Ariens 921045, Deluxe 24, 921046, Deluxe 28, 921047 Service Manual

...

Sno-Thro

E10

Service Guide

Deluxe Series

Models

921045 – Deluxe 24

(SN 000101 +)

®

921046 – Deluxe 28

(SN 000101 +)

921047 – Deluxe 30

(SN 000101 +)

921048 – Deluxe 28 SHO

(SN 000101 +)

921049 – Deluxe 30 EFI

(SN 000101 +)

921323 – Deluxe 24 CE

(SN 000101 +)

921324 – Deluxe 28 CE

(SN 000101 +)

921325 – Deluxe 30 CE

(SN 000101 +)

921326 – Deluxe 28 Track CE

(SN 000101 +)

ENGLISH

05001330D • 1/17

TABLE OF CONTENTS

PRACTICES & LAWS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

EMISSION CONTROL SYSTEM . . . . . . . . . . . . . . . . . . 2

REQUIRED OPERATOR TRAINING. . . . . . . . . . . . . . . 2

SAFETY ALERT SYMBOL . . . . . . . . . . . . . . . . . . . . . . 2

SIGNAL WORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Decal Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Decal Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DRAINING FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . 7

SERVICE POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SEPARATE HOUSING FROM FRAME. . . . . . . . . . . . . 7

Remove Auger Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reinstall Auger Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

BOTTOM COVER REMOVAL . . . . . . . . . . . . . . . . . . . . 12

Install Bottom Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ATTACHMENT DRIVE BELT REPLACEMENT . . . . . . 13

Remove Attachment Drive Belts. . . . . . . . . . . . . . . . . . . . . . . 13

Install Attachment Drive Belts. . . . . . . . . . . . . . . . . . . . . . . . . 13

TRACTION DRIVE BELT REPLACEMENT . . . . . . . . . 14

Remove Traction Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install Traction Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ATTACHMENT BRAKE REPLACEMENT . . . . . . . . . . 16

Remove Attachment Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install Attachment Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

FRICTION DISC REPLACEMENT. . . . . . . . . . . . . . . . . 17

Remove Friction Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install Friction Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

HEX SHAFT BEARING REPLACEMENT . . . . . . . . . . . 20

Remove Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SWING GATE REPLACEMENT . . . . . . . . . . . . . . . . . . 20

Remove Swing Gate Assembly. . . . . . . . . . . . . . . . . . . . . . . . 20

Install Swing Gate Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 21

AUGER REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 22

Remove Auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install Auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AUGER GEARCASE REPLACEMENT. . . . . . . . . . . . . 26

Remove Gearcase Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install Gearcase Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

IMPELLER REPLACEMENT. . . . . . . . . . . . . . . . . . . . . 27

Remove Impeller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Install Impeller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

TRACTION DRIVE CABLE REPLACEMENT. . . . . . . . 31

Remove Traction Drive Clutch Cable . . . . . . . . . . . . . . . . . . . 31

Install Traction Drive Clutch Cable . . . . . . . . . . . . . . . . . . . . . 32

DUAL-HANDLE INTERLOCK CAM REPLACEMENT . 33

Remove Interlock Cam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Install Interlock Cams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

AXLE BUSHING REPLACEMENT . . . . . . . . . . . . . . . . 35

Remove Left Axle Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Install Left Axle Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Remove Right Axle Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Install Right Axle Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

FLANGE BUSHING REPLACEMENT . . . . . . . . . . . . . 38

Install Flange Bushings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DIFFERENTIAL GEAR REPLACEMENT . . . . . . . . . . . 39

Remove Differential Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Install Differential Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CHUTE GEAR REPLACEMENT. . . . . . . . . . . . . . . . . . 41

Remove Chute Rotation Gear. . . . . . . . . . . . . . . . . . . . . . . . . 41

Remove Chute Rotation Gear. . . . . . . . . . . . . . . . . . . . . . . . . 42

Install Chute Rotation Gear. . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Install Chute Rotation Gear. . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Remove Actuation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Remove Actuation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Install Actuation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Install Actuation Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SCRAPER BLADE REPLACEMENT . . . . . . . . . . . . . . 45

Remove Scraper Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Install Scraper Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

HEADLIGHT REPLACEMENT . . . . . . . . . . . . . . . . . . . 46

Remove Bulb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Install Bulb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

GEARCASE REBUILD . . . . . . . . . . . . . . . . . . . . . . . . . 47

Disassemble Gearcase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Assemble Gearcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

TRACK DRIVE WHEEL REPLACEMENT . . . . . . . . . . 53

Remove Track Drive Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Install Track Drive Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

TRACK REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 54

Remove Track. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Install Track. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

BOGIE WHEEL REPLACEMENT . . . . . . . . . . . . . . . . . 55

Remove Bogie Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Install Bogie Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

TRACK BEARING REPLACEMENT. . . . . . . . . . . . . . . 56

Remove Bearing From Left Side of Unit . . . . . . . . . . . . . . . . . 56

Install Bearing to Left Side of Unit. . . . . . . . . . . . . . . . . . . . . . 57

Remove Bearing From Right Side of Unit. . . . . . . . . . . . . . . . 58

Install Bearing to Right Side of Unit. . . . . . . . . . . . . . . . . . . . . 59

EFI REPLACEMENT COMPONENTS . . . . . . . . . . . . . 60

ENGINE REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . 28

Remove Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Install Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

EFI TROUBLE CODE IDENTIFICATION . . . . . . . . . . . 60

CHECKING TROUBLE CODES . . . . . . . . . . . . . . . . . . 61

TROUBLE CODE DIAGNOSTICS. . . . . . . . . . . . . . . . . 61

Code 16: Low Battery Voltage . . . . . . . . . . . . . . . . . . . . . . . . 61

Code 21: Barometer Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . 62

Code 22: Engine Temperature Sensor. . . . . . . . . . . . . . . . . . 62

Code 27: Low Fuel Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . 63

Code 28: High Battery Voltage . . . . . . . . . . . . . . . . . . . . . . . . 64

DIAGNOSTICS FOR NON-TROUBLE CODES. . . . . . . 64

Engine Starts and Loses Power . . . . . . . . . . . . . . . . . . . . . . . 64

Engine No-Start Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Surging Run Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Engine Speed Does Not Change . . . . . . . . . . . . . . . . . . . . . . 66

Have Questions or Need Assistance?

ariensstore.com (Dealer Locator)

ariens.custhel p. com (Sel f-Support)

A parts manual and an operato r’s manual for your unit are

available for free download or purchase at ariens.com.

Ariens recommends using only genuine Ariens replacement parts on this unit. Using unauthorized

parts may adversely affect the performance, durability or safety of this unit and may void the warranty.

Installing unauthorized parts will not automatically void the warranty; however, the warranty will not

apply if the installation and use of unauthorized parts damages the unit. The Ariens warranty applies

solely to defects in Ariens materials and / or factory workmanship. Arien s disclaims liability for any

claims or dama ges – whet her warra nty, proper ty damage, personal injury or death – ari sing from u sing

unauthorized repl ace m en t par ts.

Before operating or servicing the unit, carefully and completely read the Operator’s Manual and

engine manual provided with the unit at time of purchase. They contain important safety instructions

and information about unit controls.

