indoor |

|

|

|

|

|

|

Normal |

Min. |

|

Fan |

|

Wheel |

Blower |

Refrig. |

|

|||||

|

Voltage/ |

Fuse/HACR |

Rated |

Locked |

Fan |

Nom. |

Rated |

Weight |

|||||||

Model |

Voltage |

Circuit |

Rated |

dia. x |

Rated |

Charge |

|||||||||

Hz/Phase |

Brkr. |

Load |

Rotor |

Dia. |

RPM |

HP |

(lbs.) |

||||||||

|

Range |

Ampacity |

Load |

width |

HP |

(oz.) |

|||||||||

|

|

(amps) |

(amps) |

(amps) |

(in.) |

|

|

|

|||||||

|

|

|

|

|

(amps) |

|

(in.) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26HWC122/123 |

208-230/60/1 |

197-253 |

8.3 |

15 |

5.0 |

26.3 |

18 |

1075 |

0.9 |

1/8 |

10 X 4 |

1/6 |

42 |

325 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

38HWC122/123 |

208-230/60/1 |

197-253 |

8.3 |

15 |

5.0 |

26.3 |

18 |

1075 |

0.9 |

1/8 |

10 X 4 |

1/6 |

42 |

325 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

38HWC182/183 |

208-230/60/1 |

197-253 |

13.6 |

20 |

8.3 |

45.0 |

18 |

1075 |

0.9 |

1/8 |

10 X 4 |

1/3 |

56 |

350 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

51HWC182/183 |

208-230/60/1 |

197-253 |

13.6 |

20 |

8.3 |

45.0 |

18 |

1075 |

0.9 |

1/8 |

10 X 4 |

1/3 |

56 |

350 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

64HWC182/183 |

208-230/60/1 |

197-253 |

13.6 |

20 |

8.3 |

45.0 |

18 |

1075 |

0.9 |

1/8 |

10 X 4 |

1/3 |

56 |

350 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36HWC242/243 |

208-230/60/1 |

197-253 |

18.6 |

25 |

11.6 |

62.5 |

18 |

1075 |

1.8 |

1/4 |

10 X 4 |

1/3 |

58 |

360 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

51HWC242/243 |

208-230/60/1 |

197-253 |

18.6 |

25 |

11.6 |

62.5 |

18 |

1075 |

1.8 |

1/4 |

10 X 4 |

1/3 |

58 |

360 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

64HWC242/243 |

208-230/60/1 |

197-253 |

18.6 |

25 |

11.6 |

62.5 |

18 |

1075 |

1.8 |

1/4 |

10 X 4 |

1/3 |

58 |

360 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

51HWC302 |

208-230/60/1 |

197-253 |

22.4 |

30 |

14.6 |

76.0 |

18 |

1075 |

1.8 |

1/4 |

10 X 4 |

1/3 |

59 |

380 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

64HWC302 |

208-230/60/1 |

197-253 |

22.4 |

30 |

14.6 |

76.0 |

18 |

1075 |

1.8 |

1/4 |

10 X 4 |

1/3 |

59 |

380 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

51HWC303 |

208-230/60/1 |

197-253 |

21.9 |

30 |

14.1 |

73.0 |

18 |

1075 |

1.8 |

1/4 |

10 X 4 |

1/3 |

59 |

380 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

64HWC303 |

208-230/60/1 |

197-253 |

21.9 |

30 |

14.1 |

73.0 |

18 |

1075 |

1.8 |

1/4 |

10 X 4 |

1/3 |

59 |

380 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Performance Ratings

Table 1-4 |

Performance Ratings - HWC122/123 |

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor Air Temperature Entering Outdoor Coil |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

