Page 1

Sno-Thro

®

Owner/Operator Manual

Models

932104 - 8524

932502 - 8524

ENGLISH

FRANÇAIS

ESPAÑOL

Transfer

model &

serial number

label from

product

registration

here.

Coller l’autocollant du

modèle et du numéro de

série dans cet encadré.

Transferir aquí la etiqueta

del modelo y número de

serie del registro del

producto.

03249000B 7/03

Supersedes 03249000, A

Printed in USA

Page 2

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, Wisconsin

54110-0157

USA

Telephone (920) 756-

2141

Facsimile (920) 756-2407

We the undersigned, ARIENS COMPANY, certify that: – Nous, soussignés ARIENS COMPANY,

certifions que : – Der Unterzeichnete, ARIENS COMPANY, bescheinigt, dass: – La sottoscritta

società, ARIENS COMPANY, certifica che: – Nosotros, los abajo firmantes, ARIENS

COMPANY, certificamos que: – Undertegnede, ARIENS COMPANY, bekrefter at: –

Undertecknad, ARIENS COMPANY, intygar att: – Allekirjoittanut, ARIENS COMPANY,

vakuuttaa, että:

MODEL CERTIFICATE OF CONFORMITY ISSUED BY THE

MANUFACTURER – CERTIFICAT DE CONFORMITÉ DU

MODÈLE DÉLIVRÉ PAR LE FABRICANT – MODELLKONFORMITÄTSBE-SCHEINIGUNG AUSGESTELLT DURCH

DEN HERSTELLER – CERTIFICATO DI COMFORMITÀ DEL

MODELLO RILASCIATO DAL PRODUTTORE – CERTIFICADO DE

CONFORMIDAD DEL MODELO PROVISTO POR EL

FABRICANTE – MODELLSERTIFIKAT FOR

OVERENSSTEMMELSE UTSTEDT AV FABRIKANT –

TILLVERKARENS MODELLCERTIFIKAT OM

ÖVERENSSTÄMMELSE – VALMISTAJAN ANTAMA VAKUUTUS

MALLIN MÄÄRÄYSTEN MUKAISUUDESTA

Type: – Tipo:

– Tyyppi: –

Typ:

Trade Name: – Appellation

commerciale : –

Handelsbezeichnung: – Nome

commerciale: – Nombre comercial: –

Handelsnavn: – Handelsbeteckning: – Kauppanimi:

Model: – Modèle : – Modell: –

Modello: – Modelo: – Modell: –

Modell: – Malli:

Serial # Range: – Gamme de

numéros de Série : –

Seriennummern: – Gamma

n. di serie: – Rango de nº de serie: –

Serienummerområde: –

Serienummer-område: –

Sarjanumerot:

Coforms to: – Conforme à : – Entspricht: – Conforme a: –

Conforme a: – Er i samsvar med: – Uppfyller: – Täyttää

seuraavat vaatimukset:

WALK BEHIND SNOW THROWER – LES CHASSES-NEIGE AUTOTRACTÉS –

HANDGEFÜHRTE SCHNEEFRÄSE – SPAZZANEVE SEMOVENTE –

CAMINAR POR DETRÁS DE LA LANZADORA DE NIEVE – SNØFRESER –

GÅ BAKOM SNÖSLUNGAN – KÄSINOHJAILTAVA LUMILINKO

ARIENS Sno-Thro

932502

> 000101

2

98/37/EC, 89/336/EEC, 92/

31/EEC, 2000/14/EC (V)

Page 3

Representative Measured Sound Power Level

(Lwa) – Niveau de puissance acoustique

représentatif – Repräsentativer gemessener

Geräuschpegel – Livello di potenza sonora

rappresentativo rilevato – Nivel de potencia

acústica representativo medido – Representativt

målt lydeffektnivå – Representativ uppmätt

ljudnivå – Edustava, mitattu äänen tehotaso

932502: 108 dB

A

Guaranteed Sound Power Level (Lwa) –

Niveau garanti de puissance acoustique –

Garantierter Geräuschpegel – Livello di

potenza sonora garantito – Nivel de potencia

acústica garantizado – Garantert lydeffektnivå

– Garanterad ljudnivå – Taattu äänen tehotaso

932502: 110 dB

A

Philip J. Smucker:

Manager of Product Conformance (Keeper of Technical

File) – Responsable de la conformité des produits (en

possession du document technique) – Leiter der

Produktübereinstimmung (Verantwortlicher für die

technische Dokumentation) – Addetto alla conformità

del prodotto (in possesso del documento tecnico) –

Signature – Firma –

Unterschrift – Signatur –

Namnteckning –

Allekirjoitus

5/21/2003

Date –

Data –

Datum –

Fecha –

Dato –

Päiväys

Gerente de conformidad de los productos (en posesión

del documento técnico) – Ansvarlig for produktsamsvar

(innehaver av teknisk fil) – Chef för

produktöverensstämmelse (innehavare av tekniska

dokument) – Tuotteen vaatimustenmukaisuudesta

vastaava johtaja (teknisen tiedoston haltija)

CE Sound and Vibration – Niveau sonore et vibration CE – CE-Geräuschpegel und

Vibrationswerte – Livello sonoro e vibrazioni CE – Sonido y vibración CE – CE-lydnivå og

Vibrasjonsmåling – CE ljudnivå och Vibrations-mätning – CE-melutaso Tärinä

Model: – Modèle : – Modell: – Modello: – Modelo:

932502

– Modell: – Modell: – Malli:

Oper. Ear Sound Pressure (Lpa) in dBA –

Pression acoustique Pression sonore à aux

oreilles de l’opérateur (L

) en dBA –

pa

Geräuschstärke am Ohr des Bedieners (Lpa) in

dBA – Potenza sonora percepita dall’operatore

(Lpa) in. dBA – Presión de sonido en el oído (Lpa)

in dB

– Lydtrykk i førerens øre (Lpa) in. dBA – vid

A

förarens position (Lwa) i dBA – Kuljettajan korvaan

kohdistuva äänipaine (L

)/dB

pa

A

95

Vibration Measure (m/sec2) @ Operator Hands –

Niveau de vibrationaux mains de l’opérateur –

Vibrationswerte An den Händen des Bedieners –

Misura delle vibrazioni alle mani dell’operatore –

Cantidad de vibración en las manos del operador

– Vibrasjonsmåling ved brukerens hender –

Vibrationsmätning vid förarens händer – Tärinä

kuljettajan käsissä

X

Y

Z

2.8

5.9

8.6

3

Page 4

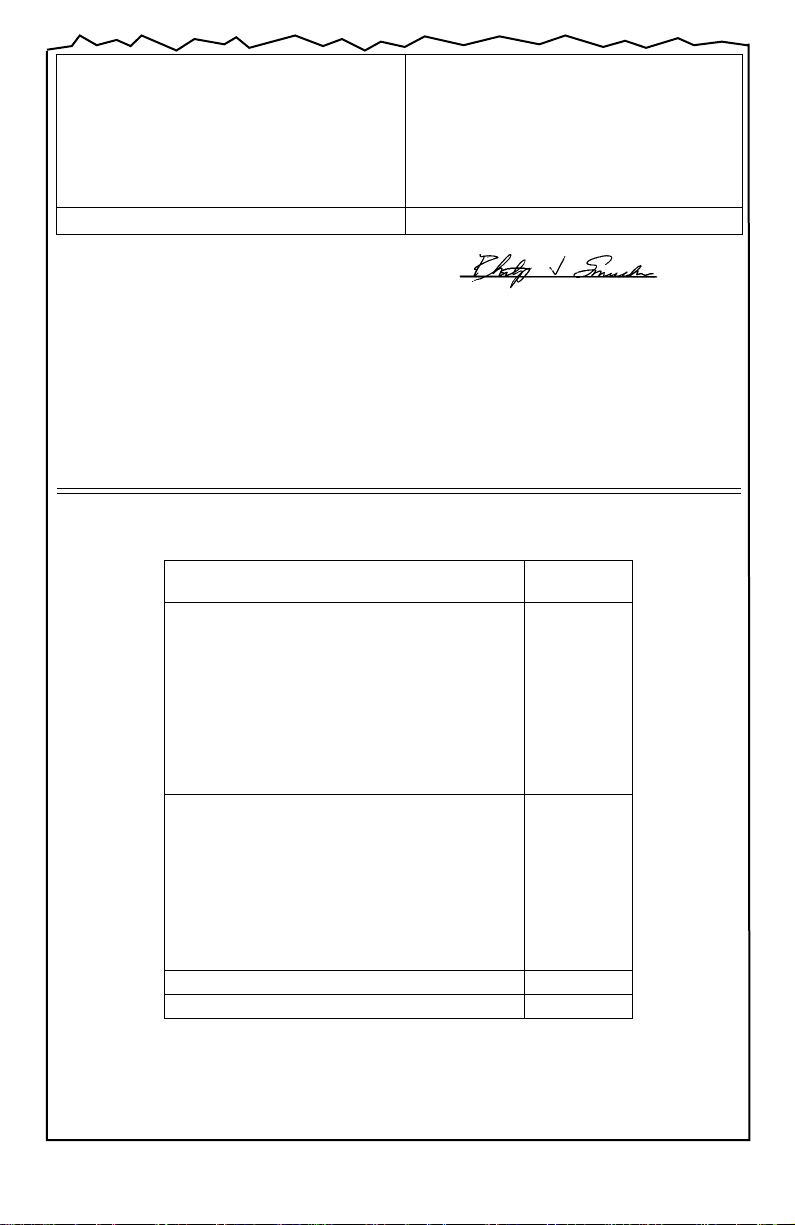

CONTROLS AND FEATURES

z

9

8

10

23

11

7

12

6

5

14

15

13

16

4

17

3

2

18

19

1

22

Figure 1

4

21 20

OS0502

OS2100

Page 5

ENGLISH

1. Traction Drive Clutch

Lever

2. Ignition Switch, push-pull

3. Choke

4. Throttle (Engine Stop)

5. Runner(s)

6. Axle Lock Pin (932104,

502)

