Page 1

Date: February 26, 2014 No. C-2014R

Replaces C-2014

Service Campaign

Ariens Company

655 W. Ryan St.

Brillion, WI 54110

www.ariens.com

Product Family: Ariens Compact Sno-Thro, Ariens Compact Track Sno-Thro, Sno-Tek,

Ariens PB-28, Gravely PB- 28

Subject: Important Product Safety Recall

Dealer Action: STOP SALE – Repair Immediately

Ariens Company has identified a potential safety concern on models and serials listed in the table below.

The auger drive pulley, #00268951, may develop a crack which could affect the brake's ability to stop the

auger/impeller, resu lti ng in an uns afe co ndi tio n.

Dealers are instructed to Stop Sale Immediately

serial ranges listed. Additionally, dealers are asked to contact consumers who purchased affected

machines from your dealership to coordinate repair of those machines as soon as possible. Ariens

Company is sending a letter to registered owners of all affected machines alerting them to this situation.

Ariens Company has been reworking product since this issue was identified, and all machines which have

been reworked by Ariens Company will have a black check mark on the carton label as well as the model/

serial label on the machine.

Dealers are asked to order kit #52001800 and install it on each affected unit. The kit consists of a

replacement pulley and hub assembly. Dealers should file a warranty claim for each pulley replacement

using a flat rate code of 20999. Please make sure that the machine is within the model/serial numbers

listed below. Warranty claims will be reimbursed for 0.50 at the dealer's standard shop labor rate.

Please direct any questions to Ariens Technical Service at:

of any unsold inventory which falls into the model and

(888) 927 – 4367

Page 1 of 8

Page 2

Date: February 26, 2014 No. C-2014R

Replaces C-2014

Model Description Serial Number Range

920013 Ariens ST22LE Compact

Sno-Thro

920014 Ariens ST24LE Compact

Sno-Thro

920021 Ariens ST22LE Compact

Sno-Thro

920022 Ariens ST24LET

Compact Track Sno –

Thro

920402 Sno-Tek 24E 143967 – 145036, 145062, 145095, 145097, 145500 – 145591,

920403 Sno-Tek 28E 126501 – 127141, 127143 – 127145, 127185, 127197 – 127237,

921025 Ar iens PB-28 All-S eason

Brush

921026 Gravely PB-28 All-

Season Brush

921313 Ariens 28” Brush – CE 40163 – 40174

939401 Sno-Tek 20E 90112, 90140 – 90619, 90621 – 90623

124912 – 124935, 124937 – 125008, 125037 – 125060,

125094 – 125271

142966 – 142999, 143264 – 143272, 143274 – 143281,

143284 – 143287, 143289, 143291 – 143304, 143306 – 143309,

143313 – 143432, 143434 – 143435, 143439 – 143445, 143448,

143450 – 143462, 143466 – 143467, 143469 – 143496, 143500,

143502 – 143506, 143511, 143513 – 143518, 143520 – 143535,

143700 – 143728

3089 – 3100, 3510 – 3940, 3942 – 4360, 4363, 4365 – 4372,

4374 – 4377, 4382 – 4384, 4386, 4389 – 4398, 4400, 4404 – 4405,

4409, 4411 – 4415, 4418 – 4593, 4595 – 4617, 4619 – 4621, 4623 –

5815, 5817, 5819 – 5847, 5849 – 5883, 5885 – 5886, 5893 – 5895,

5899, 6000 – 6151, 6153 – 6172

531 – 576, 701 – 712

145593 – 145594, 145596, 145598 – 145699, 146057

127241 – 127291, 127293 – 127326, 127328 – 127338,

127340 – 127341

40600 – 40660

40061 – 40079

ATTACHMENT DRIVE BELT PULLEY REPLACEMENT – SNO-TH RO & SNO-TE K MODELS

Models 920013, 920014, 920021, 920022, 920402, 920403, 939401

Remove Attachment Drive Belt

(Figures 1, 2 and 3)

1. Shut off engine, remove key, disconnect spark plug wire and allow unit to cool completely.

2. Loosen the hardware securing belt cover to unit.

NOTE: DO NOT completely remove the hardware from unit.