Be aware of your mechanical aptitude when applying information in this manual for service and / or

repairs. If you are not comfortable or capable of completing service and / or repairs to the machine,

take the machine to an authorized Ariens service dealer.

WELCOME

EN – 1

SAFETY

SAFETY ALERT SYMBOL

Read these safety rules and follow them closely. Failure to

follow these rules could lead to loss of control of unit,

severe personal injury or death to you or bystanders, or

result in damage to property or the machine.

PRACTICES & LAWS

Practice usual and customary safe working precautions.

Learn applicable rules and laws in your area. Always follow

the practices set forth in this manual.

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include exhaust and

evaporative emissions control system components

required to meet U.S. Environmental Protection Agency

(EPA) and/or California Air Resources Board (CARB)

regulations. Tampering with emission controls and

components by unauthorized personnel may result in

severe fines or penalties. Emission controls and

components can only be adjusted by an Ariens Company

dealer or an authorized engine manufacturer's service

center. Contact your Ariens Company Equipment Retailer

concerning emission controls and component questions.

This is the safety alert symbol. It means:

• ATTENTION!

• YOUR SAFETY IS INVOLVED!

When you see this symbol:

• BECOME ALERT!

• OBEY THE MESSAGE!

SIGNAL WORDS

The safety alert symbol above and signal words below are

used on decals and in this manual. Read and understand

all safety messages.

1. Danger

DANGER: Indicates an IMMINENTLY

HAZARDOUS SITUATION! If not avoided, WILL

RESULT in death or serious injury.

2. Warning

WARNING: Indicates a POTENTIALLY

HAZARDOUS SITUATION! If not avoided,

COULD RESULT in death or serious injury.

REQUIRED OPERATOR TRAINING

Read and understand the Operator's Manual

and decals on the unit. This information is for

your safety and the proper use of your

equipment. Failure to follow these instructions

and warnings may cause death or serious

injury. If you have purchased this product from an Ariens

dealer, the dealer can provide you with training.

Familiarize yourself and any other operators with all

controls and the safe use of the features of this unit. If you

loan, rent or sell this product to others, provide them with all

manuals.

If you have any questions, please call our customer support

line at 920-756-4688 or contact us at www.ariens.com. Do

not use this equipment if, after reading the Operator's

Manual and the on-board decals, you have any questions

about the safe use of this product.

WARNING: AVOID INJURY. This snow thrower

is capable of crushing or amputating body parts.

Failure to observe the safety instructions in the

manuals and on decals could result in serious

injury or death.

ALWAYS disengage auger, stop unit and engine,

remove key and allow moving parts to stop

before leaving operator’s position.

3. Caution

CAUTION: Indicates a POTENTIALLY

HAZARDOUS SITUATION! If not avoided, MAY

RESULT in minor or moderate injury . It may als o

be used to alert against unsafe practices.

4. Notice

NOTICE: Indicates information or procedures that are

considered important but not hazard related. If not

followed, property damage could result.

5. Important

IMPORTANT: Indicates general reference information

worthy of special attention.

EN – 2

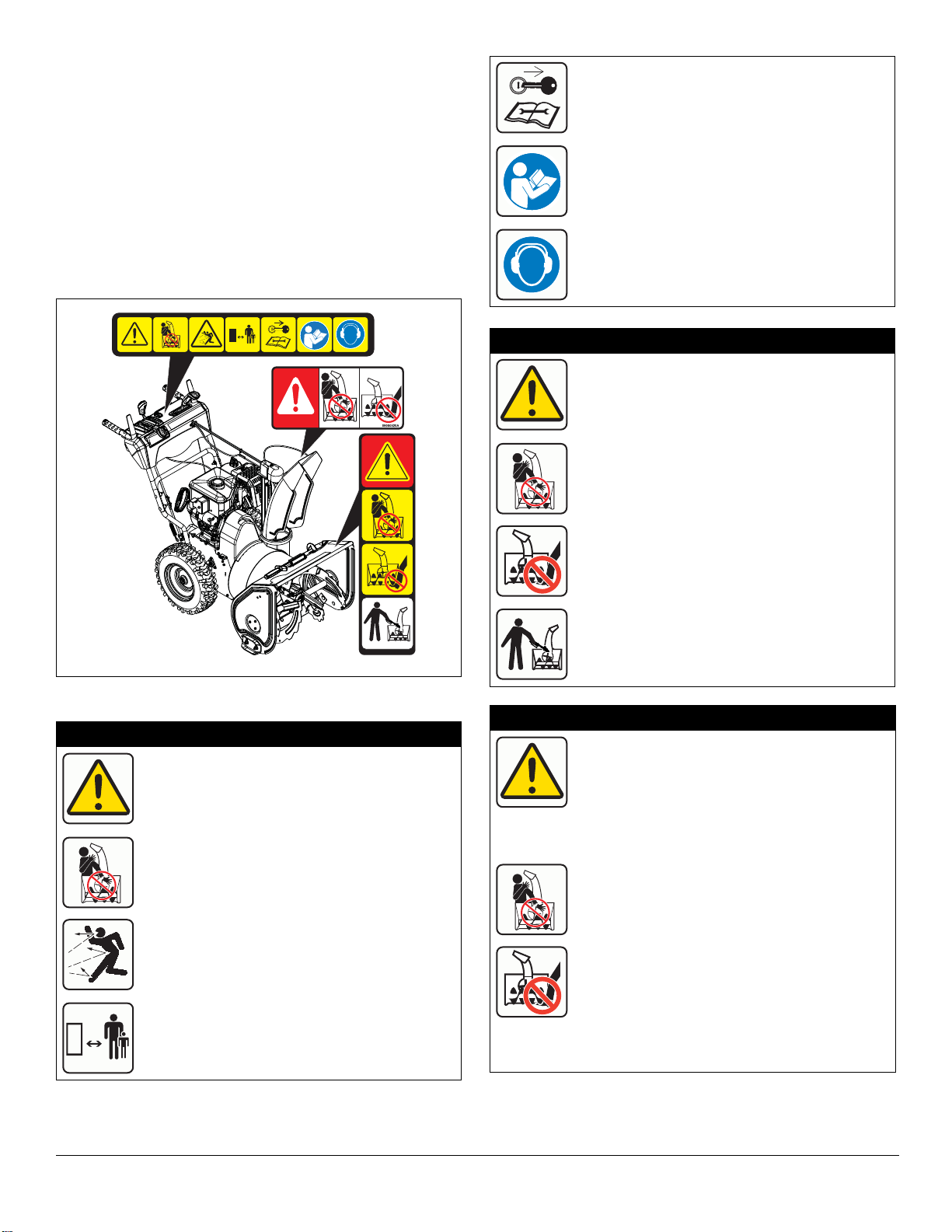

SAFETY DECALS

08000519B

080000945

Figure 1

3

2

1

The safety decals on your machine are visual reminders of

the important safety information in this manual. All

messages on your unit must be fully understood and

carefully followed. Safety decals on the machine are

explained below.

Always replace missing or damaged safety decals.

Replacement decal information is in the parts manual for

your machine. Decals can be ordered from your dealer.

See Figure 1 for safety decal locations.

Safety Decal Locations

Stop engine, remove key, and read manual

before making any repairs or adjustments.