85° |

|

|

|

|

95° |

|

|

|

|

105° |

|

|

|

|

115° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter. |

Total |

|

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Air |

|

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

|||||

Wet |

|

Watts |

Watts |

Watts |

Watts |

|||||||||||||||||

Vol. |

|

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

|||||

Bulb |

|

Input |

Input |

Input |

Input |

|||||||||||||||||

(CFM) |

|

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

|||||

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 |

|

12600 |

820 |

.78 |

.92 |

1.00 |

12000 |

910 |

.80 |

.95 |

1.00 |

11400 |

1000 |

.82 |

.95 |

1.00 |

10800 |

1090 |

.85 |

1.00 |

1.00 |

63° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

450 |

|

12800 |

820 |

.82 |

.97 |

1.00 |

12200 |

910 |

.85 |

1.00 |

1.00 |

11600 |

1000 |

.87 |

1.00 |

1.00 |

11000 |

1090 |

.90 |

1.00 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

|

13100 |

820 |

.87 |

1.00 |

1.00 |

12400 |

910 |

.90 |

1.00 |

1.00 |

11800 |

1000 |

.92 |

1.00 |

1.00 |

11200 |

1090 |

.95 |

1.00 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 |

|

13400 |

820 |

.59 |

.74 |

.89 |

12700 |

910 |

.60 |

.76 |

.91 |

12100 |

1010 |

.62 |

.79 |

1.00 |

11500 |

1110 |

.63 |

.81 |

.96 |

67° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

450 |

|

13600 |

820 |

.62 |

.78 |

.94 |

12900 |

910 |

.64 |

.80 |

.97 |

12300 |

1010 |

.65 |

.83 |

1.00 |

11700 |

1110 |

.67 |

.86 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

|

13900 |

820 |

.65 |

.82 |

.99 |

13200 |

910 |

.67 |

.84 |

1.00 |

12600 |

1010 |

.69 |

.88 |

1.00 |

11900 |

1110 |

.70 |

.91 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

400 |

|

14200 |

830 |

.40 |

.56 |

.72 |

13500 |

920 |

.40 |

.57 |

.74 |

12800 |

1020 |

.41 |

.58 |

.76 |

12100 |

1120 |

.41 |

.59 |

.78 |

71° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

450 |

|

14400 |

830 |

.42 |

.59 |

.76 |

13700 |

920 |

.42 |

.60 |

.78 |

13000 |

1020 |

.43 |

.62 |

.80 |

12300 |

1120 |

.43 |

.63 |

.82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

|

14700 |

830 |

.44 |

.62 |

.80 |

14000 |

920 |

.44 |

.63 |

.82 |

13300 |

1020 |

.45 |

.65 |

.84 |

12600 |

1120 |

.45 |

.66 |

.87 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: All values are gross capacities and do not include blower motor heat deduction.

HW/HWC-SRM

8/99

SRM-HW/HWC 8/99

Service Reference Manual |

SPECIFICATIONS |

1-5

Performance Ratings (continued)

Table 1-5 |

Performance Ratings - HWC182/183 |

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor Air Temperature Entering Outdoor Coil |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

85° |

|

|

|

|

95° |

|

|

|

|

105° |

|

|

|

|

115° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter. |

Total |

|

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Air |

|

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

|||||

Wet |

|

Watts |

Watts |

Watts |

Watts |

|||||||||||||||||

Vol. |

|

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

|||||

Bulb |

|

Input |

Input |

Input |

Input |

|||||||||||||||||

(CFM) |

|

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

|||||

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

550 |

|

18400 |

1370 |

.75 |

.90 |

1.00 |

17100 |

1470 |

.78 |

.92 |

1.00 |

15700 |

1550 |

.82 |

.96 |

1.00 |

14400 |

1640 |

.86 |

.96 |

1.00 |

63° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

600 |

|

18700 |

1380 |

.78 |

.93 |

1.00 |

17400 |

1480 |

.81 |

.96 |

1.00 |

16000 |

1560 |

.85 |

1.00 |

1.00 |

14600 |

1650 |

.89 |

1.00 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

650 |

|

18900 |

1390 |

.81 |

.96 |

1.00 |

17600 |

1490 |

.84 |

.99 |

1.00 |

16200 |

1570 |

.88 |

1.00 |

1.00 |

14800 |

1660 |

.92 |

1.00 |

1.00 |

|

550 |

|

19800 |

1410 |

.58 |

.72 |

.87 |

18500 |

1510 |

.59 |

.74 |

.89 |

17100 |

1600 |

.62 |

.78 |

.94 |

15600 |

1700 |

.64 |

.80 |

.96 |

67° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

600 |

|

20100 |

1420 |

.60 |

.75 |

.90 |

18800 |

1520 |

.62 |

.77 |

.93 |

17400 |

1610 |

.64 |

.81 |

.98 |

15900 |

1710 |

.66 |

.83 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

650 |

|

20400 |

1430 |

.62 |

.78 |

.93 |

19000 |

1530 |

.64 |

.80 |

.96 |

17600 |

1620 |

.66 |

.84 |

1.00 |

16100 |

1720 |

.68 |

.86 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

550 |

|

21200 |

1450 |

.40 |

.55 |

.69 |

19700 |

1550 |

.40 |

.56 |

.72 |

18300 |

1650 |

.41 |

.58 |

.75 |

16700 |

1750 |

.41 |

.60 |

.78 |

71° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

600 |

|

21500 |

1460 |

.42 |

.57 |

.72 |

20000 |

1560 |

.42 |

.59 |

.75 |

18600 |

1660 |

.43 |

.61 |

.78 |

17000 |

1760 |

.43 |

.62 |

.81 |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

650 |

|

21800 |

1470 |

.43 |

.59 |

.74 |

20300 |

1570 |

.43 |

.60 |

.78 |

18800 |

1670 |

.44 |

.63 |

.81 |

17200 |

1770 |

.44 |

.64 |

.84 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: All values are gross capacities and do not include blower motor heat deduction.

