Page 1

HumidiClean

™

Series HC- 6100/6300/6500/6700

Humidifiers

Installation, Operation and

Maintenance Instructions

Table of Contents

Page

Warning Labels 2-3

Description of Model Number 4

Installation 6-12

Display Menu 13-16

Start-Up Procedure and Operation 16-17

Maintenance 18-22

Troubleshooting 22-27

Typical Wiring Schematic 28-37

Repair Parts 36-42

Software Update 43-46

Communication 46-51

Warranty 52

Please read and save these instructions.

Bulletin 539-A

Page 2

The Armstrong HumidiClean humidifier converts ordinary tap water or purified water to steam

for distribution to raise the relative humidity level.

To allow HumidiClean to function to its full capability, be certain to install in accordance with

Armstrong recommendations.

DANGER: ELECTRICAL SHOCK HAZARD HIGH VOLTAGES EXIST INSIDE THE HUMIDIFIER

TO PROTECT YOURSELF AND OTHERS FROM ACCIDENTAL SHOCKS:

1. Keep the humidifier locked during normal operation and store the key in a safe location away

from the humidifier.

2. ALWAYS DISCONNECT THE POWER SUPPLY AT THE CIRCUIT BREAKER OR SAFETY

SWITCH BEFORE OPENING ANY COVERS AND DOORS!

3. Before servicing the humidifier, learn where the high voltage parts are. KEEP HANDS AND

METAL TOOLS A WA Y FROM THESE AREAS!

Warning: All wiring and installation must be completed by qualified personnel

only and per the relevant local or national codes on electrical wiring. Negligence

of this warning might result in the loss of property or personal damage.

Warning: High Temperature! Material that is not resistant to high temperature

should not come in contact with these areas. Negligence of this warning might

result in the loss of property or personal damage.

2

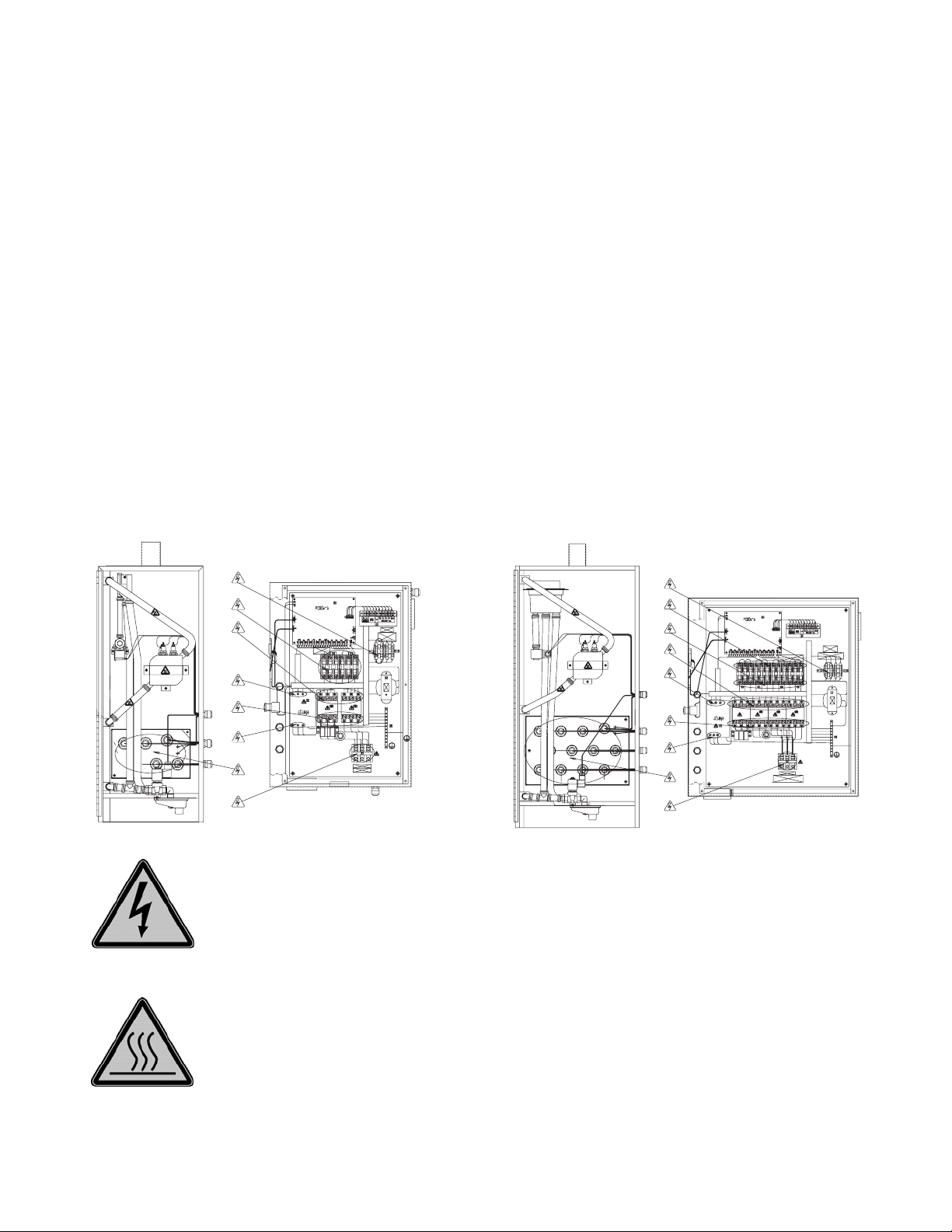

6010-ISO Electrical

Shock-Electrocution

6043-ISO Burn Hazard

Hot Surface

Model HC-6100/HC-63000 Series

Model HC-6500/HC-67000 Series

Page 3

Warning: Do not operate the supplied humidifier in combustible or explosive surroundings.

Warning: Do not operate the supplied humidifier if there is any damage to the cabinet or any

components in humidifier are damaged.

Warning: The main switch should be a connection breaker which has over current and leakage

current protecting functions per code EN60947-3 or EN60947-2 if point gap required by EN60947-3

can be fulfilled.

4. Physical environment and operating conditions

• Ambient temperature + 4°C ~ + 38°C (40°F to 100°F)

• Humidity = 50 % at 40°C (104°F), = 90 % at 20°C (68°F)

• Altitude = 1000 m (above mean sea level) (3300 ft)

5. Transportation and storage conditions

Electrical equipment shall be designed to withstand, or suitable precautions shall be taken to

protect against, the effects of transportation and storage temperatures within a range of

-25°C to + 55°C (-15°F to 130°F) and for short periods not exceeding 24h, up to +70°C (160°F).

Suitable means shall be provided to prevent damage from humidity, vibration and shock.

6. Requirements

The supply disconnecting device (i.e. a switch-disconnect, a disconnect used in combination with

switching devices, or a circuit-breaker) shall fulfill all of the following requirements:

• Isolate the electrical equipment from the supply and have one OFF (isolated) and one ON

position only, clearly marked with "O" and "I" (symbols 60417-2-IEC-5008 and

60417-2-IEC-5007, see 10.2.2), with the actuating directions in accordance with IEC60447.

Circuit-breaker that, in addition, has a reset (tripped) position between "O" and "I" are also

deemed to satisfy this requirement

• Have a visible gap or a position indicator which cannot indicate OFF (isolated) until all contacts

are actually open and there is an adequate isolating distance between all the contacts in

accordance with IEC 60947-3

• Have an external operating means (e.g. handle), (exception: power-operated switchgear need

not be operable from outside the enclosure where there are other means to open it). The

handle should be BLACK or GREY (exception: see 10.7.4)

• Be provided with a means permitting it to be locked in the OFF (isolated) position

(e.g. by padlocks). When locked, remote as well as local closing shall be prevented

• Disconnect all live conductors of its power supply circuit. However, for TN supply systems, the

neutral conductor may or may not be disconnected. It is noted that in some countries,

disconnection of the neutral conductor (when used) is compulsory

• The handle of the supply-disconnecting switch shall be located between 0.6m and 1.7m

(2 ft. and 5-1/2 ft) above the servicing level

• The disconnecting switch must have over current and overload protecting functions and

initialize them as low as possible under normal running

3

Page 4

• This disconnecting switch should have leakage current protecting function. The max leakage

current should be less than 30mA

• The disconnecting switch should have a breaking capacity sufficient to interrupt the largest

normal running current of loads. The breaking capacity required should be selected according

to the table, 7-1, 7-2, 7-3 and 7-4 located on page 7.

Model Description

A = Rated voltage of unit is 208V D = Rated voltage of unit is 480V

B = Rated voltage of unit is 240V/220V E = Rated voltage of unit is 600V

C = Rated voltage of unit is 400V/380V

Pre-Installation

1. Check Shipment. A claim should be filed with the transportation company, (and reported to

Armstrong), if any items are missing or damaged.

2. Check Local Codes. The installation of HumidiClean should be in accordance with all applicable

building, plumbing, and electrical codes.

3. Site Selection. The humidifier should be installed in an easily accessible location. Do not install

the unit where malfunction of the humidifier might cause damage to non-repairable,

irreplaceable or priceless property. Refer to Installation section for other details regarding site

selection.

4

HC - XXXX (DI) - XXX X

Series HumidiClean™ Humidifiers

Type number

6100

6300

6500

6700

Quality of Water

Blank: Tap water

DI: Deionized or reverse osmosis

Rated Power

In KW. The minimum is 3 KW, and the maximum is 96KW.