7. Belt Cover

8. Headlight (932104, 502)

9. Discharge Chute

Deflector

10. Discharge Chute

11. Impeller

12. Auger

13. Scraper Blade

14. Spark Plug and Wire

15. Primer Bulb

16. Oil Fill and Dipstick

17. Gas Tank and Cap

18. Recoil Starter Handle

19. Attachment Clutch Lever

20. Speed Selector

21. Electric Starter (932104)

22. Chute Crank

23. Fuel Shut-off Valve

FRANÇAIS

1. Levier d’embrayage de

l’entraînement de la

traction

2. Clé de contact,

pousser-tirer

3. Starter

4. Commande des gaz

(arrêt du moteur)

5. Patin(s)

6. Broche de blocage de

l’essieu (932104, 502)

7. Couvercle du courroie

8. Phare (932104, 502)

9. Déflecteur de la goulotte

d’évacuation

10. Goulotte d’évacuation

11. Turbine

12. Rotor

13. Lame racleuse

14. Bougie et fil

15. Poire d’amorçage

16. Tube de remplissage en

huile et jauge

17. Réservoir de carburant

et bouchon

18. Poignée du démarreur

à cordon

19. Levier d’embrayage

de l’outil

20. Sélecteur de vitesses

21. Démarreur électrique

(932104)

22. Manivelle de la goulotte

23. Robinet de carburant

ESPAÑOL

1. Palanca del embrague

de la transmisión de la

tracción

2. Interruptor de encendido,

tiro-empujel

3. Estrangulador

4. Acelerador (parada de

motor)

5. Guía(s)

6. Pasador de traba del eje

(932104, 502)

7. Cubierta de la correa

8. Faro (932104, 502)

9. Deflector de la tolva de

descarga

10. Tolva de descarga

11. Propulsor

12. Sinfín

13. Cuchilla raspadora

14. Bujía y cable

15. Perilla de cebado

16. Llenado de aceite y

varilla medidora

17. Depósito de gasolina

y tapa

18. Manilla de arranque de

retroceso

19. Palanca del embrague

del accesorio

20. Selector de velocidad

21. Arranque eléctrico

(932104)

22. Manivela de la tolva

23. Válvula de corte del

combustible

5

Page 6

TABLE OF CONTENTS

Controls and Features . . . . . . . . . . . . . . . . 4

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . 17

Service and Adjustments. . . . . . . . . . . . . 19

INTRODUCTION

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Troubleshooting . . . . . . . . . . . . . . . . . . . . 27

Service Parts . . . . . . . . . . . . . . . . . . . . . . . 26

Accessories . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications . . . . . . . . . . . . . . . . . . . . . . 28

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . 29

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. If used

improperly, this unit could be dangerous and

cause personal injury or property damage.

The contents will provide you with safety

instructions for the safe use of your unit during

normal operation and maintenance.

All reference to left, right, front, or rear are

given from operator standing in operation

position and facing the direction of forward

travel.

MODEL AND SERIAL NUMBERS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature package.

They are printed on a serial number label,

located on the frame of your unit.

Serial

Number

Label

Figure 2

• Record Unit Model and Serial numbers

here.

OS0521

• Record Engine Model and Serial number

here.

PRODUCT REGISTRATION

The Ariens dealer must register the product at

the time of purchase. Registering the product

will help the company process warranty claims

or contact you with the latest service

information. All claims meeting requirements

during the limited warranty period will be

honored, whether or not the product

registration card is returned. Keep a proof of

purchase if you do not register your unit.

Customer Note:

register your product, please fill out, sign, and

return the product registration card to Ariens

or go to www.ariens.com.

If the dealer does not

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The

replacement of any part on this vehicle with

anything other than an Ariens authorized

replacement part may adversely affect the

performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

warranty, property damage, personal injury or

death arising out of the use of unauthorized

replacement parts.

For a brief list of replacement parts see

Service Parts

complete parts manual, find your model and

serial number. Then go to www.ariens.com or

call 1-800-678-5443.

in this manual. To obtain a

GB - 6

© Copyright 2003 Ariens Company

Page 7

DISCLAIMER

Ariens reserves the right to discontinue, make

changes to, and add improvements upon its

products at any time without public notice or

obligation. The descriptions and specifications

contained in this manual were in effect at

printing. Equipment described within this

manual may be optional. Some illustrations

may not be applicable to your unit.

DELIVERY

Customer Note:

product without complete assembly and

instruction by your retailer, it is your

responsibility to:

1. Read and understand all assembly

instructions in this manual. If you do not

understand or have difficulty following the

instructions, contact your nearest Ariens

Dealer for assistance. Make sure all

assembly has been properly completed.

If you have purchased this

SAFETY

NOTE:

To locate your nearest Ariens Dealer,

call 1-800-678-5443 or go to www.ariens.com

on the internet.

WARNING:

adjustments can cause serious injury.

2. Understand all Safety Precautions

provided in the manuals.

3. Review control functions and operation of

the unit. Do not operate the Sno-Thro

unless all controls function as described

in this manual.

4. Review recommended lubrication,

maintenance and adjustments.

5. Review Limited Warranty Policy.

6. Fill out a Product Registration Card and

return the card to the Ariens Company or

go to www.ariens.com.

Improper assembly or

WARNING:

and feet, always disengage clutches,

shut off engine, and wait for all

movement to stop before unclogging

or working on snow thrower.

Keep hands and feet away from auger

and impeller.

To avoid injury to hands

SAFETY ALERTS

Look for these symbols to point

out important safety precautions.

They mean:

Attention!

Personal Safety Is

Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal

words below are used on decals and in this

manual. Read and understand all safety

messages.

DANGER:

HAZARDOUS SITUATION! If not

avoided, WILL RESULT in death or

serious injury.

WARNING:

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in death or

serious injury.

IMMINENTLY

POTENTIALLY

CAUTION:

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor or

moderate injury. It may also be used to

alert against unsafe practices.

POTENTIALLY

NOTATIONS

NOTE:

General reference information for

proper operation and maintenance practices.

IMPORTANT:

information required to prevent damage to unit

or attachment.

Specific procedures or

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area. Always follow the practices

set forth in this manual.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

unit is to be used by someone other than

original purchaser; loaned, rented or sold,

ALWAYS provide this manual and any needed

safety training before operation.

GB - 7

Page 8

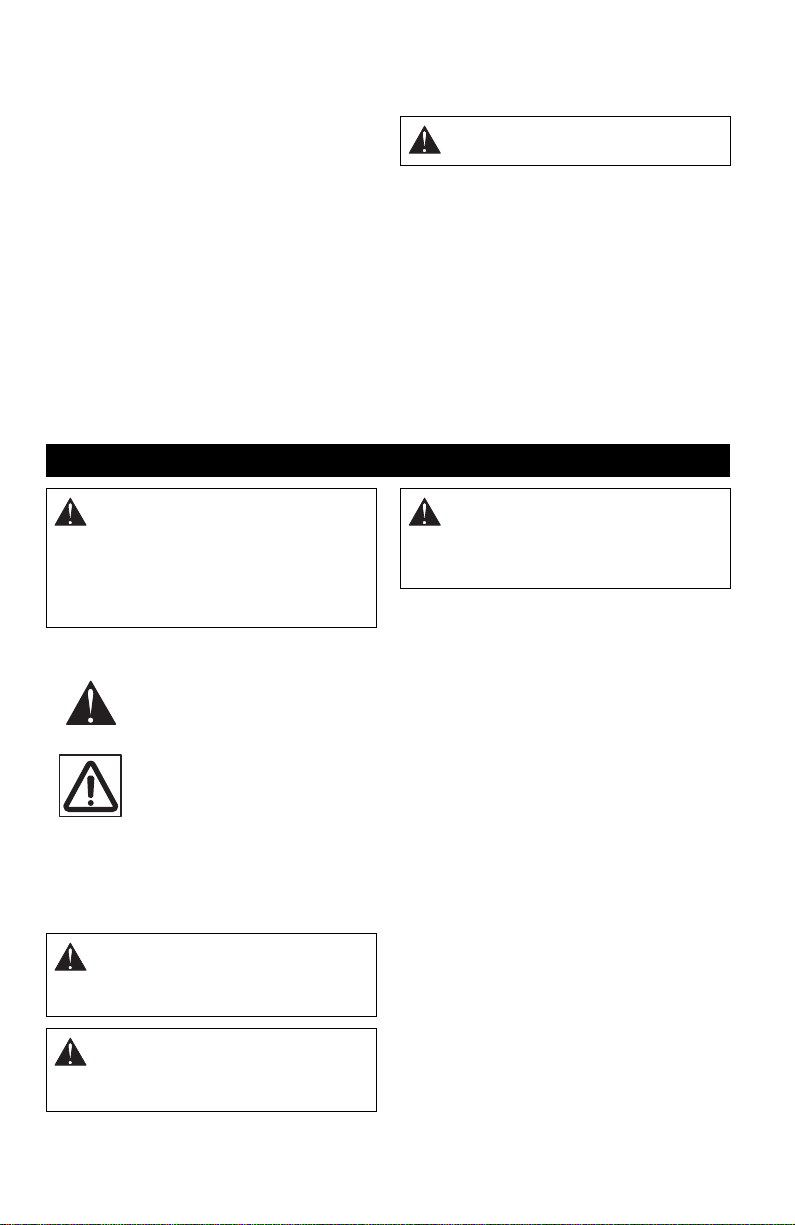

SAFETY DECALS AND

LOCATIONS

ALWAYS replace missing or damaged Safety

Decals. Refer to figure below for Safety Decal

locations.

