Page 1

■'iT'

935000 SERIES 8 & 11 H.P. YARD TRACTORS

Model 935004 (YT8-32) 8 H.P.

Gear Drive with 32” Mower

Serial No. 000601 and up

Model 935003 {YT11-38) 11 H.P.

Gear Drive with 38” Mower

Serial no. 000101 and up

Model 935005 {YT11-32) 11 H.P.

Gear Drive with 32” Mower

Serial no. 000282 and up

ATTACHMENTS

Model 835004

32” Mower Attachment

Serial no. 000101 and up

Model 835005

38” Mower Attachment

Serial no. 000101 and up

"Ifk

/4 MESSAGE TO THE ARIENS CUSTOMER. . .

Welcome to the world of Ariens equipment. We are

pleased that you have selected Ariens and sincerely

believe you have purchased the best equipment

available. The care you give your new Ariens equip

ment will greatly determine the satisfaction and service

life you will obtain from it. Use this manual and the

engine manual supplied, as your guide. By observing

the instructions and suggestions in these manuals,

your Ariens equipment will serve you well for many

years.

Your Ariens dealer will be happy to supply any service

or advice which may be required to keep your Ariens

equipment operating at peak_fi£ficiency. He stocks

genuine Ariens parts and lubricants; manufactured

with thé same precision and skill as the original equip

ment. His factory trained staff is kept well informed on

(Törtens

(>ART NUMBER 35318A

COMPANY BRILLION, WISCONSIN 54110

"A CUT ABOVE THE REST!"

the best methods of servicing Ariens equipment and is

ready and able to serve you. If engine repairs or ser

vices are required, they can be obtained from an Ariens

dealer or from an authorized engine manufacturer's

service station.

Should service be required on equipment, be prepared

to supply the serviceman with the Model Number and

Serial Number of the equipment and the engine, as well

as a full description of the trouble encountered.

Finally, your local Ariens dealer is in the best position to

answer your questions and service equipment. If for

some reason he is unable to satisfy your requirements,

assistance is always available from the Consumer

Services, Ariens Company, Brillion, Wisconsin 54110.

Telephone; (414) 756-2141.

PRINTED IN U.S.A.

Page 2

INSTRUCTIONS FOR SAFE OPERATION

1. know the controls and how to stop quickly. READ

THE OWNER'S MANUAL.

2. Do not allow children to operate the vehicle. Do

not allow adults to operate it without proper in

struction.

3. Do not carry passengers. Keep children and pets a

safe distance away.

4. Clear the work area of objects which might be

picked up and thrown.

5. Sit on seat, disengage traction and attachment

power and shift into neutral before attempting to

start the engine.

6. Disengage power to attachment, stop the engine

and place speed selector to "NEUTRAL” position

and set parking brake lock before leaving the

operator's position.

7. Disengage power to attachment and stop the

engine before making any repairs or adjustments.

8. Disengage power to attachment when transpor

ting or or not in use.

9. Take all possible precautions when leaving the

vehicle unattended, such as disengaging the at

tachment power, lowering the attachment, shif

ting into neutral, setting the parking brake lock,

stopping the engine and removing the key.

10. Do not stop or start suddenly when going uphill or

downhill. Operate up and down the face of steep

slopes; never across the face. If you cannot back

up the hill, DO NOT operate the tractor on it. It is

too steep for safe operation.

11. Reduce speed on slopes and in sharp turns to pre

vent tipping or loss of control. Exercise extreme

caution when changing direction on slopes.

1 2. Stay alert for holes in the terrain and other hidden

hazards.

1 3, Use care when pulling loads or using heavy equip

ment.

a. Use only approved hitch points

b. Limit loads to those you can safely control.

c. Do not turn sharply. Use care when backing.

d. Use counterweight when suggested in the 1

tor owner's manual or in the attachment

owner's manual.

14. Watch out for traffic when crossing or near road

ways.

15. When using any attachments, never direct

discharge of material toward bystanders nor allow

anyone near the vehicle while in operation.

16. Handle gasoline with care—it is highly flammable.

a. Use approved gasoline container.

b. Never remove the cap of the fuel tank or add

gasoline to a running or hot engine, or fill the

fuel tank indoors. Wipe up spilled gasoline.

1 7. Never store the equipment with gasoline in the

tank inside a building where fumes may reach an

open flame or spark. Allow the engine to cool

before storing in any enclosure.

18. Exhaust fumes are dangerous. Do not run the

engine indoors.

19. Keep the vehicle and attachments in good

operating condition, and keep safety devices in

place.

20. Keep all nuts, bolts, and screws tight to be sure

the equipnnent is in safe working condition.

21. To reduce fire hazard, keep the engine free of

grass, leaves, or excessive grease.

22. The vehicle and attachments should be stopped

and inspected for damage after striking a foreign

object, and the damage should be repaired before

restarting and operating the equipment, see items

6 & 7.

23. Do not change the engine governor settings or

overspeed the engine.

24. When using the vehicle with mower, proceed as

follows:

a. Mow only in daylight or in good artificial light.

b. Shut the engine off when unclogging chute.

c. Check the blade mounting bolts for proper

tightness at frequent intervals.

d. Always look behind you before backing up.

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT SAFETY INFORMA

TION IN THIS MANUAL. WHEN YOU SEE THE SYMBOL BE ALERT TO THE

POSSIBILITY OF INJURY AND CAREFULLY READ THE INFORMATION THAT

A

FOLLOWS.

A

-2-

Page 3

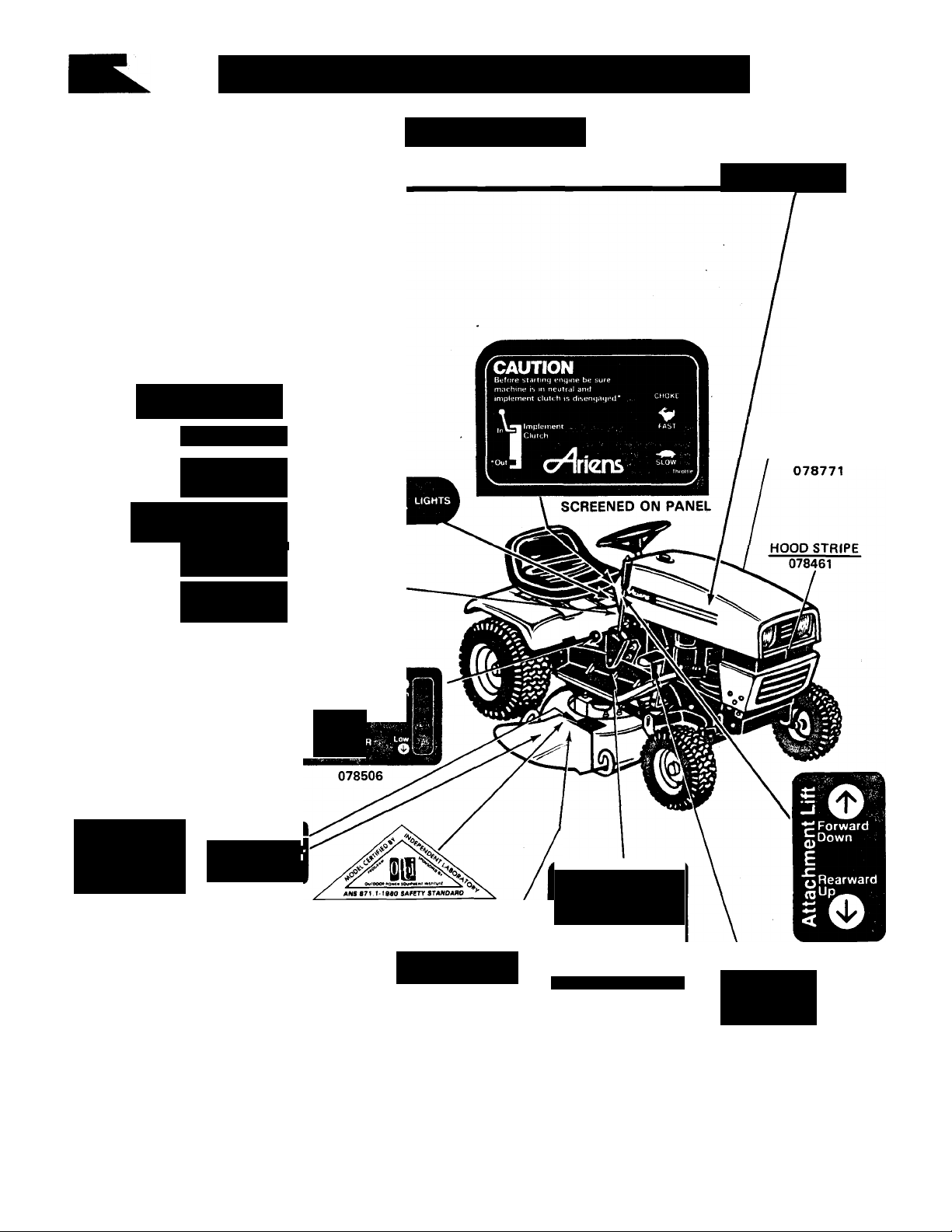

BE AWARE OF SAFETY DECALS

078810 R.H. 078813 R.H.

YT8 YT11

(935004 only) (935003, 5 only)

C7^riens\TFi!1l '

078809 L.H. 078812 R.H.

YT8 YTI1

(935004 only) (935003, 5 only)

CAUTION

■ Hc.Hlooer.itorsfn.-inuai

» Keep bfiK-irts if> place

• Keep people ,iru3 pels a safe

GO

• Heie.ise pjrktnq bfake ‘ . .

• Oi'press cloif h pedal • ■

• Sliift lo rtesiit'd speed • ’ ,

• Slowly'eie.ise dulcb

STOP

• Ofpiess ciuiicn pedal

• Oepress Bf.iKe pecla'

• Beto'p le.iviiiq opeirfto's

d);

posdton

Shift to neotr.p ^ ■

f riqaqe p.ifkirq brake

Oisemi.iqi' aliachment clulch

Shut off Ei'qine

Upmove iqnthon key

SERVICING

• Wait loi all movement to stop

• niscormecf spark plug wire ■

• Hi’loie lipptriq unit, oraii'

qas tank and remove • . '

cT^riens^y

^X-N-FU)P^

078547

ROTATING PARTS

• Keep hands and feet

away from under

entire housing

• Do not operate mower

unless grass catcher is

attached or mower guard

is in operating position

078735

078556

ROTATING PARTS

K««p narvls and taol away from ira

entir« horoing

Do not operate mower rakesa iraM

caitfwr !• attached nr mower guard

■a in novating paaiflSi

078779

-■v-J'

NO STEP

078508

-3-

Parking Brake

Depress Brake Pedal

Then Engage Parking

Brake Lock

Disengage Engage

078738

Depress brake pedal

then lift parking

brake lock.

ENGAGED &

©DISENGAGED

078584

078505

Page 4

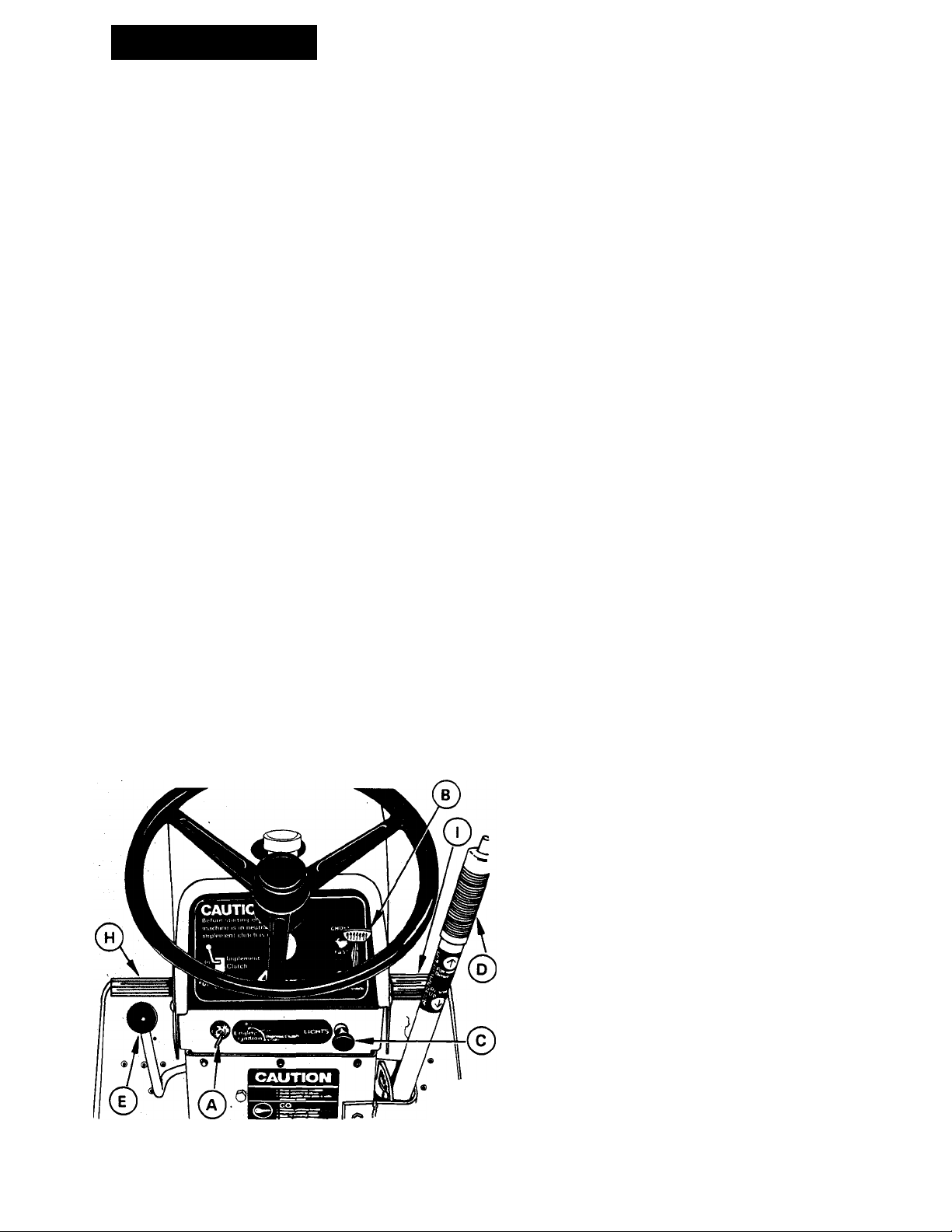

CONTROLS

@IGNITION AND STARTER SWITCH - FIGURE 1 (e)IMPLEMENT POWER CLUTCH - FIGURE 1

The ignition and starter switch has three positions:

"OFF", "RUN", and "START". Start the engine by

turning the key fully clockwise to "START" position

and then release the key as soon as the engine starts.