Symbol of Rated Voltage

Page 5

5

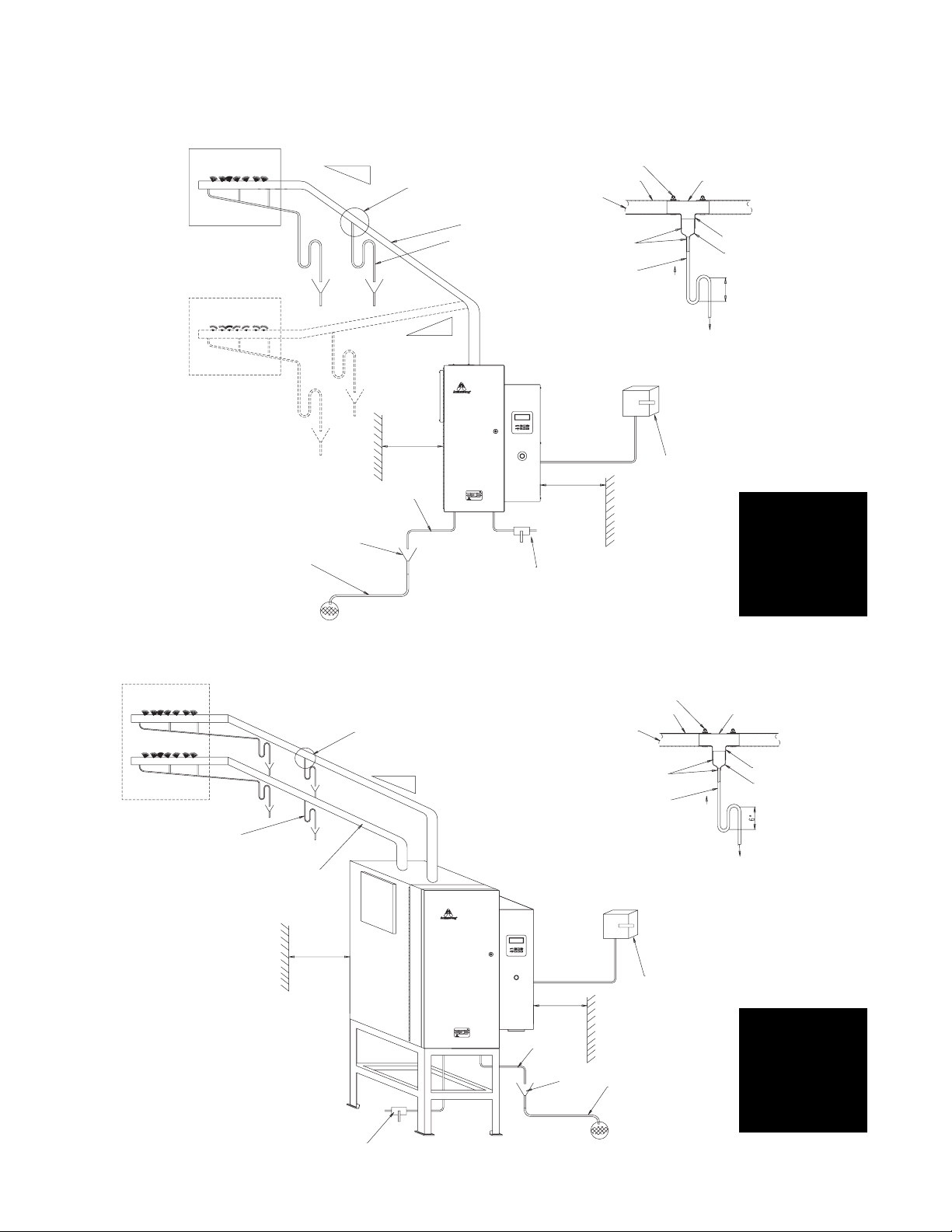

Figure 5-1 HC-6100/6300 Installation

Figure 5-2 HC-6500/6700 Installation

Note: On all

HC6000 models

24” clearance is

required on both

sides and the

front of the unit.

Note: On all

HC6000 models

24” clearance is

required on both

sides and the

front of the unit.

Pitch Min. 1” Per

12” Back to Unit

See Detail “A”

2” Insulated Copper

“P” Trap Drain Every

20’ of Piping or at

Bottom of Vertical Run

Hose Clamp

Steam Hose or Copper

Hose

Soldered Joints

1/2” or 3/8”

Copper Tube

Full Size Tee

2” Copper Tee

Reducer

UP

6” Min.

1” Copper (Min) Pitched

1” per 12” (Min) to

Open Drain

“P” Trap Drain

Every 20’ of Piping

or at Bottom of Vertical Run

2” Insulated Copper

Air Gap

1” ID Hose

See Detail “A”

Pitch Min. 1” Per

12” Back to Unit

Pitch Min. 1” Per

12” Back to Unit

24”

Water in 3/8” Copper

Type with Ball Valve

24”

Clearance

Detail “A”

Hose Clamp

Steam Hose or Copper

Hose

Soldered Joints

1/2” or 3/8”

Copper Tube

Detail “A”

To Drain

Fused Disconnector

Magnetic Breaker

within Sight of Unit

UP

Full Size Tee

2” Copper Tee

Reducer

To Drain

24”

Water in 3/8” Copper

Type with Ball Valve

Fused Disconnector

Magnetic Breaker

24”

within Sight of Unit

1” ID Hose

Air Gap

1” Copper (Min) Pitched

1” Per 12” (Min) to Open Drain

Page 6

Installation

HC-6100/6300 Mounting

The HumidiClean models HC-6100/6300 are designed to be wall mounted. Awall mounting bracket

and lag screws are provided for mounting on 410 mm (16”) centers. The operating weight of the unit is

106 kg (233 lbs). Aclearance of 600 mm (23”) on the front and sides of the cabinet is required for

servicing.

1. Position wall mounting bracket level on wall and mark hole pattern. Make sure holes line up with

studs or other sturdy structure.

2. Use 3/8" x 1-1/2" lag screws provided to secure the bracket.

3. Hang the humidifier on the wall mounting bracket. The dry weight of the unit is 70 kg (154 lbs).

HC-6500/6700 Mounting

The HC-6500/6700 HumidiClean is designed to be floor mounted on a level surface. The operating

weight is 230 kg (507 lbs), a clearance of 600 mm (23”) is required for the front and sides.

Water Fill Supply

The humidifier can use any potable or purified water supply. Water pressure must be 25-120 psig.

Water temperature must be less than 60°C (140°F).

1. Install a shut-off valve near the unit.

2. Connect the water supply to the 3/8" compression fitting on the fill water solenoid valve on models

HC-6100/6300. The HC6500/6700 is supplied with a compression filling for 10mm plastic tubing. A

6’ piece of 10mm plastic tubing is included for the larger models. The knock-out for the water

supply tubing is under the fill valve in the bottom wall.

Electrical Service Wiring

1. Connect main power supply wiring to high voltage terminals in unit. Read breaker size required on

humidifier's nameplate and refer to Table 7-1 and 7-2 for HC-6100/6300 wire (gage) required; Table

7-1, 7-3 and 7-4 for HC-6500/6700. Make sure an interlocking circuit breaker or safety switch (not

furnished) is accessible and within sight of the unit.

2. The humidifier cabinet must be grounded. A ground lug is provided in the cabinet.

3. Use only wire with copper conductors rated at 90°C (194°F) or higher for power supply and

grounding.

6

Page 7

Drainage

Connect HC-6000 drain to suitable waste drainage

system. HC-6000 drain water may be as hot as 70°C

(158°F). Use clear drain hose provided and 25 mm (1”)

copper pipe pitched away from unit at 25 mm (1”)

inch per foot. An air gap to prevent back flow is required.

See Figure 7-1.

7

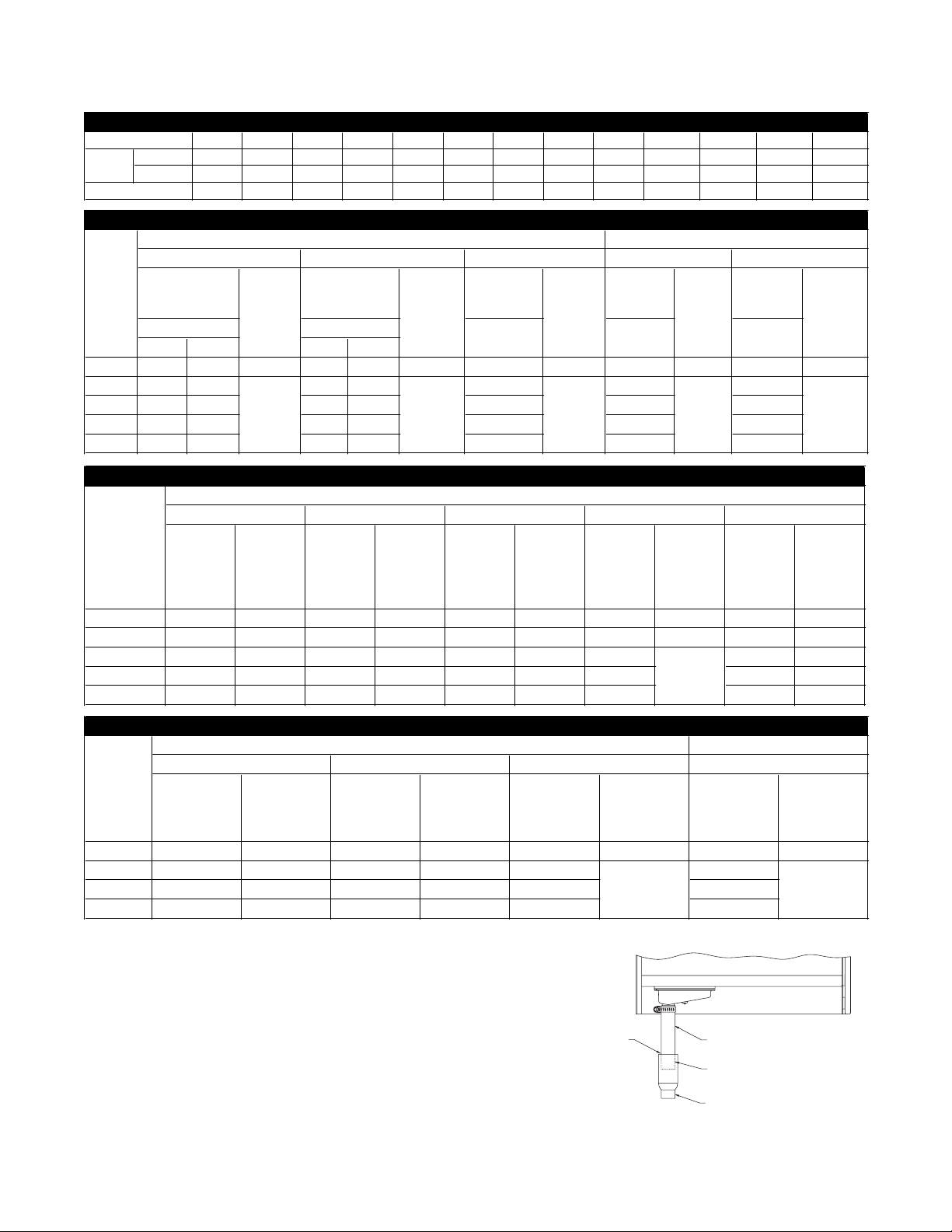

1-12 13-15 16-20 21-24 25-32 33-40 41-48 49-64 68-80 81-100 101-120 121-140 141-60