2

Figure 3

DANGER / PELIGRO

3

ROTATING PARTS

Stop engine & remove ignition key

before clearing.

PIECES EN ROTATION

Arreter le moteur et retirer la clé de

contact avant le débourrage.

PIEZAS GIRATORIAS

Detener el motor y sacar la llave

antes de despejar.

DANGER / PELIGRO

ROTATING PARTS

Keep clear of auger while engine is

running.

PIECES EN ROTATION

Ne pas s'approcher du rotor lorsque

le moteur est en marche.

PIEZAS GIRATORIAS

Mantenerse alejado del sinfín

mientras que el motor esté en

marcha.

SÉCURITÉ SEGURIDAD

SAFETY

• Read operator's manual.

• Lire le manuel du

l’opérateur.

• Allow operation only by

• Seuls les adultes

properly trained adult,

recu la formation

never children.

appropriée peuvent

• Stop engine and remove

utiliser la machine,

ignition key prior to

jamais les enfants.

leaving operator's

• Toujours arrêter le

position for any reason.

moteur et retirer la clé de

contact avant de quitter

• Keep all controls, guards

le siège de l'opérateur.

and safety devices

properly serviced and

• Les commandes,

functional.

protections et dispositifs

de sécurité doivent

• Never direct discharge

toujours être

towards persons or

correctement entretenus

property that may be

et en bon

injured or damaged by

fonctionnement.

thrown objects.

• Ne jamais orienter la

goulotte d'évacuation

vers des personnes pour

éviter tout risque de

blessure par des objets

projetés ou vers des

bâtiments pour éviter de

les endommager.

état de

ayant

08093900

• Leer el manual del

operador.

• Permitir la operación

sólo por adultos

entrenados, nunca

niños.

• Parar el motor y sacar la

llave de la ignición antes

de dejar el puesto del

operador por cualquier

motivo.

• Mantener todos los

controles, protectores y

dispositivos de

seguridad correctamente

y en buen

funcionamiento.

• Nunca dirigir la descarga

hacia personas que

puedan lesionarse o

propiedad que pueda

dañarse por los objetos

arrojados.

1

08094000A

OS2350

1. DANGER! 2. WARNING!

ROTATING PARTS.

Keep clear of auger while engine

is running.

• Read Operator’s Manual.

OS2080

• Allow operation only by

properly trained adult, never

children.

• Stop engine and remove

ignition key prior to leaving

the operator’s position for

any reason.

• Keep all controls, guards and

safety devices properly

serviced and functional.

• Never direct discharge

towards persons or property

that may be injured or

damaged by thrown objects.

GB - 8

Read Owner/Operator Manual.

OL1801

Keep people away from unit while

operating. Keep children out of

work area and under watchful

care of a responsible adult.

OL4370

Never direct discharge towards

persons or property that may be

injured or damaged by thrown

objects.

OL0910

Page 9

Stop engine, remove key, read

manual before making any

repairs, adjustments.

OL4010

Wear appropriate hearing

protection.

OL4690

3. DANGER!

ROTATING PARTS! Stop engine

and remove key before clearing.

High speed impeller rotates

below discharge opening. Wait

for all moving parts to stop

before removing clogs or

OS2070

servicing.

SAFETY RULES

Read, understand, and follow all safety

practices in Owner/Operator Manual before

beginning assembly or operating. Failure to

follow instructions could result in personal

injury and/or damage to unit.

ALWAYS remove key and/or wire from spark

plug before assembly, maintenance or service.

Unintentional engine start up can cause death

or serious injury.

Complete a walk around inspection of unit and

work area to understand:

• Work area • Your unit • All safety decals

ALWAYS check overhead and side clearances

carefully before operation. ALWAYS be aware

of traffic when operating along streets or

curbs.

Keep children and people away. Keep children

out of work area and under watchful care of a

responsible adult.

NEVER allow children to operate or play on or

near unit. Be alert and shut off unit if children

enter area.

DO NOT allow adults to operate unit without

proper training.

Keep area of operation clear of all toys, pets,

and debris. Thrown objects can cause injury.

Check for weak spots on docks, ramps or

floors. Avoid uneven work areas and rough

terrain. Stay alert for hidden hazards.

Avoid uneven and rough terrain. DO NOT

operate near drop offs, ditches, or

embankments. Unit can suddenly turn over if a

wheel is over the edge of a cliff or ditch, or if

an edge caves in.

Falling snow, fog, etc. can reduce vision and

cause an accident. Operate unit only when

there is good visibility and light.

Only trained adults may operate unit.

Training includes actual operation.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired

attention at all times.

NEVER allow anyone to operate this unit when

their alertness or coordination is impaired.

DO NOT operate unit without wearing

adequate winter outer garments. Wear

adequate safety gear, including safety glasses

with side shields, and protective gloves. Wear

proper footwear to improve footing on slippery

surfaces.

DO NOT wear loose clothing or jewelry and tie

back hair that may get caught in rotating parts.

Protect eyes, face and head from objects that

may be thrown from unit. Wear appropriate

hearing protection.

Avoid sharp edges. Sharp edges can cut.

Moving parts can cut off fingers or a hand.

ALWAYS keep hands and feet away from all

rotating parts during operation. Rotating parts

can cut off body parts.

NEVER place your hands or any part of your

body or clothing inside or near any moving

part while unit is running.

ALWAYS keep hands away from all pinch

points.

DO NOT touch unit parts which might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust or service.

Never direct discharge towards persons or

property that may be injured or damaged by

thrown objects. Use extreme caution on gravel

surfaces. Stay alert for hidden hazards or

traffic. Adjust Runners so Scraper Blade does

not contact gravel.

DO NOT throw snow any higher than

necessary.

Deflected materials can cause injury and

property damage.

Always stand clear of the discharge area when

operating this unit.

GB - 9

Page 10

Fumes from engine exhaust can cause injury

or death. DO NOT run engine in an enclosed

area. Always provide good ventilation.

ALWAYS disengage attachment, stop unit and

engine, remove key and allow moving parts to

stop before leaving operator’s position.

ROTATING IMPELLER CAN CAUSE

SERIOUS INJURY. NEVER ATTEMPT TO

UNCLOG OR CLEAN UNIT WHILE ENGINE

IS RUNNING.

Read, understand, and follow all instructions in

the manual and on the machine before

starting.

Understand:

• How to operate all controls.

• The functions of all controls.

• How to STOP in an emergency.

Before starting engine, disengage control(s).

Use only approved extension cords and

receptacles when starting units equipped with

electric starter. DO NOT connect electric

starter cord to any wiring system that is not a

three-wire grounded system.

ALWAYS allow unit and engine to adjust to

outdoor temperatures before clearing snow.

Always be sure of your footing, especially

when operating in reverse or leaving the

operator’s position. Walk, never run during

operation.

DO NOT overload the machine capacity by

attempting to clear snow at too fast a rate.

DO NOT operate at too fast a rate.

Slow down and turn corners slowly.

Do not operate in reverse unless absolutely

necessary. ALWAYS back up slowly. Always

look down and behind before and while

backing.

Disengage attachment drive when traveling

from one work area to another.

Abnormal Vibrations are a warning of trouble.

Striking a foreign object can damage unit.

Immediately stop unit and engine. Remove

key and wait for all moving parts to stop.

Remove wire from spark plug. Inspect unit and

make any necessary repairs before restart.

Before cleaning, removing clogs or making

any inspections, repairs, etc.: disengage

clutch(es), stop unit and engine, remove

key, allow moving parts to stop. Allow hot

parts to cool.

Run unit a few minutes after clearing snow to

prevent freeze-up of attachment.

Disengage attachment when not in use.

Disengage all clutches before starting engine.

Adjust runners to clear gravel or crushed rock

surfaces safely.

Never leave a running unit unattended.

ALWAYS shut off engine before leaving unit.

ALWAYS remove key to prevent unauthorized

use.

Never carry passengers.

Check clutch and brake operation frequently.

Adjust and service as required. All motion of

drive wheels and auger/impeller must stop

quickly when control levers are released.