3. Remove belt cover.

4. Remove gear cover from top of chute pedestal.

5. Remove spring clip pin from chute crank and separate.

6. Remove remote deflector control cable from control lever if equipped).

7. Remove belt finger by removing cap screws mounting belt finger to engine (Figure 2).

8. Remove attachment drive belt from engine sheave (it may be necessary to turn engine sheave using

recoil starter handle).

Page 2 of 8

Page 3

Date: February 26, 2014 No. C-2014R

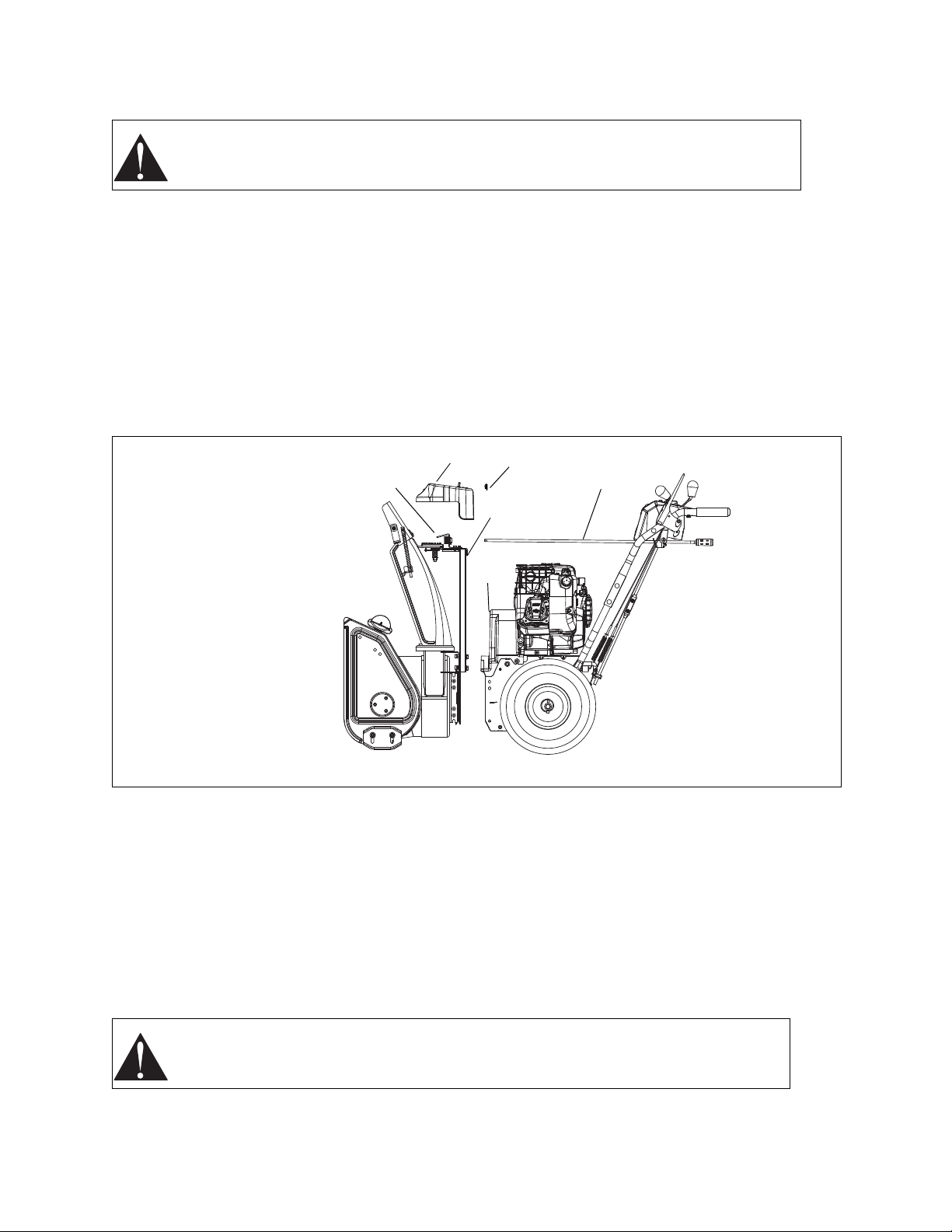

Figure 1

1

2

3

4

1. Pinion Gear

2. Belt Cover

3. Spring Clip Pin

4. Chute Crank

5. Gear Cove r

6. Chute Pedestal

6

5

Replaces C-2014

CAUTION: Always support Sno-Thro frame and housing when loosening the cap screws

holding them together. Never loosen cap screws while unit is in service position.

IMPORTANT: To avoid bending bottom cover when tipping unit apart, support handlebars firmly or tip unit

up on housing and remove bottom cover by removing six cap screws before separating unit.

9. Support Sno-Thro frame and housing.

10. Remove hex bolts securing housing to frame (two on each side). Tip housing and frame apart on

pivot pin.

11. Separate housing from unit.

12. Remove attachment drive belt from attachment pulley.

13. Remove attachment pulley and discard. DO NOT reuse pulley.

14. Replace attachment pulley with kit #52001800. Torque to 120 lbs-in.

Replace Attachment Drive Belt

NOTE: Engage attachment clutch lever while connecting housing to frame to hold brake out of the way.

IMPORTANT: With the attachment clutch lever engaged, the belt finger located opposite the belt idler must

be less than 1/8" (3.2 mm) from the belt, but not touching the belt, or belt grabbing may occur causing

impeller to rotate while the attachment clutch is disengaged (Figure 3).

1. Place new belt onto attachment pulley (Figure 2).

