Ariens 93250500 (101-1500), 93250400 (101-549), 93203700 (101-4500), 93203600 (101-7999) Owner’s Manual

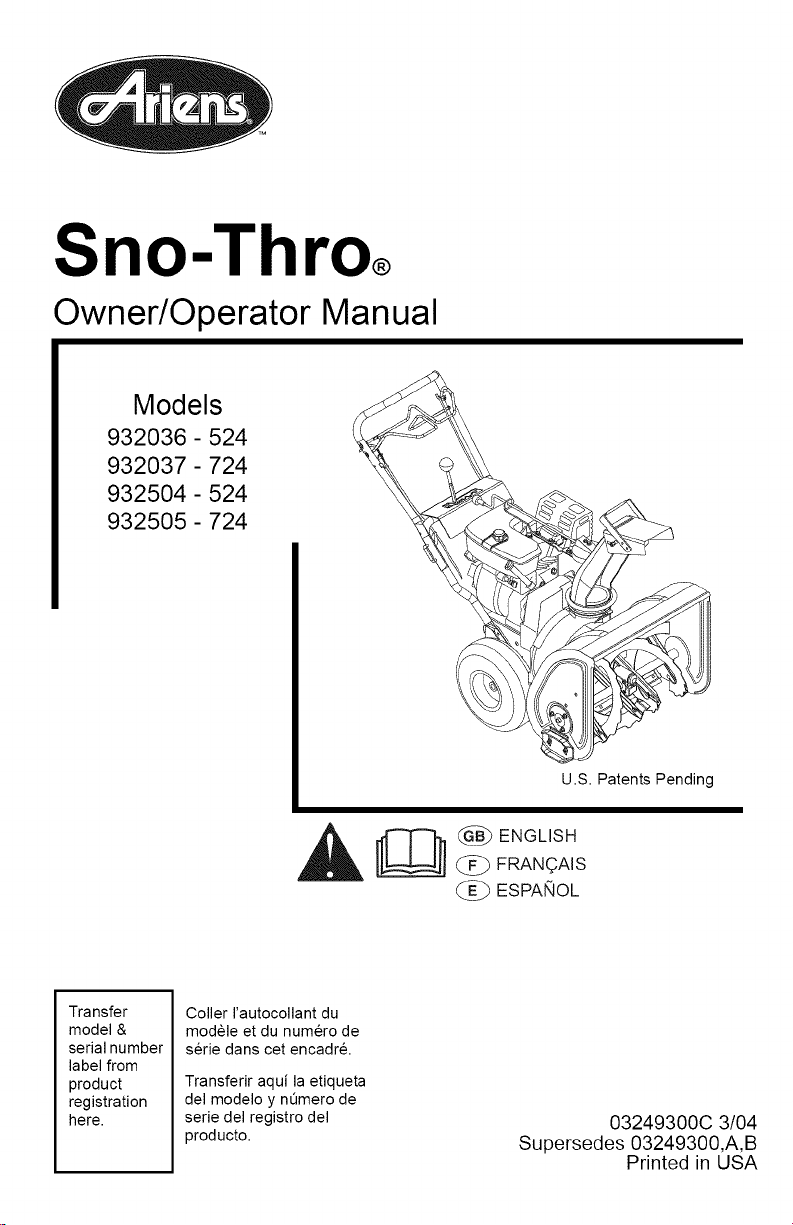

Sno-Throo

Owner/Operator Manual

Models

932036-524

932037-724

932504-524

932505-724

U.S. Patents Pending

Transfer

model &

serial number

label from

product

registration

here.

_ _ _ENGLISH

Coller I'autocollant du

module et du numero de

serie dans cet encadr&

Transferir aquila etiqueta

del modelo y nOmero de

serie del registro del

producto.

FRANQAIS

ESPAKIOL

03249300C 3/04

Supersedes 03249300,A,B

Printed in USA

Ariens Company

655 West Ryan Street

RO. Box 157

Brillion, Wisconsin

54110-0157

USA

Telephone:

(920) 756-2141

Facsimile:

(920) 756-2407

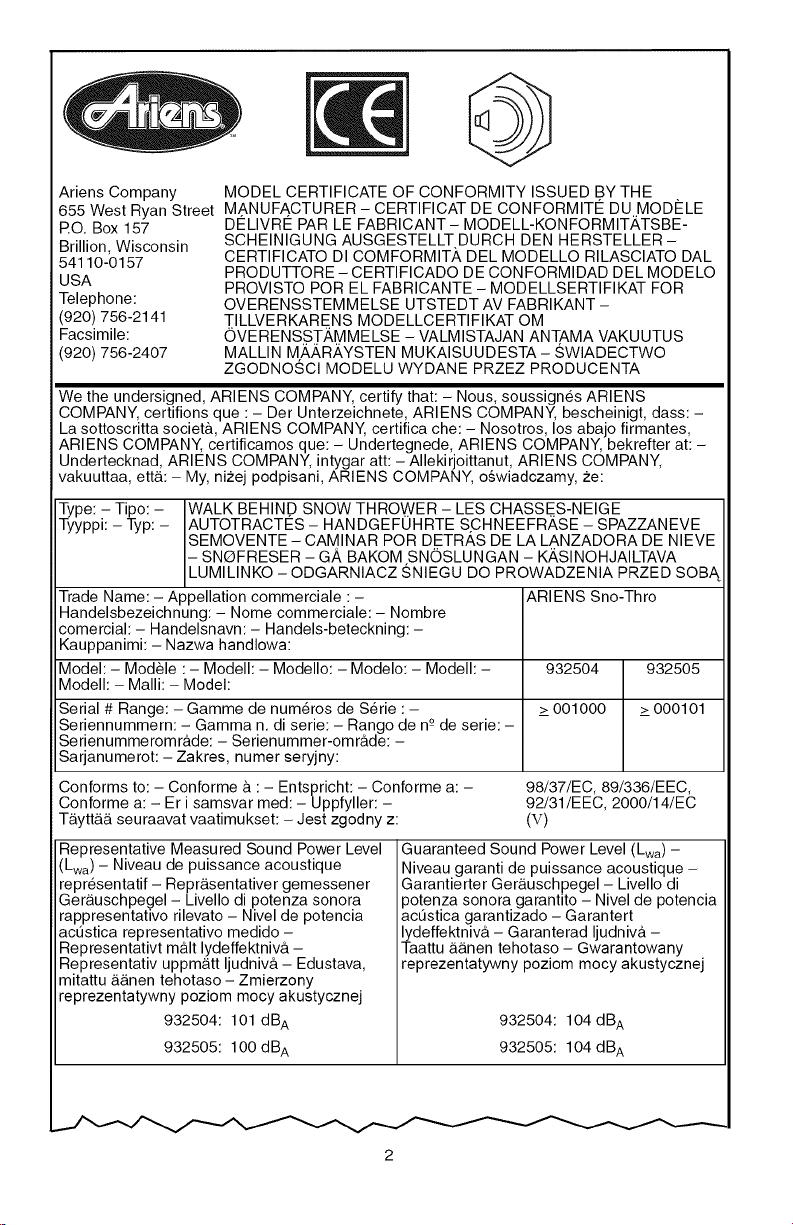

We the undersigned, ARIENS COMPANY, certify that: - Nous, soussignes ARIENS

COMPANY, certifions que :- Der Unterzeichnete, ARIENS COMPANY, bescheinigt, dass: -

La sottoscritta societ&, ARIENS COMPANY, certifica che: - Nosotros, los abajo firmantes,

ARIENS COMPANY, certificamos que: - Undertegnede, ARIENS COMPANY, bekrefter at: -

Undertecknad, ARIENS COMPANY, intygar att: - Allekirjoittanut, ARIENS COMPANY,

vakuuttaa, ett&: - My, nizej podpisani, ARIENS COMPANY, o_wiadczamy, ze:

Type: - Tipo: - WALK BEHIND SNOW THROWER - LES CHASSE_S-NEIGE

Tyyppi: - Typ: - AUTOTRACTES - HANDGEFUHRTE SCHNEEFRASE - SPAZZANEVE

Trade Name: - Appellation commerciale : - ARIENS Sno-Thro

Handelsbezeichnung: - Nome commerciale:- Nombre

comercial:- Handelsnavn:- Handels-beteckning:-

Kauppanimi: - Nazwa handlowa:

Model: - Modele : - Modell: - Modello: - Modelo: - Modell: - 932504 932505

Modell: - Malli: - Model:

Serial # Range: - Gamme de numeros de Serie : - > 001000 > 000101

Seriennummern: - Gamma n. di serie: - Rango de n° de serie: -

Serienummeromr&de: - Serienummer-omr&de: -

Sarjanumerot: - Zakres, numer seryjny:

Conforms to: - Conforme & : - Entspricht: - Conforme a: - 98/37/EC, 89/336/EEC,

Conforme a: - E ri samsvar med:- Uppfyller: - 92/31/EEC, 2000/14/EC

T&ytt&& seuraavat vaatimukset: - Jest zgodny z: (V)

Representative Measured Sound Power Level

(Lwa) - Niveau de puissance acoustique

representatif - Repr&sentativer gemessener

Ger&uschpegel - Livello di potenza sonora

rappresentativo rilevato - Nivel de potencia

act_stica representativo medido -

Representativt m< lydeffektniv& -

Representativ uppm&tt Ijudniv& - Edustava,

mitattu &&nen tehotaso - Zmierzony

reprezentatywny poziom mocy akustycznej

MODEL CERTIFICATE OF CONFORMITY ISSUED BY THE

M.ANUFA.CTURER - CERTIFICAT DE CONFORMITE_ DU MODELE

DELIVRE PAR LE FABRICANT - MODELL-KONFORMIT,_,TSBE -

SCHEINIGUNG AUSGESTELLT DURCH DEN HERSTELLER -

CERTIFICATO DI COMFORMIT,_ DEL MODELLO RILASCIATO DAL

PRODUTTORE - CERTIFICADO DE CONFORMIDAD DEL MODELO

PROVISTO POR EL FABRICANTE - MODELLSERTIFIKAT FOR

OVERENSSTEMMELSE UTSTEDT AV FABRIKANT -

TILLVERKARENS MODELLCERTIFIKAT OM

OVERENSST,_MMELSE - VALMISTAJAN ANTAMA VAKUUTUS

MALLIN M.,_,_R,_,YSTEN MUKAISUUDESTA - SWlADECTWO

ZGODNOSCI MODELU WYDANE PRZEZ PRODUCENTA

SEMOVENTE - CAMINAR POR DETRAS DE LA LANZADORA DE NIEVE

- SNOFRESER - GA BAKOM SNOSLUNGAN - K,_SINOHJAILTAVA

LUMILINKO - ODGARNIACZ SNIEGU DO PROWADZENIA PRZED SOB,_

Guaranteed Sound Power Level (Lwa) -

Niveau garanti de puissance acoustique -

Garantierter Ger&uschpegel - Livello di

potenza sonora garantito - Nivel de potencia

act_stica garantizado - Garantert

lydeffektniv& - Garanterad Ijudniv& -

Taattu &&nen tehotaso - Gwarantowany

reprezentatywny poziom mocy akustycznej

932504:101 dB A

932505:100 dB A

932504:104 dB A

932505:104 dB A

2

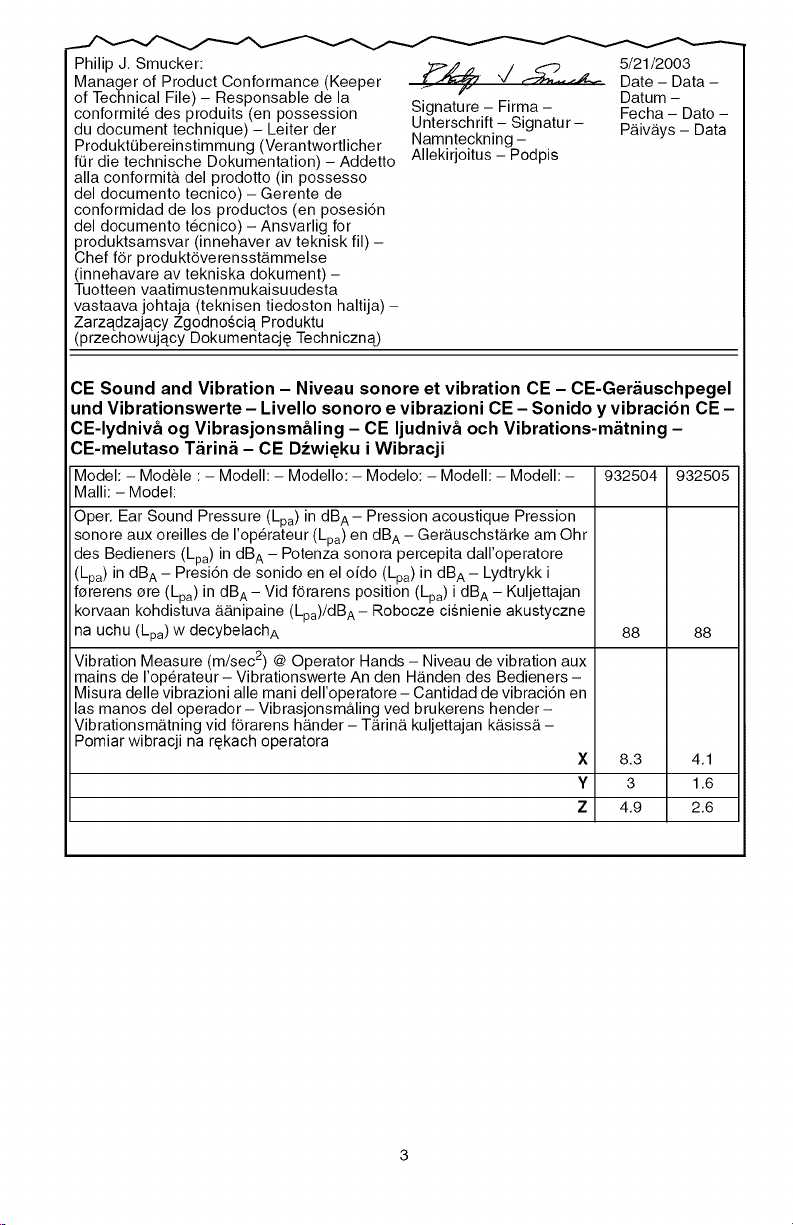

PhilipJ,Smucker: 5/21/2003

ManagerofProductConformance(Keeper Date- Data-

ofTechnicalFile)- Responsabledela Datum-

conformitedesproduits(enpossession Fecha- Dato-

dudocumenttechnique)- Leiterder P&iv&ys- Data

Produkt(Jbereinstimmung(Verantwortlicher

fordietechnischeDokumentation)- Addetto

aliaconformit&delprodotto(inpossesso

._ t _

Signature - Firma-

Unterschrift- Signatu r-

Namnteckning -

Allekirjoitus - Podpis

deldocumentotecnico)- Gerentede

conformidaddelosproductos(enposesi6n

deldocumentotecnico)- Ansvarligfor

3roduktsamsvar(innehaveravtekniskill)-

Cheff6rprodukt6verensst&mmelse

(innehavareavtekniskadokument)-

Tuotteenvaatimustenmukaisuudesta

vastaavajohtaja(teknisentiedostonhaltija)-

ZarzadzajacyZgodno_ciaProduktu

(przechowujatcyDokumentacj_Techniczna)

CE Sound and Vibration - Niveau sonore et vibration CE - CE-Ger&uschpegel

und Vibrationswerte - Livello sonoro e vibrazioni CE - Sonido y vibraci6n CE -

CE-lydniv& og Vibrasjonsm&ling - CE Ijudniv& och Vibrations-m&tning -

CE-melutaso T&rin& - CE D:_wi_ku i Wibracji

Model: - Modele : - Modell: - Modello: - Modelo: - Modell: - Modell: - 932504 932505

Malli: - Model:

