Armstrong World Industries HWC PREMIER 302, HWC PREMIER 123, HWC PREMIER 183, HWC PREMIER 243, HWC PREMIER 203 User Manual

...Page 1

Service Reference Manual

HWC Thru-the-Wall Units

Models:

HWC Premier

122, 182, 242, 302

123, 183, 243, 303

Page 2

Copyright © 1998

Armstrong Air Conditioning Inc.

All rights reserved.

Disclaimer

This manual presents information and guidelines for proper installation, adjustment, operation

and maintenance of Armstrong Magic-Pak HW/HWC Thru-the-Wall units. Read this manual

before attempting assembly, installation, start-up, adjustment or operation of the unit. If you have

any questions about the operation of the unit or a particular safety device, call or write Armstrong Air Conditioning Inc., 421 Monroe Street, Bellevue, Ohio USA 44811. Telephone: 419483-4840 Fax: 419-483-3557

The documentation and drawings contained in this manual are intended as a general guide, and

may not reflect exactly the current designs, or all of the options available to our customers.

Please call or write Armstrong Air Conditioning Inc. regarding specific details of a particular

furnace model, configuration or installation.

The information and specifications contained in this manual are subject to change without notice. Armstrong Air Conditioning Inc. reserves the right to change such specifications at any time

without incurring obligation. Every effort has been made to ensure the accuracy of the information in this manual. For the most current information, please contact the Ar mstrong Customer

Service Department.

This document is confidential. All information within is the sole property of Armstrong Air Conditioning Inc. and is loaned for mutual assistance. It may not be used for any purpose other than

originally intended, without prior written consent of Armstrong. It is not intended for use by

homeowners or as a guide for do-it-yourself projects. It provides specialized information for use

by qualified service personnel, who have the proper equipment, training and experience necessary to safely install, repair, adjust and maintain the Magic-Pak units and components described

within.

SRM-HW/HWC 8/99

Page 3

Service Reference Manual TABLE OF CONTENTS

TABLE OF CONTENTS

1 - Specifications

2 - Sequence of Operations

3 - Unit Tear Down

4 - Component Location Illustrations

5 - Unit Components

6 - Installation

7 - Accessories

8 - Parts Lists

9 - Troubleshooting/Performance/

Charge Weights

Go to: If you need information on:

Section 1 Perf ormance, electrical data and cabinet dimensions.

Section 2 Sequence of operation descriptions with accompanying schematics.

Section 3 Complete description of unit disassembly .

Section 4 Locations of major components of HW/HWC models.

Section 5 Illustrations and specifications for individual components including valv es ,

blowers, ignition controls and b lo wer control boards .

SRM-HW/HWC 8/99

Section 6 Installation requirements and startup guidelines.

Section 7 Complete listing of all Armstrong accessories available, including wall

sleeves, louvers and gas conversion kits.

Section 8 Complete service parts lists for all HW and HWC models.

Section 9 System check and troubleshooting procedures .

Page 4

Service Reference Manual SPECIFICATIONS

Section 1 - Specifications

Models Covered By This Manual ............ 1-2

Model Number Guide ............................ 1-2

Product Serial Numbers

(Beginning 1993) ................................. 1-2

Summary of Model Revisions/Variations 1-3

Heating Configuration Table ........................ 1-3

Cooling Configuration Table ......................... 1-3

HW/HWC ............................................ 1-4

Physical and Electrical ................................ 1-4

Performance Ratings .................................. 1-4

Blower Performance ................................... 1-6

Dimensions ................................................ 1-6

Wall Sleeve................................................ 1-7

1-1

SRM-HW/HWC 8/99

Page 5

SPECIFICATIONS Magic-Pak: HW/HWC

1-2

Models Covered By This Manual

HWC Gas Heating/Electric Cooling Units

HW122, 123

HW182,183

HW242, 243

HW302, 303

HW Gas Heating Only Units

26HW

38HW

51HW

64HW

Model Number Guide

HW/HWC Models

26 H W C 12 2 -- 2A

26 = Rated Input BTU/Hr x 1000

H = Gas Heat

W = Thru-the-Wall

C = Cooling

12 = Nominal Cooling BTU/Hr x 1000

2 = Cooling Efficiency 2 - 9.7 SEER

2A = Revision Code

Product Serial Numbers, Beginning 1993

84 95 A 12345

84 = Armstrong Factory Number

95 = Year (ex: 1995)

A = Month (see list below)

12345 = Sequential Number

A = Jan B = Feb C = Mar D = Apr

E = May F = June G = July H = Aug

J = Sept K = Oct L = Nov M = Dec

SRM-HW/HWC 8/99

Page 6

Service Reference Manual SPECIFICATIONS

Summary of Model Revisions/Variations

Table 1-1 Heating Configurations of HW/HWC Units

1-3

ledoMnoitarugifnoCEUFAlortnoCrewolB/noitingI

1-)303,342,381,321(CWH)llA(

9-WH)llA(ylnOtaeHsaG087901lortnoCrewolB/noitingInoitanibmoChceTUISD

)203,242,281,221(CWH)llA(

5-,6-,7-,8-,9-,01-,11-

)203,242,281,221(CWH)llA(

1-,2-,3-,4-

/taeHsaG

/taeHsaG

/taeHsaG

087901lortnoCrewolB/noitingInoitanibmoChceTUISD

looCcirtcelE

08

looCcirtcelE

08

looCcirtcelE

Table 1-2 Cooling Configurations of HWC Units

ledoMnoitarugifnoCegannoTREES*epyTrosserpmoCeciveDgnireteM

1-321CWH)llA(looCcirtcelE/taeHsaG17.9yratoRhesmuceTreirDretliF/ebuTyrallipaC

1-381CWH)llA(looCcirtcelE/taeHsaG5.17.9

noitingI

epyT

D1642notirTlawneF:lortnoCnoitingI

,104C4HCBItfarctaeH:lortnoCrewolB

0101hceTUro8400B029atledirT

92-50lawneF:lortnoCnoitingI

,104C4HCBItfarctaeH:lortnoCrewolB

0101hceTUro8400B029atledirT

hesmuceT

gnitacorpiceR

ISD

ISD

reirDretliF/ebuTyrallipaC

1-342CWH)llA(looCcirtcelE/taeHsaG27.9llorcSdnalepoCreirDretliF/ebuTyrallipaC

1-303CWH)llA(looCcirtcelEtaeHsaG5.27.9llorcSdnalepoCreirDretliF/ebuTyrallipaC

-,11-281CWH)llA(

6-,7-,9

9-,11-242CWH)llA(looCcirtcelE/taeHsaG27.9llorcSdnalepoCreirDretliF/ebuTyrallipaC

-,01-221CWH)llA(

1-,3-,4-,5-,8

-,01-242CWH)llA(

1-,3-,4-,5-,8

9-203CWH)llA(looCcirtcelE/taeHsaG5.25.9llorcSdnalepoCreirDretliF/ebuTyrallipaC

,5-,8-281CWH)llA(

2-,3-,4-

,5-,8-203CWH)llA(

1-,3-,4-

1-281CWH)llA(looCcirtcelE/taeHsaG5.15.9llorcSdnalepoCreirDretliF/ebuTyrallipaC

* For more information on the compressors used in HWC units, see the Unit Components section, beginning on page 5-28.

looCcirtcelE/taeHsaG5.17.9

looCcirtcelE/taeHsaG17.9yratoRhesmuceTreirDretliF/ebuTyrallipaC

looCcirtcelE/taeHsaG27.9llorcSdnalepoCreirDretliF/ebuTyrallipaC

looCcirtcelE/taeHsaG5.17.9yratoRhesmuceTreirDretliF/ebuTyrallipaC

looCcirtcelE/taeHsaG5.25.9llorcSdnalepoCreirDretliF/ebuTyrallipaC

hesmuceT

gnitacorpiceR

reirDretliF/ebuTyrallipaC

SRM-HW/HWC 8/99

Page 7

SPECIFICATIONS Magic-Pak: HW/HWC

1-4

HW/HWC

Physical and Electrical

Table 1-3 Physical and Electrical Specifications - HWC Units

ledoM

/egatloV

esahP/zH

lamroN

egatloV

egnaR

.niM

tiucriC

yticapmA

321/221CWH621/06/032-802352-7913.8510.53.628157019.08/14X016/124523

321/221CWH83 1/06/032-802 352-791 3.8 51 0.5 3.62 81 5701 9.0 8/1 4X01 6/1 24 523

381/281CWH831/06/032-802352-7916.31023.80.548157019.08/14X013/165053

381/281CWH15 1/06/032-802 352-791 6.31 02 3.8 0.54 81 5701 9.0 8/1 4X01 3/1 65 053

381/281CWH461/06/032-802352-7916.31023.80.548157019.08/14X013/165053

342/242CWH63 1/06/032-802 352-791 6.81 52 6.11 5.26 81 5701 8.1 4/1 4X01 3/1 85 063

342/242CWH151/06/032-802352-7916.81526.115.268157018.14/14X013/185063

342/242CWH46 1/06/032-802 352-791 6.81 52 6.11 5.26 81 5701 8.1 4/1 4X01 3/1 85 063

203CWH151/06/032-802352-7914.22036.410.678157018.14/14X013/195083

203CWH46 1/06/032-802 352-791 4.22 03 6.41 0.67 81 5701 8.1 4/1 4X01 3/1 95 083

303CWH151/06/032-802352-7919.12031.410.378157018.14/14X013/195083

303CWH46 1/06/032-802 352-791 9.12 03 1.41 0.37 81 5701 8.1 4/1 4X01 3/1 95 083

Performance Ratings

.xaM

RCAH/esuF

.rkrB

)spma(

.pmoC

detaR

daoL

)spma(

.pmoC

.D.O

dekcoL

naF

rotoR

)spma(

.moN

.aiD

MPR

).ni(

edistuO

naF

detaR

daoL

detaR

PH

)spma(

roodnI

leehW

x.aid

htdiw

rewolB

detaR

PH

.girfeR

egrahC

).zo(

thgieW

).sbl(

).ni(

Table 1-4 Performance Ratings - HWC122/123

Outdoor Air Temperature Entering Outdoor Coil

85°

latoT

Enter.

Wet

Bulb

63°

67°

71°

latoT

riA

0040062102887.29.00.10002101908.59.00.100411000128.59.00.100801090158.00.100.1

0540082102828.79.00.10022101958.00.100.100611000178.00.100.100011090109.00.100.1

0050013102878.00.100.10042101909.00.100.100811000129.00.100.100211090159.00.100.1

0040043102895.47.98.0072101906.67.19.00121010126.97.00.100511011136.18.69.

0540063102826.87.49.0092101946.08.79.00321010156.38.00.100711011176.68.00.1

0050093102856.28.99.0023101976.48.00.100621010196.88.00.100911011107.19.00.1

0040024103804.65.27.0053102904.75.47.00821020114.85.67.00121021114.95.87.

0540044103824.95.67.0073102924.06.87.00031020134.26.08.00321021134.36.28.

0050074103844.26.08.0004102944.36.28.00331020154.56.48.00621021154.66.78.

gnilooC

.loV

yticapaC

)MFC(

)hutB(

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

bluB

gnilooC

yticapaC

)hutB(

Note: All values are gross capacities and do not include blower motor heat deduction.

