Page 1

926 Series

Sno-Thro

®

Owner/Operator Manual – Livret de l'opérateur/du propriétaire –

Betriebsanleitung – Manuale del proprietario/operatore –

Käyttöohjekirja – Manual del propietario/operador – Brukerhåndbok –

Instruktionsbok – Руководство владельца/пользователя –

Instrukcja Obslugi / Operatora – Mal Sahibi/Kullanici El Kitabi – Návod

k obsluze/pro obsluhu – Handleiding voor de eigenaar/gebruiker

– Ръководство за работа за ползвателя/оператора – Tulajdonosi/

kezelői útmutató – Manualul proprietarului / operatorului – Príručka

majiteľa/obsluhy – Navodila za uporabo

Models

926321 – Pro 28

(Serial No. 101 and up)

926322 – Pro 32

ENGLISH

БЪЛГАРСКИ

ČESKY

NEDERLANDS

SUOMI

FRANÇAIS

(Serial No. 101 and up)

926323 – Pro 36

(Serial No. 101 and up)

926324 – Pro 28 Track

(Serial No. 101 and up)

926513 – Pro 32 12V

(Serial No. 101 and up)

DEUTSCH

MAGYAR

ITALIANO

NORSK

POLSKI

ROMÂNĂ

РУССКИЙ ЯЗЫК

SLOVENSKY

SLOVENSKO

ESPAÑOL

SVENSKA

04337415B 7/12

Printed in USA

Page 2

Ariens Company

655 West Ryan Street

Brillion, Wisconsin

54110 USA

Telephone

(920) 756-4688

Facsimile

(920) 756-2407

EC DECLARATION OF CONFORMITY ISSUED BY THE MANUFACTURER

DÉCLARATION DE CONFORMITÉ CE ÉMISE PAR LE FABRICANT –

EU-ÜBEREINSTIMMUNGSERKLÄRUNG DES HERSTELLERS –

DICHIARAZIONE DI CONFORMITÀ CE RILASCIATA DAL PRODUTTORE –

DECLARACIÓN DE CONFORMIDAD CE EMITIDA POR EL FABRICANTE –

EF-SAMSVARSERKLÆRING FRA PRODUSENTEN –

EG-DEKLARATIONEN OM ÖVERENSSTÄMMELSE UTFÄRDAD

AV TILLVERKAREN – VALMISTAJAN ANTAMA EYVAATIMUSTENMUKAISUUSVAKUUTUS – DEKLARACJA ZGODNOŒCI Z

PRZEPISAMI EC WYDANA PRZEZ PRODUCENTA – ES PROHLÁŠENÍ O

SHODĚ, VYDANÉ VÝROBCEM — ES VYHLÁSENIE O ZHODE VYDANÉ

VÝROBCOM

We the undersigned, ARIENS COMPANY, certify that: Nous, soussignés ARIENS COMPANY, certifions

que : Der Unterzeichnete, ARIENS COMPANY, bescheinigt, dass: La sottoscritta società ARIENS

COMPANY certifica che: Nosotros, los abajo firmantes, ARIENS COMPANY, certificamos que:

Undertegnede, ARIENS COMPANY, bekrefter at: Undertecknad, ARIENS COMPANY, intygar att:

Allekirjoittanut, ARIENS COMPANY, vakuuttaa, että: My, niŸej podpisani, ARIENS COMPANY,

oœwiadczamy, ¿e: My, nížepodepsaní, ARIENS COMPANY, prohlašujeme, že: My dolupodpísaní,

ARIENS COMPANY, vyhlasujeme, že:

Type: Type : Typ:

Tipo: Tipo: Type:

Typ: Tyyppi: Typ:

Typ: Typ:

WALK BEHIND SNOW THROWER – LES CHASSES-NEIGE AUTOTRACTÉS –

HANDGEFÜHRTE SCHNEEFRÄSE – SPAZZANEVE SEMOVENTE – CAMINAR

POR DETRÁS DE LA LANZADORA DE NIEVE – SNØFRESER – SJÄLVGÅENDE

SNÖSLUNGA – KÄSINOHJAILTAVA LUMILINKO – ODGARNIACZ ŒNIEGU DO

PROWADZENIA PRZED SOB¥ – SNÌHOVÁ FRÉZA S POJEZDEM — SNEHOVÁ

FRÉZA S POJAZDOM

Trade Name: Appellation commerciale :

Handelsbezeichnung: Nome commerciale: Nombre

comercial: Handelsnavn: Handelsbeteckning: Kauppanimi:

Ariens

Nazwa handlowa: Obchodní název: Obchodný názov:

Model , Model Name, Serial Number:

N° de série : Modell, Modellbezeichnung, Seriennummernbereich:

Model, Modelnaam, Serienummers van tot : Model, modelnavn,

serienummer: Modell, Modellnamn, Serienummerområde: Malli, Mallin

nimi, Sarjanumeroryhmä: Modell, modellnavn, serienummerområde:

Modello, Denominazione modello, Numeri di serie: Modelo, Nombre,

Rango Nº Serie: Modelo, Nome do Modelo, Intervalo do N.º de Série:

Модель, Наименование модели, Диапазон серийных номеров:

Model, Nazwa modelu, Zakres numerów seryjnych: Model,

Modèle, Nom du modèle,

926321, Pro 28, 000101 +

926322, Pro 32, 000101 +

926323, Pro 36, 000101 +

926324, Pro 28 Track, 000101 +

926513, Pro 32, 000101 +

Model Adı, Seri Numarası Sırası: Model, Označení, Sériové

číslo: Model, Označenie, Sériové číslo:

Conforms to: Est conforme à : Mit den Anforderungen der folgenden Richtlinien übereinstimmt:

È conforme a: Cumple con: Er i samsvar med: Överensstämmer med: Täyttää seuraavat vaatimukset:

Jest zgodny z: Odpovídá směrnicím: Zodpovedá smerniciam:

2006/42/EC, 2004/108/EC, 2002/88/EC

2000/14/EC Conformity Assessment Annex V. Annexe V de l'évaluation de conformité.

Konformitätsbewertung, Anhang V. Annesso V della valutazione di conformità. Anexo V de la evaluación

de la conformidad. Samsvarsvurdering etter vedlegg V. Bedömning av överensstämmelse Bilaga V.

Vaatimustenmukaisuuden arviointi, liite V. Dodatek V, Ocena zgodnoœci. Posouzení shody pøíloha V.

Posúdenie zhody Príloha V

2

Page 3

Representative Measured Sound Power Level (Lwa) –

Niveau de puissance acoustique représentatif mesuré

(L

) – Repräsentativer gemessener Geräuschpegel

wa

) – Livello di potenza sonora rappresentativo

(L

wa

rilevato (L

representativo medido (L

lydeffektnivå (L

(L

wa

Zmierzony reprezentatywny poziom mocy akustycznej

(L

wa

akustického výkonu (L

nameranej hladiny akustického výkonu (Lwa)

Engine Power (Kw @ RPM): Puissance moteur (kW @

tr/min) : Motorleistung (kW bei U/min): Motorvermogen

(Kw @ TPM): Motoreffekt (Kw @ o/min): Motoreffekt (kW

vid r/min): Moottorin teho (Kw @ RPM): Motoreffekt (Kw

@ RPM): Potenza motore (kW a giri/min.): Potencia del

motor (Kw a RPM): Potência do motor (kW a rpm):

Мощность двигателя (кВт - об/мин): Moc silnika (kW,

obr./min.): Motor Gücü (Kw @ DEV/DAK): Výkon motoru:

(kW při ot./min): Výkon motora : (kW pri ot./min.)

) – Nivel de potencia acústica

wa

) – Tyypillinen mitattu äänitehotaso (Lwa) –

wa

) – Representativt målt

wa

) – Representativ uppmätt ljudnivå

) – Representativní hodnota zmìøené hladiny

) – Reprezentatívna hodnota

wa

926321, 926322, 926323: 101 dB

926324, 926513: 102 dB

A

A

Guaranteed Sound Power Level (Lwa) –

Niveau de puissance acoustique garanti (L

Garantierter Geräuschpegel (L

potenza sonora garantito (L

acústica garantizado (L

) – Garanterad uppmätt ljudnivå (Lwa) – Taattu

(L

wa

äänitehotaso (L

reprezentatywny poziom mocy akustycznej (L

wa

) – Gwarantowany

wa

) – Livello di

wa

) – Nivel de potencia

wa

) – Garantert lydeffektnivå

Zaruèovaná hodnota hladiny akustického výkonu

) – Garantovaná hodnota hladiny akustického

(L

wa

výkonu (Lwa)

wa

) –

wa

926321, 926322, 926323: 105 dB

926324, 926513: 106 dB

926321 11.46 @ 3700

926322 11.46 @ 3700

926323 11.46 @ 3700

926324 11.46 @ 3700

926513 8.1 @ 3700

) –

A

A

Fred J. Moreaux:

Director Product Conformance & Warranty (Keeper of

Technical File) / Directeur Conformité et Garantie des

produits (Gardien du fichier technique) / Direktor

Produktkonformität und Gewährleistung

(Aufbewahrungsstelle der technischen Dokumentation) /

Directeur Productconformiteit en -garantie (Beheerder

technische documentatie) / Direktør for varekonformitet og

garanti og reklamation (registeransvarlig) / Direttore della

conformità del prodotto e garanzia (custode del file

tecnico) / Director de conformidad del producto y garantía

(Responsable de la documentación técnica) / Chef för

produktkonformitet och -garanti (administratör för teknisk

dokumentation) / Sjef for produktsamsvar og garanti

(ansvarlig for oppbevaring av den tekniske

dokumentasjonen) / Tuoteyhdenmukaisuus- ja

takuuosaston päällikkö (Teknisestä dokumentaatiosta

vastaava) / Ürün Uyumluluk ve Garanti Müdürü (Teknik

Dosya Sorumlusu) / Director da Conformidade e Garantia

de Produtos (Responsável pela documentação técnica) /

Ředitel shody produktů a záruky (uchovávatel technické

dokumentace) / Riaditeľ zhody produktov a záruky

(archivár technickej dokumentácie)

Guy Stewart :

Authorized to Compile the Technical File/ Etablissement

du fichier technique autorisé / Zur Erstellung der

technischen Akte autorisiert / Bevoegd om het

technische bestand samen te stellen / Autoriseret til at

kompilere den tekniske fil / Behörig att kompilera den

tekniska filen / Valtuutettu laatimaan teknisen tiedoston

/ Autorisert til å lage den tekniske filen / Autorizzato alla

redazione del file tecnico / Autorizado para compilar el

fichero técnico / Autorizado a compilar a documentação

técnica / Уполномочен для компилирования

технического файла / Osoba upoważniona do

sporządzenia dokumentacji technicznej / Teknik

Dosyayı düzenleme izni vardır / Osoba oprávněná k

sestavení technické dokumentace / Osoba oprávnená k

zostaveniu technickej dokumentácie

Ariens Company

Brillion, WI 54110-1072 USA

Signature Signature Unterschrift

Handtekening Underskrift Firma

Firma Signatur Namnteckning

Allekirjoitus Podpis Assinatura

Podpis Podpis

Ariens Company

6 Brookvale Court

Sowerby Road

Garstang

Preston, Lancashire

PR2 0TT UK

Signature Signature Unterschrift

Handtekening Underskrift Firma

Firma Signatur Namnteckning

Allekirjoitus Podpis Assinatura

Podpis Podpis

07/10/2012

Date Date Datum

Datum Dato Data

Fecha Dato

Datum Päiväys

Data Data Datum

Dátum

07/10/2012

Date Date Datum

Datum Dato Data

Fecha Dato

Datum Päiväys

Data Data Datum

Dátum

3

Page 4

TABLE OF CONTENTS

OS7005

Figure 1

Serial Number Label

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . 11

CONTROLS and FEATURES . . . . . . . . 15

OPERATION . . . . . . . . . . . . . . . . . . . . . 17

MAINTENANCE . . . . . . . . . . . . . . . . . . 24

SERVICE AND ADJUSTMENTS . . . . . 28

INTRODUCTION

Original instructions.