Oper. Ear Sound Pressure (Lpa) in dB A- Pression acoustique Pression

sonore aux oreilles de I'op@ateur (Lpa) en dBA- Ger&uschst&rke am Ohr

des Bedieners (Lpa) in dBA - Potenza sonora percepita dall'operatore

(Lpa) in dBA- Presi6n de sonido en el oido (Lpa) in dBA- Lydtrykk i

fererens {)re (Lpa) in dBA- Vid f6rarens position (Lpa) i dB A - Kuljettajan

korvaan kohdistuva &&nipaine (Lpa)/dB A- Robocze ci_nienie akustyczne

na uchu (Lpa) w decybelach A 88 88

Vibration Measure (m/sec 2) @ Operator Hands - Niveau de vibration aux

mains de I'op@ateur - Vibrationswerte An den H&nden des Bedieners -

Misura delle vibrazioni alle mani dell'operatore - Cantidad de vibraci6n en

las manos del operador - Vibrasjonsm&ling ved brukerens hender -

Vibrationsm&tning vid f6rarens h&nder - T&rin& kuljettajan k&siss& -

Pomiar wibracji na rCkach operatora

X 8.3 4.1

Y 3 1.6

Z 4.9 2.6

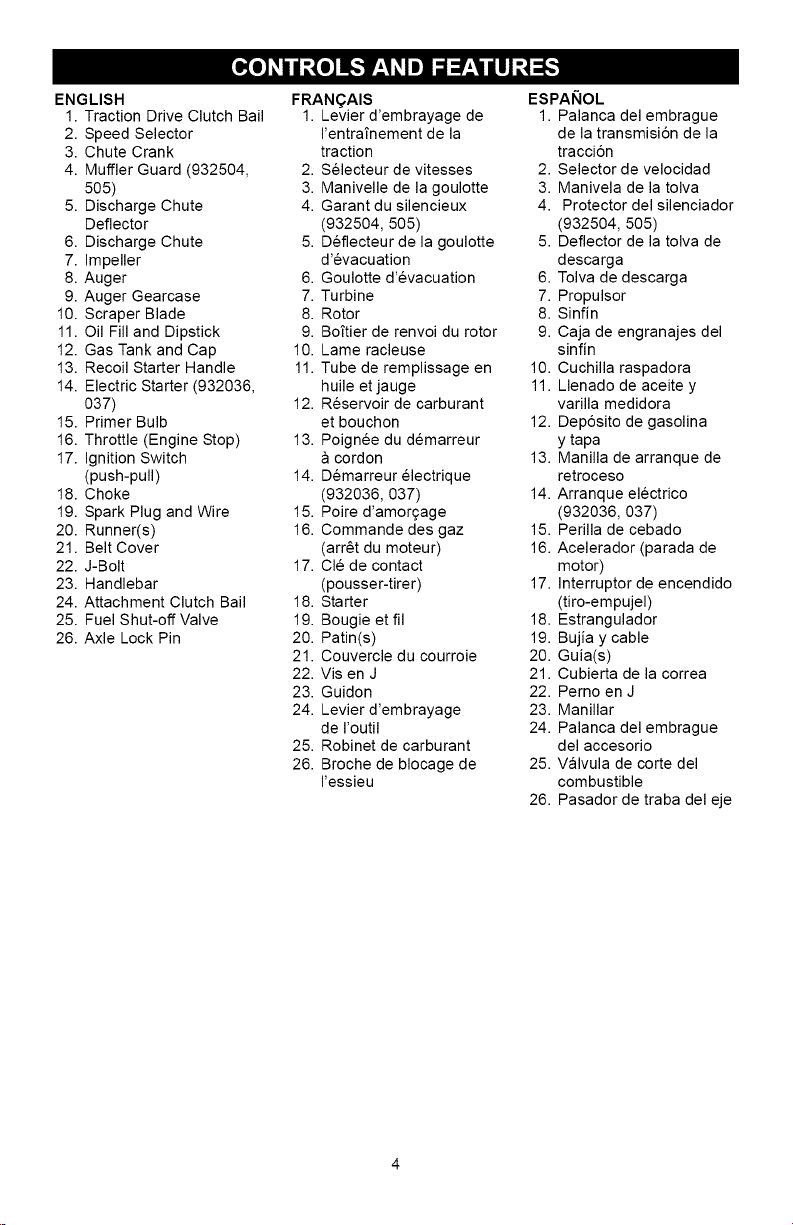

ENGLISH

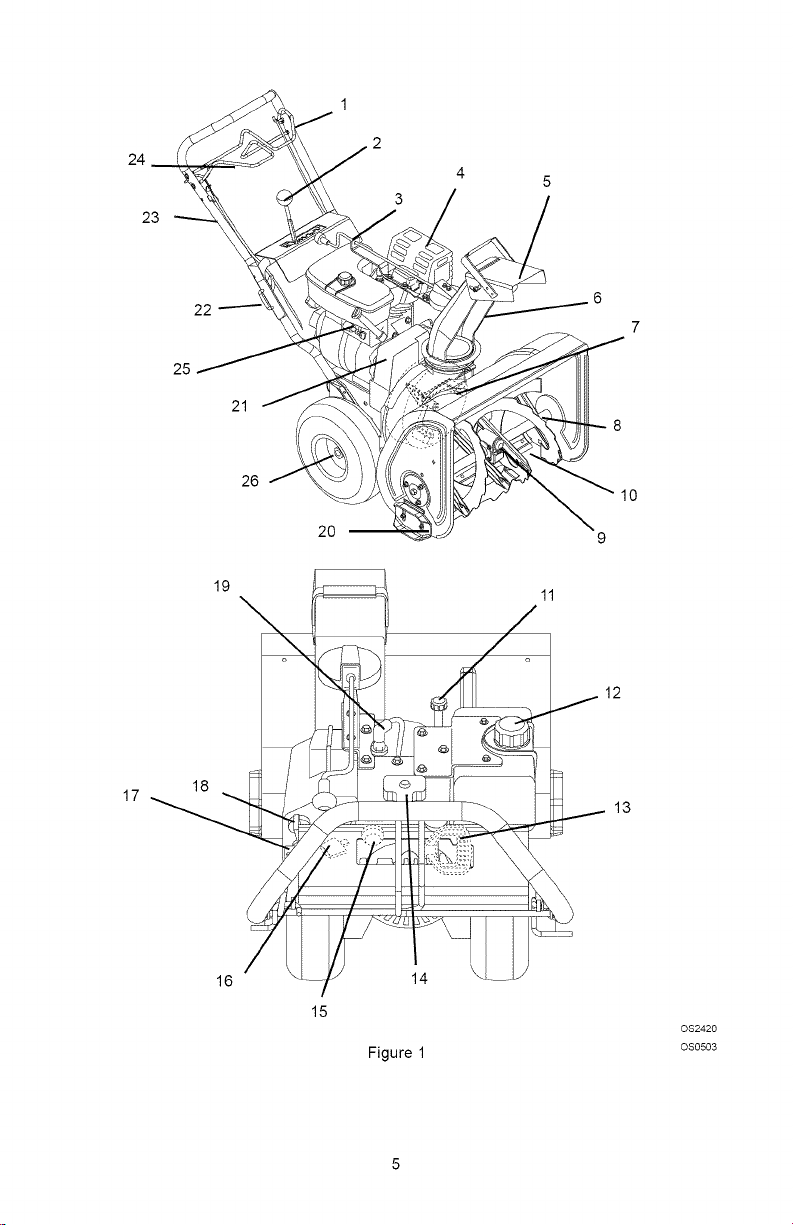

1.TractionDriveClutchBail

2.SpeedSelector

3.ChuteCrank

4.MufflerGuard(932504,

505)

5.DischargeChute

Deflector

6.DischargeChute

7.Impeller

8.Auger

9.AugerGearcase

10.ScraperBlade

11.OilFillandDipstick

12.GasTankandCap

13.RecoilStarterHandle

14.ElectricStarter(932036,

037)

15.PrimerBulb

16.Throttle(EngineStop)

17.IgnitionSwitch

(push-pull)

18.Choke

19.SparkPlugandWire

20.Runner(s)

21.BeltCover

22.J-Bolt

23.Handlebar

24.AttachmentClutchBail

25.FuelShut-offValve

26.AxleLockPin

FRAN(_AIS

1.Levierd'embrayagede

I'entrafnementdela

traction

2.Selecteurdevitesses

3.Manivelledelagoulotte

4.Garantdusilencieux

(932504,505)

5.Deflecteurdelagoulotte

d'evacuation

6.Goulotted'evacuation

7.Turbine

8.Rotor

9.Boftierderenvoidurotor

10.Lameracleuse

11.Tubederemplissageen

huileetjauge

12.Reservoirdecarburant

etbouchon

13.Poigneedudemarreur

cordon

14.Demarreurelectrique

(932036,037)

15.Poired'amor£age

16.Commandedesgaz

(arr6tdumoteur)

17.Cledecontact

(pousser-tirer)

18.Starter

19.Bougieetfil

20.Patin(s)

21.Couvercleducourroie

22.VisenJ

23.Guidon

24.Levierd'embrayage

deI'outil

25.Robinetdecarburant

26.Brochedeblocagede

I'essieu

ESPANOL

1.Palancadelembrague

delatransmisiSndela

tracciSn

2.Selectordevelocidad

3.Maniveladelatolva

4. Protectordelsilenciador

(932504,505)

5.Deflectordelatolvade

descarga

6.Tolvadedescarga

7.Propulsor

8.Sinfin

9.Cajadeengranajesdel

sinfin

10.Cuchillaraspadora

11.Llenadodeaceitey

varillamedidora

12.DepSsitodegasolina

ytapa

13.Manilladearranquede

retroceso

14.Arranqueelectrico

(932036,037)

15.Perilladecebado

16.Acelerador(paradade

motor)

17.Interruptordeencendido

(tiro-empujel)

18.Estrangulador

19.Bujiaycable

20.Guia(s)

21.Cubiertadelacorrea

22.PernoenJ

23.Manillar

24.Palancadelembrague

delaccesorio

25.Valvuladecortedel

combustible

26.Pasadordetrabadeleje

6

7

10

20

19

9

11

12

17

18

13

16

14

15

0S2420

Figure 1

0S0503

Controls and Features ................ 4

Safety .............................. 7

Assembly .......................... 12

Operation .......................... 14

Maintenance ........................ 18

Service and Adjustments ............. 20

I_bitTo_o]_l

Storage ............................ 27

Troubleshooting ..................... 28

Service Parts ....................... 27

Accessories ........................ 27

Specifications ...................... 29

Warranty ........................... 30

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. If used

improperly, this unit could be dangerous and

cause personal injury or property damage.

The contents will provide you with safety

instructions for the safe use of your unit during

normal operation and maintenance.

All reference to left, right, front, or rear are

given from operator standing in operation

position and facing the direction of forward

travel.

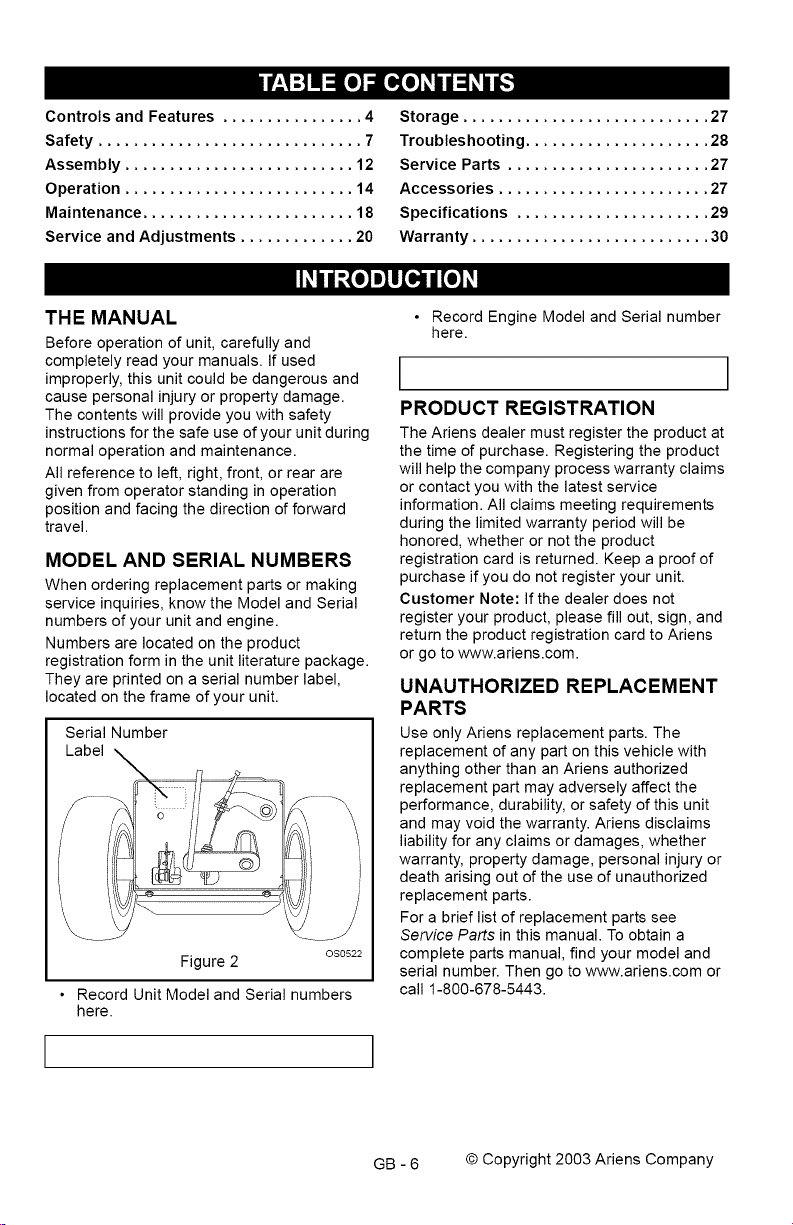

MODEL AND SERIAL NUMBERS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature package.

They are printed on a serial number label,

located on the frame of your unit.

Serial Number

Label

Figure 2

• Record Unit Model and Serial numbers

here.

OS0522

• Record Engine Model and Serial number

here.

PRODUCT REGISTRATION

The Ariens dealer must register the product at

the time of purchase. Registering the product

will help the company process warranty claims

or contact you with the latest service

information. All claims meeting requirements

during the limited warranty period will be

honored, whether or not the product

registration card is returned. Keep a proof of

purchase if you do not register your unit.

Customer Note: If the dealer does not

register your product, please fill out, sign, and

return the product registration card to Ariens

or go to www.ariens.com.

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The

replacement of any part on this vehicle with

anything other than an Ariens authorized

replacement part may adversely affect the

performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

warranty, property damage, personal injury or

death arising out of the use of unauthorized

replacement parts.

For a brief list of replacement parts see

Service Parts in this manual. Toobtain a

complete parts manual, find your model and

serial number. Then go to www.ariens.com or

call 1-800-678-5443.

GB - 6 © Copyright 2003 Ariens Company

DISCLAIMER

Ariens reserves the right to discontinue, make

changes to, and add improvements upon its

products at any time without public notice or

obligation. The descriptions and specifications

contained in this manual were in effect at

printing. Equipment described within this

manual may be optional. Some illustrations

may not be applicable to your unit.

DELIVERY

Customer Note: If you have purchased this

product without complete assembly and

instruction by your retailer, it is your

responsibility to:

1. Read and understand all assembly

instructions in this manual. If you do not

understand or have difficulty following the

instructions, contact your nearest Ariens

Dealer for assistance. Make sure all

assembly has been properly completed.

[,.'f-'1=1=l_

WARNING: To avoid injury to hands

A

and feet, always disengage clutches,

shut off engine, and wait for all

movement to stop before unclogging

or working on snow thrower.

Keep hands and feet away from auger

and impeller.

SAFETY ALERTS

Look for these symbols to point

out important safety precautions.

They mean:

Attention!

Personal Safety Is

Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal

words below are used on decals and in this

manual. Read and understand all safety

messages.

A ANGER: IMMINENTLY

HAZARDOUS SITUATION! If not

avoided, WILL RESULT in death or

serious injury.

NOTE: To locate your nearest Ariens Dealer,

call 1-800-678-5443 or go to www.ariens.com

on the internet.

A WARNING: Improper assembly or

adjustments can cause serious injury.

2. Understand all Safety Precautions

provided in the manuals.

3. Review control functions and operation of

the unit. Do not operate the Sno-Thro

unless all controls function as described

in this manual.

4. Review recommended lubrication,

maintenance and adjustments.

5. Review Limited Warranty Policy.

6. Fill out a Product Registration Card and

return the card to the Ariens Company or

go to www.ariens.com.

A ARNING: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in death or

serious injury.

_ CAUTION: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor or

moderate injury. It may also be used to

alert against unsafe practices.

NOTATIONS

NOTE: General reference information for

proper operation and maintenance practices.

IMPORTANT: Specific procedures or

information required to prevent damage to unit

or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area. Always follow the practices

set forth in this manual.

GB -7

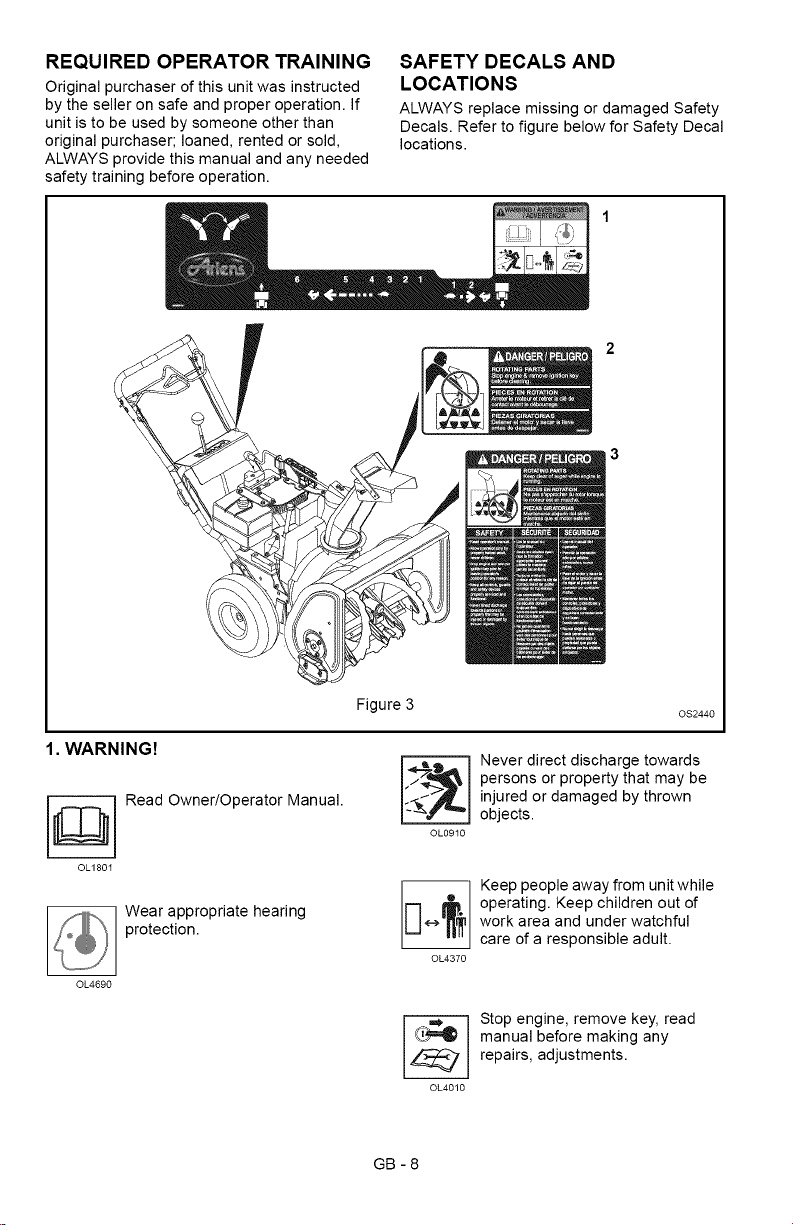

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

unit is to be used by someone other than

original purchaser; loaned, rented or sold,

ALWAYS provide this manual and any needed

safety training before operation.

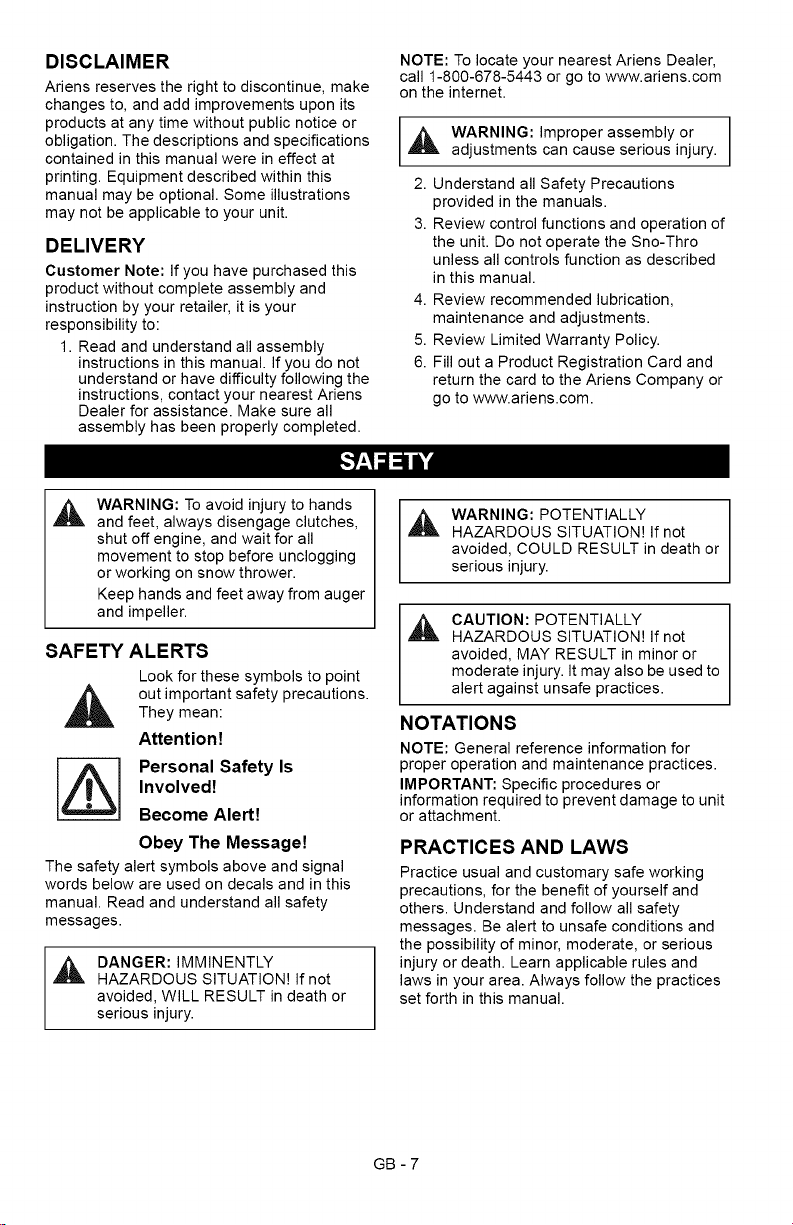

SAFETY DECALS AND

LOCATIONS

ALWAYS replace missing or damaged Safety

Decals. Refer to figure below for Safety Decal

locations.