Stop the engine by turning the key counterclockwise to

the "OFF" position.

THROTTLE-CHOKE CONTROL LEVER - FIGURE 1

This control operates both the throttle and choke.

When starting a cold engine, raise the lever past the

offset and into the "CHOKE" position. After the engine

has started, lower the lever to the throttle operating

range and allow the engine to warm at 14 throttle.

Select the appropriate engine speed in the throttle

range after the engine has warmed up.

NOTE; UNLESS OTHERWISE SPECIFIED, THE AT

TACHMENTS SHOULD BE OPERATED AT FULL

THROTTLE. THE THROTTLE IS NOT TO BE USED TO

SELECT DESIRED TRAVEL SPEEDS. OPERATE AT

FULL THROTTLE AND REGULATE GROUND SPEED

WITH THE GEAR SHIFT LEVER.

LIGHT SWITCH - FIGURE 1

©

Turn lights on by pulling the control knob out. Turn

lights off by pushing the knob in.

ATTACHMENT LIFT LEVER - FIGURE 1

©

To raise the attachment, depress thumb button, pull

the lever to the rear, and release thumb button. This

will hold the attachment in the raised position. When

using the mower attachment; select the "notch" that

allows the mower to cut at the desired height.

To lower the attachment, pull the lever to the rear,

depress the button to release the latch and allow the

lever to move forward.

The Implement Power Clutch is used to operate the at

tachments. Push the lever forward to engage the clutch

and drive the attachment. Pull the lever rearward to

disengage the clutch and stop the attachment. The

lever must be in the rear (disengaged) position to start

the engine. THIS IS A SAFETY FEATURE. The engine

will not start until the lever has been placed in the

disengaged position.

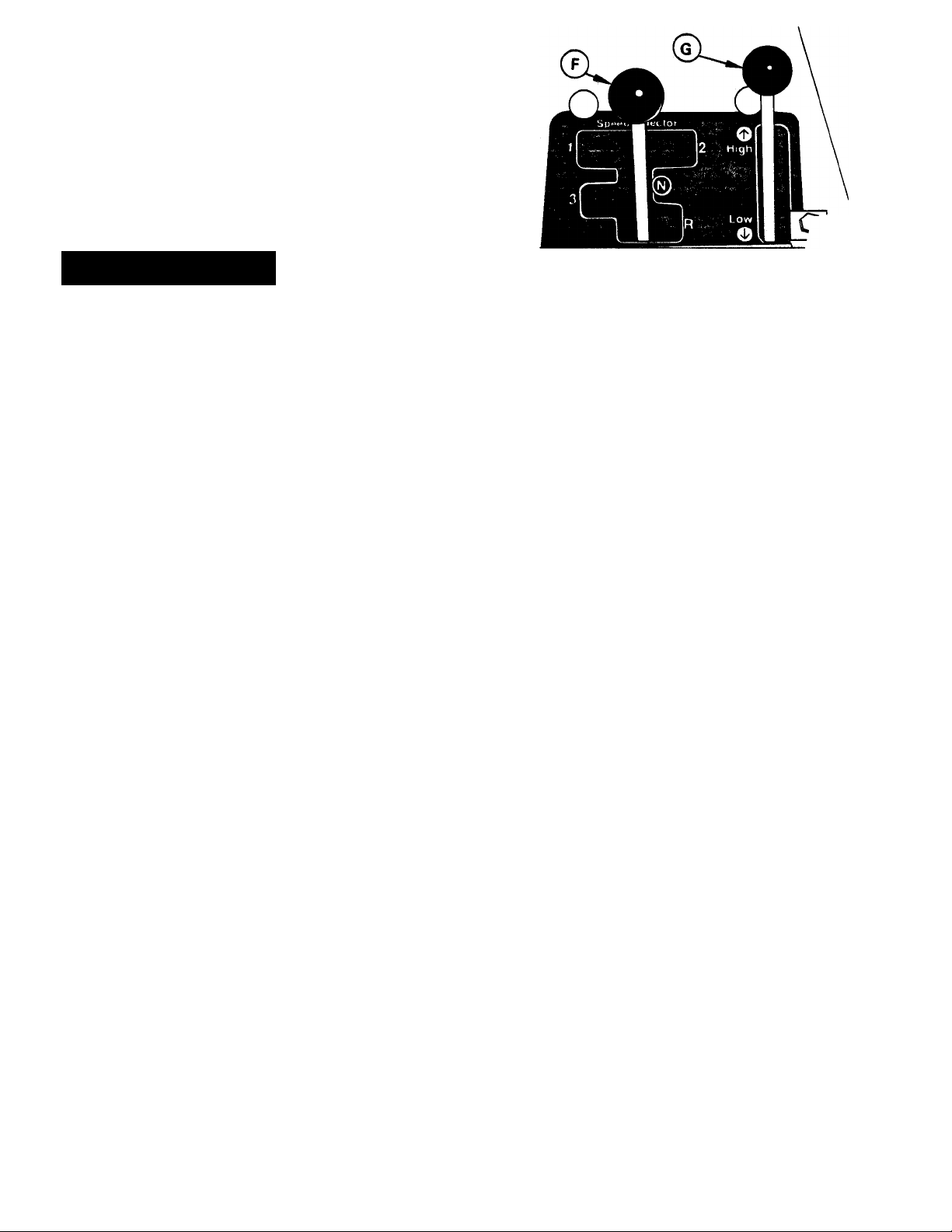

(7) SPEED SELECTOR LEVER - FIGURE 2

The Speed Selector Lever is used to select any of three

forward gears or one reverse gear. The markings " 1,2,

3" and "R" on the floor plate indicate the locations of

the gears. The slowest forward gear is indicated by

"1", the secondary gear, "2" and the fastest gear,

"3". The "R" indicates reverse. The Speed Selector

Lever must be in the "NEUTRAL" position as shown in

Figure 2 to start the engine. THIS IS A SAFETY

FEATURE.

@ HIGH-LOW SPEED RANGE SELECTOR - FIGURE 2

The High-Low Speed Selector gives a choice of six for

ward speeds; three in "HIGH" range; and three in

"LOW" range. The speed in reverse gear is the same in

both ranges. See "SPECIFICATIONS", page 40.

CLUTCH PEDAL - FIGURE 1

©

Depressing the Clutch pedal disengages the transaxie

from the engine and permits shifting the speed selector

to any desired gear. Always release the clutch pedal

slowly for smooth acceleration. Do not allow foot to

rest on pedal except when clutching.

IMPORTANT: ALWAYS DEPRESS CLUTCH PEDAL TO

EASE ENGINE STARTING. DEPRESSING CLUTCH

PEDAL RELEASES PARKING BRAKE. BE READY TO

APPLY FOOT BRAKE WHEN STARTING FROM PARK

POSITION.

FIGURE 1

BRAKE PEDAL - FIGURE 1

o

Depressing the brake pedal applys pressure to the disk

brake and stops the tractor (with the clutch depressed).

Be sure to depress clutch pedal to disengage the clutch

before braking. Brake will not stop tractor without

depressing clutch pedal.

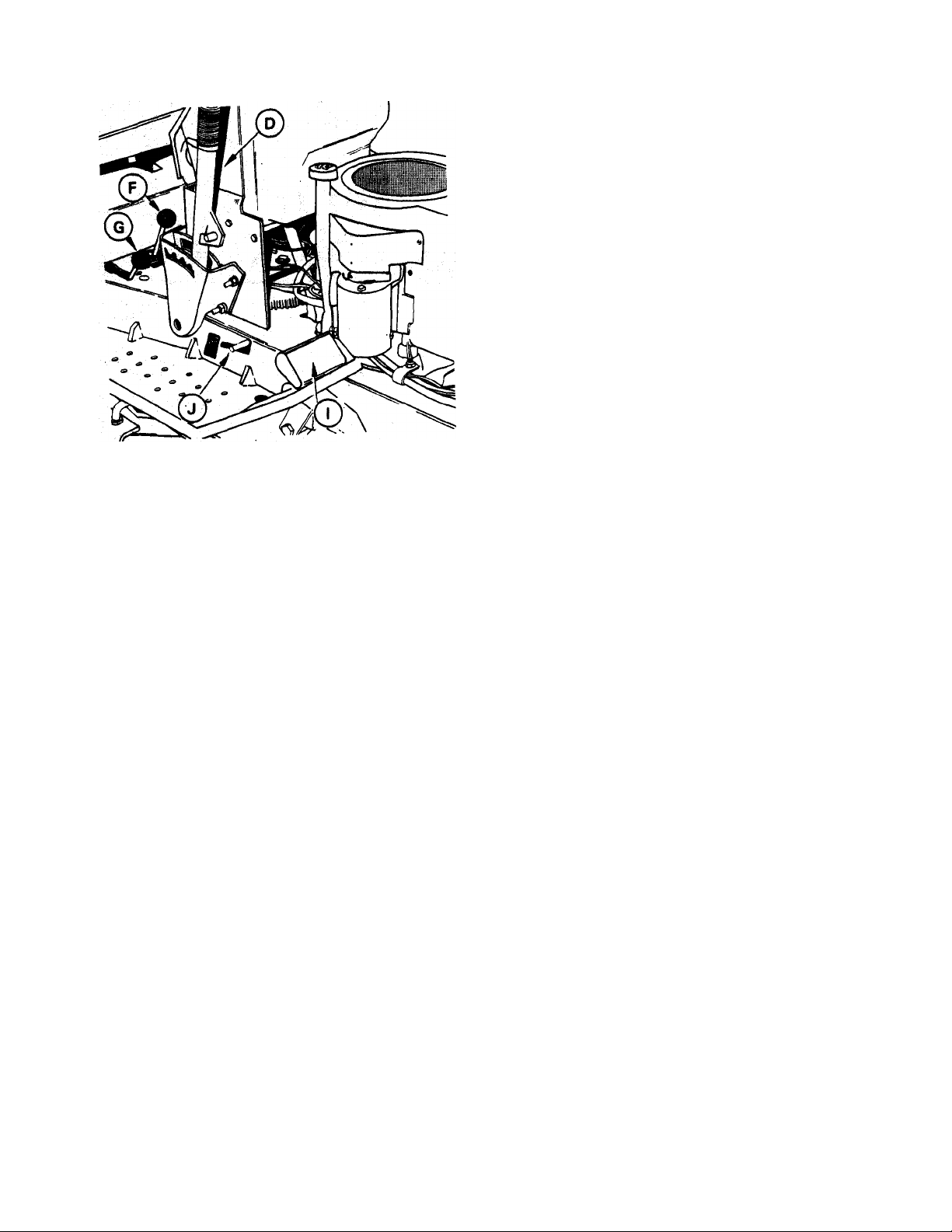

PARKING BRAKE LOCK - FIGURE 3

©

A Parking Brake Lock is provided to prevent the tractor

from moving when parked or left unattended. To lock

the brake, pull the parking brake lock up with the pedal

fully depressed. Then release the brake pedal. Figure 3

shows the parking brake lock engaged. Clutch pedal

must not be depressed when locking brake. Park"^~>

brake lock may be disengaged by depressing eit

brake or clutch pedal.

Page 5

IMPORTANT: ENGAGE THE BRAKE LOCK BEFORE

DISMOUNTING FROM THE TRACTOR OR ANY TIME IT

IS LEFT UNATTENDED.

A

CAUTION; WHEN USING TRACTOR OR ATTACH

MENT FOR THE FIRST TIME USE LOW RANGE SPEEDS

AND LOWER GEARS TO MAKE SURE OF YOUR CON

TROLS.

