Page 1

Owner’s Manual

932000 Series Compact Sno-Thros

Model 932001 (ST270) 2.7 HP

Serial no. 042101 and up

Model 932004 (ST350) 3.5 HP

Serial no. 030101 and up

Model 932006 (ST504) 5 HP

Serial no. 049501 and up

Model 932007 (TTS) 5 HP

Serial no. 001101 and up

Including;

Model 832003 ^ 24” Sno-Thro

Serial no. 049101 and up

cT^ricns

Ariens Company

655 West Ryan Street

Brillion, Wisconsin 54110

Part No. 32078C

Printed in U.S.A. 11-82

Page 2

INSTRUCTIONS FOR SAFE OPERATION

TRAINING

1. Read the Owner's Manual carefully. Be thoroughly familiar

with the controls and the proper use of the equipment.

Know how to stop the Sno-Thro and disengage the controls

quickly.

2. Never allow children to operate the Sno-Thro. Never allow

adults to operate the Sno-Thro without proper instruction.

3. Keep the area of operation clear of all persons, particularly

small children, and pets.

4. Exercise caution to avoid slipping or falling, especially

when starting or operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the Sno-Thro is to be

used and remove all doormats, sleds, boards, wires, and

other foreign objects.

2. Disengage all clutches before starting the engine (motor).

3. Do not operate the Sno-Thro without wearing adequate

winter outer garments and eye protection such as safety

glasses. Wear footwear which will improve footing on slip

pery surfaces.

4. Handle fuel with care; it is highly flammable.

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot engine.

c. Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

d. Replace gasoline cap securely and wipe up spilled fuel.

4. If the Sno-Thro should start to vibrate abnormally, stop th'^'"

engine and check immediately for the cause. Vibration i.

generally a warning of trouble.

5. Stop the engine whenever you leave the operating posi

tion, before unclogging the blower/impeller housing or

discharge guide, and when making any repairs, ad

justments, or inspections.

6. When cleaning, repairing, or inspecting, make certain the

blower/impeller and all moving parts have stopped.

Disconnect the spark plug wire.

7. Do not run the engine indoors, except when starting the

engine and for transporting the Sno-Thro in or out of the

building". Open the outside doors; exhaust fumes are

dangerous.

8. Do not clear snow across the face of slopes. Exercise ex

treme caution when changing direction on slopes. Do not

attempt to clear steep slopes.

9. Never operate the Sno-Thro without proper guards, plates,

or other safety protective devices in place.

10. Never operate the Sno-Thro near glass enclosures,

automobiles, window wells, drop-offs, etc., without pro

per adjustment of the snow discharge angle. Keep children

and pets away.

11. Do not overload the Sno-Thro capacity by attempting tt

clear snow at too fast a rate.

12. Never operate the Sno-Thro at high transport speeds on

slippery surfaces. Use care when backing.

5. Use the power cord furnished with the electric starter, if so

equipped.

6. Adjust the blower housing height to clear gravel or crush

ed rock surface with engine off.

7. Never attempt to make any adjustments while the engine is

running (except where specifically recommended by

manufacturer).

8. Let Pngine and machine adjust to outdoor temperatures

before starting to clear snow.

OPERATION

1. Do not put hands or feet near or under rotating parts. Keep

clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or crossing

gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic.

3. After striking a foreign object, stop the engine, remove the

wire from the spark plug, thoroughly inspect the Sno-Thro

for any damage, and repair the damage before restarting

and operating the Sno-Thro.

13. Never direct discharge at bystanders or allow anyone in

front of the unit.

14. Disengage power to the blower/impeller when Sno-Thro is

transported or not in use.

15. Use only attachments and accessories approved by

Ariens.

16. Never operate the Sno-Thro without good visibility or light.

Always be sure of your footing, and keep a firm hold on the

handles. Walk: never run.

MAINTENANCE AND STORAGE

1. Check Shear bolts, engine mounting bolts, etc., at fre*

quent intervals for proper tightness to be sure the equip

ment is in safe working condition.