95° 105° 115°

taT/S

taT/S

.pmoC

°57

sttaW

yrD

tupnI

bluB

taT/S

°08

°58

yrD

yrD

bluB

bluB

latoT

gnilooC

yticapaC

)hutB(

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

bluB

gnilooC

yticapaC

)hutB(

taT/S

taT/S

.pmoC

°57

sttaW

yrD

tupnI

bluB

taT/S

°08

°58

yrD

yrD

bluB

bluB

SRM-HW/HWC 8/99

Page 8

Service Reference Manual SPECIFICATIONS

Performance Ratings (continued)

Table 1-5 Performance Ratings - HWC182/183

Outdoor Air Temperature Entering Outdoor Coil

85°

Enter.

Wet

Bulb

63°

67°

71°

latoT

riA

05500481073157.09.00.100171074187.29.00.100751055128.69.00.100441046168.69.00.1

00600781083187.39.00.100471084118.69.00.100061065158.00.100.100641056198.00.100.1

05600981093118.69.00.100671094148.99.00.100261075188.00.100.100841066129.00.100.1

05500891014185.27.78.00581015195.47.98.00171006126.87.49.00651007146.08.69.

00600102024106.57.09.00881025126.77.39.00471016146.18.89.00951017166.38.00.1

05600402034126.87.39.00091035146.08.69.00671026166.48.00.100161027186.68.00.1

05500212054104.55.96.00791055104.65.27.00381056114.85.57.00761057114.06.87.

00600512064124.75.27.00002065124.95.57.00681066134.16.87.00071067134.26.18.

05600812074134.95.47.00302075134.06.87.00881076144.36.18.00271077144.46.48.

gnilooC

.loV

yticapaC

)MFC(

)hutB(

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

bluB

gnilooC

yticapaC

)hutB(

latoT

Note: All values are gross capacities and do not include blower motor heat deduction.

95° 105° 115°

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

bluB

gnilooC

yticapaC

)hutB(

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

bluB

gnilooC

yticapaC

)hutB(

taT/S

.pmoC

°57

sttaW

yrD

tupnI

bluB

1-5

taT/S

taT/S

°08

°58

yrD

yrD

bluB

bluB

Table 1-6 Performance Ratings - HWC242/243

Outdoor Air Temperature Entering Outdoor Coil

95° 105° 115°

taT/S

taT/S

.pmoC

°57

sttaW

yrD

tupnI

bluB

taT/S

°08

°58

yrD

yrD

bluB

bluB

Enter.

Wet

Bulb

63°

67°

71°

85°

latoT

latoT

riA

00700342078147.88.00.100232011267.98.00.100812083287.49.00.100012017208.59.00.1

00800742078187.39.00.100632011208.49.00.100222083228.99.00.100312017248.00.100.1

00900252088128.89.00.100142021258.99.00.100622093278.00.100.100712027298.00.100.1

00700952098175.17.58.00742031285.27.68.00632004295.57.19.00422057206.67.29.

00800362098106.57.09.00152031216.67.19.00042004226.97.69.00822057236.08.79.

00900862009136.97.59.00652041246.08.69.00542014266.48.00.100232067276.58.00.1

00700372019104.55.96.00162051204.55.07.00942034204.65.27.00732077204.75.47.

00800772019124.85.37.00562051224.85.47.00352034224.95.67.00142077224.06.87.

00900382029144.16.77.00072061244.16.87.00852044244.26.08.00642087244.36.28.

gnilooC

.loV

yticapaC

)MFC(

)hutB(

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

gnilooC

bluB

yticapaC

)hutB(

Note: All values are gross capacities and do not include blower motor heat deduction.

Table 1-7 Performance Ratings - HWC302/303

Outdoor Air Temperature Entering Outdoor Coil

95° 105° 115°

taT/S

taT/S

.pmoC

°57

sttaW

yrD

tupnI

bluB

taT/S

°08

°58

yrD

yrD

bluB

bluB

Enter.

Wet

Bulb

63°

67°

71°

85°

latoT

latoT

riA

57700582051227.48.79.00372093237.78.00.100162076247.98.00.100842099267.09.00.1

05800982061247.78.00.100672004267.09.00.100462086277.39.00.10015200039739.00.1

52900392071277.09.00.100082014297.39.00.100862096208.69.00.100452010328.69.00.1

57700403091265.96.28.00092044275.17.48.00872027285.37.88.00462050395.37.88.

05800803002285.17.58.00492054295.37.78.00182037206.57.19.00762060316.67.19.

52900213012206.37.78.00892064216.67.09.00582047226.87.49.00172070336.97.49.

57700223022204.45.86.00803084214.55.96.00392067214.65.17.00082090324.75.37.

05800623032214.65.07.00213094224.75.17.00792077224.85.37.00382001334.95.57.

52900033042224.75.27.00613005234.85.37.00103087234.06.67.00782011354.16.87.

gnilooC

.loV

yticapaC

)MFC(

)hutB(

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

bluB

gnilooC

yticapaC

)hutB(

latoT

gnilooC

yticapaC

)hutB(

latoT

gnilooC

yticapaC

)hutB(

taT/S

taT/S

taT/S

.pmoC

°57

sttaW

tupnI

.pmoC

sttaW

tupnI

°08

yrD

yrD

bluB

bluB

taT/S

taT/S

°57

°08

yrD

yrD

bluB

bluB

latoT

°58

yrD

bluB

°58

yrD

bluB

gnilooC

yticapaC

)hutB(

taT/S

latoT

gnilooC

yticapaC

)hutB(

taT/S

taT/S

.pmoC

°57

sttaW

yrD

tupnI

bluB

taT/S

.pmoC

°57

sttaW

yrD

tupnI

bluB

taT/S

°08

°58

yrD

yrD

bluB

bluB

taT/S

taT/S

°08

°58

yrD

yrD

bluB

bluB

Note: All values are gross capacities and do not include blower motor heat deduction.

SRM-HW/HWC 8/99

Page 9

SPECIFICATIONS Magic-Pak: HW/HWC

1-6

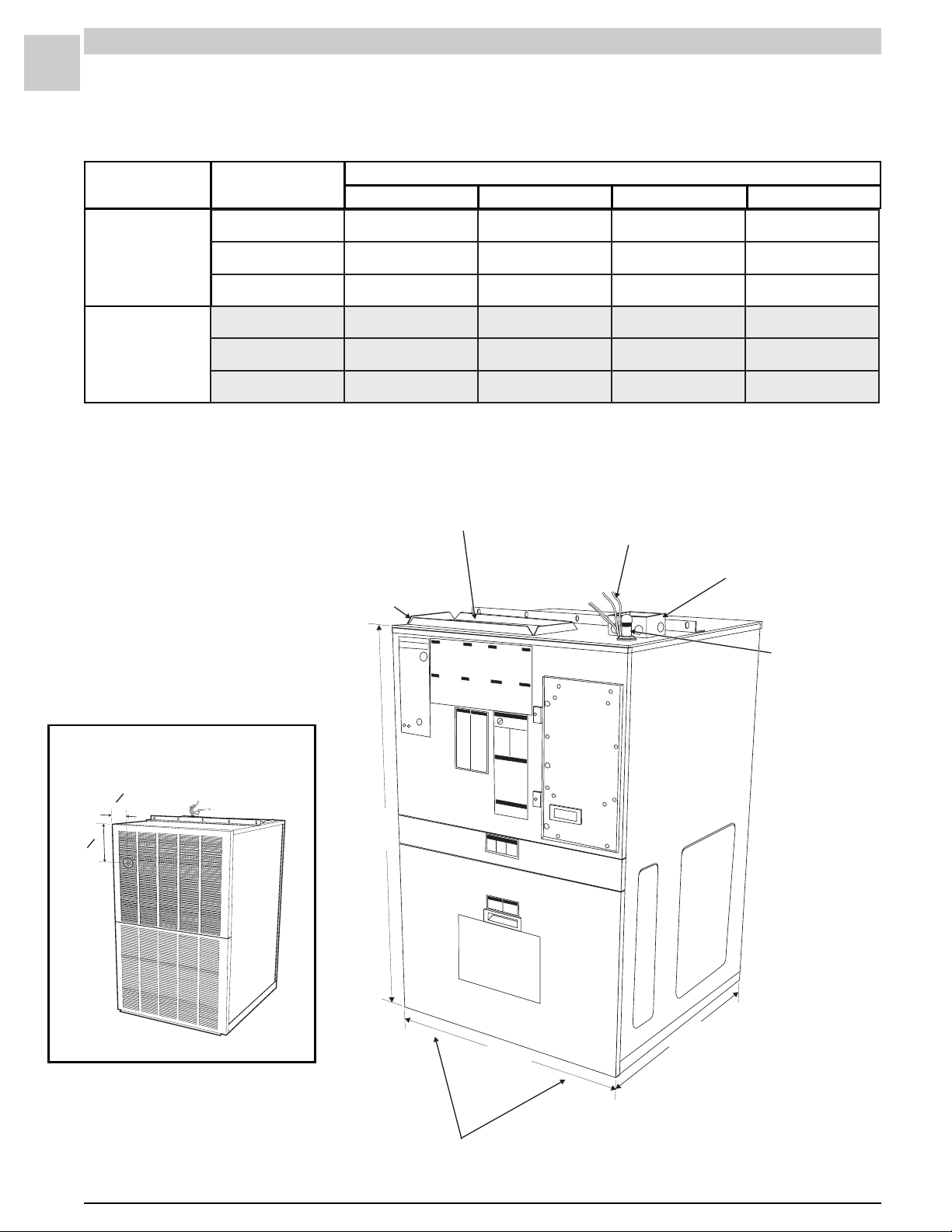

Blower Performance

Table 1-8 Blower Performance - HWC Units

Model

HWC122/123

HWC182,242,302

HWC183,243,303

Blower Speed

0.2 0.3 0.4 0.5

iH056516575045

deM574054524004

woL514504093083

iH 578 528 577 527

deM 058 508 067 017

woL 036 506 575 055

CFM @ ext. static pressure - in. w.c. with filter(s)