2. Tip housing and frame back together and secure with hex bolts.

3. Place belt onto engine sheave.

4. Replace belt finger.

5. Adjust clutch (see Attachment Clutch/Brake Adjustment on page 5).

WARNING: AVOID INJURY. Auger must stop within 5 seconds when attachment lever

is released or serious injury or unit damage may result.

Page 3 of 8

Page 4

Date: February 26, 2014 No. C-2014R

Figure 2

5

3

2

1

6

7

4

1. T r a cti on Belt Idler

2. Traction Drive Belt

3. Engine Sheave

4. Belt Finger

5. Attachment Drive Belt

6. Attac hm ent Pull ey

7. Attac hm ent Idle r Nut

8. Attac hm ent Belt Idler

8

Figure 3

1.Belt Finger

2.Attachment Drive Belt

3.Swing Gate Pivot Bushing

1

2

1/8" (3.2 mm)

(Maximum)

3

6. Replace chute crank and secure with spring clip pin.

• If Equipped: Reconnect remote deflector cable to control lever.

7. Replace gear cover on top of chute pedestal.

8. Run in the attachment belt(see Run-in Attachment Belt on page 4).

9. Replace belt cover and tighten hardware.

Replaces C-2014

RUN-IN ATTACHMENT BELT

1. Start unit in a well-ventila ted area.

2. Engage attachment clutch lever and run attachment for about 15 minutes.

3. Stop unit, wait for all moving parts to stop, and remove spark plug wire.

4. Adjust clutch idler (see Attachment Clutch/Brake Adjustment on page 5).

Page 4 of 8

Page 5

Date: February 26, 2014 No. C-2014R

Figure 4

1.Attachment Clutch Cable

2.Cable Adjustment Barrel

3.Jam Nut

2

3

1

Replaces C-2014

ATTACHMENT CLUTCH/BRAKE ADJUSTMENT

WARNING: IMPROPER ADJUSTMENT could result in unexpected movement of auger and

impeller causing death or serious injury. AUGER / IMPELLER MUST STOP within 5 seconds

when Attachment Clutch Lever is released.

WARNING: Adjustment procedure requires the engine to be run with the belt cover off.

AVOID INJURY. Read and understand the entire Safety section before proceeding.