DO NOT operate on steep slopes. DO NOT

clear snow across the face of slopes. Keep all

movement on slopes slow and gradual. DO

NOT make sudden changes in speed or

direction. Use a slow speed to avoid stops or

shifts on slopes. Avoid starting or stopping on

a slope.

DO NOT park unit on a slope unless

absolutely necessary. When parking on a

slope always block the wheels.

ALWAYS shut off engine, remove key, and

close fuel shut-off valve or drain fuel when

transporting unit on a truck or trailer.

Use extra care when loading or unloading unit

onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

Keep unit free of ice or other debris. Clean up

oil or fuel spills.

This product is equipped with an internal

combustion type engine. DO NOT use unit on

or near any unimproved, forest-covered or

brush covered land unless exhaust system is

equipped with a spark arrester meeting

applicable local, state or federal laws. A spark

arrester, if it is used, must be maintained in

effective working order by operator.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use an approved

fuel container.

NO smoking, NO sparks, NO flames. ALWAYS

allow engine to cool before servicing.

NEVER fill fuel tank when engine is running or

hot from operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled

fuel.

GB - 10

Page 11

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel it

on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a gasoline

dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle

lock-open device.

If fuel is spilled on clothing, change clothing

immediately.

Before tipping unit up onto housing, remove

fuel so no spills will occur. Ensure unit is

secure and will not tip over during

maintenance.

ALWAYS keep protective structures, guards,

and panels in good repair, in place and

securely fastened. NEVER modify or remove

safety devices.

DO NOT change engine governor settings or

over-speed engine.

ASSEMBLY

WARNING:

and understand the entire

section before proceeding.

WARNING:

boxed unit could result in personal

injury or damage to unit.

AVOID INJURY. Read

Dropping or tipping over

Safety

Fumes from engine exhaust can cause injury

or death. DO NOT run engine in an enclosed

area. Always provide good ventilation.

ALWAYS maintain unit in safe operating

condition. Damaged or worn out muffler can

cause fire or explosion.

Keep all hardware properly tightened. Check

shear bolts frequently.

Maintain or replace safety and instruction

labels, as necessary.

NEVER store unit with fuel in fuel tank, inside

a building where any ignition sources are

present.

Shut off fuel and allow engine to cool

completely before storing in closed area or

covering unit.

For extended storage, clean unit thoroughly.

See Engine Manual for proper storage.

Use only attachments or accessories

designed for your unit.

Check components frequently. If worn or

damaged, replace with manufacturer’s

recommended parts.

6. Rotate handlebar up so wing knob holes

align. Install and tighten all wing knobs.

7. Install wing nut and bolt removed in step 2

onto shift rod and tighten hardware.

4

5

2

Tools Required:

• Pliers

• Open-End Wrenches: 3/8, 7/16, 1/2, 9/16"

and/or Adjustable Wrench

• Tire Gauge

ASSEMBLY

Handlebar and Shift Rod

1. Remove lower wing knobs on handlebar

assembly (Figure 4).

2. Remove upper wing nut and bolt on shift

rod.

3. Loosen upper wing knobs on handlebar.

4. Loosen lower wing nut and bolt on shift

rod.

5. Put speed selector lever into fastest

reverse panel notch.

GB - 11

2

3

6

1. Handlebar

Assembly

2. Wing Knobs

3. Wing Nut

1

OS0901

4. Speed Selector

5. Bolt

6. Shift Rod

Figure 4

Page 12

Install Discharge Chute and Crank

Figures 5 and 6.

1. Grease discharge chute ring on blower

housing (if not already greased).

2. Remove mounting hardware from top of

engine.

3. Slide chute ring under retainer clip on

blower housing and put chute on housing.

4. Secure chute by fastening chute strap to

engine with hardware just removed.

NOTE:

Washers and lock nuts go on top of

chute strap.

5. Loosen mounting nut on chute and move

chute up or down so that chute ring is

approximately centered between retainer

clip and lower ring and tighten.

6. Slide chute crank rod through bracket

under handlebar and through hole in

panel.

7. Align chute crank rod with the universal

joint on chute and fasten with spring clip.

2

1

6

1. Mounting

Hardware

2. Discharge

Chute Crank

3. Chute Strap

3

Figure 5

4

5

OS1751

4. Gear Cover

5. Discharge

Chute

Bracket

6. Engine

Bracket

Check Function of Dual Handle

Interlock

Without the engine running, press down

(engage) both clutch levers. Release

attachment clutch lever. Attachment clutch

should remain engaged until traction clutch

lever is released, then both clutches

disengage. If they do not, contact your dealer

for repairs.

must

11

10

9

8

6

5

1. Pinion Bracket

2. Gear Strap

3. Chute Bracket

4. Retainer Clip

5. Lower Ring

6. Chute Ring

12

7

Figure 6

1

2

3

4

DS0112

7. Mounting Nut

8. Flat Gear

9. Pinion

10.Chute Strap

11.Universal Joint

12.Spring Clip

Check Tire Pressure

Check tire pressure and adjust to the pressure

listed on tire sidewall.

Check Auger Gearcase Oil

Check oil level in auger gearcase (see

and Adjustments

).

Service

Check Engine Crankcase Oil

IMPORTANT:

5W-30 oil in crankcase. Refer to Engine

Manual for detailed instructions.

The engine is shipped with

Fill Engine Fuel Tank

Refer to Engine Manual for proper fuel type

and tank capacity.

Check Function of all Controls

Ensure unit runs and performs properly. Refer

to

Operation

.

Run-in Attachment Belt

1. Start unit in a well-ventilated area

according to

Operation

2. Engage attachment clutch lever and run

attachment for about 15 minutes.

3. Stop unit, wait for all moving parts to stop,

and remove spark plug wire.

4. Adjust clutch according to

Clutch/Brake Adjustment

Adjustments.

Starting and Shut-Off

.

in

in

Attachment

Service and

GB - 12

Page 13

OPERATION

WARNING: AVOID INJURY. Read and

understand the entire Safety section

before proceeding.

WARNING: To avoid injury to hands

and feet, always disengage clutches,

shut off engine, and wait for all

movement to stop before unclogging

or working on snow thrower.

Keep hands and feet away from auger

and impeller.

CONTROLS AND FEATURES

See Figure 1 for all Controls and Features

locations.

Dual Handle Interlock

When Attachment Clutch and then Traction

Drive Clutch are engaged, the Attachment

Clutch will remain engaged (lever down) if

released. To stop attachment, release Traction

Drive Clutch and both clutches will disengage.

Traction Drive Clutch - Left Hand

Lever

Squeeze the Traction

2

1

NOTE:

When traveling to or from the area to

be cleared, press down on the handlebars

enough to raise the front of the unit slightly off

the surface. Engage the traction drive clutch

without engaging the attachment drive clutch.

Attachment Clutch - Right Hand Lever

Drive Clutch Lever

against the Handlebar

(1) to engage wheel

drive for propelling unit.

Forward speed will vary

according to snow depth

and moisture content.

Release lever (2) to stop

OL2701

movement.

Squeeze Attachment

2

Clutch Lever against

handlebar (1) to engage

attachment. Release

both clutch levers (2) to

disengage power and

apply brake to

1

attachment.

OL2691

IMPORTANT:

If the belt squeals when the

attachment clutch lever is engaged, the

attachment drive may be frozen. Immediately

release the attachment clutch lever and move

the unit into a heated area to thaw.

Ignition Switch

Key Switch has two positions:

1. “Stop” - pulled out

2. Run - pushed in

2

NOTE:

DO NOT twist key after

it is inserted.

1

OS1431

Primer Bulb

Pushing the primer bulb in adds

fuel for easier engine start.

Refer to

Starting and Shut Off

OS1321

.

Speed Selector

The Speed Selector controls the unit travel in

a forward or reverse direction when positioned

in notch of speed.

Forward:

6

5

4

3

(6) Fastest

(1) Slow

Reverse:

(1) Slow

(2) Fast

2

1

IMPORTANT:

change motion from

DO NOT

forward to reverse with

clutch engaged.

Forward speed can be

1

2

OS1191

changed without

declutching.

Choke Control Knob

1. Choke Closed position:

chokes off air to engine for

2

easier start.

2. Choke Open position:

1

allows for normal

operation.

IMPORTANT:

open choke after engine

starts.

OS1332

Gradually

GB - 13

Page 14

Throttle

The throttle controls the engine

1

speed. To increase or decrease

the engine speed, adjust to:

2

1. Fast (normal or warm starts)

2. Part-Throttle

3. Slow (cold weather starts)

3

4. Stop (engine is off)

4

STOP

OL2720

Electric Starter (932104)

The electric starter will start a properly choked

and cranked engine when the starter button is

pushed. Refer to Starting and Shut-Off.

Recoil Starter Handle

When pulled, handle will turn engine over.

IMPORTANT: DO NOT let handle snap back

against starter.

Discharge Chute Deflector

ALWAYS position discharge chute deflector at

a safe angle before starting engine.

DO NOT throw snow any higher than

necessary.

Push deflector handle forward or down to

throw snow lower. Pull deflector handle up or

to the rear to throw snow higher.

IMPORTANT: If Chute Deflector does not stay

in set position, adjust as directed in Service

and Adjustments, or repair before operation.

Discharge Chute

Discharge chute rotates 220°.

