Ariens Pro 28 EFI, Pro 32 RapidTrak, Pro 28 RapidTrak, Pro 28 EFI CE, Pro 28 EFI CE Track Service Manual

...Page 1

E10

Service Guide

Professional Series Sno-Thro

With Hydrostatic Drive

Models

926060 – Pro 28 RapidTrak

(SN 000101 +)

926068 – Pro 28 EFI

(SN 000101 +)

926069 – Pro 32 RapidTrak

(SN 000101 +)

926070 – Pro 36 EFI

(SN 000101 +)

®

926334 – Pro 32 12V CE

(SN 000101 +)

926336 – Pro 28 EFI CE

(SN 000101 +)

926337 – Pro 28 EFI CE Track

(SN 000101 +)

926338 – Pro 28 EFI CE RapidTrak

(SN 000101 +)

ENGLISH

05136630B • 12/18

Page 2

TABLE OF CONTENTS

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PRACTICES & LAWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

EMISSION CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . 2

REQUIRED OPERATOR TRAINING . . . . . . . . . . . . . . . . . . . 2

SAFETY ALERT SYMBOL. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SIGNAL WORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Decal Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Decal Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFETY RULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DRAINING FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SERVICE POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SEPARATE HOUSING FROM FRAME . . . . . . . . . . . . . . . . . 7

Remove Auger Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reinstall Auger Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

BOTTOM COVER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . 14

Remove Bottom Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install Bottom Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ATTACHMENT DRIVE BELT REPLACEMENT . . . . . . . . . . 16

Remove Attachment Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install Attachment Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TRACTION DRIVE BELT REPLACEMENT. . . . . . . . . . . . . . 16

Remove Traction Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install Traction Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DRIVE IDLER ASSEMBLY REPLACEMENT . . . . . . . . . . . . 17

Remove Attachment Drive Idler Assembly . . . . . . . . . . . . . . . . . . . . . 17

Remove Traction Drive Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . . 18

Install Traction Drive Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Install Attachment Drive Idler Assembly . . . . . . . . . . . . . . . . . . . . . . . 19

ATTACHMENT BRAKE REPLACEMENT. . . . . . . . . . . . . . . 20

Remove Attachment Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install Attachment Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

TRANSAXLE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 22

Remove Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Check Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Adjust Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

TRANSAXLE SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Add Transaxle Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Purge Air From Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

REDUCTION SHAFT BEARING REPLACEMENT . . . . . . . . 29

Remove Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Install Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

AUGER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Remove Auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Install Auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AUGER GEARCASE REPLACEMENT . . . . . . . . . . . . . . . . . 33

Remove Gearcase Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Install Gearcase Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

IMPELLER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . 34

Remove Impeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Install Impeller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ENGINE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Remove Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Install Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

BATTERY REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remove Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Install Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

TRACTION DRIVE CLUTCH CABLE REPLACEMENT . . . . 37

Remove Traction Drive Clutch Cable . . . . . . . . . . . . . . . . . . . . . . . . . 37

Install Traction Drive Clutch Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

DUAL-HANDLE INTERLOCK REPLACEMENT . . . . . . . . . . 38

Remove Interlock Cam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Install Interlock Cams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

AXLE BEARING REPLACEMENT. . . . . . . . . . . . . . . . . . . . . 40

Remove Left Axle Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Install Left Axle Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Remove Right Axle Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Install Right Axle Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

PINION SHAFT BUSHING REPLACEMENT. . . . . . . . . . . . . 42

Remove Bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Install Bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

DIFFERENTIAL GEAR REPLACEMENT. . . . . . . . . . . . . . . . 45

Remove Differential Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Install Differential Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

CHUTE GEAR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . 47

Remove Chute Rotation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Install Chute Rotation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Remove Actuation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Install Actuation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SCRAPER BLADE REPLACEMENT. . . . . . . . . . . . . . . . . . . 49

Remove Scraper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Install Scraper Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

HEADLIGHT REPLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . 50

Remove Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Install Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

EFI BATTERY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . 51

Remove Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Install Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

REPLACE ENGINE CONTROL UNIT (ECU) . . . . . . . . . . . . . 52

Remove ECU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Install ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

GEARCASE REBUILD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Disassemble Gearcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Assemble Gearcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

TRACK DRIVE WHEEL REPLACEMENT . . . . . . . . . . . . . . . 60

Remove Track Drive Wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Install Track Drive Wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

TRACK REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Remove Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Install Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

BOGIE WHEEL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 62

Remove Bogie Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Install Bogie Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

AXLE BEARING REPLACEMENT (TRACK MODELS) . . . . 63

Remove Left Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Install Left Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Remove Right Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Install Right Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

EFI TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . 69

EFI REPLACEMENT COMPONENTS . . . . . . . . . . . . . . . . . . 70

EFI TROUBLE CODE IDENTIFICATION. . . . . . . . . . . . . . . . 72

CHECKING TROUBLE CODES. . . . . . . . . . . . . . . . . . . . . . . 72

TROUBLE CODE DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . 73

Code 16: Low Battery Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Code 21: Barometer Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Code 22: Engine Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . 74

Code 23: EFI System Cannot Sustain Desired RPM. . . . . . . . . . . . . . 74

Code 27: Low Fuel Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Code 28: High Battery Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

DIAGNOSTICS FOR NON-TROUBLE CODES . . . . . . . . . . . 76

Engine Starts and Loses Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Engine No-Start Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Surging Run Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Engine Speed Does Not Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Fluttering Servo Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

SERVICE RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Page 3

Have Questions or Need Assistance?

www.ariens.com

A parts manual and an operator’s manual for your unit are

available for free download or purchase at www.ariens.com.

AriensCo recommends using only genuine Ariens replacement parts on this unit. Using unauthorized

parts may adversely affect the performance, durability or safety of this unit and may void the warranty.

Installing unauthorized parts will not automatically void the warranty; however, the warranty will not

apply if the installation and use of unauthorized parts damages the unit. The AriensCo warranty

applies solely to defects in AriensCo materials and / or factory workmanship. AriensCo disclaims

liability for any claims or damages – whether warranty, property damage, personal injury or death –

arising from using unauthorized replacement parts.

Before operating or servicing the unit, carefully and completely read the Operator’s Manual and

engine manual provided with the unit at time of purchase. They contain important safety instructions

and information about unit controls.

Be aware of your mechanical aptitude when applying information in this manual for service and / or

repairs. If you are not comfortable or capable of completing service and / or repairs to the machine,

take the machine to an authorized AriensCo service dealer.

WELCOME

EN – 2

Page 4

SAFETY

SAFETY ALERT SYMBOL

Read these safety rules and follow them closely. Failure to

follow these rules could lead to loss of control of unit,

severe personal injury or death to you or bystanders, or

result in damage to property or the machine.

PRACTICES & LAWS

Practice usual and customary safe working precautions.

Learn applicable rules and laws in your area. Always follow

the practices set forth in this manual.

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include exhaust and

evaporative emissions control system components

required to meet U.S. Environmental Protection Agency

(EPA) and/or California Air Resources Board (CARB)

regulations. Tampering with emission controls and

components by unauthorized personnel may result in

severe fines or penalties. Emission controls and

components can only be adjusted by an AriensCo dealer or

an authorized engine manufacturer's service center.

Contact your Ariens Equipment Retailer concerning

emission controls and component questions.

This is the safety alert symbol. It means:

• ATTENTION!

• YOUR SAFETY IS INVOLVED!

When you see this symbol:

• BECOME ALERT!

• OBEY THE MESSAGE!

SIGNAL WORDS

The safety alert symbol above and signal words below are

used on decals and in this manual. Read and understand

all safety messages.

1. Danger

DANGER: Indicates an IMMINENTLY

HAZARDOUS SITUATION! If not avoided, WILL

RESULT in death or serious injury.

2. Warning

WARNING: Indicates a POTENTIALLY

HAZARDOUS SITUATION! If not avoided,

COULD RESULT in death or serious injury.

REQUIRED OPERATOR TRAINING

Read and understand the Operator's Manual

and decals on the unit. This information is for

your safety and the proper use of your

equipment. Failure to follow these instructions

and warnings may cause death or serious

injury. If you have purchased this product from an Ariens

dealer, the dealer can provide you with training.

Familiarize yourself and any other operators with all

controls and the safe use of the features of this unit. If you

loan, rent or sell this product to others, provide them with all

manuals.

If you have any questions, please call our customer support

line at 920-756-4688 or contact us at www.ariens.com. Do

not use this equipment if, after reading the Operator's

Manual and the on-board decals, you have any questions

about the safe use of this product.

WARNING: AVOID INJURY. This snow thrower

is capable of crushing or amputating body parts.

