Page 1

PARTS

MANUAL

SERIAL NUMBER

MODEL NUMBER 932001 - 2.7 H.P.

SERIAL NUMBER 000101 & UP

cA^Umi

2.7 HP.

COMPACT SNO-THRO

PM-32-77

PRICE $.50

ARIENS COMPANY

BRILLION, WIS. 54110

Page 2

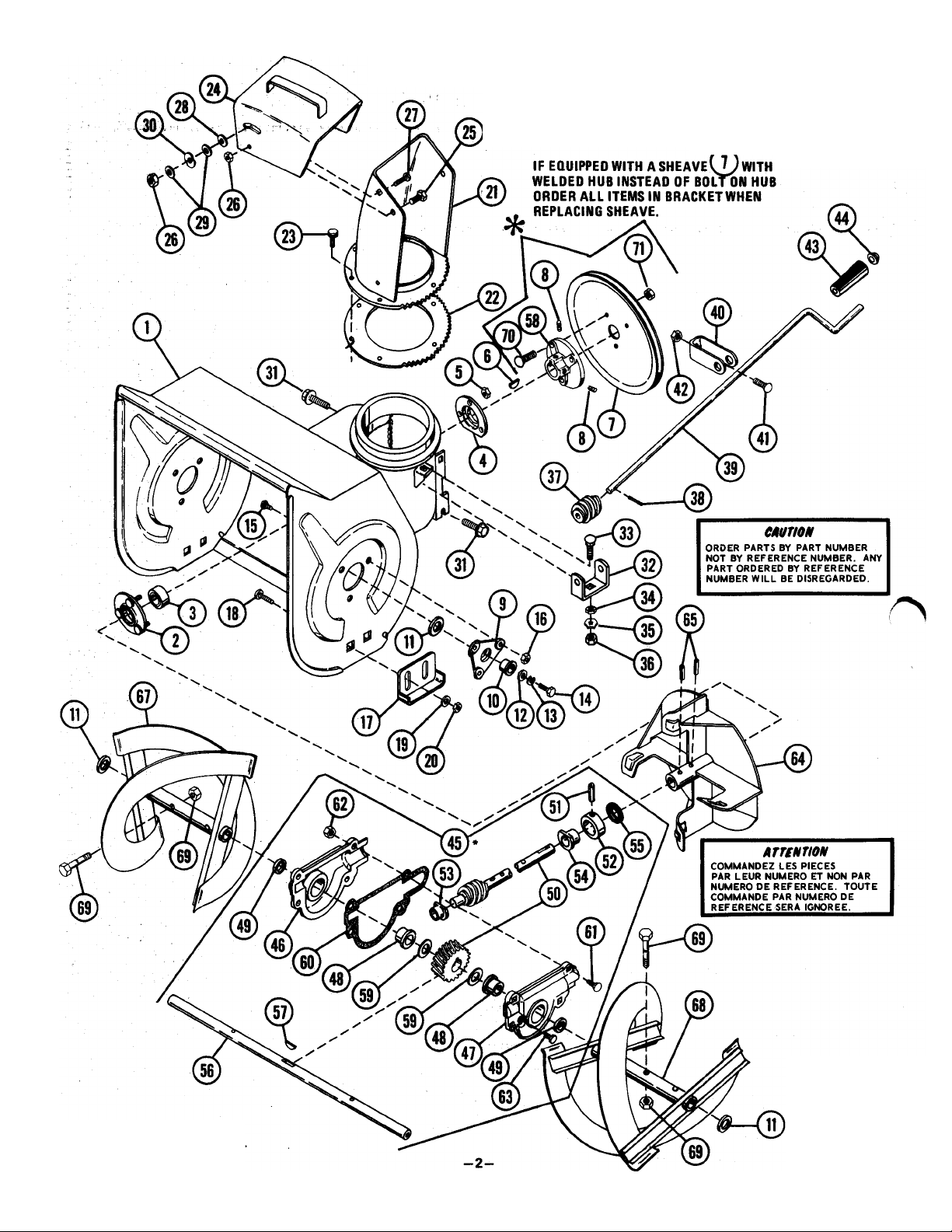

SNO-THRO PARTS LIST FOR MODELS 932001

SOUFFLEURS SNO-THRO _

MOpELES 9320(fj

* Use Ariens Liquid Grease

Part No. 000070. Approx. 2 oz

Page 3

SNO-THRO PARTS LIST FOR MODELS 932001

SOUFFLEURS SNO-THRO MODELES 932001

n

Klo DE No DE code

REF. PIÈCE D'INV.