Read Operator’s Manual.

Wear appropriate hearing protection.

2. DANGER!

Danger!

ROTATING PARTS! Only use clean-out tool

to clear blockages. NEVER use your hands.

Safety Decal Descriptions

1. CAUTION!

Danger!

Only use clean-out tool to clear blockages.

NEVER use your hands.

NEVER direct discharge towards persons or

property that may be injured or damaged by

thrown objects.

Keep people away from unit while operating.

Keep children out of work area and under

watchful care of a responsible adult.

High-speed auger/impeller rotates below

discharge opening. Wait for all moving parts

to stop before removing clogs or servicing.

3. DANGER!

Danger!

ROTATING PARTS! Keep clear of auger

while engine is running.

• Read Operator’s Manual.

• Allow operation only by properly-trained

adult, never children.

• Stop engine and remove ignition key prior

to leaving the operator’s position for any

reason.

• Keep all controls, guards and safety

devices properly se rv ic ed and funct ion al.

• NEVER direct discharge towards persons

or property that may be injured or damaged

by thrown objects.

EN – 3

SAFETY RULES

The following safety instructions are based on the B71.3

specifications of the American National Standards Institute

in effect at the time of production.

Training

Read, understand and follow all instructions on the

machine and in the manual(s) before operating this unit.

Be thoroughly familiar with the controls and the proper use

of the equipment. Know how to stop the unit and

disengage the controls quickly.

Never allow children to operate or play on or near the

equipment. Never allow adults to operate the equipment

without proper instruction.

Keep the area of operation clear of all persons,

particularly small children. Be alert and shut off unit if

children enter area.

Exercise caution to avoid slipping or falling, especially

when operating the snow thrower in reverse.

Always remove key and/or wire from spark plug before

assembly, maintenance or service. Unintentional engine

start up can cause death or serious injury.

Complete a walk-around inspection of the unit to

understand the unit, your work area and all safety decals.

Understand how to operate all controls, the functions of all

controls and how to STOP in an emergency.

Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• Never add fuel to a running engine or hot engine.

• Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

• Never fill containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers

on the ground, away from your vehicle, before filling.

• When practical, remove gas-powered equipment from

the truck or trailer and refuel it on the ground. If this is

not possible, then refuel such equipment on a trailer

with a portable container, rather than from a gasoline

dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank

or container opening at all times, until refueling is

complete. Do not use a nozzle lock-open device.

• Replace gasoline cap securely and wipe up spilled fuel.

• If fuel is spilled on clothing, change clothing

immediately.

Adjust the auger / impeller housing height to clear gravel

or crushed rock surface.

Never attempt to make any adjustments while the engine

is running (except when specifically recommended by

manufacturer).

Always allow unit and engine to adjust to outdoor

temperature before clearing snow.

Preparation

Always check overhead and side clearances carefully

before operation.

Always be aware of traffic when operating near streets or

along curbs.

Thoroughly inspect the area where the equipment is to be

used and remove all doormats, sleds, boards, toys, wires

and other foreign objects.

Disengage all clutches and shift into neutral before

starting the engine.

Use extension cords and receptacles as specified by the

manufacturer for all units with electric drive motors or

electric starting motors.

Operation

Disengage all controls before starting engine.

Never leave a running unit unattended. Always stop

engine and remove key before leaving unit to prevent

unauthorized use.

Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

Moving and/or rotating parts can cut off body parts such

as fingers or a hand. NEVER place your hands, other

body part or clothing near any moving parts while unit is

running.

Always keep hands away from all pinch points.

Do not touch parts which might be hot from operation.

Allow parts to cool before attempting to maintain, adjust or

service.

Thrown objects can cause injury. Check for weak spots on

docks, ramps or floors. Avoid uneven work areas and

rough terrain and stay alert for hidden hazards.

Exercise extreme caution when operating on or crossing

gravel drives, walks or roads. Stay alert for hidden

hazards or traffic.

EN – 4

After striking a foreign object, stop the engine, remove the

wire from the spark plug, disconnect the cord on electric

motors, thoroughly inspect the snow thrower for any

damage, and repair the damage before restarting and

operating the snow thrower.

If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration is

generally a warning of trouble.

Stop the engine whenever you leave the operating

position, before unclogging the auger / impeller housing or

discharge chute, and when making any repairs,

adjustments or insp ec tions.

When cleaning, repairing or inspecting the snow thrower,

stop the engine and make certain the auger / impeller and

all moving parts have stopped. Disconnect the spark plug

wire and keep the wire away from the plug to prevent

someone from accidentally starting the engine.

Do not run the engine indoors, except when starting the

engine and for transporting the snow thrower in or out of

the building. Open the outside doors; exhaust fumes are

dangerous.

Never operate the snow thrower without proper guards,

and other safety protective devices in place and working.

Always stand clear of the discharge area when operating

this unit.

Never direct the discharge toward people or areas where

injury or property damage can occur from thrown objects.

Keep children and others away.

Do not overload the machine capacity by attempting to

clear snow at too fast a rate.

Never operate the machine at high transport speeds on

slippery surfaces. Loo k behind and us e care when

operating in reverse.

Do not operate in reverse unless absolutely necessary.

Always back up slowly and look down and behind before

and while backing.

Do not carry passengers.

Disengage attachment when not in use and when

traveling from one work area to another.

Disengage power to the auger / impeller when snow

thrower is transported or not in use.

Use only attachments and accessories approved by the

manufacturer of the snow thrower (such as wheel weights,

counterweights or cabs).

This product is equipped with an internal combustion

engine. Do not use unit on or near any unimproved,

forest-covered or brush-covered land unless exhaust

system is equipped with a spark arrester meeting

applicable local, state or federal laws. A spark arrester, if

used, must be maintained in effective working order by

operator.

Never operate the snow thrower without good visibility or

light. Always be sure of your footing, and keep a firm hold

on the handles. Walk; never run.

Never operate unit after or during the use of medication,

drugs or alcohol. Safe operation requires complete and

unimpaired attention at all times.

Never allow anyone to operate this unit when their

alertness or coordination is impai r ed.

Never touch a hot engine or muffler.

Avoid contact with sharp edges; sharp edges can cut.

Do not throw snow higher than necessary.

Clearing a Clogged Discharge Chute

Hand contact with the rotating auger / impeller inside the

discharge chute is the most common cause of injury

associated with snow throwers. Never use your hand to

clean out the discharge chute.

To clear the chute:

1. SHUT THE ENGINE OFF!

2. Wait 10 seconds to be sure the auger / impeller

blades have stopped rotating.

3. Always use a clean-out tool, not your hands.

Maintenance and Storage

Secure unit so it will not tip over during maintenance.

Before cleaning, removing clogs or making any

inspections, repairs, etc., disengage clutch(es), stop

engine, remove key, allow moving parts to stop and hot

parts to cool.

Check shear bolts and other bolts at frequent intervals for

proper tightness to be sure the equipment is in safe

working condition.

Check clutch and brake operation frequently.

Do not change engine governor settings and do not over-

speed engine.

Adjust and service as required. Motion of drive wheels

and auger / impeller must stop quickly when clutch levers

are released.

Always maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or explosion.

Keep unit free of ice or other debris. Clean up oil or fuel

spills.