1. WARNING!

Read Owner/O 3erator Manual.

OL180I

Wear appropriate hearing

protection.

OL4690

Figure 3

GB -8

persons or property that may be

injured or damaged by thrown

Never direct discharge towards

objects.

OL0910

operating. Keep children out of

work area and under watchful

Keep people away from unit while

care of a responsible adult.

OL4370

Stop engine, remove key, read

manual before making any

repairs, adjustments.

OL4010

©$2440

2. DANGER!

ROTATING PARTS! Stop engine

and remove key before clearing.

High speed impeller rotates

below discharge opening. Wait

for all moving parts to stop

before removing clogs or

©$2070

servicing.

&DANGER!

Keep clear of auger while engine

is running.

_ ROTATING PARTS.

• Read Operator's Manual.

• Allow operation only by

properly trained adult, never

children.

Stop engine and remove

ignition key prior to leaving

the operator's position for

any reason.

Keep all controls, guards and

safety devices properly

serviced and functional.

Never direct discharge

towards persons or property

that may be injured or

damaged by thrown objects.

SAFETY RULES

Read, understand, and follow all safety

practices in Owner/Operator Manual before

beginning assembly or operating. Failure to

follow instructions could result in personal

injury and!or damage to unit.

ALWAYS remove key and!or wire from spark

plug before assembly, maintenance or service.

Unintentional engine start up can cause death

or serious injury.

Complete a walk around inspection of unit and

work area to understand:

• Work area • Your unit • All safety decals

ALWAYS check overhead and side clearances

carefully before operation. ALWAYS be aware

of traffic when operating along streets or

curbs.

Keep children and people away. Keep children

out of work area and under watchful care of a

responsible adult.

NEVER allow children to operate or play on or

near unit. Be alert and shut off unit if children

enter area.

DO NOT allow adults to operate unit without

proper training.

Keep area of operation clear of all toys, pets,

and debris. Thrown objects can cause injury.

Check for weak spots on docks, ramps or

floors. Avoid uneven work areas and rough

terrain. Stay alert for hidden hazards.

Avoid uneven and rough terrain. DO NOT

operate near drop-offs, ditches, or

embankments. Unit can suddenly turn over if a

wheel is over the edge of a cliff or ditch, or if

an edge caves in.

Falling snow, fog, etc. can reduce vision and

cause an accident. Operate unit only when

there is good visibility and light.

Only trained adults may operate unit.

Training includes actual operation.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired

attention at all times.

NEVER allow anyone to operate this unit

when their alertness or coordination is

impaired.

DO NOT operate unit without wearing

adequate winter outer garments. Wear

adequate safety gear, including safety glasses

with side shields, and protective gloves. Wear

proper footwear to improve footing on slippery

surfaces.

DO NOT wear loose clothing or jewelry and tie

back hair that may get caught in rotating parts.

Protect eyes, face and head from objects that

may be thrown from unit. Wear appropriate

hearing protection.

Avoid sharp edges. Sharp edges can cut.

Moving parts can cut off fingers or a hand.

ALWAYS keep hands and feet away from all

rotating parts during operation. Rotating parts

can cut off body parts.

NEVER place your hands or any part of your

body or clothing inside or near any moving

part while unit is running.

ALWAYS keep hands away from all pinch

points.

DO NOT touch unit parts which might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust or service.

GB - 9

Neverdirectdischargetowardspersonsor

propertythatmaybeinjuredordamagedby

thrownobjects.Useextremecautionongravel

surfaces.Stayalertforhiddenhazardsor

traffic.AdjustRunnerssoScraperBladedoes

notcontactgravel.

DONOTthrowsnowanyhigherthan

necessary.

Deflectedmaterialscancauseinjuryand

propertydamage.

Alwaysstandclearofthedischargeareawhen

operatingthisunit.

Fumesfromengineexhaustcancauseinjury

ordeath.DONOTrunengineinanenclosed

area.Alwaysprovidegoodventilation.

ALWAYSdisengageattachment,stopunitand

engine,removekeyandallowmovingpartsto

stopbeforeleavingoperator'sposition.

ROTATING IMPELLER CAN CAUSE

SERIOUS INJURY. NEVER ATTEMPT TO

UNCLOG OR CLEAN UNIT WHILE ENGINE

IS RUNNING.

Read, understand, and follow all instructions in

the manual and on the machine before

starting.

Understand:

• How to operate all controls.

• The functions of all controls.

• How to STOP in an emergency.

Before starting engine, disengage control(s).

Use only approved extension cords and

receptacles when starting units equipped with

electric starter. DO NOT connect electric

starter cord to any wiring system that is not a

three-wire grounded system.

ALWAYS allow unit and engine to adjust to

outdoor temperatures before clearing snow.

Always be sure of your footing, especially

when operating in reverse or leaving the

operator's position. Walk, never run during

operation.

DO NOT overload the machine capacity by

attempting to clear snow at too fast a rate.

DO NOT operate at too fast a rate.

Slow down and turn corners slowly.

Do not operate in reverse unless absolutely

necessary. ALWAYS back up slowly. Always

look down and behind before and while

backing.

Disengage attachment drive when traveling

from one work area to another.

Abnormal Vibrations are a warning of trouble.

Striking a foreign object can damage unit.

Immediately stop unit and engine. Remove

key and wait for all moving parts to stop.

Remove wire from spark plug. Inspect unit and

make any necessary repairs before restart.

Before cleaning, removing clogs or making

any inspections, repairs, etc.: disengage

clutch(es), stop unit and engine, remove

key, allow moving parts to stop. Allow hot

parts to cool.

Run unit a few minutes after clearing snow to

prevent freeze-up of attachment.

Disengage attachment when not in use.

Disengage all clutches before starting engine.

Adjust runners to clear gravel or crushed rock

surfaces safely.

Never leave a running unit unattended.

ALWAYS shut off engine before leaving unit.

ALWAYS remove key to prevent unauthorized

use.

Never carry passengers.

Check clutch and brake operation frequently.

Adjust and service as required. All motion of

drive wheels and auger/impeller must stop

quickly when control levers are released.

DO NOT operate on steep slopes. DO NOT

clear snow across the face of slopes. Keep all

movement on slopes slow and gradual. DO

NOT make sudden changes in speed or

direction. Use a slow speed to avoid stops or

shifts on slopes. Avoid starting or stopping on

a slope.

DO NOT park unit on a slope unless

absolutely necessary. When parking on a

slope always block the wheels.

ALWAYS shut off engine, remove key, and

close fuel shut-off valve or drain fuel when

transporting unit on a truck or trailer.

Use extra care when loading or unloading unit

onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

Keep unit free of ice or other debris. Clean up

oil or fuel spills.

GB- 10

Thisproductisequippedwithaninternal

combustiontypeengine.DONOTuseuniton

ornearanyunimproved,forest-coveredor

brushcoveredlandunlessexhaustsystemis

equippedwithasparkarrestermeeting

applicablelocal,stateorfederallaws.Aspark

arrester,ifitisused,mustbemaintainedin

effectiveworkingorderbyoperator.

Fuelishighlyflammableanditsvaporsare

explosive.Handlewithcare.Useanapproved

fuelcontainer.

NOsmoking,NOsparks,NOflames.ALWAYS

allowenginetocoolbeforeservicing.

NEVERfillfueltankwhenengineisrunningor

hotfromoperation.

NEVERfillordrainfueltankindoors.

Replacefuelcapsecurelyandcleanupspilled

fuel.

Neverfillcontainersinsideavehicleorona

truckortrailerbedwithaplasticliner.Always

placecontainersonthegroundawayfrom

yourvehiclebeforefilling.

Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,then

refuelsuchequipmentonatrailerwitha

portablecontainer,ratherthanfromagasoline

dispensernozzle.

Keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.Donotuseanozzlelock-

opendevice.

Iffuelisspilledonclothing,changeclothing

immediately.

Beforetippingunitupontohousing,remove

fuelsonospillswilloccur.Ensureunitis

secureandwillnottipoverduring

maintenance.

ALWAYSkeepprotectivestructures,guards,

andpanelsingoodrepair,inplaceand

securelyfastened.NEVERmodifyorremove

safetydevices.

DONOTchangeenginegovernorsettingsor

over-speedengine.

Fumesfromengineexhaustcancauseinjury

ordeath.DONOTrunengineinanenclosed

area.Alwaysprovidegoodventilation.

ALWAYSmaintainunitinsafeoperating

condition.Damagedorwornoutmufflercan

causefireorexplosion.

Keepallhardwareproperlytightened.Check

shearboltsfrequently.

Maintainorreplacesafetyandinstruction

labels,asnecessary.

NEVERstoreunitwithfuelinfueltank,inside

abuildingwhereanyignitionsourcesare

present.

Shutofffuelandallowenginetocool

completelybeforestoringinclosedareaor

coveringunit.

Forextendedstorage,cleanunitthoroughly.

SeeEngineManualforproperstorage.

Useonlyattachmentsoraccessoriesdesigned

foryourunit.

Checkcomponentsfrequently.Ifwornor

damaged,replacewithmanufacturer's

recommendedparts.

GB-11

,_ WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

,_ WARNING: Dropping or tipping over

boxed unit could result in personal

injury or damage to unit.

Tools Required:

• Pliers

• Open-End Wrenches: 3/8, 7/16, 1/2,

9/16 in. and/or Adjustable Wrench

• Tire Gauge

ASSEMBLY

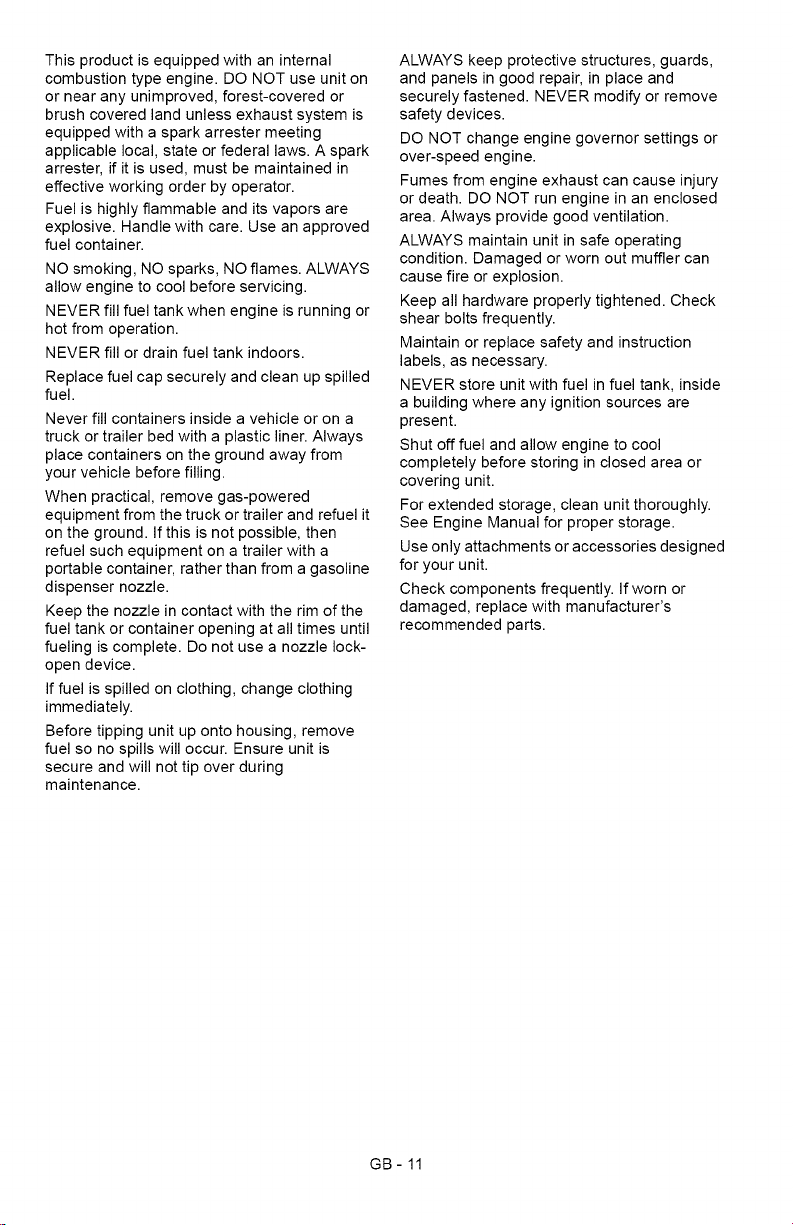

Unfold Handlebar (Figure 4)

1. Loosen wing knobs and release J-bolts

from lower handlebar.

2. Unfold upper handlebar and align

handlebar holes.

3. Put J-bolts through the upper handlebar

and lower handlebar holes.

4. Tighten wing knobs to secure upper

handlebar.