DESCRIPTION

REF. PART STOCK

NO. NO. CODE

532003

1

010142 M BEARING FLANGE

2

3 054063

003017

4

065040

5

066001

6

073080

7

060005

8

032044

9

055113 F

10

11 064009 M

12 064128 M

063003

13

14 059002 M CAP SCREW, 5/16-18 X 5/8, GR 2

15 070011

16 065056

010165

17

062010

18

064002

19

065039

20

21 022159

022160

22

074034

23

24 522006

25

059039

065042

26

27 062034

28 064168

29 064123

013202

30

31 070009

32 022123

33 062011

34

063032

35

063023

BLOWER HOUSING, W/Decals 1

S

F

GEARING, Radial

BEARING FLANGE

M

LOCKNUT

M

KEY, Woodruff, SAE 11

M

SHEAVE

M

SET SCREW

M

SUPPORT, Bearing

M

FLANGED BUSHING 2

WASHER, 3/4 STD. 4

WASHER

M LOCKWASHER 5/16 STD.

RIBBED NECK BOLT 1/4-20x5/8

M

FLANGED WHIZ LOCKNUT 1/4-20 6

M

RUNNER 2

F

CARRIAGE BOLT, 3/8-16x3/4

M

WASHER, 5/16 STD. 4

M

M LOCKNUT, 3/8-16

CHUTE, Discharge 1

S

GEAR, Lower Collar 1

S

TAPTITE

M

DEFLECTOR CHUTE W/Decal 1

s

M CAP SCREW, 5/16-18 X 1/2, GR 2 2

M LOCKNUT, 5/16-18 3

CARRIAGE BOLT, 5/16-18x3/4 1

M

M WASHER, Plastic 5/16

WASHER, 5/16 STD 2

M

WAVE WASHER 1

M

FLANGE WHIZLOCK SCREW 5/16-18x1/2

M

WORM CLEVIS 1

s

CARRIAGE BOLT, 5/16-18x3/4 1

M

LOCKWASHER 1

M

LOCKWASHER 1

M

QUANTITÉ

NO REQ'D

No DE No DE CODE

REF. PIÈCE DTNV.

REF. PART STOCK

NO. NO. CODE

36 065015

1

1

1

3

1

1

2

2

2

2

2

6

4

4

6

1

4

37

38

39

40

41

42

43 075039

44

45

46 032032

47

48 055102

49

50 532001

51

52 032035

53 055111

54

55 056058

56 032036

57

58

59 064161

60 032038

61

62 065056

63 070010

64

65 058007

66 064009

67 032041

68 032042 s RAKE, Left

69

70 070053

71 065078

022110 M

058034 M

022081 S

532004

062001

065040

010198

532002

032033

056043

058003

055112

066014

002862

062012

032040

532005

DESCRIPTION

M

NUT, Hex, 5/16-18

WORM GEAR

ROLL PIN, 1/8 X 3/4

CHUTE CONTROL CRANK

M

BRACKET, W/Decal

M

CARRIAGE BOLT, 1/4-20x1-1/4

M.

LOCKNUT, 1/4-20

M

GRIP

M

CAP

M

GEAR CASE ASSEMBLY

s

GEAR CASE, Right Half

s

GEAR CASE, Left Half

F

FLANGED BUSHING

F

SEAL

M

FAN SHAFTS: WORM GEAR

M

ROLL PIN, 3/16 X 1-1/4

s

THRUST COLLAR

F

FLANGED BUSHING

F

FLANGED BUSHING

F

"0" RING

S

RAKE SHAFT

M

KEY, Woodruff, SAE 61

M

HUB

M

WASHER

F

GASKET

M

CARRIAGE BOLT, 1/4-20x3/4

M

FLANGED WHIZLOCK NUT

FLANGE WHIZLOCK SCREW 3/8-16x1/2

M

M

FAN

M

ROLL PIN, 1/4 X 1-1/4

M

WASHER, 3/4 STD.

s RAKE, Right

SHEAR BOLTW/Nut

F

M

RIBBED NECK BOLT

M

FLANGE WHIZLOCK NUT

QUANTITÉ

NO REQ’D

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

2

1

4

4

1

1

2

2

1

1

2

3

3

^ If equipped with a sheave^ 7ywith welded hub instead of bolt on hub,

order all items in bracket wHen replacing sheave.