(AWG) 14 12 10 10 8 8 6 4 3 1 0 0 0

(mm2) 3 4 6 6 10 10 16 25 35 50 50 70 95

15 20 25 30 40 50 60 80 100 125 150 175 200

Table 7-1. Recommended Branch Circuits

Rating Amp

Wire

Circuit Breaker

Nominal

Amperage

Rating

Nominal

Amperage

Rating

Nominal

Amperage

Rating

Single Three Single Three

208 13.3 7.7 3.8 (8.3) 39 23 11 (24) 37 18 (40) 46 22 (48) 74 36 (80)

240 12.9 7.5 38 22 36 44 72

400 — 4.7 — 14 23 28 46

480 — 3.8 — 11 18 22 36

600 — 3 — 9 15 18 30

HC6100/HC6100DI

HC6300/HC6300DI

Table 7-2. Steam Capacities and Rating Amperages

Nominal

Amperage

Rating

Volts

(Vac)

Phase

3 KW Unit

15 KW Unit

Three

Phase

4.1 (9)

9 KW Unit

Nominal

Amperage Rating

Phase

12 (27)

Steam

Output

kg/hr

(lb/hr)

Steam

Output

kg/hr

(lb/hr)

20 (45)

25 (54)

41 (90)

Steam

Output

kg/hr

(lb/hr)

18 KW Unit

30 KW Unit

Three

Phase

Three

Phase

Steam

Output

kg/hr

(lb/hr)

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating Three

Phase

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating Three

Phase

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating Three

Phase

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating Three

Phase

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating Three

Phase

Steam

Output

kg/hr

(lb/hr)

208 84 41 (90) — — — — — — 125 61 (135)

240 — — — — 96 54 (120) — — — —

400 — — 51 45 (100) — — 73 — —

480 — — — — — — 58 — —

600 — — — — — — 47 — —

65 (144)

Table 7-3. Steam Capacities and Rating Amperages

Volts (VAC)

HC6500/6500DI

30 KW Unit

33.5 KW Unit

40 KW Unit

48 KW Unit

45 KW Unit

Nominal

Amperage

Rating

Three Phase

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating

Three Phase

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating

Three Phase

Steam

Output

kg/hr

(lb/hr)

Nominal

Amperage

Rating

Three Phase

Steam

Output

kg/hr

(lb/hr)

240/220 — — 144 82 (180) ————

400/380 77 30 (68) — — 110 145

480 — — — — 87 116

600 — — — — 70 93

98 (216)

130 (288)

Table 7-4. Steam Capacities and Rating Amperages

Volts

(Vac)

HC6500/HC6500DI

HC6700/HC6700DI

50.3 KW Unit

60 KW Unit

72 KW Unit

96 KW Unit

Figure 7-1 HC-6100/6300/6500/6700

Table 7-1. Recommended Branch Circuits

Table 7-2. Steam Capacities and Rating Amperages

Table 7-3. Steam Capacities and Rating Amperages

Table 7-4. Steam Capacities and Rating Amperages

Air Gap

1” I.D. Clear Hose

Supplied with Unit

Fit Hose Inside

1-1/2” Pipe

1” or Larger

Copper Pipe

Page 8

Duct Steam Distribution

1. The dispersion tube should be proper length. Verify correct size from Table 8-1.

2. Install dispersion tube(s) horizontally in duct so holes face upward. Air flow must be vertical up or

horizontal. Do not restrict duct with a height of 200 mm (8”) or less. Installations over 10 m/s

(2000 FPM) air velocity are not recommended. Consult factory if air flow is vertical down or air

velocity is over 10 m/s (2000 FPM). Do not install in ducted systems with static pressure exceeding

150 mm (6”).

3. The dispersion tube(s) should be located upstream of a straight duct run, without obstructions, 3 m

(10 feet) or more in length. Consult the factory if this distance is not available.

4. Use the template provided to cut dispersion tube installation holes. Fasten the mounting plate to

duct with sheet metal screws. If the dispersion tube is 900 mm (35”) or longer, support the far

end with threaded rod or similar means.

5. Note: For steam being generated from a deionized (DI) or reverse osmosis (RO) water source, the

use of 50 mm (2”) insulated stainless steel piping in lieu of copper is required. Pipe used for steam

dispersion piping must be oil and contaminate free. Premature element failure could result if oils or

contaminates are present. Contact the factory with questions. Connect dispersion tube(s) to

HumidiClean tank using 50 mm (2”) nominal insulated copper pipe and hose cuffs provided. We do

not suggest steam distribution piping of field supplied rubber based compounds to be used for any

HumidiClean application. Pitch pipe back to unit 25 mm (1”) per foot. The steam pipe must be free

of kinks and sags to allow for gravity drainage of condensate. Maximum pipe run distance from

tank to dispersion tube is 12 m (40 feet) equivalent piping length. Avoid excessive use of elbows or

45°changes in direction. A"P" trap drain should be installed every 6 m (20 feet), of piping run or at

the bottom of vertical runs that cannot drain back to the tank. See Fig. 8-3 for "P" trap detail.

6. If duct static pressure plus piping back pressure is greater than 0.5 in HG (6" WC), please consult

the factory.

8

Figure 8-3

Figure 8-2

Minimum

mm (in)

Maximum

mm (in)

D-1 DL-1 305 (12) 280 (11) 406 (16)

D-1.5 DL-1.5 457 (18) 432 (17) 559 (22)

D-2 DL-2 610 (24) 584 (23) 864 (34)

D-3 DL-3 914 (36) 889 (35) 1168 (46)

D-4 DL-4 1219 (48) 1194 (47) 1473 (58)

D-5 DL-5 1524 (60) 1499 (59) 1778 (70)

D-6 DL-6 1829 (72) 1803 (71) 2083 (82)

D-7 DL-7 2133 (84) 2108 (83) 2388 (94)

D-8 DL-8 2438 (96) 2413 (95) 2692 (106)

D-9 DL-9 2743 (108) 2718 (107) 2997 (118)

D-10 DL-10 3048 (120) 3023 (119) 3302 (130)

Table 8-1. Dispersion Tube Length

Steam Disp. Tube

Length "L"

mm (in)

Duct Width

1-1/2"

2-3/8"

Model

HC6100,

HC6100DI

Model

HC6100,

HC6100DI

"D" Dia.

Model HC6300,

HC6300DI, HC6500,

HC6500DI, HC6700,

HC6700DI

Model HC6300,

HC6300DI, HC6500,

HC6500DI, HC6700,

HC6700DI "DL" Dia.

Table 8-1. Dispersion Tube Length

Fitting Style

Equivalent Linear

Piping (feet)

2" - 45° Elbow 2.8

2" - 90° Elbow 5.5

2" - 90° Long Elbow 3.5

2" - Tee 12

Table 8-2. Linear Piping

Page 9

Area Steam Distribution

The EHF-3 fan package (minimum of 2 required for HC-6500/6700) is designed to be hung on a wall

to operate as a remote mounted, direct area discharge option. It incorporates a blower rated at 120v-

2.90 amps. CFM rating is 465 @ 1530 RPM. The fan package requires a separate 120 volt power supply (optional step down transformer available). Consult Armstrong Installation Bulletin IB-95 for more

information.

Alternative for shortened non-wettable vapor trail

For applications with particularly limited downstream absorption distance, Armstrong HumidiPack or

ExpressPack may be considered. HumidiPack is a prefabricated separator/header and multiple dispersion tube assembly. ExpressPack is a multi-tube steam dispersion panel which is shipped unassembled. The Armstrong HumidiPack or ExpressPack provide uniform distribution and shortened non-wetting vapor trail. Consult Armstrong Installation Bulletin No. 560 or Bulletin 573 for more information.

Control Wiring

When knock-out for sensor wiring is removed, an IP65 compliant cable bushing will be required to

keep the electric cabinet in compliance with IP32.

Wiring for low voltage controls should not be run in same conduit as the power supply. Use of shielded

wire or a separate dedicated metal conduit is required. When shielded cable is used, shield is to be

grounded at the humidifier only. The wire should not be longer than 30 meters (100 ft). If the wire is

out of this limit, please contact Armstrong. Refer to Figures 10-1 and 10-2 for wiring schematics.

Control Humidistat

1. Locate control humidistat where it will sense the average air condition of the space to be

humidified. Avoid areas of restricted circulation or locations where the sensor will be

subjected to drafts, localized heat or moisture sources.

2. Optional duct mounted humidistats are available to sense return or exhaust air, if

preferred.

3. Set DIP switch S-2 on the PC board to the proper range for the humidistat control signal to be

used. See Figure 9-1 . Also set voltage source DIP switch (S1 and S3) to proper range. See

Fig. 9-1 for location of switches and pages 10 and 11 in tandem with the applicable wiring diagram

below for correct switch settings.

4. Wire standard Armstrong 0-10 Vdc humidistat as shown in Figure 10-1. For use of alternative

humidistats or RH sensor, please refer to Figure 10-2.

9

Figure 9-1

Page 10

Figure 10-1

Standard Humidistat

H200-XX-XX-XX

10

A18609 or

A18610

0-10 Vdc

Stat

(Standard)

A8581

High Limit

Humidistat

A9023

Pressure Switch

Modulating High

Limit Sensor

Main Stat/Sensor In

Supply

Outdoor

Temperature Sensor

Ground

Ground

Class 2

Alarm

High Limit/

Air Flow Switch

To Set Up:

1) S1-1, 3 Off, S1-2 On

2) S3-1 On, S3-2, 3, 4 Off

3) S2-1, 2, 3 Off

4) Select 0-10vdc “Signal Type” in the Operational Setup Menu.

5) Select Humidistat Sensor Select in the Operational Setup Menu.

Figure 10-2

On/Off Humidistats

Main Stat/Sensor In

Modulating

High Limit Sensor

Outdoor

Temperature Sensor

Ground

1) S1-1, 3 On, S1-2 Off

2) S3-4 On, S3-1, 2, 3 Off

3) S2 Off (All)

4) Select “On/Off” Control Type

in the Unit Configuration Menu.

Supply

Brown

Orange

Part #: A8581

or A8581A

Page 11

11

Supply

Control

Signal

4-20ma Setup 10 vdc Setup

1) S3-1 On, 3-2, 3, 4 Off (Default)

2) S1-2 On, S1-1, 3 Off (Default)

3) S2-1 On, S2-2, 3 Off if 4-20ma

S2-1, 2, 3 All Off If 0-10vdc

4) Select Corresponding Control Signal

Type In Operation Setup Menu.