Failure to observe the safety instructions in the

manuals and on decals could result in serious

injury or death.

ALWAYS disengage auger, stop unit and engine,

remove key and allow moving parts to stop

before leaving operator’s position.

3. Caution

CAUTION: Indicates a POTENTIALLY

HAZARDOUS SITUATION! If not avoided, MAY

RESULT in minor or moderate injury. It may also

be used to alert against unsafe practices.

4. Notice

NOTICE: Indicates information or procedures that are

considered important but not hazard related. If not

followed, property damage could result.

5. Important

IMPORTANT: Indicates general reference information

worthy of special attention.

EN – 3

Page 5

SAFETY DECALS

Figure 1

3

2

1

The safety decals on your machine are visual reminders of

the important safety information in this manual. All

messages on your unit must be fully understood and

carefully followed. Safety decals on the machine are

explained below.

Always replace missing or damaged safety decals.

Replacement decal information is in the parts manual for

your machine. Decals can be ordered from your dealer.

See Figure 1 for safety decal locations.

Safety Decal Locations

Stop engine, remove key, and read manual

before making any repairs or adjustments.

Read Operator’s Manual.

Wear appropriate hearing protection.

Safety Decal Descriptions

1. CAUTION!

Danger!

080000945

2. DANGER!

Danger!

ROTATING PARTS! Only use clean-out tool

to clear blockages. NEVER use your hands.

High-speed auger/impeller rotates below

discharge opening. Wait for all moving parts

to stop before removing clogs or servicing.

08000519B

3. DANGER!

Danger!

Only use clean-out tool to clear blockages.

NEVER use your hands.

NEVER direct discharge towards persons or

property that may be injured or damaged by

thrown objects.

Keep people away from unit while operating.

Keep children out of work area and under

watchful care of a responsible adult.

ROTATING PARTS! Keep clear of auger

while engine is running.

• Read Operator’s Manual.

• Allow operation only by properly-trained

adult, never children.

• Stop engine and remove ignition key prior

to leaving the operator’s position for any

reason.

• Keep all controls, guards and safety

devices properly serviced and functional.

• NEVER direct discharge towards persons

or property that may be injured or damaged

by thrown objects.

EN – 4

Page 6

SAFETY RULES

The following safety instructions are based on the B71.3

specifications of the American National Standards Institute

in effect at the time of production.

Training

Read, understand and follow all instructions on the

machine and in the manual(s) before operating this unit.

Be thoroughly familiar with the controls and the proper use

of the equipment. Know how to stop the unit and

disengage the controls quickly.

Never allow children to operate or play on or near the

equipment. Never allow adults to operate the equipment

without proper instruction.

Keep the area of operation clear of all persons,

particularly small children. Be alert and shut off unit if

children enter area.

Exercise caution to avoid slipping or falling, especially

when operating the snow thrower in reverse.

Always remove key and/or wire from spark plug before

assembly, maintenance or service. Unintentional engine

start up can cause death or serious injury.

Complete a walk-around inspection of the unit to

understand the unit, your work area and all safety decals.

Understand how to operate all controls, the functions of all

controls and how to STOP in an emergency.

Preparation

Always check overhead and side clearances carefully

before operation.

Always be aware of traffic when operating near streets or

along curbs.

Thoroughly inspect the area where the equipment is to be

used and remove all doormats, sleds, boards, toys, wires

and other foreign objects.

Disengage all clutches and shift into neutral before

starting the engine.

Use extension cords and receptacles as specified by the

manufacturer for all units with electric drive motors or

electric starting motors.

Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• Never add fuel to a running engine or hot engine.

• Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

• Never fill containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers

on the ground, away from your vehicle, before filling.

• When practical, remove gas-powered equipment from

the truck or trailer and refuel it on the ground. If this is

not possible, then refuel such equipment on a trailer

with a portable container, rather than from a gasoline

dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank

or container opening at all times, until refueling is

complete. Do not use a nozzle lock-open device.

• Replace gasoline cap securely and wipe up spilled fuel.

• If fuel is spilled on clothing, change clothing

immediately.

Adjust the auger / impeller housing height to clear gravel

or crushed rock surface.

Never attempt to make any adjustments while the engine

is running (except when specifically recommended by

manufacturer).

Always allow unit and engine to adjust to outdoor

temperature before clearing snow.

Operation

Disengage all controls before starting engine.

Never leave a running unit unattended. Always stop

engine and remove key before leaving unit to prevent

unauthorized use.

Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

Moving and/or rotating parts can cut off body parts such

as fingers or a hand. NEVER place your hands, other

body part or clothing near any moving parts while unit is

running.

Always keep hands away from all pinch points.

Do not touch parts which might be hot from operation.

Allow parts to cool before attempting to maintain, adjust or

service.

Thrown objects can cause injury. Check for weak spots on

docks, ramps or floors. Avoid uneven work areas and

rough terrain and stay alert for hidden hazards.

Exercise extreme caution when operating on or crossing

gravel drives, walks or roads. Stay alert for hidden

hazards or traffic.

EN – 5

Page 7

After striking a foreign object, stop the engine, remove the

wire from the spark plug, disconnect the cord on electric

motors, thoroughly inspect the snow thrower for any

damage, and repair the damage before restarting and

operating the snow thrower.

If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration is

generally a warning of trouble.

Stop the engine whenever you leave the operating

position, before unclogging the auger / impeller housing or

discharge chute, and when making any repairs,

adjustments or inspections.

When cleaning, repairing or inspecting the snow thrower,

stop the engine and make certain the auger / impeller and

all moving parts have stopped. Disconnect the spark plug

wire and keep the wire away from the plug to prevent

someone from accidentally starting the engine.

Do not run the engine indoors, except when starting the

engine and for transporting the snow thrower in or out of

the building. Open the outside doors; exhaust fumes are

dangerous.

Never operate the snow thrower without proper guards,

and other safety protective devices in place and working.

Always stand clear of the discharge area when operating

this unit.

Never direct the discharge toward people or areas where

injury or property damage can occur from thrown objects.

Keep children and others away.

Do not overload the machine capacity by attempting to

clear snow at too fast a rate.

Never operate the machine at high transport speeds on

slippery surfaces. Look behind and use care when

operating in reverse.

Do not operate in reverse unless absolutely necessary.

Always back up slowly and look down and behind before

and while backing.

Do not carry passengers.

Disengage attachment when not in use and when

traveling from one work area to another.

Disengage power to the auger / impeller when snow

thrower is transported or not in use.

Use only attachments and accessories approved by the

manufacturer of the snow thrower (such as wheel weights,

counterweights or cabs).

This product is equipped with an internal combustion

engine. Do not use unit on or near any unimproved,

forest-covered or brush-covered land unless exhaust

system is equipped with a spark arrester meeting

applicable local, state or federal laws. A spark arrester, if

used, must be maintained in effective working order by

operator.

Never operate the snow thrower without good visibility or

light. Always be sure of your footing, and keep a firm hold

on the handles. Walk; never run.

Never operate unit after or during the use of medication,

drugs or alcohol. Safe operation requires complete and

unimpaired attention at all times.

Never allow anyone to operate this unit when their

alertness or coordination is impaired.

Never touch a hot engine or muffler.

Avoid contact with sharp edges; sharp edges can cut.

Do not throw snow higher than necessary.

Clearing a Clogged Discharge Chute

Hand contact with the rotating auger / impeller inside the

discharge chute is the most common cause of injury

associated with snow throwers. Never use your hand to

clean out the discharge chute.

To clear the chute:

1. SHUT THE ENGINE OFF!

2. Wait 10 seconds to be sure the auger / impeller

blades have stopped rotating.

3. Always use a clean-out tool, not your hands.

Maintenance and Storage

Secure unit so it will not tip over during maintenance.

Before cleaning, removing clogs or making any

inspections, repairs, etc., disengage clutch(es), stop

engine, remove key, allow moving parts to stop and hot

parts to cool.

Check shear bolts and other bolts at frequent intervals for

proper tightness to be sure the equipment is in safe

working condition.

Check clutch and brake operation frequently.

Do not change engine governor settings and do not overspeed engine.

Adjust and service as required. Motion of drive wheels

and auger / impeller must stop quickly when clutch levers

are released.

Always maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or explosion.

Keep unit free of ice or other debris. Clean up oil or fuel

spills.

Always keep protective structures, guards, and panels in

good repair and secured in place. Never modify or remove

safety devices.

Never store the machine with fuel in the fuel tank inside a

building where ignition sources are present such as hot

water heaters, space heaters or clothes dryers. Close fuel

valve and allow the engine to cool completely before

storing in any enclosure or covering the unit.