SUGGESTED PARTS STOCKING CODE

F - FAST S -SLOW

M - MEDIUM 0 - CUSTOMER ORDER ONLY

NOTE: DECALS SEE PAGE 8.

CODE SUGGÉRÉ D'INVENTAIRE DES PIÈCES

F - FAST (rapide) S -SLOW (lent)

M - MEDIUM (moyen) O - Commande du client seulement

NOTE: DÉCALQUES (voir p. 8.)

-3-

Page 4

TRACTOR PARTS FOR MODEL 932001

PIECES DU TRACTEUR DES MODELE 932001

$0*

S',

S'

r,>P\ 1

I TO ENGINE

MAGNETO

@ @

hd

m @

S®

I

ORDER PARTS BY PART NUMBER

NOT BY REFERENCE NUMBER. ANY |

PART ORDERED BY REFERENCE

NUMBER WILL BE DISREGARDED.

—4--

mmH

>r-®

COMMANDEZ LES PIECES

ikTUHim

PAR LEUR NUMERO ET NON PAR

NUMERO DE REFERENCE. TOUTE

COMMANDE PAR NUMERO DE

REFERENCE SERA IGNOREE.

Page 5

TRACTOR PARTS FOR MODEL 932001

PIECES DU TRACTEUR DES MODELE 932001

No DE No DE

REF. PIÈCE

REF. PART

N0. N0.

1

2 032002

3

4

5

6 064123

7

8 032004

9

10 032005

11 031053

12

13 067004 M PIN, Cotter, 1/8x1

14

15 083141 M SPRING, Extension

16 032006 s IDLER ARM

17 010358

18

19

20 065042

21 055109

22 032007

23 066003

24

25

26

27

28 068062 s RIVET

29

30 032009 S LEVER

31 032010

32

33 032011

34 032012

35 057043

36

37

38

39 065040

40 032013

41 058009

42

43 067001

44 032014

45 055110

46

47 065094

48

49 032016

50 058065

51 071121

1

1 53

1 54 075085

1 55

CODE

D'INV.

STOCK

CODE

032001

065039

032003

083090

059045

070012

064003 M

012086 F

059002 M

064002

073074

060014

632001 s

022178

055037

058026

032029

022013

059028 M CAP SCREW, 1/4-20x1/2

022011 s PINION

062049

032015

071122

058064

032017

DESCRIPTON

0 TRACTOR FRAME

S SHIFTING FORK

M LOCKNUT 3/8-16

SHIFT HANDLE

s

SPRING

M

WASHER, 5/16 STD

M

M CAP SCREW, 5/16-18 X 1-1/2 GR 2

QUADRANT

s

M

FLANGE WHIZLOCK SCREW 1/4-20 x 3/8

CLUTCH FORK

s

SPACER

s

WASHER, 1/2 STD

CAP

M

SPACER BUSHING

CAP SCREW, 5/16-18 X 5/8 GR 2

M

WASHER, 5/16, STD

M

LOCKNUT, 5/16-18

F

FLANGED BUSHING

M

HEX SHAFT

M

KEY, Woodruff, SAE 9

M

SHEAVE

M

SETSCREW 1/4-20x1/4

BRAKE CLUTCH ARM W/Lining

s

BRAKE LINING

F FLANGED BUSHING

S LEVER CLUTCH

M

ROLL PIN, 5/32x7/8

M FRICTION PLATE

M

BEARING FLANGE

F SNAP RING

FRICTION WHEEL HUB

S

F FRICTION DISC

M

LOCKNUT, 1/4-20

M

HEX SHAFT

M ROLL PIN, 1/8x1

M

PIN, Cotter, 3/32 x 3/4

M

BUSHING FLANGE

F

FLANGED BUSHING

M

CARRIAGE BOLT 10-24x3/8

M

TWIN WHIZLOCK NUT 10-24

S

AXLE SHAFT

s

GEAR

M

GROOVE PIN, 3/16x1-1/4

s

WHEEL ASSEMBLY, Right

s

WHEEL ASSEMBLY, Left

M

ROLL PIN, 7/32x1-1/4

M

HOLE PLUG

s

BRACKET

QUANTITÉ

NO. REQ'D.

No DE No DE CODE

REF. PIÈCE D'INV.