OPERATION

WHEN USING ATTACHMENTS

A rear weight box and wheel weights are available to

increase traction when using the Sno-Thro or the front

blade attachments. Rear tire chains are also available

for use in snow conditions.

FIGURE 2

4. Raise Throttle-Choke Control Lever ® Figure 1,

past the offset in the slot to the "CHOKE" posi

tion.

NOTE: OPERATOR MUST BE ON SEAT TO START

UNIT. TRACTOR HAS A SEAT SWITCH FOR SAFETY.

NOTE: TOO MUCH REAR WHEEL TRACTION WILL

RESULT IN DRIVE TRAIN OVERLOAD AND POSSIBLE

DAMAGE. THEREFORE: WEIGHT BOX LIMIT IS 125

LBS. REAR TIRE CHAINS ARE NOT TO BE USED ON

DRY SOIL OR GRAVEL.

PRE-STARTING INSPECTION

1. Check oil in engine crankcase. Add oil as required

to maintain proper level. See "LUBRICATION"

section.

2. Check fuel supply. Fill with clean, fresh regular or

unleaded gasoline only. See "LUBRICATION"

section.

3. Check air cleaner and tire pressures.

4. Check for engine, transmission or differential oil

leaks. See your Ariens dealer for repairs.

5. Make visual checks regarding safety precautions,

obstructions and maintenance.

STARTING THE ENGINE

Use the following procedure to start the engine.

1. Depress Clutch Pedal (h) and hold the tractor in

position by depressing the Brake pedal © .

2. Place the Speed Selector Lever 0 in the

"NEUTRAL" position as shown in Figure 2.

5. Turn ignition key ® shown in Figure 1 clockwise

all the way. Release key as soon as the engine

starts and gradually lower the Throttle Choke

Control Lever past the offset until the engine runs

at Vi throttle.

NOTE: A WARM ENGINE WILL REQUIRE LESS CHOK

ING THAN A COLD ENGINE.

If the engine fails to start on the first attempt, turn key

to the "OFF" position, wait a few minutes and try

again. Do not operate starter continuously for more

than 30 seconds at a time.

Always allow engine to warm up before applying load.

In below freezing weather, allow engine to run at a fast

idle for a period of at least five minutes before moving

the tractor or starting the attachment. SERIOUS

DAMAGE TO THE ENGINE AND TRANSMISSION

COULD RESULT IF THIS PROCEDURE IS NOT

FOLLOWED.

STOPPING THE ENGINE

Always use the following procedure to stop the engine;

1. Move the Speed Selector Lever © (Figure 1) to

the "NEUTRAL" position.

2. Disengage the Implement Power Clutch © ,

Figure 1.

3. Engage Parking Brake Lock ® by depressing

the Brake Pedal © (Figure 1) and pulling up on

the Parking Brake Lock Q (Figure 3).

NOTE: THE ENGINE WILL NOT START UNLESS THE

SPEED SELECTOR LEVER IS IN THE "NEUTRAL" POSI

TION.

3. Place Implement Power CLutch Lever © Figure

1, in the rear (disengaged) position.

NOTE: THIS IS A SAFETY FEATURE. THE ENGINE

WILL NOT START UNLESS THE CLUTCH LEVER IS IN

THE DISENGAGED POSITION.

4. Lower attachment to the ground.

5. Lower Throttle Lever and allow the engine to idle

for a short period of time. DO NOT STOP A HOT

ENGINE AT HIGH SPEED AS INTERNAL ENGINE

DAMAGE COULD RESULT.

6. Turn ignition key counterclockwise to the "OFF"

position to stop the engine.

Page 6

7. BE CAREFUL: REMOVE IGNITION KEY BEFORE

DISMOUNTING FROM TRACTOR. THIS WILL

PREVENT CHILDREN AND INEXPERIENCED

OPERATORS FROM STARTING THE TRACTOR.

FIGURE 3

(YT11 Illustrated)

7. To stop the tractor, fully depress Clutch and Brake

Pedals and place Speed Selector Lever in'*

"NEUTRAL". Fully depress Brake Pedal and

engage the Parking Brake Lock when parking.^«:

leaving the tractor. (Figures 1, 2 & 3).

EMERGENCY STOPPING

Always use caution when mowing-be alert for

children, pets or obstacles in path. If necessary to make

emergency stop, step firmly on Brake Pedal and Clutch

Pedal.

A

IMPORTANT: DO NOT FORCE SPEED SELECTOR

LEVER IF GEAR DOES NOT ENGAGE. APPLY SLIGHT

PRESSURE ON THE SPEED SELECTOR LEVER WHILE

RELEASING THE CLUTCH PEDAL. THE CLUTCH

PEDAL MUST BE DEPRESSED TO ENGAGE ANY

SELECTED GEAR. DEPRESSING THE PEDAL TOO LIT

TLE WILL CAUSE GEAR CLASH AND POSSIBLE

DAMAGE TO THE TRANSMISSION. HOLD LEVER

TOWARD ENGAGED POSITION WHILE DECLUT

CHING.

WARNING:

OPERATING THE TRACTOR

1. Start the engine using the procedure explained

under "Pre-starting Inspection" and "Starting the

Engine".

NOTE: THE SPEED SELECTOR LEVER MUST BE IN THE

NEUTRAL POSITION, THE IMPLEMENT POWER

CLUTCH LEVER DISENGAGED AND THE OPERATOR

ON SEAT TO START THE ENGINE.

2. Release Parking Brake Lock 0 by depressing the

Brake ©or Clutch Pedal ® (Figure 1) until the lock

disengages.

3. Depress Clutch Pedal, place Speed Selector

Lever 0 and High-Low Range Selector ©

(Figure 1) into the desired gear and slowly release

the pedal to provide smooth acceleration.

4. Select the desired throttle speed with the

Throttle-Choke Control Lever. When operating a

power-driven attachment, operate the engine at

full throttle, (3250 RPM) unless otherwise

specified and control travel speed by selecting an

appropriate gear.

5. To raise or lower the attachment use the Attach

ment Lift Lever ®.

6. To start the attachment, engage the Implement

Power Clutch ® slowly with the engine running at

Va throttle, then increase speed to full throttle.

1. BEFORE SERVICING ANY ATTACHMENT:

a. DISENGAGE POWER.

b. SHUT OFF ENGINE. ^

c. make' sure attachment has STOPPED

REVOLVING.

d DISCONNECT ENGINE SPARK PLUG CABLE

TO PREVENT ACCIDENTAL RESTART. .

2. KEEP CHILDREN, BYSTANDERS, AND PETS OUT

OF THE WORKING AREA.

3. KEEP HANDS, FEET AND CLOTHING AWAY

FROM POWER DRIVEN PARTS.

4. KEEP ALL SHIELDS AND GUARDS IN PLACE.

GRASS BAGGING

Ariens recommends grass cutting with grass bagger

without vanes before installing vanes for increased per

formance. If performance is satisfactory without vanes

(available for mowers of 32" cutting width or less), do

not use vanes. The vanes use more power and generate

more noise. Use vanes only if satisfactory performance

cannot be obtained without them. Generally, broadleaf

grasses can be cut and bagged without vanes. The

finer grasses may require the use of vanes. In extremely

wet conditions, vanes may also be of help.

-6-

Page 7

ADJUSTMENTS

SEAT ADJUSTMENT

BRAKE PEDAL SPRING ADJUSTMENT - FIGURE 3

The seat is adjustable front or back to many positions.

Adjustment is made by loosening the two rear mountng

bolts located under rear of the seat, sliding the seat to

the most comfortable position and then tightening the

mounting bolts.

SHIFT LEVER DETENT ADJUSTMENT

Check tightness of screws holding shift handle in the

detent positions. Screws must be tightened securely.

This will eliminate jumping out of gear. See Figure 4.

SHIFT

HANDLE

• TIGHTEN DETENT SCREWS THROUGH

HOLES TO HOLD SHIFT LEVER IN GEAR .

FIGURE 4

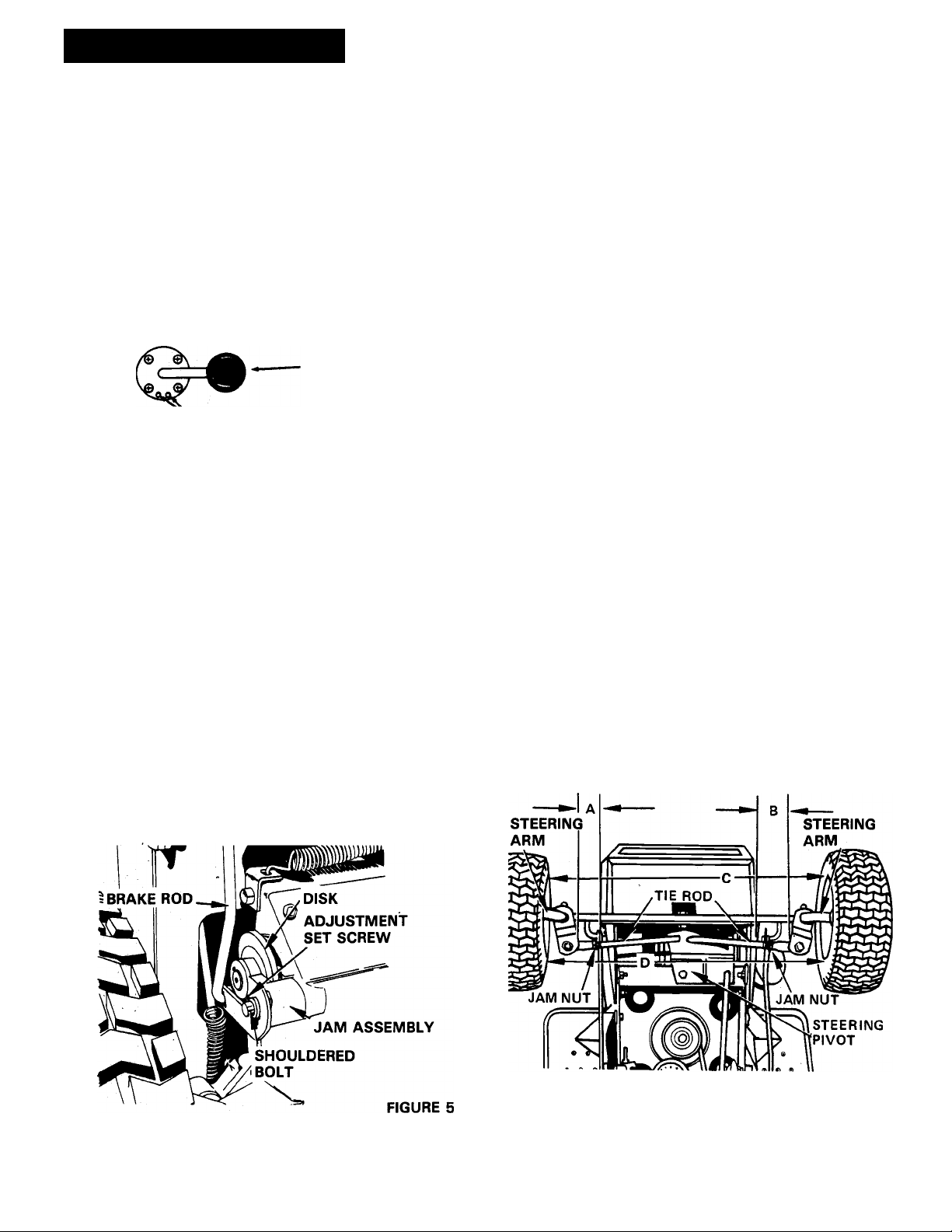

DISK BRAKE ADJUSTMENT - FIGURE 5

Once each season, or if the brake begins to slip and

does not hold the tractor, it is necessary to adjust the

disk brake located on the lower left side of the transaxle

assembly. See Figure 5. Adjust as follows:

1. Position the tractor on a smooth level surface and

place the speed selector lever in “NEUTRAL" so

the tractor can be pushed by hand to check the

brake.

2. Adjust the setscrew in the brake jaw assembly

clockwise until the brake just starts to lock. This

can be felt by pushing the tractor by hand. Leave

the brake pedal up during this adjustment.

The tension on the brake pedal itself is adjustable. If the

brake pedal does not return or feels loose, adjust the

nut on the end of the brake rod just inside the frame

next to the parking brake slot. Tighten the nut until the

spring adjacent to the nuts is 1 % inches in length.

FRONT WHEEL TOE-IN ADJUSTMENT - FIGURE 6

Proper toe-in of the front wheel is necessary to assure

proper steering and to reduce tire wear. Correct toe-in

is when the front of the wheels are Vs" to Vi" closer

together than the rear of the wheels (measured at the

horizontal center line of the rim flanges).

If the steering develops a wandering characteristic or if

excessive tire wear develops, the toe-in of the front

wheels should be checked. If the toe-in is not correct,

adjust as follows;

1. Turn steering wheel until the rear edge of the

steering pivot is perpendicular (90 degrees) to the

tractor frame as shown in Figure 6.

2. Adjust length of tie rods until distances from

steering arm to frame (A and B) are equal and so

distance C is between Vs" to Vi" less than

distance D.