Main Stat/Sensor In

Modulating

High Limit Sensor

Outdoor

Temperature Sensor

Ground

S5079a,b,c

Figure 11-1

0-10 Vdc or 4-20mA Control Signal

Figure 11-2

RH Sensors/Transmitters

Supply

Main Stat/Sensor In

Modulating

High Limit Sensor

Outdoor

Temperature Sensor

Ground

SYM Function Description

Input Signal Type SelectS2

Power Supply

S1

and

For Sensors Select

S3

(S1 and S3 together)

At one time, only one digit of S3-1, 2, 3 or 4 should be on.

Main Control

Sensor

High Limit

Sensor

Outside

Temperature Sensor

(Optional)

Switch Positions

Settings

1: Stat/Main Sensor

2: High Limit Sensor

3: Outside Temp. Sensor

On: Current Signal

Off: Voltage Signal

4&5: Outside Temp. Sensor

4 on 5 off: Thermistor

4 off and 5 on: Temp. Sensor

24Vac: S4-2 on S4-1, 3 Off S3-1 on S3-2, 3, 4 off

24Vac: S4-1, 3 on S4-2 Off S3-2 on S3-1, 3, 4 off

10Vac: S4-1, 3 on S4-2 Off S3-3 on S3-1, 2, 4 off

5Vac: S4-1, 3 on S4-2 Off S3-4 on S3-1, 2, 3 off

S1 S3

Select RH sensor in sensor select window in operation setup menu

if using high limit sensor, select high limit sensor, set high limit set

point, 85% default.

If using out temperature sensor, select “outside temperature”.

Select signal type in operation setup menu.

Select desired RH in operation setup menu.

Verify PID settings in operation setup menu.

Page 12

High Limit Humidistat

Remove the jumper tab from ground and in of high limit/pressure switch connections and wire the high

limit stat between these terminals. Refer to Figure10-1 (the overall wiring diagram) for more inform

ation. Aduct mounted high limit humidistat is recommended to prevent over-saturation of the duct air.

Use an on-off controller that opens on fault (high humidity). Humidistat should be set for a maximum

of 90% RH. Alternately, a modulating high limit humidistat may be used on applications such as

variable air volume (VAV). Locate the high limit humidistat approximately 3m (10 feet) downstream of

the dispersion manifold. If 3m (10 feet) is not available, consult the factory. Note: High limit humidistat

will be wired in series with duct pressure switch, if used, see Figure 10-1.

Airflow/Pressure Switch

An airflow switch is recommended to deactivate the humidifier when there is insufficient air flow in a

duct system. Aduct pressure switch is preferred as an airflow sensor. The pressure switch should

open on insufficient airflow (opens on fault). Airflow switch should be mounted in supply air duct

upstream of humidifier dispersion. Remove the jumper tab from ground and in of high limit/pressure

switch connections and wire the airflow sensor between these terminals. See Figure 10-1 (the overall

wiring diagram) for more information. Complete installation and wiring instructions are contained in the

duct pressure switch package. Note: Duct pressure switch will be wired in series with high limit

humidistat, if used, see Figure 10-1.

State light will flash green if either high limit or air pressure switches are open.

Alarm Circuit

The terminals 3 & 4 (normally open relay external alarm) are connections for a class II NEC alarm

circuit (switch closure only, 1 amp. maximum @ 24 Vdc or 0.5 amp. @ 125 Vac). The switch will close

if the unit encounters an error or when service life has expired it will not engage if high humidity/sail

switch circuit is open.

12

Page 13

The menu can be accessed via the keypad below the LCD, on the front of electric cabinet. Use the UP

or DOWN to change the menu in current level; press ESC to previous menu level; press ENTER to

access the current menu. Pressing ENTER will activate selection cursor, press UP(DOWN) to increase

(decrease) the value, press ENTER to confirm the change or ESC to cancel.

13

Display Menu

Armstrong HC-6000

Enter to get into main menu

This screen will only display for 1 minute after the unit is

powered up; then it will automatically go to 'Unit Status'.

Language

Language select

Unit Status

Unit status display

Operation Setup

Operation variable setup

Unit Configuration

Unit configuration setup

English

English - Default

Chinese

Unit Status 1

Unit Demand: XXX% Demand

Steam Output: XXX lb/hr Steam Output

Unit Status 2

Water Level: Normal Water Level State: Low, Normal and High

Gen, Fill, Drain Idle = No demand; unit idle

Gen = Steam Generation

Fill = Filling

Drain = Draining

Heat = Elements are energized to heat water to selected

aquastat setting

Temperature

Wa ter Tem p: XXX C/XXX F Tem perature of water

Heat TEMP: XXX C/XXX F Temperature of heating elements

Timers

End of Life: 0:00 EOL-TMR:0000:00 (Default)

RUNTIME:0000:00

DRAIN-TMR: 0000:00

ONTIME:0000:00

OFFTIME:0000:00

RH Display

Room Current RH: XX% This menu will be displayed only when "RH Sensor" is selec ted

Room Current RH: XX% (Default)

Room Desired RH: XX%

Duct Current RH: XX%

High Limit Setpoint : XX%

Outside Temperature: XX°C/XX°F

Run Menu

Language

Unit Status

Run Menu

Language

Unit Status

Page 14

14

Enter Password 0000 (Default)

Desired RH

This menu is displayed when RH sens or i s selected

Desired RH: XX % Default: 50%

Current RH: XX%

Steam Generation

Steam Gen (Default)

Manual Drain

Manual Fill

Unit Stop

Modulating Fill Cycle

Enabled (Default)

Disabled

If modulating fill cycle is enabled:

Fill Valve Off Time

30 seconds

Fill Valve On Time

10 seconds

Error Reset Error Reset

Error Reset? Confirm Cancel

Aquastat

Temperature of water 180°F/80°C

The maximum is 80°C/180° F, the minimum is 4°C/40°F. If

the set point is lower than 40°F, t hen f unction is disabled. When

disabled the unit will go into a 3 minute warm-up when turned on.

Network Setup

Disabled Disabled (Default)

Enabled

Mode Change

Slave ID 1 (Default) Value: 1 to 127

Communication Type

MODBUS MODBUS (Default)

PSP (includes LonWorks/BACNet)

Password

New Password 0-9 Default: 0000

A-Z

a-z

End of Life

500

(Run Time Accumulation Hours) 750

1000 (Default)

1250

1500

1750

2000

2250

2500

2750

3000

No Beds

LT RT move the cursor UP DN to increase/decrease value

Operation Setup

Operation Setup

Page 15

15

Drain Frequency

6

Default: 12 hours 12 (Default)

244896

No Drain

Real Time

Real Time Set

24 Hour Clock

Drain Time

1

5 (Default)

10

Load Default

Reset all to Default? Confirm Cancel

Signal Type

0-10 Vdc (Default)

0-5VDC

1.9V - 3.9V

4-20mA

Sensor Select

Humidistat (Default)

RH Sensor

High Limit Sensor

High Limit Set Point 85% (Default)

Outside Temperature

High Limit Set 1°C / Low Limit Set 1°C

Lowest RH Set Point 15% (Default)

PID Settings

PB Proportion Brand 0-900

PID PB 10; PID IRV 10 IRV Integral Reset Value 0-500

PIDF DG 200; PID SI 10 DG Derivative Gain 0-500

SI Interval 0-30

Records

Error List 01 05-04-01 16:00 (example)

See Page 25 for list of possible errors.

Fill time out to low level

Display the RH graph RH graph of the last 30 days

This menu can be shown when RH sensor i s selected

Set Date and Time

YYYY-MM-DD; Time (24 Hr. Format) Date and Time from realtime IC

Save Settings

SAVE SETTINGS

Confirm Cancel

Must be done after any 'Ope

ration Setup' menu changes.

Operation Setup - Continued

Operation Setup - Continued

Page 16

16

Enter Password ARMH

Run Mode

Run (Default)

Test

Contactor Count

123

4

Control Type

PWM (Default)

On/Off

Power Settings

1000 W

3000 W

5000 W

6650 W

8000 W

Ionic Time Reset

Clear Ionic Time

Confirm Cancel

Error Record Clear

Clear Error List

Confirm Cancel

User Password Reset

User Password Reset

Confirm Cancel

Temperature Compensation Factory Use Only

Water Compensation

Heater Compensation

Unit Configuration

Start-Up Procedure (Before “Power On”)

1. Examine the electrical compartment for any loose or disconnected component wiring. Check all

high voltage screw terminal connections at contactor, terminal strip, fuse block & power module for

tightness.

2. Remove Side Panel. Remove tank access panel by unscrewing all black knobs. Make sure all

ionic beds are fastened securely to mounting pins. Position access panel on tank making sure the

gasket is in place and tighten all black knobs. Note: Ionic beds not used on DI/RO units.

3. Check and recheck incoming voltage source and control wiring for proper connections and

tightness of connections.

4. Turn on water supply and check for leaks.

5. Make sure access doors and panels are secure.

Page 17

Principle of Operation

The HumidiClean humidifier converts ordinary tap water or purified water to steam for distribution to

raise the relative humidity level. The demand for humidity is sensed by a humidistat or sensor which

sends a control signal to the HumidiClean. The HumidiClean is connected to the power supply (208,

220/240, 380/400, 480 or 600 Vac) through a separate circuit breaker supplied by the customer.

When power is initially supplied to the unit from the circuit breaker, the LCD will display "ARMSTRONG HC6000". The "POWER" LED will come on and the unit's fill valve solenoid is energized to

allow water to enter the tank at a rate of 1.5 L/min (.31 GPM)(HC-6500/6700 fill rate is 7.5 L/min (1

GPM)). Note: When unit is turned on the drain valve will energize for 6 sec. or until water level drops

below the high water probe. If water level in tank is above the low water level switch, assuming the air

proving switch is close, the high limit humidity switch is closed and the unit status is ‘STEAM GEN’, the

heating elements will be activated.

The water fill solenoid continues to be activated until the water level in the tank has energized the high

water switch. Note: If fill or drain valves are not energized when power is first applied, check LCD for

diagnostic code. See DIAGNOSTICS section. The heating elements will remain on to preheat the

water inside the tank until the temperature of water has reached the aquastat set point. During this

preheat cycle the amperage draw of the tank can be checked with a clamp on amp meter. The amperage draw on all high voltage wires connected to the main power supply terminal block should correspond to the value on the nameplate. If aquastat has been disabled, the humidifier will go into a 3

minute warm-up once the water hits the low water probe.