Table 1-6 |

Performance Ratings - HWC242/243 |

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor Air Temperature Entering Outdoor Coil |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

85° |

|

|

|

|

95° |

|

|

|

|

105° |

|

|

|

|

115° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter. |

Total |

|

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Air |

|

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

|||||

Wet |

|

Watts |

Watts |

Watts |

Watts |

|||||||||||||||||

Vol. |

|

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

|||||

Bulb |

|

Input |

Input |

Input |

Input |

|||||||||||||||||

(CFM) |

|

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

|||||

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

|

24300 |

1870 |

.74 |

.88 |

1.00 |

23200 |

2110 |

.76 |

.89 |

1.00 |

21800 |

2380 |

.78 |

.94 |

1.00 |

21000 |

2710 |

.80 |

.95 |

1.00 |

63° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

|

24700 |

1870 |

.78 |

.93 |

1.00 |

23600 |

2110 |

.80 |

.94 |

1.00 |

22200 |

2380 |

.82 |

.99 |

1.00 |

21300 |

2710 |

.84 |

1.00 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

|

25200 |

1880 |

.82 |

.98 |

1.00 |

24100 |

2120 |

.85 |

.99 |

1.00 |

22600 |

2390 |

.87 |

1.00 |

1.00 |

21700 |

2720 |

.89 |

1.00 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

|

25900 |

1890 |

.57 |

.71 |

.85 |

24700 |

2130 |

.58 |

.72 |

.86 |

23600 |

2400 |

.59 |

.75 |

.91 |

22400 |

2750 |

.60 |

.76 |

.92 |

67° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

|

26300 |

1890 |

.60 |

.75 |

.90 |

25100 |

2130 |

.61 |

.76 |

.91 |

24000 |

2400 |

.62 |

.79 |

.96 |

22800 |

2750 |

.63 |

.80 |

.97 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

|

26800 |

1900 |

.63 |

.79 |

.95 |

25600 |

2140 |

.64 |

.80 |

.96 |

24500 |

2410 |

.66 |

.84 |

1.00 |

23200 |

2760 |

.67 |

.85 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

|

27300 |

1910 |

.40 |

.55 |

.69 |

26100 |

2150 |

.40 |

.55 |

.70 |

24900 |

2430 |

.40 |

.56 |

.72 |

23700 |

2770 |

.40 |

.57 |

.74 |

71° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

|

27700 |

1910 |

.42 |

.58 |

.73 |

26500 |

2150 |

.42 |

.58 |

.74 |

25300 |

2430 |

.42 |

.59 |

.76 |

24100 |

2770 |

.42 |

.60 |

.78 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

|

28300 |

1920 |

.44 |

.61 |

.77 |

27000 |

2160 |

.44 |

.61 |

.78 |

25800 |

2440 |

.44 |

.62 |

.80 |

24600 |

2780 |

.44 |

.63 |

.82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: All values are gross capacities and do not include blower motor heat deduction.

Table 1-7 |

Performance Ratings - HWC302/303 |

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor Air Temperature Entering Outdoor Coil |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

85° |

|

|

|

|

95° |

|

|

|

|

105° |

|

|

|

|

115° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter. |

Total |

|

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Total |

Comp. |

S/T at |

S/T at |

S/T at |

Air |

|

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

Cooling |

75° |

80° |

85° |

|||||

Wet |

|

Watts |

Watts |

Watts |

Watts |

|||||||||||||||||

Vol. |

|

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

Capacity |

Dry |

Dry |

Dry |

|||||

Bulb |

|

Input |

Input |

Input |

Input |

|||||||||||||||||

(CFM) |

|

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

(Btuh) |

Bulb |

Bulb |

Bulb |

|||||

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

775 |

|

28500 |

2150 |

.72 |

.84 |

.97 |

27300 |

2390 |

.73 |

.87 |

1.00 |

26100 |

2670 |

.74 |

.89 |

1.00 |

24800 |

2990 |

.76 |

.90 |

1.00 |

63° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

850 |

|

28900 |

2160 |

.74 |

.87 |

1.00 |

27600 |

2400 |

.76 |

.90 |

1.00 |

26400 |

2680 |

.77 |

.93 |

1.00 |

25100 |

3000 |

79 |

.93 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

925 |

|

29300 |

2170 |

.77 |

.90 |

1.00 |

28000 |

2410 |

.79 |

.93 |

1.00 |

26800 |

2690 |

.80 |

.96 |

1.00 |

25400 |

3010 |

.82 |

.96 |

1.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

775 |

|

30400 |

2190 |

.56 |

.69 |

.82 |

29000 |

2440 |

.57 |

.71 |

.84 |

27800 |

2720 |

.58 |

.73 |

.88 |

26400 |

3050 |

.59 |

.73 |

.88 |

67° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

850 |

|

30800 |

2200 |

.58 |

.71 |

.85 |

29400 |

2450 |

.59 |

.73 |

.87 |

28100 |

2730 |

.60 |

.75 |

.91 |

26700 |

3060 |

.61 |

.76 |

.91 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

925 |

|

31200 |

2210 |

.60 |

.73 |

.87 |

29800 |

2460 |

.61 |

.76 |

.90 |

28500 |

2740 |

.62 |

.78 |

.94 |

27100 |

3070 |

.63 |

.79 |

.94 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

775 |

|

32200 |

2220 |

.40 |

.54 |

.68 |

30800 |

2480 |

.41 |

.55 |

.69 |

29300 |

2760 |

.41 |

.56 |

.71 |

28000 |

3090 |

.42 |

.57 |

.73 |

71° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

850 |

|

32600 |

2230 |

.41 |

.56 |

.70 |

31200 |

2490 |

.42 |

.57 |

.71 |

29700 |

2770 |

.42 |

.58 |

.73 |

28300 |

3100 |

.43 |

.59 |

.75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

925 |

|

33000 |

2240 |

.42 |

.57 |

.72 |

31600 |

2500 |

.43 |

.58 |

.73 |

30100 |

2780 |

.43 |

.60 |

.76 |

28700 |

3110 |

.45 |

.61 |

.78 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: All values are gross capacities and do not include blower motor heat deduction.