2. Never store the Sno-Thro with fuel in fuel tank inside a

building where iginition sources are present such as hot

water and space heaters, clothes dryers, etc. Allow the

engine to cool before storing in any enclosure.

3. Always refer to Owner’s Manual for important details if the

Sno-Thro is to be stored for an extended period.

4. Run the Sno-Thro a few minutes after throwing snow to

prevent freeze-up'Of the blower/impeller.

- 2 -

Page 3

CONTENTS

Instructions for Safe Operation........................................................................................................................... 2

Safety Decals..

.................................................................................................................................................... -3

Operation......................................................................................................................................................... 4-S

Adjustments/Maintenance................................................................................................................................ 6°9

Storage.............................................................................................................................................................. §

Lubrication........................................................................................................................................................ 10

Sno-Thro Service Guide................................................................................................................................. 11

Basic Consumm^User Service Components..................................................................................................... 12

Assembly & Pre>Service............................................................................................................................... 13-16

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT SAFETY INFORMA

TION IN THIS MANUAL. WHEN YOU SEE THE SYMBOL BE ALERT TO THE

POSSIBILITY OF INJURY AND CAREFULLY READ THE INFORMATION THAT

A

FOLLOWS.

AWARNING

ROTATING PARTS

Stop engine and remove

spark plug ignition wire before

removing obstructions.

BE AWARE OF SAFETY DECALS

CAUTION; 00 NOT PUT YOUR HAND INTO THE DEFLECTOR OR

CHUTE. USE THE HANDLE PROVIDED TO ADJUST THE CHUTE

DEFLECTOR TO DESIRED HEIGHT.

CAUTION; A HIGH SPEED IMPELLER (FAN) ROTATES INSIDE

HOUSING TO THROW THE SNOW. NEVER REACH OR PUSH ANY

OBJECT INTO THE DISCHARGE CHUTE OR DELFECTOR TO

REMOVE ANY MATERIAL WITH THE SNO-THRO RUNNING.

IMPORTANT: CHECK FOR FROZEN IMPELLER (FAN) BEFORE

STARTING ENGINE. IF FAN IS FROZEN, FREE IT BY THAWING

THE SNO-THRO IN A HEATED BUILDING. THE BEST METHOD IS

TO PREVENT FREEZING BY ALLOWING THE BLOWER TO RUN

FOR A SHORT TIME AFTER SNOW THROWING TO ALLOW

SLUSH AND WATER TO BLOW OUT.

CAUTION: KEEP HANDS. FEET AND OBJECTS EXCEPT SNOW

OUT OF THE AUGER.

CAUTION: WET SNOW TENDS TO INCREASE THE CHANCE OF

MUFFLER & ADJACENT AREAS MAY EXCEED 15(T F

AWARMNG

ROTATING PARTS

Keep clear of collector

rakes while engine ■

is running

CLOGGING AND TO DECREASE THE DISCHARGE DISTANCE. IF A

CLOG OCCURS, STOP ENGINE, REMOVE SPARK PLUG WIRE,

AND TURN DISCHARGE CHUTE TO RIGHT. POKE OUT WET

SNOW WITH A BROOM HANDLE, STICK OR SIMILAR OBJECT. IF

AN OBSTRUCTION BECOMES LODGED IN IMPELLER OR AUGER

USE THE BROOM HANDLE (NOT YOUR HANDS!) TO PUSH AND

ROTATE THE IMPELLER BACKWARDS (COUNTER-CLOCKWISE)

VIEWED FROM OPERATOR POSITION) AND CLEAR CLOG. IF

THIS IS UNSUCCESSFUL. REMOVE DISCHARGE CHUTE FOR

ACCESS TO CLOG. YOUR ARIENS DEALER CAN PROVIDE FUR

THER ASSISTANCE.