MANUALS

Before operation of unit, carefully and

completely read your manuals. If used

improperly, this unit could be dangerous and

cause personal injury or property damage.

The contents will provide you with safety

instructions for the safe use of your unit

during normal operation and maintenance.

All reference to left, right, front, or rear are

given from operator standing in operation

position and facing the direction of forward

travel.

ENGINE MANUAL

The engine on this unit is covered by a

separate manual specific to the engine. This

manual is included in the literature package

that shipped with the unit. Refer to this

manual for engine service recommendations.

If the engine manual is not available, contact

the engine manufacturer for a replacement

manual.

MODEL AND SERIAL NUMBERS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are printed on a serial number

label, located on the frame of your unit.

STORAGE . . . . . . . . . . . . . . . . . . . . . . . 36

SERVICE PARTS . . . . . . . . . . . . . . . . . 37

ACCESSORIES. . . . . . . . . . . . . . . . . . . 37

TROUBLESHOOTING . . . . . . . . . . . . . 38

SPECIFICATIONS . . . . . . . . . . . . . . . . . 40

WARRANTY . . . . . . . . . . . . . . . . . . . . . 41

• Record Unit Model and Serial

numbers here.

• Record Engine Model and Serial

numbers here.

PRODUCT REGISTRATION

The Ariens dealer must register the product

at the time of purchase. Registering the

product will help the company process

warranty claims or contact you with the latest

service information. All claims meeting

requirements during the limited warranty

period will be honored, whether or not the

product registration card is returned. Keep a

proof of purchase if you do not register your

unit.

Customer Note: If the dealer does not

register your product, please fill out, sign, and

return the product registration card to Ariens

or go to www.ariens.eu.

EN - 4

Page 5

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The

replacement of any part on this vehicle with

anything other than an Ariens authorized

replacement part may adversely affect the

performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

warranty, property damage, personal injury or

death arising out of the use of unauthorized

replacement parts. To locate your nearest

Ariens Dealer, go to www.ariens.eu on the

internet.

DISCLAIMER

Ariens reserves the right to discontinue,

make changes to, and add improvements

upon its products at any time without public

notice or obligation. The descriptions and

specifications contained in this manual were

in effect at printing. Equipment described

within this manual may be optional. Some

illustrations may not be applicable to your

unit.

DELIVERY

Customer Note: If you have purchased this

product without complete assembly and

instruction by your retailer, it is your

responsibility to:

1. Read and understand all assembly

instructions in this manual. If you do not

understand or have difficulty following

the instructions, contact your nearest

Ariens Dealer for assistance. Make sure

all assembly has been properly

completed.

NOTE: To locate your nearest Ariens Dealer,

go to www.ariens.eu on the Internet.

WARNING: Improper assembly or

adjustments can cause serious

injury.

2. Understand all Safety Precautions

provided in the manuals.

3. Review control functions and operation

of the unit. Do not operate the Sno-Thro

unless all controls function as described

in this manual.

4. Review recommended lubrication,

maintenance and adjustments.

5. Review Limited Warranty Policy.

NOTE: This machine comes with a threeyear limited warranty. The selling dealer is

responsible for explaining the terms and

limitations of the warranty coverage offered in

the country of sale.

6. Fill out a Product Registration Card and

return the card to the Ariens Company or

go to www.ariens.eu.

EN - 5

Page 6

SAFETY

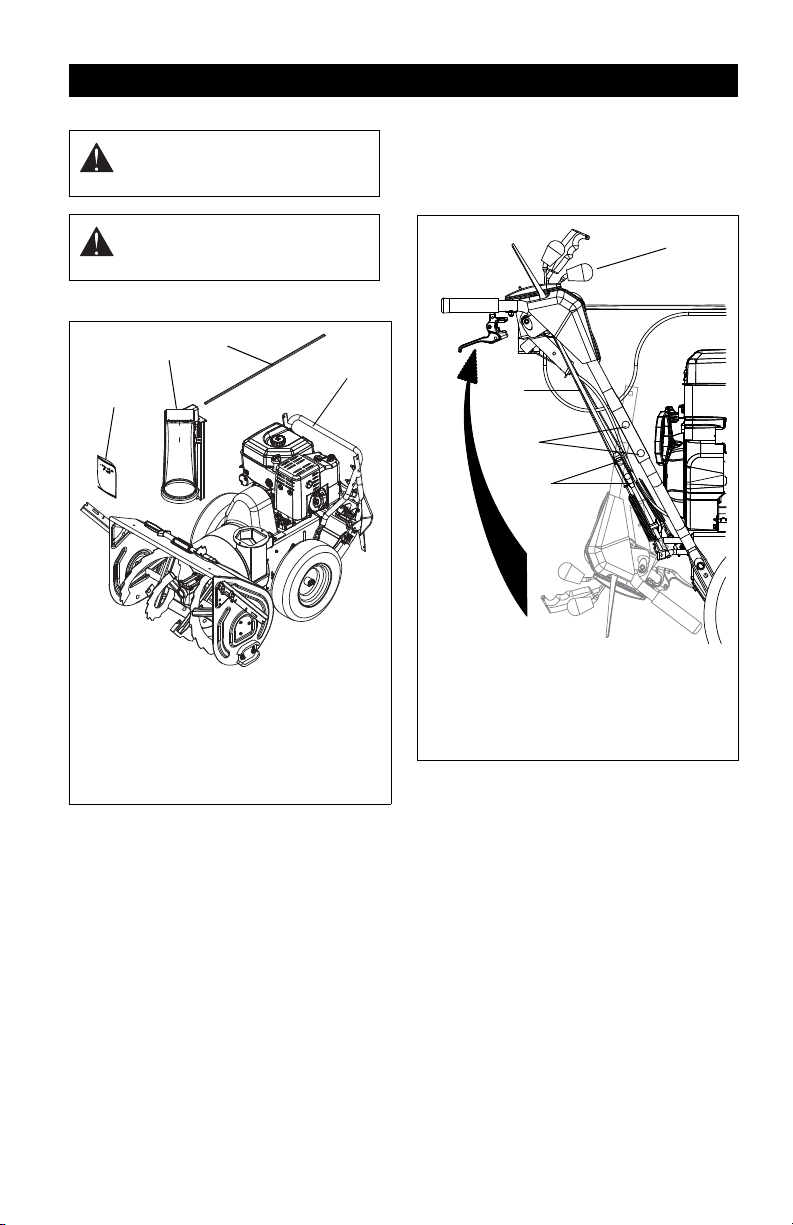

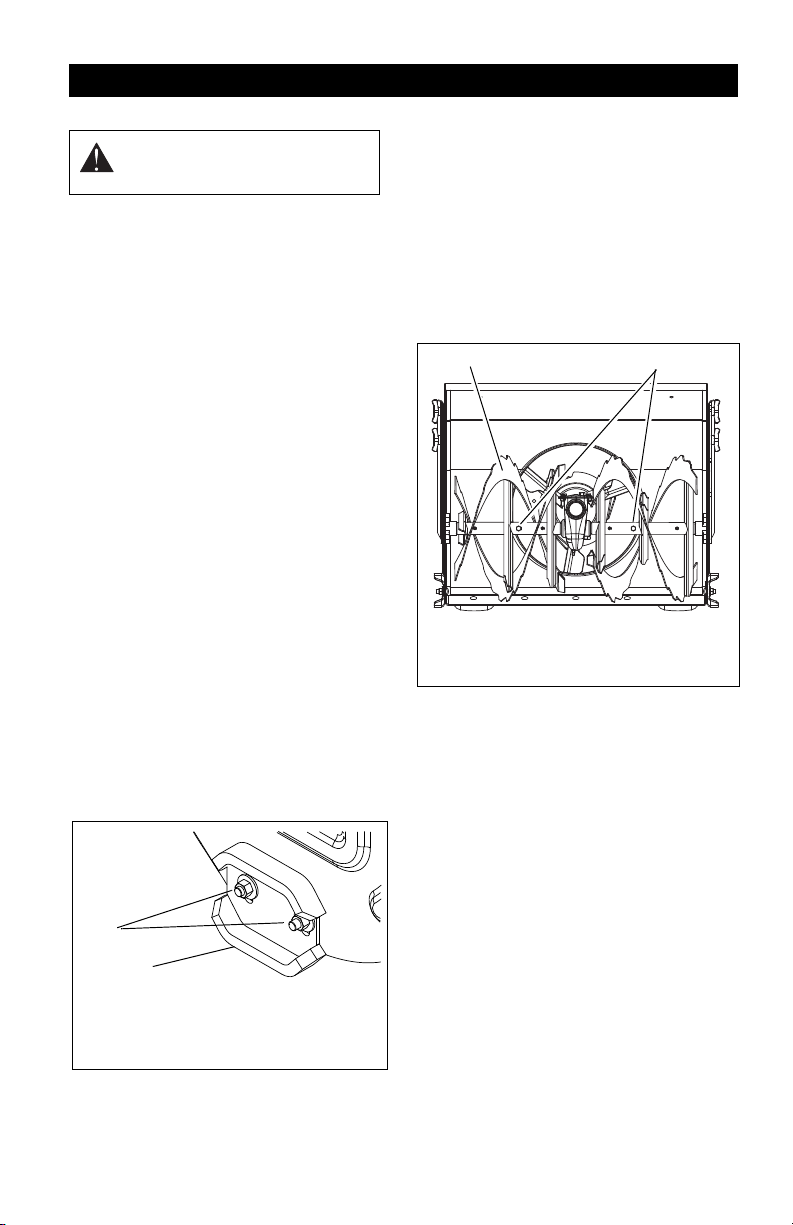

OS7015

1

2

3

Figure 2

WARNING: To avoid injury to hands

and feet, always disengage

clutches, shut off engine, and wait

for all movement to stop before

unclogging or working on snow

thrower.

Hand contact with the rotating

impeller is the most common cause

of injury associated with snow

throwers. Never use your hand to

clean out the discharge chute.

Keep hands and feet away from

auger and impeller.

SAFETY ALERTS

Look for these symbols to point

out important safety

precautions. They mean:

Attention!

Personal Safety Is

Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal

words below are used on decals and in this

manual. Read and understand all safety

messages.

DANGER: IMMINENTLY

HAZARDOUS SITUATION! If not

avoided, WILL RESULT in death or

serious injury.

WARNING: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in death

or serious injury.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area. Always follow the practices

set forth in this manual.

REQUIRED OPERATOR

TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

unit is to be used by someone other than

original purchaser; loaned, rented or sold,

ALWAYS provide this manual and any

needed safety training before operation.

SAFETY DECALS AND

LOCATIONS

ALWAYS replace missing or damaged Safety

Decals. Refer to Figure 2 below for Safety

Decal locations.

CAUTION: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor or

moderate injury. It may also be used

to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for

proper operation and maintenance practices.

IMPORTANT: Specific procedures or

information required to prevent damage to

unit or attachment.

EN - 6

Page 7

1. DANGER!

2. DANGER!

Danger!

ONLY use clean-out tool to

clear blockages. NEVER

use your hands.

Never direct discharge

towards persons or

property that may be

injured or damaged by

thrown objects.

Keep people away from

unit while operating. Keep

children out of work area

and under watchful care of

a responsible adult.