After the heat-up time, the HumidiClean will continue to produce steam based on the demand signal,

read from the humidistat or calculated by reading the relative humidity and setpoint. If the demand signal drops below 2% or the high limit/sail switch circuit opens, the contactor(s) will open and the unit

status will be "IDLE". Note: If the humidifier shuts off due to low humidistat demand, a demand signal

of 4% or greater is needed to re-initiate "STEAM GEN." If all the signals are consistent as stated

above, HumidiClean will produce steam continuously and refill the tank with water when the low water

level is reached. These fill intervals will operate based on modulating fill settings in software.

Power to the heating elements is switched on and off by the triacs in the power module to achieve a

modulating output based on the demand signal. The triac utilizes a 1/2 second cycle time. For example, with a 50% humidistat demand signal the triacs would be on for 1/4 second and off for 1/4 second.

If the triacs are fully on, the green "SIGNAL" LED on the power module will be on constantly. When

the triacs start to modulate (switch power to the heating elements on and off) the LED will show the

triac on condition and will appear to flicker or blink.

As HumidiClean continues to produce steam, the unit will accumulate and memorize the heating element active time for the purpose of defining a drain cycle and service life (this memory is not affected

by power outages). When the HumidiClean heating elements have been on for the drain frequency

setting, the unit activates the drain and fill solenoids and begins draining the tank. The tank will drain

with the water being tempered from an activated water fill solenoid. The drainage from the tank will

pass the low water switch, opening the switch and shutting off power to the heating elements. The

drainage from the tank should not exceed 70°C (158°F). The drain cycle is controlled by the user

inputted valves in the operation setup menu. Once the unit has timed out of the drain cycle and all of

the switches are still in position to generate steam, the water fill solenoid switch is activated to fill the

tank and the cycle starts over again.

17

Page 18

Completing a Service Life Cycle

When 90% of the setting service time has accumulated, the "STATE" LED on the control panel will

blink in yellow. (Refer to EOL settings, for bed life duration settings). If the HumidiClean is not serviced

at this time; the unit will continue to operate for the remaining 10% of the service life setting. When

100% of the bed life setting has been reached, the "STATE" LED will be on in red. The unit will drain

the tank and not respond to a call for demand.

A. Servicing the Unit

1) Save the settings, consult the OPERATION SETUP menu

2) Go to Steam Gen. Menu

a) Drain tank by operating menu from "STEAM GEN." to "MANUAL DRAIN" position.

b) Once the tank is drained, shut power off to unit and allow the tank to cool.

c) Remove the cabinet access panels, and slowly open tank access panel.

3)

Ionic Bed Inspection

Remove and inspect one of the ionic beds and inspect the drain screen at the bottom of the

tank. If the bed does not appear to be saturated with mineral deposit (a full bed will

weigh 1.1 kg (2.6 lbs) dry and if the drain screen is clear, you have two options.

a) Reset the Ionic Bed service life Proceed with Step 4.

b) Change the service life settings (see Operation Setup).

4)

Ionic Bed Replacement

If the beds are saturated, remove all of them. Remove any large pieces of scale from the tank.

Cleaning the side of the tank is advised at this point.

a) Chemically clean the unit with Rite-Qwik.

i) Pour 3.75L (1 gallon) of Rite-Qwik into tank followed by 3.8 L (1 gallon) of

fresh water. The HC-6500/6700 model requires 7.6 L (2 gallons) of Rite-Qwik

and 7.6 L (2 gallons) of water.

ii) Allow the solution to work until the bubbling action ceases, not to exceed 1

hour.

iii) Clean the water level electrodes, using an emery cloth. See Page 21 for

complete instructions.

iv) Check water level canister for debris.

v) Replace the electrodes.

vi) Ensure drain lines are free of leaks and secure.

vii) Check inlet screen on fill valve and remove any debris.

vii) Fill the tank with water and drain. (Perform this step several times.)

b) Install the new Ionic Beds.

18

Page 19

5) Restoring the Unit to Operation

a) Turn power on at breaker.

b) Unit should begin to fill. Maximum fill time is approximately 30-45 minutes before

contactor(s) will be closed.

c) If this does not take place, operate the menu, and change the status to "STEAM

GEN."

B.

Modifying the Bed Life Setting

1) Complete the steps for servicing the unit as outlined above.

2) Change the EOL settings to desired value in Unit Status menu.

3) Save settings in menu.

End of Season Drain

If at any time during normal operation there is not a demand for a continuous 72 hour period,

HumidiClean drains the tank and the PC Board initiates a drying cycle by cycling the heating elements

for short intervals in order to dry the ionic beds.

Maintenance

The HumidiClean is designed to minimize maintenance. As stated in the PRINCIPLE OF OPERATION

section, after the HumidiClean has accumulated 90% of the selected Service Life, in hours of heater

on time, the "STATE" LED will flash (blink) in yellow. At this time the ionic beds in the tank should be

replaced. If service is not performed, the unit will continue to operate for the remaining hours before

shutting down completely.

Note: Service Life can be adjusted based on water quality. If Ionic Beds are relatively free of scale

deposits or scale is forming on tank walls and elements because beds are saturated with scale, please

consult the factory for Service Life adjustment procedures.

Replacing the Ionic Beds

1) Save the settings, consult the OPERATION SETUP menu

2) Go to Steam Gen. Menu

a) Drain tank by operating menu from "STEAM GEN." to "MANUAL DRAIN" position.

b) Once the tank is drained, shut power off to unit and allow the tank to cool.

c) Remove the cabinet access panels, and slowly open tank access panel.

3) Unsnap ionic beds from support pins and slide them out through the access opening.

19

Page 20

Figure 20-1 HC-6100/6300

Figure 20-2 HC-6500/6700

4. Inspect tank drain screen and elements inside the tank. The elements should appear to be flaking

off scale. If the drain screen appears to building deposits in the screen holes it should be cleaned.

Remove any scale that appears in the bottom of the tank.

5. Install six (6) new ionic beds (14 for the HC-6500/6700), snapping them into place on the

support pins.

6. Make sure access panel gasket is lapped over all edges of tank access opening. Replace and

secure tank access panel.

7. Make sure both access doors/panels are secure.

8. Turn on power at circuit breaker.

20

Locating

Pins

Steam Outlet

Equalizing Connection

to Top of Level Canister

Cover

Ionic Beds

Equalizing Connection

to Bottom of Level Canister

Heating

Elements

Drain Oulet

Connection

Mounting Bolt

Locations

Steam Outet

Equalizing Connection

to Top of Canister

Cover

Ionic Beds

Equalizing Connection

to Bottom of Level Canister

Heating

Elements

Drain Outlet

Connection

Mounting Bolt

Locations

Locating

Pins

Page 21

9. Operate the unit configuration menu “Ionic Time Reset”, to reset the ionic bed life. All the

accumulated ionic bed time has been reset to zero. The unit should now be heard filling.

NOTE: The accumulated ionic bed time can be reset to zero at anytime. However, the unit

should not be reset without first inspecting the ionic beds.

10. After the unit has heated up and started making steam, turn main power off and double check tank

access panel gasket for steam leakage. Hand tighten wing nuts or reposition gasket if necessary.

Cleaning the Water Level Electrodes

1. If there is water in the steam generating tank, operate menu to "MANUAL DRAIN". The drain valve

should energize, and the unit should completely drain.

2. After the tank has drained, turn off the main

power at the disconnect.

3. Unclamp and remove the 5/8" ID Silicone tubing

from the top outlet of the level canister.

4. Disconnect wires #21 (high level probe), #20

(low level probe) and #19 (common probe) from

the probes, noting the probe and wire locations.

Note: Level control float switches are used

for DI, RO, or very pure water. Cleaning

should not typically be required.

5. Unscrew the probes from the level canister

using the hex nut fitting on the probe

(Note: Level canister bushings may be removed with the probes, if necessary).

6. Use a wire brush, wire wheel, or similar means to clean scale deposits off the stainless steel tip of

the probe. Cleaning of the Teflon insulating jacket (white portion) should not be needed.

7. Wipe probes with a clean dry cloth.

8. Inspect the interior of the level canister. If large amounts of scale or debris are present, remove the

canister from the cabinet by removing the two clamping bracket screws and disconnecting the 5/8"

ID Silicone hose at the bottom of the canister. Flush the canister with water to remove debris

and reinstall.

9. Reinstall the probes and probe wires in their proper locations. The high water probe (shortest)

goes in the right hole of the canister. The low water probe (medium length) goes in the left front

hole of the canister. The common probe (longest) goes in the left, rear hole of the canister.

10. Reconnect the 5/8" ID Silicone hose(s).

21

Page 22

Removing the Tank, HC-6100/6300 Only

1. Operate menu to "MANUAL DRAIN" and allow unit to complete a deep drain.

(Caution: Tank will still be quite warm).

2. Turn off circuit breaker.

3. Unlock and open front and side doors. Remove left side panel.

4. Disconnect 3 hoses from front of tank; rubber hose cuff at steam outlet; heating element leads at

contactor, fuses, or power module; and thermocouple wires.

5. Loosen and remove 2 mounting bolts at the bottom of tank. Slide tank out left side of cabinet

(be sure tank had time to cool after operation).

Troubleshooting

Notice: This troubleshooting guide is offered to aid in servicing the HC-6000 humidifiers. It is intended

for use by electricians and technical service personnel familiar with electrical and electronic equipment. Many steps in the troubleshooting procedures require measurements of high voltages and

involve working near exposed live parts. KNOW WHERE THE HIGH VOLTAGE PARTS ARE, AND

KEEP HANDS AND METAL TOOLS AW AY FROM THEM. All resistance checks should be made with

main power OFF and the component disconnected from wiring. All continuity checks should be made

with main power OFF. If unsure concerning any of the following procedures, PLEASE consult the

Armstrong Humidification Group at Phone: (269) 273-1415.

Humidifier will not fill with water when power is applied.

1. Make sure the status in menu is "Steam Gen.".

2. Make sure "STATE" LED is red. If so, refer to MAINTENANCE or DIAGNOSTICS section of

this manual.

3. Make sure "POWER" LED is lit. If not, check voltage at secondary side of the main power

transformer. Voltage should be 24-28 VAC. No or low voltage is an indication of a problem with the

supply voltage or transformer. Verify supply voltage and make sure it is the same as voltage rating

on humidifier nameplate. Check secondary power fuses.

4. Check the voltage to the fill valve. Voltage should be 24-28VAC (voltage should be taken with

wires connected). If voltage is present, fill valve solenoid coil is probably defective. Coil resistance

should be 18Ω (8.3Ω for HC-6500/6700) with wires disconnected.

5. Check for water in cabinet bottom or in fill cup overflow line. If present, see "Water in bottom of

cabinet" on page 24.