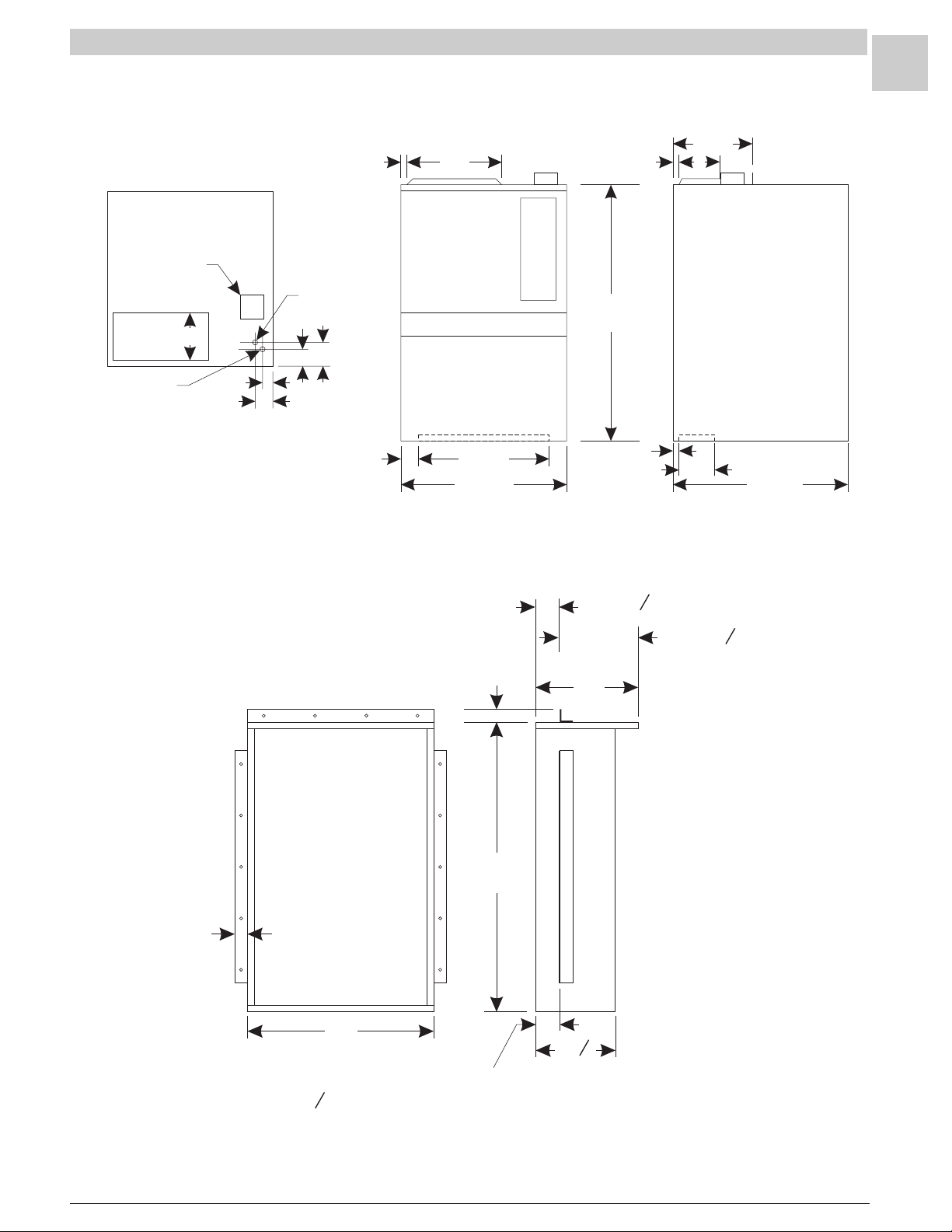

Dimensions (all measurements in inches)

SUPPLY AIR DUCT CONNECTION

8" x 16"

¾" DUCT CONNECTION FLANGE

LOW VOLTAGE

THERMOSTAT CONNECTIONS

HIGH VOLTAGE

JUNCTION BOX

4" x 4" x 2"

Measurements from Side and

Top to Center of V ent Outlet

1

"

4

2

3

"

4

6

GAS LINE

CONNECTION

"

8

/

1

43

"

7

16

/

27

7

/

"

8

29

RETURN AIR OPENING ON BOTTOM

6" x 22"

SRM-HW/HWC 8/99

Page 10

Service Reference Manual SPECIFICATIONS

Dimensions (cont.)

3

/

8

13

11

8

Line Voltage

Box

Supply

½ Gas Inlet

16

Supply

Low

Voltage

1

/

8

43

8

7

4

/

8

2

3

/

4

1

3

Return

1-7

7

/

8

2

27

22

7

/

8

Wall Sleeve (all measurements in inches)

2

45

1 or 3

16

1

3

4

6

15 or 12

7

/

16

29

1

4

SRM-HW/HWC 8/99

2

29

12

1

"

2

Flanges may be assembled

3

"

1" or 3 from this side of the sleeve

4

Page 11

Service Reference Manual SEQUENCE OF OPERATIONS

Section 2 - Sequence of Operation

HWC123,183,243,303........................ 2-4

Simplified Sequence ........................................ 2-5

Detailed Sequence .......................................... 2-6

POWER ...................................................................... 2-6

CALL FOR HEAT ........................................................ 2-6

LIMIT/ROLLOUT OPENS ........................................... 2-7

PRESSURE SWITCH OPENS (BLOCKED FLUE)..... 2-7

FAILED FLAME SENSE/TRIAL FOR IGNITION......... 2-8

CALL FOR COOLING................................................. 2-8

FAN ON....................................................................... 2-9

HW (Heating Only)

(w/UTEC 1097 Spark Ignition System) 2-10

Simplified Sequence ...................................... 2-11

Detailed Sequence ........................................ 2-12

POWER .................................................................... 2-12

CALL FOR HEAT ...................................................... 2-12

LIMIT/ROLLOUT OPENS ......................................... 2-13

PRESSURE SWITCH OPENS (BLOCKED FLUE)... 2-13

FAILED FLAME SENSE/TRIAL FOR IGNITION....... 2-14

FAN ON..................................................................... 2-14

2-1

HWC122,182,242,302

(w/Fenwal 2461D Ignition Control) ..... 2-16

Simplified Sequence ...................................... 2-17

Detailed Sequence ........................................ 2-18

POWER .................................................................... 2-18

CALL FOR HEAT ...................................................... 2-18

LIMIT OPENS ........................................................... 2-19

PRESSURE SWITCH OPENS (BLOCKED FLUE)... 2-19

ROLLOUT SWITCH ACTIVATED.............................. 2-19

CALL FOR COOLING............................................... 2-19

FAN ON..................................................................... 2-20

HW (Heating Only)

(w/Fenwal 2461D Ignition Control) ..... 2-22

Simplified Sequence ...................................... 2-23

Detailed Sequence ........................................ 2-24

POWER .................................................................... 2-24

CALL FOR HEAT ...................................................... 2-24

LIMIT OPENS ........................................................... 2-25

PRESSURE SWITCH OPENS (BLOCKED FLUE)... 2-25

ROLLOUT SWITCH ACTIVATED.............................. 2-25

SRM-HW/HWC 2/99

Page 12

2-2

SPECIFICATIONS Magic-Pak: HW/HWC

HWC122,182,242,302

(w/Fenwal 05-29 Ignition Control) ....... 2-26

Simplified Sequence ...................................... 2-27

Detailed Sequence ........................................ 2-28

POWER .................................................................... 2-28

CALL FOR HEAT ...................................................... 2-28

FLAME SENSE......................................................... 2-29

LIMIT OPENS ........................................................... 2-29

ROLLOUT SWITCH ACTIVATED.............................. 2-29

CALL FOR COOLING............................................... 2-29

FAN ON..................................................................... 2-30

HW (Heating Only)