Always keep protective structures, guards, and panels in

good repair and secured in place. Never modify or remove

safety devices.

Never store the machine with fuel in the fuel tank inside a

building where ignition sources are present such as hot

water heaters, space heaters or clothes dryers. Close fuel

valve and allow the engine to cool completely before

storing in any enclosure or covering the unit.

EN – 5

Always refer to operator's manual for important details if

the snow thrower is to be stored for an extended period.

Maintain or replace safety and instruction labels as

necessary.

Run the machine a few minutes after throwing snow to

prevent freeze-up of the auger / impeller.

Personal Protection

Do not operate the equipment without wearing adequate

winter garments. Avoid loose fitt ing clothing that can get

caught in moving parts. Wear footwear that will improve

footing on slippery surfaces.

Wear adequate safety gear, including safety glasses with

side shields and protective gloves.

Do not wear loose clothing or jewelry, and tie back hair

that may get caught in rotating parts.

NEVER attempt to unclog or clean unit while engine is

running. Rotating auger / impeller can cause serious

injury.

Protect eyes, face and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Always wear safety glasses or eye shields during

operation or while performing an adjustment or repair to

protect ey es f rom f orei gn o bje cts t hat may be thr ow n fr om

the machine.

Slope Operation

Exercise extreme caution when operating on slopes. DO

NOT operate on steep slopes. DO NOT clear snow across

the face of slopes; go up and down. Keep all movement

on slopes slow and gradual.

Use a slow speed to avoid stops or shifts on slopes. Avoid

starting or stopping on a slope. Do not park unit on a slope

unless absolutely necessary. When parking on a slope

always block the wheels.

Do not operate near drop-offs, ditches, or embankments.

Unit can suddenly turn over if a wheel is over the edge of

a cliff or ditch, or if an edge caves in.

Never fill fuel containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers on

the ground away from your vehicle before filling.

When prac ti ca l, r e mo v e ga s -po w e re d e qu i pm e nt f r o m the

truck or trailer and refuel it on the ground. If this is not

possible, then refuel on a trailer with a portable container,

rather than from a gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do

not use a nozzle lock-open device.

If fuel is spilled on clothing, change clothing immediately.

Properly remove fuel before tipping unit up onto housing

to avoid spills.

Towing/Transporting

Always stop engine, remove key and close fuel valve or

drain fuel when transporting unit on a truck or trailer.

Use extra care when loading or unloading unit onto trailer

or truck. Secure unit chassis to transport vehicle . N ever

secure from rods or linkages that could be damaged. Do

not transport machine while engine is running.

Accessories

Use only Ariens Company-recommended attachments or

accessories that are designed for your unit and that are

appropriate to your use and can be used safely in your

application.

Fuel

DO NOT run engine in an enclosed area. Always provide

good ventilation. Fumes from engine exhaust can cause

injury or death.

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use only an approved gasoline

container with an appropriately-sized dispensing spout.

No smoking, no sparks, no flames. Always allow engine to

cool before servicing.

Never fill fuel tank when engine is running or hot from

operation.

Never fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled fuel.

EN – 6

DRAINING FUEL SYSTEM

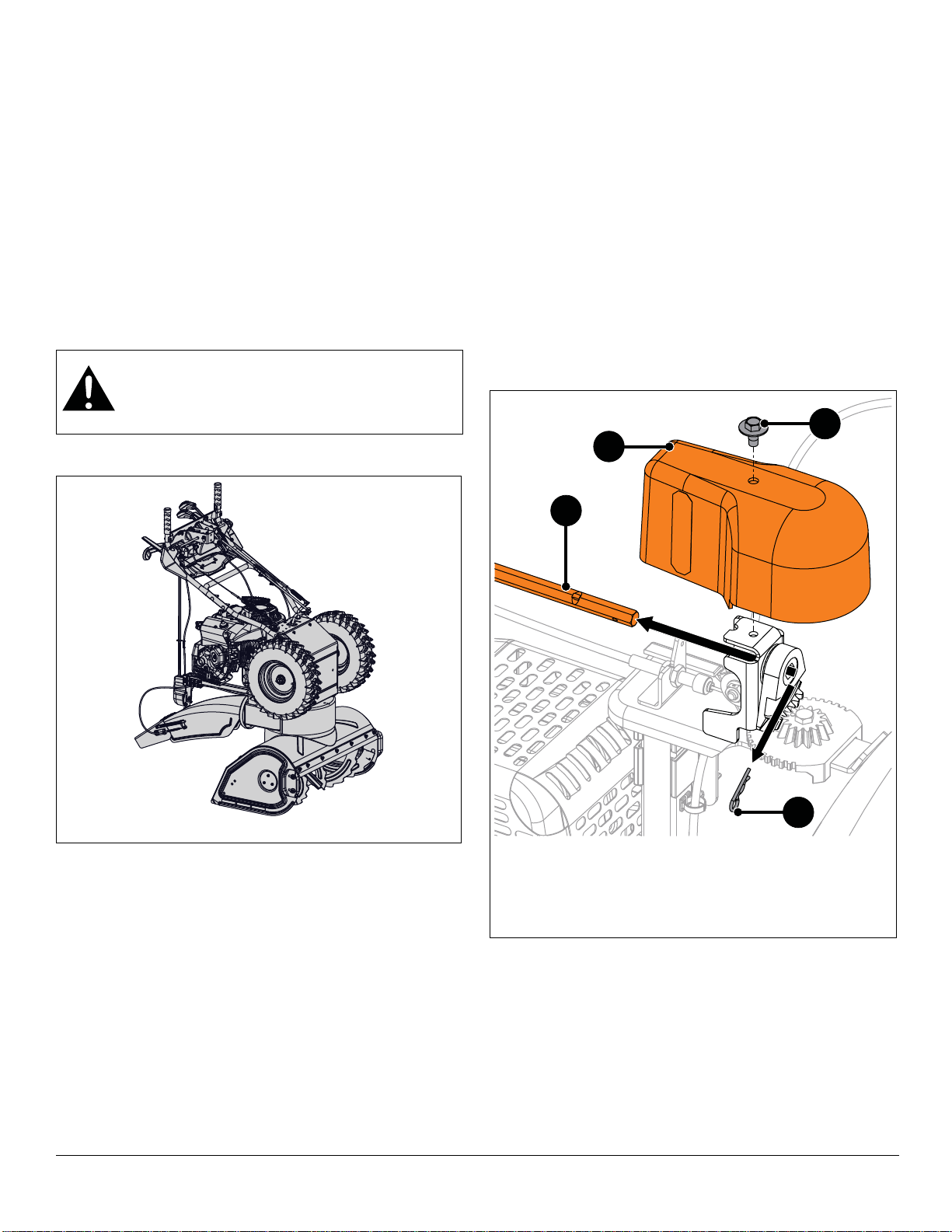

Figure 2

Figure 3

1. Tapping Screw

2. Chute Gear Cover

3. Hex Rod

4. Hairpin

1

2

3

4

SEPARATE HOUSING FROM FRAME

1. Move unit to an open, well-ventilated area with no

flames or sparks.

2. Remove fuel tank cap and siphon fuel into a clean

gasoline container.