6. If no voltage is present to fill valve, check water level. If it is above 2/3 full in electrode level

canister (float canister for DI units), the drain valve has to open to drain water below high water

level before the fill valve is energized.

7. Check for 24-28 Vac power to drain valve (voltage should be taken with wires connected). If power

to drain valve is OK, check drain valve coil resistance with wires disconnected. It should be

approximately 10Ω (8.3Ω HC-6500/6700).

22

Page 23

8. If drain valve and fill valve are both energized and water is below the 1/3 full level in the electrode

canister (float canister for DI units), make sure the status of Steam Generation in menu is "STEAM

GEN.". Perform continuity check to be sure.

9. If drain valve only is energized and water level is below the 2/3 full level in electrode canister (float

canister for DI units), there may be excessive debris in electrode canister (float canister for DI

units). Inspect and clean if needed. See page 21 for Cleaning Procedure for Electrodes.

10. PC board may be defective. Consult the factory.

Humidifier fills with water, but does not turn "STEAM GEN" message on for 3 minutes

after reaching low water level.

1. Perform steps 1 through 3 from above "Humidifier will not fill..."

2. For Tap Water: Check AC voltage across the common electrode (longest) and the low level

electrode (medium length). The voltage will be approximately 17-20 VAC if the circuit is open.

When the water level closes, circuit voltage should drop to <5 volts.

(a) If voltage is not 17-20 VAC with circuit open, check continuity of wires from electrodes to

PC board. If continuity is OK, the PC board is likely defective.

(b) If voltage is 17-20 VAC with circuit open, but does not drop when water contacts the two

electrodes, the water may be too pure (consult factory) or if the voltage drops very slowly to

about 5 volts then the electrodes need cleaning. See page 21 for cleaning procedure for

electrodes.

3. For DI Water: Check continuity across the two wires to the low water float switch. If no continuity,

switch may be defective or "hung up". Make sure movement of switch is vertical so the float arm

swings freely.

4. If high limit/sail circuit is closed, low water level circuit is closed, and there is a calling for humidity,

the status of steam generation should be "STEAM GEN.". If not, PC board or wiring harness is

defective.

"STEAM GEN." turns on after initial fill to low water level, but amperage draw check

shows low or no amperage draw.

1. Check for line voltage to heating elements at secondary side of contactor and/or power module.

Verify power supply is same as voltage rating on humidifier nameplate.

2. If voltage is correct, the heating elements are likely defective. Turn off main power, disconnect all

elements and check element resistances (see resistance chart on Page 36 and 38). Look for open

circuits or elements with high resistance.

3. If voltage is not present at elements, check primary voltage fusing.

23

Page 24

4. If fuses are OK, check voltage to contactor coil.

(a) If voltage is 24-28VAC at contactor coil, check coil resistance. It should be 8Ω with wires

disconnected. If resistance is OK, check voltage drops across the contactor.

(b) If no voltage to contactor coil, check continuity of wires from PC board to contactor. If

continuity is OK, PC board is likely defective.

5. Check voltage signal to power module. The voltage across TAB8-1 and TAB8-2 (low voltage signal

to power module) should be 12 Vdc.

(a) If no or low voltage, the PC board is likely defective.

(b) If voltage is OK, but green "SIGNAL" LED on the power module is not on, power module is

defective.

6. If green "LOAD" LED on power module is on, check voltage drops across power module.

Humidifier overfills with water on initial fill.

1. Check electrode canister (float canister for DI units) and level electrodes for debris or scale build

up. Clean as needed. See Page 21 for cleaning procedure for electrodes. On DI Units, the high

water float switch may be defective or "hung up". Check continuity across wires to the switch.

Make sure switch movement is vertical so float lever arm swings freely.

2. The fill valve may be stuck open. Turn off power to the humidifier. If fill valve does not close,

clean or replace valve.

3. If the high water circuit is closed and the fill valve shuts off when the power is turned off, the PC

board is defective.

Humidifier runs continuously, %RH is well over set-point.

1. Verify humidistat signal isn't sending false 100% demand.

2. Verify humidistat or RH sensor is wired correctly and stat/sensor dip switches (S2 & S3, See

Fig. 10-1 and 11-1) on the PC board are set correctly for the humidistat signal.

3. If humidifier generates steam with the humidistat disconnected.

(a) Check for power at the contactor coil. If 24-28 VAC, PC board is defective.

(b) Check voltage drop across contactor. If voltage drop is low (it should be line voltage),

remove, disassemble and inspect contactor.

(c) Check green "SIGNAL" LED on power module. If it is ON or blinking, PC board is likely

defective.

(d) Check voltage drop across power module. If voltage drop is low (it should be line voltage),

power module triacs may be failed closed. Shut off main power and perform continuity check

across high voltage input and output terminals. Continuity indicates a shorted triac. Note:

Some power modules have two triacs rather than three. Check schematic on power module

to verify.

24

Page 25

Humidifier runs continuously, %RH is well under set-point.

1. Verify humidistat/RH sensor is wired correctly and dip switches (S2 & S3, See Fig. 10-1, 11-1

and 11-1) on the PC board are set correctly for the humidistat signal.

2. Check humidistat demand signal at low voltage terminal strip. It should be close or at 100%.

3. If humidifier is a three phase model, verify all three phases of power are present and equal.

4. Check amperage draw on all high voltage power lines with a clamp on amp meter. They should be

same or very close to amperage rating on the humidifier's nameplate if the humidistat demand is

100%.

5. Turn off power. Disconnect heating elements and check resistances - see Tables on Pages 35 and

37. If an open circuit or abnormally high resistance is measured, the heating element(s) is

defective. Also, check to see if heating element leads have shorted to ground.

6. If heating elements are OK, check voltages at secondary side of the power module and contactor.

If no or low voltage, check primary fusing.

7. If fuses are OK, check voltage to contactor coil.

(a) If voltage is 24-28VAC at contactor coil, check coil resistance. It should be approximately

8Ω? with wires disconnected. If resistance is OK, check voltage drops across the contactor.

(b) If no voltage to contactor coil, check continuity of wires from PC board to contactor. If

continuity is OK, PC board is likely defective.

8. Check voltage signal to power module. The voltage across TAB8-1 and TAB8-2 (low voltage signal

to power module) should be 12 Vdc at 100% power.

(a) If no or low voltage, the PC board is likely defective.

(b) If voltage is OK, but green "LOAD" LED on the power module is not on, power module is

defective.

9. If green "SIGNAL" LED on power module is on, check voltage drops across power module.

10. If supply voltage and amperage draws are correct and elements appear OK, unit is probably

undersized (not enough capacity for the application). Check sizing or consult factory.

Humidifier does not drain when manual drain.

1. Disconnect and check resistance of drain valve coil. Resistance should be approximately

10Ω (8.3Ω HC-6500/6700).

2. Make sure drain line is pitched and sized correctly. Check for blockage or obstructions in the drain

line. An air gap or funnel must be used as described in Drain Line Section. - See Figure 8-3.

3. If humidifier does not drain at specified interval or when service is to be performed and drain

valve and piping appear OK, there is blockage of the tank drain screen or the PC board may be

defective.

25

Page 26

Dispersion tube spits water or water is present in duct

Hint: It is very helpful to cut a small observation window in the duct and cover it with Plexiglas so the

steam discharge from the manifold can be observed. This way the problem can be narrowed down to

piping/steam quality (steps 1 and 2) or a condensation problem (steps 3 and 4).

1. Check distribution piping for proper pitch and size. Make sure there are no loops, dips or sags

where pockets of water can collect. If such conditions exist and are unavoidable, a 'P' trap is

needed to drain the low spots.

2. Make sure any drains are piped correctly and pitched to a floor drain.

3. Check duct downstream of manifold. If any obstructions (coils, elbows, fans) are within 10', the

vapor (condensed steam) discharged from the manifold may be impinging on the obstacle before it

has a chance to adsorb into air. This is especially true if the duct air is cold (<50°F), duct air

velocity is high (>2000 FPM), or duct %RH is high (>90%). If these conditions exist and

impingement is suspected, consult factory.

4. The duct air may be saturated with moisture (100% RH). Ahigh limit humidistat/RH sensor is

recommended to prevent this. See Installation section.

Water in bottom of cabinet

1. Verify that pressure equalizing tubing is hooked up from top of electrode level canister to the tank.

2. Check steam distribution piping for obstructions.

3. Verify duct air velocity is less than 2000 FPM and manifold is not in a vertical down air flow.

4. Check for leaks at fittings and clamps in water supply lines.

5. Verify that tank access panel gasket is on lip of access hole and the access panel is secured

tightly.

6. Make sure the duct pressure and steam distribution back pressure does not total more than

6" WC.

Diagnostics

There are some diagnostic routines programmed into the PC board. If these routines detect a problem

the unit will shut down and display the error message on LCD, the "STATE" LED will be on in red.

1 FILL TIME OUT TO LOW LEVEL - - The low level switch has not closed after 35 minutes of fill

valve on time. This is only on initial start-up or after a complete drain down. Check: defective fill

valve, debris in fill valve inlet screen or on tank drain screen, water leakage from tank or inlet tubing,

no water flow or low water pressure, drain valve stuck open or leaking, defective low water level switch

(electrodes need to be cleaned).

26

Page 27

2 WATER LEVEL DROPPED BELOW LOW LEVEL - - The low level switch has not closed after 5

minutes of fill valve on time. This is only after initial start-up fill and boil-down sequence.

Check: debris in water switch canister, defective fill valve, no water flow or low water pressure, drain

valve stuck open, defective low water level switch (electrodes need to be cleaned).

3 WATER LEVEL ABOVE HIGH LEVEL TIME OUT - - The high water switch is still closed 5 minutes

after the fill valve has turned off upon hitting the high water level and a 30 second drain does not drop

the water below the high water level. Check: defective high water level switch, debris in level canister,

fill valve stuck open, drain valve is defective or scale buildup in drain line.

4 ILLEGAL LEVEL SWITCH STATE - - The high level switch is closed and the low level switch is

open. Check: defective level switch(es), debris in electrode level canister, scale on electrodes or canister, improper wiring of electrodes or float switches.

5 OVER TEMPERATURE - - Internal temperature exceeds safe level. Check: low water in tank,

scale buildup on Thermocouple heating element surface, defective Thermocouple. See Clearing

"Error" Codes section.