|

|

SPECIFICATIONS |

|

|

|

Magic-Pak: HW/HWC |

|||||

1-6 |

|

|

|

||||||||

|

Blower Performance |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

Table 1-8 Blower Performance - HWC Units |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

Blower Speed |

|

|

CFM @ ext. static pressure - in. w.c. with filter(s) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

0.2 |

|

0.3 |

0.4 |

|

0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hi |

|

650 |

|

615 |

575 |

|

540 |

|

|

|

HWC122/123 |

|

|

|

|

|

|

|

|

|

|

|

Med |

|

475 |

|

450 |

425 |

|

400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low |

|

415 |

|

405 |

390 |

|

380 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hi |

|

875 |

|

825 |

775 |

|

725 |

|

|

|

HWC182,242,302 |

|

|

|

|

|

|

|

|

|

|

|

Med |

|

850 |

|

805 |

760 |

|

710 |

|

|

|

|

HWC183,243,303 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Low |

|

630 |

|

605 |

575 |

|

550 |

|

|

|

|

|

|

|

|

|

|

|

|

|

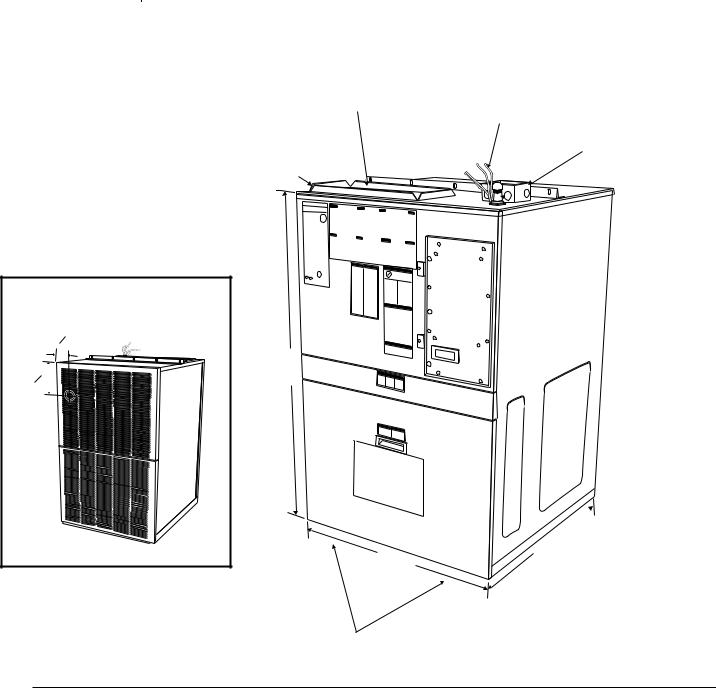

Dimensions (all measurements in inches)

SUPPLY AIR DUCT CONNECTION

8" x 16" LOW VOLTAGE THERMOSTAT CONNECTIONS

|

HIGH VOLTAGE |

¾" DUCT CONNECTION FLANGE |

JUNCTION BOX |

4" x 4" x 2" |

GAS LINE

GAS LINE

CONNECTION

Measurements from Side and Top to Center of Vent Outlet

41 2"

634"

" /8 1

43

27 |

7 |

|

/8" |

RETURN AIR OPENING ON BOTTOM 6" x 22"

"