3. Reinstall fuel tank cap and tighten.

4. Start engine to burn remaining fuel in fuel system and

leave engine running until it “runs dry” and stops.

Refer to Operator’s Manual for engine start procedure.

5. Stop engine, remove key and close fuel valve.

SERVICE POSITION

See Figure2.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

NOTICE: NEVER store unit in service position.

Remove Auger Housing

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for moving parts to

stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove hardware retaining chute gear cover to chute

pedestal and remove cover.

IMPORTANT: For Models 921045, 921046, 921047,

921048, 921049, 921323, 921324, 921325, advance to

step 7.

Model 921326

See Figure 3.

1. Remove hairpin from hex rod and remove hex rod

from chute gears.

EN – 7

See Figure4.

Figure 4

1. Hairpin

2. Chute Control Assembly

3. Sleeve Bushing

4. Cable Snap

5. Chute Lock Cable

6. Cable Eyelet

1

2

5

4

3

6

Figure 5

1. Tapping Screw

2. Chute Gear Cover

3. Spring Clip

4. Chute Rotation Rod

1

2

4

3

2. Remove hairpin and cable eyelet from chute control

assembly.

3. With a pliers, squeeze tabs on cable snap and remove

from chute control assemb ly.

4. Guide cable end through lower hole in chute control

assembly and through hole in dash panel.

IMPORTANT: Reinstall hairpin to chute control assembly

so parts are not misplaced.

Models 921045, 921046, 921047, 921048, 921049,

921323, 921324, 921325

7. Remove spring clip from chute rotation rod and

remove rod from chute gears. See Figure 5.

5. Remove hex rod from dash panel.

6. Advance to step 9.

8. Remove chute rotation rod from dash panel.

EN – 8

All Models

Figure 6

1. Sleeve Bushing

2. Hairpin

3. Cable Snap

4. Deflector Arm

5. Deflector Anchor

1

2

5

3

4

Figure 7

Figure 8

Figure 9

1. Hex Bolt

2. Locking Was he r

3. Flat Steel Washer

1

2

3

See Figure6.

9. Remove hairpin, sleeve bushing and cable eyelet from

deflector arm under dash panel.

10. With a pliers, squeeze tabs on cable snap and remove

from deflector anchor.

IMPORTANT: Reinstall sleeve bushing and hairpin so parts

are not misplaced.

See Figure 8.

12. Remove tapping screw securing left side of belt cover

to frame.

13. Loosen, but DO NOT remove tapping screw securing

right side of belt cover to frame and remove belt cover.

11. Remove chute deflector cable from J-clamp on engine

mount. See Figure7.

14. Remove hardware retaining belt finger to engine and

remove belt finger. See Figure 9.

EN – 9

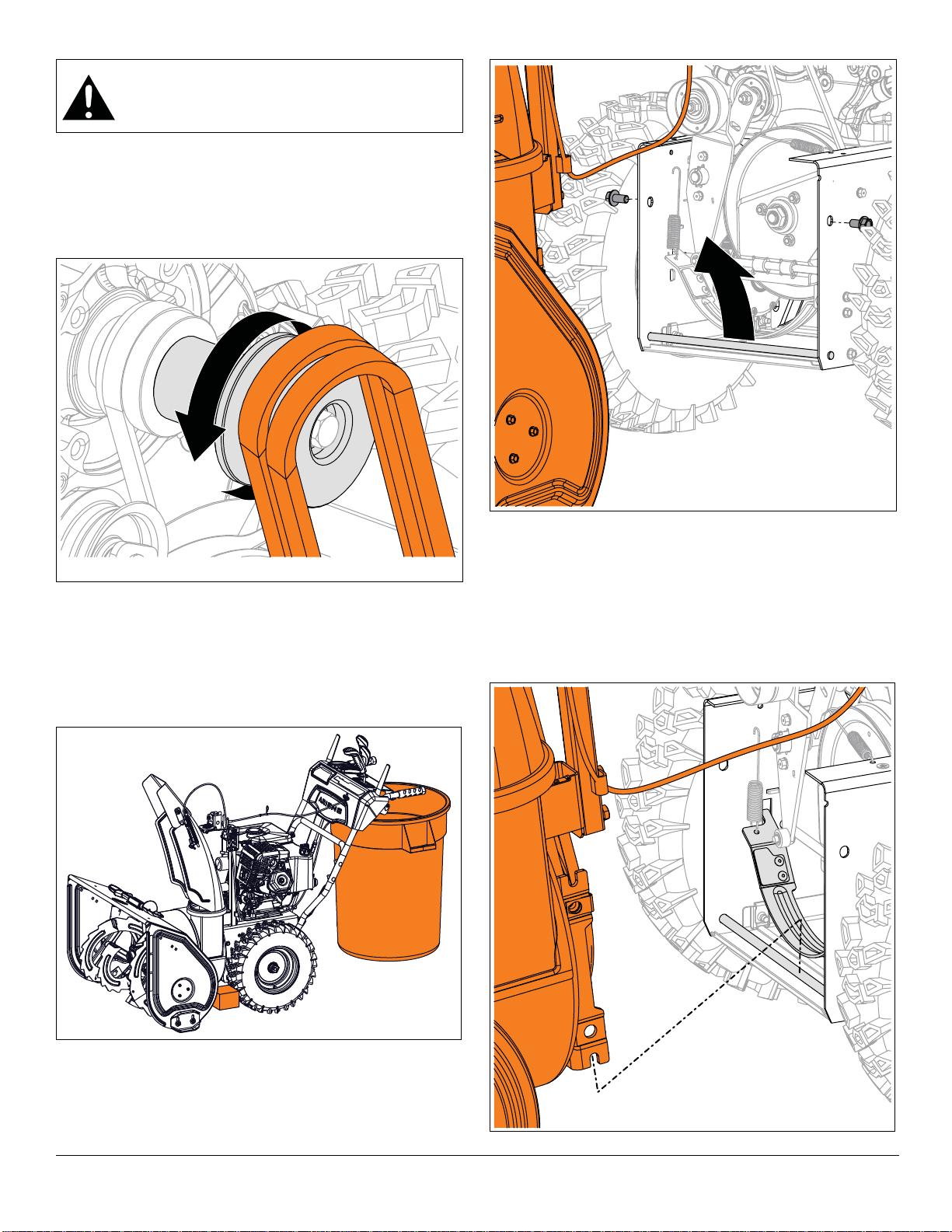

WARNING: AVOID INJURY. Attachment sheave

Figure 10

Figure 11

Figure 12

Figure 13

edges are sharp. Wear thick gloves to remove

belts from attachment sheave.

See Figure10.

15. Remove attachment drive belts from attachment

sheave.

To assist belt removal, slowly pull recoil starter handle

while gently guiding belts out of attachment sheave.

See Figure11.

16. Position support, such as a trash can, under

handlebars so tractor / frame remains upright when

separated from auger housing.

17. Chock or block wheels to prevent tractor / frame

movement.

Reinstall Auger Housing

See Figure 13.

1. With assistance from an adult helper, engage

attachment clutch lever so attachment brake will not

obstruct attachment drive pulley in step 2.

2. Tilt auger housing rear up and lower mount brackets

onto mount rod.

See Figure12.