Always refer to operator's manual for important details if

the snow thrower is to be stored for an extended period.

EN – 6

Page 8

Maintain or replace safety and instruction labels as

necessary.

Run the machine a few minutes after throwing snow to

prevent freeze-up of the auger / impeller.

Personal Protection

Do not operate the equipment without wearing adequate

winter garments. Avoid loose fitting clothing that can get

caught in moving parts. Wear footwear that will improve

footing on slippery surfaces.

Wear adequate safety gear, including safety glasses with

side shields and protective gloves.

Do not wear loose clothing or jewelry, and tie back hair

that may get caught in rotating parts.

NEVER attempt to unclog or clean unit while engine is

running. Rotating auger / impeller can cause serious

injury.

Protect eyes, face and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Always wear safety glasses or eye shields during

operation or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown from

the machine.

Slope Operation

Exercise extreme caution when operating on slopes. DO

NOT operate on steep slopes. DO NOT clear snow across

the face of slopes; go up and down. Keep all movement

on slopes slow and gradual.

Use a slow speed to avoid stops or shifts on slopes. Avoid

starting or stopping on a slope. Do not park unit on a slope

unless absolutely necessary. When parking on a slope

always block the wheels.

Do not operate near drop-offs, ditches, or embankments.

Unit can suddenly turn over if a wheel is over the edge of

a cliff or ditch, or if an edge caves in.

When practical, remove gas-powered equipment from the

truck or trailer and refuel it on the ground. If this is not

possible, then refuel on a trailer with a portable container,

rather than from a gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do

not use a nozzle lock-open device.

If fuel is spilled on clothing, change clothing immediately.

Properly remove fuel before tipping unit up onto housing

to avoid spills.

Towing/Transporting

Always stop engine, remove key and close fuel valve or

drain fuel when transporting unit on a truck or trailer.

Use extra care when loading or unloading unit onto trailer

or truck. Secure unit chassis to transport vehicle. Never

secure from rods or linkages that could be damaged. Do

not transport machine while engine is running.

Accessories

Use only AriensCo-recommended attachments or

accessories that are designed for your unit and that are

appropriate to your use and can be used safely in your

application.

Fuel

DO NOT run engine in an enclosed area. Always provide

good ventilation. Fumes from engine exhaust can cause

injury or death.

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use only an approved gasoline

container with an appropriately-sized dispensing spout.

No smoking, no sparks, no flames. Always allow engine to

cool before servicing.

Never fill fuel tank when engine is running or hot from

operation.

Never fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled fuel.

Never fill fuel containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers on

the ground away from your vehicle before filling.

EN – 7

Page 9

DRAINING FUEL SYSTEM

Figure 2

Figure 3

1. Tapping Screw

2. Chute Gear Cover

3. Hairpin

4. Hex Rod

1

2

4

3

SEPARATE HOUSING FROM FRAME

1. Move unit to an open, well-ventilated area with no flames or sparks.

2. Remove fuel tank cap and siphon fuel into a clean gasoline container.

3. Reinstall fuel tank cap and tighten.

4. Start engine to burn remaining fuel in fuel system and leave engine running until it “runs dry” and stops. Refer to Operator’s Manual for engine start procedure.

5. Stop engine, remove key and close fuel valve.

SERVICE POSITION

See Figure 2.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

IMPORTANT: NEVER store unit in service position.

Remove Auger Housing

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

See Figure 3.

3. Remove hardware retaining chute gear cover to chute pedestal and remove cover.

4. Remove hairpin from hex rod and remove hex rod from chute gears.

5. Remove hex rod from dash panel.

EN – 8

Page 10

IMPORTANT: Discharge chute control designs differ based

Figure 4

Generation 2 Chute Control Design

Figure 5

1. Clevis Pin

2. Cable Anchor

1

2

Generation 3 Chute Control Design

on serial number. Generation 2 chute control designs

appear as shown in Figure 4 and Generation 3 chute

control designs appear as shown in Figure 5. Continue to

step 6 for service to units with Generation 2 designs and

advance to step 10 for service to units with Generation 3

designs.

Generation 2 Chute Control Designs

See Figure 4.

6. Remove hairpin and cable eyelet from chute control assembly.

7. With a pliers, compress cable anchor tabs and remove anchor from chute control assembly.

8. Guide cable end through hole in dash panel.

IMPORTANT: Reinstall hairpin into clevis pin so it is not

misplaced.

Generation 3 Chute Control Designs

See Figure 5.

10. Remove hairpin from clevis pin and partially remove clevis pin from chute control assembly.

IMPORTANT: Chute control will come apart if clevis pin is

fully removed.

11. With a pliers, compress cable anchor tabs and remove anchor from chute control assembly.

12. Guide cable end through hole in dash panel.

IMPORTANT: Reinstall hairpin into clevis pin so it is not

misplaced.

9. Advance to step 13.

EN – 9

Page 11

See Figure 6.

Figure 6

1. Sleeve Bushing

2. Hairpin

3. Cable Anchor

4. Deflector Arm

5. Deflector Bracket

1

2

5

3

4

Figure 7

Figure 8

13. Remove hairpin, sleeve bushing and cable eyelet from deflector arm under dash panel.

14. With a pliers, compress cable anchor tabs and remove anchor from deflector bracket.

IMPORTANT: Reinstall sleeve bushing and hairpin so parts

are not misplaced.

See Figure 8.

16. Remove tapping screw securing left side of belt cover to frame.

17. Loosen, but DO NOT remove tapping screw securing right side of belt cover to frame. Remove belt cover.

15. Remove chute deflector cable from J-clamp on engine mount. See Figure 7.

EN – 10

Page 12

18. Remove hardware retaining belt finger to engine and

Figure 9

Figure 10

Figure 11

remove belt finger. See Figure 9.

WARNING: AVOID INJURY. Attachment sheave

edges are sharp. Wear thick gloves to remove

belts from attachment sheave.

See Figure 11.

20. Position support, such as a trash can, under handlebars so tractor / frame remains upright when separated from auger housing.

21. Chock or block wheels to prevent tractor / frame movement.

See Figure 10.