7/16 29

HW/HWC-SRM

8/99

Service Reference Manual |

SPECIFICATIONS |

1-7

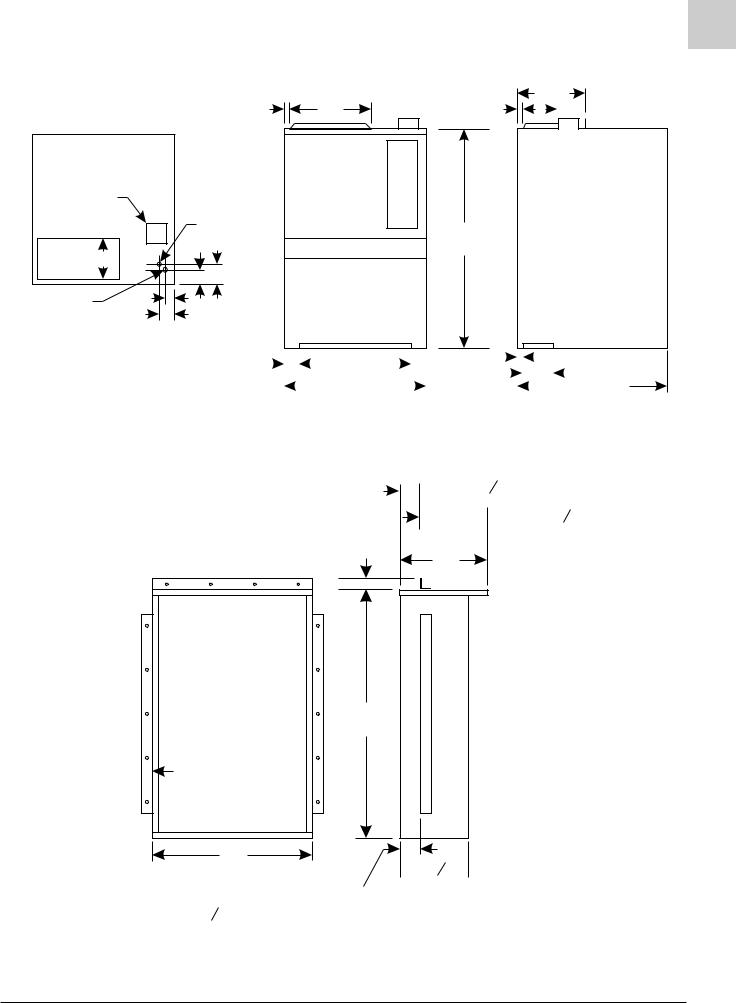

Dimensions (cont.)

|

1 |

|

1 |

133/8 |

|

16 |

8 |

||

|

|

Supply |

|

|

Line Voltage |

|

|

|

|

Box |

Low |

|

|

|

|

|

|

|

|

|

Voltage |

|

43 1/8 |

|

|

|

|

|

|

Supply |

8 |

|

|

|

|

2 7/8 4 |

|

|

|

½ Gas Inlet |

1 3/4 |

|

|

|

|

3 |

Return |

|

|

|

|

|

|

|

2 |

/ |

|

|

|

|

|

|

|

22 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

78 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

27 7/8 |

|

|

|

|

|

|

|

|

|

|

|

|

29 7/16 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Wall Sleeve (all measurements in inches)

1 or 3 3 4

1 or 3 3 4

15 or 1214

15 or 1214

2

16

45

2

29

12 1 2"

12 1 2"

Flanges may be assembled

1" or 33 4" from this side of the sleeve

SRM-HW/HWC 8/99

SRM-HW/HWC 2/99

Service Reference Manual |

SEQUENCE OF OPERATIONS |

2-1

Section 2 - Sequence of Operation

HWC123,183,243,303 ........................ |

2-4 |

Simplified Sequence ........................................ |

2-5 |

Detailed Sequence .......................................... |

2-6 |

POWER ...................................................................... |

2-6 |

CALL FOR HEAT ........................................................ |

2-6 |

LIMIT/ROLLOUT OPENS ........................................... |

2-7 |

PRESSURE SWITCH OPENS (BLOCKED FLUE) ..... |

2-7 |

FAILED FLAME SENSE/TRIAL FOR IGNITION ......... |

2-8 |

CALL FOR COOLING ................................................. |

2-8 |

FAN ON....................................................................... |

2-9 |

HW (Heating Only)

(w/UTEC 1097 Spark Ignition System) 2-10

Simplified Sequence ...................................... |

2-11 |

Detailed Sequence ........................................ |

2-12 |

POWER .................................................................... |

2-12 |

CALL FOR HEAT ...................................................... |

2-12 |

LIMIT/ROLLOUT OPENS ......................................... |

2-13 |

PRESSURE SWITCH OPENS (BLOCKED FLUE) ... |

2-13 |

FAILED FLAME SENSE/TRIAL FOR IGNITION ....... |

2-14 |

FAN ON..................................................................... |

2-14 |

HWC122,182,242,302

(w/Fenwal 2461D Ignition Control) ..... 2-16

Simplified Sequence ...................................... |

2-17 |

Detailed Sequence ........................................ |

2-18 |

POWER .................................................................... |

2-18 |

CALL FOR HEAT ...................................................... |

2-18 |

LIMIT OPENS ........................................................... |

2-19 |

PRESSURE SWITCH OPENS (BLOCKED FLUE) ... |

2-19 |

ROLLOUT SWITCH ACTIVATED.............................. |

2-19 |

CALL FOR COOLING ............................................... |

2-19 |

FAN ON..................................................................... |

2-20 |

HW (Heating Only)