18. Remove hardware securing auger housing to frame.

19. Lift auger housing rear slightly to disengage from

mount rod and separate from unit.

EN – 10

3. Release attachment clutch lever.

Figure 14

Figure 15

1. Belt Finger

2. Attachment Drive Belt s

Measure

Here

1

2

4. Align holes in mount brackets with holes in frame and

secure housing to frame with two hex bolts, but DO

NOT tighten.

IMPORTANT: Unit must be on a flat, level surface during

steps 5 – 7.

5. Check tire pressure and adjust if necessary. Refer to

Operator’s Manual for specification.

6. Torque hex bolts installed in step 4 to

33.8 – 70.1 N•m (24.9 – 51.7 lb-ft).

7. Loosen skid shoe hardware and adjust skid shoes.

Refer to Operator’s Manual for adjustment procedure.

See Figure14.

WARNING: AVOID INJURY. Attachment sheave

edges are sharp. Wear thick gloves to install

belts onto attachment sheave.

8. Reinstall attachment drive belts onto attachment

sheave.

To assist belt installation, slowly pull recoil starter handle

while gently guiding belts onto attachment sheave.

See Figure15.

9. Reinstall belt finger and secure with two flat steel

washers, two locking washers and two hex bolts.

10. Check belt finger clearance:

• Engage attachment clutch lever and make sure belt

finger located opposite belt idler is less than 3.2 mm

(1/8") from belt, but not touching the belt.

• If needed, adjust clearance by loosening hex bolts,

repositioning belt finger, and tightening bolts.

11. Reinstall belt cover and secure left side with tapping

screw. Position right side under tapping screw and

tighten.

IMPORTANT: For Model 921326, advance to step 15.

Models 921045, 921046, 921047, 921048, 921049,

921323, 921324, 921325

12. Reinstall short end of chute rotation rod into dash

panel until opposite end clears chute gears.

13. Insert chute rotation rod into chute gear and secure

with spring clip.

14. Advance to step 20.

Model 921326

15. Insert hex rod end without ears into dash panel until

opposite end clears chute gears.

16. Position discharge chute facing forward.

17. Position chute rotation lever upright and insert hex rod

through chute gear until it stops. Secure with hairpin.

18. Insert chute lock cable through hole in dash panel and

insert cable snap into chute control assembly.

19. Remove hairpin from chute control assembly and

reinstall cable eyelet onto assembly. Reinstall hairpin.

See Figure 4.

All Models

20. Reinstall gear cover and secure with tapping screw.

21. Reinstall chute deflector cable into J-clamp on engine

mount.

EN – 11

22. Reinstall deflector cable snap onto deflector anchor.

Figure 16

23. Remove sleeve bushing and hairpin from deflector

arm and reinstall cable eyelet onto deflector arm.

Reinstall sleeve bushing and hairpin. See

Figure 6.Reconnect spark plug wire.

IMPORTANT: Check all adjustments after first use.

WARNING: AVOID INJURY. Auger / impeller

must stop within 5 seconds when attachment

clutch lever is released.

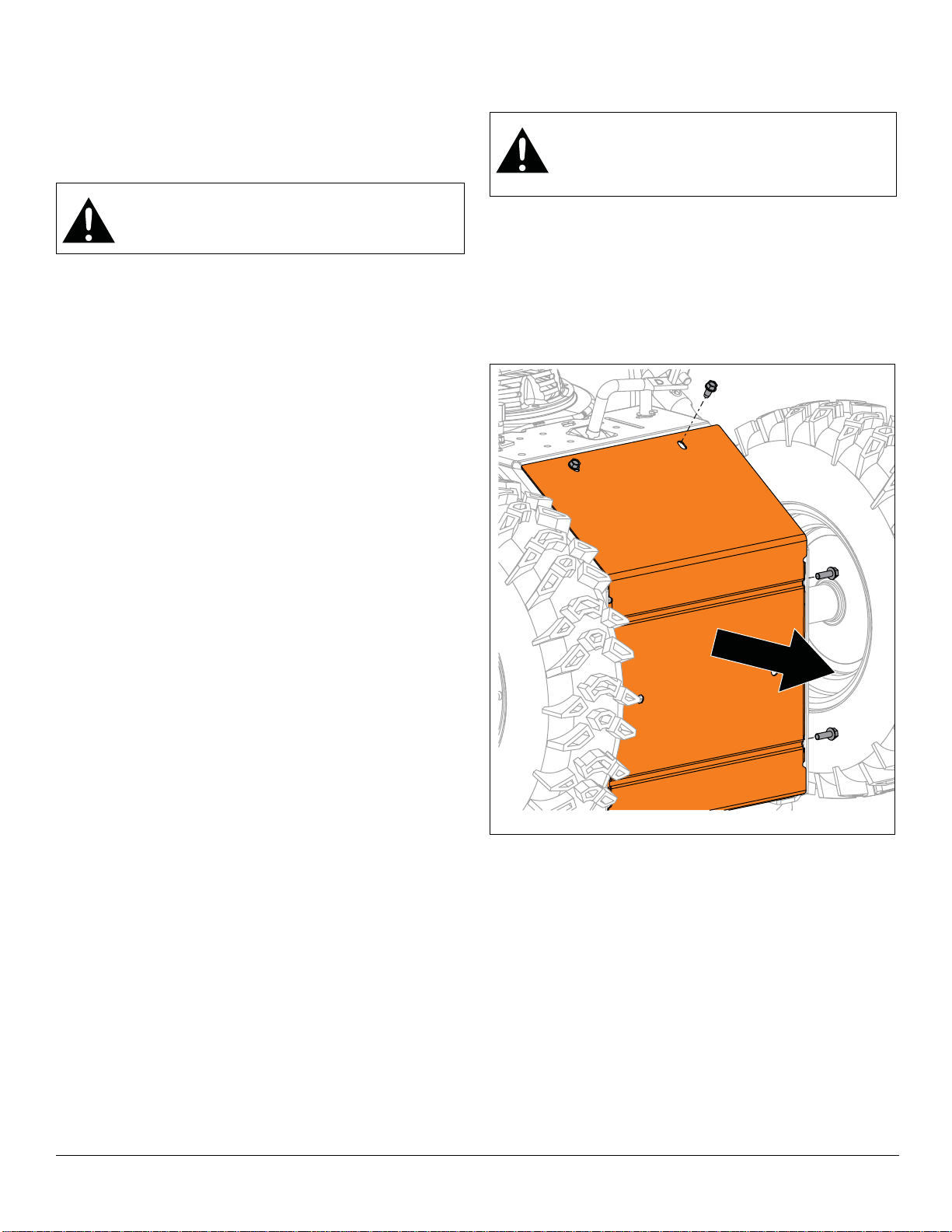

BOTTOM COVER REMOVAL

IMPORTANT: Save all hardware for reinstallation.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

1. Stop engine, remove key and wait for all moving parts

to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Place unit in service position. See Service Pos it i on on

page 7.

4. Remove hardware retaining bottom cover to frame

and remove cover. See Figure 16.

IMPORTANT: For track models, track angle must be in the

“Raised Position” to remove bottom cover. Refer to

Operator’s Manual. See Figure 17.