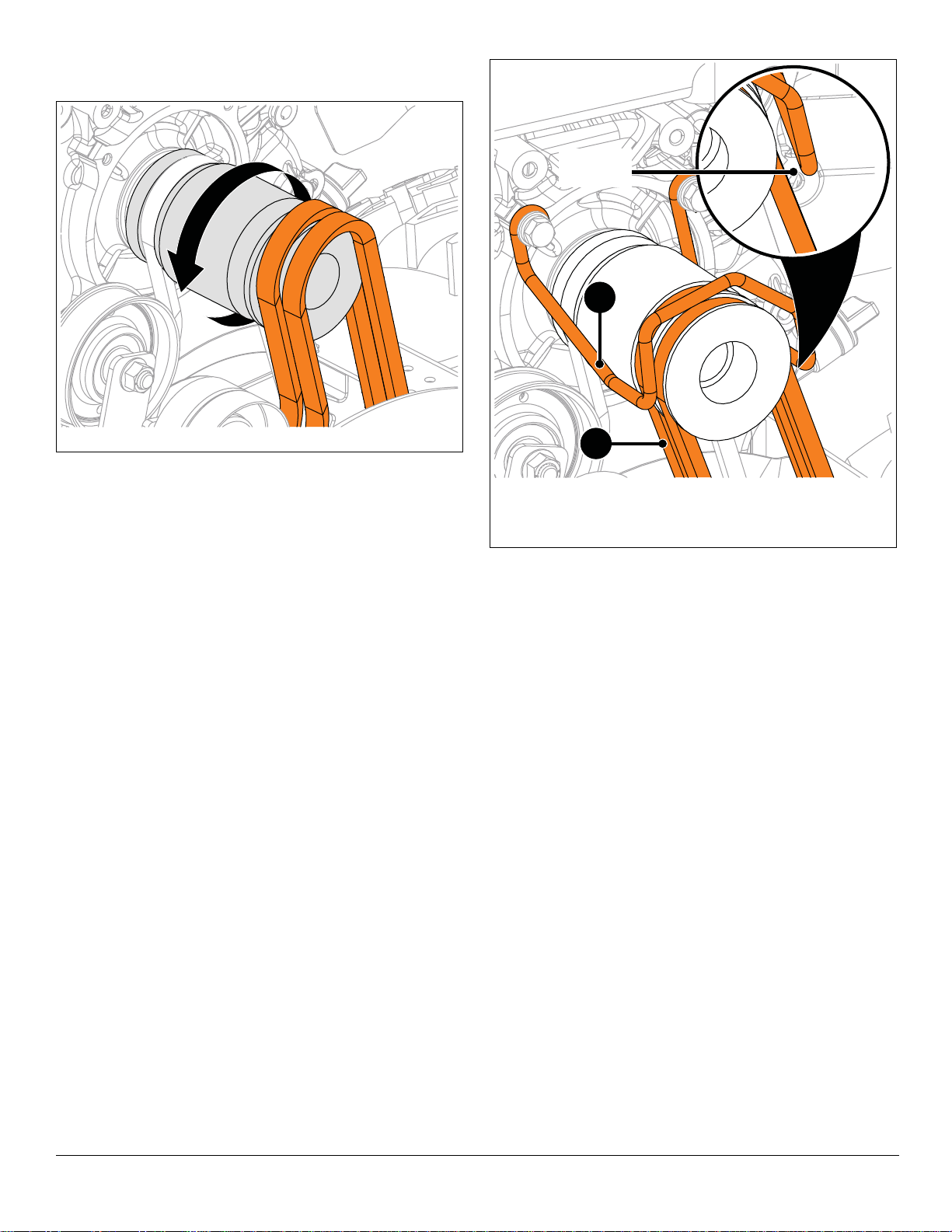

19. Remove attachment drive belts from attachment sheave.

To assist belt removal, slowly pull recoil starter handle

while gently pulling belts from attachment sheave.

EN – 11

Page 13

See Figure 12.

Figure 12

1. Tapping Screw

2. Mount Rod

1

2

Figure 13

22. Remove hardware securing auger housing to frame.

23. Lift auger housing rear slightly to disengage from mount rod and separate from unit.

Reinstall Auger Housing

See Figure 13.

1. With help from an adult assistant, engage attachment clutch lever so attachment brake will not obstruct attachment drive pulley in step 2.

2. Tilt auger housing rear up and lower into frame so housing mount brackets engage mount rod.

3. Release attachment clutch lever.

4. Align holes in housing mount brackets with holes in frame and reinstall two tapping screws, but DO NOT tighten.

IMPORTANT: Unit must be on a flat, level surface during

steps 6 – 8.

5. Check tire pressure and adjust if necessary. Refer to Operator’s Manual for specification.

6. Loosen skid shoe hardware and adjust skid shoes. Refer to Operator’s Manual for adjustment procedure.

7. Torque tapping screws installed in step 5 to

33.8 N•m – 70.1 N•m (24.9 lb-ft – 51.7 lb-ft).

See Figure 14.

WARNING: AVOID INJURY. Attachment sheave

edges are sharp. Wear thick gloves to install

belts onto attachment sheave.

8. Reinstall attachment drive belts onto attachment sheave.

EN – 12

Page 14

To assist belt installation, slowly pull recoil starter handle

Figure 14

Figure 15

1. Belt Finger

2. Attachment Drive Belts

1

2

Measure

Here

while gently guiding belts onto attachment sheave.

9. Reinstall belt finger and secure with two flat steel washers, two locking washers and two hex bolts.

See Figure 15.

10. Check belt finger clearance:

• Engage attachment clutch lever and make sure belt

finger located opposite belt idler is less than 3.2 mm

(1/8") from belt, but not touching the belt.

• If needed, adjust clearance by loosening hex bolts,

repositioning belt finger, and tightening bolts.

11. Reinstall belt cover and secure left side with tapping screw. Position right side under tapping screw and tighten.

12. Insert hex rod end without ears into dash panel until opposite end clears chute gear.

13. Position discharge chute facing forward.

14. Position chute rotation lever upright and insert hex rod through chute gear until it stops.

15. Reinstall hairpin into hex rod.

16. Insert chute lock cable through hole in dash panel and insert cable anchor into chute control assembly.

17. For service to models with a Generation 3 chute control design, continue to step 18. For service to models with a Generation 2 chute control design, advance to step 20.

EN – 13

Page 15

Generation 3 Chute Control Design

Figure 16

Generation 3 Chute

Control Design

Figure 17

Generation 2 Chute Control Design

See Figure 16.

18. Remove hairpin from clevis pin and reinstall cable eyelet onto clevis pin.

19. Insert clevis pin through chute control bracket and secure with hairpin.

24. Remove sleeve bushing and hairpin from deflector arm and reinstall cable eyelet onto deflector arm. Reinstall sleeve bushing and hairpin. See Figure 6.

25. Reconnect spark plug wire.

26. Adjust chute lock cable and deflector cable. Refer to operator’s manual for instructions.

IMPORTANT: Check all adjustments after first use.

WARNING: AVOID INJURY. Auger / impeller

must stop within 5 seconds when attachment

clutch lever is released.

Generation 2 Chute Control Design

20. Remove hairpin from chute control assembly and reinstall cable eyelet onto assembly. Reinstall hairpin. See Figure 17.

All Models

21. Reinstall gear cover and secure with tapping screw.

22. Reinstall chute deflector cable into J-clamp on engine mount.

23. Reinstall deflector cable anchor into deflector bracket.

EN – 14

Page 16

BOTTOM COVER REMOVAL

Figure 18

Figure 19

Figure 20

Remove Bottom Cover

IMPORTANT: Save all hardware for reinstallation.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Place unit in service position. See Service Position on

page 7.

4. Models 926068, 926070, 926336: Advance to step 7.

Models 926060, 926069, 926338: Continue to step 5.

Model 926337: Place track carriage in the “Raised

Position” and advance to step 7. Refer to Operator’s

Manual. See Figure 18.

Models 926060, 926069, 926338

CAUTION: AVOID INJURY. Track carriage will

rotate freely when height adjuster plate is

removed and height adjuster is free. Keep hands

away from pinch points.

6. Move height adjuster to the right, rotate away from bottom cover and remove bottom cover. See Figure 20.

See Figure 19.

5. Remove hardware securing height adjuster plate to height adjuster bracket.

EN – 15

Page 17

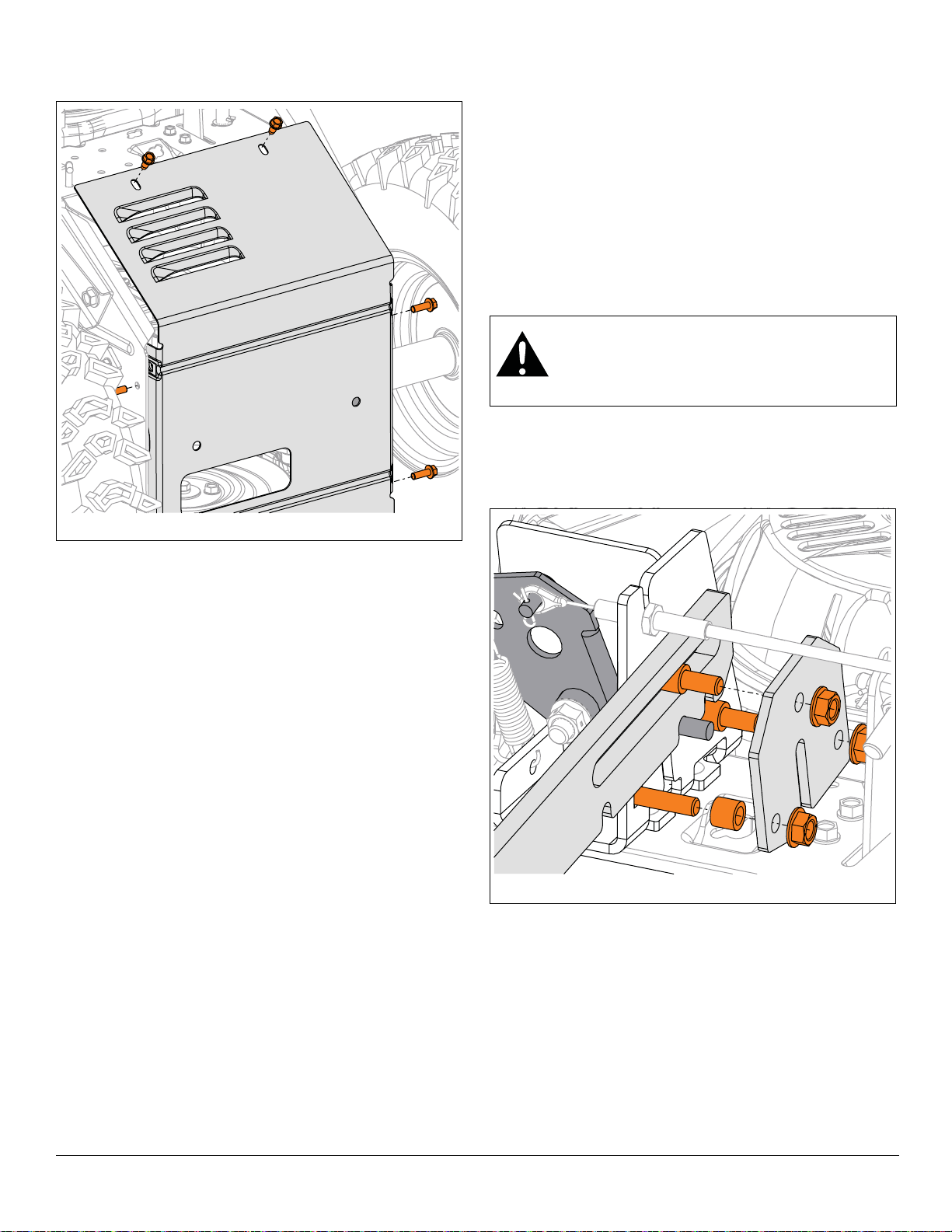

7. Remove hardware retaining bottom cover to frame

Figure 21

Figure 22

and remove cover. See Figure 21.