Stop engine, remove key,

read manual before

making any repairs or

adjustments.

Read Owner/Operator

Manual.

Wear appropriate hearing

protection.

3. DANGER!

ROTATING PARTS! ONLY

use clean-out tool to clear

blockages. NEVER use

your hands. High speed

impeller rotates below

discharge opening. Wait

for all moving parts to

stop before removing

clogs or servicing.

Danger!

ROTATING PARTS.

Keep clear of auger while

engine is running.

• Read Operator’s

Manual.

• Allow operation only by

properly trained adult,

never children.

• Stop engine and

remove ignition key

prior to leaving the

operator’s position for

any reason.

• Keep all controls,

guards and safety

devices properly

serviced and functional.

• Never direct discharge

towards persons or

property that may be

injured or damaged by

thrown objects.

Danger!

EN - 7

Page 8

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include

exhaust and evaporative emissions control

system components required to meet U.S.

Environmental Protection Agency (EPA)

and/or California Air Resources Board

(CARB) regulations. Tampering with emission

controls and components by unauthorized

personnel may result in severe fines or

penalties. Emission controls and components

can only be adjusted by an Ariens Company

dealer or an authorized engine

manufacturer's service center. Contact your

Ariens Company Equipment Retailer

concerning emission controls and component

questions.

SAFETY RULES

Read, understand, and follow all safety

practices in Owner/Operator Manual before

beginning assembly or operating. Failure to

follow instructions could result in personal

injury and/or damage to unit.

ALWAYS remove key and/or wire from spark

plug before assembly, maintenance or

service. Unintentional engine start up can

cause death or serious injury.

Complete a walk around inspection of unit

and work area to understand:

• Work area • Your unit • All safety decals

ALWAYS check overhead and side

clearances carefully before operation.

ALWAYS be aware of traffic when operating

along streets or curbs.

Keep children and people away. Keep

children out of work area and under watchful

care of a responsible adult.

NEVER allow children to operate or play on

or near unit. Be alert and shut off unit if

children enter area.

DO NOT allow adults to operate unit without

proper training. Only trained adults may

operate unit. Training includes actual

operation.

Keep area of operation clear of all toys, pets,

and debris. Thrown objects can cause injury.

Check for weak spots on docks, ramps or

floors. Avoid uneven work areas and rough

terrain. Stay alert for hidden hazards.

DO NOT operate near drop-offs, ditches, or

embankments. Unit can suddenly turn over if

a wheel is over the edge of a cliff or ditch, or if

an edge caves in.

Falling snow, fog, etc. can reduce vision and

cause an accident. Operate unit only when

there is good visibility and light.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired

attention at all times.

NEVER allow anyone to operate this unit

when their alertness or coordination is

impaired.

DO NOT operate unit without wearing

adequate winter outer garments. Wear

adequate safety gear, including safety

glasses with side shields, and protective

gloves. Wear proper footwear to improve

footing on slippery surfaces.

DO NOT wear loose clothing or jewelry and

tie back hair that may get caught in rotating

parts.

Protect eyes, face and head from objects that

may be thrown from unit. Wear appropriate

hearing protection.

Avoid sharp edges. Sharp edges can cut.

Moving parts can cut off fingers or a hand.

ALWAYS keep hands and feet away from all

rotating parts during operation. Rotating parts

can cut off body parts.

NEVER place your hands or any part of your

body or clothing inside or near any moving

part while unit is running.

ALWAYS keep hands away from all pinch

points.

DO NOT touch unit parts which might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust or service.

Never direct discharge towards persons or

property that may be injured or damaged by

thrown objects. Use extreme caution on

gravel surfaces. Stay alert for hidden hazards

or traffic. Adjust Skid Shoes so Scraper Blade

does not contact gravel.

DO NOT throw snow any higher than

necessary.

Deflected materials can cause injury and

property damage.

Always stand clear of the discharge area

when operating this unit.

Fumes from engine exhaust can cause injury

or death. DO NOT run engine in an enclosed

area. Always provide good ventilation.

ALWAYS disengage attachment, stop unit

and engine, remove key and allow moving

parts to stop before leaving operator’s

position.

ROTATING AUGER CAN CAUSE SERIOUS

INJURY. NEVER ATTEMPT TO UNCLOG

OR CLEAN UNIT WHILE ENGINE IS

RUNNING.

Read, understand, and follow all instructions

in the manual and on the machine before

starting.

Understand:

• How to operate all controls.

• The functions of all controls.

• How to STOP in an emergency.

Before starting engine, disengage control(s).

Use only approved extension cords and

receptacles when starting units equipped with

electric starter. DO NOT connect electric

starter cord to any wiring system that is not a

three-wire grounded system.

ALWAYS allow unit and engine to adjust to

outdoor temperatures before clearing snow.

EN - 8

Page 9

DO NOT overload the machine capacity by

attempting to operate or to clear snow at too

fast a rate.

Slow down and turn corners slowly.

Do not operate in reverse unless absolutely

necessary. ALWAYS back up slowly. Always

look down and behind before and while

backing.

Disengage attachment drive when traveling

from one work area to another.

Abnormal Vibrations are a warning of trouble.

Striking a foreign object can damage unit.

Immediately stop unit and engine. Remove

key and wait for all moving parts to stop.

Remove wire from spark plug. Inspect unit

and make any necessary repairs before

restart.

Before cleaning, removing clogs or making

any inspections, repairs, etc.: disengage

clutch(es), stop unit and engine, remove key,

allow moving parts to stop. Allow hot parts to

cool.

Run unit a few minutes after clearing snow to

prevent freeze-up of attachment.

Disengage attachment when not in use.

Disengage all clutches before starting engine.

Adjust skid shoes to clear gravel or crushed

rock surfaces safely.

Never leave a running unit unattended.

ALWAYS shut off engine before leaving unit.

ALWAYS remove key to prevent unauthorized

use.

Never carry passengers.

Check clutch and brake operation frequently.

Adjust and service as required. All motion of

drive wheels and auger/impeller must stop

quickly when control levers are released.

DO NOT operate on steep slopes. DO NOT

clear snow across the face of slopes. Keep all

movement on slopes slow and gradual. DO

NOT make sudden changes in speed or

direction. Use a slow speed to avoid stops or

shifts on slopes. Avoid starting or stopping on

a slope.

DO NOT park unit on a slope unless

absolutely necessary. When parking on a

slope always block the wheels.

ALWAYS shut off engine, remove key, and

close fuel shut-off valve or drain fuel when

transporting unit on a truck or trailer.

Use extra care when loading or unloading

unit onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

Keep unit free of ice or other debris. Clean up

oil or fuel spills.

This product is equipped with an internal

combustion type engine. DO NOT use unit on

or near any unimproved, forest-covered or

brush covered land unless exhaust system is

equipped with a spark arrester meeting

applicable local, state or federal laws. A spark

arrester, if it is used, must be maintained in

effective working order by operator.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use only an

approved gasoline container with an

appropriately sized dispensing spout.

NO smoking, NO sparks, NO flames.

ALWAYS allow engine to cool before

servicing.

NEVER fill fuel tank when engine is running

or hot from operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up

spilled fuel.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel

it on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lockopen device.

If fuel is spilled on clothing, change clothing

immediately.

Avoid Electric Shock. Objects contacting both

battery terminals at the same time may result

in injury and unit damage. DO NOT reverse

battery connections.

Explosive Gases from battery can cause

death or serious injury. Poisonous battery

fluid contains sulfuric acid and its contact with

skin, eyes or clothing can cause severe

chemical burns.

No flames, No sparks, No smoking near

battery.

ALWAYS wear safety glasses and protective

gear near battery.

DO NOT TIP battery beyond a 45° angle in

any direction.

ALWAYS keep batteries out of reach of

children.

Battery posts, terminals and related

accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and reproductive

harm. Wash hands after handling.

Follow First Aid directions for contact with

battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15

minutes and get medical attention

immediately!

• Internal Contact: Drink large quantities

of water. Follow with Milk of Magnesia,

beaten egg or vegetable oil. Get

medical attention immediately!

• In case of internal contact, DO NOT

induce vomiting!

Properly remove fuelbefore tipping unit up

onto housing, so no spills will occur.

Secure unit so it will not tip over during

maintenance.

EN - 9

Page 10

ALWAYS keep protective structures, guards,

and panels in good repair, in place and

securely fastened. NEVER modify or remove

safety devices.

DO NOT change engine governor settings or

over-speed engine.

Fumes from engine exhaust can cause injury

or death. DO NOT run engine in an enclosed

area. Always provide good ventilation.

ALWAYS maintain unit in safe operating

condition. Damaged or worn out muffler can

cause fire or explosion.

Keep all hardware properly tightened. Check

shear bolts frequently.

Maintain or replace safety and instruction

labels, as necessary.

NEVER store unit with fuel in fuel tank, inside

a building where any ignition sources are

present such as hot water heaters, space

heaters, or clothes dryers. Allow the engine to

cool before storing in any enclosure.

Shut off fuel and allow engine to cool

completely before storing in closed area or

covering unit.

For extended storage, clean unit thoroughly.

See Engine Manual for proper storage.

Use only attachments or accessories

designed for your unit.

Check components frequently. If worn or

damaged, replace with manufacturer’s

recommended parts.