NOTE: THIS PRODUCT IS EQUIPPED WITH AN INTERNAL

COMBUSTION TYPE ENGINE. DO NOT USE UNIT ON OR NEAR

ANY UNIMPROVED, FOREST-COVERED OR BRUSH-COVERED

LAND UNLESS THE EXHAUST SYSTEM IS EQUIPPED WITH A

SPARK ARRESTER MEETING APPLICABLE LOCAL, STATE OR

FEDERAL LAWS. A SPARK ARRESTER, IF IT IS USED. MUST

BE MAINTAINED IN EFFECTIVE WORKING ORDER BY THE

OPERATOR. SEE YOUR ARIENS DEALER OR ENGINE

MANUFACTURER’S SERVICE CENTER.

-3

Page 4

OPERATION

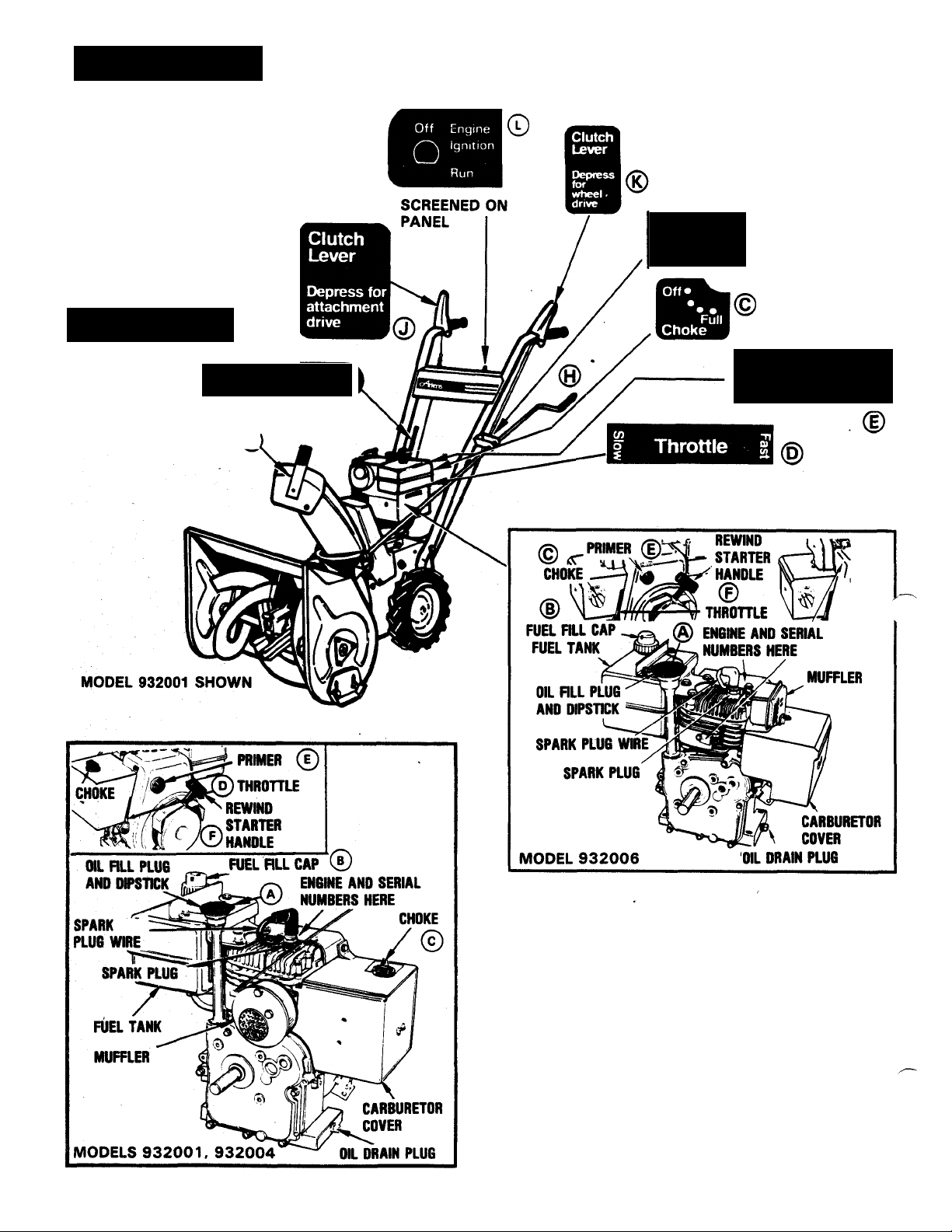

FIGURE 1

Speed Selector

4 3 2 1

(932006)

(932001, 932004) 0

Speed Selector

3 2 1 R

©

Discharge

Right Left

Engine Primer

Push to prime

-4-

Page 5

OPE

jmm

BEFORE STARTING — FIGURE 1

MPORTANT; REVIEW THE CONTROL AND COMPONENT LOCA

TIONS AND DECALS ON YOUR SNO-THRO AND SHOWN IN

FIGURE 1. READ AND REFER TO THE ENGINE INSTRUCTIONS

PROVIDED.

1. Fill crankcase with oil. Refer to Engine Instructions

Manual supplied with Sno-Thro. ©

2. Add unleaded or leaded regular gas. Do not mix oil with

gasoiine. ©

CAUTION: MAKE VISUAL CHECKS WITH REGARDS TO SAFETY

PRECAUTIONS SUCH AS OUTLINED ON PAGE 2.

TO START — FIGURE 1

1. Turn key to “RUN” position. ©

2. Move Choke Knob to “FULL” choke position.©

NOTE; 932000 SERIES CHOKE CONTROLS ARE LOCATED ON

THE ENGINE CARBURETOR COVER BOX.

3. Move Throttle to “FAST” position.®

TO OPERATE - FIGURE 1

1. Move Chute Deflector to desired height. ®

2. Turn Hand Crank to direct Discharge Chute. ® Direct