Install Bottom Cover

1. Reinstall bottom cover and secure with two tapping screws and four hex bolts.

2. Models 926068, 926070, 926334, 926336, 926337:

advance to step 6.

Models 926060, 926069, 926338

See Figure 22.

3. Reposition height adjuster stop against height adjuster bracket. Align slot with top hole in height adjuster bracket.

IMPORTANT: Align one of the three notches in height

adjuster with lock finger to hold adjuster position.

CAUTION: AVOID INJURY. Height adjuster is

unsecured until hardware is reinstalled. Be

careful not to bump adjuster from position on

lock finger. Keep hands away from pinch points.

4. Reinstall carriage bolts through height adjuster bracket and reinstall spacers onto bolts.

5. Reinstall height adjuster plate and secure with three flange nuts.

All Models

6. Return unit to operating position.

EN – 16

Page 18

ATTACHMENT DRIVE BELT

Figure 23

Figure 24

REPLACEMENT

TRACTION DRIVE BELT REPLACEMENT

Remove Attachment Drive Belts

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From Frame on page 7.

4. Remove attachment drive belts from attachment drive pulley. See Figure 23.

Remove Traction Drive Belt

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From Frame on page 7.

4. Remove hardware retaining belt finger and remove belt finger. See Figure 24.

Install Attachment Drive Belts

1. Install belts onto attachment drive pulley.

2. Reinstall auger housing to frame. See Reinstall Auger Housing on page 11.

3. Adjust attachment drive clutch. See Operator’s Manual for adjustment procedure.

NOTICE: Check all adjustments after first use.

WARNING: AVOID INJURY. Auger / impeller

must stop within 5 seconds when attachment

clutch lever is released.

5. Push traction drive idler away from belt and remove belt from idler pulley first, then transaxle pulley. Remove belt. See Figure 25.

EN – 17

Page 19

DRIVE IDLER ASSEMBLY

Figure 25

1. Traction Idler

2. Idler Pulley

3. Transaxle Pulley

1

2

3

Figure 26

REPLACEMENT

Remove Attachment Drive Idler Assembly

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From Frame on page 7.

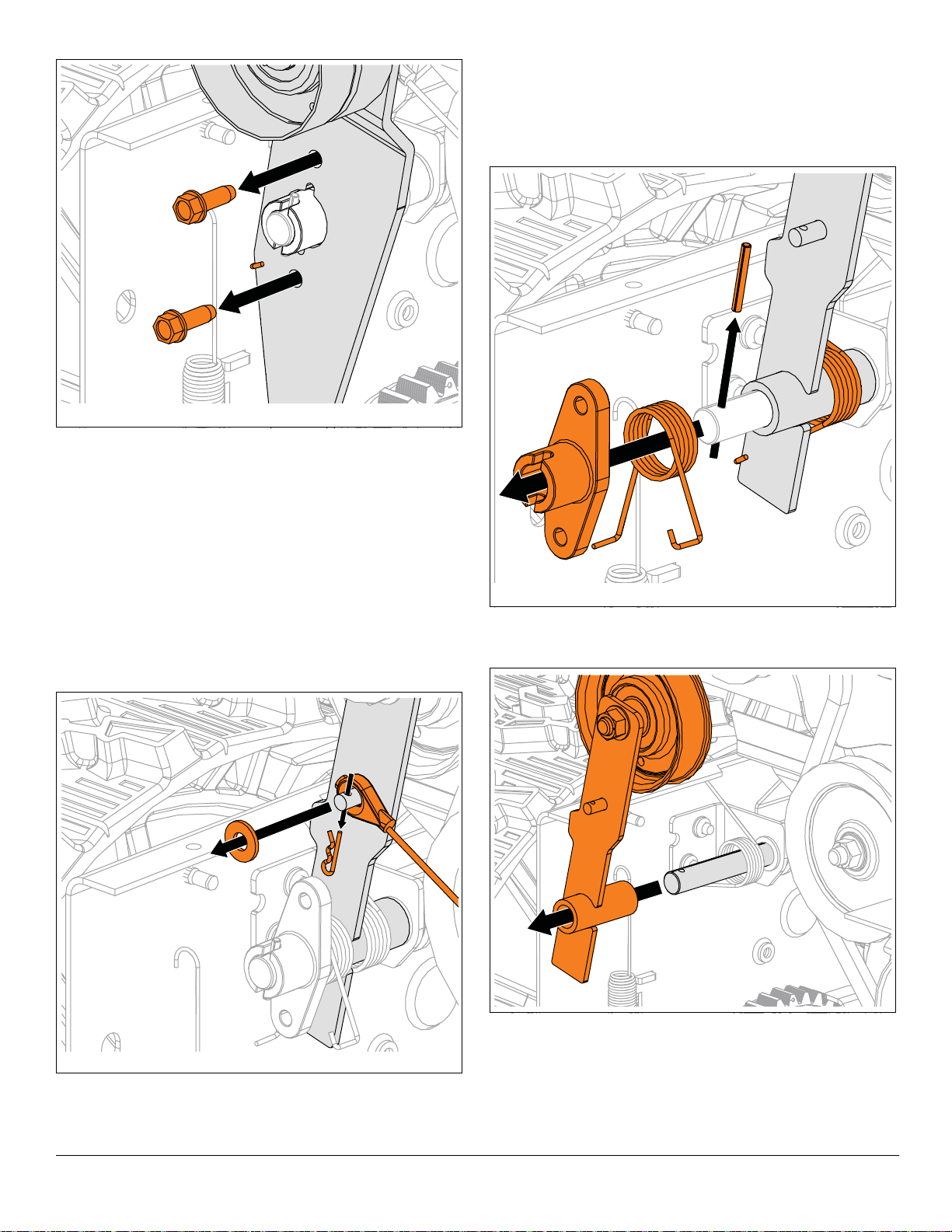

4. Remove attachment brake spring from frame. See Figure 26.

Install Traction Drive Belt

1. Install belt onto engine sheave first, then transaxle pulley and idler pulley.

2. Reinstall belt finger and secure with two round head square neck bolts and two locking nuts.

3. Reinstall housing to frame. See Reinstall Auger Housing on page 11.

4. Adjust traction drive clutch. Refer to Operator’s Manual for adjustment procedure.

5. Reconnect spark plug wire.

IMPORTANT: Check all adjustments after first use.

See Figure 27.

5. Remove torsion spring tension from around attachment idler arm.

6. Remove tapping screws retaining attachment idler arm to hub and remove idler assembly.

EN – 18

Page 20

Remove Traction Drive Idler Assembly

Figure 27

Figure 28

Figure 29

Figure 30

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove attachment drive idler assembly. See

Remove Attachment Drive Idler Assembly on page 17.

See Figure 28.

4. Remove hairpin and flat steel washer from traction drive idler arm.

5. Remove traction drive cable from idler arm.

See Figure 29.

6. Remove roll pin, attachment idler arm hub and front torsion spring from drive idler pivot rod.

7. Remove rear torsion spring from around idler pivot rod.

8. Remove traction idler arm assembly from pivot rod. See Figure 30.

EN – 19

Page 21

Install Traction Drive Idler Assembly

Figure 31

Figure 32

Figure 33

Figure 34

See Figure 31.

1. Reposition torsion spring leg around idler arm.

IMPORTANT: Ensure idler arm has tension.

2. Reinstall second torsion spring and attachment idler arm hub onto pivot rod.

Install Attachment Drive Idler Assembly

See Figure 33.