NOTE: USE FOLLOWING PROCEDURE TO SHORTEN

OR LENGTHEN TIE RODS.

1. Loosen jam nuts on ends of tie rods. Figure 6.

2. Remove the locknuts and pull out the ball joints.

Rotate tie rods until distances A and B, Figure 6,

are equal and distance C is Vs" to Vi" less than D.

3. Tighten jam nuts securely. Replace ball joints in

holes and secure with locknuts.

Turn setscrew Vi turn counterclockwise

locking point to adjust the brake.

from

FIGURE 6

-7-

Page 8

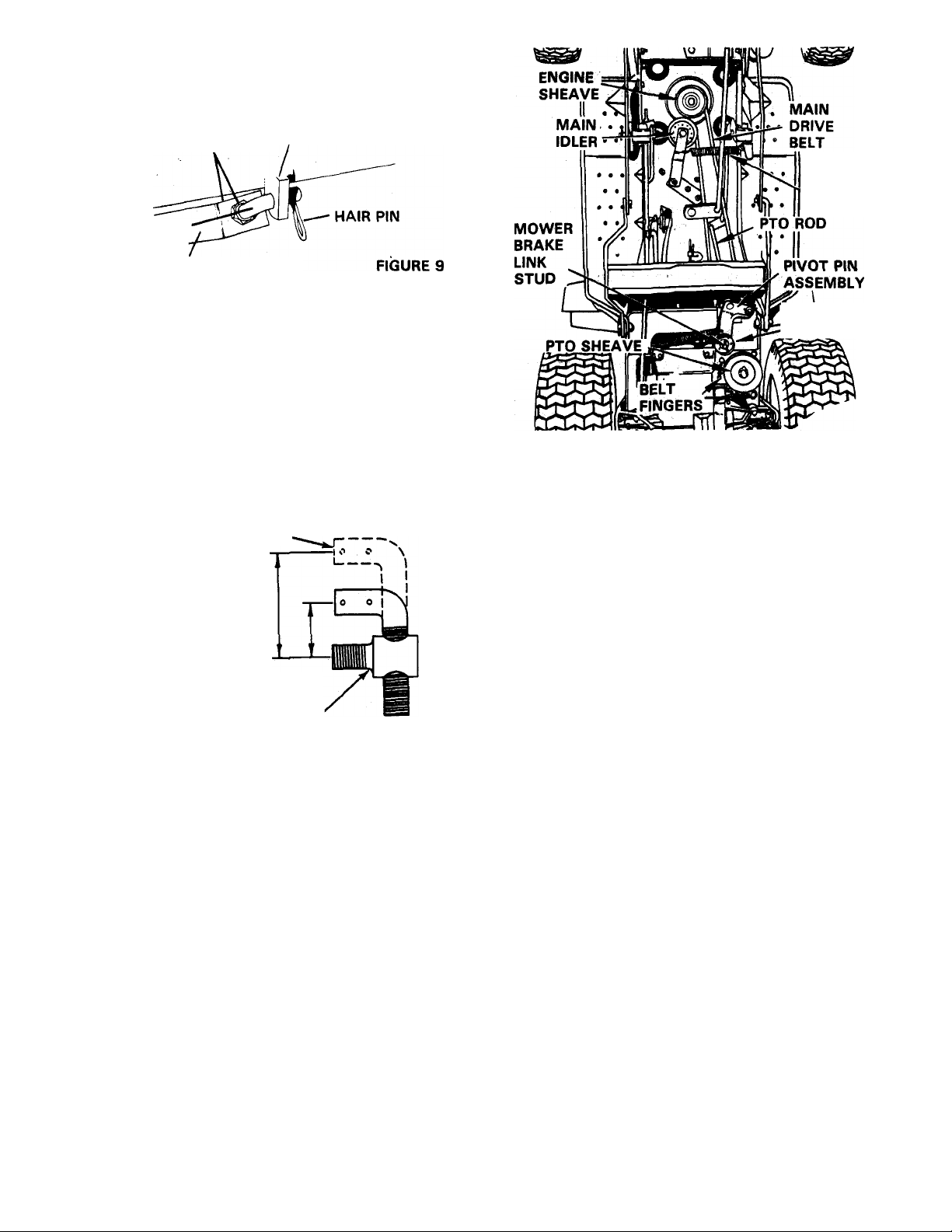

REMOVAL OF MOWER PAN - FIGURES 7 & 9

In order to perform some maintenance it may be

necessary to remove the mower pan as follows:

1. Lower the mower pan. Remove the hairpin cotter

and washer from the stud on the attachment idler

(Figure 9) and disconnect the mower brake link.

2. Raise the mower deck. Loosen the belt fingers on

the tractor PTO sheave, slide them to one side,

and remove the mower belt from this sheave. See

Figure 9.

3. Lower the mower pan and remove the hairpin

cotters and washers. The two pins and washers

on the front secure the mower pan to the front

hangers and can be disconnected to free the front

of the pan. The other two pins and washers join

the front of the pan to the belt tightener bracket.

Loosen the hex nuts and turn the rear hanger

hooks to the side to free them from the rear

hangers. See Figure 7.

4. Place front hanger on top of rear hanger. Raise the

Attachment Lift Lever to pull the hangers up out

of the way. Pull the mower pan from under the

tractor.

The front and rear hangers may be assembled and

engaged with washers and hairpin cotters.

3. Lower the Attachment Lift Lever. Slide the pan

back (while lifting the rear of the pan) so that thé

pan hanger hooks slide up on the rear hanger.

Assemble the front hangers to the tabs on

mower pan, while, at the same time, assemb'

the front and rear hangers. Secure with fo^i

washers and hairpin cotters. Connect the Belt

Tightener Bracket to the pan.

4. Raise the Attachment Lift Lever to maximum

height. Connect the Mower Belt to the tractor

PTO Sheave.

5. Connect the blade brake arm to the stud on the

center of the Attachment Clutch Idler. Secure

with a washer and a hairpin cotter.

6. Adjust the belt fingers on the tractor PTO Sheave

to clear the belt by 1 /8 to 1 /1 6”. Tighten the belt

finger hardware.

INSTALL BLADE BRAKE ARM AS SHOWN

35261 BRACKET

32235 (32” MOWER) 73108

35248 (38” MOWER)

64093 WASHER

67020 HAIRPIN

IDLER

64093 WASHER /

67020 HAIRPIN

NUT

FIGURE 8

CLEVIS PIN

REAR BRACKET

REAR HANGER HOOK'^^^-^ RRAPkPT

INSTALLATION OF MOWER PAN - FIGURES 7 & 8

Position the tractor on a smooth, level surface and in

stall the mower pan as follows:

1. Lower the Attachment Lift LeVer. One front set of

pins and washers will connect the tabs on the

front of the mower pan to the front hangers, the

second set of pins and washers connect the front

of the pan to the belt tightener bracket. The rear

set of pins and washers connect the rear hangers

to the frame.

HAIR PINS &.

WASHERS BELT*

FRONT HANGER

TIGHTENER

FIGURE 7

MOWER PAN LEVELING - FIGURES 7, 9 &13

The mower pan is designed to cut evenly with the rear

of the pan 1/8 inch higher than the front. To level the

mower pan proceed as follows:

1. Position the tractor on a smooth, level surface.

Adjust tire pressure as follows (light loading):

Front - 10 psi / Rear - 6 psi

2. Measure the distance from surface to mower

blades at the front and rear of the pan. The rear of

blades should be 1/8 inch higher than front and

blades should hang even side to side.

3. If adjustment is required, turn the hex nuts on the

rear hanger hooks to mo\/e the hooks up or down

to secure the proper adjustment. When the pan is

leveled and hangs evenly, tighten the hex nuts

securely. See Figure 7.

4. Adjust mower belt for proper center distance. See

Figure 9 and 13. Adjust nuts on the adjustor rod

to move mower pan forward or backward. Adjust

1 to 1 'h inch clearance between belt as shown in

Figure 13 with mower pan in highest position.

2. With the Mower Belt in place on the pan and the

lift arm in its highest position, position the pan

under the tractor and forward against the front

wheels.

CAUTION: ADJUSTMENT TOO FAR FORWARD W,.^

NOT ALLOW MOWER BELT TO DECLUTCHI CHECK

FOR PROPER MOWER BELT DECLUTCHING IN ALL

HEIGHT POSITIONS. IF MOWER BELT DOES NOT

-8-

Page 9

DECLUTCH, ADJUST MOWER PAN BACKWARD UN

TIL PROPER DECLUTCHING OCCURS. (P.T.O.

SHEAVE MUST NOT HAVE A TENDENCY TO DRIVE

MOWER BELT AND/OR OVERRIDE BRAKE.)

MOUNTING POST

ADJUSTMENT NUTS

ADJUSTOR ROD

BELT TIGHTENER BRACKET

ON FRONT AXLE

MAIN IDLER

SPRING

MOWER PAN CUTTING HEIGHT - FIGURE 10

After the mower pan has been leveled properly, minor

adjustments can be made in the pan cutting height by

increasing or decreasing the center distance between

35321 rod end and 35322 adjustment link. Increasing

center distance lowers cutting height. Decreasing

center distance raises cutting height. Raising the At

tachment Lift Lever to another notch in the lift quadrant

will also raise the cutting height of the mower pan. Ad

just to suit individual grass cutting conditions.

35322

ADJUSTMENT LINK

THIS DISTANCE

CHANGES CUTTING

HEIGHT

35321 ROD END

FIGURE 10

DRIVE BELT REPLACEMENT - FIGURES 11 & 12

ATTACHMENT

IDLER & ARM

FIGURE 11

7. Remove hair pin and Mower Brake Link from

Attachment Idler. See Figure 11.

8. Disconnect Attachment Idler spring from an

chor on right side of transaxle. (Use vise

grips). See Figure 11.

9. Remove cotter pin, washer and PTO Rod

from the Attachment idler arm. Figure 11.

10. Loosen fasteners holding two belt fingers

around Traction Drive Belt to frame, and

rotate fingers away from belt. See Figure 1 2.

11. Depress Clutch Pedal with left foot and un

wrap Traction Drive Belt from transaxle and

upper groove of top PTO Sheave. Figure 1 2.

A. Removal of Worn Belt

NOTE: REMOVE SPARK PLUG WIRE.

1. Loosen fasteners holding two belt fingers

near PTO Sheave and rotate fingers away

from sheave. See Figure 11.

2. Move Implement Clutch Lever to "OUT”.

3. Raise mower to highest position with At

tachment Lift Lever..

4. Unwrap mower drive belt from PTO Sheave

(DO NOT PRY).

5. Lower mower to lowest position with At

tachment Lift Lever.

6. Move Implement Clutch Lever to "IN”.

12. Release clutch, disconnect traction clutch

spring from Traction Clutch Idler Arm. (Use

vise grips). See Figure 12.

13. Rotate Attachment Idler until hair pin at top

of idler assembly pivot pin can be removed

rearward. See Figure 12.

14. Remove PTO pivot pin, hair pin and washer.

Figure 1 2.

1 5. Lower Attachment Idler assembly until Trac

tion Clutch Idler Arm is free of pivot pin.

16. Disconnect Main Idler spring from anchor

point at left side of frame. (Use vise grips).

17. With a ®/ie” open end wrench, hold the

jackshaft via the milled flats under the PTO

Sheave. Remove large nut and internal tooth

lockwasher on top of jackshaft. Figure 1 2.

-9-

Page 10

T8. Slide or drive, if necessary, “the jackshaft

downward until it clears the top PTO

Sheave. If the shaft must be driven use a %

or ®/g” diameter punch so as not to flatten

the top threads.

19. With the top PTO Sheave clear of the

jackshaft the Main Drive Belt can be un

wrapped.

20. Slide rear of belt ahead and between upper

traction and lower Attachment Idler

assemblies. See Figure 11.

14. Grasp Traction Clutch Idler spring with vise

grips and connect hook to Traction Clutch

Idier Arm. See Figure 12.

1 5. Depress traction clutch pedal and wrap Trac

tion Drive Belt around upper groove on PTO

Sheave and Transaxle Sheave. DO NOT

PRY. See Figure 12.

16. Release Clutch Pedal and align and tighten

traction belt fingers to Vie” to Ve” from belt.

17. Move Implement Clutch Lever to "OUT”.

21. Unwrap main belt from Engine Sheave and

remove from tractor.

B. Installation of New Belt

1. Wrap new main belt around Engine Sheave.

2. Feed other end rearward, above steering arm

and through, between upper Traction and

lower Attachment Idler pivot assemblies.

3. Push Attachment Idler arm upward until

pivot pin is completely positioned through

the traction clutch idler arm pivot.

4. Rotate Attachment Idler Arm so that hair pin

can be reinstalled in a forward direction.

Place washer over pivot pin and install hair

pin.

5. Move Implement Clutch to "IN”.

6. Feed PTO Rod between Main Drive Belt

lengths and install end through hole in At

tachment Idler Arm. See Figure 11.

7. Install washer and cotter pin in PTO Rod.

18. Raise Attachment Lift Lever to highest posi

tion.