snow away from area to be cleared; the chute will adjust to

220° turn.

3. Move Speed Selector to desired speed.©

4. Depress Attachment Clutch Lever to engage snow

throwing.®

IMPORTANT; IF THE IMPELLER (FAN) IS FROZEN OR RUSTED,

THE BLOWER ATTACHMENT WILL NOT FUNCTION CAUSING

POSSIBLE DAMAGE TO BLOWER BELT AND DRIVE COM

PONENTS. BE CAREFUL TO GRADUALLY ENGAGE ATTACH

MENT CLUTCH LEVER.

5. Depress Traction Clutch Lever to drive the Sno-Thro

wheels. ®

NOTE; BOTH HANDLEBAR CLUTCH LEVERS MUST BE

DEPRESSED TO OPERATE AND BLOW SNOW.

TO STOP - FIGURE 1

4. Push Primer Bulb two or three times when engine is cold.

Below -15® F additional priming may be required.®

Turn Discharge Chute ® to left before starting. Pull Re

wind Starter. ®

a. Pull rope out slowly until the engine reaches the start of

the. compression cycle. (The rope will pull slightly

harder at this point.)

b. Let the rope rewind slowly.

c. Pull the rope with a rapid full arm stroke. Let the rope

rewind slowly — do not let the rewind handle snap.

NOTE: IF YOUR SNO-THRO IS EQUIPPED WITH AN ELECTRIC

STARTER, REFER TO THE INSTRUCTIONS PROVIDED WITH THE

STARTER.

6. When the engine starts move the Choke Knob gradually to

the “OFF” position, from 3/4, to 1/2, to “OFF”. If

engine falters move Choke Knob immediately to “FULL”

then gradually to “OFF”. ®

NOTE: TO START A WARM ENGINE DISREGARD STEP 3 (MOVE

CHOKE “OFF”), DISREGARD STEP 5 (DO NOT PUSH PRIMER).