REF. PART STOCK

NO. NO. CODE

1

1

1

1

1

1

1

1

8

1

1

4

1

1

1

1

1

1

9

8

4

1

1

1

6

1

1

2

2

1

1

1

1

2

2

1

1

4

7

1

2

1

1

2

2

8

8

1

1

56 059062

57

58 022135

59 060012

60

61

62 058035

63 032028

64

65 002813

66 012132

67

68 062022

69

70 065015

71

72

73

74

75 072106 F

76 032019

77

78

79

80

81 083171

82 032021

83

84

85 532006

86 059069

87

88

89

90 532008

91 532007

92

93

94

95

96 063019 M

97

98

99

100

101 069099

102 070053

103

1

1

1

2

2

1

QUANTITÉ

DESCRIPTION

M

CAP SCREW, 1/4-20x1-3/4, GR 2

059022

032027

067020

083091

012131

063003

062048 M

083172

032018 s SHEAVE, Camshaft 1

066015 M KEY, Woodruff, SAE 5

066013 M

072107

032020 M

059053

032050

032022

M

CAP SCREW, 5/16-18 X 3/4 GR 2

s

ROD ADAPTER

M

SETSCREW 5/16-18 X 3/8 1

M

ROD, Traction Clutch 1

M

HAIR PIN, 3/32x1-3/16

M

ROLL PIN, 1/8 X 1/2

s

STRAP

M

BRAKE SPRING

M

CLEVIS PIN

M

IDLER

M

BEARING SPACER 2

M

CARRIAGE BOLT, 5/16-18 x 1-3/8

M

LOCKWASHER 5/16 STD 6

M

NUT 5/16-18

CARRIAGE BOLT 5/16-18x1-1/4

M

SPRING, Extension

VEE BELT

SHEAVE, Engine

s

KEY, Straight, 3/16x3/16x1

F

VEE BELT 1

BELT FINGER 1

M

CAP SCREW, 5/16-18 X 1/2 GR 2 1

M

SPRING, Extension

COVER, Bottom

s

HUB

s

M BELT COVER

NO. REQ'D.

s HANDLEBAR W/Decal

M

022129

074039 M

075081 M GRIP

032026 M

002042

083008

011134

065075

022161

063018

075086 M

065078

CAP SCREW, 5/16-18 X 1-1/4, GR 2

s

HANDLE PIVOT

SCREW, Self Tapping

s

HANDLE W/Decat

s

HANDLE W/Decal

RDD, Clutch

M

CHAIN 8i CONNECTOR

M

CLUTCH SPRING 1

M

KEY SWITCH

LOCKWASHER

M

NUT, Special

s WIRE, Shorting

M

LOCKWASHER

GRIP, Speed Control

M CLAMP, 2 Wire

RIBBED NECK BOLT, 5/16-18 x 3/4

M

LOCKNUT, 5/16-18

M

ENGINE, Tecumseh HSK35-45503M

NOTE: DECALS SEE PAGE 8.

NOTE; DÉCALQUES (voir p. 8.)

3

3

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

4

2

1

1

1

1

1

1

1

1

1

1

3

3

1

SUGGESTED PARTS STOCKING CODE

F - FAST S - SLOW

M -MEDIUM O -CUSTOMER ORDER ONLY

CODE SUGGÉRÉ D'INVENTAIRE DES PIÈCES

F - FAST (rapide) S -SLOW (lent)

M — MEDIUM (moyen) O - Commande du client seulement

-5-

Page 6

MAINTENANCE

BELT REPLACEMENT

CAUTION:

SINCE REPLACING THE BELTS WILL INVOLVE TURNING

THE ENGINE OVER WITH THE STARTER, THE SPARK

PLUG WIRE MUST BE DISCONNECTED DURING THIS

PROCEDURE.

The drive belt and the attachment drive belt are both ac

cessible by tipping apart the blower housing and tractor as

follows;

REPLACEMENT OF TRACTION DRIVE BELT

With the blower and tractor tipped apart, spring the idler

from the drive belt and remove from around the lower sheave

and engine sheave. Install the new belt on the engine sheave

and lower sheave. Then spring the idle back into position on

the outside of the drive belt.

With the belts in position and the idler in place, check the

belt alignment. The engine sheave and the tractor sheave

must align with one another. If the sheaves are not properly

aligned, loosen the setscrews on the engine sheave and align

the sheaves. Retighten the setscrews.

BLOWER CLUTCH ADJUSTMENT

o

1. Remove the nut and washer holding the worm clevis on

the bracket. Remove the chute crank by sliding it back in

the bracket and out of the way.

2. Remove the two flanged whiziock screws securing the belt

guard to the tractor. Remove the belt guard.