19. Wrap Mower Belt around bottom PTO

Sheave. DO NOT PRY.

20. Re-align fingers around bottom PTO Sheave •

pulley Vie” to Vg” away from pulley and

tighten.

21. Move Implement Clutch Lever to "IN” posi

tion.

22. Attach Mower Brake Link to Stud under At

tachment Idler and secure with hair pin. See

Figure 8.

23. Leave spark plug wire disconnected.

24. Lower Attachment Lift Lever to lowest posi

tion.

25. Move Implement Clutch Lever to "OUT”.

Place Speed Selector Lever in "NEUTRAL".

26. Crank engine with starter about six revolu

tions.

8. Connect Attachment Idler spring to anchor

on right front corner of transaxle. (Use vise

grips).

9. Wrap main belt around lower (larger) groove

of top PTO Sheave. See Figure 1 2.

10. Align top PTO Sheave bore above jackshaft

spindle bore and slide jackshaft upward and

through top PTO Sheave. Be sure spacer

washer is between upper spiindie bearing and

top PTO Sheave. See Figure 12.

11. Insert key in PTO jackshaft and top PTO

Sheave assembly.

12. Install internal tooth lockwasher on top’of

jackshaft and secure assembly with nut. Use

flats on bottom of jackshaft to hold'.

1 3. Reconnect Main Idler Spring to anchor hole

on left side of frame. Be sure Main Idler is on

backside of Main Drive Belt and spring is

above steering link. See Figure 11.

-10-

27. Inspect Main Drive Belt and Main Idler for

alignment and clearance from sharp edges.

28. Replace spark plug wire and test function.

TRACTION

MAIN CLUTCH

DRIVE 'CLE”

BELT

35026 I

CAM TRACTION

ACTUATOR

IDLER

1 1

TRACTION DRIVE BELT

TRANSAXLE

SHEAVE

■ 1

BELT

FINGER

FIGURE 12

Page 11

REPUCEMENT OF TRACTION DRIVE BELT • FIGURE 12

The Traction Drive Belt is easily replaced by lifting the

rear deck; loosening the belt fingers; including belt

finger on Traction Clutch Idler Arm; depressing the

Clutch Pedal and removing the belt. Replacement is

similar, depress the Clutch Pedal; install the belt and

replace the belt fingers. Adjust the three belt fingers to

provide Vi to Vie inch clearance from the belt with

clutch engaged (pedal up).

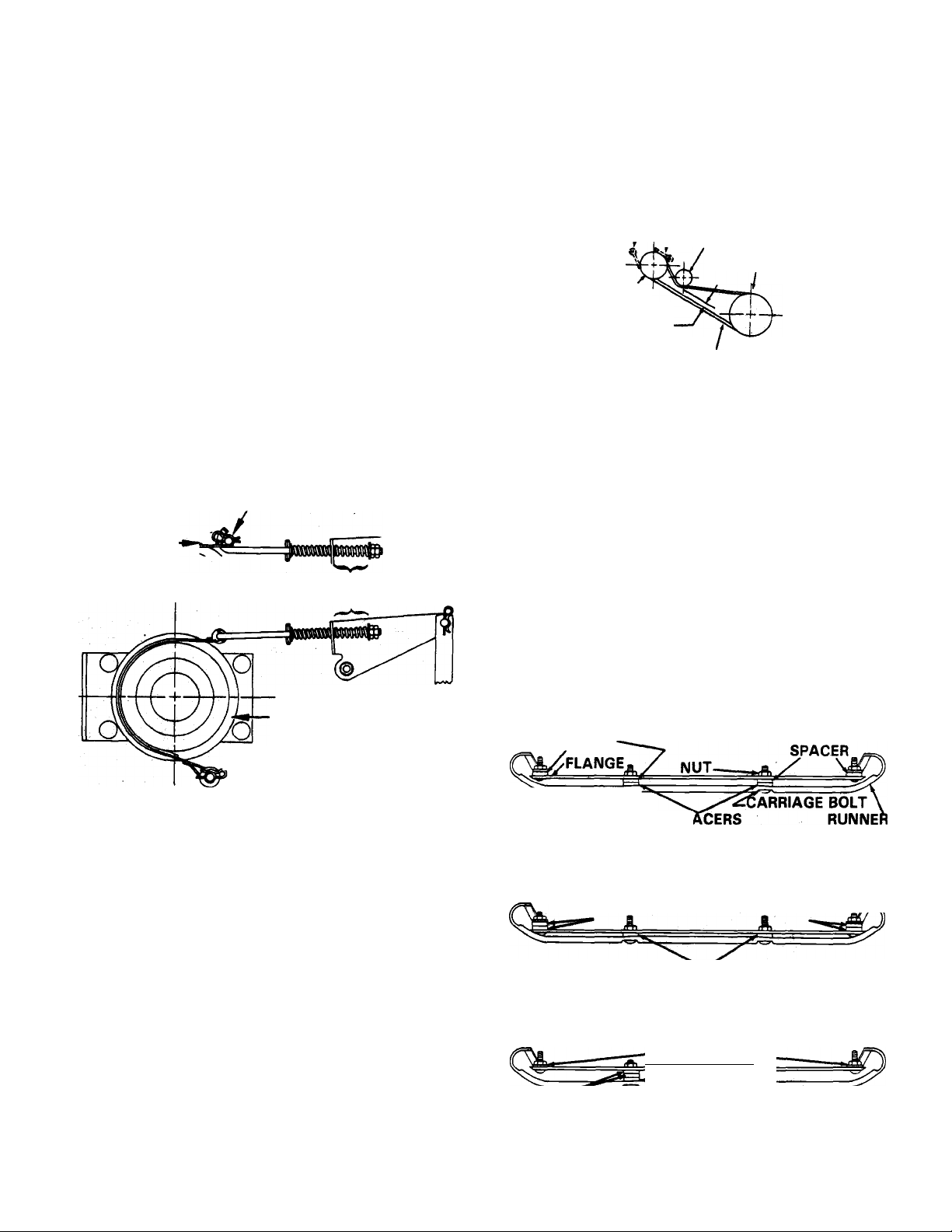

MOWER BELT - FIGURES 13 & 14

If belt squeals when Implement Power Clutch is proper

ly engaged, check adjustment of belt. If squeals con

tinue, belt may require replacement.

A. Removal

1. Place the Attachment Lift Lever in the lowest

position, (forward). Disengage the Attach

ment Clutch (lever to rear).

strength and stability. This assures that the belts will

deliver maximum performance and durability for each

product's specific applications.

The selling price of ARIENS BELTS reflects these quali

ty features. Our name and number stamped on your

replacement belt is your assurance of receiving the

quality you are paying for.

TOP VIEW

P.T.O.

31755 BELT FINGERS

ATTACHMENT IDLER ICLUTCHINQI

MOWER SHEAVE

P.T.O. SHEAVE

BELT CLEARANCE:

MAX. IN HIGHEST

POSITION; 1" MIN. IN

LOWEST POSITION.

MOWER BELT

FIGURE 14

2. Loosen the belt fingers at the PTO Sheave

and turn them away from the sheave.

3. Remove the hair pin or cotter pin securing

the brake band and rotate the band away

from the sheave. See Figure 13.

HAIR PIN

32" MOWER

ONLY

ADJUST FOR 1-1/8"

SPRING LENGTH

MOWER SHEAVE

38" MOWER ONLY

- HAIRPIN FIGURE 13

4. Raise the mower pan to its mid position and

remove the Mower Belt from the PTO

Sheave; lower the pan and remove the belt

from mower pan. See Figure 14.

B. Replacement

1. Position the replacement Mower Belt around

the sheave on the mower pan. Reposition

the brake band around the sheave and

secure with the cotter or hair pin. See Figure

13.

2. Raise the mower pan to its center position

and install the Mower Belt around the PTO

Sheave. See Figure 14.

A NOTE ABOUT ARIENS BELTS

MOWER BRAKE ADJUSTMENT - FIGURE 13

With the Mower Belt adjusted and the Implement

Power Clutch disengaged, adjust the nut on the end of

the brake rod until the spring is 1 Vs" in length. See

FIgur« 13.

MOWER RUNNER ADJUSTMENT

After adjusting the cutting height and blade pitch as

described elsewhere In this section, thè mower runners

may be adjusted, as desired, to allow smooth, even

cutting of grass at different cutting height settings. Ad

justment must be even from side to side. Assemble out

side spacers to runners and mower before center

spacers. This will aid in alignment and ease of installa

tion. Do not tighten hardware until outside spacers are

installed.

1. To pre-set the runners prior to a test cutting they

may be adjusted as shown in Figure 1 5.

SPACER

CARRIAGE BOL^

6071 SP

FIGURE 15

2. To obtain smoothest cutting in lowest cutting

height settings, the runners may be adjusted as

shown in Figure 1 6.

2 SPACERS 2 SPACERS

6071 SPACERS

FIGURE 16

To obtain smoothest cutting in higher cutting

height settings, the runners should be adjusted as

shown in Figure 1 7.

-NO SPACERS-Tc-

ARIENS BELTS are individually engineered to the

highest standards of material quality, design, and con

struction including special cording locations for

2 SPACERS

2 SPACERS

'6071 SPACER

Flfsi"-

Page 12

MAIIMTEIMAIMCE

CAUTION; REMOVE BATTERY FROM TRACTOR

BEFORE TIPPING OR LIFTING THE UNIT FOR AD

JUSTMENTS. BATTERY IS NOT SEALED AND SPILLED

ACID WILL DAMAGE PRODUCT. WHEN HANDLING

BATTERY BE SURE TO AVOID CONTACT WITH BAT

TERY ACID, WHICH CAN CAUSE SERIOUS INJURY TO

EYES, ETC. FOLLOW ALL CHARGING INSTRUCTIONS

CAREFULLY. WHEN "JUMP STARTING" THE UNIT BE

SURE TO CONNECT THE NEGATIVE BOOSTER CABLE

TO FRAMES (NOT TERMINAL.)

GENERAL

All dealers will provide any service which may be re

quired to keep the Yard Tractor operating at peak effi

ciency. Ariens Company recommends that you contact

an Ariens dealer before making any adjustments to this

tractor. Refer to the Engine Instructions for engine

maintenance instructions. If repairs or service are re

quired for the engine, see your Ariens dealer or the

nearest authorized engine service station.

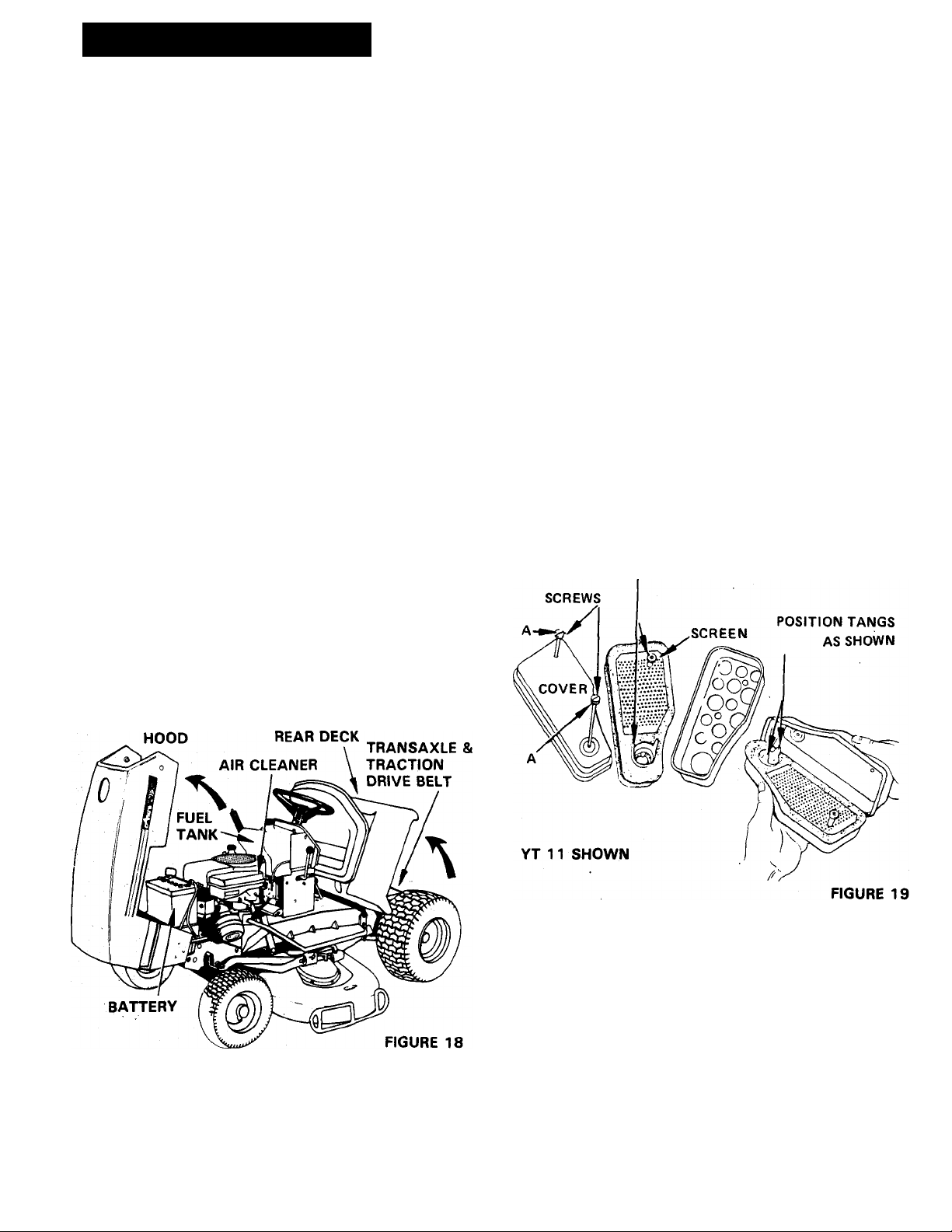

RAISING THE HOOD - FIGURE 18

1. The engine, battery, electrical components, air

cleaner, fuel filter and fuel tank are readily ac

cessible by raising the hood.

operating in extremely dusty conditions, perform thi<^^

service at more frequent intervals. Use the followinv

procedure to service the air cleaner.