TO TRANSPORT (TRACTION DRIVE) — FIGURE 1

1. Move Speed Selector to desired speed.®

Press down on the top of the handlebars enough to raise

the front of the Sno-Thro slightly off the ground.

1. Release Traction Clutch Lever.®

2. Except for emergency stops, allow the Sno-Thro Attach

ment Clutch to be engaged and the engine run for a short

time to throw out slush and water and prevent freezing of

the fan.

3. Release Attachment Clutch Lever.®

4. Turn key to “OFF” position. ®

5. Move Choke Knob to “FULL” position.®

6. Move Throttle to “FAST” position. ®

OPERATING TIPS

1. Snow is best removed as soon as possible after snow fall.

2. To clear an area property run the Sno-Thro in an overlapp

ing series of paths. For large areas start in the middle and

blow snow to each side so it doesn’t have to be moved

more than once.

3. Snow should be discharged with the direction of wind

whenever possible. Do not blow snow any higher than

necessary.

4. Chemicals used to melt ice and snow may damage the

finish of your Sno-Thro. When possible, wipe the Sno-Thro

clean with a rag (use of automotive wiper washer fluid may

be applied) to remove residue.

3. Depress Traction Clutch Lever to transport. ©

- 5 -

Page 6

ADJUSTMENTS/ MAINTENANCE

Ariens Company recommends that you have adjustments made

by your local Aliens dealer. He has the tools and know-how to

properly perform these maintenance adjustments which may be

required to keep the Sno-Thro operating at peak efficiency. The

Sno-Thro is equipped with the finest quality engine obtainable.

However, should servicing be required, it can be obtained from

an Ariens dealer or an authorized engine manufacturer’s service

station. Should you decide to make adjustments on your SnoThro yourself, Ariens recommends that you call your dealer for

the answers to any questions that might arise in performing this

work.

SHEAR BOLT REPLACEMENT - FIGURE 2

Occasionally an object may enter the blower and jam the rakes.

When this occurs, the shear bolts securing the rakes to the shaft

will break and allow the rake to turn freely on the shaft preven

ting damage to the gear drive. When this happens, turn off the

engine, remove wire from spark plug, remove the broken shear

bolt and replace with a new ARIENS shear bolt. Use of any other

type of shear bolt may result in severe damage to the machine.

USE ONLY ARIENS SHEAR BOLTS FOR REPLACEMENT. Each

time a shear bolt is replaced (and once each year) the rake

should be rotated on the shaft and the shaft lubricated. Refer to

“LUBRICATION” section.

RUNNERS AND SCRAPER BLADE — FIGURES 2 & 3

Lever touching the hub. If the Activator Lever touches the hub,

the attachment idler (Figure 9) must be adjusted in the idler arm.

Loosen the cap screw on the idler and move idler IN TOWARD the

belt. Readjust the spring in the chain for proper action.

Make sure that all linkage works freely so that blower idler snaps

quickly and freely to disengaged position when Attachment

Clutch Lever is released. Make sure that the blower impeller

(fan) comes to a quick (5 seconds) stop when Attachment Clutch

Lever is released.

NOTE: SEE, ALSO. “ASSEMBLY AND PRE-SERVICE” SECTION

OF THIS MANUAL.

The runners on each side of the blower housing, and the scraper

blade, along the bottom of the housing, are all adjustable to suit

conditions. Raising or lowering the runners controls the distance

the scraper blade is held above the surface being cleared. Run

ners are adjusted by loosening the two nuts securing each run

ner. Move the runner to the desired position and retighten the

nuts. Be sure to adjust both runners to the same height to keep

blower housing level. Uneven runners make the machine difficult

to steer and will result in an uneven clearing job.

Adjustment of the runners is critical to good cleaning. If the

machine is to be used on a gravel surface lower the runners so

the blower will not pick up gravel. After the remaining sno.w is

packed down, the runners may be raised for close scraping. On

smooth concrete or blacktopped surfaces, the runners may be

raised so the scraper blade rests on the surface and scrapes

clean.