ALWAYS position discharge chute in safe

direction and angle, away from operator and

bystanders, before starting engine.

Chute Crank

IMPORTANT: If chute does not stay in set

position, adjust as directed in Service and

Adjustments, or repair before operation.

Rotate the Chute with Discharge Chute Crank

Handle.

IMPORTANT: DO NOT force frozen chute

controls. Start engine and run for 3-5 minutes

to thaw. If still frozen, take to warm place until

controls are free.

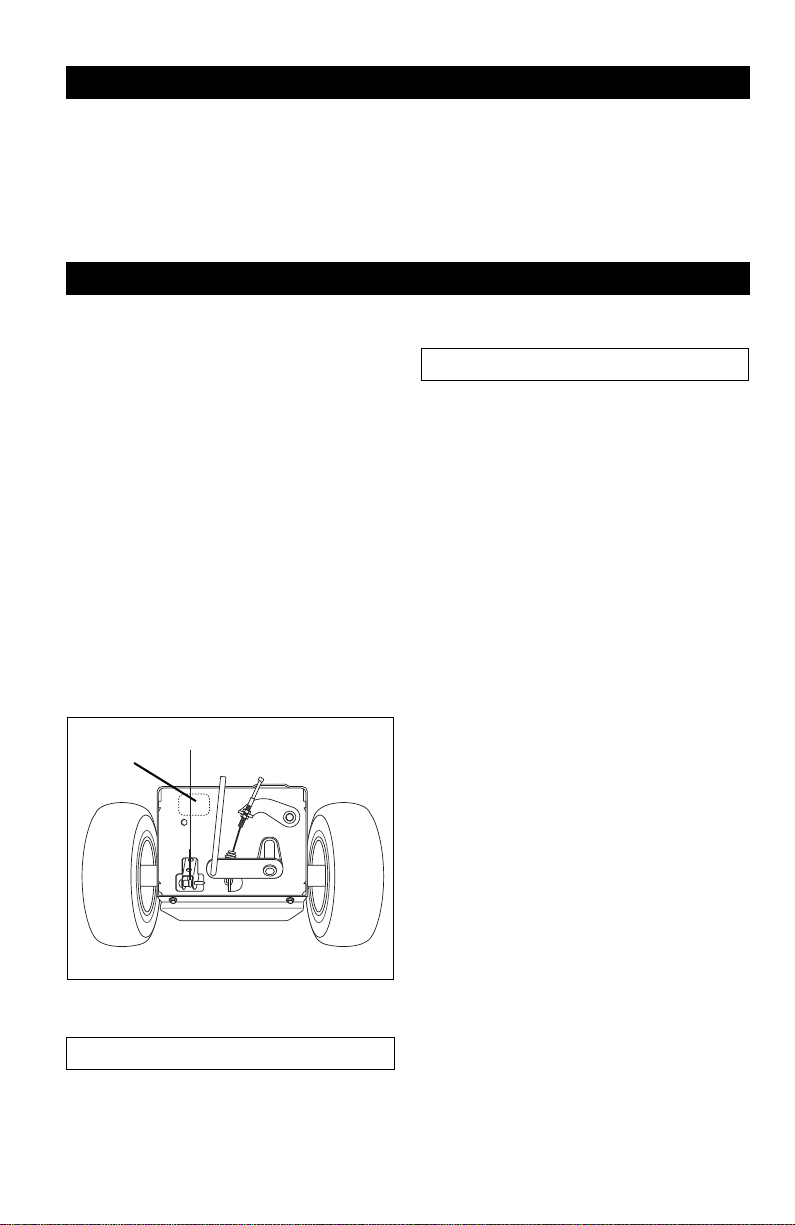

Axle Lock Pin (Figure 7)

Wheel Unlocked

Wheel Locked

Figure 7

Axle

Lock

Pin

Scraper Blade

The scraper blade allows the back of the

housing to keep better contact with the surface

being cleared. It also prevents damage to the

housing from normal wear.

IMPORTANT: DO NOT allow Scraper Blade to

wear too far or Auger/Impeller housing will

become damaged.

Runners

The runners control the distance between the

scraper blade and the ground. Adjust runners

equally to keep blade level with the ground.

Refer to Pre-Start for recommended settings.

Use the axle lock pin to lock or unlock the right

wheel. Lock the right wheel to increase

traction; unlock the right wheel to allow for

easier turning of the unit.

GB - 14

Page 15

FILLING FUEL TANK

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Fuel Shut-Off Valve

IMPORTANT: The fuel shut-off valve MUST be

in the closed position prior to transporting the

unit.

The fuel shut-off valve has two positions:

• Closed Position: Use this position to

service, transport, or store the unit.

• Open Position: Use this position to run the

unit.

To add fuel to fuel tank:

1. ALWAYS place unit in open or well

ventilated area.

2. Stop engine and allow to cool.

3. Clean Fuel Cap and surrounding area to

prevent dirt from entering Fuel Tank.

4. Remove Cap.

IMPORTANT: DO NOT use gasohol or

gasoline containing alcohol. See Engine

Manual for correct type and grade of fuel.

5. Fill fuel tank to within 1/2 in. (1.2 cm)

below bottom of filler neck with unleaded

gasoline.

NOTE: Tank capacity is 1 gallon (3.8 liters).

6. Replace Fuel Cap and tighten.

7. ALWAYS clean up any spilled fuel.

PRE-START

1. Frozen Impeller

IMPORTANT: Before starting engine, check

impeller to be sure it is not frozen.

To check impeller:

1. With key in “Stop” position, squeeze

Attachment Clutch Lever to Engaged

position.

2. Pull Recoil Starter Handle.

3. If Impeller is frozen, (cannot pull Starter

Handle) move unit to a heated area and

thaw to prevent possible damage.

2. Check Function of Clutches

If clutches do not engage or disengage

properly, adjust or repair before operation (see

Service and adjustments).

3. Check Dual Handle Interlock

Without the engine running, press down

(engage) both clutch levers. Release

attachment clutch lever. Attachment clutch

should remain engaged until traction clutch

lever is released, then both clutches must

disengage.

If clutches do not engage or disengage

properly, adjust or repair before operation (see

Service and Adjustments).

4. Adjust Axle Lock

Use the axle lock pin to lock or unlock the right

wheel. Lock the right wheel to increase

traction; unlock the right wheel to allow for

easier turning of the unit.

5. Adjust Runners

Check and adjust Runners (see Service and

Adjustments). Allow 1/8 in. (3 mm) between

scraper blade and hard, smooth surface(s).

Allow 1-1/4 in. (30 mm) between scraper blade

and uneven or gravel surfaces.

6. Check Engine Fuel & Crankcase Oil

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

Check and add fuel if required. Check that the

engine crankcase oil is full using dipstick.

Refer to Engine Manual for detailed

instructions.

TO STOP IN AN EMERGENCY

Immediately release both control levers to stop

unit in an emergency. Stop engine, remove

key and wait for all rotating parts to stop before

leaving operator’s position.

STARTING AND SHUT OFF

WARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in

personal injury and/or damage to

unit. DO NOT attempt to start your

unit at this time. Read entire

Owner/Operator Manual and the

Engine Manual first.

IMPORTANT: Allow unit and engine to adjust

to the outdoor temperatures before clearing

snow. Before shut-off, run the attachment a

few minutes to prevent freeze-up.

NOTE: Try out each control without the engine

running to see how it works and what it does.

Manual Start

1. Turn discharge chute straight ahead.

GB - 15

Page 16

2. Make sure that the traction clutch and

attachment drive clutch levers are fully

disengaged.

3. Push Primer Bulb 2 or 3 times for cold

engine.

NOTE: When temperature is below -15˚ F

(-26˚ C) additional priming may be needed.

4. If engine is cold, apply choke. See Engine

Manual for detailed instructions.

NOTE: A warm engine requires less choking

than a cold engine.

5. Set throttle to proper starting position.

6. Insert key into ignition switch and push

into RUN position. DO NOT twist key after

it is inserted.

7. Grasp starter handle and pull rope out

slowly until it pulls harder. Let rope rewind

slowly.

8. Pull rope with a rapid continuous full arm

stroke. Let rope rewind slowly.

IMPORTANT: DO NOT let Starter Handle

snap against Starter.

9. Repeat steps 7 and 8 until engine starts.

(If engine does not start, refer to

Troubleshooting.)

10. Adjust choke as needed.

11. Set throttle to Part Throttle or Slow

position for adaptation to outside

temperature or travel. Set throttle to Fast

position for normal operation.

Electric Start

1. Connect extension cord to prongs on

starter.

IMPORTANT: Prevent damage to unit. Know

voltage of your starter and only use matching

outlets.

2. Plug extension into 120V 3-wire,

grounded outlet.

3. Turn discharge chute straight ahead.

4. Make sure that the traction clutch and

attachment drive clutch levers are fully

disengaged.

5. Push Primer Bulb 2 or 3 times for cold

engine.

NOTE: When temperature is below -15˚ F

(-26˚ C) additional priming may be needed.

6. Insert key into ignition switch on engine

and push into "Run" position. DO NOT

twist key after it is inserted.

7. If engine is cold, apply choke. A warm

engine requires less choking than a cold

engine. See Engine Manual for detailed

instructions.