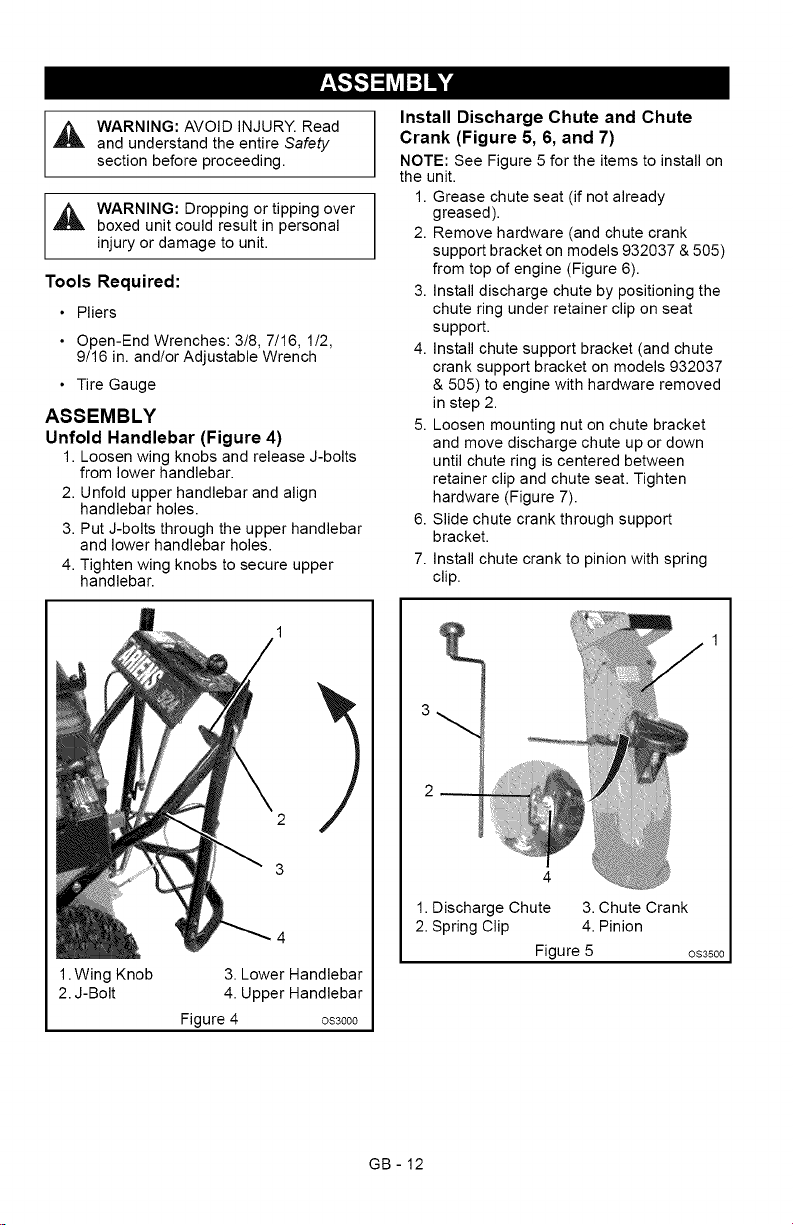

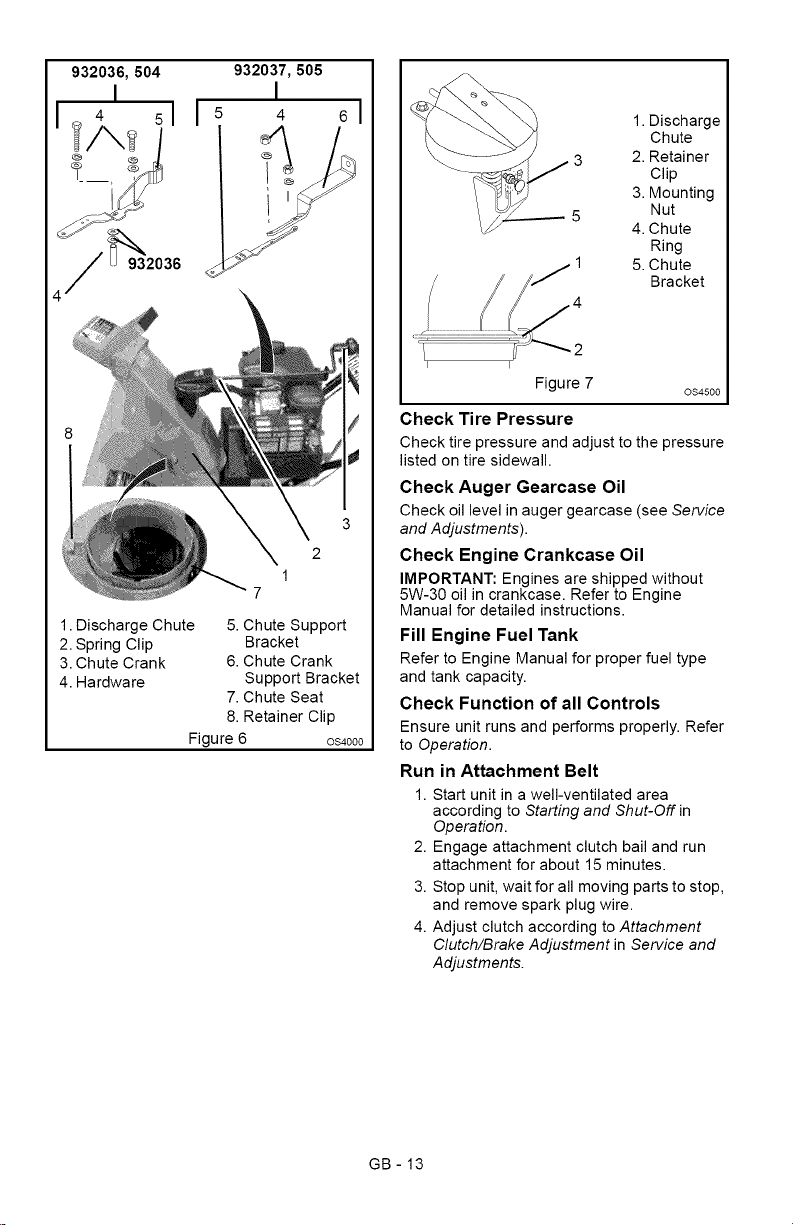

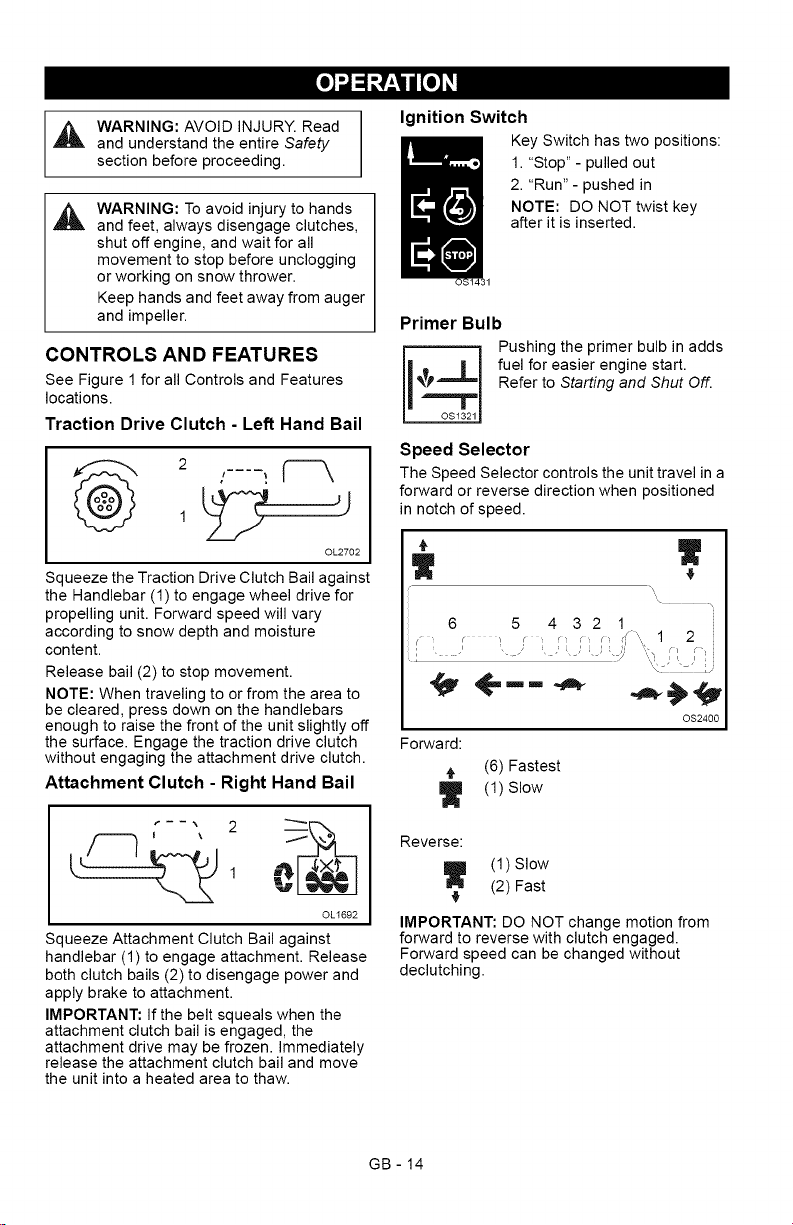

Install Discharge Chute and Chute

Crank (Figure 5, 6, and 7)

NOTE: See Figure 5 for the items to install on

the unit.

1. Grease chute seat (if not already

greased).

2. Remove hardware (and chute crank

support bracket on models 932037 & 505)

from top of engine (Figure 6).

3. Install discharge chute by positioning the

chute ring under retainer clip on seat

support.

4. Install chute support bracket (and chute

crank support bracket on models 932037

& 505) to engine with hardware removed

in step 2.

5. Loosen mounting nut on chute bracket

and move discharge chute up or down

until chute ring is centered between

retainer clip and chute seat. Tighten

hardware (Figure 7).

6. Slide chute crank through support

bracket.

7. Install chute crank to pinion with spring

clip.

2

3

4

1.Wing Knob 3. Lower Handlebar

2. J-Bolt 4. Upper Handlebar

Figure 4 os3000

4

1. Discharge Chute 3. Chute Crank

2. Spring Clip 4. Pinion

Figure 5 os3500

GB- 12

932036, 504

I

932037,505

I

4 61

1. Discharge

Chute

3 2. Retainer

5 Nut

Clip

3. Mounting

4. Chute

Ring

5. Chute

Bracket

1. Discharge Chute

2. Spring Clip

3. Chute Crank

4. Hardware

2

1

7

5. Chute Support

Bracket

6. Chute Crank

Support Bracket

7. Chute Seat

8. Retainer Clip

Figure 6 OS4000

Figure 7

Check Tire Pressure

Check tire pressure and adjust to the pressure

listed on tire sidewall.

Check Auger Gearoase Oil

Check oil level in auger gearcase (see Service

and Adjustments).

Check Engine Crankcase Oil

IMPORTANT: Engines are shipped without

5W-30 oil in crankcase. Refer to Engine

Manual for detailed instructions.

Fill Engine Fuel Tank

Refer to Engine Manual for proper fuel type

and tank capacity.

Check Function of all Controls

Ensure unit runs and performs properly. Refer

to Operation.

Run in Attachment Belt

1. Start unit in a well-ventilated area

according to Starting and Shut-Off in

Operation.

2. Engage attachment clutch bail and run

attachment for about 15 minutes.

3. Stop unit, wait for all moving parts to stop,

and remove spark plug wire.

4. Adjust clutch according to Attachment

Clutch/Brake Adjustment in Service and

Adjustments.

OS4500

GB- 13

,_ WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

WARNING: To avoid injury to hands

and feet, always disengage clutches,

shut off engine, and wait for all

movement to stop before unclogging

or working on snow thrower.

Keep hands and feet away from auger

and impeller.

CONTROLS AND FEATURES

See Figure 1 for all Controls and Features

locations.

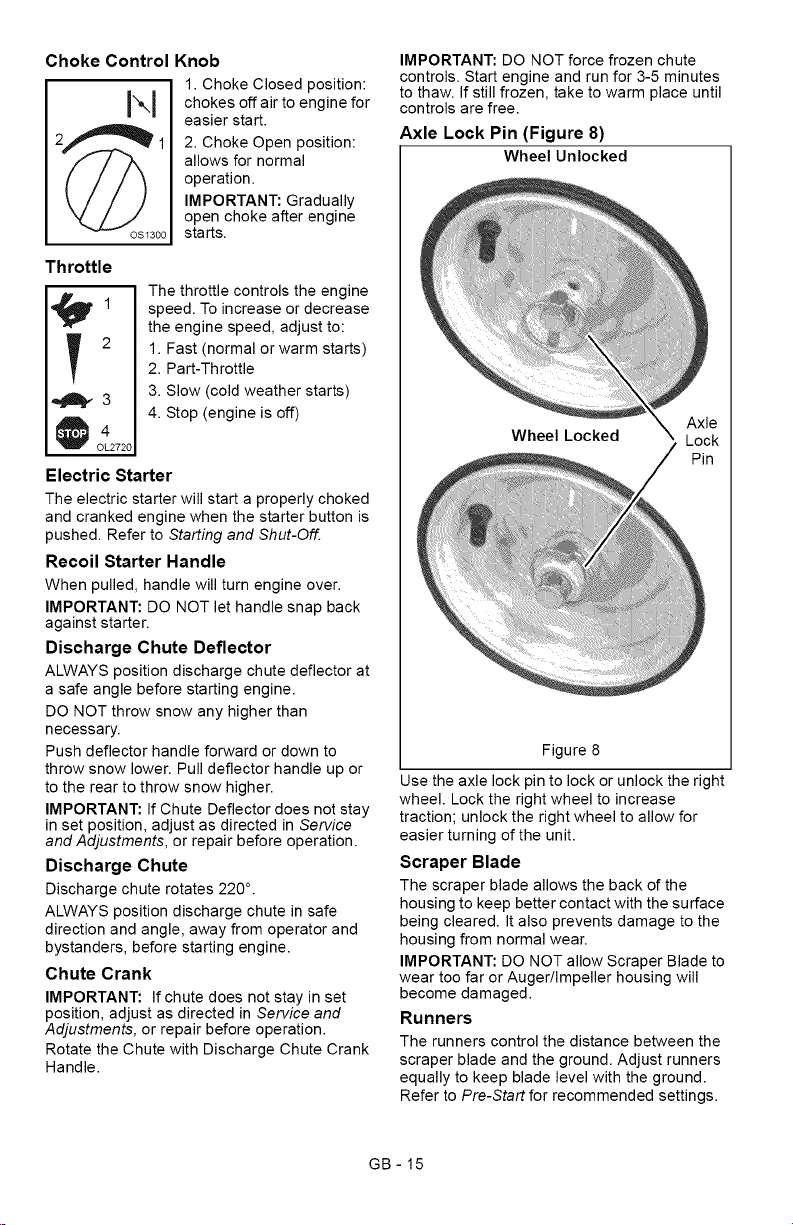

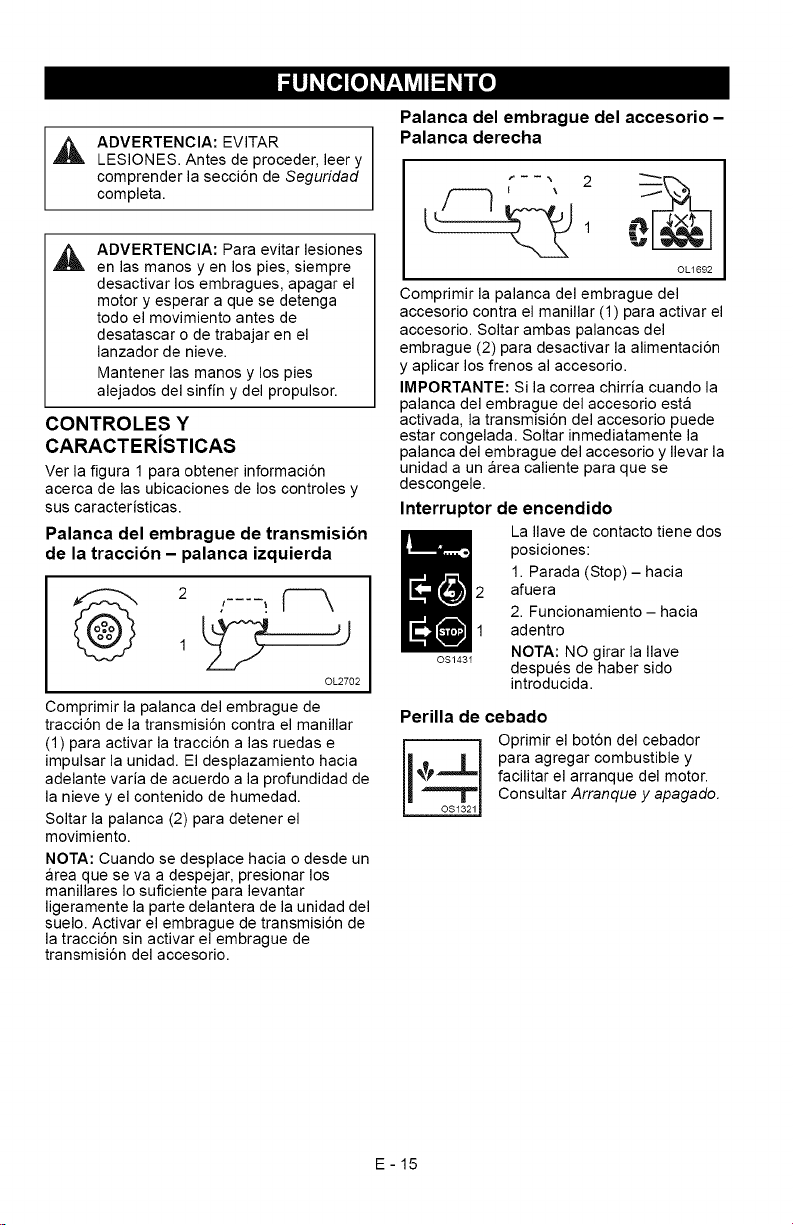

Traction Drive Clutch - Left Hand Bail

2 / .... !

Ignition Switch

1. "Stop"- pulled out

2. "Run"- pushed in

NOTE: DO NOT twist key

after it is inserted.

i Key Switch has two positions:

1

Primer Bulb

-- Pushing the primer bulb in adds

Refer to Starting and Shut Off.

fuel for easier engine start.

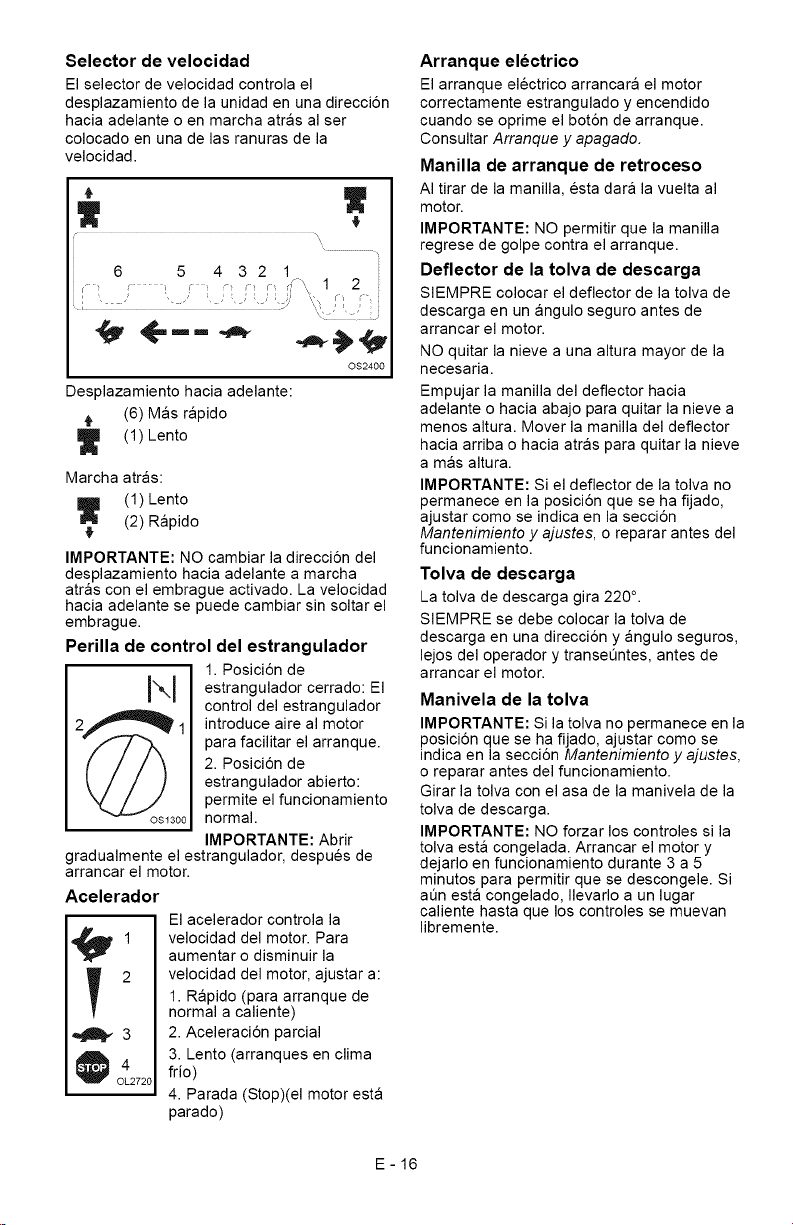

Speed Selector

The Speed Selector controls the unit travel in a

forward or reverse direction when positioned

in notch of speed.

0L2702

Squeeze the Traction Drive Clutch Bail against

the Handlebar (1) to engage wheel drive for

propelling unit. Forward speed will vary

according to snow depth and moisture

content.

Release bail (2) to stop movement.

NOTE: When traveling to or from the area to

be cleared, press down on the handlebars

enough to raise the front of the unit slightly off

the surface. Engage the traction drive clutch Forward:

without engaging the attachment drive clutch.

Attachment Clutch - Right Hand Bail m

W W

Reverse:

b/-q 1 C

OLI692

Squeeze Attachment Clutch Bail against

handlebar (1) to engage attachment. Release

both clutch bails (2) to disengage power and

apply brake to attachment.

IMPORTANT: If the belt squeals when the

attachment clutch bail is engaged, the

attachment drive may be frozen. Immediately

release the attachment clutch bail and move

the unit into a heated area to thaw.

IMPORTANT: DO NOT change motion from

forward to reverse with clutch engaged.

Forward speed can be changed without

declutching.

6 5 4321 _

mm

(6) Fastest

(1) Slow

_ 1) Slow

!_ (2) Fast

1 2

©$2400

GB - 14

Choke Control Knob

1. Choke Closed position:

chokes off air to engine for

I\l

easier start.

2. Choke Open position:

allows for normal

operation.

IMPORTANT: Gradually

open choke after engine

starts.

00

Throttle

The throttle controls the engine

speed. To increase or decrease

the engine speed, adjust to:

1. Fast (normal or warm starts)

2. Part-Throttle

_a

@4

Electric Starter

The electric starter will start a properly choked

and cranked engine when the starter button is

pushed. Refer to Starting and Shut-Off,

Recoil Starter Handle

When pulled, handle will turn engine over.

IMPORTANT: DO NOT let handle snap back

against starter.

Discharge Chute Deflector

ALWAYS position discharge chute deflector at

a safe angle before starting engine.

DO NOT throw snow any higher than

necessary.

Push deflector handle forward or down to

throw snow lower. Pull deflector handle up or

to the rear to throw snow higher.

IMPORTANT: If Chute Deflector does not stay

in set position, adjust as directed in Service

and Adjustments, or repair before operation.