(w/Fenwal 05-29 Ignition Control) ....... 2-32

Simplified Sequence ...................................... 2-33

Detailed Sequence ........................................ 2-34

POWER .................................................................... 2-34

CALL FOR HEAT ...................................................... 2-34

FLAME SENSE......................................................... 2-35

LIMIT OPENS ........................................................... 2-35

ROLLOUT SWITCH ACTIVATED.............................. 2-35

HWC123,183,243,303

w/Low Ambient Control ...................... 2-36

HWC122,182,242,302

w/Low Ambient Control ...................... 2-38

SRM-HW/HWC 2/99

Page 13

Service Reference Manual SEQUENCE OF OPERATIONS

BLANK PAGE

2-3

SRM-HW/HWC 2/99

Page 14

2-4

SPECIFICATIONS Magic-Pak: HW/HWC

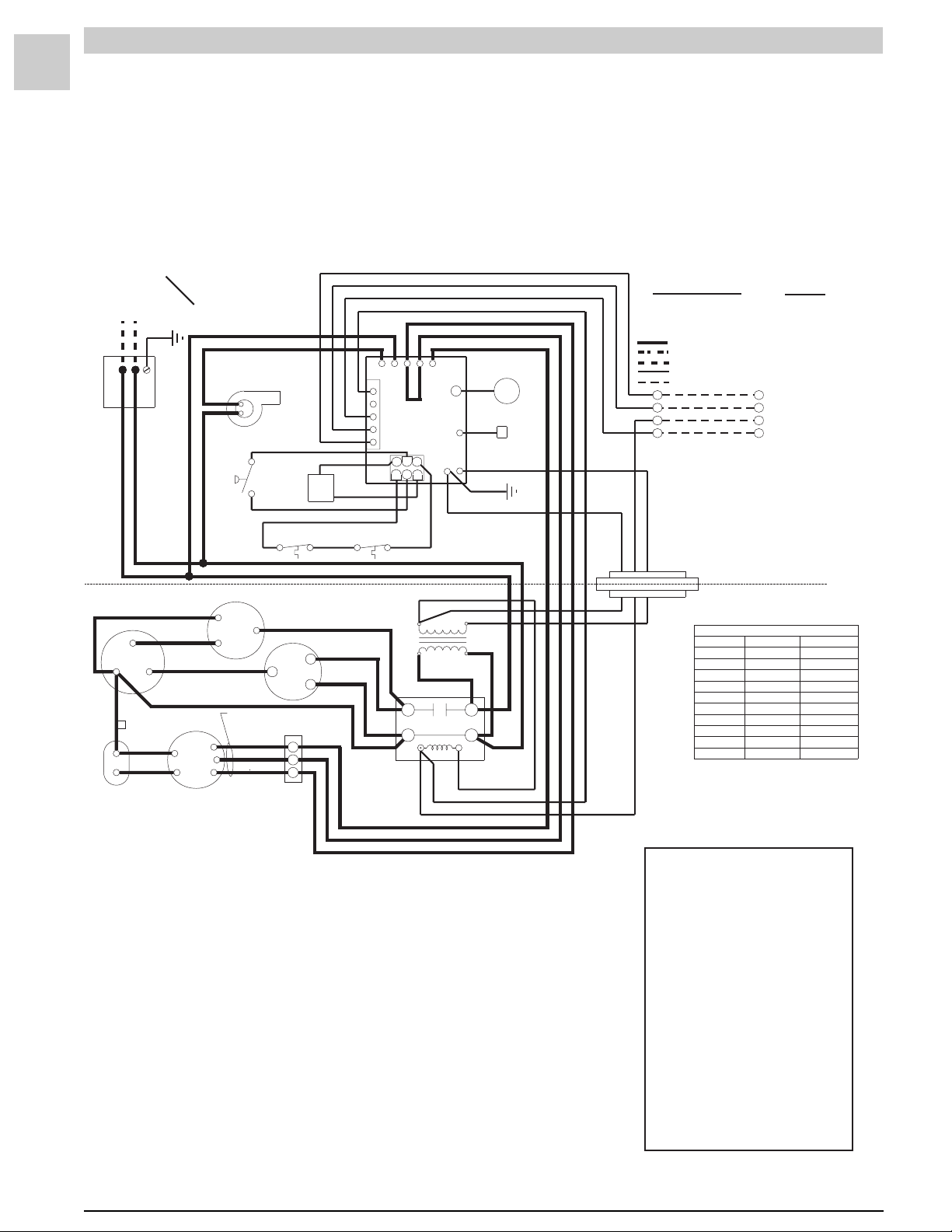

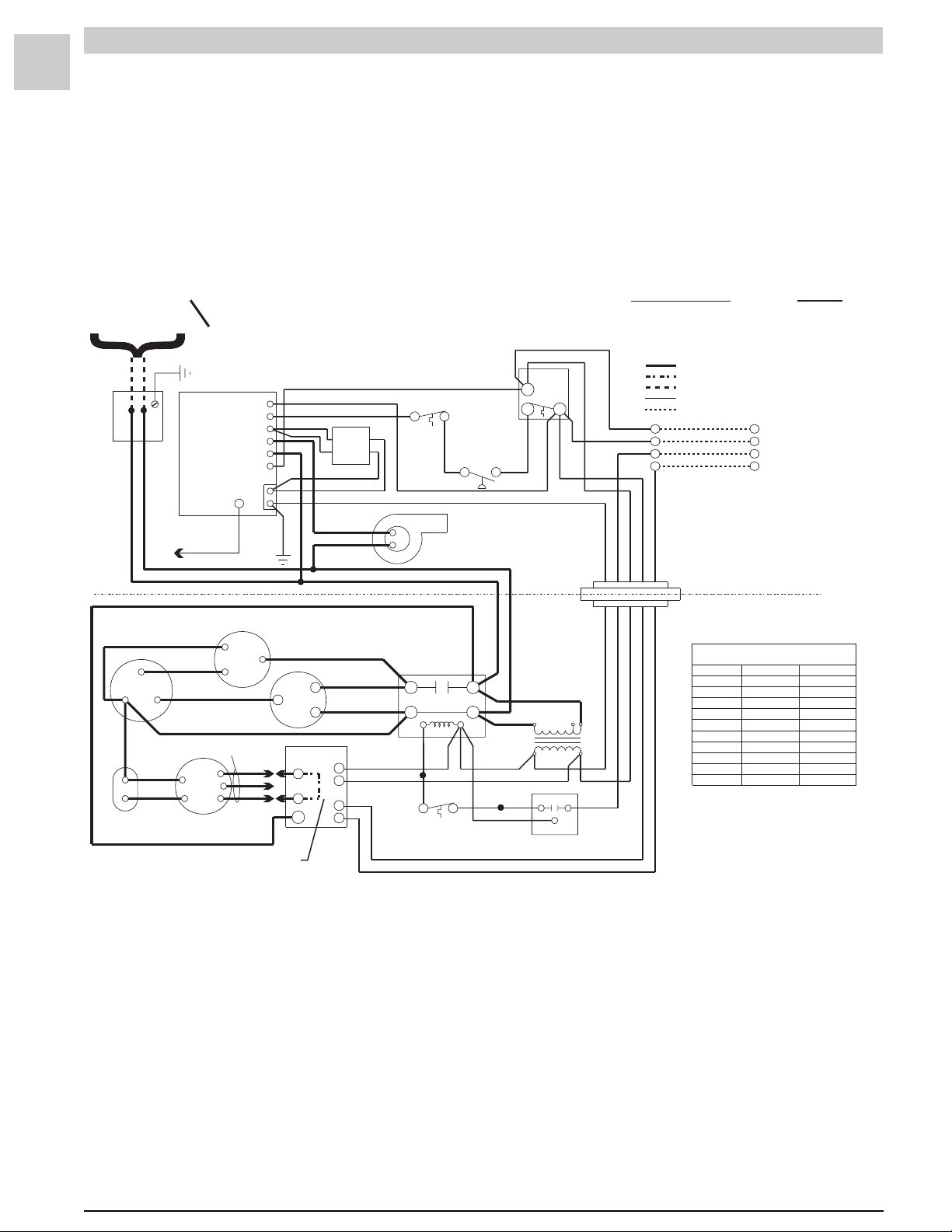

HWC123, 183, 243, 303

(w/United Technologies 1097 Spark Ignition System)

208/230-1-60

POWER SUPPLY

}

BLACK

BLACK

CAPACITOR-RUN

FAN

COM HERM

RED

D

YELLOW

BROWN

CAPA CIT ORCAPA CIT OR

BLOWER

COPPER CONDUCTORS

VIOLET

BROWN

YELLOWYELLOW

RED

BLOWER

MOTOR

ONLY

BLACK BLACK

COMBUSTION

BLOWER

BLACK

CONDENSER FANCONDENSER FAN

SEE

FORWIRING

SWITCH

CHARTCHART

BLACK

BLUEBLUE

RED

VIOLET

PRESSURE

VIOLET

AUTO RESET

LIMIT SWITCH

S

COMP

H

M

L

RED

GAS

VALVE

ORN

ORN

BLACK

C

R

BLOWER

BLOWER

CONTROL

CONTROL

GREEN

WHITE

RED

BLUE

MANUAL RESET

LIMIT SWITCH

BLACK

RED

CONNECTION DIAGRAMCONNECTION DIAGRAM

YELLOW

RED

BLUE

COOL

HEAT

IGNITION

CONTROLCONTROL

5

6

2

3

ORN

208 V

CONTACTOR

T1

T2

BLACK

UNUSED

24VAC

GND

RED

BLACK

TRANSFORMERTRANSFORMER

240 V

BLK

ELECTRODE

WHT

FLAME ROD

GREEN

BLK

L1

L2

BLUE

YELLOW

CMB

1

2

3

4

5

L1

BLACK

RGWCY

4

1

BLUE

RED

CIRCUITS ENERGIZED

OPERATING MODE CIRCUIT

HEATING R-W

COOLING R-G-Y

FAN R-G

LINE VOLT A GE-FACTORY

LINE VOLTAGE-FA CTORYWHEN USED

LINE VOLTAGE-FIELD

LOWVOLTAGE-FACTORY

LOWVOLTAGE-FIELD

R

G

Y

W

NOTE:

IF ANY OF THE ORIGINAL

WIRES ARE REPLACED,THE

BLUE

YELLOW

RED

SAME SIZE AND TYPE WIRE

MUST BE USED.

CONNECTORCONNECTOR

BLOCKBLOCK

EVAP. MOTOR SPEED CONNECTIONSEVAP.MOTOR SPEED CONNECTIONS

JUMPER REQUIRED

*

R

G

Y

}

W

THERMOST AT

COOLINGCOOLINGHEATINGHEATINGMODELSMODELS

MED (BLUE)MED (BLUE)LOW (RED)26HWC12326HWC123

MED (BLUE)MED (BLUE)HIGH(BLACK)HIGH(BLACK)38HWC12338HWC123

LOW (RED)LOW (RED)LOW (RED)38HWC183

LOW (RED)LOW (RED)MED (BLUE)51HWC18351HWC183

LOW (RED)LOW (RED)HIGH(BLACK)HIGH(BLACK)64HWC18364HWC183

MED (BLUE)MED (BLUE)LOW (RED)38HWC24338HWC243

MED (BLUE)MED (BLUE)MED (BLUE)51HWC24351HWC243

MED (BLUE)MED (BLUE)HIGH(BLACK)HIGH(BLACK)64HWC24364HWC243

HIGH(BLACK)MED (BLUE)51HWC30351HWC303

HIGH(BLACK)HIGH(BLACK)HIGH(BLACK)64HWC30364HWC303

*

*

*

#45004-1

Note: On units that are equipped with a low ambient switch (designated

with an “SA” in the model number), sequence of oper ation during

cooling call is modified when outdoor temperatures fall below the

normal operating range. F or more inf ormation on the low ambient

switch equipped version of this unit, see the section beginning on

page 2-36.

FIGURE 2-1 Connection Diagram

The following blower/ignition control board

DIAGNOSTICS

LED codes will indicate normal or abnormal

operations:

SLOW FLASH Normal Operation, No

FAST FLASH Normal Operation, Call for

2 FLASH System Lockout - Failed to

3 FLASH Pressure Switch Open or

4 FLASH High Limit or Rollout

5 FLASH Flame Sensed and Gas

STEADY Internal Failure

Call for Heat

Heat

Detect or Sustain Flame

Closed

Switch Open

Valve Not Energized

(Micro-controlle r Failure;

Self-check)

SRM-HW/HWC 2/99

Page 15

Service Reference Manual SEQUENCE OF OPERATIONS

Simplified Sequence - HWC123,183, 243, 303

Refer to Figure 2-1

2-5

• 208/230V power is supplied to the junction box on

top of the unit

• 24V power is supplied from the unit transformer to

the thermostat

CALL FOR HEAT

1. The thermostat closes the R-W circuit, sending a

24-volt signal to the unit.

2. The 24-volt signal energizes the combustion b low er,

causing the pressure switch to close.

3. The combustion blow er runs f or 30 seconds as a

pre-purge to trial for ignition.

4. The ignition control energizes the spark ignition and

opens the gas valve, causing the b urners to light.

When the gas valve energizes , a 30-second circulating air blower “on” dela y begins .

5. Flame sense is sent to the ignition control through

the flame sensor and flame sense wire.

6. After the 30-second delay, the circulating air blower

energizes and runs until the heat call is satisfied.

7. When the heat call is satisfied, the gas valve deenergizes. This shuts down the burners.

8. A 5-second combustion blow er post-purge dela y

and a 120-second circulating air blower “off” delay

start.

9. After the delay times elapse, the combustion b lo w er

and the circulating air blower stop .

CALL FOR COOLING

1. The thermostat energizes the R, Y and G circuit,

sending a 24-volt signal to the cooling contactor and

the ignition control to start the cooling sequence.

2. The contactor closes immediately, causing the

compressor and the condenser fan to run.

3. The 24-volt Y signal starts a 5-second circulating air

blower “on” delay .

4. After 5 seconds, the circulating air blower starts and

runs until the R, Y and G circuit is interrupted by the

thermostat.

5. When the R, Y and G circuit is interrupted, the

cooling contactor immediately de-energizes. This

causes the compressor and the condenser fan to

stop.

6. The ignition control starts a 90-second circulating

air blower “off” delay.

7. After 90 seconds, the circulating air blower stops .

FAN ON

1. The thermostat energizes the R-G circuit, causing

the circulating air blower to energize in cooling

speed.

2. The circulating air blower remains running in cooling

speed until the thermostat is switched to the “A UTO”

position.

FLAME SENSE

1. After the burners have been lit, the ignition control

starts a 10-second trial for ignition delay .

2. If after 10 seconds a flame has not been sensed by

the ignition control, the ignition control de-energizes

the gas valve and the spark ignitor .

3. The unit initiates three trials for ignition (flame

sense) before system lock out.

4. System lockout lasts 60 minutes or until po wer is

reset to unit (whichever comes first).