8. Set throttle to proper starting position.

9. Press starter button on engine until

engine starts.

IMPORTANT: DO NOT operate starter more

than 15 seconds per minute, as overheating

and damage can occur. (If engine does not

start, refer to Troubleshooting.)

10. Adjust choke as needed.

11. Disconnect power cord from outlet, then

starter.

12. Set throttle to Part Throttle or Slow

position for travel or adaptation to outside

temperature. Once achieved, set throttle

to Fast position for normal operation.

Shut Off

1. Release Traction Drive Clutch Lever and

allow unit to come to a complete stop.

2. Run Impeller a few minutes after use to

prevent freeze-up of Impeller.

3. Release Attachment Clutch Lever and

wait for all moving parts to come to a

complete stop.

4. Move Throttle to the “Stop” position.

5. Remove key.

SNOW REMOVAL

IMPORTANT: Allow unit and engine to adjust

to the outdoor temperatures before clearing

snow.

NOTE: Attachment clutch should be engaged

before wheel drive clutch when throwing snow.

1. Select Speed Control position and

direction.

2. Engage Attachment Clutch - Right Hand

Lever.

3. Engage Traction Drive Clutch - Left Hand

Lever.

IMPORTANT: DO NOT overload unit capacity

by attempting to clear snow at too fast a rate.

Use slow speed to clear deep or hard packed

snow.

Tips for Operation

Snow is best removed as soon as possible

after snow fall.

To clear an area, run unit in an overlapping

series of paths. For large areas; start in the

middle and throw snow to each side, so snow

is not cleared more than once.

ALWAYS direct snow away from area to be

cleared and with direction of the wind.

TRAVELING

To travel from one work area to another:

1. Set Throttle to Slow or Part-Throttle

position.

GB - 16

Page 17

2. Press down on handlebars enough to

raise front of unit slightly off surface.

3. Engage wheel drive clutch without

engaging attachment drive clutch.

TRANSPORT

ALWAYS shut off engine, remove key, and

close fuel shut-off valve when transporting unit

on a truck or trailer.

MAINTENANCE

Ariens Dealers will provide any service or

adjustments which may be required to keep

your unit operating at peak efficiency. Should

engine service be required, contact an Ariens

dealer or an authorized engine manufacturer's

service center.

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

SERVICE POSITION

WARNING: Before tipping unit up

onto housing, remove fuel so no

spills will occur. Ensure unit is

secure and will not tip over during

maintenance.

Place unit on a flat level surface. Tip unit

forward onto front of impeller housing for

service. Assure unit is secure and will not tip

over. Strap and clamp onto bench if needed.

MAINTENANCE SCHEDULE

The chart below shows the recommended

maintenance schedule that should be

performed on a regular basis. More frequent

service may be required.

Use extra care when loading or unloading unit

onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

MAINTENANCE SCHEDULE

Service

Performed

Check Dual

Handle

Interlock

Check

Fasteners

Check

Clutches

Clean Engine •

Check Engine

Oil

Change

Engine Oil

Check Tire

Pressure

Check Auger

Gearcase

General

Lubrication

Each

Use

•

•

•

Every

5 hrs.

•

*

Every

Yearly

25

hrs.

•

•

••

••

* After first two hours of operation.

CHECK DUAL HANDLE

INTERLOCK

Without the engine running, press down

(engage) both clutch levers. Release

attachment clutch lever. Attachment clutch

should remain engaged until traction clutch

lever is released, then both clutches must

disengage.

CHECK FASTENERS

Make sure all hardware is tightened properly.

GB - 17

Page 18

CHECK CLUTCHES

Auger / impeller must stop within 3 seconds

when attachment clutch/impeller brake lever is

released.

Wheels must stop quickly when traction drive

clutch lever is released.

If clutches do not engage or disengage

properly, adjust or repair before operation (see

Service and Adjustments).

CLEAN ENGINE

Refer to Engine Manual for detailed

instructions.

CHECK ENGINE OIL

The engine crankcase oil should be checked

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on dipstick

at all times or engine damage will result (See

Engine Manual).

Park unit on a level surface. Refer to Engine

Manual for detailed instructions.

CHECK AUGER GEARCASE

IMPORTANT: Proper oil level must be

maintained.

Gear cases are filled to the correct level at the

factory. Unless there is evidence of leakage,

no additional lubricant should be required.

Check oil level each season or every 25 hours

of operation.

To ensure adequate lubricant level:

1. Remove filler plug (Figure 8). Lubricant

must be at least up to bottom of lubricant

filler hole with unit resting on a

level-surface.

2. Add lubricant if required. Allow oil to drain

to level of plug and replace plug.

IMPORTANT: Use only Ariens special gear

lubricant L-2 (Part Number 00008000).

1

CHANGE ENGINE OIL

Change oil after first 2 hours of operation,

thereafter change oil every 25 hours (more

often if required). Refer to Engine Manual for

detailed instructions.

Run engine just prior to changing oil. Warm oil

will flow more freely and carry away more

contamination.

CHECK TIRE PRESSURE

Keep tires at pressure listed on the tire

sidewall.

1. Auger Gearcase

2. Filler Plug

Figure 8

2

OS1870

GB - 18

Page 19

GENERAL LUBRICATION

IMPORTANT: Wipe each fitting clean before

and after lubrication.

IMPORTANT: DO NOT allow grease or oil to

get on friction disc, friction plate or belts.

NOTE: Apply Stens Mix Hi-Temp Grease or

equivalent to the lubrication fittings. See

Service Parts.

Sno-Thro should be lubricated (Figure 9) at

beginning of season or every 25 operating

hours.

Auger Shaft

NOTE: To grease auger shaft, remove shear

bolt nuts, and shear bolts. Turn auger on shaft

while applying grease at zerk fittings. Replace

shear bolt per instructions in Service and

Adjustments.

Grease

Oil

Figure 9

SERVICE AND ADJUSTMENTS

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

DISCHARGE CHUTE DEFLECTOR

Deflector must stay in selected position while

throwing snow.

To adjust, loosen then retighten hardware to

desired deflector drag force (Figure 10).

OS1731

OS1373

DISCHARGE CHUTE

Adjusting Hardware

Discharge Chute

Deflector

Figure 10

If chute does not stay in position while

operating, tighten nut on carriage bolt at pivot

point to increase tension on spring (Figure 11).

OS0113

GB - 19

Page 20

Smooth and easy rotation of properly

lubricated chute with crank is obtained by

adjusting pinion and chute gear teeth so they

mesh together.

1

2

3

4

1. Pinion

2. Chute Gear

3. Carriage Bolt

4. Spring

Figure 11

DS0113

RUNNERS

Runners should be adjusted (Figure 12) as

conditions require.

1. Position unit on a hard, flat, smooth level

surface.

2. Adjust runners by inserting a spacer of

desired thickness under center of scraper

blade, loosen runner hardware, slide

runners to flat surface. Allow 1/8 in.

(3 mm) between scraper blade and hard

smooth surfaces. Allow 1-1/4 in. (30 mm)

between scraper blade and uneven or

gravel surfaces. Retighten hardware.

NOTE: Keep housing level by adjusting

runners equally.

SCRAPER BLADE

IMPORTANT: Damage to auger/impeller

housing will result if blade wears down too far.

Scraper blade is adjustable to compensate for

wear.

To adjust scraper blade:

1. Tip unit back onto handlebar, support

housing and loosen nuts retaining blade.

2. Adjust runners to fully raised position

(housing closest to ground).

3. Reposition scraper blade flush with

runners and tighten lock nuts.

SHEAR BOLTS

IMPORTANT: Use only Ariens shear bolts for

replacement. Use of any other type of shear

bolt may result in severe damage to unit.

Occasionally a foreign object may enter the

auger/impeller housing and jam the auger,

breaking shear bolts (Figure 13) which secure

the auger to the shaft. This allows auger to

turn freely on the shaft preventing damage to

gear drive.

For Replacement:

1. Slide auger outward against roll pin and

align hole in shaft with hole in auger

(holes in shaft for roll pins and shear bolts

line up).

2. Drive shear bolt through hole (if shear bolt

was broken this will drive remaining part

from shaft).

3. Secure shear bolt with nut.

3

2

1

1. Runner

2. Runner Hardware

Figure 12

GB - 20

1

2

OS0402

1. Auger

2. Shear Bolts

3. Roll Pin

Figure 13

Page 21

SPEED SELECTOR ADJUSTMENT

3

4

2

1

1. Shift Rod

2. Adjustment Pivot Pin

3. Speed Selector Lever

4. Hairpin

Figure 14

To adjust (Figure 14):

1. Remove hair pin from adjustment pivot

pin.

2. Pull shift rod and adjustment pivot pin out

of speed selector lever.

3. Place the speed selector in the fastest

forward speed position.

4. Pull the shift rod straight down towards

the ground as far as it will go.

5. Thread the adjustment pivot pin along the

shift rod until it aligns with the mating hole

on the speed selector lever.

6. Reinsert the pivot pin into the hole on the

speed selector lever.

7. Check forward and reverse speeds.

a. Start unit.

b. Shift speed selector into first forward

speed.

c. Engage traction clutch. Unit should

move forward.

d. Stop unit.

e. Shift speed selector into first reverse

speed.

f. Engage traction clutch. Unit should

move backward.

g. Shut off unit.