Discharge Chute

Discharge chute rotates 220 °.

ALWAYS position discharge chute in safe

direction and angle, away from operator and

bystanders, before starting engine.

Chute Crank

IMPORTANT: If chute does not stay in set

position, adjust as directed in Service and

Adjustments, or repair before operation.

Rotate the Chute with Discharge Chute Crank

Handle.

3. Slow (cold weather starts)

4. Stop (engine is off)

0L2720

IMPORTANT: DO NOT force frozen chute

controls. Start engine and run for 3-5 minutes

to thaw. If still frozen, take to warm place until

controls are free.

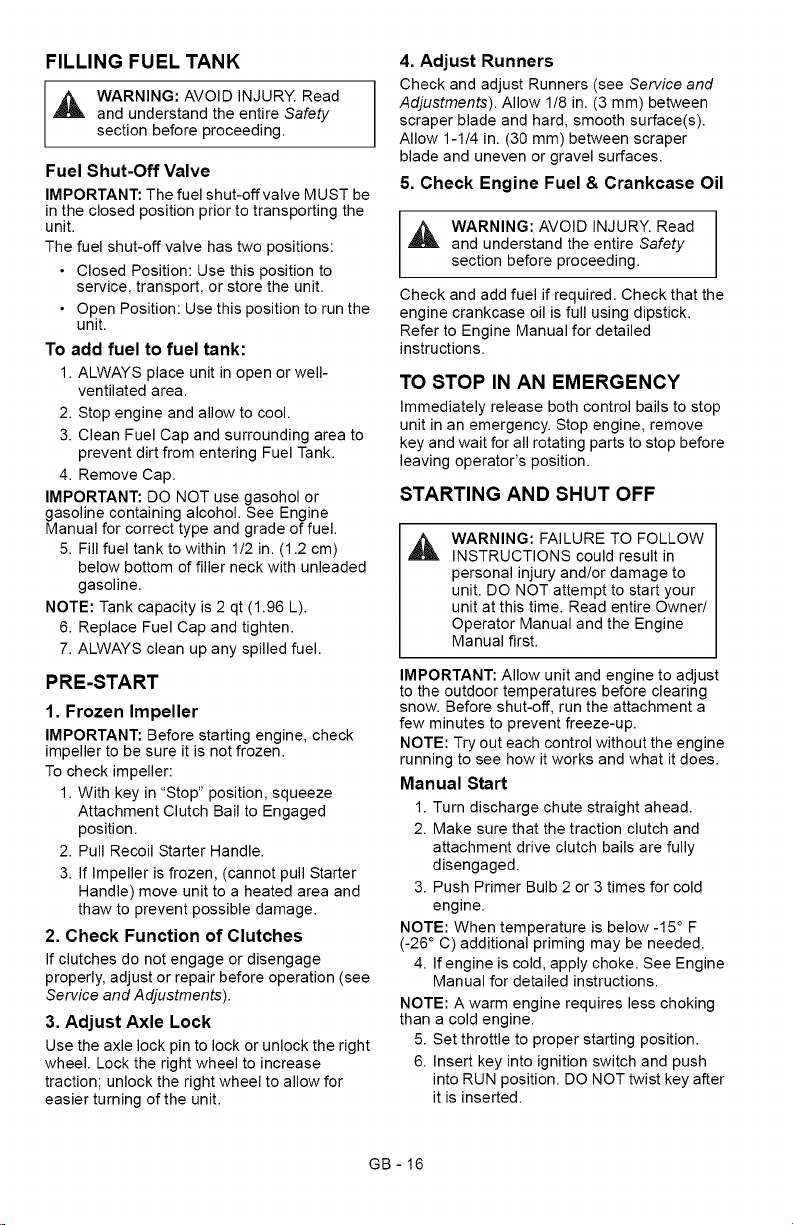

Axle Lock Pin (Figure 8)

Wheel Unlocked

Wheel Locked

Figure 8

Use the axle lock pin to lock or unlock the right

wheel. Lock the right wheel to increase

traction; unlock the right wheel to allow for

easier turning of the unit.

Scraper Blade

The scraper blade allows the back of the

housing to keep better contact with the surface

being cleared. It also prevents damage to the

housing from normal wear.

IMPORTANT: DO NOT allow Scraper Blade to

wear too far or Auger/Impeller housing will

become damaged.

Runners

The runners control the distance between the

scraper blade and the ground. Adjust runners

equally to keep blade level with the ground.

Refer to Pre-Startfor recommended settings.

GB- 15

FILLING FUEL TANK

,_ WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Fuel Shut-Off Valve

IMPORTANT: The fuel shut-off valve MUST be

in the closed position prior to transporting the

unit.

The fuel shut-off valve has two positions:

• Closed Position: Use this position to

service, transport, or store the unit.

• Open Position: Use this position to run the

unit.

To add fuel to fuel tank:

1. ALWAYS place unit in open or well-

ventilated area.

2. Stop engine and allow to cool.

3. Clean Fuel Cap and surrounding area to

prevent dirt from entering Fuel Tank.

4. Remove Cap.

IMPORTANT: DO NOT use gasohol or

gasoline containing alcohol. See Engine

Manual for correct type and grade of fuel.

5. Fill fuel tank to within 1/2 in. (1.2 cm)

below bottom of filler neck with unleaded

gasoline.

NOTE: Tank capacity is 2 qt (1.96 L).

6. Replace Fuel Cap and tighten.

7. ALWAYS clean up any spilled fuel.

PRE-START

1. Frozen Impeller

IMPORTANT: Before starting engine, check

impeller to be sure it is not frozen.

To check impeller:

1. With key in "Stop" position, squeeze

Attachment Clutch Bail to Engaged

position.

2. Pull Recoil Starter Handle.

3. If Impeller is frozen, (cannot pull Starter

Handle) move unit to a heated area and

thaw to prevent possible damage.

2. Check Function of Clutches

If clutches do not engage or disengage

properly, adjust or repair before operation (see

Service and Adjustments).

3. Adjust Axle Lock

Use the axle lock pin to lock or unlock the right

wheel. Lock the right wheel to increase

traction; unlock the right wheel to allow for

easier turning of the unit.

4. Adjust Runners

Check and adjust Runners (see Service and

Adjustments). Allow 1/8 in. (3 mm) between

scraper blade and hard, smooth surface(s).

Allow 1-1/4 in. (30 mm) between scraper

blade and uneven or gravel surfaces.

5. Check Engine Fuel & Crankcase Oil

_, ARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Check and add fuel if required. Check that the

engine crankcase oil is full using dipstick.

Refer to Engine Manual for detailed

instructions.

TO STOP IN AN EMERGENCY

Immediately release both control bails to stop

unit in an emergency. Stop engine, remove

key and wait for all rotating parts to stop before

leaving operator's position.

STARTING AND SHUT OFF

_L, ARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in

personal injury and/or damage to

unit. DO NOT attempt to start your

unit at this time. Read entire Owner/

Operator Manual and the Engine

Manual first.

IMPORTANT: Allow unit and engine to adjust

to the outdoor temperatures before clearing

snow. Before shut-off, run the attachment a

few minutes to prevent freeze-up.

NOTE: Try out each control without the engine

running to see how it works and what it does.

Manual Start

1. Turn discharge chute straight ahead.

2. Make sure that the traction clutch and

attachment drive clutch bails are fully

disengaged.

3. Push Primer Bulb 2 or 3 times for cold

engine.

NOTE: When temperature is below -15 ° F

(-26 ° C) additional priming may be needed.

4. If engine is cold, apply choke. See Engine

Manual for detailed instructions.

NOTE: A warm engine requires less choking

than a cold engine.

5. Set throttle to proper starting position.

6. Insert key into ignition switch and push

into RUN position. DO NOT twist key after

it is inserted.

GB- 16

7.Graspstarterhandleandpullropeout

slowlyuntilitpullsharder.Letroperewind

slowly.

8.Pullropewitharapidcontinuousfullarm

stroke.Letroperewindslowly.

IMPORTANT:DONOTletStarterHandle

snapagainstStarter.

9.Repeatsteps7and8untilenginestarts.

(Ifenginedoesnotstart,referto

Troubleshooting.)

10. Adjust choke as needed.

11. Set throttle to Part Throttle or Slow

position for adaptation to outside

temperature or travel. Set throttle to Fast

position for normal operation.

Electric Start

1. Connect extension cord to prongs on

starter.

IMPORTANT: Prevent damage to unit. Know

voltage of your starter and only use matching

outlets.

2. Plug extension into 120V 3-wire,

grounded outlet.

3. Turn discharge chute straight ahead.

4. Make sure that the traction clutch and

attachment drive clutch bails are fully

disengaged.

5. Push Primer Bulb 2 or 3 times for cold

engine.

NOTE: When temperature is below -15 ° F

(-26 ° C) additional priming may be needed.

6. Insert key into ignition switch on engine

and push into "Run" position. DO NOT

twist key after it is inserted.

7. If engine is cold, apply choke. A warm

engine requires less choking than a cold

engine. See Engine Manual for detailed

instructions.

8. Set throttle to proper starting position.

9. Press starter button on engine until

engine starts.

IMPORTANT: DO NOT operate starter more

than 15 seconds per minute, as overheating

and damage can occur. (If engine does not

start, refer to Troubleshooting.)

10. Adjust choke as needed.

11. Disconnect power cord from outlet, then

starter.

12. Set throttle to Part Throttle or Slow

position for adaptation to outside

temperature or travel. Set throttle to Fast

position for normal operation.

Shut Off

1. Release Traction Drive Clutch Bail and

allow unit to come to a complete stop.

2. Run Impeller a few minutes after use to

prevent freeze-up of Impeller.

3. Release Attachment Clutch Bail and wait

for all moving parts to come to a complete

stop.

4. Move Throttle to the "Stop" position.

5. Remove key.

SNOW REMOVAL

IMPORTANT: Allow unit and engine to adjust

to the outdoor temperatures before clearing

snow.

NOTE: Attachment clutch should be engaged

before wheel drive clutch when throwing snow.

1. Select Speed Control position and

direction.

2. Engage Attachment Clutch - Right Hand

Bail.

3. Engage Traction Drive Clutch - Left Hand

Bail.

IMPORTANT: DO NOT overload unit capacity

by attempting to clear snow at too fast a rate.

Use slow speed to clear deep or hard packed

snow.

Tips for Operation

Snow is best removed as soon as possible

after snow fall.

To clear an area, run unit in an overlapping

series of paths. For large areas, start in the

middle and throw snow to each side, so snow

is not cleared more than once.

ALWAYS direct snow away from area to be

cleared and with direction of the wind.

TRAVELING

To travel from one work area to another:

1. Set Throttle to Slow or Part-Throttle

position.

2. Press down on handlebars enough to

raise front of unit slightly off surface.

3. Engage wheel drive clutch without

engaging attachment drive clutch.

TRANSPORT

ALWAYS shut off engine, remove key, and

close fuel shut-off valve when transporting unit

on a truck or trailer.

Use extra care when loading or unloading unit

onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

GB- 17

_oid

Ariens Dealers will provide any service or

adjustments which may be required to keep

your unit operating at peak efficiency. Should

engine service be required, contact an Ariens

dealer or an authorized engine manufacturer's

service center.

,_ WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

SERVICE POSITION

WARNING: Before tipping unit up

,&

onto housing, remove fuel so no

spills will occur. Ensure unit is

secure and will not tip over during

maintenance.

Place unit on a flat level surface. Tip unit

forward onto front of impeller housing for

service. Ensure unit is secure and will not tip

over. Strap and clamp onto bench if needed.

MAINTENANCE SCHEDULE

The chart below shows the recommended

maintenance schedule that should be

performed on a regular basis. More frequent

service may be required.

Service Each Every Every Yearly

Performed Use 5 hrs. 25

Check

Fasteners

Check

Clutches

Clean Engine

Check Engine

Oil

Change *

Engine Oil

Check Tire

Pressure

Check Auger

Gearcase

General

Lubrication

After first two hours of operation.

hrs.

CHECK FASTENERS

Make sure all hardware is tightened properly.

CHECK CLUTCHES

Auger / impeller must stop within 3 seconds

when attachment clutch/impeller brake bail is

released.

Wheels must stop quickly when traction drive

clutch bail is released.

If clutches do not engage or disengage

properly, adjust or repair before operation (see

Service and Adjustments).

CLEAN ENGINE

Refer to Engine Manual for detailed

instructions.

CHECK ENGINE OIL

The engine crankcase oil should be checked

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on dipstick

at all times or engine damage will result (See

Engine Manual).

Park unit on a level surface. Refer to Engine

Manual for detailed instructions.

CHANGEENGINE OIL

Change oil after first 2 hours of operation,

thereafter change oil every 25 hours (more

often if required). Refer to Engine Manual for

detailed instructions.

Run engine just prior to changing oil. Warm oil

will flow more freely and carry away more

contamination.

CHECK TIRE PRESSURE

Keep tires at pressure listed on the tire

sidewall.

CHECK AUGER GEARCASE

IMPORTANT: Proper oil level must be

maintained.

Gear cases are filled to the correct level at the

factory. Unless there is evidence of leakage,

no additional lubricant should be required.

Check oil level each season or every 25 hours

of operation.

To ensure adequate lubricant level:

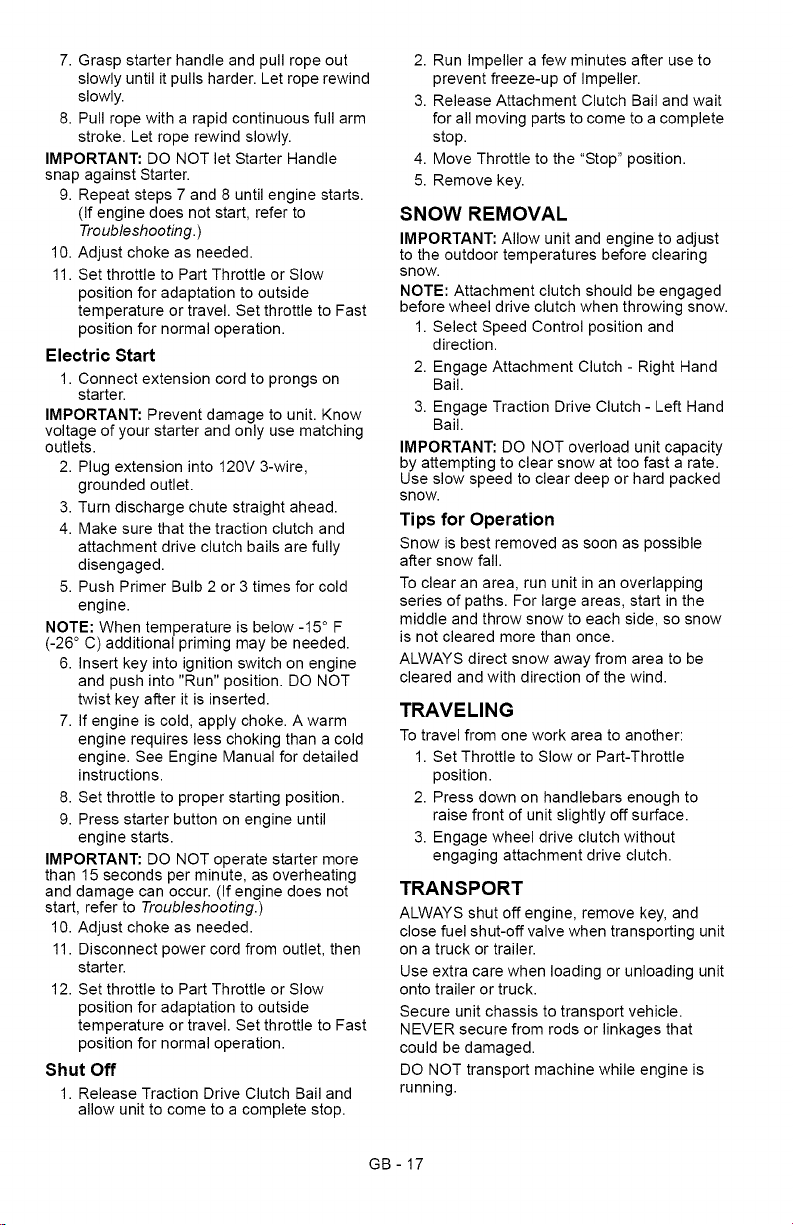

1. Remove filler plug (Figure 9). Lubricant

must be at least up to bottom of lubricant

filler hole with unit resting on a level-

surface.

GB- 18

2.Addlubricantifrequired.Allowoiltodrain

tolevelofplugandreplaceplug.

IMPORTANT:UseonlyAriensspecialgear

lubricantL-2(PartNumber00008000).

2

0S1830

1.AugerGearcase

2.FillerPlug

Figure 9

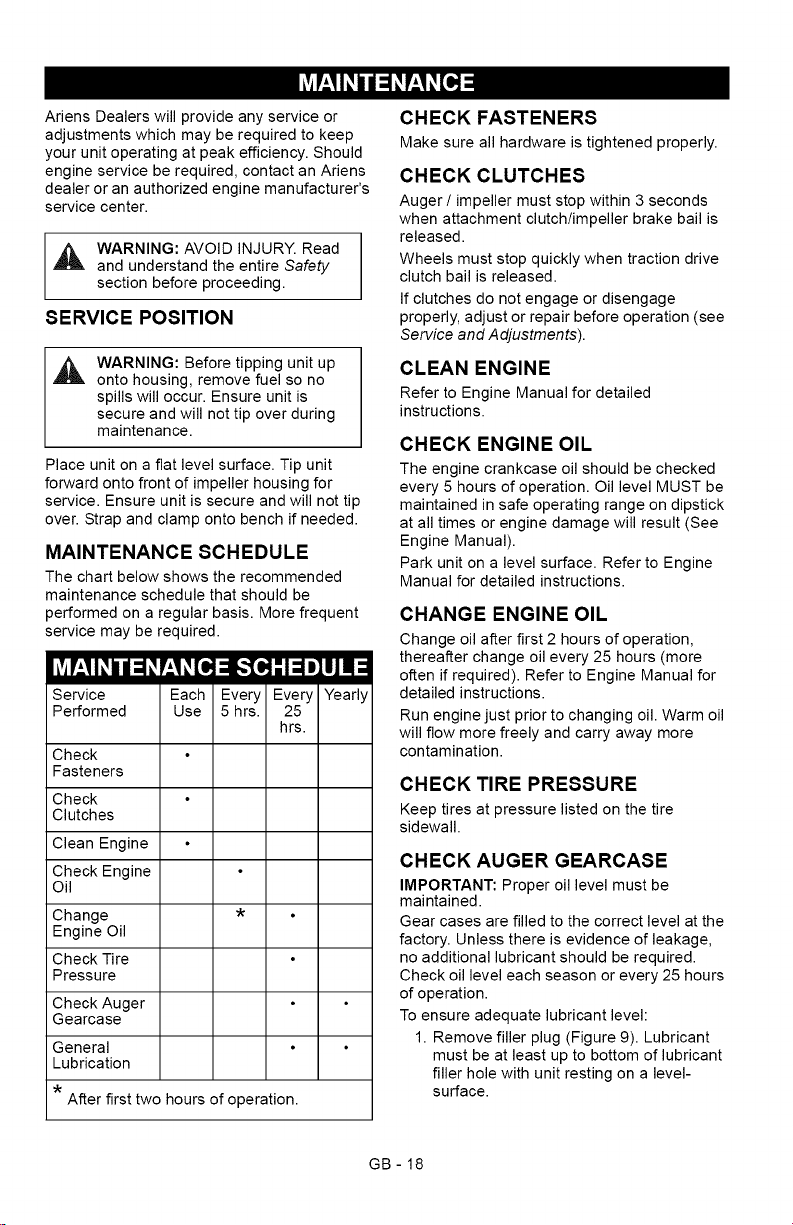

GENERAL LUBRICATION

IMPORTANT: Wipe each fitting clean before

and after lubrication.