EN – 12

Install Bottom Cover

Figure 17

Figure 18

1. Reinstall bottom cover and secure with two tapping

screws and four hex bolts.

2. Return unit to operating position.

ATTACHMENT DRIVE BELT REPLACEMENT

Remove Attachment Drive Belts

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts

to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From

Frame on page 7.

4. Remove attachment drive belts from attachment drive

pulley. See Figure 18.

Install Attachment Drive Belts

1. Install belts onto attachment drive pulley.

2. Reinstall auger housing to frame. See Reinstall Auger

EN – 13

Housing on page 10.

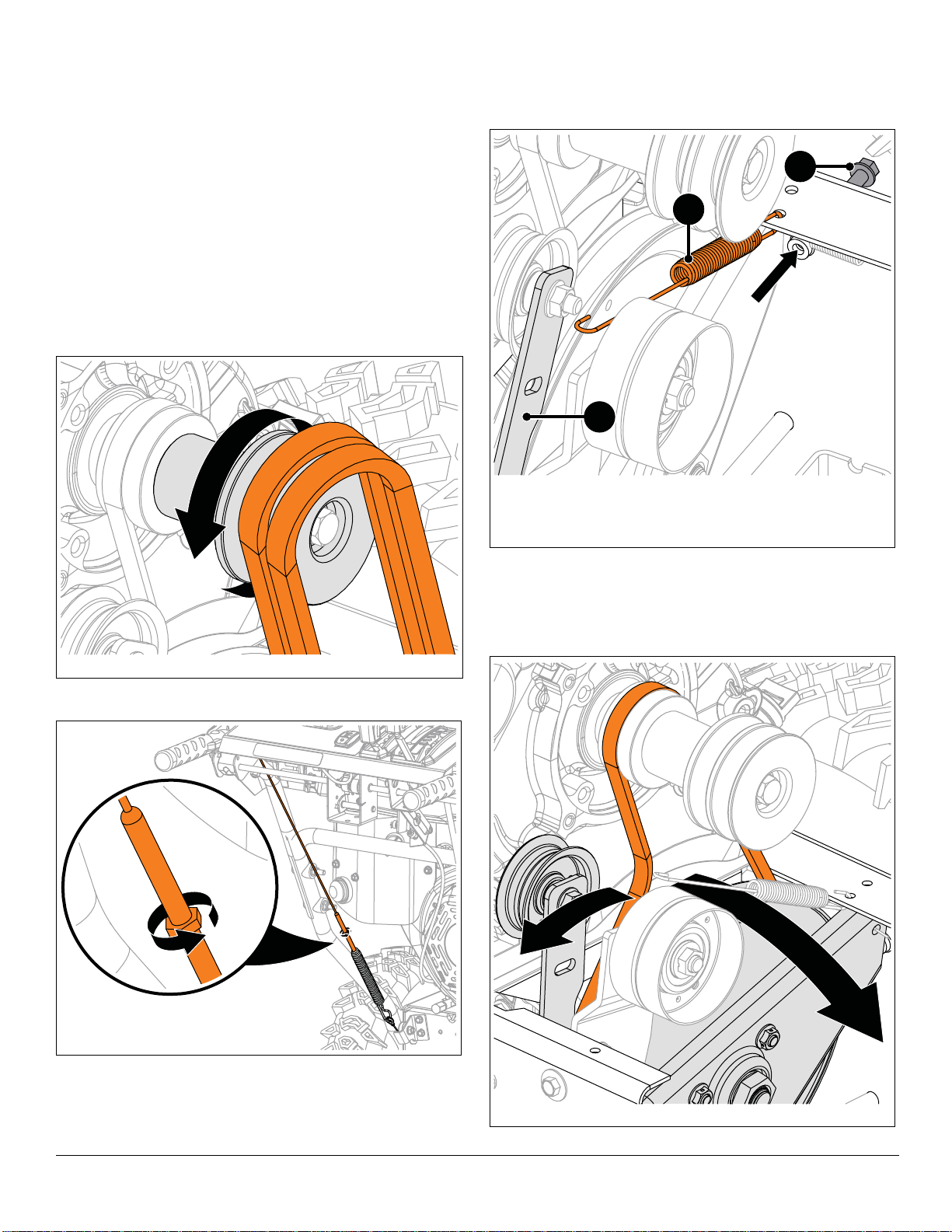

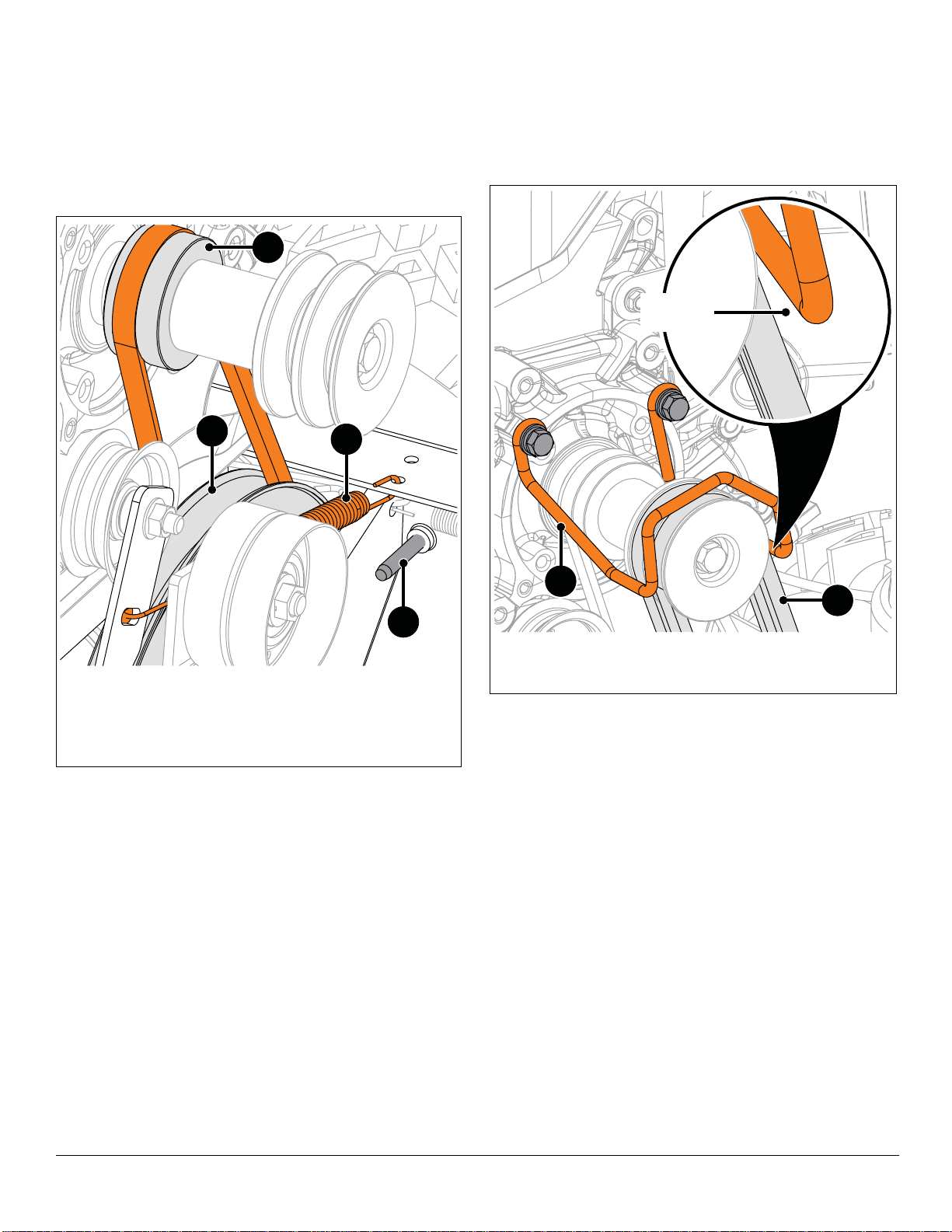

TRACTION DRIVE BELT

Figure 19

Figure 20

Figure 21

1. Idler Spring

2. Traction Idler Arm

3. Stop Bolt

1

2

3

Figure 22

REPLACEMENT

Remove Traction Drive Belt

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts

to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove belt cover and belt finger as shown in

Figure 8 and Figure 9.

4. Slowly pull recoil starter handle while gently guiding

attachment belts off engine sheave. See Figure 19.

To assist belt removal, slowly pull recoil starter handle

while gently guiding belts out of attachment sheave.

See Figure 21.

6. Disconnect idler spring from traction idler arm.

7. Remove stop bolt from frame.

5. Loosen traction drive clutch cable. See Figure 20.

See Figure 22.

8. Rotate traction idler arm away from belt and rotate

swing gate assembly forward.

9. Remove belt.

EN – 14

Install Traction Drive Belt

Figure 23

1. Traction Sheave

2. Traction Drive Pulley

3. Stop Bolt

4. Traction Idler Spring

1

2

4

3

Figure 24

1. Belt Finger

2. Attachment Drive Belt s

Measure

Here

1

2

See Figure23.

1. Install belt onto traction sheave and around traction

drive pulley.

2. Return swing gate assembly to upright position and

reinstall stop bolt.

3. Reinstall traction idler spring onto traction idler arm.

6. Check belt finger clearance:

• Engage attachment clutch lever and make sure belt

finger located opposite belt idler is less than 3.2 mm

(1/8") from belt, but not touching the belt.

• If needed, adjust clearance by loosening hex bolts,

repositioning belt finger, and tightening bolts.

4. Reinstall attachment drive belts onto attachment

sheave.

To assist belt installation, slowly pull recoil starter handle

while gently guiding belts onto attachment sheave.

See Figure24.

5. Reinstall belt finger and secure with two flat steel

washers, two locking washers and two hex bolts.

7. Adjust traction drive clutch. Refer to Operator’s

Manual for adjustment procedure.

8. Reconnect spark plug wire.

IMPORTANT: Check all adjustments after first use.

EN – 15

ATTACHMENT BRAKE REPLACEMENT

Figure 25

1. Top Locking Flange Nut

2. Hex Bolt

3. Attachment Brake Arm

4. Extension Spring

1

2

4

3

Figure 26

Attachment Clutch Disengaged / Brake Engaged

1. Brake Pad

2. Brake Roller

1

2

Figure 27

Attachment Clutch Engaged / Brake Disengaged

1. Brake Pad

2. Brake Roller

1

2

Remove Attachment Brake

IMPORTANT: Save all hardware for reinstallation.

1. Stop engine, remove key and wait for all moving parts

to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Remove auger housing. See Separate Housing From

Frame on page 7.

See Figure25.

4. Disconnect extension spring from attachment brake

arm.

5. Remove hardware retaining attachment brake arm to

brake mount bracket.

6. Remove brake arm.

See Figures 26 and 27.