6 WATER LEVEL HAS NOT DROPPED BELOW LOW LEVEL - - The low water level switch has not

opened after a complete drain. Unit drains frequency and duration can be set in menu. Check: defec-

tive low water level switch or electrodes, defective drain valve, debris on low water level float switch or

electrodes, tank drain screen, or in drain valve

Clearing "ERROR" codes

After correcting the problem, the error state must be cleared by depressing the button "Error Clearing".

Confirm the operation, the unit should resume normal operation (If the water level is above the low

water, the unit will drain below the low water level and refill before energizing the contactor). Turning

the power on and off will not clear the error condition.

Safety Switches

When the high limit or air proving (pressure) switch opens the state light will flash green and the

message “High Humidity/Sail Switch Circuit is Open” will be shown on the front display. This is a soft

error, it does not have to be reset. When the circuit closes the unit will go back to normal operation.

27

Page 28

HC6100-Wye Wiring layout

28

Page 29

HC6100-Delta Wiring layout

29

Page 30

30

HC6100-PAR Single Phase Wiring Layout

Page 31

HC6300-Wye Wiring layout

31

Page 32

HC6300-Delta Wiring layout

32

Page 33

HC6500-Wye Wiring layout

33

Page 34

HC6500-Delta Wiring layout

34

Page 35

35

HC6500-WYE (2 contactors) Wiring Layout

Page 36

36

HC6500-Delta (2 contactors) Wiring Layout

Page 37

HC6700-Wye Wiring layout

37

Page 38

Item No. Water Compartme nt Part No.

— PVC Tubing 5/8" A7618A

— Clamp Hose Flat .63 Olive B2716-11

— Hose Clamp, Minerature, Worm B2911-8

25

Kit Fill Valve Assy HC-6100 and

HC-6300 Tap Water

A23520

21 Tubing Rd 5/8" I. D. Silicon A19699

22 Tee Barbed HDPE 5/8 A23237

24 Elbow Barbed 5/8 A10579

27 Fill Cup for Series HC-6000 RDHC6000-038

27 Bracket For Fill Cu p B2929

28 Bracket for Liquid Level B5135

28 Brkt HC-6000 Liquid Level A22010

20 Drain Valve B2004C

18 Drain Cup RDEHU305-2021

17 Reducing Bushing Brass 1"-1/2" RDHC6000-041

30 Probe Level Assy Tap C4561

29 Container For Probe Level C4559

—

Long Probe For Water Level

(Low and Common)

B5268

— Short Probe For Water Level (High) B5269

— Reducing Bushing For Water Level A21391

— Float Level Assy DI/RO C4560

— Float Switch DI/Ro B5139

Item No. Steam Generator Part No.

1 SS Tank For HC-6100/6300 RDHC6000-009-1

—

Thermistor 5 KOHM

With Wire (Aquastat)

RDHC6000-006

— Tank (HC6100/6300) D6476

— Black Knob (6) Used with tank cover D6478

— Tank Cover D6477

— Tank Gasket B7872

— Ionic Bed B5213

— Lock and two keys for cabinet A10789

— 2-3/8" IDx12" EPDM hose cuff B2851A

— 2" IDx12" EPDM hose cuff B2851

— 1-1/2" IDx9-5/8" EPDM hose cuff B2250

— 1" IDx18" EPDM hose cuff A9620-1

— Hardware Assembly B5287

— Passivated Tank D2171

25

S-assy Ionic Bed HC-6000

(six required for HC-6100 and HC-6300)

B5213

HC-6000 Repair Parts

Item No. Electrical Compartment and Front Panel Part No.

31 Label Front Panel With Keypad RDHC6000-014

16 Emergency Stop Button (2 N.O.) RDEHU700-065

1 Main PCB For HC-6000 D5814

— Wire Harness For HC-6100 RDHC6000-013-1

— Wire Harness For HC-6300 RDHC6000-013-2

32 LCD & Display Board For HC-6000 RDHC6000-012

14 Fan DC24 (Sanyo 9A0924H4D03) With 2 Cover RDHC6000-004

12 Terminal Block #000 Wire B5607

11 Definite-Purpose Contactor 50AMP B2721

6 Fuse 3AMP A10718

7 Fuse 1A RDEHU700-073

5 Fuse Block 3AMP A8649

13 Module Power Din 9KW HC-6000 B5091

13 Module Power Din 15KW HC-6000 B5092

13 Module Power Din 9/15KW HC-6000 B5093

13 Module Power Din 15KW HC-6000 B5151

8 Trans Power 120/240-24V C1833

8 Trans Power 600-24V C1833A

8 Trans Power 480-24V C1833B

8 Trans Power 208-24V C1833F

8 Trans Power 380-24V C1833D

3 Fuse Holder 30AMP HC-6000 B4039

3 Fuse Holder 30AMP 250V HC-6000 B7494

4 Fuse 30AMP HC-6000 B4040

4 Fuse 30AMP HC-6000 250V B7495

38

Item No.

Electrical Compartment and Front Panel

Part No.

Item No.

Water Compartment

Part No.

Item No.

Steam Generator

Part No.

Page 39

39

Without TC

2PCS/Unit

With TC

1PCS/Unit

Without TC

2PCS/Unit

With TC

1PCS/Unit

208 B5808-1 B5809-1 B5810-1 B5811-1

240 B5808-2 B5809-2 B5810-2 B5811-2

380 B5808-1 B5809-1 B5810-1 B5811-1

480 B5808-3 B5809-3 B5810-3 B5811-3

600 B5808-4 B5809-4 B5810-4 B5811-4

Without TC

2PCS/Unit

With TC

1PCS/Unit

Without TC

2PCS/Unit

With TC

1PCS/Unit

208 B5047-1 B5048-1 B5043-1 B5044-1

240 B5047-2 B5048-2 B5043-2 B5044-2

380 B5047-1 B5048-1 B5043-1 B5044-1

480 B5047-3 B5048-3 B5043-3 B5044-3

600 B5047-4 B5048-4 B5043-4 B5044-4

Without TC

2PCS/Unit

With TC

1PCS/Unit

Without TC

2PCS/Unit

With TC

1PCS/Unit

208 B5049-1 B5050-1 B5045-1 B5046-1

240 B5049-2 B5050-2 B5045-2 B5046-2

380 B5049-1 B5050-1 B5045-1 B5046-1

480 B5049-3 B5050-3 B5045-3 B5046-3

600 B5049-4 B5050-4 B5045-4 B5046-4

Without TC

5PCS/Unit

With TC

1PCS/Unit

Without TC

5PCS/Unit

With TC

1PCS/Unit

208 B5047-1 B5048-1 B5043-1 B5044-1

240 B5047-2 B5048-2 B5043-2 B5044-2

380 B5047-1 B5048-1 B5043-1 B5044-1

480 B5047-3 B5048-3 B5043-3 B5044-3

600 B5047-4 B5048-4 B5043-4 B5044-4

Without TC

5PCS/Unit

With TC

1PCS/Unit

Without TC

5PCS/Unit

With TC

1PCS/Unit

208 B5049-1 B5050-1 B5045-1 B5046-1

240 B5049-2 B5050-2 B5045-2 B5046-2

380 B5049-1 B5050-1 B5045-1 B5046-1

480 B5049-3 B5050-3 B5045-3 B5046-3

600 B5049-4 B5050-4 B5045-4 B5046-4

HC-6100

Voltage

3kW

3kW DI

HC-6100

Voltage

9kW

15kW

HC-6100 DI

Voltage

9kW

15kW

HC-6300

Voltage

18kW

30kW

HC-6300 DI

Voltage

18kW

30kW

HC-6100

HC-6100

HC-6100 DI

HC-6300

HC-6300 DI

Heating Elements

TC= Thermocouple

Page 40

40

Item

No.

Electrical Compartment

and Front Panel

Part

No.

31 Label Front Panel With Keypad RDHC6000-014

16 Emergency Stop Button RDEHU700-065

1 Main PCB For HC-6000 D5814

— Wire Harness For HC-6500 RDHC6013-3

— Wire Harness For HC-6700 RDHC6000-013-4

32 LCD & Display Board For HC-6000 RDHC6000-012

14 Fan DC24 with 2 Cover RDHC6000-004

12 Terminal Block #000 Wire B5607

11 Definite-Purpose Contactor 50AMP B2721

6 Fuse 3AMP A10718

7 Fuse 1A RDEHU700-073

5 Fuse Block 3AMP A8649

13 Module Power Din 15KW HC-6000 B5092

13 Module Power Din 15KW HC-6000 B5151

8 Trans 208/240/380/480/600-24V B5605

3 Fuse Holder 30 AMP HC-6000 B4039

3 Fuse Holder 30 AMP HC-6000 A21882

4 Fuse 30 AMP HC-6000 B4040

4 Fuse 40 AMP HC-6000 A21883

4 Fuse 50 AMP HC-6000 A21884

Item

No.

Water Compartme nt

Part

No.

— PVC Tubing 5/8" A7618A

— Clamp Hose Flat .63 Olive B2716-11

— Hose Clamp, Minerature, Worm B2911-8

25 Fill Valve RDHC6000-001

21 Tubing Rd 7/8 Od Silicon A19699

23 Clamp Hose Flat .88 B2716-18

22 Tee Barbed HDPE 5/8 A23237

24 Elbow Barbed 5/8 A10579

27 Fill Cup for Series HC-6000 RDHC6000-038

27 Bracket For Fill Cup B2929

28 Bracket Liquid Level B5135

28 Brkt HC-6000 Liquid Level A22010

20 Drain Valve RDHC6000-002

18 Drain Cup RDEHU305-2021

17 Reducing Bushing Brass 1"-1/2" RDHC6000-041

30 Probe Level Assy Tap C4561

29 Container For Probe Level C4559

—

Long Probe For Water Level

(Low and Common)

B5268

— Short Probe For Water Level (High) B5269

— Reducing Bushing For Water Level A21391

— Float Level Assy DI/RO C4560

— Float Switch DI/Ro B5139

Item

No.

Steam Generator Part No.

26

S-assy Ionic Bed HC-6000

(14 required for Model HC-6500 and HC-6700)

B5213

— Thermistor 5 KOHM With Wire (Aquastat) RDHC6000-006

Item

No.

Electrical Compartment

and Front Panel

Part No.

Item

No.

Water Compartment

Part No.

Item

No.

Water Compartment

Part No.