IMPORTANT: DO NOT allow grease or oil to

get on friction disc, friction plate or belts.

NOTE: Apply Stens Mix Hi-Temp Grease or

equivalent to the lubrication fittings. See

Service Parts.

Sno-Thro should be lubricated (Figure 10) at

beginning of season or every 25 operating

hours.

Auger Shaft

NOTE: To grease auger shaft, remove shear

bolt nuts, and shear bolts. Turn auger on shaft

while applying grease at zerk fittings. Replace

shear bolt per instructions in Service and

Adjustments.

= i

\

OS1373

Grease Oil

Figure 10

GB- 19

,t_ WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

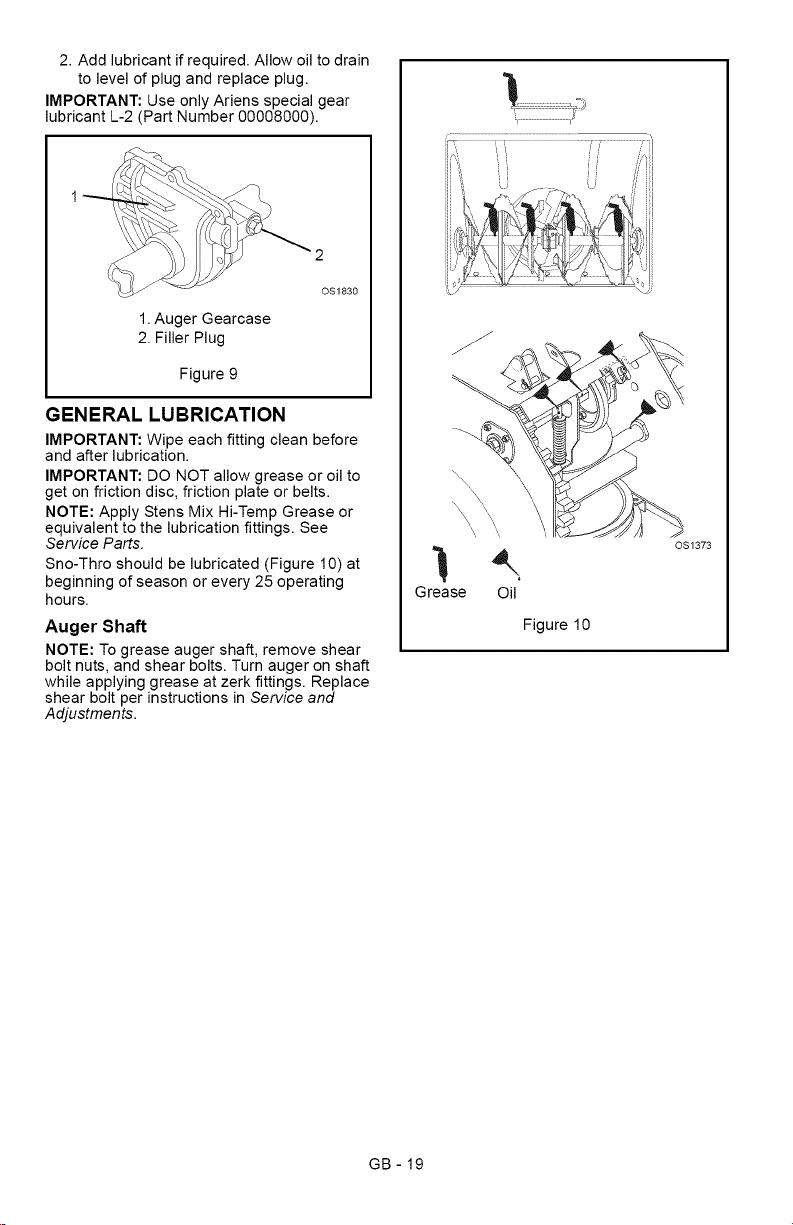

DISCHARGE CHUTE DEFLECTOR

Deflector must stay in selected position while

throwing snow.

To adjust, loosen then retighten hardware to

desired deflector drag force (Figure 11).

Adjusting

Hardware

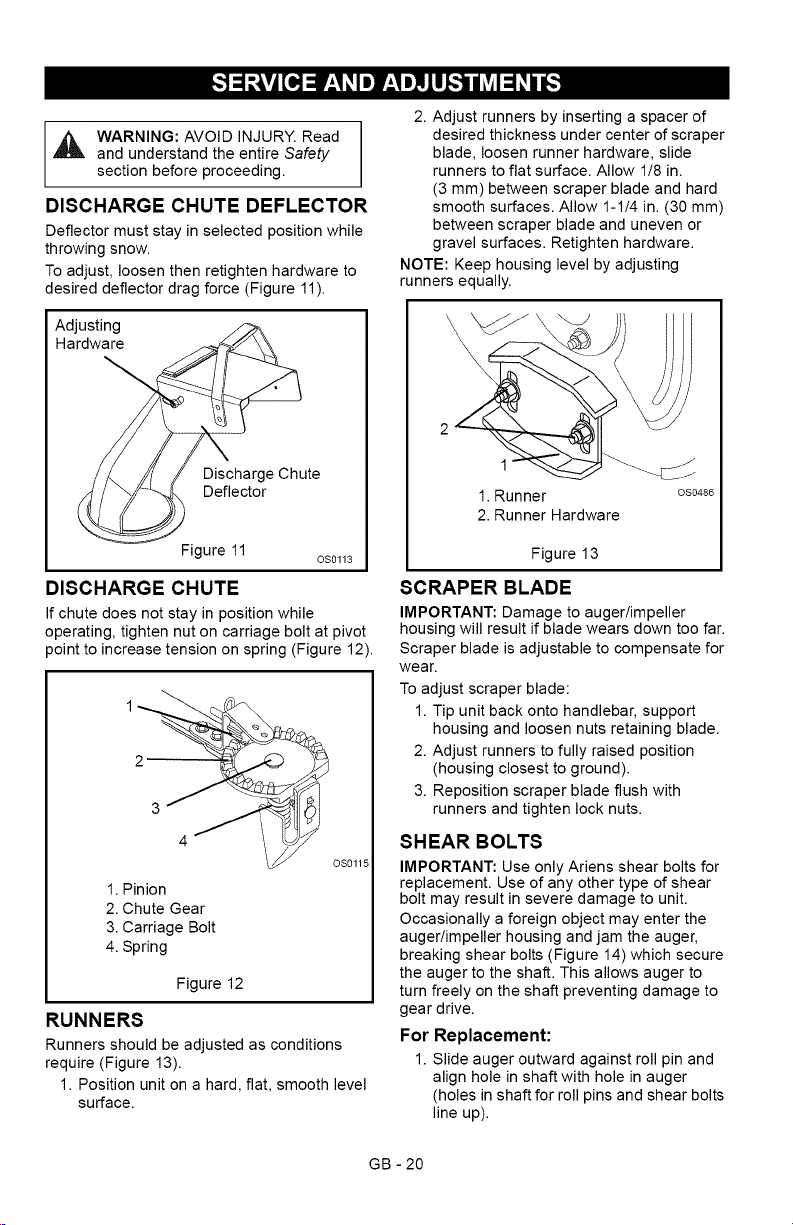

2. Adjust runners by inserting a spacer of

desired thickness under center of scraper

blade, loosen runner hardware, slide

runners to flat surface. Allow 1/8 in.

(3 mm) between scraper blade and hard

smooth surfaces. Allow 1-1/4 in. (30 mm)

between scraper blade and uneven or

gravel surfaces. Retighten hardware.

NOTE: Keep housing level by adjusting

runners equally.

Discharge Chute

Deflector

Figure 11

©S0113

DISCHARGE CHUTE

If chute does not stay in position while

operating, tighten nut on carriage bolt at pivot

)oint to increase tension on spring (Figure 12).

2 3

4

OS0115

1. Pinion

2. Chute Gear

3. Carriage Bolt

4. Spring

Figure 12

RUNNERS

Runners should be adjusted as conditions

require (Figure 13).

1. Position unit on a hard, flat, smooth level

surface.

1

1. Runner

2. Runner Hardware

Figure 13

OS0486

SCRAPER BLADE

IMPORTANT: Damage to auger/impeller

housing will result if blade wears down too far.

Scraper blade is adjustable to compensate for

wear.

To adjust scraper blade:

1. Tip unit back onto handlebar, support

housing and loosen nuts retaining blade.

2. Adjust runners to fully raised position

(housing closest to ground).

3. Reposition scraper blade flush with

runners and tighten lock nuts.

SHEAR BOLTS

IMPORTANT: Use only Ariens shear bolts for

replacement. Use of any other type of shear

bolt may result in severe damage to unit.

Occasionally a foreign object may enter the

auger/impeller housing and jam the auger,

breaking shear bolts (Figure 14) which secure

the auger to the shaft. This allows auger to

turn freely on the shaft preventing damage to

gear drive.

For Replacement:

1. Slide auger outward against roll pin and

align hole in shaft with hole in auger

(holes in shaft for roll pins and shear bolts

line up).

GB - 20

2.Driveshearboltthroughhole(ifshearbolt

wasbrokenthiswilldriveremainingpart

fromshaft).

3.Secureshearboltwithnut.

ii U

8. Adjust pivot pin as needed so unit travels

forward when speed selector lever is in

first forward position and backward when

speed selector lever is in first reverse

position.

9. Secure adjustment pivot pin to speed

selector lever with hairpin.

1 2

1.Auger

2. Shear Bolt(s)

3. Roll Pin

Figure 14

OS0402

SPEED SELECTOR ADJUSTMENT

To adjust (Figure 15):

1. Remove hair pin from adjustment pivot

pin.

2. Pull shift rod and adjustment pivot pin out

of speed selector lever.

3. Place the speed selector lever in the

fastest forward speed position.

4. Pull the shift rod straight down towards

the ground as far as it will go.

5. Thread the adjustment pivot pin along the

shift rod until it aligns with the mating hole

on the speed selector lever.

6. Reinsert the pivot pin into the hole on the

speed selector lever.

7. Check forward and reverse speeds.

a. Start unit.

b. Shift speed selector into first forward

speed.

c. Engage traction clutch. Unit should

move forward.

d. Stop unit.

e. Shift speed selector into first reverse

speed.

f. Engage traction clutch. Unit should

move backward.

g. Shut off unit.

1

0Ss0195

1. Shift Rod

2. Adjustment Pivot Pin

3. Speed Selector Lever

4. Hair Pin

Figure 15

GB -21

ATTACHMENT DRIVE BELT

REPLACEMENT

Remove Attachment Drive Belt

(Figures 16 and 17)

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

2. Remove two screws securing belt cover

to unit and remove belt cover.

3. Remove spring pin from chute crank rod

assembly and separate.

4. Remove hardware holding chute strap to

engine and lift discharge chute off

housing.

5. Remove belt finger by removing cap

screws mounting belt finger to engine

(Figure 17).

6. Remove attachment drive belt from

engine sheave (it may be necessary to

turn engine sheave using recoil starter

handle).

CAUTION: Always support

Sno-Thro frame and housing when

loosening the cap screws holding

them together. Never loosen cap

screws while unit is in service

position.

IMPORTANT: To avoid bending bottom cover,

when tipping unit apart, support handlebars

firmly or tip unit up on housing and remove

bottom cover by removing four cap screws

before separating unit.

7. Support Sno-Thro frame and housing.

8. Remove top two cap screws and loosen

lower cap screws holding blower housing

to frame (one on each side).

9. Separate housing from unit. Lower

handlebar on floor.

10. Remove attachment drive belt from lower

pulley (hold brake away from belt).

7

8/

1. Housing Bolt

Holes

2. Belt Cover

3. Pinion and Gear

4. Spring Clip Pin

Replace Attachment Drive Belt

1. Place new belt onto lower pulley and

while holding brake out of way, tip unit

together.

2. Secure blower housing to frame with cap

screws.

3. Place belt onto engine sheave.

4. Make sure engine sheave and

attachment pulley align. If alignment is

necessary, loosen engine sheave set

screws, reposition sheave and retighten

set screws.

5. Replace belt finger.

IMPORTANT: BELT FINGER MUST BE

between 1/16 to 1/8 in. (1.6-3 mm)from belt

with attachment clutch engaged or belt

grabbing may occur causing impeller to rotate

while attachment clutch is disengaged

(Figure 17).

6. Adjust clutch per Attachment Clutch/

Impeller Brake Adjustment below.

7. Reinstall chute strap and mounting

hardware onto engine.

8. Replace chute crank and secure with

spring pin.

9. Replace belt cover and secure with cap

screws.

5. Chute Crank

6. Chute Strap

7. Chute Strap

Mounting

Hardware

8. Bottom Cover

Figure 16 os0803

GB - 22

Figure17

5

6

1.Attachment Belt

Idler

2. Belt Finger

3. Attachment Drive

Belt

4. Traction Drive Belt

5. Camshaft Pulley

6. Engine Sheave

7. Traction Belt Idler

8. Attachment Pulley

9. Attachment Idler

Nut

OS0464

TRACTION DRIVE BELT

REPLACEMENT

NOTE: Housing and frame must be tipped

apart and attachment drive belt removed from

engine sheave in order to change traction

drive belt (Figures 16 and 17).

CAUTION: Always support Sno-

A

Thro frame and blower housing

when loosening the cap screws

holding them together. Never loosen

cap screws while unit is in service

position.

1. Remove attachment drive belt (See

Remove Attachment Drive Belt).

2. Pull idler away from traction drive belt and

remove belt from idler, camshaft pulley

and driven pulley (it may be necessary to

turn camshaft pulley using recoil starter

handle).

NOTE: To gain clearance, engage traction

clutch and if necessary pull back attachment

idler arm clevis pin.

3. Replace traction drive belt making sure

pulleys align. If alignment is necessary,

loosen camshaft pulley set screws,

reposition pulley and retighten set

screws.

4. Replace attachment drive belt (See

Replace Attachment Drive Belt).

GB - 23

ATTACHMENT CLUTCH/BRAKE

ADJUSTMENT

WARNING: IMPROPER

ADJUSTMENT could result in

unexpected movement of auger and

impeller causing death or serious

injury. AUGER / IMPELLER MUST

STOP within 3 seconds when

Attachment Clutch/Impeller Brake

Bail is released.

WARNING: Adjustment procedure

requires the engine to be run with

the belt cover off. AVOID INJURY.

Read and understand the entire

Safety section before proceeding.

1. Remove belt cover.

2. Check belt alignment (Figure 17).

Engine sheave and attachment pulley

must align vertically. Also, belt must be

centered in the idler pulley.

To align, move engine sheave:

a. Loosen set screws.

b.Slide sheave and key to desired

position.

c. Tighten set screws.

3. Adjust cable slack.

IMPORTANT: The clutch cable must be slack

when clutch bail is disengaged.

a. Center the upper cable adjuster on the

mounting bracket, if necessary

(Figure 17).

Upper Cable

Adjuster

Figure 18 ©$2460

b.With the clutch bail disengaged,

loosen the control cable mounting nuts

on the attachment clutch arm

(Figure 21).

c. Pull up on the cable body to remove

cable slack.

d. Finger tighten mounting nuts and then

loosen the top nut five turns.

e. Tighten the bottom nut with a wrench.

4. Check attachment clutch bail

measurement.

a. Start engine and run at full throttle.

b. Slowly squeeze the attachment clutch

bail until auger shaft begins to rotate.

c. Measure the distance from the end of

the clutch bail to the handlebar as

shown in Figure 20. The distance

between the clutch bail and the

handlebar should be 3-1/2 + 1/8 in.

(8.9 cm + 3 mm).

d. Shut off engine.

5. Adjust attachment clutch bail

measurement, if necessary.

a. Loosen idler nut (Figure 17).

b. To increase distance between clutch

bail and handlebar, move the idler

towards the attachment belt.

c. To decrease the distance between the

clutch bail and handlebar, move the

idler away from the attachment belt.

d. Tighten idler adjustment nut.

e. Check clutch bail measurement.

6. Check Brake

When the clutch bail is disengaged, the

brake must contact the attachment belt.

When the clutch bail is engaged, the

brake must be more than 1/16 in.

(1.6 mm) away from the belt (Figure 19).

7. Repeat steps 3-6 until attachment clutch

bail distance and brake contact are

correct.

IMPORTANT: If attachment clutch/brake

cannot be adjusted within tolerances, see your

Dealer for repairs.

8. Check belt finger clearance.

With clutch bail engaged, belt fingers

should be 1/16-1/8 in. (1.6 - 3.0 mm)from

belt. Adjust belt fingers as necessary.

9. Replace belt cover.

10. Check that auger/impeller stops within

3 seconds after attachment clutch/

impeller brake bail is released.

GB - 24

1/16in.