3. Engage and disengage attachment clutch to verify

brake roller on attachment idler does not interfere with

brake pad.

IMPORTANT: Make sure brake roller does not bind.

Install Attachment Brake

1. Position pivoting end of attachment brake arm in brake

mount bracket and secure with one hex bolt and top

locking flange nut, but DO NOT overtighten.

2. With flathead screwdriver or similar pry bar, reconnect

extension spring to attachment brake arm.

4. Reinstall auger housing to frame. See Reinstall Auger

Housing on page 10.

EN – 16

WARNING: AVOID INJURY. Before placing unit

Figure 28

1. Brake Pad

2. Attachment Pulley & Belt

1

2

Figure 29

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

5. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Bottom

Cover Removal on page 12.

See Figure28.

6. Check attachment brake:

• When attachment clutch is disengaged, brake must

contact attachment belt or pulley, whichever is

closest.

• When attachment clutch is engaged, brake must be

more than 1.6 mm (1/16”) away from attachment belt

or pulley, whichever is closest.

IMPORTANT: If attachment clutch / brake is out of

adjustment, refer to Operator’s Manual for adjustment

procedure.

FRICTION DISC REPLACEMENT

Remove Friction Disc

IMPORTANT: Save all hardware for reinstallation.

WARNING: AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See Draining Fuel System on page 7.

Make sure unit is secure and will not tip.

1. Stop engine, remove key and wait for all moving parts

to stop and for hot parts to cool.

2. Disconnect spark plug wire from engine.

3. Place unit in service position and remove bottom

cover. See Service Position on page 7 and Bottom

Cover Removal on page 12.

See Figure 29.

4. Remove hairpin securing adjustment pivot pin to shift

arm.

5. Remove adjustment pivot pin from shift arm.

7. Reinstall bottom cover and secure with two tapping

screws and four hex bolts.

8. Return unit to operating position.

9. Reconnect spark plug wire and fill fuel tank.

IMPORTANT: Check all adjustments after first use.

WARNING: AVOID INJURY. Auger / impeller

must stop within 5 seconds when attachment

clutch lever is released.

6. Remove snap clips from axle ends and remove

wheels.

7. Remove hardware securing bearing to left side of

frame and remove bearing. See Figure 30.

EN – 17

8. Remove two spring clips from hex shaft. See

Figure 30

1. Bearing Flange

2. Hex Shaft

3. Bearing

1

2

3

Figure 31

Figure 32

Figure 31.

9. Remove hex shaft from friction disc assembly and

remove friction disc assembly. See Figure 32.

EN – 18

Install Friction Disc

Figure 33

Figure 34

Figure 35

1. Install friction disc assembly around shift fork roller

bearing and align with hex shaft. See Figure 33.

2. Reinstall hex shaft through friction disc, pinion

sprocket and into frame. See Figure 34.

6. Reinstall adjustment pivot pin onto shift arm and

secure with hairpin.

7. Reinstall bottom cover and secure with two tapping

screws and four hex bolts.

8. Reinstall wheels onto axle and secure with snap clips.

9. Return unit to operating position.

10. Fill fuel tank and reconnect spark plug wire.

11. Adjust speed selector lever. Refer to Operator’s

Manual for adjustment procedure.

IMPORTANT: Check all adjustments after first use.

See Figure35.

3. Reinstall spring clips into hex shaft.

4. Reinstall bearing onto hex shaft end.

5. Reinstall bearing flange over bearing and secure to

frame with three tapping screws.

EN – 19

Loading...

Loading...