1.

2. Secure attachment drive idler assembly to hub with original tapping screws.

3. Reposition torsion spring leg around idler arm.

IMPORTANT: Ensure idler assembly has tension.

See Figure 32.

3. Align attachment arm idler hub with hole through pivot rod and reinstall roll pin.

4. Reinstall traction drive cable end onto traction drive idler arm and secure with original flat steel washer and hairpin.

4. Reinstall attachment brake spring onto frame. See Figure 34.

5. Reinstall attachment drive idler assembly. See Install Attachment Drive Idler Assembly on page 19.

EN – 20

5. Reinstall auger housing. See Reinstall Auger Housing

on page 11.

Page 22

6. Adjust attachment drive clutch. Refer to Operator’s

Figure 35

Manual for adjustment procedure.

7. Reconnect spark plug wire.

IMPORTANT: Check all adjustments after first use.

ATTACHMENT BRAKE REPLACEMENT

Remove Attachment Brake

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From Frame on page 7.

See Figure 35.

4. Disconnect extension spring from frame.

5. Remove hardware retaining attachment brake arm to brake mount bracket.

6. Remove attachment brake arm.

Install Attachment Brake

1. Position pivoting end of attachment brake arm in brake

2. With flathead screwdriver or similar pry bar, reconnect

See Figures 36 and 37.

3. Engage and disengage attachment clutch to verify

IMPORTANT: Make sure brake roller does not bind.

EN – 21

mount bracket. Secure with hex bolt and top locking

flange nut, but DO NOT overtighten.

extension spring to attachment brake arm.

brake roller on attachment idler does not interfere with

brake pad.

Page 23

Figure 36

1. Brake Pad

2. Brake Roller

1

2

Attachment Clutch Disengaged / Brake Engaged

Figure 37

Attachment Clutch Engaged / Brake Disengaged

WARNING: AVOID INJURY. Before placing unit

Figure 38

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

5. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Remove

Bottom Cover on page 14.

See Figure 38.

6. Check attachment brake:

• Brake must contact attachment belt when

attachment clutch is disengaged.

• Brake must be more than 1.6 mm (1/16") away from

attachment belt when attachment clutch is engaged.

4. Reinstall attachment drive belts. See Install Attachment Drive Belts on page 16.

7. Reinstall bottom cover and secure with two tapping screws and four hex bolts.

8. Return unit to operating position.

9. Reconnect spark plug wire and fill fuel tank.

IMPORTANT: Check all adjustments after first use.

WARNING: AVOID INJURY. Auger / impeller

must stop within 5 seconds when attachment

clutch lever is released.

EN – 22

Page 24

TRANSAXLE REPLACEMENT

Figure 39

Figure 40

Figure 41

1. Cable Pulley

2. Cable Pulley Bracket

3. Traction Drive Cable

1

2

3

Remove Transaxle

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

WARNING: AVOID INJURY. Before rotating unit

forward, drain fuel from tank and fuel system.

See Draining Fuel System on page 7. Make sure

unit is secure and will not tip.

3. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Bottom

Cover Removal on page 14.

4. Return tractor to operating position and support handlebars. Make sure unit is secure and will not tip.

5. Remove auger housing. See Separate Housing From Frame on page 7.

6. Remove hardware retaining belt finger and remove belt finger. See Figure 39.

8. Remove hairpin and flat steel washer retaining traction drive cable end to traction idler arm. Remove cable end from arm. See Figure 40.

See Figure 41.

9. Loosen, but DO NOT remove hardware retaining cable pulley to cable pulley bracket and remove traction drive cable from pulley.

10. Remove hardware retaining cable pulley bracket to frame and remove bracket.

7. Remove traction drive belt.

11. Remove hardware retaining idler pulley and remove pulley. See Figure 42.

EN – 23

Page 25

12. Remove hardware retaining transaxle shroud and

Figure 42

Figure 43

Figure 44

Figure 45

remove shroud. See Figure 43.

13. Remove hairpin and flat steel washer securing shift rod to transaxle. See Figure 44.

14. Remove hairpin securing shift rod to bell crank at unit rear and remove shift rod. See Figure 45.

EN – 24

Page 26

15. Remove hairpin securing transaxle bypass rod to

Figure 46

Figure 47

Figure 48

Figure 49

1. E-Ring

2. Pinion Sprocket

3. Spacer Bushing

4. Key

1

2

4

3

transaxle and remove bypass rod from transaxle. See

Figure 46.

16. Remove bypass rod through unit rear.

17. Remove hardware securing transaxle to transaxle mount. See Figure 47.

See Figure 48.

18. Tilt transaxle so tension is removed from chain and remove chain from transaxle.

19. Remove transaxle.

20. Remove E-ring, pinion sprocket, spacer bushing and key from transaxle driveshaft. See Figure 49.

EN – 25

Page 27

Install Transaxle

Figure 50

Figure 51

1. Install key, pinion sprocket and spacer bushing onto transaxle driveshaft. Secure with E-ring.

See Figure 50.

2. Position transaxle inside unit and install chain around pinion sprocket.

3. Level transaxle and align with transaxle mount. Support transaxle, but DO NOT reinstall mounting hardware.

IMPORTANT: Each side of chain should have an equal

amount of links / tension between pinion sprocket and

pinion gear. If tension is uneven, manually turn pinion gear

toward side with greater tension until equal.

See Figure 51.

4. Reinstall shift rod into transaxle and bell crank.

IMPORTANT: Shift rod ends are not equal length. The long

end inserts through transaxle, and the short end inserts

through bell crank.

5. Secure shift rod to transaxle with one flat steel washer and hairpin. Secure shift rod to bell crank with one hairpin.

EN – 26

Page 28

6. Reinstall transaxle bypass rod through unit rear and

Figure 52

Figure 53

into bypass arm on transaxle. Secure with hairpin. See

Figure 52.

See Figure 53.

7. Align transaxle with transaxle mount.

8. Reinstall two hex bolts through transaxle mount and transaxle. Secure with two flat steel washers, two locking washers and two hex nuts, but DO NOT tighten hardware.

9. Check chain tension and adjust if necessary. See

Check Chain Tension on page 28 and Adjust Chain

Tension on page 28.

10. Tighten hardware if chain tension is within specification.

See Figure 54.

11. Reinstall hex bolt and locking nut securing front of transaxle to transaxle bracket and tighten.

12. Adjust transaxle chain tension. See Adjust Chai n Tension on page 28.

13. Reinstall transaxle shroud and secure with tapping screw.

EN – 27

Page 29

See Figure 55.

Figure 54

Figure 55

1. Stepped Spacer

2. Pocket Bushing

3. Idler Pulley

4. Flat Steel Washer

5. Locking Nut

1

2

5

4

3

14. Reinstall stepped spacer onto hex bolt and insert bolt through frame front from inside frame.

IMPORTANT: Make sure bushing is in correct orientation

so stepped-down end of bushing inserts through frame.

15. Reinstall pocket bushing onto hex bolt so flat face of bushing is forward.

16. Reinstall idler pulley onto hex bolt and secure with one flat steel washer and locking nut.

17. Reinstall traction drive belt. See Install Traction Drive Belt on page 17.

18. Reinstall housing to frame. See Reinstall Auger Housing on page 11.

19. Reinstall bottom cover. See Install Bottom Cover on

page 15.

20. Return unit to operating position.

21. Fill fuel tank and reconnect spark plug wire.

IMPORTANT: Check all adjustments after first use.

EN – 28

Page 30

Check Chain Tension

Figure 56

Figure 57

1. Oil Vent / Fill Plug

1

1. Push on front chain length and observe amount of deflection.

• If chain deflects less than 3.2 mm (1/8"), chain is too

tight and requires adjustment.

• If chain deflects 3.2 mm – 7.9 mm (1/8" – 5/16"),

chain tension is within specification and does not

require adjustment.

• If chain deflects more than 7.9 mm (5/16"), chain is

loose and requires adjustment.

Adjust Chain Tension

1. Remove auger housing. See Separate Housing From Frame on page 7.

See Figure 56.

2. Loosen hardware retaining transaxle to transaxle mount bracket.

3. Position a pry bar or similar tool under transaxle and pivot about pinion shaft.

• To increase chain tension, push down slightly on pry

bar and raise transaxle.

• To decrease chain tension, release pressure from

pry bar and lower transaxle.

4. Check chain tension and continue adjustment if necessary.

5. Hold transaxle position and tighten hardware securing transaxle to transaxle mount.

TRANSAXL E S ERVICE

Add Transaxle Fluid

SAE 0W-40 is approved for all-season applications in

Hydro-Gear® RT-310™ transaxles.