OSs0194

8. Adjust pivot pin as needed so unit travels

forward when speed selector lever is in

first forward position and backward when

speed selector lever is in first reverse

position.

9. Secure adjustment pivot pin to speed

selector lever with hairpin.

ATTACHMENT DRIVE BELT

REPLACEMENT

Remove Attachment Drive Belt

(Figures 15 and 16)

1. Shut off engine, remove key, disconnect

spark plug wire and allow unit to cool

completely.

2. Remove two screws securing belt cover

to unit and remove belt cover.

3. Remove spring pin from chute crank rod

assembly at universal joint and separate.

4. Remove hardware holding chute strap to

engine mounting bracket and lift

discharge chute off housing.

5. Remove belt finger by removing cap

screws mounting belt finger to engine.

6. Remove attachment drive belt from

engine sheave (it may be necessary to

turn engine sheave using recoil starter

handle).

CAUTION: Always support

Sno-Thro frame and housing when

loosening the cap screws holding

them together. Never loosen cap

screws while unit is in service

position.

IMPORTANT: To avoid bending bottom cover,

when tipping unit apart, support handlebars

firmly or tip unit up on housing and remove

bottom cover by removing four cap screws

before separating unit.

7. Support Sno-Thro frame and housing.

8. Remove top two cap screws and loosen

lower cap screws holding blower housing

to frame (one on each side).

9. Separate housing from unit. Lower

handlebar on floor.

10. Remove attachment drive belt from lower

pulley (hold brake away from belt).

GB - 21

Page 22

1

2

3

8

9

5

4

6

7

1. Pinion and Gear

2. Spring Clip Pin

3. Chute Crank

4. Chute Strap

5. Chute Strap Mounting Hardware

6. Housing Bolt Holes

7. Bottom Cover

8. Belt Cover

9. Universal Joint

Replace Attachment Drive Belt

1. Place new belt onto lower pulley and

while holding brake out of way, tip unit

together.

2. Secure blower housing to frame with cap

screws.

3. Place belt onto engine sheave.

4. Make sure engine sheave and attachment

pulley align. If alignment is necessary,

loosen engine sheave set screws,

reposition sheave and retighten set

screws.

5. Replace belt finger.

IMPORTANT: BELT FINGER MUST BE

between 1/16 to 1/8 in. (1.6–3 mm) from belt

with attachment clutch engaged or belt

grabbing may occur causing impeller to rotate

while attachment clutch is disengaged

(Figure 16).

6. Adjust clutch per Attachment

Clutch/Impeller Brake Adjustment below.

7. Reinstall chute strap and mounting

hardware onto engine.

8. Replace chute crank and secure with

spring pin.

9. Replace belt cover and secure with

screws.

Figure 15

3

OS0802

4

5

6

7

1. Attachment Belt Idler

2. Belt Finger

3. Attachment Drive Belt

4. Traction Drive Belt

5. Camshaft Pulley

6. Engine Sheave

7. Traction Belt Idler

8. Attachment Pulley

2

9. Attachment Idler Nut

1

9

8

Figure 16

OS0464

GB - 22

Page 23

TRACTION DRIVE BELT

REPLACEMENT

NOTE: Housing and frame must be tipped

apart and attachment drive belt removed from

engine sheave in order to change traction

drive belt (Figures 15 & 16).

CAUTION: Always support

Sno-Thro frame and blower housing

when loosening the cap screws

holding them together. Never loosen

cap screws while unit is in service

position.

1. Remove attachment drive belt (See

Remove Attachment Drive Belt).

2. Pull idler away from traction drive belt and

remove belt from idler, camshaft pulley

and driven pulley (it may be necessary to

turn camshaft pulley using recoil starter

handle).

NOTE: To gain clearance, engage traction

clutch and if necessary pull back attachment

idler arm clevis pin.

3. Replace traction drive belt making sure

pulleys align. If alignment is necessary,

loosen camshaft pulley set screws,

reposition pulley and retighten set screws.

4. Replace attachment drive belt (See

Replace Attachment Drive Belt).

ATTACHMENT CLUTCH/BRAKE

ADJUSTMENT

WARNING: IMPROPER

ADJUSTMENT could result in

unexpected movement of auger and

impeller causing death or serious

injury. Auger / impeller must stop

within 3 seconds when Attachment

Clutch/Impeller Brake lever is

released.

WARNING: Adjustment procedure

requires the engine to be run with

the belt cover off. Read, understand

and follow all Operational, Fuel and

Maintenance and Service Safety

Rules before adjusting your unit.

1. Remove belt cover.

2. Check belt alignment (Figure 16).

Engine sheave and attachment pulley

must align vertically. Also, belt must be

centered in the idler pulley.

To align, move engine sheave:

a.Loosen set screws.

b.Slide sheave and key to desired

position.

c.Tighten set screws.

3. Adjust cable slack.

IMPORTANT: The clutch cable must be slack

when lever is disengaged.

a.With the clutch lever disengaged,

loosen control cable mounting nuts

(Figure 19).

b.Pull up on cable body to remove cable

slack.

c.Finger tighten mounting nuts, and then

loosen the top nut two turns.

d.Tighten the bottom nut with a wrench.

4. Check attachment clutch lever

measurement.

a.Start engine and run at full throttle.

b.Slowly squeeze the attachment clutch

lever until auger shaft begins to rotate.

c.Measure the distance from the end of

the clutch lever to the hand grip as

shown in Figure 18. The distance

between the clutch lever and the hand

grip should be 4–1/2 ± 1/8 in.

(11.43 ± 3 mm).

d.Shut off engine.

5. Adjust attachment clutch lever

measurement, if necessary.

NOTE: 1/16 in. (1.6 mm) idler movement will

change clutch lever measurement about

1/4 in. (6 mm).

a.Loosen idler nut (Figure 16).

b.To increase distance between clutch

lever and hand grip, move the idler

towards the attachment belt.

c.To decrease the distance between the

clutch lever and hand grip, move the

idler away from the attachment belt.

d.Tighten idler adjustment nut.

e.Check clutch lever measurement.

6. Check Brake

When the clutch lever is disengaged, the

brake must contact the attachment belt.

When the clutch lever is engaged, the

brake must be more than 1/16 in.

(1.6 mm) away from the belt (Figure 17).

7. Repeat steps 4–6 until attachment clutch

distance and brake contact are correct.

IMPORTANT: If attachment clutch/brake

cannot be adjusted within tolerances, see your

Dealer for repairs.

GB - 23

Page 24

8. Check belt finger clearance.

With clutch lever engaged, belt fingers

should be 1/16–1/8 in. (1.6-3 mm) from

belt. Adjust belt fingers as necessary.

9. Replace belt cover.

10. Check that auger/impeller stops within

3 seconds after attachment

clutch/impeller brake bail is released.

1

2

1/16 in.

(1.6 mm)

OS2030

1. Drive Belt

2. Brake Shoe and Pad

Figure 17

Traction Drive

Clutch Lever

6-1/8 ± 1/4 in

(15,5 cm ± 6 mm)

TRACTION DRIVE CLUTCH

ADJUSTMENT

If drive slips, adjust traction clutch to

compensate for friction disc wear.

To test traction clutch (Figure 18):

1. Put unit in first forward speed.

2. Without engine running, push unit forward

while slowly moving the traction drive

clutch lever toward the handle grip.

3. Measure distance between lever and

handlebar when the wheels brake. If

distance is not 6–1/8 in. ± 1/4 in.

(15.5 cm ± 6 mm), adjust the traction

clutch.

To adjust traction clutch (Figure 19):

1. Loosen jam nut on traction cable

adjustment barrel.

2. Turn the adjustment barrel up the cable to

decrease the distance between clutch

lever and handlebar.

Turn the adjustment barrel down the cable

to increase the distance between clutch

lever and handlebar.

3. Check traction clutch lever distance and

repeat adjustment steps if necessary.

4. Tighten jam nut on traction cable

adjustment barrel.

3

1

2

9

4

5

Attachment

Clutch Lever

4-1/2 ± 1/8 in

(11,43 cm ± 3 mm)

Figure 18

OS0456

GB - 24

8

6

7

1. Traction Clutch Cable

2. Shift Rod

3. Attachment Control Cable

4. Mounting Nuts

5. Attachment Clutch Arm

6. Speed Selector Arm

7. Cotter Pin and Clevis

8. Traction Drive Clutch Arm

9. Adjustment Barrel

Figure 19

OS0522

Page 25

FRICTION DISC REPLACEMENT

Remove (Figure 20 and 21)

1. Shut off engine, remove key, disconnect

spark plug wire, and allow unit to cool

completely.

CAUTION: Remove fuel from fuel

tank prior to placing unit in service

position.

2. Place unit on a level surface and tip unit

up onto front housing.

3. Remove wheels.

4. Remove bottom cover.

5. Disconnect shift rod from speed selector

arm.

1

2

1

2

3

5

4

2

6

2

5

9

8

7

1. Shift Rod 2. Speed

Selector Arm

Figure 20

OS5500

6. Carefully tap roll pins out of hex shaft.

7. Remove outside bearing flange and

bearing from each side of unit.

8. Remove friction disc from shift carrier.

9. Remove roller chain from sprocket on hex

shaft.