1. Raise the tractor hood. Remove screws, "A", Figure

1 5, and lift off complete air cleaner assembly.

2. Remove screen and spacers from the foam ele

ment, Figure 1 9.

3. Wash foam element in kerosene or liquid

detergent and water to remove dirt. Wrap foam in

cloth and squeeze dry. Let dry overnight.

4. Saturate foam element in clean oil. Squeeze to

remove the excess oil.

5. Re-assemble parts and re-install complete

assembly on the carburetor.

NOTE: WHEN RE-ASSEMBLING THE PARTS, MAKE

CERTAIN THE FOAM ELEMENT EXTENDS OVER THE

EDGE OF THE AIR CLEANER BODY. THE FOAM ELE

MENT WILL FORM A PROTECTIVE SEAL.

IMPORTANT: NEVER RUN THE ENGINE WITH THE AIR

CLEANER REMOVED!

2. To raise the hood, grasp each side and raise it up

wards and forward until it stops.

RAISING THE REAR DECK - FIGURE 18

The trahsaxle, PTO and jackshaft assembly, clutch

idler, and Traction Drive Belt are readily accessible by

raising the rear deck until the seat rests against the

steering wheel.

LIFT UP

LIFT UP

SPACERS

ENGINE COOLING SYSTEM - FIGURE 20

1. The engine is air cooled. Grass particles, chaff and

dirt may clog the cooling systehi, especially when

mowing dry grass or operating in extremely dusty

conditions. Continued operation with a clogged

cooling system may cause severe overheating and

possible engine damage. ^

AIR CLEANER SERVICE - FIGURE 19

Clean the air cleaner and re-oil the element every 25

hours under normal operating conditions. When

2. It is essential that the rotating screen, engine cool

ing fins and the exhaust system be kept free of

dirt and debris which could cause the engine to

overheat.

- 12

Page 13

To avoid overheating and possible engine

damage, periodically remove the shrouding from

around the cooling fins. Figure 16, and clean the

area shown within the heavy black line of all

grass,dirt or chaff accumulation.

KEEP AREAS WITHIN

HEAVY LINES CLEAR

OF ALL DEBRIS

TIRES PRESSURES - TABLE 1

Check tires pressures at least once each month. Inflate

tires to pressures shown using a low pressure tire

gauge for accurate readings. Keep tires properly in

flated at all times. Over-inflation will cause operator

discomfort. Under-inflation will cause short tire life.

Make sure the tire valve caps are in place.

TIRE SIZE

Ught

LOADING

Medium

Heavy

FIGURE 20

SEAT MAINTENANCE

Clean the seat regularly, using a vinyl cleaner (not a sol

vent.) Extreme temperatures can damage the seat

when left without protection against the weather. If the

seat should tear, apply vihyl repair tape to the damaged

area.

BATTERY SERVICE

NOTE: REFER TO "BATTERY SET-UP AND

MAINTENANCE” SECTION, PAGE 36.

1. Check the battery electrolyte level once each

week or every 25 hours of operation. Check it

monthly if the tractor is idle or is in storage. Add

distilled water to bring the level to the bottom of

the split ring in the filler tube of each cell.

2. Each spring and fall clean the battery and ter

minals with ammonia or bicarbonate of soda solu

tion followed by flushing with clean water. Keep

ing the battery clean will prolong battery life.

After cleaning, apply a light coat of grease to the

terminal and cable ends.

3. Keep cable clamps securely tightened to terminals

and keep battery hold-down clamps tight to pre

vent vibration. Do not overtighten clamps. This

could warp the case.

WARNING; STORAGE BATTERIES GIVE OFF HIGHLY

INFLAMMABLE HYDROGEN GAS. DO NOT ALLOW

SPARKS OR FLAME NEAR BATTERY. DO NOT LAY

TOOLS ACROSS BATTERY TERMINALS WHICH MAY

CAUSE A SPARK RESULTING IN AN EXPLOSION.

Front

13 X 5.00 - 6

Rear

18 X 8.50 - 8

(Lawn Work) (Sno-Thro)

8 psi 12 psi

(Lawn Work)

6 psi

(Sno-Thro)

8 psi

16 psi

10 psi

TABLE 1

FUEL FILTER SERVICE - IFIGURE 21

Wheri dirt or other foreign material is allowed to enter

the fubi tank it will collect in the fuel filter eventually

causing fuel stoppage. If this occufs, replace filter.

MOWER BLADE AND VANES MAINTENANCE

Check tire pressure. Uneven tire pressure may cause

uneven grass cutting.

Models with 32” mowers are equipped with high lift

blades standard. Vanes (Service Part No. 527011)

may be bolted to the blades to improve discharge and

bagging or collecting of grass. These vanes may or may

not be helpful depending on your type of grass and

cutting conditions.

Ariens recommends that the user try the mower

without vanes first and if the performance is satisfac

tory, use without vanes since the vanes use more

power and generate more noise. Use vanes (Service

Part No. 52701 1) only if satisfactory performance can

not be obtained without them. Generally, broadleaf

grasses can be cut and bagged without vanes. The

finer grasses may require vanes. In extremely wet con

ditions, vanes may also be of help.

Routinely check for wear on the mower blade and

vanes, if used. This is especially true in sandy soil con

ditions.

4. Maintain the battery at full charge during storage

and during the winter months to prevent freezing.

When water is added during freezing weather, run

the engine at least on hour to bring the battery up

to a full state of charge.

5. When installing the battery, make certain the

ground cable is connected to the negative(-) ter

minal on battery. See Figure 22. Be sure positive

cable is connected to positive {+) terminal.

CAUTION: WEAR OF THE MOWER BLADE CAN

CAUSE STRUCTURAL WEAKNESS. DO NOT INSTALL

NEW OR REPLACEMENT VANES ON WORN BLADES.

THIS IS A POTENTIAL HAZARD.

Replace worn parts with Ariens original equipment,

blades, vanes, and Grade 8 hardware as specified. Cap

screws must be installed with heads on top of the

vanes and vanes on top of the blade.

13 -

Page 14

NOTE; CAPSCREWS MUST BE

LOCATED ON TOP OF VANES

AS SHOWN.

NOTE: MOUNT VANt

TO BLADE As

SHOWN ONLY

WITH WORD

"FRONT"

EXPOSED

IMPORTANT: THE VANES (SERVICE PART NO.

527011) MUST BE USED IN PAIRS. THEY CANNOT

BE INTERCHANGED WITH Dlf^FERENT OR WORN

VANES ON THÉ SAME BUDE. USING ON| OF EACH

OF A DIFFERENT TYPE OR WORN VANE WILL CAUSE

THE BLADE TO BE OUT OF BALANCE AND SEVERE

VIBRATION WILL OCCUR. EVEN WEAR ON THE

PARTS AND PROPER BALANCE IS ENSURED BY

REPLACING VANESPAIRS.

GRADE 8

CAPSCREWS

VANE

LOCKNUTS

FIGURE 22

protection while removing mower blade. Remove the

nyt and lockwasher- securing the blade and remove *

blade. See Figure 23.

Sharpen, blade by following the same contour of the’

cutting edge; be careful not to rourvd off the outer cor

ners of cutting edge.

Sharpen both cutting edges fqpally to,<keep the blade

balanced.

The mower blade should always be kept sharp and pro

perly balanced. Disconnect spark plyg wire. Remove

Mower Pan, clear dirt and grass from underside, and

check blade. Use a heavy glove or padding for hand

Replace mower blade In position oh mower and secure

with lockwasher and nut. Torque to 50-55 lbs. Be sur^-.^

to use a heavy gloye or padding for hand protectio 1

while fastening blade.

-14 -

Page 15

FILLING THE FUEL TANK - FIGURE 24

Before filling the tank, wipe all dust and dirt from

around the cap to prevent dirt from falling into the tank.

Use an approved gasoline container and keep it clean.

Fill tank completely. The tank capacity is 1.7 gallons

(6.5 liters). Use clean, fresh "regular” grade of

automotive gasoline. Use leaded or unleaded type. Do

not use premium gasoline. Do not mix oil with gasoline.

Refer to Engine Instructions also.

DANGER: ALWAYS USE CAUTION WHEN HANDLING

GASOLINE. NEVER FILL THE FUEL TANK WHEN THE

ENGINE IS RUNNING OR WHEN THE ENGINE IS HOT.

NEVER SMOKE WHILE FILLING THE TANK. REMOVE

THE IGNITION KEY BEFORE FILLING TANK.

ENGINE OIL - FIGURE 24

Fill crankcase with oil as recommended below. Refer,

also, to Engine Manufacturer's Instructions supplied

with the product. Check oil level before each use and

change oil regularly according to Engine.

Manufacturer's Instructions. Check oil level with trac

tor on a level surface. Keep dipstick area clean.

IMPORTANT: ENGINE WILL SMOKE EXCESSIVELY IF

DIPSTICK IS NOT PUSHED DOWN UNTIL IT SNAPS IN

TO PLACE.

CHANGE ENGINE CRANKCASE OIL

1. When the tractor is new, the oil should be chang

ed after the first five hours of operation.

Thereafter under normal operating conditions the

oil should be changed every 25 hours of opera

tion. If extremely dusty or dirty conditions prevail,

change oil more frequently.

2. Drain crankcase by opening petcock or removing

the drain plug. Figure 24, while the engine is

warm. Allow the oil to run into a container.

NOTE: WITH THE ENGINE WARM, THE OIL WILL

FLOW MORE FREELY PERMITTING MORE CON

TAMINANTS TO BE DRAINED FROM THE

CRANKCASE.

3. Close petcock or replace the drain plug. Remove

dipstick and refill crankcase with the proper type

and viscosity of oil as shown in Tables 2 & 3.

Check oil on the dipstick to make sure that the

level is to the "FULL" mark. DO NOT OVERFILL.

■MJ

•Sjl

SEASON

Summer:

(Above 32°F)

Winter:

(Below 32°F)

ENGINE CRANKCASE CAPACITY IS 2 PINTS. DO NOT

OVERFILL.

SEASON ENQINE OIL RECOMMENDA

Summer:

(Above 32°F)

Winter:

(Below 32°F)

Below 0°F:

ENGINE OIL RECOMMENDA

TIONS - YT8

SAE SOW or substitutes:

SAE 10W30, 10W40

SAE 5W30 or substitute:

SAE 10W

TABLE 2

TIONS - YT11

SAE SOW or substitutes:

SAE 10W30, 10W40

SAE 10W30, 10W40

SAE 5W20, 5W30; or

substitutes: 5W20, 5W30,

5W40 synthetic oil

STEERING GEARS - FIGURE 24

Apply a light coat of Ariens Moly Lithium grease to

steering gears every 50 hours of operation. See Figure

24.

ENGINE CRANKCASE CAPACITY IS 3 PINTS (1.4

LITERS). DO NOT OVERFILL.

TABLE 3

TRANSAXLE OIL LEVEL

The Transaxle is lubricated at the factory and should re

quire no further lubrication by the owner.

- 15 -

Page 16

LUBRICATION

GREASE FITTINGS

Each fitting should be wiped clean before and aft

lubrication. Grease each fitting every 50 hours of

operation with Ariens Moly Lithium grease. Following is

a list of the grease fittings with reference numbers that

identify each location on the corresponding illustra

tions.

1. Right and Left Steering King Pins — Figure 25.

2. Right and Left Front Wheels — Figure 25.

3. Jackshaft Spindle Housing — Figures 25 & 27.

4. Grease mower input (center) spindle.

5. Transaxle is sealed for dirt-free operation.

However, should repairs be needed, requiring ad

ditional lubrication, use Ariens Moly Lithium

Grease, Part No. 1 50.

FIGURE 25

JACKSHAFT

SPINDLE

HOUSING

TRACTION DRIVE BELT O

o

POINTS TO OIL - FIGURES 25, 26 & 27

1. Periodically oil the lift point pivots, front axle

pivot, control linkage pivots and the shaft pivots

to insure long life and smooth operation of the

parts. See Figures 25 and 27.

2. Lubricate slide for shift interlock switch. See

Figure 26.