Page 41

HC-6000 Repair Parts

41

Component Voltage Resistance Component Voltage Resistance

Fill Valve 24Vac 18

Ω

Fill Valve 24Vac 8.8

Ω

Drain Valve 24Vac 10

Ω

Drain Valve 24Vac 4.1

Ω

Contractor 24Vac 7-9

Ω

Thermocouple in Heating Elements - 0.51

Ω

Thermocouple in Heating Elements - 0.51

Ω

208, 240, 380V, 30/33, 5/40/45/50,3/60kW 240Vac 7.4-9.1

Ω

208Vac and 380Vac 3kW 220 Vac 46.0-48.6

Ω

380V 48/72kW 220Vac 5.2-6.3

Ω

240Vac and 380Vac 3kW 240 Vac 55-58

Ω

480V 48/72kW 277Vac 8.1-10.0

Ω

480Vac and 380Vac 3kW 277 Vac 72-78.2

Ω

600V 48/72kW 346Vac 12.8-15.7

Ω

600Vac and 380Vac 3kW 346 Vac 112.4-122.4

Ω

Power Transformer

208Vac and 380Vac15/30kW 220Vac 9.2-10.7

Ω

208Vac

18Ω across H1-H2

240Vac 15/30kW 240Vac 10.9-12.6

Ω

240Vac 21Ω across H1-H3

480Vac 15/30kW 277Vac 14.5-16.8

Ω

277Vac 24Ω across H1-H4

600Vac 15/30kW 346Vac 22.7-26.3

Ω

380Vac 40Ω across H1-H5

208Vac and 380Vac9/18kW 220Vac 15.3-17.7

Ω

480Vac 53Ω across H1H6

240Vac 9/18kW 240Vac 18.2-21.1

Ω

600Vac 97Ω across H1-H2

480Vac 9/18kW 277Vac 24.3-28.2

Ω

208Vac 1Ω across X1-X2

600Vac 9/18kW 346Vac 37.9-43.9

Ω

240Vac 1Ω across X1-X2

120Vac

13.6Ω across H1-H2

15.1Ω across H3-H4

277Vac 1Ω across X1-X2

208Vac 22Ω across H1-H2 380Vac 1Ω across X1-X2

240Vac 29Ω across H1-H2 480Vac 1Ω across X1-X2

380Vac 77Ω across H1-H2 600Vac 1Ω across X1-X4

480Vac 125Ω across H1-H2

600Vac 194Ω across H1-H2

Power Transformer

(secondary)

All

Voltage

0.6Ω across X1-X2

0.4Ω across X1-X2

Secondary Loop

Note:

All measurements should be made with the main power off and

the wires to the component being tested disconnected.

Resistance Value of 6100/6300 Components

Heating Elements

Power Transformer

Resistance Value of 6500-6700 Comoponents

Heating Elements

Primary Loop

Page 42

HC-6000 Repair Parts

42

HC6500/HC6700

30kW 33.5kW 40kW

Voltage

208

204

380

480

600

HC6500/HC6700

48kW

Voltage

HC6500/HC6700 DI

HC6500/HC6700 DI

Voltage

Without TC

5PCS/Unit

208---------204 - - - - B5438-1 B5438-1 - - - 380 B5437-1 B5438-1 B5438-1 B5438-1 - - B5437-1 B5438-1 B5437-1 B5438-1

480 B5437-2 B5438-2 - - - - B5437-2 B5438-2 B5437-2 B5438-2

600 B5437-3 B5438-3 - - - - B5437-3 B5438-3 B5437-3 B5438-3

Voltage

208

204

380

480

600

Without TC

5PCS/Unit

208---------204 - - - - B5440-1 B5440-1 - - - 380 B5439-1 B5440-1 B5440-1 B5440-1 - - B5439-1 B5440-1 B5439-1 B5440-1

480 B5439-2 B5440-2 - - - - B5439-2 B5440-2 B5439-2 B5440-2

600 B5439-3 B5440-3 - - - - B5439-3 B5440-3 B5439-3 B5440-3

With TC

1PCS/Unit

48kW 50.3kW 60kW 72kW 96kW

With TC

1PCS/Unit

Without TC

5PCS/Unit

B5433-1 B5434-1 - - - - B5433-1 B5434-1

- - - - B5433-1 B5434-1 - -

- - B5433-1 B5434-1 - - - -

--------

--------

Without TC

8PCS/Unit

Without TC

5PCS/Unit

B5435-1 B5436-1 - - - - B5435-1 B5436-1

- - - - B5435-1 B5436-1 - -

- - B5435-1 B5436-1 - - - -

--------

--------

Without TC

8PCS/Unit

With TC

1PCS/Unit

50.3kW 60kW 72kW

With TC

1PCS/Unit

30kW 33.5kW 40kW

With TC

1PCS/Unit

With TC

1PCS/Unit

Without TC

5PCS/Unit

Without TC

8PCS/Unit

Without TC

5PCS/Unit

Without TC

8PCS/Unit

With TC

1PCS/Unit

With TC

1PCS/Unit

With TC

1PCS/Unit

With TC

1PCS/Unit

Without TC

5PCS/Unit

Without TC

8PCS/Unit

Without TC

5PCS/Unit

Without TC

8PCS/Unit

With TC

1PCS/Unit

With TC

1PCS/Unit

With TC

1PCS/Unit

With TC

1PCS/Unit

Without TC

8PCS/Unit

Without TC

11PCS/Unit

Without TC

8PCS/Unit

Without TC

11PCS/Unit

45kW

With TC

1PCS/Unit

96kW

With TC

1PCS/Unit

45kW

With TC

1PCS/Unit

With TC

1PCS/Unit

Page 43

Procedure of HC6000 Version 7 Soft Refresh

This section is used for HC6000 software reprogramming only. Please follow the instructions carefully,

or pc board could become un-functional.

1. Install the driver program for Atmel MCU, SAM-BA on your computer first. The link for the Atmel

program AT91-ISP.exe and the latest version of can be found at the following location:

www.armstronginternational.com/hc6000refresh

2. Before refreshing the code, the old code in CPU must be erased:

a. Turn off the power supply from the breaker, and push the emergency stop button in.

b. Put Dip Switch S4-3 in the on position (Test Mode Select), turn on the breaker and pull out

emergency button. The indicator LED D47 on main board will remain ON. Keep the power

supply on for at least 8 seconds.

(This is the step to erase the old code.)

c. Turn off the power supply and put dip switch S4-3 to the off position.

d. Turn on the power supply, the indicator LED D47 will remain ON.

3. Loading the new code:

a. Connect the main board to computer with an USB cable. The computer should find the new

hardware, "ATMELAT91xxxxx Test Board "and install driver for board automatically. If system

can not find the board automatically, please install driver manual, the path of the install file

.inf is: c:/wingdows/info/atm6124.inf

b. Run program SAM-BA select the connection port as "\usb\ARM0", select board as

AT91SAM7S256-EK", please see figure 1 below.

Fig.1 SAM-BA Start Up Window

c. Click "Connect" button to enter the download window. Please see figure 2 on page 43.

43

Page 44

Fig.2 Code Download Window

d. Click the "open folder" button on the right of textbox "Send File Name" to open the latest code,

please see figure 3 below. You will then have to locate the .bin file that you downloaded from

the website and then hit open.

Fig. 3 Open the Latest Code Window

44

Page 45

e. Click the button "Send File" to send the latest code into board. You will be asked to unlock the

involved lock regions (0 to 7), click the button "Yes" to begin send code into board. Please see

figure 4 below.

Fig.4 Message Unlock Involved Lock Regions Window

f. When sending was finished, you will be asked to lock all locks that you have opened just now,

click the button "Yes" to lock these locks. You can verify that the code was send to the board

by scrolling up in the message box. See Figure 5 below.

Fig. 5 Verifying Code was Sent

45

Page 46

g. When operation has finished, close the "SAM-BA" window first, and then click the icon "remove

the USB hardware" to disconnect the link between computer and board. After reminder by

system, disconnect the power supply from breaker and pull out the USB cable.

h. The soft refresh of HC-6000 is complete restart the unit.

Introduction to Communications

HC6000 series provides two types of remote communication port: RS-485 and RS-232.

1) Run Modbus-RTU on RS-485 port

2) Run PSP on RS-232 port( the protocol was provided for ProtoCessor Module only, users

can select different modules to connect different port)

Please see instruction details for Modbus_RTU used in HC6000:

When you want to use modules, please change the configuration from communication to "PSP" per

menu (See section 3.2.3 communication setup).

When you need to use Modbus-485 in control board, please change the configuration from communi-

cation to "Modbus" per menu (See section 3.2.3 communication setup).

Modbus_RTU in HC6000, abiding by the order No. 02, 04 and 06 in Modbus, can read data in 10000

and 30000(address), and write data in 40000.

By using Modbus_RTU in HC6000, users can get PSP server end program and Modbus program. Part

of the PSP program will be written according to "ProtoCessor Simple Protocol (PSP) Specification"

provided by Protocessor. PSP Configuration from the Protocol module is as follows:

46

Page 47

Table 46-1 Modbus Variable Lists

47

data type attribute data address description

10001 Fill valve status 0:off 1:on

10002 Drain valve status 0:off 1:on

10003 contactor 1 status 0:off 1:on

10004 contactor 2 status 0:off 1:on

10005 contactor 3 status 0:off 1:on

10006 contactor 4 status 0:off 1:on

10008 Network control 0:Local 1:Remote

1 comm type 0:485 1:PSP

2 Sensor select 0:Humidistat 1:RH sensor

3 High limit sensor select 0:not use 1:use

4 Outside temperature 0:not use 1:use

5 Network enable 0:disable 1:enable

6 Modulating Fill enable 0:enable 1:disable

30001 Desired RH

30002 Output

30003 Water level 0:low 1:normal 2:high 3:exception

30004

Run status 0:Idle 1:Gen 10:frequent Draining 4:bed dring

5:Failure 6:Drain 7:heat 9:Fill

30005 Bed life (Hours)

30006 Bed life (Minutes)

30007 Run Time (Hours)

30008 Run Time (Minutes)

30009 Drain Freq (Hours)

30010 Drain Freq (Minutes)

30011 Idle Time (Hours)

30012 Idle Time (Minutes)

30013 RH value

30014 Duct value

30015 Outside temperature

30016 Water temperature

30017 Heat temperature

30018

Failure 1:Over temperature 2:High humidity/sail switch circuit is

open 3:Illegal level switch state 4:Unit have reached 100% of

bed life 5:Fill time out to low level 6:Water level dropped below

level during normal run 7:Fill time out from low to high level

8:Water level above high level time out 9:Water level has not

dropped below low level during an emptydrain 10:End of bed

dring

30019 Contactor number

30020 Contactor Power 0:1000W 1:3000 2:5000W 3:6650W 4:8000W

function 1,read only : function 5,15 write

MODBUS POLL: READ COILS

For modbus function number