(w/Fenwal 2461D Ignition Control) ..... 2-22

Simplified Sequence ...................................... |

2-23 |

Detailed Sequence ........................................ |

2-24 |

POWER .................................................................... |

2-24 |

CALL FOR HEAT ...................................................... |

2-24 |

LIMIT OPENS ........................................................... |

2-25 |

PRESSURE SWITCH OPENS (BLOCKED FLUE) ... |

2-25 |

ROLLOUT SWITCH ACTIVATED.............................. |

2-25 |

SPECIFICATIONS |

Magic-Pak: HW/HWC |

2-2

HWC122,182,242,302 |

|

(w/Fenwal 05-29 Ignition Control) ....... |

2-26 |

Simplified Sequence ...................................... |

2-27 |

Detailed Sequence ........................................ |

2-28 |

POWER .................................................................... |

2-28 |

CALL FOR HEAT ...................................................... |

2-28 |

FLAME SENSE ......................................................... |

2-29 |

LIMIT OPENS ........................................................... |

2-29 |

ROLLOUT SWITCH ACTIVATED.............................. |

2-29 |

CALL FOR COOLING ............................................... |

2-29 |

FAN ON..................................................................... |

2-30 |

HW (Heating Only) |

|

(w/Fenwal 05-29 Ignition Control) ....... |

2-32 |

Simplified Sequence ...................................... |

2-33 |

Detailed Sequence ........................................ |

2-34 |

POWER .................................................................... |

2-34 |

CALL FOR HEAT ...................................................... |

2-34 |

FLAME SENSE ......................................................... |

2-35 |

LIMIT OPENS ........................................................... |

2-35 |

ROLLOUT SWITCH ACTIVATED.............................. |

2-35 |

HWC123,183,243,303 |

|

w/Low Ambient Control ...................... |

2-36 |

HWC122,182,242,302 |

|

w/Low Ambient Control ...................... |

2-38 |

HW/HWC-SRM

2/99

Service Reference Manual |

SEQUENCE OF OPERATIONS |

2-3

BLANK PAGE

SRM-HW/HWC 2/99

SPECIFICATIONS |

Magic-Pak: HW/HWC |

2-4

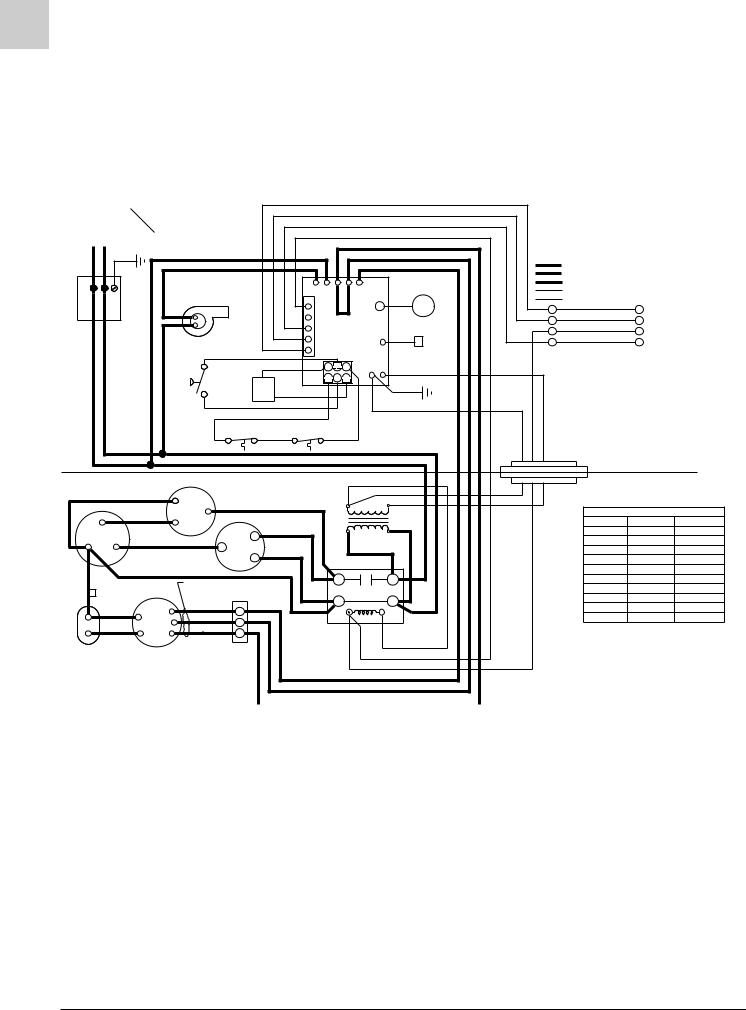

HWC123, 183, 243, 303

(w/United Technologies 1097 Spark Ignition System)

|

|

|

|

|

|

|

|

CONNECTION DIAGRAM |

|

|

|

CIRCUITS ENERGIZED |

||||||||

208/230-1-60 |

COPPER CONDUCTORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

OPERATING MODE |

CIRCUIT |

|||||||

POWER SUPPLY |

|

ONLY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HEATING |

|

R-W |

|||

} |

|

|

|

|

|

|

|

|

|

|

YELLOW |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COOLING |

R-G-Y |

||||

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAN |

|

R-G |

||

|

|

|

|

|

|

|

|

|

|

|

|

BLUE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLACK |

|

|

|

LINE VOLTAGE-FACTORY |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LINE VOLTAGE-FACTORY WHEN USED |

||

|

|

BLACK |

|

GREEN RED |

WHITE |

2 |

CY |

BLACK L1 |

|

COOL |

UNUSED HEAT |

|

|

|

|

|

|

LINE VOLTAGE-FIELD |

|

|

|

|

|

COMBUSTION |

|

|

CMB |

|

|

|

|

|

|

|

ELECTRODE |

|

|

|

LOW VOLTAGE-FACTORY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW VOLTAGE-FIELD |