Remove the top cap screws and loosen the lower cap screws

3.

on each side that secures the blower housing to the frame.

As the blower housing and tractor are tipped apart, roll

the belt off the engine sheave between the sheave and belt

finger. This can be easily done by pulling the recoil

starter rope to rotate the engine sheave. With the belt dis

connected, the blower housing may then be tipped from

the frame.

TRACTION IDLER

The blower clutch is adjusted by connecting the spring on

the clutch rod into the proper link on the clutch handle chain.

Properly adjusted, the spring should be slightly extended with

the clutch handle down. This should occur without the

attachment activator lever touching the hub. If the activator

lever touches the hub, the blower belt idler pulley must be ad

justed in the idler arm. Loosen the cap screw on the idler

and move the idler IN TOWARD the belt. Readjust the spring

in the chain for proper action.

BLOWER CLUTCH ROD

HUB

TRACTION CLUTCH ROD .

ACTIVATOR LEVER ^ ^

M\

ROD ADAPTOR

ALLEN SCREW

DRIVE DISC ADJUSTMENT

The only adjustment for the drive disc is made by adjusting

the length of the traction clutch rod. With the clutch handle

in the full upright position and the clutch bracket down

against the stop, tighten the alien screw in the rod adapter.

To check the adjustment, push the Sno-Thro with the clutch

handle up; it should roll freely. While pushing the Sno-Thro,

slowly lower the clutch handle. The wheels should start to

drag with the clutch handle approximately halfway down to

the handlebar grip when properly set. If necessary, adjust

the clutch rod in the rod adapter to secure this adjustment.

NOTE; The hex nut on the clutch link just above the spring

on the clutch linkage is NOT an adjustment. This nut should

be tightened just enough to hold the spring snug and prevent

the spring from rattling when traction clutch is released.

FIGURE 4

REPLACEMENT OF THE BLOWER DRIVE BELT

The blower drive belt remains on the sheave on the blower

housing. Place the new belt on the sheave. Hold it in position

On the sheave as the blower is tipped into position on the

tractor. Be sure the brake shoe seats on the belt as the units

are tipped together. Once assembled, roll the blower belt on to

the engine sheave and position the idler on the outside of

the belt.

REPLACEMENT OF FRICTION WHEEL

1. Tip the machine up on the blower housing and brace

securely. Remove two cap screws at back of frame securing

the bottom cover and loosen two cap screws at front

frame sides and remove the cover.

2. Remove the four whiziock nuts holding the bearing flange

on the right hand side of the frame. Remove the bearing

flange and carriage bolts.

-6-

Page 7

3. Remove the hairpin cotter from the traction clutch rod.

Pull this rod from the clutch fork arm and tip it up and out

of the way.

4. Slide the friction wheel assembly and hex shaft to the right

until the left end of the hex shaft comes free of the left

bearing. Then slip the whole assembly back to the right and

pull it forward out of the frame.

5. With the friction wheel assembly out of the frame, the

three cap screws holding the friction wheel to the hub

may be removed and the friction wheel removed.

6. Position a new friction wheel on the hub and secure with

the three cap screws. Tighten securely.

7. Slip the right end of the complete friction wheel assembly

and hex shaft into the hole in the right side of the frame.

Position the friction wheel hub in the forks. Slide the hex

shaft to the left and into the left bearing being sure flat

washer is in position. See that the pinion gear meshes with

the iarge gear.

8.

Replace the bearing flange on the right side of the frame

and secure with the four carriage bolts and nuts. Reconnect

the traction clutch rod in the clutch fork arm and secure

with a hairpin cotter. Readjust the drive disc as described

in the paragraph on page 6.

NOT AN ADJUSTMENT ^

FORK

TRACTOR DRIVE

At start of season, grease gears, hex and axle shaft as in

dicated in the figure below. Use Ariens Moly Lithium grease.

Put two or three drops of light oil on shift lever and other

linkage points. CAUTION: Do not allow grease or oil to

come in contact with friction wheel, drive disc or belts.

FLAT WASHER

{OUTSIDE OF

PINION)

TRACTION CLUTCH ROD

BEARING FLANGE

FRICTION WHEEL

LUBRICATION

ENGINE

Fill the crankcase with Ariens Sno-Thro oil 5W-20 when using

the Sno-Thro.

Use Ariens Gard-N-Yard oil MS classification SAE-30 when

using lawn attachments.