SAE 20W-50 is approved for non-winter applications where

operation does not occur in ambient temperatures below

4.4° C (40° F) ONLY. Biodegradable oils are NOT approved

for use in Hydro-Gear® RT-310 transaxles.

1. Remove transaxle as instructed in Remove Transaxle

on page 22, but DO NOT remove E-ring, sleeve

bushing and pinion sprocket from transaxle driveshaft.

See Figure 57.

2. Place transaxle on a level surface and remove fill plug.

NOTICE: Transaxle is equipped with a bladder-style oil

reservoir that expands as oil temperature increases. It is

NOT necessary to leave an air pocket in the reservoir for oil

expansion.

3. Add oil to top of fill port.

4. Reinstall fill plug to fill port and tighten.

6. Perform steps 13 – 21 of Install Transaxle on page 25

and see Check Chain Tension on page 28. Repeat

chain adjustment if necessary.

5. Reinstall transaxle. See Install Transaxle on page 25.

EN – 29

Page 31

Purge Air From T ransaxle

Figure 58

Due to the effects air has on efficiency in hydrostatic drive

applications, it’s critical that air is purged from the system.

The purge procedure in this section should be performed

each time a hydrostatic system has been opened for

maintenance or after adding oil. Without purging the

system, the drive may lose efficiency.

Symptoms of efficiency loss include:

• Noisy operation

• Lack of power or drive after short-term operation

• High operation temperature and excessive oil

expansion

1. Position a jack under unit and lift unit so wheels are off the ground. Make sure unit is secure and will not tip.

2. Pull transmission bypass lever out and start unit. Refer to Operator’s Manual for engine start procedure.

3. Slowly cycle the speed selector lever through all forward and reverse positions 5 – 6 times.

4. Position speed selector lever in neutral and push transmission bypass lever in.

5. Repeat step 3.

IMPORTANT: Wheel rotation should increase and

decrease accordingly as speed selector lever moves

between all forward and reverse speeds.

6. Stop engine, close fuel valve and release jack so unit lowers to the ground. Remove jack.

If unit drives normally, no further adjustment is needed. If

drive malfunctions, continue to steps 7 – 10.

7. Wait for all moving parts to stop and for hot parts to

cool and remove transaxle from unit. See Remove

Transaxle on page 22.

8. Remove fill plug and add oil. See Add Transaxle Fluid

on page 28.

9. Reinstall transaxle. See Install Transaxle on page 25.

10. Test forward and reverse speeds. If necessary, purge air from the system again until unit drives normally.

NOTICE: When unit moves forward and reverse at normal

speed, purging is complete.

REDUCTION SHAFT BEARING REPLACEMENT

Models 926060, 926069, 926338

Remove Bearings

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

WARNING: AVOID INJURY. Before rotating unit

forward, drain fuel from tank and fuel system.

See Draini ng Fuel System on page 7. Make sure

unit is secure and will not tip.

3. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Bottom

Cover Removal on page 14.

4. Remove spring clip and sleeve bushing from reduction shaft end. See Figure 58.

5. Move reduction shaft as far right as possible and remove spring clip from shaft. See Figure 59.

EN – 30

Page 32

See Figure 60.

Figure 59

Figure 60

1. Transmission Bracket

2. Sleeve Bushing

1

2

Figure 61

Figure 62

6. Move reduction shaft as far left as possible.

7. Remove hardware retaining bearing flanges and remove parts from transmission bracket.

IMPORTANT: Be aware of sleeve bushing on right

reduction shaft end.

Install Bearings

1. Press bearings into bearing flanges and install onto reduction shaft.

2. Install shaft into transmission bracket and position bearing flanges outside transmission bracket.

3. Secure each bearing flange to transmission bracket with 3 tapping screws.

4. Install sleeve bushing onto right side of pinion shaft. See Figure 61.

8. Remove bearing flanges from reduction shaft and remove bearings.

5. Align pinion sprocket keyways with reduction shaft keyway and insert reduction shaft through sprockets. See Figure 62.

6. Reinstall spring clip into right side of reduction shaft.

7. Reinstall sleeve bushing and spring clip onto left side of reduction shaft.

EN – 31

Page 33

AUGER REPLACEMENT

Figure 63

1. Bearing Plate

1

Figure 64

Figure 65

Remove Auger

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From Frame on page 7.

See Figure 63.

CAUTION: AVOID INJURY. Attachment drive

pulley edges are sharp. Wear gloves when

handling pulley.

4. Hold attachment drive pulley in place and remove hardware securing pulley to impeller shaft. Remove pulley.

5. Loosen, but DO NOT remove hardware securing bearing plate to auger housing.

6. Remove hardware retaining support bushings to auger housing. See Figure 64.

7. Remove auger assembly from housing. See Figure 65.

See Figure 66.

IMPORTANT: Flange bushing is to remain inside support

bushing.

8. Remove support bushing from auger shaft end.

9. Remove shear bolt from auger shaft.

10. Remove auger from auger shaft. Use of penetrating oil or heat may be necessary to remove auger.

IMPORTANT: If rust is present on auger shaft, remove with

sand paper and wipe clean with oil.

EN – 32

Page 34

Install Auger

Figure 66

Figure 67

1. Auger Kicker

2. Grease Zerk

1

2

Figure 68

See Figure 67.

1. Install auger onto auger shaft with auger kickers facing gearcase.

IMPORTANT: Make sure auger helix direction matches

original auger orientation.

2. Apply grease to grease zerks and spin auger by hand to spread grease along auger shaft.

3. Repeat step 2.

4. Reinstall support bushing onto auger shaft end.

5. Align holes in auger with holes in auger shaft and reinstall shear bolt. Torque bolt to 7.9 N•m – 16.5 N•m (5.8 lb-ft – 12.2 lb-ft). If torque wrench is unavailable, tighten until bolts no longer spin freely. DO NOT overtighten.

6. Reinstall auger assembly into housing so impeller shaft is seated in ball bearing at housing rear. See Figure 68.

7. Align holes in bushings on auger ends with holes in housing and partially thread all six tapping screws.

8. Tighten tapping screws.

EN – 33

Page 35

See Figure 69.

Figure 69

1. Impeller Shaft

2. Hex Nut

1

2

Figure 70

9. Tighten three hex nuts securing bearing plate to auger housing.

10. Apply anti-seize compound to impeller shaft end.

11. Reinstall attachment drive pulley onto impeller shaft and secure with locking washer and hex bolt. Torque to 7.9 N•m – 16.5 N•m (5.8 lb-ft – 12.2 lb-ft).

AUGER GEARCASE REPLACEMENT

Remove Gearcase Assembly

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove augers. See Remove Auger on page 31.

See Figure 70.

4. Remove two flat steel washers from auger shaft.

5. Remove two roll pins retaining impeller to impeller shaft and remove impeller.

IMPORTANT: Use of penetrating oil or heat may be

necessary to remove impeller.

12. Reinstall housing to frame. See Reinstall Auger Housing on page 11.

13. Reconnect spark plug wire.

Install Gearcase Assembly

1. Install impeller onto impeller shaft.

2. Align holes in impeller with holes in impeller shaft and reinstall roll pins.

3. Reinstall one flat steel washer onto each auger shaft end.

4. Reinstall augers. See Install Auger on page 32.

5. Reconnect spark plug wire.

EN – 34

Page 36

IMPELLER REPLACEMENT

Figure 71

1. Bearing Plate

1

Figure 72

Figure 73

1. Impeller Shaft

2. Hex Nut

1

2

Remove Impeller

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From Frame on page 7.

See Figure 71.

4. Remove hardware securing attachment drive pulley to auger housing and remove pulley.

5. Loosen, but DO NOT remove hardware securing bearing plate to housing.

6. Remove hardware securing auger bushings to auger housing.

See Figure 73.

4. Tighten three hex nuts securing bearing plate to housing.

5. Apply anti-seize compound to impeller shaft end.

6. Reinstall attachment drive pulley onto impeller shaft and secure with locking washer and hex bolt. Torque to 7.9 N•m – 16.5 N•m (5.8 lb-ft – 12.2 lb-ft).

7. Remove auger assembly from housing. See Figure 65.

8. Remove two roll pins securing impeller to impeller shaft and remove impeller. See Figure 70.

IMPORTANT: Use of penetrating oil or heat may be

necessary to remove impeller.

Install Impeller

1. Install impeller onto impeller shaft and align with holes in impeller with holes in impeller shaft. Reinstall roll pins.