|

||

|

|

|

BLOWER |

|

|

1 |

|

|

|

|

|

|

|

|

|

|

R |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

G |

|

BLACK |

BLACK |

BLACK BLACK |

PRESSURE SWITCH |

|

|

3 |

RGW |

|

|

|

|

|

24VAC |

|

|

|

|

|

THERMOSTAT |

|

|

|

|

|

|

|

|

|

|

|

|

Y |

|

Y |

|

||||||

|

|

|

|

|

|

4 |

|

|

|

IGNITION |

|

|

WHT |

|

|

W |

|

W } |

|

|

|

|

|

|

|

|

5 |

|

|

CONTROL |

|

FLAME ROD |

|

|

|

|

|

|

|||

|

|

|

VIOLET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

RED |

|

|

4 |

5 6 |

GND |

|

|

|

|

|

NOTE: |

|

|

|||

|

|

|

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

GAS |

|

|

|

|

|

|

|

|

|

|

IF ANY OF THE ORIGINAL |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WIRES ARE REPLACED, THE |

|||

|

|

|

|

VALVE BLUE |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

VIOLET |

|

|

|

|

|

|

|

|

GREEN |

|

|

|

SAME SIZE AND TYPE WIRE |

||||

|

|

|

|

|

|

|

|

|

ORN |

|

|

|

BLUE |

YELLOW |

RED |

MUST BE USED. |

|

|||

|

|

|

|

ORN |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUTO RESET |

MANUAL RESET |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

LIMIT SWITCH |

LIMIT SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

ORN |

|

|

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

BLACK |

|

|

|

|

|

|

|

|

|

|

|

CONDENSER FAN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VIOLET |

|

|

|

|

|

|

|

|

|

|

|

|

BLUE |

|

|

CONNECTOR BLOCK |

|

|

|

|

|

|

|

|

|

|

|

|

|

TRANSFORMER |

RED |

|

|

|

|

|

|||

CAPACITOR-RUN |

|

|

BLACK |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EVAP. MOTOR SPEED CONNECTIONS |

|||||

|

|

BROWN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODELS |

HEATING |

COOLING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|||

FAN |

|

|

BLACK |

|

|

|

|

|

|

|

|

|

|

|

26HWC123 |

LOW (RED) |

MED (BLUE) |

|||

|

|

|

|

|

|

|

208 V |

|

|

|

|

|

|

|||||||

COM |

HERM |

YELLOW |

|

C |

|

|

|

|

|

|

|

240 V |

|

|

|

38HWC123 |

HIGH(BLACK) MED (BLUE) |

|||

S |

COMP |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|

38HWC183 |

LOW (RED) |

LOW (RED)* |

||

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

R |

|

|

|

|

|

CONTACTOR |

|

|

|

|

51HWC183 |

MED (BLUE) |

LOW (RED) |

|||

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

64HWC183 |

HIGH(BLACK) LOW (RED) |

|||||

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

SEE CHART |

|

|

|

|

|

T1 |

|

|

|

L1 |

|

|

|

38HWC243 |

LOW (RED) |

MED (BLUE) |

||

D |

|

|

FOR WIRING |

BLOWER |

|

|

|

|

|

|

|

|

|

|

|

|

|

51HWC243 |

MED (BLUE) |

MED (BLUE)* |

|

|

|

|

CONTROL |

|

|

|

T2 |

|

|

|

L2 |

|

|

|

64HWC243 |

HIGH(BLACK) MED (BLUE) |

|||

|

|

|

BLACK |

|

|

|

|

|

|

|

|

|

|

51HWC303 |

MED (BLUE) |

HIGH(BLACK) |

||||

|

YELLOW |

|

H |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

BLUE |

|

|

|

|

|

|

|

|

|

|

|

|

|

64HWC303 |

HIGH(BLACK) HIGH(BLACK)* |

|||

|

|

BLOWER |

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

BROWN |

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

*JUMPER REQUIRED |

|

|||

|

MOTOR |

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

CAPACITOR |

|

|

|

|

|

|

|

|

|

|

|

|

BLUE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

BLOWER |

|

|

|

|

|

|

|

|

|

|

|

|

|

YELLOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#45004-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIAGNOSTICS |

||

|

|

|

|||

|

|

|

The following blower/ignition control board |

||

|

|

|

LED codes will indicate normal or abnormal |

||

|

|

|

operations: |

|

|

|

|

|

SLOW FLASH |

Normal Operation, No |

|

|

|

|

|

Call for Heat |

|

Note: On units that are equipped with a low ambient switch (designated |

FAST FLASH |

Normal Operation, Call for |

|||

with an “SA” in the model number), sequence of operation during |

|

Heat |

|||

2 FLASH |

System Lockout - Failed to |

||||

cooling call is modified when outdoor temperatures fall below the |

|||||

|

Detect or Sustain Flame |

||||

normal operating range. For more information on the low ambient |

3 FLASH |

Pressure Switch Open or |

|||

switch equipped version of this unit, see the section beginning on |

|||||

|

Closed |

||||

page 2-36. |

4 FLASH |

High Limit or Rollout |

|||

|

|

|

|

Switch Open |

|

|

|

|

5 FLASH |

Flame Sensed and Gas |

|

|

|

|

|

Valve Not Energized |

|

|

|

|

STEADY |

Internal Failure |

|

|

|

|

|

(Micro-controller Failure; |

|

|

|

|

|

Self-check) |

|

FIGURE 2-1 Connection Diagram |

|

|

|||

|

|

||||

HW/HWC-SRM

2/99

Service Reference Manual |

SEQUENCE OF OPERATIONS |

2-5

Simplified Sequence - HWC123,183, 243, 303

Refer to Figure 2-1

•208/230V power is supplied to the junction box on top of the unit

•24V power is supplied from the unit transformer to the thermostat

CALL FOR HEAT

1.The thermostat closes the R-W circuit, sending a 24-volt signal to the unit.

2.The 24-volt signal energizes the combustion blower, causing the pressure switch to close.

3.The combustion blower runs for 30 seconds as a pre-purge to trial for ignition.

4.The ignition control energizes the spark ignition and opens the gas valve, causing the burners to light. When the gas valve energizes, a 30-second circulating air blower “on” delay begins.

5.Flame sense is sent to the ignition control through the flame sensor and flame sense wire.

6.After the 30-second delay, the circulating air blower energizes and runs until the heat call is satisfied.

7.When the heat call is satisfied, the gas valve deenergizes. This shuts down the burners.

8.A 5-second combustion blower post-purge delay and a 120-second circulating air blower “off” delay start.

9.After the delay times elapse, the combustion blower and the circulating air blower stop.

FLAME SENSE

1.After the burners have been lit, the ignition control starts a 10-second trial for ignition delay.

2.If after 10 seconds a flame has not been sensed by the ignition control, the ignition control de-energizes the gas valve and the spark ignitor.

3.The unit initiates three trials for ignition (flame sense) before system lockout.

4.System lockout lasts 60 minutes or until power is reset to unit (whichever comes first).

CALL FOR COOLING

1.The thermostat energizes the R, Y and G circuit, sending a 24-volt signal to the cooling contactor and the ignition control to start the cooling sequence.

2.The contactor closes immediately, causing the compressor and the condenser fan to run.

3.The 24-volt Y signal starts a 5-second circulating air blower “on” delay.

4.After 5 seconds, the circulating air blower starts and runs until the R, Y and G circuit is interrupted by the thermostat.

5.When the R, Y and G circuit is interrupted, the cooling contactor immediately de-energizes. This causes the compressor and the condenser fan to stop.

6.The ignition control starts a 90-second circulating air blower “off” delay.

7.After 90 seconds, the circulating air blower stops.

FAN ON

1.The thermostat energizes the R-G circuit, causing the circulating air blower to energize in cooling speed.

2.The circulating air blower remains running in cooling speed until the thermostat is switched to the “AUTO” position.

SRM-HW/HWC 2/99

Detailed Sequence follows

SPECIFICATIONS |

Magic-Pak: HW/HWC |

2-6

Detailed Sequence - HWC123, 183, 243, 303

Refer to Figure 2-1

POWER

Line Voltage

With the unit at rest (no call from the thermostat), line voltage will be present:

L1 Power

1.Through the L1 black lead to the L1 terminal on the ignition control

2.At the L1 contactor terminal

3.At the transformer terminal marked 208-240V

L2 Power

1.Through the L2 black lead to the induced draft blower

2.At the L2 contactor terminal

3.A transformer common terminal

4.At the T2 contactor terminal

5.At the R terminal of the compressor

6.At the capacitor common terminals

Low Voltage (24 VAC)

With the unit at rest (no call from the thermostat), 24 volts A/C will be present:

1.From the transformer 24V terminal to pin 4 of the 6-pin chassis low voltage harness

2.From pin 4 of the chassis low voltage harness to the

24VAC hot terminal on the ignition control

3.From the 24VAC hot terminal to pin 5 of the 5-pin thermostat harness (internal to board)

4.From the 24VAC hot terminal also to pin 6 of the 6- pin ignition wire harness

5.From pin 6 of the ignition wire harness through the auto reset limit switch and the manual reset rollout switch to pin 1 of the 6-pin ignition wire harness

Note: While the unit is at rest, the green LED shows consistent slow flash. This indicates normal operation - system at rest (standby mode).

CALL FOR HEAT

Line Voltage

The ignition control receives a signal from the R-W circuit indicating a call for heat.

1.The combustion blower relay energizes, sending L1 power to CMB BLWR terminal on the ignition

control. This causes the combustion blower to start by completing the line voltage circuit through the L2 wire connection in the unit.

2.As the 24-volt signal is sent to pin 4 of the 6-pin ignition wire harness by the ignition control, a 30second circulating air blower “on” delay starts. After the delay, the ignition control energizes the heat speed blower relay. This sends L1 power to the

ACB HEAT terminal on the ignition control.

3.L1 power is then sent to the circulating air blower terminal block where it is connected to the blower motor. The circulating air blower starts by completing the L1-L2 circuit through the L2 connection at the blower motor capacitor.