SRM-HW/HWC 2/99

Detailed Sequence follows

Page 16

2-6

SPECIFICATIONS Magic-Pak: HW/HWC

Detailed Sequence - HWC123, 183, 243, 303

Refer to Figure 2-1

POWER

Line Voltage

With the unit at rest (no call from the thermostat), line

voltage will be present:

L1 Power

1. Through the L1 black lead to the L1 terminal on the

ignition control

2. At the L1 contactor terminal

3. At the transformer terminal marked 208-240V

L2 Power

1. Through the L2 black lead to the induced draft

blower

2. At the L2 contactor terminal

3. A transformer common terminal

4. At the T2 contactor terminal

5. At the R terminal of the compressor

6. At the capacitor common terminals

Low Voltage (24 VAC)

With the unit at rest (no call from the thermostat), 24

volts A/C will be present:

control. This causes the combustion blower to

start by completing the line voltage circuit through

the L2 wire connection in the unit.

2. As the 24-volt signal is sent to pin 4 of the 6-pin

ignition wire harness by the ignition control, a 30-

second circulating air blower “on” dela y starts.

After the delay, the ignition control energizes the

heat speed blower relay. This sends L1 power to the

ACB HEAT terminal on the ignition control.

3. L1 power is then sent to the circulating air blower

terminal block where it is connected to the blower

motor. The circulating air blower starts by

completing the L1-L2 circuit through the L2 connection at the blower motor capacitor.

4. The combustion blower and the circulating air

blower continue to run until the R-W circuit is

interrupted. After a 5-second post-purge dela y, the

CMB BLWR terminal on the ignition control deenergizes. This interrupts L1 pow er to the combus-

tion blower. After a 120-second circulating air

blower “off” delay, the ACB HEAT terminal de-

energizes. This interrupts L1 to the circulating air

blower. As L1 pow er is interrupted, the blo wers

shut off.

Low Voltage

1. From the transformer 24V terminal to pin 4 of the

6-pin chassis low voltage harness

2. From pin 4 of the chassis low v oltage harness to the

24VAC hot terminal on the ignition control

3. From the 24VAC hot terminal to pin 5 of the 5-pin

thermostat harness (internal to board)

4. From the 24VAC hot terminal also to pin 6 of the 6-

pin ignition wire harness

5. From pin 6 of the ignition wire harness through the

auto reset limit switch and the manual reset

rollout switch to pin 1 of the 6-pin ignition wire

harness

Note: While the unit is at rest, the green LED shows

consistent slow flash. This indicates normal

operation - system at rest (standby mode).

CALL FOR HEAT

Line Voltage

The ignition control receives a signal from the R-W

circuit indicating a call for heat.

1. The combustion blower relay energizes, sending

L1 power to CMB BLWR terminal on the ignition

1. A call for heat closes the R-W circuit, sending a 24volt signal to the low v oltage white wire in the unit.

2. The 24-volt signal is received at pin 3 of the 5-pin

thermostat harness on the ignition control.

3. The 24-volt signal causes the combustion blower

relay to close, causing the combustion blower to

run. At this time, a 24-v olt signal is also sent out

through pin 2 of the 6-pin ignition wire harness.

4. The 24-volt signal from pin 2 of the 6-pin ignition

wire harness energizes one side of the Normally

Open pressure switch. As the induced draft

blower reaches full speed, the pressure switch

closes and a 24-volt signal is sent to pin 5 of the 6pin ignition wire harness.

5. When the 24-volt signal is received at pin 5 of the 6pin ignition wire harness, the ignition control starts

a 30-second pre-purge delay.

6. After the 30-second pre-purge, the ignition control

initiates a trial for ignition. The spark ignition

cable terminal and pin 4 of the 6-pin ignition wire

harness energize simultaneously .

7. When the 24-volt signal is present at pin 4 of the 6pin ignition wire harness, the ignition control starts

a 30-second circulating air blower “on” delay.

8. The 24-volt signal from pin 4 of the 6-pin ignition

wire harness is received at the gas valve, causing

it to open and the burners to ignite.

SRM-HW/HWC 2/99

Page 17

Service Reference Manual SEQUENCE OF OPERATIONS

9. After 30-second “on” delay, the circulating air

blower relay energizes the heat terminal and the

circulating air blower is energized.

10. The unit will continue to operate normally until the

R-W circuit is interrupted.

11. When the heat call is satisfied, the thermostat will

interrupt the R-W circuit. This causes the 24-volt

signal to the white wire in the unit to be de-energized.

12. The gas valve closes immediately as 24V through

pin 4 of the 6-pin ignition wire harness is deenergized by the ignition control.

13. The ignition control initiates a 120-second circu-

lating air blower “off” delay and 5-second com-

bustion blower post-purge delay.

14. After 5 seconds, the combustion blower shuts off.

15. After 120 seconds, the circulating air blower

shuts off and the system returns to standby mode.

Note: During a call for heat, the green LED shows

consistent fast flash (as long as the R-W circuit is

closed). When the R-W circuit is interrupted

(indicating the heat call has been satisfied), the

green LED returns to a consistent slow flash.

LIMIT/ROLLOUT OPENS

In all modes of operation, 24V AC is supplied to the

ignition control 24VAC hot terminal and is passed

through the ignition control to pin 6 of the 6-pin

ignition wire harness.

1. A 24-volt signal is sent from pin 6 of the 6-pin

ignition wire harness to one side of the Normally

Closed manual reset rollout switch, across the

rollout switch to one side of the Normally Closed

auto reset limit switch and across the limit switch

to pin 1 of the 6-pin ignition wire harness.

2. This circuit energizes whenever line v oltage po wer

is supplied to the unit.

3. If the circuit is interrupted by either switch opening,

the 24-volt signal to pin 1 of the 6-pin ignition wire

harness de-energizes.

4. This causes the combustion blower relay to

energize, sending L1 power to the CMB BLWR

terminal on the ignition control. It also causes the

circulating air blower heat speed relay to energize, sending L1 power to the ACB HEAT terminal

on the ignition control. This causes both blowers

to start immediately.

5. The ignition control lockouts the spark ignition

cable terminal and pin 4 of the 6-pin ignition wire

harness until the 24-volt signal is restored at pin 1 of

the 6-pin ignition wire harness.

6. The circulating air blower and the combustion

blower are energized until the 24-volt signal is

restored at pin 1 of the 6-pin ignition wire harness.

7. The green ignition control LED shows a 4 flash fault

code (indicating limit switch/rollout switch open).

8. When the 24-volt signal is restored at pin 1 of the 6pin ignition wire harness, the ignition control starts

a 5-second combustion blower post-purge delay

and a 120-second circulating air blower “off”

delay .

9. Once the delays hav e timed out, both b low ers stop

and the green LED flashes a consistent slow flash if

no heat call is present. (A consistent fast flash

appears if there is a call for heat.)

Note: The limit switch resets automatically when

temperatures are acceptable, b ut the rollout

switch must be manually reset by pushing in on

the small button on top of the switch.

The reason why the switches opened must be

determined before any corrective action is taken.

PRESSURE SWITCH OPENS (BLOCKED FLUE)

When the R-W circuit is energized, a 24-volt signal is

sent to the ignition control. This starts the call for

heat.

1. The 24-volt signal from the R-W circuit energizes

the combustion blower relay, sending L1 power to

the CMB BLWR terminal on the ignition control.

This starts the ignition control.

2. At the same time the combustion blower relay

energizes, the 24-volt signal is sent to pin 2 of the 6pin ignition wire harness and from pin 2 to one side

of the Normally Open pressure switch.

3. When the combustion blower causes the pres-

sure switch to close, a 24-volt signal is sent across

the switch to pin 5 of the 6-pin ignition wire harness.

The 24-volt signal energizes at pin 5 and the ignition

sequence continues.

4. If the combustion blower fails to close the pres-

sure switch, the 24-volt signal is not sent to pin 5

of the 6-pin ignition wire harness and the ignition

control does not initiate a 30-second pre-purge

delay.

5. No signal is sent to the spark ignition cable

terminal on the ignition control or to the gas valve

through pin 4 of the 6-pin ignition wire harness.

6. The combustion blower continues to run for 60

seconds. After 60 seconds, the ignition control

automatically de-energizes the combustion

blower relay. This interrupts L1 pow er to the CMB

BLWR terminal on the ignition control.

7. The combustion blower remains de-energized for

approximately six minutes. During this 6-minute

lockout, the green LED flashes three times (indicating pressure switch fault—open or closed).

2-7

SRM-HW/HWC 2/99

Page 18

2-8

SPECIFICATIONS Magic-Pak: HW/HWC

8. The 24-volt signal will only be supplied to the limit

switch circuit through pin 6 of the 6-pin ignition wire

harness and to the pressure switch circuit through

pin 2 of the 6-pin ignition wire harness.

9. The system will repeat this sequence until the

pressure switch closes and the 24-v olt signal is

restored at pin 5 of the 6-pin ignition wire harness.

FAILED FLAME SENSE/TRIAL FOR IGNITION

When the pressure switch closes and a 24-v olt signal

is sent to pin 5 of the 6-pin ignition wire harness, the

spark ignition cable terminal and pin 4 of the 6-pin

ignition wire harness energize.

1. As spark voltage is supplied to the ignitor elec-

trodes, the gas valve opens and this causes the

burners to ignite.

2. The ignition control continues to energize spark

voltage until a flame sense signal is supplied to the

flame terminal on the ignition control.

3. If a flame sense signal is not received at the flame

terminal on the ignition control, the spark igni-

tion cable terminal remains energized for 10

seconds.

4. After the 10-second trial for ignition, the ignition

control de-energizes the spark ignition cable

terminal and pin 4 of the 6-pin ignition wire harness.

This causes the gas valve to close and the electrode spark to stop.

5. Once the 24-volt signal is sent to pin 4 of the 6-pin

ignition wire harness, a 30-second circulating air

blower “on” delay starts. After the dela y is timed

out, the circulating air blower starts.

6. After the spark ignition cable terminal de-energizes, the ignition control initiates a 30-second

combustion blower inter-purge delay.

7. After 30-second inter-purge, the ignition control

energizes the spark ignition cable terminal and

pin 4 of the 6-pin ignition wire harness. If the flame

sense signal is received at the flame terminal of the

ignition control, the unit continues heat call.

8. If the flame sense signal is not received, the system

goes through three trials following the abov e

sequence.

9. After three trials, the system goes into lockout and

only the high limit switch circuit and pressure

switch circuit remain energized during the 60minute lockout period.

10. If the flame sense is lost during the heat cycle, the

gas valve de-energizes immediately and the

system goes into the trial sequence.

CALL FOR COOLING

Line Voltage

1. L2 power passes through the fix ed closed L2-T2

terminals on the contactor to the RUN terminal of

the compressor and the COMMON terminal of the

capacitor.

2. L1 power is sent to the L1 terminal of the contactor.

When the Y signal energizes the contactor, the T2

terminal becomes energized. L1 pow er is sent to

the compressor COMMON terminal and the

condenser fan. This energizes the compressor

and condenser fan motors.

3. When pin 1 (Y terminal) of the 5-pin thermostat

harness receives a 24-volt signal from the thermo-

stat, a 5-second circulating air blower delay

starts.

4. After the 5-second delay, the ignition control

energizes the cooling speed relay. This sends L1

power to the ACB COOL terminal of the ignition

control.

5. L1 power is sent to the circulating air blower

terminal block, energizing the circulating air

blower motor.