(1.6mm)

1.DriveBrake

2.BrakeShoeandPad

Figure19

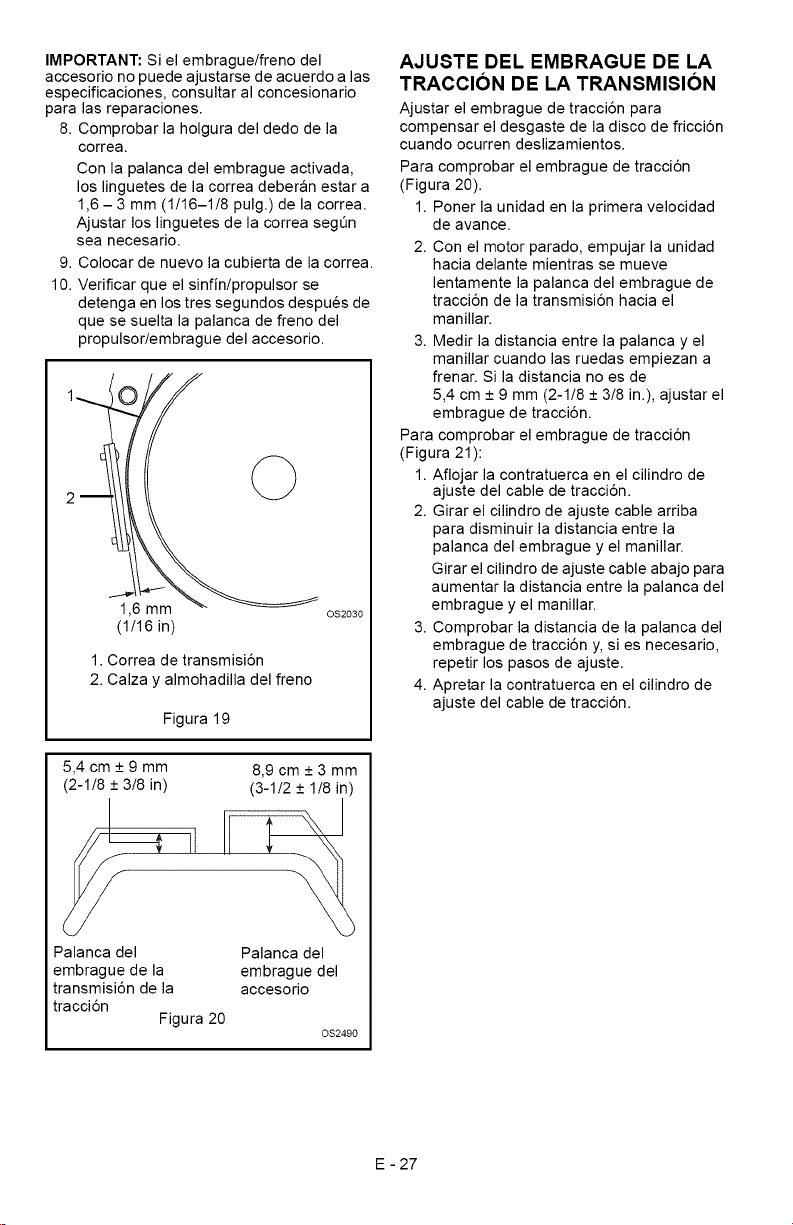

To adjust traction clutch (Figure 21):

1. Loosen jam nut on traction cable

adjustment barrel.

2. Turn adjustment barrel up the cable to

decrease the distance between clutch bail

and handlebar.

Turn the adjustment barrel down the cable

to increase the distance between clutch

bail and handlebar.

3. Check traction clutch bail distance and

repeat adjustment steps if necessary.

4. Tighten jam nut on traction cable

adjustment barrel.

OS2030

j5

2-1/8 + 3/8 in.

(5.4 cm + 9 mm)

Traction Drive

Clutch Bail

Figure 20

3-1/2 + 1/8 in.

(8.9 cm + 3 mm

Attachment

Clutch Bail

TRACTION DRIVE CLUTCH

ADJUSTMENT

If drive slips, adjust traction clutch to

compensate for friction disc wear.

To test traction clutch (Figure 20):

1. Put unit in first forward speed.

2. Without engine running, push unit forward

while slowly moving the traction drive

clutch bail toward the handlebar.

3. Measure distance between bail and

handlebar when the wheels begin to

brake. If distance is not 2-1/8 + 3/8 in.

(5.4 cm + 9 mm), adjust the traction

clutch.

OS2490

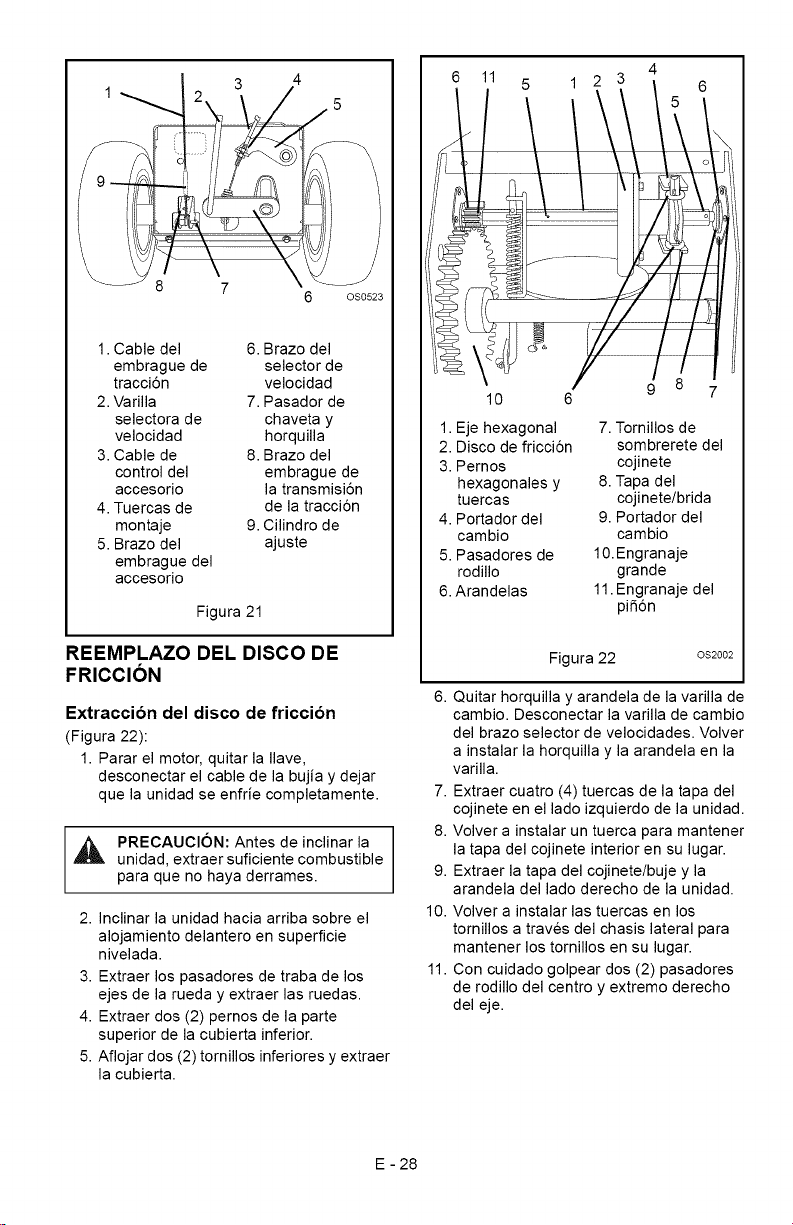

1.Traction Clutch

Cable

2. Shift Rod

3. Attachment

Control Cable

4. Mounting Nuts

5. Attachment

Clutch Arm

Figure 21

7

6. Speed Selector

Arm

7. Cotter Pin and

Clevis

8. Traction Drive

Clutch Arm

9. Adjustment

Barrel

OS0523

GB - 25

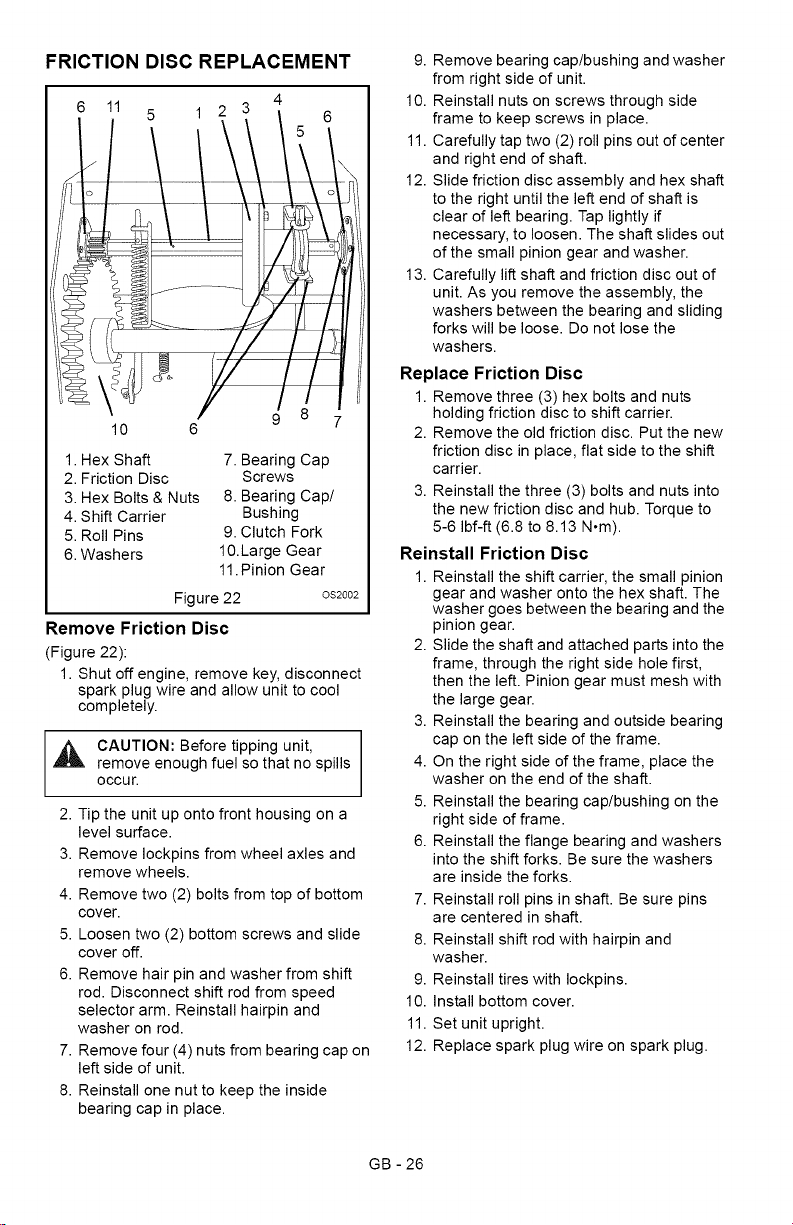

FRICTION DISC REPLACEMENT

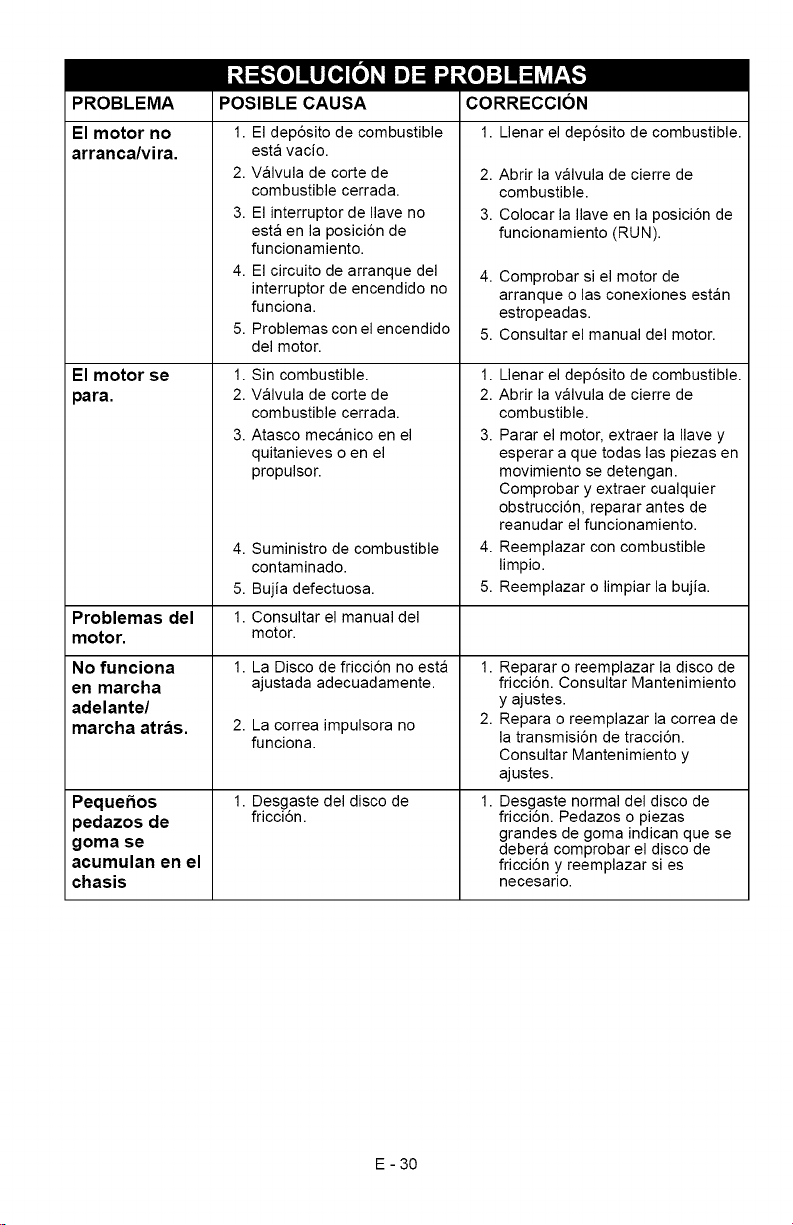

11

4

\

10 6

1. Hex Shaft 7. Bearing Cap

2. Friction Disc Screws

3. Hex Bolts & Nuts 8. Bearing Cap/

4. Shift Carrier Bushing

5. Roll Pins 9. Clutch Fork

6. Washers 1&Large Gear

Remove Friction Disc

(Figure 22):

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

,_ CAUTION: Before tipping unit,

remove enough fuel so that no spills

OCCUr.

2. Tip the unit up onto front housing on a

level surface.

3. Remove Iockpins from wheel axles and

remove wheels.

4. Remove two (2) bolts from top of bottom

cover.

5. Loosen two (2) bottom screws and slide

cover off.

6. Remove hair pin and washer from shift

rod. Disconnect shift rod from speed

selector arm. Reinstall hairpin and

washer on rod.

7. Remove four (4) nuts from bearing cap on

left side of unit.

8. Reinstall one nut to keep the inside

bearing cap in place.

11.Pinion Gear

Figure 22 os2002

9. Remove bearing cap/bushing and washer

from right side of unit.

10. Reinstall nuts on screws through side

frame to keep screws in place.

11. Carefully tap two (2) roll pins out of center

and right end of shaft.

12. Slide friction disc assembly and hex shaft

to the right until the left end of shaft is

clear of left bearing. Tap lightly if

necessary, to loosen. The shaft slides out

of the small pinion gear and washer.

13. Carefully lift shaft and friction disc out of

unit. As you remove the assembly, the

washers between the bearing and sliding

forks will be loose. Do not lose the

washers.

Replace Friction Disc

1. Remove three (3) hex bolts and nuts

holding friction disc to shift carrier.

2. Remove the old friction disc. Put the new

friction disc in place, flat side to the shift

carrier.

3. Reinstall the three (3) bolts and nuts into

the new friction disc and hub. Torque to

5-6 Ibf-ft (6.8 to 8.13 N°m).

Reinstall Friction Disc

1. Reinstall the shift carrier, the small pinion

gear and washer onto the hex shaft. The

washer goes between the bearing and the

pinion gear.

2. Slide the shaft and attached parts into the

frame, through the right side hole first,

then the left. Pinion gear must mesh with

the large gear.

3. Reinstall the bearing and outside bearing

cap on the left side of the frame.

4. On the right side of the frame, place the

washer on the end of the shaft.

5. Reinstall the bearing cap/bushing on the

right side of frame.

6. Reinstall the flange bearing and washers

into the shift forks. Be sure the washers

are inside the forks.

7. Reinstall roll pins in shaft. Be sure pins

are centered in shaft.

8. Reinstall shift rod with hairpin and

washer.

9. Reinstall tires with Iockpins.

10. Install bottom cover.

11. Set unit upright.

12. Replace spark plug wire on spark plug.

GB - 26

,_ WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

SHORT TERM

IMPORTANT: NEVER spray unit with high

pressure water or store unit outdoors.

Run with attachment clutch engaged a few

minutes after each use to free unit of any loose

or melting snow.

Close fuel shut-off valve.

Inspect unit for visible signs of wear, breakage

or damage.

Keep all nuts, bolts and screws properly

tightened and know unit is in safe working

condition.

Store unit in a cool, dry protected area.

LONG TERM

Clean unit thoroughly with mild soap and low

pressure water and lubricate (see

Maintenance). Touch up all scratched painted

surfaces.

Remove weight from wheels by putting blocks

under frame or axle.

When storing unit for extended periods of

time, remove all fuel from tank and carburetor

(run dry). Refer to Engine Manual.

Order the following parts through your

Dealer:

Part No. Description

00036800 Stens Mix Hi-Temp Grease

21533400 Spark Plug (932036, 504)

21533500 Spark Plug (932037, 505)

07219100 Impeller Belt (932036, 504)

07232500 Impeller Belt (932037, 505

07210600 Traction Belt (932036, 504)

07210700 Traction Belt (932037, 505)

53200500 Shear Bolts

03248300 Friction Disc

To obtain a complete parts manual, find your

model and serial number. Then go to

www.ariens.com or call 1-800-678-5443.

See your authorized Ariens dealer to add the

additional accessories available to your

Sno-Thro.

Part No. Description

73203100 Slicer Bar*

72200600 120 Volt Starter Kit

73202500 240 Volt Starter Kit*

72406500 Front Weight Kit*

*Available in CE countries.

(3, 3 oz. cartridges)

GB - 27

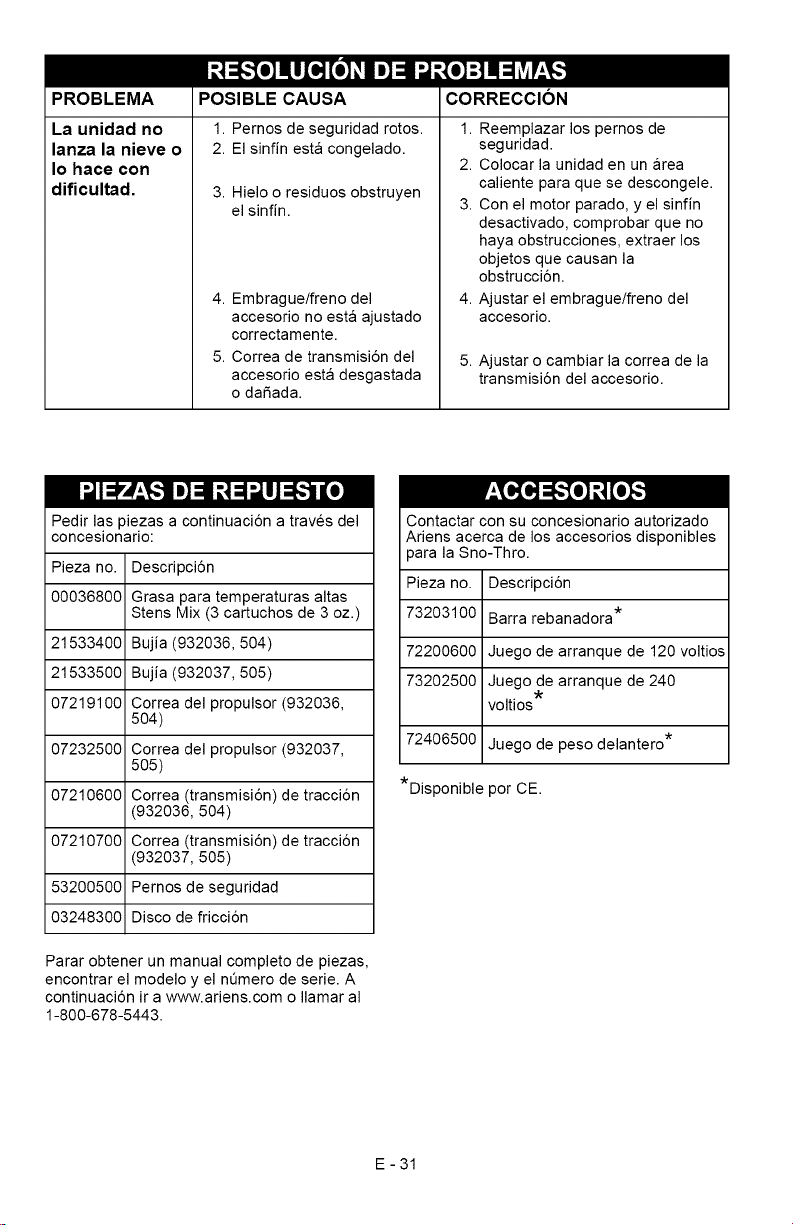

PROBLEM

/i_(oll]__oIo_

PROBABLE CAUSE

CORRECTION

Engine will not

crank/start.