2. Reinstall auger assembly into housing so impeller shaft is seated in ball bearing at housing rear. See Figure 68.

3. Align holes in bushings on auger ends with holes in housing and secure with six tapping screws. See Figure 72.

7. Reinstall auger housing to frame. See Reinstall Auger Housing on page 11.

8. Reconnect spark plug wire.

EN – 35

Page 37

ENGINE REPLACEMENT

Figure 74

Figure 75

Remove Engine

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key an d wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Drain gasoline from fuel system and tank. See

Draining F uel System on page 7.

4. Remove belt cover. See Figure 8.

5. Remove hardware securing belt finger to engine and remove belt finger. See Figure 9.

See Figure 74.

6. Remove chute deflector cable from J-clamp on engine mount.

7. Remove hardware securing engine mount to frame.

Install Engine

1. Install key into crankshaft keyway.

2. Align engine sheave keyway with crankshaft key and reinstall sheave onto crankshaft. Secure with spacer bushing, locking washer and hex bolt.

WARNING: AVOID INJURY. Engine is heavy.

NEVER lift engine without a suitable lifting device

or adult assistant.

WARNING: AVOID INJURY. Engine is heavy.

NEVER lift engine without a suitable lifting device

or adult assistant.

8. Using a suitable lifting device or an adult assistant, lift engine and tilt forward slightly to relieve tension from belts. Remove belts from engine sheaves.

9. Lower engine onto a flat, level surface.

See Figure 75.

10. Remove hardware securing engine sheave to crankshaft.

11. Remove engine sheave and key from crankshaft.

3. Using a suitable lifting device or adult assistant, lift engine over frame and tilt slightly forward so belts reach over engine sheave.

4. Level engine and lower onto bolts in frame.

5. Secure engine to frame with four locking nuts. Torque to 11.9 N•m – 17.9 N•m (8.8 lb-ft – 13.2 lb-ft).

6. Reinstall belt finger and secure with two flat steel washers, two locking washers and two hex bolts as shown in Figure 15.

7. Check belt finger clearance:

• Engage attachment clutch lever and make sure belt

finger located opposite belt idler is less than 3.2 mm

(1/8") from belt, but not touching the belts.

• If needed, adjust clearance by loosening hex bolts,

repositioning belt finger, and tightening bolts.

8. Reinstall belt cover and secure left side to frame with one tapping screw. Position right side of belt cover under tapping screw and tighten.

9. Reconnect spark plug wire and fill fuel tank.

EN – 36

Page 38

BATTERY REPLACEMENT

Figure 76

Figure 77

Model 926334

Remove Battery

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove wing knobs and other hardware retaining battery cover and remove cover. See Figure 76.

Install Battery

1. Install battery in battery tray so negative terminal is positioned on the right side (from perspective of the operator in operator’s position).

2. Reconnect positive battery cable to positive battery terminal first, then the negative cable to negative terminal. Secure with two hex bolts, two flat steel washers, two locking washers and two hex nuts. See Figure 77.

3. Reinstall battery cover and route battery cables through cutout in cover. Secure with two hex bolts, two flat steel washers and two wing knobs. See Figure 76.

4. Disconnect negative, then positive battery cable from battery terminal.

5. Remove battery.

EN – 37

Page 39

TRACTION DRIVE CLUTCH CABLE

Figure 78

1. Traction Idler Arm

2. Hairpin

3. Flat Steel Washer

4. Cable Pulley

5. Traction Drive Cable

1

4

5

3

2

Figure 79

Figure 80

1

2

3

1. Upper Traction Clutch Cable

2. Lower Traction Clutch Cable

3. Cable Pulley

REPLACEMENT

Remove Traction Drive Clutch Cable

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove belt cover. See Figure 8.

See Figure 78.

4. Remove hardware securing traction clutch cable eyelet to traction idler arm and remove cable.

5. Loosen, but DO NOT remove hardware securing cable pulley to pulley bracket. Remove cable from pulley.

See Figure 80.

8. Remove upper traction clutch cable from lower traction clutch cable.

9. Loosen, but DO NOT remove hardware retaining cable pulley to pulley bracket.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

6. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Remove

Bottom Cover on page 14.

7. Remove hardware securing upper traction clutch cable to clutch lever and remove cable. See Figure 79.

10. Remove lower traction drive clutch cable.

EN – 38

Page 40

Install Traction Drive Clutch Cable

Figure 81

1. Upper Traction Clutch Cable

2. Lower Traction Clutch Cable

3. Cable Pulley

4. Shoulder Bolt

1

2

4

3

Figure 82

1. Spring Clip

2. Interlock Cam

3. Spring

4. Interlock Bracket

1

3

4

2

1. Reinstall upper traction clutch cable to traction clutch lever and secure with one flat steel washer and hairpin. See Figure 79.

2. Connect lower traction clutch cable to upper traction clutch cable.

See Figure 81.

3. Route lower traction clutch cable through hole in back cover.

4. Align lower traction clutch cable in cable pulley and tighten shoulder bolt.

DUAL-HANDLE INTERLOCK REPLACEMENT

Remove Interlock Cam

IMPORTANT: Save all hardware for reinstallation.

See Figure 82.

1. Disconnect spring from interlock bracket.

2. Remove spring clips securing interlock cams to camshafts.

5. Reinstall bottom cover and secure with four hex bolts and two tapping screws.

6. Retrieve cable end from inside tractor / frame and align in cable pulley. See Figure 78.

7. Install cable end onto traction idler arm and secure with one flat steel washer and hairpin. See Figure 78.

8. Tighten shoulder bolt securing cable pulley to pulley bracket.

9. Return unit to operating position.

10. Reinstall belt cover and secure left side to frame with one tapping screw. Position right side of belt cover under tapping screw and tighten.

11. Adjust traction drive clutch. Refer to Operator’s Manual for adjustment procedure.

12. Fill fuel tank and reconnect spark plug wire.

IMPORTANT: Check all adjustments after first use.

EN – 39

Page 41

IMPORTANT: Interlock cams will fall from camshafts in

Figure 83

Figure 84

Figure 85

Figure 86

next step.

3. Remove hardware retaining camshafts to clutch levers and remove camshafts from interlock bracket. See Figure 83.

4. Remove cams.

Install Interlock Cams

IMPORTANT: Make sure nylon bushings are seated in

interlock bracket. See Figure 84.

2. Install interlock cam onto camshaft so flat edge is positioned downward. Secure with spring clip. See Figure 85.

See Figure 86.

3. Position left interlock cam inside interlock bracket and align with left camshaft.

4. Insert camshaft through cam.

5. Secure camshaft to clutch lever with one tapping screw.

6. Rotate cam so flat edge is positioned upward and secure with spring clip.

7. Reconnect spring to interlock bracket.

1. Reinstall right camshaft and secure to clutch lever with one tapping screw.

EN – 40

8. Check dual-handle interlock function. Refer to Operator’s Manual for test procedure.

IMPORTANT: If dual-handle interlock continues to

malfunction, see your Ariens dealer.

Page 42

AXLE BEARING REPLACEMENT

Figure 87

1. Axle Bearing

2. Sleeve Bushing

3. Key

4. Bearing Plate

3

2

1

4

Figure 88

Models 926068, 926070, 926336

Remove Left Axle Bearing

IMPORTANT: Save all hardware for reinstallation.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Remove

Bottom Cover on page 14.

4. Remove snap clip from left axle end and remove wheel.

See Figure 87.

5. Remove key and sleeve bushing from axle.

6. Remove hardware securing axle bearing and bearing plate to frame.

IMPORTANT: Bearing plate is not a wear item and is not

necessary to replace.

7. Remove axle bearing.

Install Left Axle Bearing

1. Install bearing onto axle and align with bearing plate.

2. Insert three hex bolts from inside frame through bearing and secure with three locking nuts.

3. Reinstall sleeve bushing and key onto axle.

4. Reinstall bottom cover and secure with two tapping screws and four hex bolts.

5. Reinstall wheel and secure with snap clip.

6. Return unit to operating position.

7. Reconnect spark plug wire and fill fuel tank.

Remove Right Axle Bearing

IMPORTANT: Save all hardware for reinstallation.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

1. Stop engine, remove key and wait for all moving parts to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Remove

Bottom Cover on page 14.

4. Remove snap clips from axle ends and remove wheels.

See Figure 88.

5. Remove E-ring from axle end.

6. Remove axle from differential.

EN – 41

Page 43

See Figure 89.

Figure 89

Figure 90

Figure 91

1. Short Axle

2. Flat Steel Washer

3. Differential Gear

4. Pinion Gear

1

3

2

4

IMPORTANT: Two flat steel washers will become free