EN - 10

Page 11

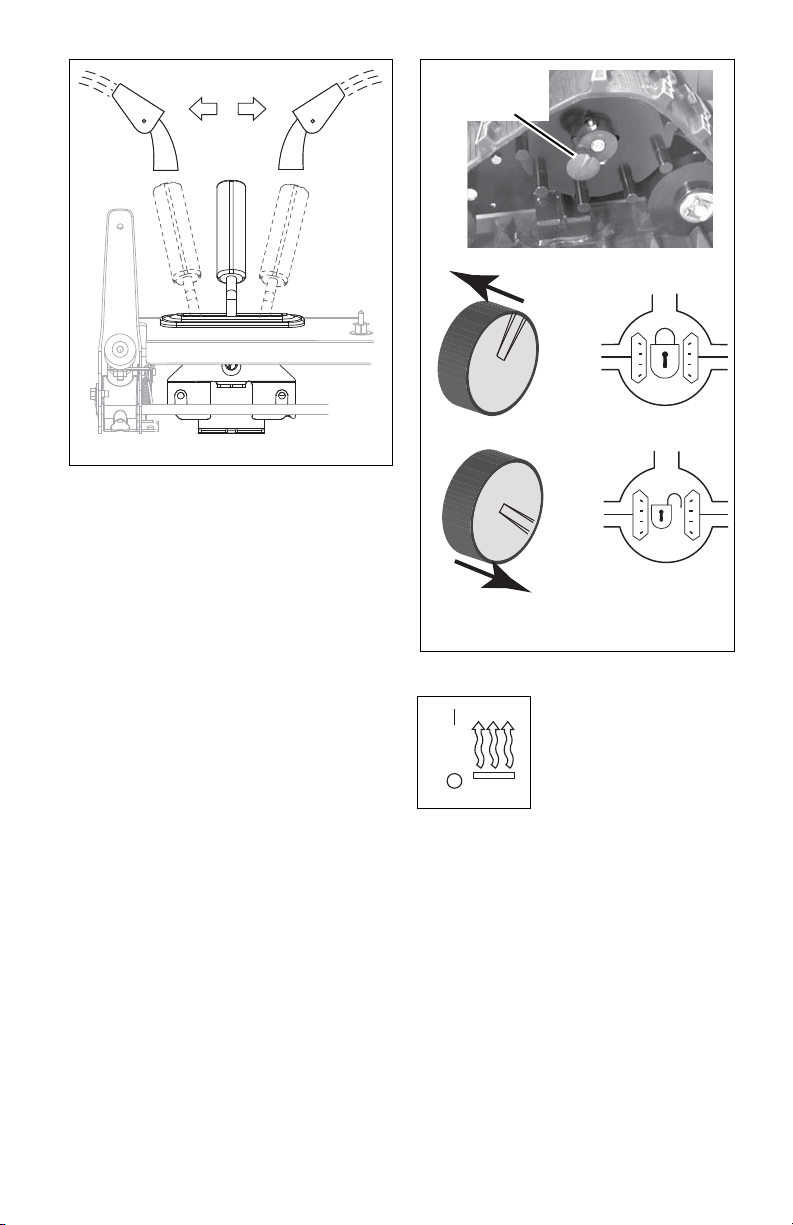

WARNING: AVOID INJURY. Read

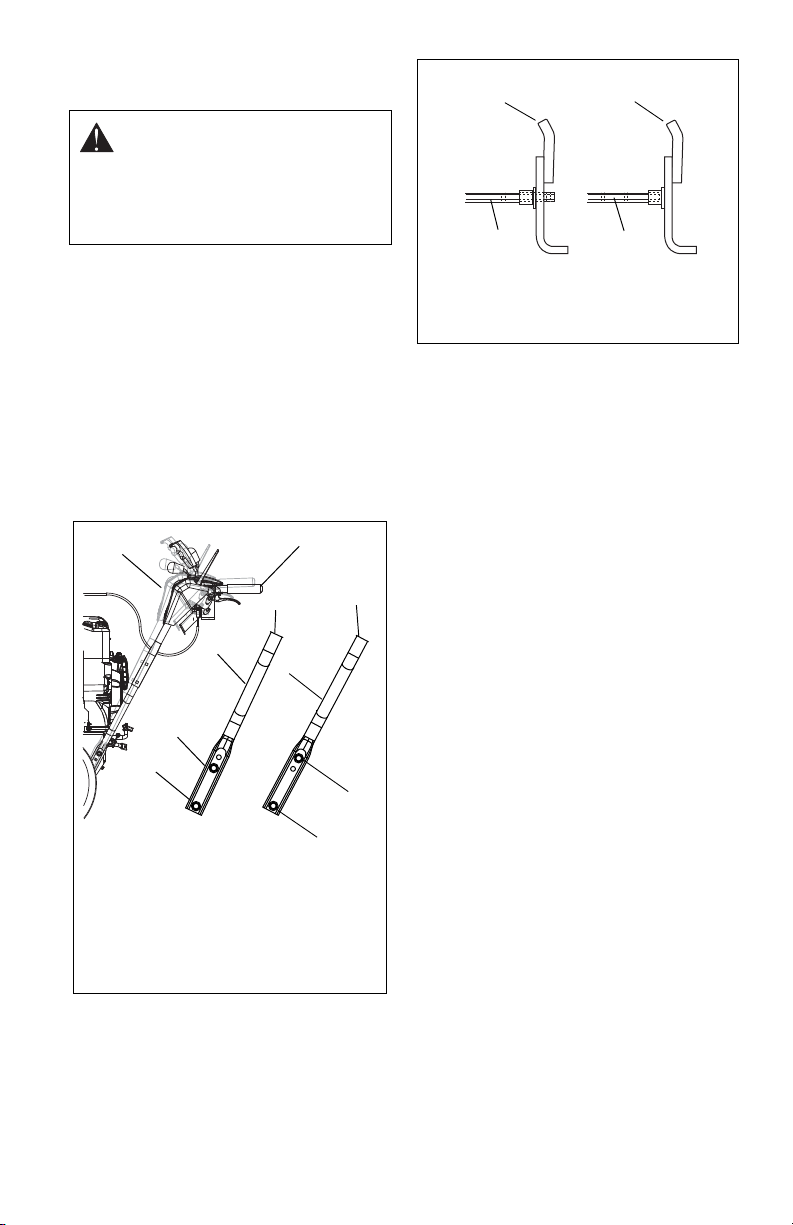

Figure 3

1. Sno-Thro Unit

2. Discharge Chute

3. Chute Rod

4. Literature Pack

1

2

4

3

OS7020

1. Handlebar

Hardware

2. Shift Rod

Hardware

3. Shift Rod

4. Speed

Selector

Lever

Figure 4

OS7030

1

3

2

4

and understand the entire Safety

section before proceeding.

WARNING: Dropping or tipping

over boxed unit could result in

personal injury or damage to unit.

PACKAGE CONTENTS

ASSEMBLY

IMPORTANT: Be careful not to damage cable

spring hooks when rotating handlebars

upward.

5. Install and tighten all hardware on the

handlebar assembly and shift rod.

ASSEMBLY

Tools Required:

• Pliers

• Open-End Wrenches: 3/8, 7/16, 1/2,

9/16 in. and/or Adjustable Wrench

•Tire Gauge

Unfold Handlebar

(Figure 4)

1. Remove the lower and loosen the upper

hardware on the handlebar assembly.

2. Loosen the hardware on the shift rod.

3. Put the speed selector lever in the

second reverse position.

4. Rotate the handlebars into operating

position.

NOTE: The handlebar has two height

positions. Adjust the handlebar height to

provide better operator comfort. See

Handlebar Height on page 29.

6. Check tension on auger and traction

clutch cables.

IMPORTANT: Cables should not be slack or

under tension. Adjust as necessary.

Install Discharge Chute, Chute

Control and Chute Rod

(Figures 5 and 6)

1. Grease underside of discharge chute

ring (if not already greased).

2. Remove mounting hardware from auger

housing.

3. Install discharge chute over opening in

the auger housing. Finger tighten the

mounting hardware removed in step 2.

NOTE: Leave discharge chute pedestal loose

to help install the chute rod.

EN - 11

Page 12

4. Remove the gear cover from top of

Figure 5

1. Mounting Holes

2. Discharge Chute

3. Discharge Chute Ring

4. Chute Pedestal

5. Mounting Hardware

1

5

4

2

OS7040

3

Figure 6

1. Chute Rod

2. Gear Cover

3. Control Assembly

4. Gear Assembly

5. Chute Control Cable

6. Alignment Marker

7. Hair Pin

3

2

1

7

4

5

6

chute pedestal.

5. Release the lock teeth on the gear

assembly with your finger and rotate the

discharge chute so it points straight

ahead.

NOTE: Make sure alignment markers are

lined up when discharge chute is pointing

straight ahead.

6. Remove rubber grommet from control

panel.

7. Make sure the chute control cable is

routed between the lower handlebar and

the bottom of the control panel, insert

control assembly into slot in control

panel from below and install assembly

into nylon bushing in control panel.

8. Reinstall rubber grommet over control

assembly knob and into control panel.

NOTE: To ensure the discharge chute follows

its full range of travel, make sure the control

lever is centered in the slot and pointing

straight up before installing the chute rod.

9. Insert chute rod end without ears into

control lever and slide into control panel

until opposite end of rod clears the gear

assembly.

10. Align end of chute rod with hex hole in

gear assembly and insert until ears hit

gear.

11. Insert hairpin into hole in chute rod near

gear assembly.

12. Hook the chute control cable onto the

chute rod.

IMPORTANT: The chute control cable hook

will prevent the cable from contacting the

engine or muffler guard. Make sure this cable

stays connected while unit is in operation.

13. Check to make sure the chute control

cable ends are properly seated in control

assembly and control arm.

14. Adjust control cable as necessary to

remove cable slack. Be sure lock arm is

fully seated in gear teeth.

15. Replace gear cover on top of chute

pedestal.

16. Orient the chute and pedestal to its most

vertical position and tighten pedestal

hardware to 20 – 42 N•m.

17. Make sure the discharge chute rotates

left and right when you push the

discharge chute control lever left and

right.

EN - 12

Page 13

NOTE: If chute does not stay in position,

Figure 7

1. Cable Anchor

2. Cable End

3. Deflector Cable

4. Cable Fitting

5. Cable Bracket

1

2

3

5

4

3

OS7070

adjust as directed in Discharge Chute Control

on page 30, or repair before operation.

Remote Deflector Control

(Figure 7)

Connect the cable end to the cable anchor on

the discharge deflector before clipping the

cable to the cable bracket on the discharge

chute.

1. Route deflector remote cable along the

left side of the chute pedestal.

2. Insert the barrel on the cable end into

the bracket on left side of chute deflector

(Figure 7).

3. Hold seal out of the way while routing

the cable through the bracket on the left

side of the discharge chute, and then

push the cable fitting into the bracket.

4. Push the seal securely over the end of

the cable fitting to prevent water from

entering the cable.

Check deflector travel. Adjust nut on cable

end under handlebar to obtain full travel, if

necessary (see Remote Deflector Control on

page 29).

Check Function of Dual Handle

Interlock

Without the engine running, press down

(engage) both clutch levers. Release

attachment clutch lever. Attachment clutch

should remain engaged until traction clutch

lever is released, then both clutches must

disengage. If they do not, contact your Dealer

for repairs.

Check Tire Pressure

(926321, 322, 323, 513)

Check tire pressure and adjust to the

pressure listed on tire sidewall.

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is

possible when they are serviced

incorrectly:

• Do not attempt to mount a tire

without the proper equipment and

experience to perform the job.

• Do not inflate the tires above the

recommended pressure.

• Do not weld or heat a wheel and

tire assembly. Heat can cause an

increase in air pressure resulting

in an explosion. Welding can

structurally weaken or deform the

wheel.

• Do not stand in front or over the

tire assembly when inflating. Use a

clip-on chuck and extension hose

long enough to allow you to stand

to one side.

Connect Battery (926513)

1. Remove wing nuts from battery cover.

2. Install wire lead to battery terminal.

3. Install battery cover and tighten wing

nuts.

EN - 13

Page 14

Check Track Tension (926324)

Check tracking of unit with the differential

locked, and tension of tracks (see Track

Tension Adjustment on page 35).

Check Auger Gearcase Oil

Check oil level in auger gearcase (see Check

Auger Gearcase on page 25).

Check Engine Crankcase Oil

IMPORTANT: The engine is shipped with oil

in crankcase. Refer to Engine Manual for

detailed instructions.

Fill Fuel Tank

Fill fuel tank. DO NOT OVERFILL! See

FILLING FUEL TANK on page 21.

Check Function of all Controls

Ensure unit runs and performs properly. Refer

to OPERATION on page 17.

Run-in Attachment Belt

1. Start unit in a well-ventilated area

according to Starting and Shut Off on

page 22.

2. Engage attachment clutch lever and run

attachment for about 15 minutes.

3. Stop unit, wait for all moving parts to

stop, and remove spark plug wire.

4. Adjust belt finger, if necessary. See

Check Belt Finger Clearance on

page 32.

5. Adjust clutch idler according to

Attachment Clutch/Brake Adjustment on

page 31.