SNO-THRO UNIT

Check the lubrication in the blower gear case by removing

the filler plug on the side of the gear case just above the left

hand auger shaft. Lubricant should be even with the hole

with the machine sitting level.

y

/ A

To Drain Gear Case: Remove fill plug. Tip up on blower

housing and allow oil to drain. Tip unit back on wheels.

Fill gear case with Ariens Liquid Grease (Part No. 000070).

SHEAR BOLT I

SHAFT

Oil rake shaft periodically or each time a shear bolt is re

placed. At the end of the season, remove shear bolts, oil

rake shaft through shear bolt holes, turn rakes on shaft

several times and replace shear bolts.

Oil the discharge chute with several drops of heavy oil.

FILLER PLUG

Refer to engine owners manual for appropriate crankcase oil

substitutes.

Fill the fuel tank with fresh, clean, unleaded automotive type

gasoline. (Leaded "regular" grade gasoline is an acceptable

substitute.)

NOTE: For detailed instructions on engine refer to manu

facturer's booklet packed with the machine.

-7-

Page 8

ARIENS COMPANY BRILLION. WISCONSIN U S A

A WARNING

STOP ENGINE ANO REMOVE SPARK

ROTATING PARTS

PLUG IGNITION WIRE BEFORE

REMOVING OBSTRUCTIONS

78323

A WARNING

ROTATING PARTS

KEEP CLEAR OF COLLECTOR

RAKES WHILE ENGINE

IS RUNNING

78327

A SAFETY

INSTRUCTIONS

AVOID POTENTIAL HAZARDS

I. вело eWNCRS МШП F9R OPftIfIM ДМ

SirnV INSIRyCTIONS.

t. OtSElIVI «Ц UBIIS MO NSIRUenONS.

1. RDNOI om«T INTIRLOCN tVSUM. II II

FOR YOUR PROtfCTION.

«. HOP IRCINt MO WMI FOR RU MOVEMCRt

TO HOP HFORI UNCIOCCINC OR

SERVICINC MACHINE.

S. NEVER mow CIIHOREN 10 OPfRAIE INI

EOUIPMENI. NEVER ALLOW AOULIS 10

OPERATE 1HE EOUIPMENI WITHOUT PNOPEI

INSTRUCTION.

I. KEEP THE AREA OF OPERATION CLUR OF

Ш PERSONS. tSPECIRUV CHILDREN.

I NEVER RIRSCT DISCHARGE AT 0TS1AH0ENI

OR ALLOW АНТОНЕ IN FNONT OF UNIT.

S. RfFP MACHINE PROPEtlV MAINTAINIO ANO

SEOVICEO WITH RLl SNIEIOI. CUAIOS, ANO

PROTECTIVE OCVICES IN PUCE.

78416

78061

SPEED SELECTOR

13 — 2-1

---------

78456

CLUTCH

LEVER

DEPRESS

ni

mACNMENT

Nin

78455

FOR

WHEEL

DRIVE

78324

DISCHARGE

RIGHT LEFT

78325

FAST -

STOP^

CHOKE-THROTTLE DECALS

available from TECUMSEH

OFF 1/2 3/4 FULL

CHOKE

ATTENTION

WHEN USING SUMMER ATTACHMENTS

REMOVE HEATER BOX AND INSTALL

AIR CLEANER

78189

KEY

SWITCH

F

OPCRATINO INSTNUCTIONS

мер» TO OWNCRS MANUAL

TO AT ANT TURN KIT SWITCH OH AND PULL STAATEN

TO STOP TURN KEY SWITCH TO OPS ANO REMOVE KEY

78457

TMHMTILt

ELECTRIC STMTHI

PUSH ID 5ТЛЙТ

78357

(120V AC STARTER

KIT ONLY)

78345

78174

ENGINE PRilVIER

PUSH TO PRIME

78395

COMPLIANCE WITH CANADIAN RADIO INTERFERENCE REGULATIONS CERTIFIED

_______REPLACE SPARK PLUG WITH RESISTOR SPARK PLUG ONLY '

CERTFIE CONFORME AU REGLEMENT CANADIEN SUR LE BROUILLAGE RAOIOELECTRIOUE

REMPLACER LA ROUPIE PAR UNE ROUGIE A RESISTANCE SEULEMENT '

78400

A HIGH SPEED IMPELLER ROTATES

INSIDE THIS HOUSING TO THROW

THE SNOW. NEVER REACH OR PUSH

ANY OBJECT INTO THE DISCHARGE

CHUTE WITH THE IMPELLER

ROTATING!

Loading...

Loading...