6. When the R, Y and G circuit is interrupted by the

thermostat, the contactor is immediately de-

energized. This interrupts L1 power to the com-

pressor and condenser fan motors, stopping

both.

7. The ignition control starts a 90-second circulat-

ing air blower “off” delay, after which the ACB

COOL terminal de-energizes. This interrupts L1

power to the circulating air blower motor, causing

it to stop.

Low Voltage

1. The thermostat energizes the R, Y and G circuit,

sending a 24-volt signal to the contactor coil and to

pin 1 of the 5-pin thermostat harness connected to

the ignition control.

2. The contactor closes immediately upon receiving

the 24-volt signal, causing the compressor and

condenser fan motors to start.

3. The 24-volt signal is also sent to pin 1 of the 5-pin

thermostat harness, initiating a 5-second circulat-

ing air blower “on” delay.

4. After the 5-second delay, the ignition control

energizes the cooling speed relay and the circulat-

ing air blower starts.

5. When the cooling call is satisfied, the thermostat

interrupts the R, Y and G circuit. The contactor

de-energizes immediately, causing the compressor

and the condenser fan to stop. The ignition

control starts a 90-second circulating air blower

“off” delay.

SRM-HW/HWC 2/99

Page 19

Service Reference Manual SEQUENCE OF OPERATIONS

6. After the 90-second delay, the ignition control deenergizes the cooling speed relay and the circulat-

ing air blower stops.

FAN ON

1. When the thermostat is switched to the “FAN ON”

position, the R-G circuit sends a 24-volt signal to

pin 4 of the 5-pin thermostat harness.

2. The 24-volt signal energizes the cooling speed

relay, sending L1 power to the ACB COOL terminal

of the ignition control.

3. L1 power is sent to the circulating air blower

terminal block, causing the circulating air blower

to run in cooling speed.

4. The circulating air blower continues to run in

cooling speed until the thermostat is switched to

“AUT O”, interrupting the R-G circuit.

Note: With the thermostat in the “FAN ON” position

during heat call, ignition control will not energize

the heat speed relay. The circulating air blower

continues to run in cooling speed unless the limit

switch circuit opens, which would cause the heat

speed relay and the induced draft blower relay

to become energized. This would de-energize the

cooling speed relay until either the limit switch

circuit is closed or the thermostat is switched to

the “AUT O” position.

2-9

SRM-HW/HWC 2/99

Page 20

2-10

SPECIFICATIONS Magic-Pak: HW/HWC

HW (Heating Only)

(w/United Technologies 1097 Spark Ignition System)

208/230-1-60

}

POWER SUPPLY

BLACK

BLACK

COPPER CONDUCTORS

ONLY

BLACK BLACK

COMBUSTION

BLOWER

BLACK

VOILET

PRESSURE

SWITCH

VOILET

AUTO RESET

LIMIT SWITCH

ORANGE

YELLOW

CONNECTION DIAGRAM

CNB

L1

1

2

3

4

RGWCY

5

4

1

MANUAL RESET

LIMIT SWITCH

TRANSFORMER

RED

GAS

VALVE

ORANGE

GREEN

WHITE

RED

BLUE

COOL

HEAT

IGNITION

CONTROL

6

5

2

3

ORANGE

YELLOW

RED

BLUE

BLACK

UNUSED

GND

BLACK

RED

WHT

24VAC

GREEN

ELECTRODE

FLAME ROD

208 V

240 V

WIRE NUT

BLUE

RED

CIRCUITS ENERGIZED

OPERATING MODE CIRCUIT

HEATING R-W

COOLING R-G-Y

FAN R-G

LINE VOLTAGE-FA CTORY

LINE VOLTAGE-FACTORYWHEN USED

LINE VOLTAGE-FIELD

LOWVOLTAGE-FACTOR Y

LOWVOLTAGE-FIELD

BLUE

YELLOW

R

G

Y

W

RED

NOTE:

IF ANY OF THE ORIGINAL

WIRES ARE REPLACED,THE

SAME SIZE AND TYPE WIRE

MUST BE USED.

CONNECTOR

BLOCK

R

G

Y

}

W

EVAP. MOTOR

EVAP. MOTOR

SPEED CONNECTIONS

SPEED CONNECTIONS

51HW

64HW

HEATINGHEATINGMODELS

LOW (RED)LOW (RED)26HW

HIGH (BLACK)38HW

MED (BLUE)

HIGH (BLACK)

THERMOST AT

SEE

CHART

FORWIRING

CAPACITORCAPACITOR

BLOWER

YELLOW

BROWN

BLOWER

MOTOR

BLACK

BLUE

RED

H

M

L

TERMINAL BLOCK

FIGURE 2-2 Connection Diagram

#45008-2

The following blower/ignition control board

LED codes will indic a te n o rmal or abnormal

operations:

SLOW FLASH Normal Operation, No

FAS T F L A SH Normal Operation,Call for

2 FLASH System Lockout - Failed to

3 FLASH Pressure Switch Open or

4 FLASH High Limit or Rollout

5 FLASH Flame Sensed and Gas

STEADY Internal Failure

DIAGNOSTICS

Call for Heat

Heat

Detect or Sustain Flame

Closed

Switch Open

Valve Not Energized

(Micro-controlle r Failure;

Self-check)

SRM-HW/HWC 2/99

Page 21

Service Reference Manual SEQUENCE OF OPERATIONS

Simplified Sequence - HW (w/UTEC 1097 Board)

Refer to Figure 2-2

CALL FOR HEAT

1. The indoor thermostat energizes the R-W circuit,

sending a 24-volt signal to the ignition control.

2. The 24-volt signal causes the induced draft blo wer

to start, which closes the pressure switch.

3. Once the pressure switch closes, a 30-second

induced draft blower pre-purge starts.

4. After the 30-second induced draft blower pre-purge ,

the gas valve opens and the b urners ignite. This

starts a 30-second circulating air blower “on” dela y.

5. The unit continues to operate in the heat mode until

the indoor thermostat setting is reached. At that

time, the R-W circuit is interrupted.

6. The 24-volt signal to the ignition control is interrupted, causing the gas valve to close and the

burners to shut down.

7. A 5-second post-purge starts and following that the

induced draft blower stops .

8. A 120-second circulating air blower “off” delay

starts. After the elapsed time, the circulating air

blower stops .

2-11

FAN ON

1. When the thermostat is switched to the “FAN ON”

position, a 24-volt signal is sent to the ignition

control.

2. The ignition control immediately energizes the

cooling speed of the circulating air blower.

3. The circulating air blower runs in the cooling speed

until the thermostat fan switch is mov ed bac k to the

“AUT O” position. At this time, the circulating air

blower stops .

During the call for “FAN ON”, the circulating air blower

heat speed will not be energized by the ignition control

unless the limit switch circuit is interrupted.

SRM-HW/HWC 2/99

Detailed Sequence follows

Page 22

2-12

SPECIFICATIONS Magic-Pak: HW/HWC

Detailed Sequence - HW (w/UTEC 1097 Board)

Refer to Figure 2-2

POWER

Line Voltage

With the unit at rest (no call from the thermostat), line

voltage will be present:

L1 Power

1. Through the L1 black lead to the L1 terminal on the

ignition control

2. At the transformer terminal marked 208-240V

L2 Power

1. Through the L2 black lead to the induced draft

blower

2. Transformer common terminal

3. At the circulating air blower capacitor terminal

Low Voltage (24 VAC)

With the unit at rest (no call from the thermostat), 24

volts A/C will be present:

1. At the transformer 24V terminal

2. At the 24VAC hot terminal on the ignition control

3. At pin 5 of the 5-pin thermostat harness (red wire

pin)

4. At pin 6 of the 6-pin ignition wire harness

5. Through the auto reset limit switch and the

manual reset rollout switch to pin 1 of the 6-pin

ignition wire harness

Note: While the unit is at rest, the green LED shows

consistent slow flash. This indicates normal

operation - system at rest (standby mode).

CALL FOR HEAT

Line Voltage

The ignition control receives a signal from the R-W

circuit indicating a call for heat.

1. The combustion blower relay energizes, sending

L1 power to CMB BLWR terminal on the ignition

control. This causes the combustion blower to

start.

2. As the 24-volt signal is sent to pin 4 of the 6-pin

ignition wire harness by the ignition control, a 30-

second circulating air blower “on” delay starts.

After the delay, the ignition control energizes the

heat speed blower rela y. This sends L1 power to

the ACB HEAT terminal on the ignition control.

3. L1 power is then sent to the circulating air blower

terminal block where it is connected to the blower

motor, starting the circulating air blower.

4. The combustion blower and the circulating air

blower continue to run until the R-W circuit is

interrupted. After a 5-second post-purge dela y, the

CMB BLWR terminal on the ignition control deenergizes. This interrupts L1 pow er to the combus-

tion blower. After a 120-second circulating air

blower “off” delay, the ACB HEAT terminal de-

energizes. This interrupts L1 to the circulating air

blower. As L1 pow er is interrupted, the blo wers

shut off.

Low Voltage

1. A call for heat closes the R-W circuit, sending a 24volt signal to the low v oltage white wire in the unit.

2. The 24-volt signal is received at pin 3 of the 5-pin

thermostat harness on the ignition control.

3. The 24-volt signal causes the combustion blower

relay to close, causing the combustion blower to

run. At this time, a 24-v olt signal is also sent out

through pin 2 of the 6-pin ignition wire harness.

4. The 24-volt signal from pin 2 of the 6-pin ignition

wire harness energizes one side of the Normally

Open pressure switch. As the induced draft

blower reaches full speed, the pressure switch

closes and a 24-volt signal is sent to pin 5 of the 6pin ignition wire harness.

5. When the 24-volt signal is received at pin 5 of the 6pin ignition wire harness, the ignition control starts

a 30-second pre-purge delay.

6. After the 30-second pre-purge, the ignition control

initiates a trial for ignition. The spark ignition

cable terminal and pin 4 of the 6-pin ignition wire

harness energize simultaneously .

7. When the 24-volt signal is present at pin 4 of the 6pin ignition wire harness, the ignition control starts

a 30-second circulating air blower “on” delay.

8. The 24-volt signal from pin 4 of the 6-pin ignition

wire harness is received at the gas valve, causing

it to open and the burners to ignite.

9. After 30-second “on” delay, the circulating air

blower relay energizes the heat terminal and the

circulating air blower is energized.

10. The unit will continue to operate normally until the

R-W circuit is interrupted.

11. When the heat call is satisfied, the thermostat will

interrupt the R-W circuit. This causes the 24-volt

signal to the white wire in the unit to be de-energized.

SRM-HW/HWC 2/99

Page 23

Service Reference Manual SEQUENCE OF OPERATIONS

12. The gas valve closes immediately as 24V through

pin 4 of the 6-pin ignition wire harness is deenergized by the ignition control.

13. The ignition control initiates a 120-second circu-

lating air blower “off” delay and 5-second com-

bustion blower post-purge delay.

14. After 5 seconds, the combustion blower shuts off.

15. After 120 seconds, the circulating air blower

shuts off and the system returns to standby mode.

9. Once the delays hav e timed out, both b low ers stop

and the green LED flashes a consistent slow flash if

no heat call is present. (A consistent fast flash

appears if there is a call for heat.)