10. Remove spacer from hex shaft.

11. Hold shift carrier and slide hex shaft

slowly to the right.

12. Slide shaft only far enough to remove the

old friction disc from hex shaft.

Install (Figure 20 and 21)

1. Place flat side of new friction disc against

shift carrier.

2. Hold shift carrier, slide hex shaft back

toward the left through roller chain and

spacer, and through the opening in the

side of the unit.

7

9

8

1. Roller Chain

2. Roll pin

3. Hex Shaft

4. Friction Disc

5. Speed Fork

6. Shift Carrier

10

3

Figure 21

6

4

7. Outside Bearing

Flange

8. Ball Bearing

9. Inside Bearing

Flange

10.Spacer

OS5000

3. Install roller chain on sprocket teeth of

hex shaft.

4. Install bearings and outside bearing

flanges.

5. Bolt new friction disc to shift carrier.

Tighten hardware to 5-6 lbf-ft (6.8 to

8.13 N•m).

6. Install roll pins in hex shaft. Ensure roll

pins are centered in hex shaft.

7. Install shift rod on speed selector arm.

8. Install bottom cover.

9. Install wheels.

10. Set unit upright.

11. Install spark plug wire on spark plug.

12. Adjust speed selector lever (see Speed

Selector Adjustment on page 21).

GB - 25

Page 26

STORAGE

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

SHORT TERM

IMPORTANT: NEVER spray unit with high

pressure water or store unit outdoors.

Run with attachment clutch engaged a few

minutes after each use to free unit of any

loose or melting snow.

Close fuel shut-off valve.

Inspect unit for visible signs of wear, breakage

or damage.

Keep all nuts, bolts and screws properly

tightened and know unit is in safe working

condition.

Store unit in a cool, dry protected area.

LONG TERM

Clean unit thoroughly with mild soap and low

pressure water and lubricate (see

Maintenance). Touch up all scratched painted

surfaces.

Remove weight from wheels by putting blocks

under frame or axle.

When storing unit for extended periods of time,

remove all fuel from tank and carburetor (run

dry). Refer to Engine Manual.

ACCESSORIES

See your authorized Ariens dealer to add the

additional accessories available to your

Sno-Thro.

Part No. Description

73203100 Slicer Bar

72403600 120 Volt Starter Kit

72402200 240 Volt Starter Kit*

72406500 Front Weight Kit

72406600 Deflector Remote Control Kit

* Available in CE countries.

SERVICE PARTS

Order the following parts through your

Dealer:

Part No. Description

00036800 Stens Mix Hi-Temp Grease

21533400 Spark Plug

07234000 Impeller Belt

07228600 Traction Belt

51001500 Shear Bolt Kit

03248300 Friction Disc

To obtain a complete parts manual, find your

model and serial number. Then go to

www.ariens.com or call 1-800-678-5443.

(3, 3 oz. cartridges)

GB - 26

Page 27

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTION

Engine will

not

crank/start.

Engine stops.

Engine

problems.

Does not

operate in

Forward /

Reverse.

1. Fuel tank is empty.

2. Fuel shut-off valve closed.

3. Build up of dirt and residue

around

governor/carburetor.

4. Key Switch not in run

position.

5. Ignition switch starter

circuit not functioning.

1. Out of fuel.

2. Fuel shut-off valve closed.

3. Mechanical jam in blower

rake or impeller.

4. Polluted fuel supply.

5. Faulty spark plug.

1. See Engine Manual.

1. Friction disc not adjusted

properly.

2. Traction belt not

functioning.

3. Speed selector not

adjusted properly.

1. Fill fuel tank.

2. Open fuel shut-off valve.

3. Clean area around

governor/carburetor.

4. Put Key Switch into run position.

5. Check for a bad starter or

connections.

1. Fill fuel tank.

2. Open fuel shut-off valve.

3. Turn off engine, remove key, and

wait for all moving parts to stop.

Check for and remove

obstruction and repair before

restart.

4. Replace with clean fuel.

5. Replace or clean spark plug.

1. Repair or replace friction disc.

See Service and Adjustments.

2. Repair or replace traction drive

belt. See Service and

Adjustments.

3. Adjust speed selector. See

Service and Adjustments.

Small rubber

beads collect

in frame

Unit throws

snow poorly

or does not

throw snow.

1. Friction disc wear. 1. Normal friction disc wear.

1. Shear bolts broken.

2. Attachment clutch/brake

not adjusted properly.

3. Attachment drive belt worn

or damaged.

GB - 27

Chunks or large pieces of rubber

mean friction disc should be

checked and replaced as

necessary.

1. Replace shear bolts (see Shear

Bolts on page 20).

2. Adjust attachment clutch/brake

(see Attachment Clutch/Brake

Adjustment on page 23).

3. Replace attachment drive belt

(see Attachment Clutch/Brake

Adjustment on page 23).

Page 28

SPECIFICATIONS

Model Number 932502 932104

Description 8524 8524

Engine - Tecumseh HMSK85-155913C HMSK85-155912C

-1

Power Max - HP (Kw/min

Fast Idle Speed-RPM (min

)

-1

)

Displacement - in. (cc) 19.43 (318.3)

Electric Start Optional

240V

Fuel See Engine Manual

Tank Capacity - qt. (L) 4 (3.8)

Snow Clearing Width -

in. (cm)

Chute

Rotation Angle 220˚

Rotation Control at

Handlebar

Dual Handle Interlock Ye s

Impeller

Diameter - in. (cm) 12 (30.5)

-1

Speed-RPM-Max (min

)

Auger

Diameter - in. (cm) 15 (38.1)

-1

Speed-RPM-Max (min

)

Auger Brake Ye s

Drive Disc-O-Matic

Speeds 6 Forward and 2 Reverse

Pneumatic Tires - in. (cm) 15 (38.1)

Size and Weight

Height - in. (cm) 42 (106.7)

Length - in. (cm) 59.1 (150.2)

Width - in. (cm) 26.6 (67.6)

Weight - lbs (Kg) 235(106.6) 240 (108.9)

Headlight Ye s

8.5 (6.3)

3600 ± 150

120V

24 (61.0)

Ye s

1410

141

GB - 28

Page 29

3-Year Limited Sno-Thro Warranty

Ariens Company warrants to the original purchaser that consumer products manufactured

by Ariens Company will be free from defects in material and workmanship for a period

of three (3) years after the date of purchase, and will repair any defect in material or

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

920-756-2141

Fax 920-756-2407

www.ariens.com

This warranty is subject to the following conditions, limitations, and exclusions:

This warranty is valid only if the following conditions are

met:

• The purchaser must perform maintenance and minor

adjustments explained in the owner’s manual.

• The purchaser must promptly notify Ariens Company or an

authorized Ariens service representative of the need for

warranty service.

• Returning the product registration card to Ariens Company

will enable the company to contact the registrant with repair

or replacement part information.

The following items are not covered by this warranty:

• Engines and engine accessories are covered only by the

warranty made by the engine manufacturer, and are not

covered by this warranty.

• Parts that are not genuine Ariens service parts are not

covered by this warranty.

• Shoes, runners, scraper blades, shear bolts, headlights, light

bulbs are not covered by this warranty.

• Any defect which is the result of misuse, alteration, improper

assembly, improper adjustment, neglect, or accident is not

covered by this warranty.

• Products which were not purchased in the United States,

Puerto Rico, or Canada are not covered by this warranty. In

all other countries, contact place of purchase.

workmanship, and repair or replace any defective part, subject to the conditions, limitations

and exclusions set forth herein.

The three-year duration of this warranty applies only if the product is put to ordinary,

reasonable, and usual personal, family, or household uses. If the product is put to any

business, commercial, or industrial use, then the duration of this warranty is ninety (90)

days after the date of purchase, or one (1) year after the date of purchase if the product

is labeled as a Professional/Commercial Product. If any product is rented or leased,

then the duration of this warranty is ninety (90) days after the date of purchase.

Genuine Ariens service parts and accessories not purchased with the product covered

by this warranty, but which are later purchased and used with that product, are warranted

to be free from defects in material and workmanship for a period of ninety (90) days

after date of purchase, and Ariens Company will repair or replace any such part or

accessory free of charge, except for labor, during that period.

This warranty is subject to the following limitations:

• The purchaser must transport the product to and from the

place of warranty service.

• Warranty service must be performed by an authorized Ariens

service representative. (To find an authorized Ariens service

representative, contact Ariens Company at the website,

number or address above.)

• Batteries are warranted only for a period of twelve (12)

months after date of purchase, on a prorated basis. For the

first ninety (90) days of the warranty period, a defective

battery will be replaced free of charge. If the applicable

warranty period is more than 90 days, Ariens Company will

cover the prorated cost of any defective battery, for up to

twelve (12) months after the date of purchase.

• Normal maintenance items including, but not limited to, belts,

idlers, cables, friction wheels, tires, wheels, electrical

components are warranted for a two-year period from the

date of purchase unless a shorter period would apply based

on how the product is used, then the shorter period will

apply.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express

or implied, other than what is expressly made

in this warranty. If the law of your state provides

that an implied warranty of merchantability, or

an implied warranty of fitness for particular

purpose, or any other implied warranty, applies

to Ariens Company, then any such implied