IMPORTANT; KEEP GREASE AND OIL OFF THE BELTS

TO AVOID BELT SLIPPAGE AND DETERIORATION.

CTi !r~] LJ

o

FIGURE 27

- 16

Page 17

STORAGE

NOTE; THESE INSTRUCTIONS WILL ASSIST YOU IN

PREPARATION BEFORE AND AFTER STORAGE.

ENGINE

NEVER STORE PRODUCT IN AN ENCLOSED AREA

WHERE FUEL FUMES MAY REACH AN OPEN FLAME,

SPARK, OR PILOT OF FURNACE, ETC. DRAIN FUEL

OUTDOORS, AWAY FROM OPEN FLAME, AND USE

ONLY AN APPROVED FUEL CONTAINER.

If product is not to be used for thirty days or more,

prepare as follows:

1. Run engine until fuel tank is empty and engine

stops due to lack of fuel.

2. Be sure all fuel is removed from fuel tank (as well

as any contamination). The carburetor and fuel

tank must be clean and dry to prevent gum

deposits from forming and the engine from

malfunctioning.

3. If gasahol has been used, complete the steps

above, then put a small amount of regular gasoline

into the fuel tank and repeat the steps.

4. Remove all oil, grease, dirt and debris from the

engine.

8. Recap the spark plug according to Engine Instruc

tions supplied with your tractor. Replace the spark

plug if required.

BATTERY

Refer to "Battery Set-Up and Maintenance", page 36

of this manual.

GENERAL

NOTE: YOUR AUTHORIZED ARIENS DEALER IS

TRAINED AND EQUIPPED TO SERVICE YOUR TRAC

TOR. A PERIODIC CHECK-UP BY YOUR DEALER WILL

HELP REDUCE YOUR MAINTENANCE COSTS.

Store product in a cool, dry place to reduce tire

deterioration. Blocking under the product frame will

take the weight off the tires.

Inspect product for visible signs of wear, breakage or

damage. Order any parts required and make necessary

repairs to avoid delays when beginning use again. Your

Ariens dealer will be able to assist you.

Clean the product thoroughly.. Touch up all scratched

and exposed areas with paint to avoid rust. Your Ariens

dealer stocks the following aerosol paints:

5. Change the engine oil. See "LUBRICATION" sec

tion of this manual.

6. Check and, if necessary, clean the air cleaner and

replace fuel filter.

7. For extra protection remove the spark plug and

pour one tablespoonful of engine crankcase type

oil into the cylinder. Turn engine over manually

(two revolutions of crankshaft).

Ariens Charcoal Brown

Ariens Sunset Orange

Ariens White

NOTE: ARIENS RECOMMENDS USING A HIGH QUALI

TY PRIMER AS A BASE FOR THE TOUCH UP PAINT.

THE TOUCH UP PAINT WILL NOT PROVIDE THE HIGH

GLOSS FINISH OF ORIGINAL BAKED-ON PAINT. COL

OR MAY VARY SLIGHTLY, ALSO.

Part No. 64

Part No. 65

Part No. 66

- 17 -

Page 18

FRAME/CHÂSSIS

935003, 935004 & 935005

. '"’ií

■ 1

Jâ)

•H®

18-

Page 19

r

FRÂME/CHÂSSIS

935003/935004 & 935005

Node N0 DECODE

REF. PIEC^ D'INV

REF. PART STOCK

NO. NO. CODE

1

535028

2

063004

3

065018 M Nut, 3/8-16 UNO 26

5

059135 M

6 063003 M Lockwasher, STO 5/16"

7

065015

8

035006 0 Strut Right Foot Board

9 035007

10

062011

16

035043 F Idler Arm

17 035044

18 055036

19

064043 M Washer, 3/8" STO x 13/16 x .065 PL

20

067004

21

035038 0

22 075054

23 035039

24

035040

25 035041

26 064002 M

27

006071 M

29 075026

31 535026

31 535027

32

029206

064007

33

34

063002 M Lockwasher, STO 1/4" 14

35 065032 M Nut, 1/4-20 UNC 14

36 031149 F Headlight 2

0 Main Frame W/Oecals

M Lockwasher, STO. 3/8"

M

0 Strut Left Foot Board

M

S

F Flange Bushing

M "Cotter Pin, 1/8x1

M Bumper

S Seat Channel R.H.

S Seat Channel L.H.

M Seat

M Grommet

s

s

s

M

DESCRIPTION

Cap Screw, 5/16-18 x 3/4. 14

Nut, 5/16-16

Carriage Bolt, 5/16-18 x 5/8

Idler Pivot

Rear Osck

Washer, STO 5/16 x 7/8 x .083 PL

Spacer Bushing

Hood 8i Grill W/Decals, YT8

Hood 8i Grill W/Oecals, YT11

Headlight Insert 1

Washer, Std. 1/4 x 47/64 x .065 PL 14

QUANTITÉ

NO. REQ'D

Node No DE

REF. PIECE

REF. PART

NO. NO.

1

8

3

40

17 41

15 42

1

43

1. 44

4

45

1 46

1

2

1

47

1

48

1

49 073111

2 50

1 51

1 52

1 53

54

6

2 56

58

1

60 083058

1

61

1

62

63 031904

64

65 065039

66 030055

67

68 064117 M

CODE

D'INV.

STOCK

CODE

37

031159

38

061045 M

39

065095

075058 M Stop

029122

061041

035050 0 Cash Biise

062011

059022

631006 S

061040 M Machine Screw, 10-24 x PL

059161

063011

065055 M Nut

031716

029131

065096 M Nut

062013

029123

064008 M Washer, STO 3/8"

063032

065098

069110 M Clip

S Headlight Retainer Ring

M

M Hood Hinge

M

M Carriage Bolt, 5/16-18 UNC x % PL

M Cap Screw, 5/16-18 x % GR 2 HHPL

M Cap Screw, 3/8-16 x IK: GR 5

F Idler

M Lockwasher

F

F

M Carriage Bolt, 3/8x16x1

S Brace

M

M

M

M Locknut

M Locknut, 2 Way 3/8-16 UNC

M Wire Slip

DESCRIPTION

Machine Screw, 5/16-18 UNC x 1/2"

Crown Nut, 5/16-18 UNC

Machine Screw, 1/4-20 UNC x 5/8"

Tail Light Assembly, consists of:

031375 Lens

Bulb, STD GE No. 1895

Seat Switch

Switch, Shift

Spring

Lockwasher, 5/16" Shake Proof

Foam Tape, 31" Long

Shim Washer

QUANTITÉ

NO. REQ'D

2

2

2

2

2

6

1

8

4

1

1

1

2

1

1

2

2

1

1

1

2

2

1

2

1

7

2

2

1

1

1

SUGGESTED PARTS STOCKING CODE

F -FAST S -SLOW

M - MEDIUM 0 - CUSTOMER ORDER ONLY

F - FAST (rapide) S -SLOW (lent)

CODE SUGGÉRÉ D’INVENTAIRE DES PIÈCES

M - MEDIUM (moyen) 0 - Commande du client seulement

- 19-

Page 20

LtFT LEVER/RELEUAGE MANUEL

935003, 935004 & 935005

THIS SIDE STRAIGHT ON YT8

-20-

Page 21

LIFT LEVER/RELEUAGE MANUEL

935003, 935004 & 935005

Node

NoOE

REF.

PIECE

PART

REF.

NO

NO

1 035033

065034 M

2

064043

3

067004

4

5 003016

6 065060

7 035035 s

035036

8

035037 M Brake Rod

9

10 064002

065042

11

12

083091

13 083178 M

14

075029

058040 M

15

16 035045

17 035046

083104

18

064096 M

19

035047 0

20

21

058040

22 075053

23

012128

24

035048

035322

25

067021 M

26

27

035049

035057

28

29 035058

30 035059 0

31 059135

32 063003 M

33 065015

055037 F

34

083132 M

35

36 064003 M

37

058003 M

075001 M Shift Ball

38

39 035060 s

40 062011 M

41

027078

42 061050 M

CODE

D'INV

STOCK

CODE

S

M Washer, SAE 3/8

M Cotter Fin, 1/8 X 1, PL

M

M

M Parking Brake Rod

M

M Locknut, 5/16-18 2 way

M Brake Spring

M Pedal Cover

0

0 Lift Quadrant

M

M

s

M

s

DESCRIPTION

Clutch Pedal

Locknut, 5/8-18 Centerlock

Shoulder Bolt

Locknut, 3/8-16 Centerlock

Brake Pedal

Washer, STD 5/16

Extension Spring

Pin, Groove, % X 1 • 1 % E

Lift Handle

Spring

Washer, 29/64 ID x % x 16 GA

Plunger Rod

Roll Pin, % X 1%

Grip

Flange Bushing

Lift Arm

s Adjustable Link

Cotter Pin, 1/8 X I'/i, PL

s Lift Link

PTO Lever

s

PTO Handle

s

Bracket

Cap Screw, 5/16-18 x % GR 5

M

Lockwasher, 5/16 SAE STD.

M Nut, 5/16-18

Flange Bushing

Compression Spring

Washer, SAE 'll STD. x 1/16 x .096 PL

Roll Pin, 3/16x1%

Switch Bracket

Carriage Bolt, 5/16-18 x 3/4, PL

F Switch Interlock

Machine Screvk, 10-24 x 1" PL

SUGGESTED PARTS STOCKING CODE

F-FAST S-SLOW

M - MEDIUM 0 - CUSTOMER ORDER ONLY

QUANTITE

NO. REQ'D

Node

Node

REF.

PIECE

REF.

PART

NO.

NO.

43

1

1

4 45 035005 S

5

065051

44

035061

035241 S Rear Hanger, YT11 1

46

CODE

D'INV

STOCK

CODE

2 46 035223

47 035225 S

2

1 48

1 49 031381

1

4

3

1 53

1

2 55

1

1 58 065018

1

1

1 61

1 63 064008

2

1

2

1

1

2

1

1

1

1

5

7

9

1

1

1

1

1

1

5

1

1

035224

50

067029

-51 035321

52 067010

064003

54

035023 0

035024 0 Hanger Bracket

57 063004

59 535028

60 059154 M

035034

64

031755

65 035026 M

059034

66

67 035027 M

064007 M

68

71 035167

72

035166 M Cam

73

059128

74

035008

75

035009

76 064062 M

77

067021 M Cotter Pin, 1/8x1 'h

78 062010

79

064008

80 065124

81 065017 M

82

035206 M Rod

83

064007

84

065122

85

065046

F - FAST Irapide) S - SLOW (lent)

M - MEDIUM (moyen) 0 - Commande du client seulement

DESCRIPTON

M Keps Nut, 10-24

S Rod

Pedal Pivot

Rear Hanger, YT8

S

Front Hanger Arm - Right

Front Hanger Arm - Left

S

M

Clevis Pin

Hair Pin, Internal .094

M

Rod End

s

M Hair Pin, Internal

Washer, .505 ID x .680 00 x .072

M

Draw Bar

Lockwasher, 3/8 SAE STD.

M

M Nut, 3/8-16

Frame, w/Decals

0

Cap Screw, 3/8-16 x 3/16 GR 5, HHPL

s Clutch Rod

M Washer, STD. 3/8

F Belt Finger

Cam Actuator

Cap Screw, 5/16-18 x 7/8 GR 2 HHPL 2

M

Spacer

Washer, STD. 1/4

M Link

M

Cap Screw, 5/16-18 x 1% GR 5 2

0

Center Lift Bracket 1

0 Center Lift Lever

Washer, 49/64 ID x 1-1/8 x .062 1

M Carriage Bolt, 3/8-16 x 3/4

M

Washer, 3/8 STD x 1 x .083 PL

M

Locknut, 5/16-18 GR C 5

Jam Nut, 1/2-13

M Washer, 1/4 Std.