Note: The limit switch resets automatically when

temperatures are acceptable, b ut the rollout

switch must be manually reset by pushing in on

the small button on top of the switch.

2-13

Note: During a call for heat, the green LED shows

consistent fast flash (as long as the R-W circuit is

closed). When the R-W circuit is interrupted

(indicating the heat call has been satisfied), the

green LED returns to a consistent slow flash.

LIMIT/ROLLOUT OPENS

In all modes of operation, 24V AC is supplied to the

ignition control 24VAC hot terminal and is passed

through the ignition control to pin 6 of the 6-pin

ignition wire harness.

1. A 24-volt signal is sent from pin 6 of the 6-pin

ignition wire harness to one side of the Normally

Closed manual reset rollout switch, across the

rollout switch to one side of the Normally Closed

auto reset limit switch and across the limit switch

to pin 1 of the 6-pin ignition wire harness.

2. This circuit energizes whenever line v oltage po wer

is supplied to the unit.

3. If the circuit is interrupted by either switch opening,

the 24-volt signal to pin 1 of the 6-pin ignition wire

harness de-energizes.

4. This causes the combustion blower relay to

energize, sending L1 power to the CMB BLWR

terminal on the ignition control. It also causes the

circulating air blower heat speed relay to energize, sending L1 power to the ACB HEAT terminal

on the ignition control. This causes both blowers

to start immediately.

5. The ignition control lockouts the spark ignition

cable terminal and pin 4 of the 6-pin ignition wire

harness until the 24-volt signal is restored at pin 1 of

the 6-pin ignition wire harness.

6. The circulating air blower and the combustion

blower are energized until the 24-volt signal is

restored at pin 1 of the 6-pin ignition wire harness.

7. The green ignition control LED shows a 4 flash fault

code (indicating limit switch/rollout switch open).

8. When the 24-volt signal is restored at pin 1 of the 6pin ignition wire harness, the ignition control starts

a 5-second combustion blower post-purge delay

and a 120-second circulating air blower “off”

delay.

The reason why the switches opened must be

determined before any corrective action is taken.

PRESSURE SWITCH OPENS (BLOCKED FLUE)

When the R-W circuit is energized, a 24-volt signal is

sent to the ignition control. This starts the call for

heat.

1. The 24-volt signal from the R-W circuit energizes

the combustion blower relay, sending L1 power to

the CMB BLWR terminal on the ignition control.

This starts the ignition control.

2. At the same time the combustion blower relay

energizes, the 24-volt signal is sent to pin 2 of the 6pin ignition wire harness and from pin 2 to one side

of the Normally Open pressure switch.

3. If the combustion blower causes the pressure

switch to close, a 24-volt signal is sent across the

switch to pin 5 of the 6-pin ignition wire harness.

The 24-volt signal energizes at pin 5 and the ignition

sequence continues.

4. If the combustion blower fails to close the pres-

sure switch, the 24-volt signal is not sent to pin 5

of the 6-pin ignition wire harness and the ignition

control does not initiate a 30-second pre-purge

delay.

5. No signal is sent to the spark ignition cable

terminal on the ignition control or to the gas valve

through pin 4 of the 6-pin ignition wire harness.

6. The combustion blower continues to run for 60

seconds. After 60 seconds, the ignition control

automatically de-energizes the combustion

blower relay. This interrupts L1 pow er to the CMB

BLWR terminal on the ignition control.

7. The combustion blower remains de-energized for

approximately six minutes. During this 6-minute

lockout, the green LED flashes three times (indicating pressure switch fault—open or closed).

8. The 24-volt signal will only be supplied to the limit

switch circuit through pin 6 of the 6-pin ignition wire

harness and to the pressure switch circuit through

pin 2 of the 6-pin ignition wire harness.

9. The system will repeat this sequence until the

pressure switch closes and the 24-volt signal is

restored at pin 5 of the 6-pin ignition wire harness.

SRM-HW/HWC 2/99

Page 24

2-14

SPECIFICATIONS Magic-Pak: HW/HWC

FAILED FLAME SENSE/TRIAL FOR IGNITION

When the pressure switch closes and a 24-v olt signal

is sent to pin 5 of the 6-pin ignition wire harness, the

spark ignition cable terminal and pin 4 of the 6-pin

ignition wire harness energize.

1. As spark voltage is supplied to the ignitor elec-

trodes, the gas valve opens and this causes the

burners to ignite.

2. The ignition control continues to energize spark

voltage until a flame sense signal is supplied to the

flame terminal on the ignition control.

3. If a flame sense signal is not received at the flame

terminal on the ignition control, the spark igni-

tion cable terminal remains energized for 10

seconds.

4. After the 10-second trial for ignition, the ignition

control de-energizes the spark ignition cable

terminal and pin 4 of the 6-pin ignition wire harness.

This causes the gas valve to close and the electrode spark to stop.

5. Once the 24-volt signal is sent to pin 4 of the 6-pin

ignition wire harness, a 30-second circulating air

blower “on” delay starts. After the dela y is timed

out, the circulating air blower starts.

6. After the spark ignition cable terminal de-energizes, the ignition control initiates a 30-second

combustion blower inter-purge delay.

7. After 30-second inter-purge, the ignition control

energizes the spark ignition cable terminal and

pin 4 of the 6-pin ignition wire harness. If the flame

sense signal is received at the flame terminal of the

ignition control, the unit continues heat call.

8. If the flame sense signal is not received, the system

goes through three trials following the abov e

sequence.

9. After three trials, the system goes into lockout and

only the limit switch circuit and pressure switch

circuit remain energized during the 60-minute

lockout period.

10. If the flame sense is lost during the heat cycle, the

gas valve de-energizes immediately and the

system goes into the trial sequence.

4. The circulating air blower continues to run in

cooling speed until the thermostat is switched to

“AUTO”, interrupting the R-G circuit.

Note: With the thermostat in the “FAN ON” position

during heat call, ignition control will not energize

the heat speed relay. The circulating air blower

continues to run in cooling speed unless the limit

switch circuit opens, which would cause the heat

speed relay and the induced draft blower relay

to become energized. This would de-energize the

cooling speed relay until either the limit switch

circuit is closed or the thermostat is switched to

the “AUT O” position.

FAN ON

1. When the thermostat is switched to the “FAN ON”

position, the R-G circuit sends a 24-volt signal to

pin 4 of the 5-pin thermostat harness.

2. The 24-volt signal energizes the cooling speed

relay, sending L1 power to the ACB COOL terminal

of the ignition control.

3. L1 power is sent to the circulating air blower

terminal block, causing the circulating air blower

to run in cooling speed.

SRM-HW/HWC 2/99

Page 25

Service Reference Manual SEQUENCE OF OPERATIONS

2-15

BLANK PAGE

SRM-HW/HWC 2/99

Page 26

2-16

SPECIFICATIONS Magic-Pak: HW/HWC

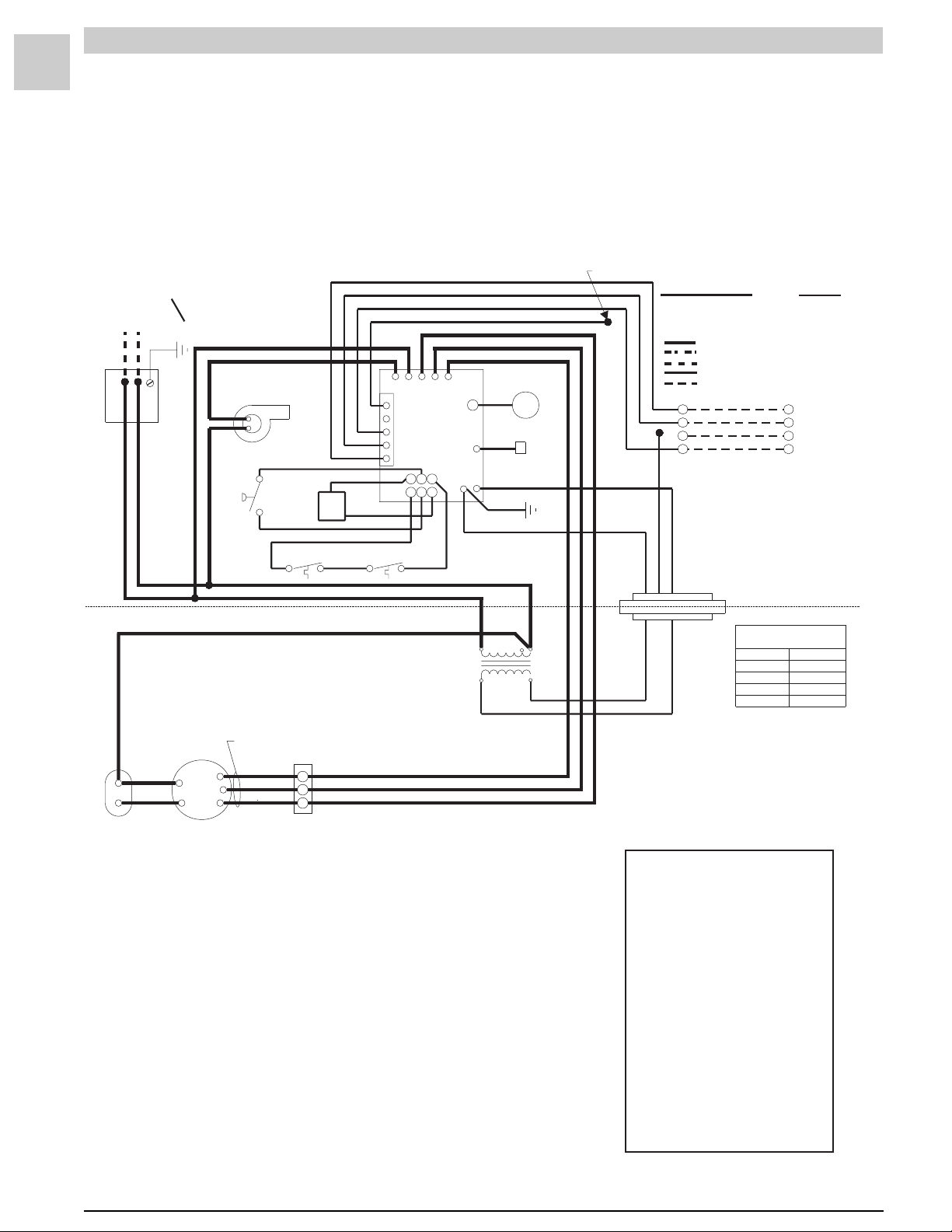

HWC122, 182, 242, 302

(w/Fenwal T(w/Fenwal T

(w/Fenwal T

(w/Fenwal T(w/Fenwal T

208/230-1-60

COPPER CONDUCTORS

POWER SUPPLY

TH

P.S W

V1

IND

BLACK

BLACK

IGNITION

CONTROL

ELECTRODE

CABLE

BLACK

CONDENSER FAN

HERM

RED

BROWN

YEL

VIOLET

BROWN

RED

MOTOR

SEE TABLE

FORWIRING

CAPACITOR-RUN

FAN

COM

CAPACITY BLOWER

BLOWER

24VAC

YELLOW

L1

V2

GND

BLK

BLUE

RED

SEE TABLE

riton 2461D DSI Ignition Contrriton 2461D DSI Ignition Contr

riton 2461D DSI Ignition Contr

riton 2461D DSI Ignition Contrriton 2461D DSI Ignition Contr

CIRCUITS ENERGIZED

OPERATING MODE

ONLY

GREEN

BLACK

S

BLOWER

CONTROL

ORN

ORN

C

H

L1

WHITE

RED

C

R

BLUE

BLUE

BLACK

BLACK

BLACK

RED

BLK

GAS

VALVE

C

R

W

G

PINK

BLUE

MANUAL

RESET

WHITE

PRESSURE

BROWN

COMBUSTION

BLACK

BLACK

T1

CONTACTOR

T2

YEL

BLK

COMP T’STAT

(IF USED)