Remove Attachment Cable Slack

(Figures 4 and 5)

1. Shut off engine, remove key, disconnect spark plug wire and allow unit to cool completely.

2. Loosen hardware securing belt cover to unit.

3. DO NOT completely remove the hardware from unit.

4. Remove belt cover.

5. Loosen jam nut on cable adjustment barrel, and then turn the adjustment barrel down to shorten

cable and remove all cable slack (Figure 4).

6. With the attachment clutch disengaged, check that the attachment idler arm lightly touches the frame

(Figure 5).

7. Tighten jam nut on cable adjustment barrel.

Page 5 of 8

Page 6

Date: February 26, 2014 No. C-2014R

Figure 5

With the attachment clutch

disengaged, check the

attachment idler arm position

here. The attachment idler arm

should lightly touch the frame.

Draw check mark on model/

serial number label.

Figure 6

Replaces C-2014

8. Draw a check mark on the model/serial number label with an indelible black marking pen to signify

that the repair has been completed (Figure 6).

Page 6 of 8

Page 7

Date: February 26, 2014 No. C-2014R

-A--A-

Figure 7

1.Brush Assembly

2.Cable Attaching Hardware

3.Remote Trigger Cable

4.Bottom Cover

5.Assembly Bolt Holes

1

2

3

4

5

Replaces C-2014

ATTACHMENT DRIVE BELT PULLEY REPLACEMENT – POWER BRUSHES

Models 921025, 921026, 921313

Remove Attachment Drive Belt

(Figures 7 and 8)

1. Shut off engine, disconnect spark plug wire and allow unit to cool completely.

2. Remove the hardware attaching the remote trigger cable to the brush assembly.

3. Remove two screws securing belt cover to unit and remove belt cover.

4. Remove belt finger by removing cap screws mounting belt finger to engine (Figure 8).

5. Remove attachment drive belt from engine sheave (it may be necessary to turn engine sheave using

recoil starter handle).

WARNING: Always support Sno-Brush frame and brush assembly when

loosening the cap screws holding them together.

IMPORTANT: To avoid bending bottom cover, when tipping unit apart, support handlebars firmly and

remove bottom cover by removing six cap screws before separating unit.

6. Support frame and brush assembly.

7. Remove cap screws holding brush assembly to frame (two on each side).

8. Separate assembly from unit. Lower handlebar on floor.

9. Remove attachment drive belt from lower pulley (hold brake away from belt).

10. Remove attachment pulley and discard. DO NOT reuse pulley.

11. Replace attachment pulley with kit #52001800. Torque to 120 lbs-in.

Replace Attachment Drive Belt

(Figures 8 and 9)

1. Place new belt onto lower pulley and while holding brake out of way, tip unit together.

2. Secure brush to frame with cap screws.

3. Place belt onto engine sheave.

4. Replace belt finger.

Page 7 of 8

Page 8

Date: February 26, 2014 No. C-2014R

Figure 8

5

3

2

1

6

7

8

4

1.Traction Belt Idler

2.Traction Drive Belt

3.Engine Sheave

4.Belt Finger

5.Attachment Drive Belt

6.Attachment Pulley

7.Attachment Idler Nut

8.Attachment Belt Idler

Figure 9

1.Belt Finger

2.Belt

1

2

1/8in. (3.18mm)

(Maximum)

Replaces C-2014

IMPORTANT: With the clutch lever engaged, the belt finger located opposite the belt idler must be less

than 1/8 in. (3.2 mm) from the belt, but not touching the belt, or belt grabbing may occur causing brush to

rotate while the attachment clutch is disengaged (Fig ure 9).

5. Adjust clutch (see Attachment Clutch/Brake Adjustment on page 5).

6. Replace belt cover and secure with cap screws.

7. Replace bottom cover and secure with cap screws.

8. Reinstall remote trigger cable to brush assembly.

9. Run in the attachment belt (see Run-in Attachment Belt on page 4).

10. Replace the belt cover.

11. Draw a check mark on the model/serial number label with an indelible black marking pen to signify

that the repair has been completed. See Figure 6.

Page 8 of 8

Loading...

Loading...