M

Locknut, 3/8-16 4

M Locknut, %-13

CODE SUGGERE D'INVENTAIRE DES PIECES

QUANTITE

NO. REQ'D

1

1

2

1

1

1

2

6

1

4

4

1

2

2

2

1

6

1

1

2

1

2

2

1

1

1

2

2

1

4

2

3

1

21 -

Page 22

TRANSAXLE/ESSIEU ARRIÈRE

935003, 935004 & 935005

(5)^ 1 Г®

17) (0\ ^

-22-

Page 23

TRANSAXLE/ESSIEU ARRIÈRE

935003, 935004 & 935005

Node no de code

REF, PIECi D'INV

REF. PART STOCK

NO. NO. CODE

1

035010 0 Transaxle Mount

2

073105

3 060014 M Setscrew 2

4

059160

5 063004 M Lockwesher, STD 3/8" 10 48

6

065018

7

024331

8

035011 S

9 065122

10

067001

11 035012 M

12 013166

13 059162

14

064007 M Washer, STD y

15 063027 M Lockwasher, Internal 1 58

16 065070

17

059083

18

064088

19 035015

20 066013

21 035016

22 072116

072117

23

24

065025

031755

25

26

059181

063004 M

27

28

065024

035017

29

30 059135

055036

31

32 035013

035014

33

34 054120

35 022093

36

035018

37

073108

035019 S Idler Mtg. Bolt (YT 11 only)

38

39 035020

40 083068

41

070009

42 035021

035022

43

M Transaxle Sheave

M

M

M Tab

M

M

M Spacer 1

M

M

M Cap Screw, )i-20 x 2 GR 5

M Washer, .754 ID x 1V4 00 x 1/8" 2 61

M

M

M Double Sheave (PTO) 1

F Main Drive Belt

F

M

F Belt Finger

M Cap Screw, 3/8-16 x 1 GR 5 HHPL 3

M Nut

S

M Cap Screw, 5/16-18 x %

F

0 Spindle Housing

S Spacer 1

F

F Zerk Fitting

S

F

S Spring Anchor

F Drive Spring

M Fig, Whiziock Screw, 5/16-18 x ’/2"

S

S Belt Retainer

DESCRIPTION

Cap Screw, 3/8-16 x 2% GR 5

Nut, 3/8" X 16 UNC 10

Selector Rod 1

Locknut 8

Cotter Pin

Range Selector Lever 1 54

Cap Screw, V«-20 x 2 GR 5

Crown Locknut GR C

Jackshaft Spindle

key. Straight SAE 1035

Traction Belt

Jam Locknut 3/4-10 1 071130 S Rim

Lockwasher

Idler Pivot

Flange Bushing

Bearing

Idler Arm

Attachment Idler

Idler Arm

QUANTITÉ

NO. REQ'D

1 44 059027 M

1 45 064052

4

1 50

1

1

2

1 60

1

1 63

1 Consists Of:

1 071018

4

2 66

2

1

4 69

4 70

1

2

1

1 75 064093

1

1

1

1

1

1

1

Node No DE CODE

REF. PIECE DTNV,

PART STOCK

REF,

NO. CODE

NO.

M

Washer, .380/.385 x 13/16 x .246 PL

46

067020

47

073109

083117

49 035163 0 Plate

061043

51

061040

035164

52

53 035161

535007 M

55 075001

56

035153

57 535004 M

535005

59

535009

035157

035249 F

62 066014

064048

64 635007 S Tire & Wheel Assembly 2

071088 0

65 035169

057074

67 003377 M Hub Cap 2

68 035068

635012 0 Transaxle 1

066019 M

71 066003

72 059145

73 067004

74 035034 s

76 065124 M

77 064002 M Washer, STD 5/16"

060035

78

059027 M Cap Screw, 3/8-16 x 1%,

80

035261 s

81

M

F Main Idler 1

M

M

M Machine Screw, 10-24 x '/^

0 Cover

M

Hi-Lo Shift Lever

Shift Lever Assembly

M

M

Disc Brake

Brake Jaw Assembly

Lever, Actuating Assembly

M

M

Shim Kit

Shoulder Bolt 1

S

M Key, Woodruff No. 61

M

S

Tire

Tube Available

S Spindle Cup 2

M

S

M

M

M

M

Washer, .385 ID x 13/16 OD x .062

M Setscrew, N0. 8-32 1

DESCRIPTION

Cap Screw, 3/8-16 x 1%

Hair Pin, Internal 3/32 x 1-3/16 2

Extension Spring

Machine Screw, 8-32 x

Knob

Puck, Friction

Washer, .755 ID x 1.375 OD x .062

"E" Ring 2

Spacer

Key, Straight 3/16x3/16x2

Key, 3/16 X 3/16 X 2

Cap Screw, 3/8-16 x 1 GR 5

Cotter Pin, 1/8x1

Clutch Rod

Locknut, 5/16-18 GR C 5

Gr 2, HHPL,(YT8 only)

Bracket,(YT 8 only)

QUANTITÉ

NO. REQ'D

1

2

1

1

3

4

1

1

1

1

1

1

1

1

2

1

4

2

2

1

4

1

1

1

3

1

1

SUGGESTED PARTS STOCKING CODE

F - FAST S -SLOW

M - MEDIUM 0 - CUSTOMER ORDER ONLY

CODE SUGGÉRÉ D'INVENTAIRE DES PIÈCES

F — FAST (rapide) S — SLOW (lent)

M — MEDIUM (moyen) 0 — Commande du client seulement

-23-

Page 24

TRANSAXLE PARTS/PI^CES DE ESSIEU

935003, 935004 & 935005

A 535025 CONSISTS OF THESE PARTS

®-0

-24-

Page 25

TRANSAXLE PARTS/PIÈCES DE ESSIEU

935003, 935004 & 935005

NO DECODE

NoDE

REF.

PIECÉ D'INV

REF.

PART STOCK

NO. CODE

N0.

1

057083 M

2

535011

3 035121

4

035122

5 035123

6 035124

7

035125

8

035126

9 035127 M

10

035128

11

035120

12

066006

066041

13

14 066014

15 035129

16

035130 M Flange Bearing

17

535001 M

18 035132

19

035115

035134

20

035254

21

22 535002

23

035136

24

535003 M

25 035138 M Spur Gear 33T

26 035139

27

035140

28 066039

035141

29

30

535010 M

035142

31

32 057087

33 035143 M Spur Gear 32T

34 035144

35 035145 M Cross Shaft

36 064134

37

035146

38 035147

39

035148

40

064158

41

035149

42

056103

43 935151

44

059132

45

961056

46

059050

47

.035253

48 035153

49

035256

535004

50

M

M Flange Bushing

M

S

S

M

M

M

U

M

M Hi-Pro Key

M

s

s

M

s

M

s

s

s

s

M Woodruff Key

M L.H. Axle

M

M Snap Ring

M

M

s

s

s

M

M R.H. Axle

F Felt Seal

0

M

M

M

M

M Brake Disc

M

M Brake Jaw Assembly

DESCRIPTION

Snap Ring 3

Shim Kit (Washers)

Spacer

Spur Gear 13T 1

Spur Gear 25T

Clutch Collar

Spur Gear ЗОТ 1

Spacer

Spur Gear 20T

Washer .020 1

Woodruff Key 2

Woodruff Key

Intermediate Shaft

Gear Assembly 12T

Spur Gear 37T

Washer .045

Spur Gear 25T

Washer .025

Shaft Support Assembly

Spur Gear 2 ОТ

Bevel Gear Assembly

Spur Gear 30T

Drive Shaft

Shim Kit

Splined Miter Gear 15T

Miter Gear 15T

Washer .031

Spur Gear 35T

Gear Lock

Spur Gear 22T

Washer .062

Lower Housing

Cap Screw

Machine Screw

Cap Screw

Friction Puck (Inner)

Brake Pad

QUANTITÉ

NO. REQ'D

AR

3

2

2

3

2

1

2

1

1

1

1 •

1

4

1

2

1

1

1

1

1

1

2

1

AR

2 83 083181

2

1

2

1 87

1

1 89

1

1

1

1

2

1

8

1

6

1

1

1

1

Node No DE

REF. PIECE

REF. PART

NO. NO.

51 060035

52 535005

53 535009

54 035157 M

55 035249

56 083180

57

58

59

60 535006

61

62

65 066003 M Woodruff Key 1

66 535008 M

67

68

69

70

71

72 083182 M

73 060008

74

75 035150

76 035155 M

77 035164

78 035160

79 035161

80

81 035163

82 061043

84

85

86 075001

88 063002

93

94

95 035257

95

NOTE: USE

NO.

CODE

D'INV.

STOCK

CODE

061035

035158

064178 M

057084

056104

059015

035137

035154

035156

035135

061040

535024

035165

535007

035159

063024

066038

535011

064178 M

ARIENS MOLY LITHIUIVl GREASE, PART

150.

DESCRIPTION

M

M

M

M

M

M

S

s

M

M

M

s

s

s

M

M

M

M

s

0

M

M

s

M

M

M

M

M

s

M

M

M Hi Pro Key

M

M

Setscrew 1

Actuator Lever Assembly

Shim Kit

Shoulder Bolt

Friction Puck (Outer)

Compression Spring 1

Machine Screw 1

Idler Shaft

Washer .020 thick

Idler Gear Assembly 1

Snap Ring 1

"0" Ring

Input Shaft Assembly

Cap Screw

Lockout Plate

Fork Support Plate

Shifter Fork

Detent Ball

Detent Spring

Setscrew

Machine Screw

Wave Washer

Nylon Insert

Nylon Cover

Upper Housing

Hi'Lo Shift Lever

Hi'Lo Shifter Fork Assembly

Hi'Lo Cover Plate

Hex Head Machine Screw

Detent Spring

Detent Pin

Shift Lever Assembly

Shift Knob

Shifter Fork

Washer

Washer

Shim Package

Washer .030 Thick AR

Washer .020 Thick AR

QUANTITÉ

NO._ REQ'D

1

1

1

1

1

1

1

1

4

1

1

2

2

2

4

1

1

1

1

1

1

1

3

T

1

1

1

1

14

1

1

1

SUGGESTED PARTS STOCKING CODE

F - FAST S - SLOW

M -MEDIUM 0 -CUSTOMER ORDER ONLY

F - FAST (rapide) S - SLOW (lent)

CODE SUGGÉRÉ D'INVENTAIRE DES PIÈCES

M — MEDIUM (moyen) 0 — Commande du client seulement

-25-

Page 26

FRONT AXLE & STEERING/ESSIEU DIRECTEUR

935003, 93S0Ö4 8i 935005

-26-

Page 27

FRONT AXLE & STEERING/ESSIEU DIRECTEUR

935003, 935004 & 935005

Node no CE code

RÈF. PIECÈ D'INV

REF. PART STOCK

N0. N0. CODE

1

535029 0

2 035032

3 059146 M

4

065127 M

5 064004

6 067014 M

7

035078

8

054025

9

059135 M

10

063003 M

11

065015

12

055080

13

035053

14

029133

15

029019

16

058003

17

029021

035054

18

19

055083

059073

20

21

064111 M

22

035055

23

067006 M

24

035215

25 055102

26 035212

27

035213

28 064017 M

058007

29

30

022093

31

035031

32

031129

065044

33

34

065121 M

35

035025

36

013155 M

37

535028 0 Frame W/Decals

S Spacer

M

0 Steering Bracket

M

M

M

M

M

M

M

M

s Arm 8i Shaft

M

M

M

M

F

s R.H. Spindle

s L.H. Spindle

M Roll Pin, 1/4 X 1-1/4

F

M

M

M

s

QUANTITÉ

DESCRIPTION

NO. REQ'D

Front Axle Ass'y

Cap Screw, )i-13 x 11i GR 5

Locknut, )i-13 GR C

Washer, 21/32 ID x 1 5/16 x 3/32

Cotter Pin, 1/8 X IK

Flange Bearing

Cap Screw, 5/16-18 X %

Lock washer, 5/16" SAE STD

Nut, 5/16-18 UNC

Flange Bushing

Steering Column

Needle Roller

Pinion Gear, Steering

Roll Pin, 3/16-1K

Steering Bevel Gear

Sleeve Bushing

Cap Screw, 5/16-18 X 1% GR 2 HHPL 2

Washer, STD 5/8"

Spacer

Cotter Pin, 3/16 X IK

Steering Link

Flange Bushing

Washer, .765 ID x 1-3/8 OD x 3/32

Spin Drive Zerk Fitting

Drag Link

Ball Joint

Jam Nut, 1/2-20 2

Locknut, 1/2-20 Nylon Insert

Steering Pivot

Steering Wheel

Node No DE CODE

REF. PIECE D'INV.

REF. PART STOCK

NO. NO. CODE

1

38

1

1

1 41 063004 M

2

2

1

1

2

2 47

2

1

1

1

1

1

1 51

1

2

3 55 064043 M

1

1

1

4

1

1 62 061017

2

3

2

2

2

2

1

1

1

035003 . 0

39 035210

40 062010 M

42

065018 M

43

012129 M

44

058009

45 064003 M

067004

46

635006

48 064017 M

49

035169

50 067027 M

064180 M

52

062016

53

035168 S

54

064078

58

067020

59 035051 s

60 035052 F

60 035214

61

025203

63 065051 M

64

059135

65 063003 M

66

065015

67 059004 M

069053

68

69

031108

70

062013

71

064062 M

72

069110

73 065026

74

063011

DESCRIPTION

Steering Pivot Channel

0

Front Axle Support 1

Carriage Bolt. 3/8-16 x 3/4

Lockwasher. 3/8 SAE STD.

Nut. 3/8-16

Flange Bushing

M

Roil Pin. 1/8x1

Washer. 17/32 ID x 1-1/16 OD x 3/32

M

Cotter Pin, 1/8 X 1" PL

S

Tire 8i Wheel Ass'y Consists of:

71028 Tire

71129 Rim

54089 Bearings

Washer. .755 ID x 1.375 OD x .062

M

Spindle Cup

Cotter Pin. Tee Hd. 1/4 x IK

Washer. .531 ID x .827 OD x .062

M

Carriage Bolt, 3/8-16 x IK"

Pivot Arm

M

Washer. .626 ID x 3.85 OD x 21 Ga

Washer. 13/32 ID x 13/16 OD x 1/16

M

Hair Pin, Internal 3/32 x 1-3/16 PI

Brace

Module, YT11

Module. YT8

F

S

Connector

M

Machine Screw, 10-24 x 5/8 PL

Nut. Keps 10-24

M