EN - 14

Page 15

CONTROLS AND FEATURES

Figure 8

1

2

4

7

6

8

9

10

3

5

5

3

11

1

4

7

6

8

9

10

11

2

14

14

12

13

13

15

16

17

12

1. Skid Shoes

2. Clean-Out Tool

3. Remote Discharge Chute Deflector

4. Belt Cover

5. Headlight

6. Auger

7. Auger Gearcase

8. Scraper Blade

9. Discharge Chute

10. Impeller

11. Chute Rod

12. Handlebar Hardware

13. Heated Handles

14. Drift Cutters

15. Differential Lock Knob (926324)

16. Battery (926513)

17. Height Adjuster Trigger (926324

EN - 15

Page 16

Figure 9

3

1

2

7

4

8

9

6

14

12

11

15

13

10

5

17, 18

4

16

1. Oil Drain

2. Fuel Shut-Off Valve

3. Primer Bulb

4. Recoil Starter Handle

5. Throttle

6. Choke Control Knob

7. Ignition Key

8. Fuel Tank and Cap

9. Oil Fill/Dipstick

10. Electric Starter

11. Attachment Clutch Lever

12. Speed Selector

13. Traction Drive Clutch Lever

14. Deflector Remote Control

15. Chute Control

16. Muffler Guard

17. Heated Handle Switch

18. Electric Start 12V Key Start

(926513)

EN - 16

Page 17

OPERATION

1

2

OL2701

1

2

OL2691

OS0232

1

2

3

OS7320

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

WARNING: To avoid injury to hands

and feet, always disengage

clutches, shut off engine, and wait

for all movement to stop before

unclogging or working on snow

thrower.

Keep hands and feet away from

auger and impeller.

CONTROLS AND FEATURES

See CONTROLS and FEATURES on

page 15 for all Controls and Features

locations.

Dual Handle Interlock

When Attachment Clutch and then Traction

Drive Clutch are engaged, the Attachment

Clutch will remain engaged (lever down) if

released. To stop attachment, release

Traction Drive Clutch and both clutches will

disengage.

Traction Drive Clutch –

Left Hand Lever

Squeeze the Traction

Drive Clutch Lever

against the Handlebar

(1) to engage wheel

drive for propelling unit.

Forward speed will

vary according to snow

depth and moisture

content.

Release lever (2) to

stop movement.

NOTE: When traveling

be cleared, press down on the handlebars

enough to raise the front of the unit slightly off

the surface. Engage the traction drive clutch

without engaging the attachment drive clutch.

to or from the area to

Attachment Clutch –

Right Hand Lever

Squeeze Attachment

Clutch Lever against

handlebar (1) to

engage attachment.

Release both clutch

levers (2) to disengage

power and apply brake

to attachment.

IMPORTANT: If the

belt squeals when the

attachment clutch lever

is engaged, the

in the auger housing. Immediately release the

impeller may be frozen

attachment clutch lever and move the unit

into a heated area to thaw.

NOTE: If belt squeals when impeller turns

freely, see Attachment Clutch/Brake

Adjustment on page 31.

Ignition Switch (220V start)

(926321, 322, 323, 324)

Operate the ignition switch with

the removable key. To start the

engine, turn the key to Start. To

stop the engine, turn the key to

Off.

Ignition Switch (12V start on dash

panel) (926513)

The ignition switch is

operated by a removable

key. It has three positions:

1.Stop

2.Run

3.Start

Primer Bulb

Pushing the primer bulb in adds

fuel for easier engine start.

Refer to Starting and Shut Off

on page 22.

EN - 17

Page 18

Speed Selector

OS1196

6

1

1

2

CHOKE

RUN

2

1

OS7275

3

2

1

Figure 10

OS7101

Snow Clean-Out Tool

Position the Speed Selector in

the appropriate speed notch to

control forward and reverse

travel.

Forward:

(6) Fastest

(1) Slowest

Reverse:

(1) Slow

(2) Fast

IMPORTANT: DO NOT change

motion from forward to reverse

with clutch engaged. Forward

speed can be changed without

declutching.

Choke Control Knob

1.Choke Closed

position: chokes off

air to engine for

easier start.

2.Choke Open

position: allows for

normal operation.

IMPORTANT:

Gradually open choke

after engine starts.

Throttle

The throttle controls the engine speed. To

increase or decrease the engine speed,

adjust to:

1. Fast (normal or warm starts)

2. Part-Throttle

3. Slow (cold weather starts)

Electric Starter

The electric starter will start a properly

choked and cranked engine when the key is

turned (12V) or starter button (240V) is

pushed. Refer to Starting and Shut Off on

page 22.

Recoil Starter Handle

When pulled, handle will turn engine over.

IMPORTANT: DO NOT let handle snap back

against starter.

Snow Clean-Out Tool

(Figure 10)

WARNING: Hand contact with the

rotating impeller is the most

common cause of injury associated

with snow throwers. Never use your

hand to clean out the discharge

chute.

To clear the discharge chute:

1. Shut off the engine.

2. Wait 10 seconds and make sure impeller

blades have stopped rotating.

3. Remove the snow clean-out tool from

the auger housing and use it to remove

the clog from the discharge chute.

4. Replace the snow clean-out tool on the

auger housing.

Remote Deflector Control

Place deflector into position before operation.

DO NOT throw snow any higher than

necessary.

Place deflector remote in a forward notch to

throw snow lower. Place deflector remote in a

rearward notch to throw snow higher.

Discharge Chute

Discharge chute rotates 200°.

ALWAYS position discharge chute in safe

direction and angle, away from operator and

bystanders, before starting engine.

Quick-Turn Chute Control

(Figure 11)

IMPORTANT: If chute does not stay in set

position, adjust as directed in Discharge

Chute Control on page 30, or repair before

operation.

Rotate discharge chute with Quick-Turn

Chute Control (Figure 11).

EN - 18

Page 19

IMPORTANT: DO NOT force frozen chute

Figure 11

OS7105

Figure 12

1

2

Differential

Lock Knob

OS1950

1

2

controls. If frozen, take to warm place until

controls are free.

Differential Lock (926324)

(Figure 12)

The differential can be locked for maximum

traction or unlocked to allow for easier

turning. The differential lock knob is located

on the right Track Assembly. With the

differential locked power is applied equally to

both tracks.

To engage the differential lock:

Pull and turn knob to LOCKED (1) position

and release (knob will snap in place when

positioned correctly).

To release the differential lock:

Pull and turn knob to the UNLOCKED (2)

position and release (knob will be positioned

out slightly from unit when positioned

correctly).

Heated Handles

Turn the heated handles

switch to the ON (1)

position to activate. Turn

the switch to the OFF (2)

position to deactivate.

Scraper Blade

The scraper blade allows better contact with

the surface being cleared. It also prevents

damage to the housing from normal usage.

IMPORTANT: DO NOT allow Scraper Blade

to wear too far or Auger/Impeller housing will

become damaged.

Skid Shoes

The skid shoes control the distance between

the scraper blade and the ground. Adjust skid

shoes equally to keep blade level with the

ground. Refer to Pre-Start on page 21 for

recommended settings.

EN - 19

Page 20

Drift Cutters

Figure 13

OS7110

Stored Position

Operating Position

Figure 14

Deep Cutting

OS7111

Transport

Normal

(Figure 13)

Drift cutters break up snow drifts that are

taller than the auger housing and direct the

snow into the auger. Store the drift cutters on

the auger housing when not in use. Install

them as shown below so they are taller than

the snow to be cleared.

Track Angle (926324)

(Figure 14)

The track angle can be adjusted to position

the auger housing for level clearing, deep

cutting or transport.

Squeeze the handlebar trigger and press

down on the handlebars to move the auger

housing into an up position. Release the

trigger to hold the position.

Lift up on the handlebars and squeeze and

release the handlebar trigger to move the

auger housing into a down position.

EN - 20

Page 21

FILLING FUEL TANK

1

2

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

GASOLINE

IMPORTANT: ALWAYS use gasoline that

meets the following guidelines:

• Clean, fresh gasoline.

• A minimum of 87 octane/87 AKI (91

RON). High altitude use may require a

different octane. Consult your engine

manual.

• Gasoline with up to 10% ethanol

(gasohol) or up to 10% MTBE (methyl

tertiary butyl ether) is acceptable.

• Use of any gasoline other than those

approved above will void the engine

warranty. If the pumps are not marked

for the content of alcohol or ethers,

check ethanol and MTBE levels with

the fuel supplier.

• Do not modify the fuel system to use

different fuels.

• Never mix oil and gasoline.

NOTE: All gasoline is not the same. If the

engine experiences starting or performance

problems after using a new gasoline, switch

to a different fuel provider or fuel brand.

IMPORTANT: Excessively oxygenated or

reformulated fuels (fuels blended with

alcohols or ethers) can damage the fuel

system or cause performance problems. If

any undesirable operating problems occur,

use a gasoline with a lower percentage of

alcohol or ether.

Add Fuel Stabilizer to

Extend Fuel Storage Life

IMPORTANT: Fuel stabilizer is recommended

for extended storage (see Fuel System on

page 36).

Add Fuel to Fuel Tank

1. ALWAYS place unit in open or wellventilated area.

2. Stop engine and allow to cool.

3. Clean Fuel Cap and surrounding area to

prevent dirt from entering Fuel Tank.

4. Remove fuel caps.

IMPORTANT: Refer to Engine Manual for

correct type and grade of fuel.

5. Fill fuel tank to the bottom of filler neck.

See SPECIFICATIONS 40 on page 4 for

fuel tank capacity.

IMPORTANT: DO NOT OVERFILL! This

equipment and/or its engine may include

evaporative emissions control system

components, required to meet EPA and/or

CARB regulations, that will only function

properly when the fuel tank has been filled to

the recommended level. Overfilling may

cause permanent damage to evaporative

emissions control system components. Filling

to the recommended level ensures a vapor

gap required to allow for fuel expansion. Pay

close attention while filling the fuel tank to

ensure that the recommended fuel level

inside the tank is not exceeded. Use a

portable gasoline container with an

appropriately sized dispensing spout when

filling the tank. Do not use a funnel or other

device that obstructs the view of the tank

filling process.

6. Replace fuel cap and tighten.

7. ALWAYS clean up spilled fuel.

Fuel Shut-Off Valve

IMPORTANT: The fuel shut-off valve MUST

be in the closed position prior to transporting

the unit.

The fuel shut-off valve

has two positions:

Open (1): Use this

position to run the unit.

Closed (2): Use this

position to service,

transport, or store the

unit.

PRE-START

1. Frozen Impeller

IMPORTANT: Before starting engine, check

impeller to be sure it is not frozen.

To check impeller:

1. With ignition key switch in “Stop”

position, squeeze Attachment Clutch

Lever to Engaged position.

2. Pull Recoil Starter Handle.

3. If Impeller is frozen, (cannot pull Starter

Handle) move unit to a heated area and

thaw to prevent possible damage.

2. Check Function of Clutches

If clutches do not engage or disengage

properly, adjust or repair before operation.

See Attachment Clutch/Brake Adjustment on

page 31 and Trac tion Drive Clutch

Adjustment on page 33.

EN - 21

Page 22

3. Check Dual Handle Interlock

Without the engine running, press down

(engage) both clutch levers. Release

attachment clutch lever. Attachment clutch

should remain engaged until traction clutch

lever is released, then both clutches must

disengage.

If clutches do not engage or disengage

properly, adjust or repair before operation.

See Attachment Clutch/Brake Adjustment on

page 31 and Traction Drive Clutch

Adjustment on page 33.

4. Check Axle Lock (926324)

Use the axle lock knob to lock or unlock the

right side differential. Lock the differential to

engage both tracks and increase traction;

unlock the right side to allow for easier

turning of the unit (see Differential Lock

(926324) on page 19).

5. Check Skid Shoes

Check and adjust Skid Shoes (See Skid

Shoes on page 28). Allow 3 mm between

scraper blade and hard, smooth surface(s).

Allow 22mm between scraper blade and

uneven or gravel surfaces.

Check Engine Fuel & Crankcase Oil

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Check and add fuel if required. Check that

the engine crankcase oil is full using dipstick.

Refer to Engine Manual for detailed

instructions.

TO STOP IN AN EMERGENCY

Immediately release both control levers to

stop unit in an emergency. Stop engine,

remove key and wait for all rotating parts to

stop before leaving operator’s position.