LIMIT

SWITCH

SWITCH

BLOWER

L1

L2

FORMER

BLUE

RED

BLK

WHITE

GREEN

NO

NC

WHITE

CONNECTOR

BLOCK

BLACK

BLACK

TRANS-

YEL YEL

BLUE

208V

CONTR

LOAD

COM

TIME DELAY

(IF USED)

RED

C

WHITE

BLUE

BLUE

240V

HEATING

COOLING

FAN

LINE VOLTAGE - FACTORY

LINE VOLTAGE - FACTORY (WHEN USED)

LINE VOLTAGE - FIELD

LOWVOLTAGE - FACTORY

LOWVOLTAGE - FIELD

R

W

Y

G

YELLOW

GREEN

WHITE

RED

RED

NOTE:

EVAPORATOR MOTOR

SPEED CONNECTIONS

MODELS

26HWC122

38HWC122

38HWC182

51HWC182

64HWC182

38HWC242

51HWC242

64HWC242

51HWC302

64HWC302

*

ol)ol)

ol)

ol)ol)

CIRCUIT

R-W

R-G-Y

R-G

R

W

THERMOSTAT

Y

G

IF ANY OF THE ORIGINAL

WIRES ARE REPLACED ,

THE SAME SIZE AND TYPE

WIRE MUST BE USED.

HEATING

LOW (RED)

HIGH (BLK)

LOW (RED) LOW (RE D )

MED (BLUE)

HIGH (BLK)

LOW (RED)

MED (BLUE)

HIGH (BLK)

MED (BLUE)

HIGH (BLK)

JUMPER REQUIRED

COOLING

MED (BLUE)

MED (BLUE)

LOW (RED)

LOW (RED)

MED (BLUE)

MED (BLUE)

MED (BLUE)

HIGH (BLK)

HIGH (BLK)

#39007D5

*

*

*

Note: On units that are equipped with a low ambient switch (designated with an “SA” in the model

number), sequence of operation during cooling call is modified when outdoor temperatures fall

below the normal operating range. F or more inf ormation on the low ambient s witch equipped

version of this unit, see the section beginning on page 2-38.

FIGURE 2-3 Connection Diagram

SRM-HW/HWC 2/99

Page 27

Service Reference Manual SEQUENCE OF OPERATIONS

Simplified Sequence - HWC122,182, 242, 302

(w/Fenwal Triton 2461D DSI Ignition Control)

Refer to Figure 2-3

2-17

CALL FOR HEAT

1. A call for heat closes the circuit between wires R

(red) and W (white) on the unit’s thermostat connections.

2. A low voltage (24 volts) signal is sent to the ignition

control, closing a relay which sends line voltage to

the induced draft blower. At the same time, a 24volt signal is also sent to the blow er control board.

This causes the blower control board to begin the

countdown to closing the relay that starts the

circulating air blower .

3. After the induced draft blower creates enough

negative pressure, the pressure s witch closes.

4. When the pressure switch closes, the 24-v olt signal

is sent to the ignition control. This starts a 30second pre-purge countdown, after which a trial for

ignition is made.

5. At the same time that the trial for ignition is made,

the gas valve energizes and gas flo ws to the

burners.

6. With the burners in operation, the trial for ignition

continues for se ven seconds. At the end of this

time, the ignition control stops sparking.

7. Approximately 30 seconds after the burners ignite,

the timer on the blower control board closes a rela y,

sending line voltage to and starting the circulating

air blower.

8. The unit continues to operate as long as there is a

24-volt signal between R and W. When the call f or

heat is satisfied, the 24-volt signal between R and W

discontinues. When W de-energizes, the pow er to

the induced draft blow er and the gas valve is

interrupted. The 24-volt signal to the blo wer control

board is also interrupted, causing the module to

start the countdown to blower “off” (approximately

90 seconds).

9. If at any time during a call for heat the limit switch

opens, the 24-volt signal to the white wire going to

terminal P.SW on the ignition control is interrupted.

This de-energizes the gas valve immediately. The

circulating air blower and the induced draft b lower

continue to run. When the unit cools down enough

for the limit switch to close , the 24-volt signal is

again sent to the P.SW terminal on the ignition

control. With terminal P.SW energized, the ignition

control again makes a trial for ignition and relights

the burners.

CALL FOR COOLING

1. A call for cooling closes the circuit from R to Y and

G.

2. A 24-volt signal is sent to blower control board

terminal G and to the compressor contactor. The

contactor closes, sending line voltage to the compressor and the outdoor condenser fan.

3. With a 24-volt signal at terminal G on the blower

control board, the circulating air blower starts in

cooling speed approximately 15 seconds later (or

immediately - see note below).

4. When the cooling call is completed, G and Y deenergize. The contactor opens immediately, stopping the compressor and the outdoor cooling fan.

When G de-energizes, the timer to turn off the

circulating air blower starts. The circulating air

blower turns off after 90 seconds (see note below).

FAN ON

1. When the thermostat switch is moved to the “FAN

ON” position, the circuit between R and G closes.

2. The 24-volt signal from G goes to the blo wer control

board which starts the timer.

3. Fifteen seconds after terminal G on the blower

control board energizes (or immediately after - see

note below), the circulating air blower starts.

4. When terminal G on the blower control board deenergizes, the timer to turn off the circulating air

blower starts. The circulating air blow er turns off

after 90 seconds (see note below).

Note: Heatcraft blow er control boards ha v e a G “on”

delay of 15 seconds and an “off” dela y of 90

seconds. Tridelta blower control boards have no

“on” time delay and a 60 -130 second “off” delay.

SRM-HW/HWC 2/99

Detailed Sequence follows

Page 28

2-18

SPECIFICATIONS Magic-Pak: HW/HWC

Detailed Sequence - HWC122, 182, 242, 302

(w/Fenwal Triton 2461D DSI Ignition Control)

Refer to Figure 2-3

POWER

Line Voltage

When the service disconnect switch is closed, power is

sent to the unit (unit in standby, no signal from the

thermostat). Power (208 - 230 v olts A/C) is supplied

to both black wires located in the junction block on top

of the unit.

Line voltage will be present at the follo wing locations:

First black wire

1. L-1 on the ignition control

2. L-1 on the contactor

3. L-1 on the blower control board

4. Terminal on the transformer marked 208V or

240V (whichever is being used)

Second black wire

1. Supplies power to the induced draft blower

2. L-2 on the contactor

3. Common terminal on the transformer

4. T-2 on the contactor

5. Red wire on the R terminal of the compressor

6. Red wire to the common terminals on the capaci-

tors

Low Voltage (24 VAC)

With the unit at rest (no call from the thermostat), 24

volts A/C will be found at these points:

1. Red wire exiting the top of the unit

2. Terminal marked 24 VAC on the ignition control

3. Terminal R on the blower control board

CALL FOR HEAT

Line Voltage

The thermostat closes the circuit between R and W.

The following is the sequence of operation f or the line

voltage side of the unit:

1. Terminal TH (24-volt) energizes on the ignition

control, causing the relay in the ignition control

to close. This sends line voltage to the terminal

marked IND, causing the induced draft blower to

start.

2. When W energizes, a 24-v olt signal is also sent to

the W terminal on the blower control board. The

24-volt signal to the blower control board starts

the timer on the board. After 60 seconds , the heat

speed relay on the blower control board closes.

This sends line voltage from the terminal marked

HEAT to the circulating air blower, starting the

blower. The induced draft blower and the circu-

lating air blower continue to operate until the heat

call is satisfied, interrupting the circuit between R

and W. The W terminal de-energizes, causing the

blower rela y to open appro ximately 90 seconds

later. This interrupts the line v oltage to the circulat-

ing air blower and the blow er shuts do wn.

Low Voltage

1. A call for heat closes the circuit in the thermostat

between R and W, sending a 24-volt signal to the

white wire on the unit.

2. The white wire goes to the C terminal on the limit

switch, ignition control terminal TH and terminal

W on the blower control board.

3. When W energizes, the timer starts a countdown to

blower “on”. The blow er starts in approximately 60

seconds.

4. The 24-volt signal sent to terminal TH closes the

relay in the ignition control. This starts the

induced draft blower by energizing terminal IND

on the ignition control.

5. As the induced draft blower comes up to speed

and creates enough negative pressure, the pres-

sure switch closes. The 24-volt signal from the

pressure switch energizes terminal P.SW, causing

the ignition control to start a trial for ignition

(sparking).

6. As the trial for ignition starts, the V1 terminal on the

ignition control energizes. At the same time, a 24volt signal is sent to the gas valve, opening the

valve . The unit contin ues to operate as long as W is

energized.

7. When the call for heat is satisfied, the circuit between R and W is interrupted.

8. With W de-energized, the gas valve closes immediately and the induced draft blower shuts down

sever al seconds later .

9. The blower control board starts a countdown to

blower “off”. Appro ximately 90 seconds later, the

blower shuts do wn.

SRM-HW/HWC 2/99

Page 29

Service Reference Manual SEQUENCE OF OPERATIONS

LIMIT OPENS

If the limit switch opens for an y reason during a call f or

heat, the following happens:

1. If the limit switch senses that the temperature in

the unit is too high, the contacts between terminals

C and NC on the limit switch open and the contacts between C and NO close. This interrupts the

24-volt signal to the pressure switch and also de-

energizes terminal P.SW on the ignition control.

The gas valve closes immediately, as the 24-volt

signal to terminal P.SW is no longer present. The

induced draft blower and the circulating air

blower continue to run. Power to blower control

board terminal W is maintained. The blowers

continue to run until the limit switch closes or the

heat call at the thermostat is satisfied.

2. When the limit switch senses that temperatures in

the unit are normal, the contacts between terminals

C and NO open, the contacts between terminals C

and NC close and operation of the unit returns to

normal.

PRESSURE SWITCH OPENS (BLOCKED FLUE)

1. If blockage of the flue occurs, the negativ e pressure

in the induced draft blower is reduced. At the set

point of the pressure switch, the contacts open.

This interrupts the 24-volt signal to terminal P.SW

on the ignition control. The gas valve closes

immediately, as the relay in the ignition control

opens and interrupts the signal to terminal V2 of the

ignition control.

2. Terminal W on the blower control board stays

energized and the circulating air blower continues to run. If the negativ e pressure is restored, the