Engine stops.

Engine

problems.

Does not

operate in

Forward/

Reverse.

Small rubber

beads collect

in frame.

Unit throws

snow poorly

or does not

throw snow.

1. Fuel tank is empty.

2. Fuel shut-off valve closed.

3. Build up of dirt and residue

around governor/

carburetor.

4. Key Switch not in run

position.

5. Electric starter not

functioning.

1. Out of fuel.

2. Fuel shut-off valve closed.

3. Mechanical jam in blower

rake or impeller.

4. Polluted fuel supply.

5. Faulty spark plug.

1. See Engine Manual.

1. Friction disc not adjusted

properly.

2. Traction belt not

functioning.

1. Friction disc wear.

1. Shear bolts broken.

2. Auger is frozen in place.

3. Ice or debris is obstructing

auger.

4. Attachment clutch/brake

out of adjustment.

5. Attachment drive belt

slipping.

1. Fill fuel tank.

2. Open fuel shut-off valve.

3. Clean area around governor/

carburetor.

4. Put Key Switch into run position.

5. Check for a bad starter or

connections.

1. Fill fuel tank.

2. Open fuel shut-off valve.

3. Turn off engine, remove key, and

wait for all moving parts to stop.

Check for and remove

obstruction and repair before

restart.

4. Replace with clean fuel.

5. Replace or clean spark plug.

1. Repair or replace friction disc.

See Friction Disc Replacement.

2. Repair or replace traction drive

belt. See Traction Drive Belt

Replacement.

1. Normal friction disc wear.

Chunks or large pieces of rubber

mean friction disc should be

checked and replaced as

necessary.

1. Replace shear bolts (see Shear

Bolts).

2. Move unit to a warm area to

thaw.

3. With engine off, and auger

disengaged, check for

obstructions and remove.

4. Adjust attachment clutch/brake.

See Attachment Clutch/Brake

Adjustment.

5. Adjust or replace attachment

drive belt. See Attachment Drive

Belt Replacement,

GB - 28

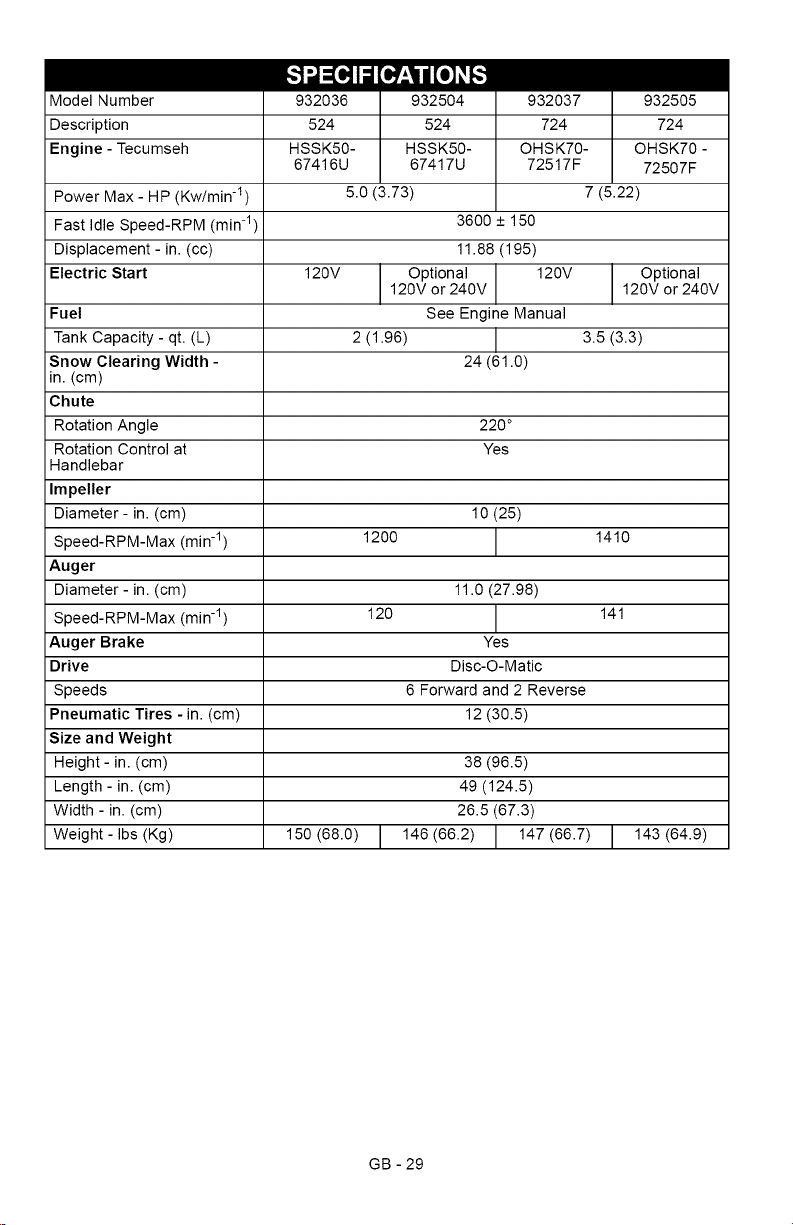

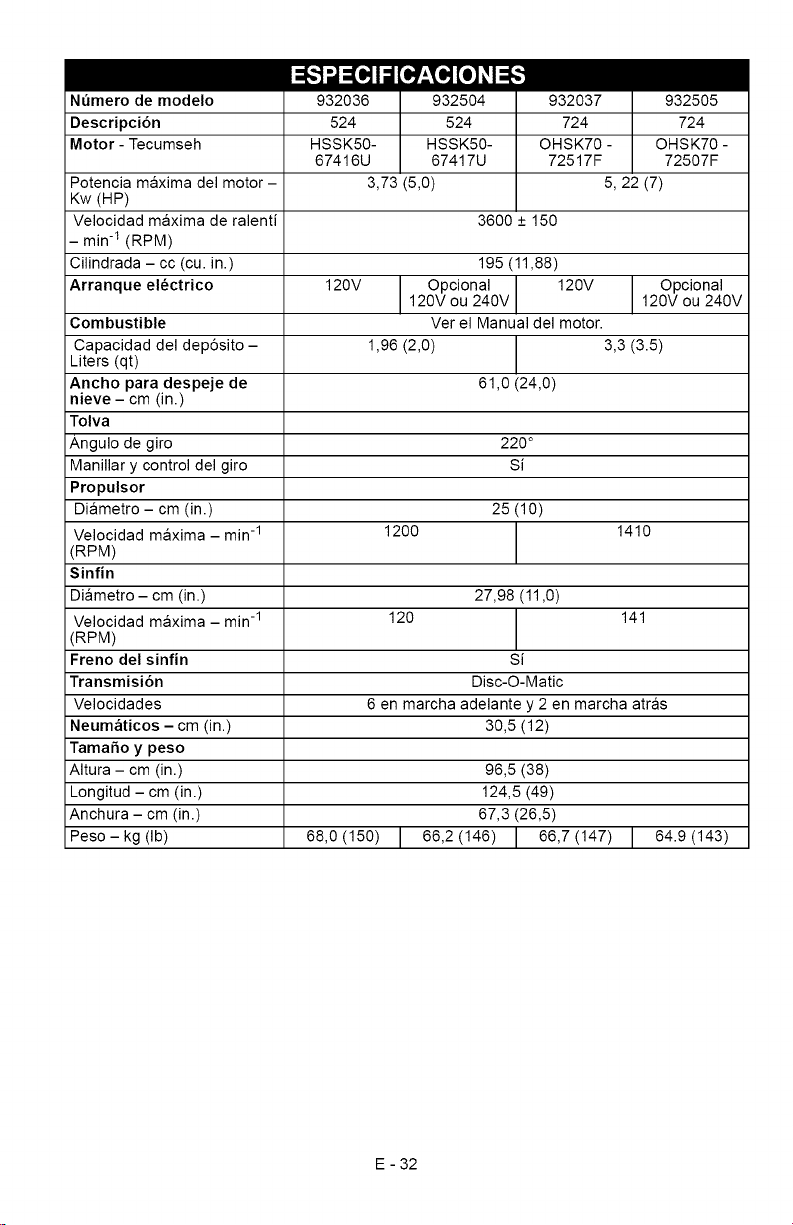

[,,,,___o]_,,,_

Model Number

Description

Engine - Tecumseh

Power Max - HP (Kw/min q)

Fast Idle

Displacement- in. (cc) 11.88 (195)

Electric Start 120V Optional 120V Optional

Fuel See Engine Manual

Tank Capacity - qt. (L) 2 (1.96) 3.5 (3.3)

Snow Clearing Width - 24 (61.0)

in. (cm)

Chute

Rotation Angle 220 °

Rotation Control at Yes

Handlebar

Impeller

Diameter- in. (cm) 10 (25)

Speed-RPM-Max

Auger

Diameter -in. (cm) 11.0 (27.98)

Speed-RPM-Max

Auger Brake Yes

Drive Disc-O-Matic

Speeds 6 Forward and 2 Reverse

Pneumatic Tires -in. (cm) 12 (30.5)

Size and Weight

Height - in. (cm) 38 (96.5)

Length -in. (cm) 49 (124.5)

Width - in. (cm) 26.5 (67.3)

Weight-lbs(Kg) 150(68.0) I 146(66.2) I 147(66.7) I 143(64.9)

Speed-RPM

(minq) 3600 + 150

(minq) 1200 1410

(minq) 120 141

932036

524

HSSK50-

67416U

932504

524

HSSK50-

67417U 72517F

5.O

(3.73)

120V or 240V 120V or 240V

932037 932505

724 724

OHSK70- OHSK70-

7 (5.22)

72507F

GB - 29

3-Year Limited Sno-Thro Warranty

Ariens Company warrants to the original purchaser that consumer products manufactured

by Adens Company will be free from defects in material and workmanship for a period

of three (3) years after the date of purchase, and wilt repair any defect in material or

Ariens Company

655 West Ryan Street

P.O. Box 157

Briliion, Wt 54110-0157

920-756-2141

Fax 920-756-2407

'¢¢¢¢w.ariens.com

This warranty is subject to the following conditions, limitations, and exclusions:

This warranty is valid only if the following conditions are

met:

- The purchaser must perform maintenance and minor

adjustments explained in the owner's manual.

- The purchaser must promptly notify Ariens Company or an

authorized Ariens service representative of the need for

warranty service.

- Returning the product registration card to Ariens Company

will enable the company to contact the registrant with repair

or replacement part information.

The following items are not covered by this warranty:

- Engines and engine accessories are covered only by the

warranty made by the engine manufacturer, and are not

covered by this warranty.

- Parts that are not genuine Adens service parts are not

covered by this warranty.

- Shoes, runners, scraper blades, shear botts headlights, light

bulbs are not covered by this warranty.

- Any defect which is the result of misuse, alteration, improper

assembly, improper adjustment, neglect, or accident is not

covered by this warranty.

- Products which were not purchased in the United States

Puerto Rico, or Canada are not covered by this warranty. In

all other countries, contact place of purchase.

workmanship, and repair or replace any defective part, subject to the conditions, limitations

and exclusions set forth herein.

The three-year duration of this warranty applies only if the product is put to ordinary,

reasonable, and usual personal, family, or household uses. tf the product is put to any

business, commercial, or industrial use, then the duration of this warranty is ninety (90)

days after the date of purchase, or one (1) year after the date of purchase if the product

is labeled as a Professional/Commercial Product. tf any product is rented or leased,

then the duration of this warranty is ninety (90) days after the date of purchase.

Genuine Adens service parts and accessories not purchased with the product covered

by this warranty, but which are later purchased and used with that product, are warranted

to be free from defects in material and workmanship for a period of ninety (90) days

after date of purchase, and Adens Company will repair or replace any such part or

accessory free of charge, except for labor, during that period.

This warranty is subject to the following limitations:

- The purchaser must transport the product to and from the

place of warranty service.

- Warranty service must be performed by an authorized Ariens

service representative. (To find an authorized Ariens service

representative contact Ariens Company at the website,

number or address above.)

- Batteries are warranted only for a period of twelve (12)

months after date of purchase on a prorated basis. For the

first ninety (90) days of the warranty period a defective

battery wilt be replaced free of charge, tf the applicable

warranty period is more than 90 days, Ariens Company wilt

cover the prorated cost of any defective battery, for up to

twelve (12) months after the date of purchase.

- Normal maintenance items including, but not limited to, belts,

idlers, cables, friction wheels, tires, wheels, electrical

components are warranted for a two-year period from the

date of purchase unless a shorter period would apply based

on how the product is used, then the shorter period wilt

apply.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express

or implied, other than what is expressly made

in this warranty. If the law of your state provides

that an implied warranty of merchantability, or

an implied warranty of fitness for particular

purpose, or any other implied warranty, applies

to Ariens Company, then any such implied

warranty is limited to the duration of this

warranty. Some states do not allow limitations

on how long an implied warranty lasts, so the

above limitation may not apply to you.

LIMITATION OF REMEDY AND DAMAGES

Ariens Company's liability under this warranty, and under any

implied warranty that may exist, is limited to repair of any

defect in workmanship, and repair or replacement d any

defective part. Ariens Corn pany shall not be Liable for incidental,

special, or consequential damages (including lost profits).

Some states do not allow the exclusion of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights,

and you may also have other rights which vary

from state to state.

Form:ALW3-122002

GB - 30

AriensCompany

655WestRyanStreet

EO.Box157

Brillion,WI54110-0157

920-756-2141

Fax920-756-2407

www.ariens.com

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Sno-Throo

Owner/Operator Manual

Models

932036-524

932037-724

932504-524

932505-724

U.S. Patents Pending

Transfer

model &

serial number

label from

product

registration

here.

_ _ _ENGLISH

Coller I'autocollant du

module et du numero de

serie dans cet encadr&

Transferir aqui la etiqueta

del modelo y nOmero de

serie del registro del

producto.

FRANQAIS

ESPAKIOL

03249300C 3/04

Supersedes 03249300,A,B

Printed in USA

Ariens Company

655 West Ryan Street

RO. Box 157

Brillion, Wisconsin

54110-0157

USA

Telephone:

(920) 756-2141

Facsimile:

(920) 756-2407

We the undersigned, ARIENS COMPANY, certify that: - Nous, soussignes ARIENS

COMPANY, certifions que :- Der Unterzeichnete, ARIENS COMPANY, bescheinigt, dass: -

La sottoscritta societ&, ARIENS COMPANY, certifica che: - Nosotros, los abajo firmantes,

ARIENS COMPANY, certificamos que: - Undertegnede, ARIENS COMPANY, bekrefter at: -

Undertecknad, ARIENS COMPANY, intygar att: - Allekirjoittanut, ARIENS COMPANY,

vakuuttaa, ett&: - My, nizej podpisani, ARIENS COMPANY, o_wiadczamy, ze:

Type: - Tipo: - WALK BEHIND SNOW THROWER - LES CHASSE_S-NEIGE

Tyyppi: - Typ: - AUTOTRACTES - HANDGEFUHRTE SCHNEEFRASE - SPAZZANEVE

Trade Name: - Appellation commerciale : - ARIENS Sno-Thro

Handelsbezeichnung: - Nome commerciale:- Nombre

comercial:- Handelsnavn:- Handels-beteckning:-

Kauppanimi: - Nazwa handlowa:

Model: - Modele : - Modell: - Modello: - Modelo: - Modell: - 932504 932505

Modell: - Malli: - Model:

Serial # Range: - Gamme de numeros de Serie : - >001000 > 000101

Seriennummern: - Gamma n. di serie: - Rango de n° de serie: -

Serienummeromr&de: - Serienummer-omr&de: -

Sarjanumerot: - Zakres, numer seryjny:

Conforms to: - Conforme & : - Entspricht: - Conforme a: - 98/37/EC, 89/336/EEC,

Conforme a: - E ri samsvar med:- Uppfyller: - 92/31/EEC, 2000/14/EC

T&ytt&& seuraavat vaatimukset: - Jest zgodny z: (V)

Representative Measured Sound Power Level

(Lwa) - Niveau de puissance acoustique

representatif - Repr&sentativer gemessener

Ger&uschpegel - Livello di potenza sonora

rappresentativo rilevato - Nivel de potencia

act_stica representativo medido -

Representativt m< lydeffektniv& -

Representativ uppm&tt Ijudniv& - Edustava,

mitattu &&nen tehotaso - Zmierzony

reprezentatywny poziom mocy akustycznej

MODEL CERTIFICATE OF CONFORMITY ISSUED BY THE

M.ANUFA.CTURER - CERTIFICAT DE CONFORMITE_ DU MODELE

DELIVRE PAR LE FABRICANT - MODELL-KONFORMIT,_,TSBE -

SCHEINIGUNG AUSGESTELLT DURCH DEN HERSTELLER -

CERTIFICATO DI COMFORMIT,_ DEL MODELLO RILASCIATO DAL

PRODUTTORE - CERTIFICADO DE CONFORMIDAD DEL MODELO

PROVISTO POR EL FABRICANTE - MODELLSERTIFIKAT FOR

OVERENSSTEMMELSE UTSTEDT AV FABRIKANT -

TILLVERKARENS MODELLCERTIFIKAT OM

OVERENSST,_MMELSE - VALMISTAJAN ANTAMA VAKUUTUS

MALLIN M.,_,_R,_,YSTEN MUKAISUUDESTA - SWlADECTWO

ZGODNOSCI MODELU WYDANE PRZEZ PRODUCENTA

SEMOVENTE - CAMINAR POR DETRAS DE LA LANZADORA DE NIEVE

- SNOFRESER - GA BAKOM SNOSLUNGAN - K,_SINOHJAILTAVA

LUMILINKO - ODGARNIACZ SNIEGU DO PROWADZENIA PRZED SOB,_

Guaranteed Sound Power Level (Lwa) -