STARTING AND SHUT OFF

WARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in

personal injury and/or damage to

unit. DO NOT attempt to start your

unit at this time. Read entire

Owner/Operator Manual and the

Engine Manual first.

IMPORTANT: Allow unit and engine to adjust

to the outdoor temperature before clearing

snow. Before shut-off, run the attachment a

few minutes to prevent impeller freeze-up.

NOTE: Try out each control without the

engine running to see how it works and what

it does.

Manual Start

1. Turn discharge chute straight ahead.

2. Make sure that the traction clutch and

attachment drive clutch levers are fully

disengaged.

3. Push Primer Bulb 2 or 3 times for cold

engine.

NOTE: When temperature is below -26° C

additional priming may be needed.

4. If engine is cold, apply choke. See

Engine Manual for detailed instructions.

NOTE: A warm engine requires less choking

than a cold engine.

5. Set throttle to proper starting position.

6. Turn on engine shut-off switch ("ON").

7. Insert key into ignition switch.

12 V – Turn key to RUN position.

220 V – Push key into RUN position. DO

NOT twist key after it is inserted.

8. Grasp starter handle and pull rope out

slowly until it pulls harder. Let rope

rewind slowly.

9. Pull rope with a rapid continuous full arm

stroke. Let rope rewind slowly.

IMPORTANT: DO NOT let Starter Handle

snap against Starter.

10. Repeat steps 8 and 9 until engine starts.

(If engine does not start, refer to

TROUBLESHOOTING on page 38.)

11. Adjust choke as needed.

12. Set throttle to Part Throttle or Slow

position for adaptation to outside

temperature or travel. Set throttle to Fast

position for normal operation.

Electric Start (220V)

13.

(926321, 322, 323, 324) Connect

extension cord to starter.

IMPORTANT: Prevent damage to unit. Know

voltage of your starter and only use matching

outlets.

14. Plug extension cord into 220 V 3-wire,

grounded outlet.

IMPORTANT: Use an extension cord that is

capable of handling current requirements.

See your Ariens dealer for recommended

extension cord.

15. Turn discharge chute straight ahead.

16. Make sure that the traction clutch and

attachment drive clutch levers are fully

disengaged.

17. Push Primer Bulb 2 or 3 times for cold

engine.

NOTE: When temperature is below -26° C

additional priming may be needed.

18. Insert key into ignition switch on engine

and push into "Run" position. DO NOT

twist key after it is inserted.

EN - 22

Page 23

19. If engine is cold, apply choke. A warm

engine requires less choking than a cold

engine. See Engine Manual for detailed

instructions.

20. Set throttle to proper starting position.

21. Turn on engine shut-off switch ("ON").

22. Press starter button on engine until

engine starts.

IMPORTANT: DO NOT operate starter more

than 15 seconds per minute, as overheating

and damage can occur. (If engine does not

start, refer to TROUBLESHOOTING on

page 38.)

23. Adjust choke as needed.

24. Disconnect power cord from outlet, then

starter.

25. Set throttle to Part Throttle or Slow

position for adaptation to outside

temperature or travel. Set throttle to Fast

position for normal operation.

Electric Start (12V) (926513)

1. Turn discharge chute straight ahead.

2. Make sure that the traction clutch and

attachment drive clutch levers are fully

disengaged.

3. Push Primer Bulb 2 or 3 times for cold

engine.

NOTE: When temperature is below -26° C

additional priming may be needed.

4. If engine is cold, apply choke. See

Engine Manual for detailed instructions.

NOTE: A warm engine requires less choking

than a cold engine.

5. Set throttle to proper starting position.

6. Turn ignition key to the START position

until engine starts and release into the

RUN position.

IMPORTANT: DO NOT operate starter more

than 15 seconds per minute, as overheating

and damage can occur. If engine will not

start, see TROUBLESHOOTING on page 38

or refer to Engine Manual.

7. Adjust choke as needed.

8. Set throttle to Part Throttle or Slow

position for travel or adaptation to

outside temperature. Once achieved, set

throttle to Fast position for normal

operation.

Shut Off

1. Release Traction Drive Clutch Lever and

allow unit to come to a complete stop.

2. Run Impeller a few minutes after use to

prevent freeze-up of Impeller.

3. Release Attachment Clutch Lever and

wait for all moving parts to come to a

complete stop.

4. Move Throttle to the “Slow” position.

5. Turn off engine shut-off switch ("OFF").

6. Remove key.

SNOW REMOVAL

IMPORTANT: Allow unit and engine to adjust

to the outdoor temperature before clearing

snow.

NOTE: Attachment clutch should be engaged

before wheel drive clutch when throwing

snow.

1. Select Speed Control position and

direction.

2. Engage Attachment Clutch – Right Hand

Lever.

3. Engage Traction Drive Clutch – Left

Hand Lever.

IMPORTANT: DO NOT overload unit capacity

by attempting to clear snow at too fast a rate.

Use slow speed to clear deep or hard packed

snow.

Tips for Operation

Snow is best removed as soon as possible

after snow fall.

To clear an area, run unit in an overlapping

series of paths. For large areas, start in the

middle and throw snow to each side, so snow

is not cleared more than once.

ALWAYS direct snow away from area to be

cleared and with direction of the wind.

TRAVELING

To travel from one work area to another:

1. Set Throttle to Slow or Part-Throttle

position.

2. 926321, 322, 323, 513: Press down on

handlebars enough to raise front of unit

slightly off surface.

926324: Place the unit in the transport

position (see Track Angle (926324) on

page 20).

3. Engage wheel or track drive clutch

without engaging attachment drive

clutch.

TRANSPORT

ALWAYS shut off engine, remove key, and

close fuel shut-off valve when transporting

unit on a truck or trailer.

Use extra care when loading or unloading

unit onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

EN - 23

Page 24

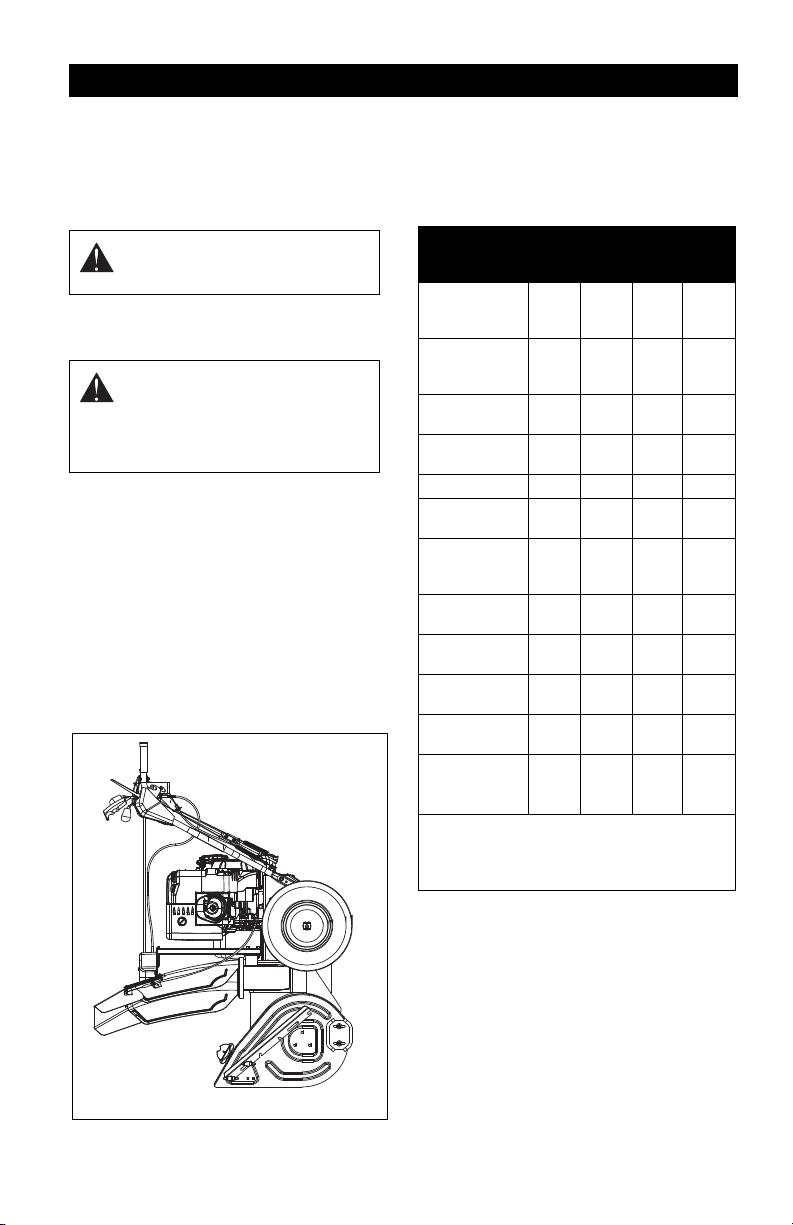

MAINTENANCE

Figure 15

Service Position

OS7121

Ariens Dealers will provide any service or

adjustments which may be required to keep

your unit operating at peak efficiency. Should

engine service be required, contact an Ariens

dealer or an authorized engine

manufacturer's service center.

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

SERVICE POSITION

(Figure 15)

WARNING: Before tipping unit up

onto housing, remove fuel so no

spills will occur and remove battery

(if equipped). Ensure unit is secure

and will not tip over during

maintenance.

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

2. Close fuel shut-off valve (see Fuel Shut-

Off Valve on page 21).

3. Drain fuel tank and fuel system (see

Engine Manual for complete

instructions).

4. Place unit on a flat level surface. Tip unit

forward onto front of auger housing for

service.

IMPORTANT: Ensure unit is secure and will

not tip over. Strap and clamp onto bench if

needed.

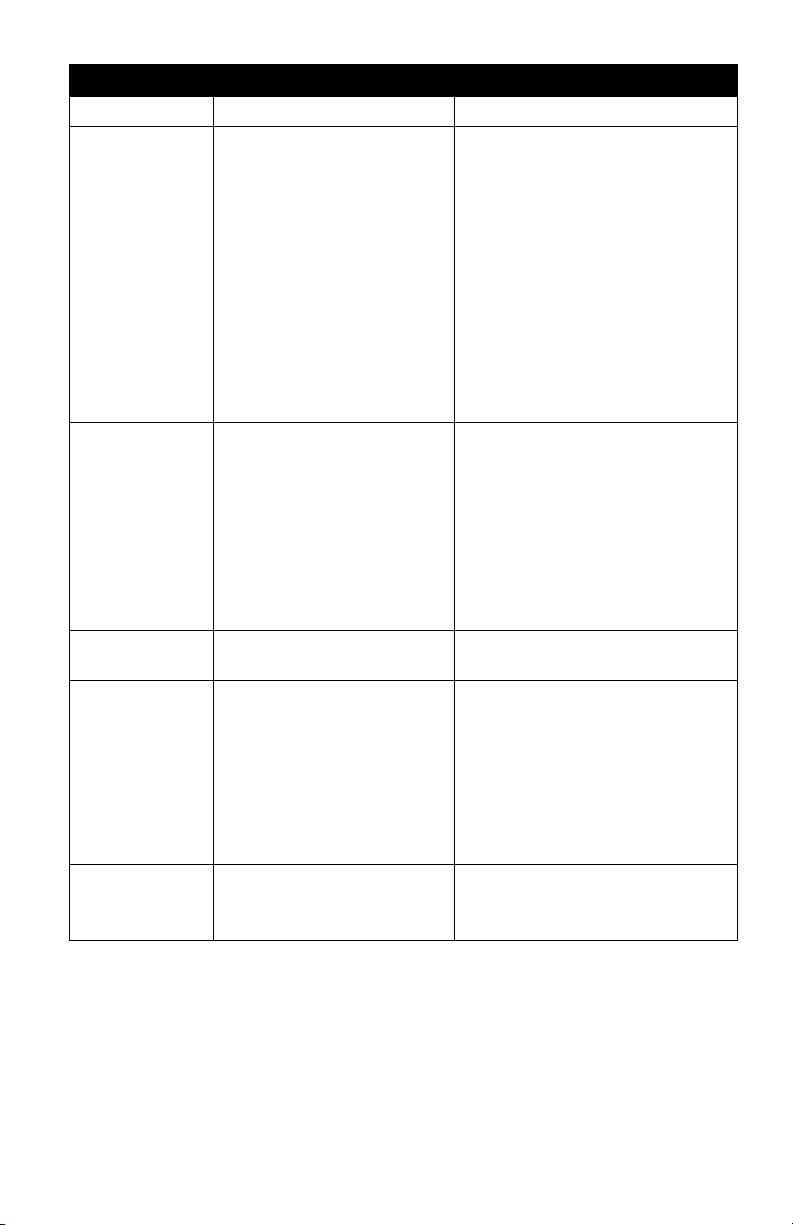

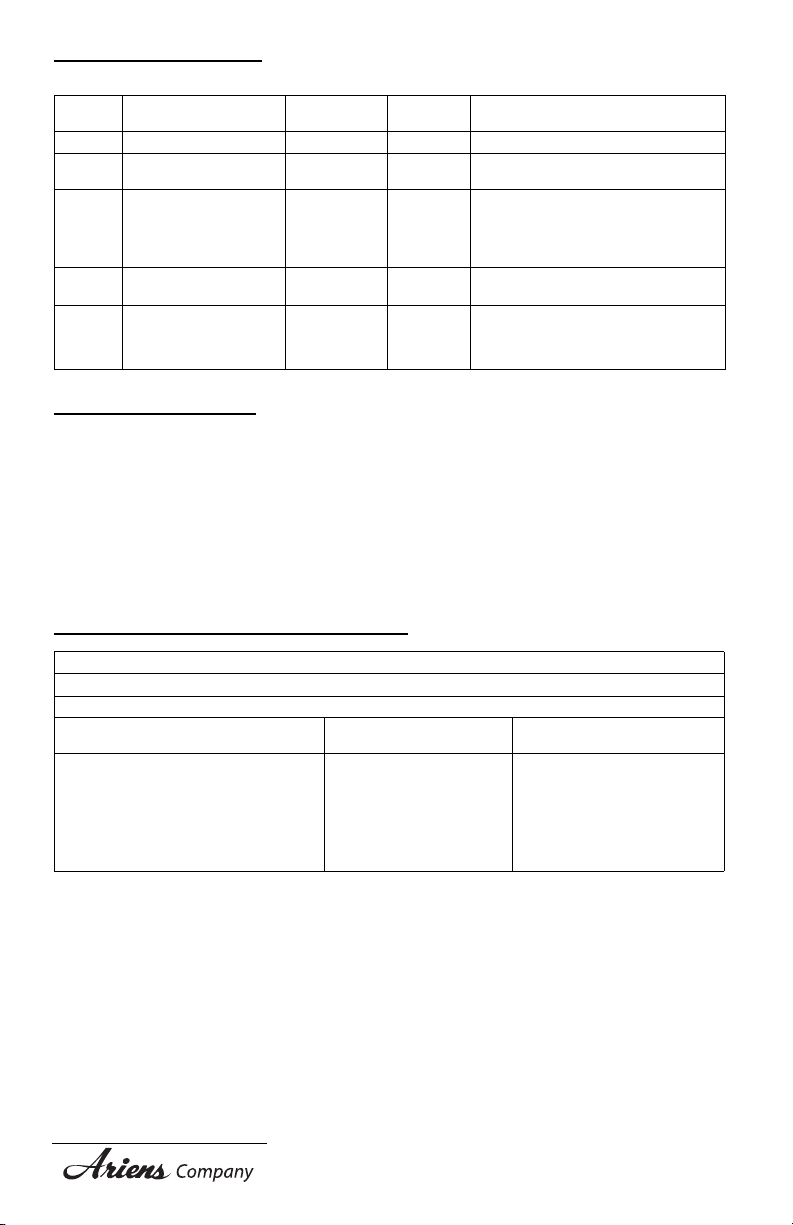

MAINTENANCE SCHEDULE

The chart below shows the recommended

maintenance schedule that should be

performed on a regular basis. More frequent

service may be required.

MAINTENANCE

SCHEDULE

Service

Performed

Check Dual

Handle

Interlock

Check

Fasteners

Check Clutch

Operation

Clean Engine •

Check Engine

Oil

Check Clutch

Cable

Adjustment

Change

Engine Oil **

Check Tire

Pressure

Check Auger

Gearcase

General

Lubrication

Battery

Maintenance

(926515)

Use

Each

•

•

•

••

5 hrs.

Every

* •

Every

Yea rl y

25 hrs.

•

••

••

••

* After first five hours of operations.

** Refer to Engine Manual for detailed

instructions.

CHECK DUAL HANDLE

INTERLOCK

Without the engine running, press down

(engage) both clutch levers. Release

attachment clutch lever. Attachment clutch

should remain engaged until traction clutch

lever is released, then both clutches must

disengage.

EN - 24

Page 25

CHECK FASTENERS

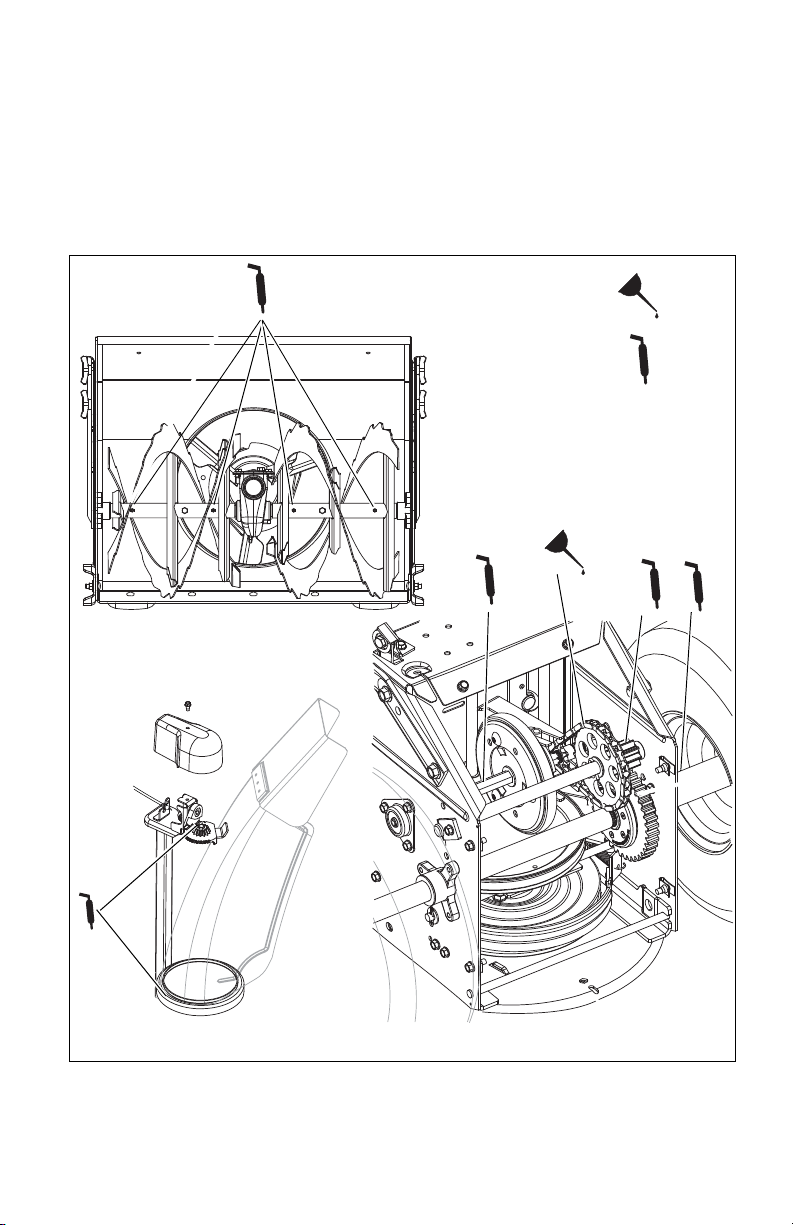

Figure 16

1. Auger Gearcase

2. Oil Fill Plug

3. Seal Washer

2

1

3

Make sure all hardware is tightened properly.

CHECK CLUTCH OPERATION

Auger / impeller must stop within 5 seconds

when attachment clutch/impeller brake lever

is released.

Wheels must stop quickly when traction drive

clutch lever is released.

If clutches do not engage or disengage

properly, adjust or repair before operation.

See Attachment Clutch/Brake Adjustment on

page 31 and Traction Drive Clutch

Adjustment on page 33.

CHECK CLUTCH CABLE

ADJUSTMENT

Make sure the attachment clutch and traction

drive clutch are adjusted to the range

specified in Attachment Clutch/Brake

Adjustment on page 31 and Traction Drive

Clutch Adjustment on page 33.

CLEAN ENGINE

Refer to Engine Manual for detailed

instructions.

CHECK ENGINE OIL

The engine crankcase oil should be checked

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on

dipstick at all times or engine damage will

result (See Engine Manual).

Park unit on a level surface. Refer to Engine

Manual for detailed instructions.

CHANGE ENGINE OIL

Refer to Engine Manual for detailed

instructions.

NOTE: Run engine just prior to changing oil,

warm oil will flow more freely and carry away

more contaminants.

CHECK TIRE PRESSURE

(926321, 322, 323, 513)

Keep tires at pressure listed on the tire

sidewall. See Check Tire Pressure on

page 13.

CHECK AUGER GEARCASE

(Figure 16)

IMPORTANT: Proper oil level must be

maintained.

Gear cases are filled to the correct level at

the factory. Unless there is evidence of

leakage, no additional lubricant should be

required. Check oil level each season or

every 25 hours of operation.

IMPORTANT: Be sure unit is resting on a

level surface before checking lubricant levels.

To ensure adequate lubricant level:

1. Remove filler plug and seal washer

(Figure 16). Lubricant must be 6.05 cm

– 6.68 cm from the flat surface of the

gear case cover.

IMPORTANT: DO NOT remove the gear case

cover.

2. Check oil level with suitable dipstick

device. Add lubricant if required.

NOTE: Inspect seal washer for wear or

rubber deterioration and replace as needed.

IMPORTANT: Use only Ariens L3 synthetic

severe duty gear lube (Part Number

00068800). Use of other lubricants will void

unit warranty.

3. Reinstall filler screw and seal washer to

9N•m.

IMPORTANT: DO NOT OVER-TORQUE!

IMPORTANT: Be sure to install seal washer

with rubber side down (Figure 16).

IMPORTANT: Improper torquing, omission of

seal washer, or incorrect installation of seal

washer will void unit warranty.

EN - 25

Page 26

GENERAL LUBRICATION

Figure 17

Oil

Grease

(Figure 17)

IMPORTANT: Wipe each fitting clean before

and after lubrication.

IMPORTANT: DO NOT allow grease or oil to

get on friction disc, friction plate or belts.

NOTE: Apply Ariens Hi-Temp Grease or

equivalent to the lubrication fittings. See

SERVICE PARTS on page 37.

Sno-Thro should be lubricated (Figure 17) at

beginning of season or every 25 operating

hours.

Auger Shaft

To grease auger shaft, remove shear bolt

nuts and shear bolts per instructions in Shear

Bolts on page 28. Apply grease at the grease

zerks and then turn the auger assemblies on

the auger shaft. Replace shear bolts.

Apply oil to auger shaft end bushings.

EN - 26

Page 27

Clean Battery (926513)

Figure 18

OS7450

Cover plate and

mounting screws.

Figure 19

Fuse and fuse holder.

OS7455

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

IMPORTANT: Battery is maitenance-free. Do

not tamper with our attempt to open battery.

See SERVICE AND ADJUSTMETNS on

page 28 for charging procedures.

Term inals

Keep battery and its terminals clean.

IMPORTANT: Remove battery from unit

before cleaning.

REmove corrosion from battery terminals and

cable conections with wire brush, then wash

with a weak baking soda solution.

After cleaning, apply a thin coat of grease or

petroleum jely to terminals and cable ends to

retard corrosion.

Replace Fuse (926513)

1. Remove the two screws and the cover

plate from beneath the battery.

2. Locate the fuse holder on the wiring

harness and remove the fuse.

3. Install a new fuse of the same amprating and type.

4. Replace the cover plate and secure in

position with the two screws removed in

step 1.

NOTE: Make sure the wire harness does not

get pinched between the cover plate and the

auger housing.

EN - 27

Page 28

SERVICE AND ADJUSTMENTS

Figure 20

2

1

OS0483

1. Skid Shoes

2. Skid Shoe Hardware

Figure 21

1. Auger

2. Shear Bolts

OS7150

1

2

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

SCRAPER BLADE

IMPORTANT: Damage to auger/impeller

housing will result if blade wears down too

far.

Scraper blade is adjustable to compensate

for wear.

To adjust scraper blade:

1. Tip unit back onto handlebar, support

housing and loosen nuts retaining blade.

2. Reposition scraper blade and tighten

lock nuts.

3. Adjust skid shoes.

IMPORTANT: ALWAYS adjust skid shoes

after adjusting scraper blade to prevent

premature wear to scraper blade or damage

to housing.

SKID SHOES

(Figure 20)

Skid Shoes should be adjusted as conditions

require.

1. Position unit on a hard, flat, smooth level

surface.

2. Adjust skid shoes by inserting a spacer

of desired thickness under center of

scraper blade, loosen skid shoe

hardware, slide skid shoes to flat

surface. Allow 3 mm between scraper

blade and hard smooth surfaces. Allow

22 mm between scraper blade and

uneven or gravel surfaces. Retighten

hardware.

NOTE: Keep housing level by adjusting skid

shoes equally.

SHEAR BOLTS

(Figure 21)

IMPORTANT: Use only Ariens OEM shear

bolts for replacement. Use of any other type

of shear bolt may result in severe damage to

unit. See SERVICE PARTS on page 37.

Occasionally a foreign object may enter the

auger/impeller housing and jam the auger,

breaking shear bolts which secure the auger

to the shaft. This allows auger to turn freely

on the shaft which may help prevent damage

to gear drive.

For Replacement:

1. Align shear bolt holes in auger with

shear bolt holes in the shaft.

2. Drive shear bolt through hole (if shear

bolt was broken this will drive remaining

part from shaft).

3. Secure shear bolt with nut.

NOTE: DO NOT overtighten the shear bolt.

Tighten shear bolt to 7.9 – 16.5 N•m.

EN - 28

Page 29

HANDLEBAR HEIGHT

Figure 22

1. Upper Position

2. Lower Position

3. Handlebar

4. Upper Mounting Bolt

5. Lower Mounting Bolt

1

2

3

4

3

5

5

4

1

2

OS7155

Figure 23

1. Chute Control Assembly

2. Chute Rod

1

1

2

2

Upper Position

Lower Position

(Figure 22 and 23)

CAUTION: AVOID INJURY. Adjust

the attachment clutch, speed

selector and traction clutch after

changing the handlebar height. See

Attachment Clutch/Brake

Adjustment on page 31 and Speed

Selector Adjustment on page 30.

To raise or lower the handlebar:

1. Remove hair pin holding chute rod to

control assembly.

2. Place unit in service position (see

Service Pos i tion on page 24).

3. Remove bottom cover.

4. Remove top mounting bolts from the

handlebars and adjust the handlebar up

or down as needed until the handlebar

mounting holes align with holes in unit

frame.

5. Secure handlebar to frame with

hardware removed in step 4 using the

different hardware locations shown in

Figure 22.

7. Check and adjust speed selector. See

Speed Selector Adjustment on page 30.

8. Check tension on auger and traction

clutch cables.

IMPORTANT: Cables should not be slack nor

under tension. Adjust as necessary.

9. Re-install bottom cover.

REMOTE DEFLECTOR CONTROL

(Figure 24)

Deflector must stay in selected position while

throwing snow.

If deflector does not stay in set position:

1. Tighten nut beneath control panel to

increase pressure on deflector control.

If deflector does not follow full range of travel:

1. Push deflector remote all the way

forward.

2. Loosen adjusting nuts on cable support

bracket underneath the dash panel

(Figure 24).

3. To adjust the deflector lower:

Slide cable down. Tighten bottom nut.

4. To adjust deflector higher:

Slide cable up. Tighten top nut.

5. Check travel and repeat adjustment as

necessary.

NOTE: Insert the hair pin with the loop end on

the left side of the chute rod so the control

lever will cover its full range of travel.

6. Align correct chute rod holes in chute

control assembly as shown in Figure 23,

and then secure chute rod in position

with hair pin remove in step 1.

EN - 29

Page 30

DISCHARGE CHUTE CONTROL

Figure 24

2

1

1. Adjusting Nuts

2. Cable Support Bracket

Forward Adjustment Nut

Rearward

Adjustment Nut

Figure 25

(Figure 25)

If chute does not stay in position while

throwing snow or if chute does not rotate

freely, adjust the cable under the gear cover

so the chute lock fingers engage or

disengage the locking gear.

If chute does not stay in position:

Loosen the cable by loosening the rear

adjustment nut, and then tightening the

forward adjustment nut against the bracket

until the lock arm engages the gear teeth.

If chute does not rotate freely:

Tighten the cable by loosening the forward

adjustment nut, and then tightening the rear

adjustment nut against the bracket until all

cable slack is removed (Figure 25).

SPEED SELECTOR

ADJUSTMENT

(Figure 26)

To adjust:

1. Disconnect adjustment pivot pin from

speed selector lever by removing hair

pin.

2. Place the speed selector on the dash in

the fastest forward speed position.

3. Turn the speed selector lever straight

down towards the ground as far as it will

go.

4. Thread the adjustment pivot pin along

the shift rod until it aligns with the mating

hole on the speed selector lever. Insert

the pivot pin into hole.

5. Secure adjustment pivot pin with hairpin.

6. Make sure the speed selector shifts into

each speed position.

7. Check forward and reverse speeds:

a. Start unit.

b. Shift speed selector into the first

forward speed.

c. Engage the traction clutch. Unit

should move forward.

d. Stop unit.

e. Shift speed selector into first

reverse speed.

f. Engage the traction clutch. Unit

should move backward at speed

equal to first forward.

g. Shut off unit.

8. Adjust pivot pin on the shift rod as

necessary so unit travels forward when

speed selector is in first forward position

and travels backward when speed

selector is in first reverse position.

9. Connect the pivot pin to the speed

selector arm with the hardware removed

in step 1.

EN - 30

Page 31

ATTACHMENT CLUTCH/BRAKE

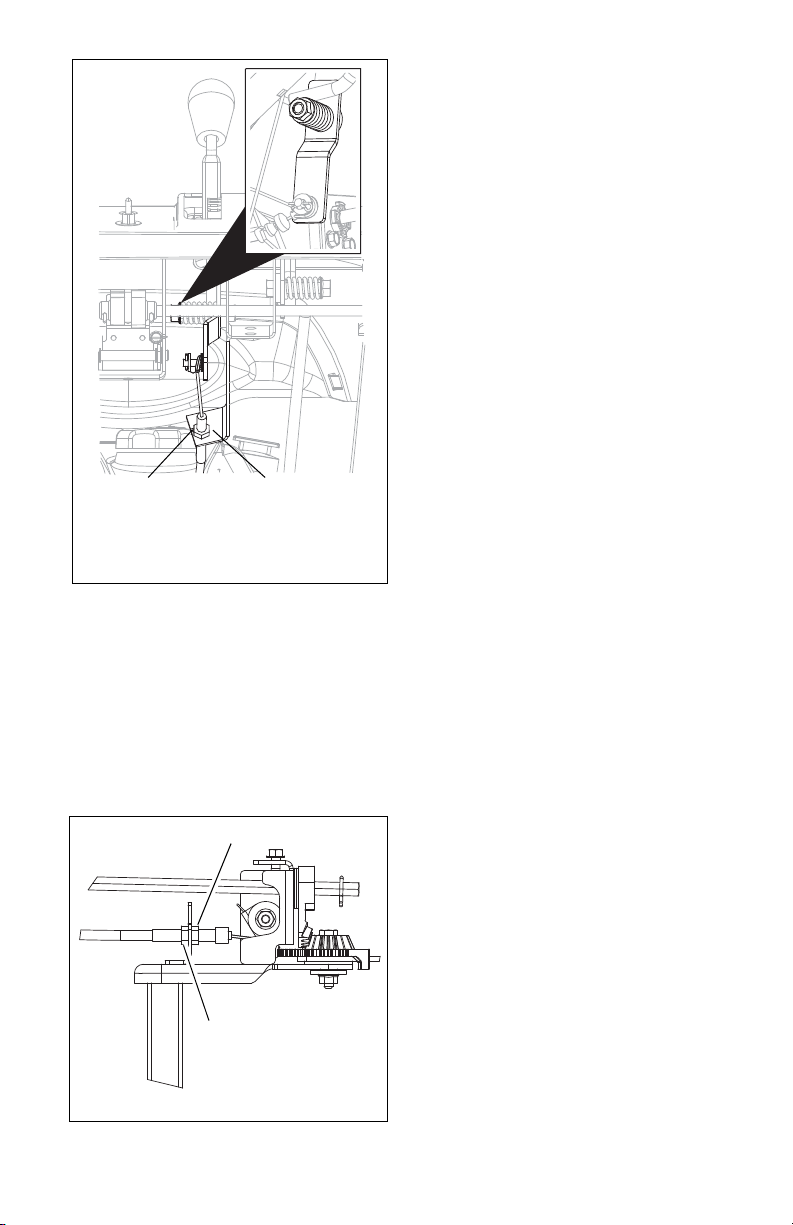

Figure 26

1. Shift Rod

2. Adjustment Pivot Pin

3. Speed Selector Lever

4. Hairpin

2

3

1

4

OS7185

Figure 27

1. Attachment Clutch Cable

2. Adjustment Barrel

3. Jam Nut

2

3

1

OS7185

OS7191

Figure 28

OS7196

With the attachment clutch disengaged,

check the attachment idler arm position

here. The attachment idler arm should

lightly touch the frame.

ADJUSTMENT

IMPORTANT: IMPROPER

ADJUSTMENT could result in

unexpected movement of auger and

impeller causing death or serious

injury. Auger/Impeller must stop

within 5 seconds when Attachment

Clutch/Impeller Brake lever is

released.

Remove Attachment Cable Slack

(Figure 27 and 28)

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

2. Loosen hardware securing belt cover to

unit.

NOTE: DO NOT completely remove the

hardware from unit.

3. Remove belt cover.

4. Loosen jam nut on cable adjustment

barrel, and then turn the adjustment

barrel up or down to lengthen or shorten