The runners may be removed from the blower housing and re

installed in upside-down position to reduce contact area and thus

reduce tendency to ride up when clearing hard-packed snow.

The scraper is adjustable so it may be lowered to compensate for

wear. See Page 12 illustration. Loosen locknuts securing

scraper blade to adjust. Retighten locknuts. If the blade Is al

lowed to wear down too far the blower housing may be damaged.

ATTACHMENT CLUTCH ADJUSTMENT — FIGURES 4 &

5

The Attachment Clutch is adjusted by connecting the spring on

the clutch rod into the proper link on the Clutch Lever. Properly

adjusted, the spring should be slightly extended with the clutch

lever down. This should occur without the Attachment Activator

6-

Page 7

ADJUSTMENTS/ MAINTENANCE

CHUTE CRANK ADJUSTMENT ~ FIGURE 6

In the event the chute crank fails to rotate smoothly, loosen the

nut securing the worm clevis to the bracket. This hoie in the

bracket is slotted to permit adjustment. Position the worm so

there is a little clearance between worm and the gear teeth on the

blower. Tighten the nut. Rotate the discharge chute through its

full travel to see that it turns easily. Readjust if required.

Lubricate as described in “LUBRICATION” section for smooth

operation.

TRACTION CLUTCH ADJUSTMENT - FIG. 5, 7 & 13B

The only adjustment for the drive disc is made by adjusting the

length of the traction clutch rod. Loosen setscrew in the rod

adapter and allow clutch lever to lay down on handle grip. Shift

Speed Selector to third gear. Raise rod adapter bracket until it

clears the top of the slot in frame by 1/16“ and tighten

setscrew. See Figure 13B

Check for proper adjustment by removing the bottom cover and

measuring the space between the roll pin and bracket on the

traction rod. This space must be 1/8 - 3/16“ with clutch lever

engaged, for proper operation. See Figure 7.

REPLACEMENT OF FRICTION WHEEL - FIGURE 7

FIGURE 5

1. Adjust fuel tank level to prevent spilled gasoline. Tip the

machine up on the blower housing and brace securely.

Remove two cap screws at back of frame securing the bot-

^ tom cover and loosen two cap screws at front frame sides

^ and remove the cover.

2. Remove the four whiziock nuts holding the bearing flange

on the right hand side of the frame. Remove the bearing

flange and carriage bolts.

3. Remove the hairpin cotter from the traction clutch rod. Pull

this rod from the clutch fork arm and tip it up and out of

the way .

4. Slide the friction wheel assembly and hex shaft to the right

until the left end of the hex shaft comes free of the left

bearing. Then slip the whole assembly back to the left and

pull it forward out of the frame.

5. With the friction wheel assembly out of'the frame, the

three cap screws holding the friction wheel to the hub may

be removed and the friction wheel removed.

6. Position a new friction wheel on the hub and secure with

the three cap screws. Tighten securely.

7. Slip the right end of the complete friction wheel assembly

and hex shaft into the hole in the right side of the frame.

Position the friction wheel hub in the forks. Be sure

washers are in place on bearing flange pins. Slide the hex

shaft to the left and into the left bearing being sure flat

washer is in position. See that the pinion gear meshes with

the large gear.

7 -

FIGURE 7

Page 8

ADJUSTMENTS/ MAINTENANCE

REPLACEMENT OF FRICTION WHEEL — CONTINUED

8. Replace the bearing flange on the right side of the frame

and secure with the four carriage bolts and nuts. Recon

nect the traction clutch rod in the clutch fork arm and

secure with a hairpin cotter. Readjust the traction clutch

as described in “TRACTION CLUTCH ADJUSTMENT”

section.

BELT REPLACEMENT - GENERAL — FIGURES 8 & 9

CAUTION: SINCE REPUCING THE BELTS WILL INVOLVE TURN

ING THE ENGINE OVER WITH THE STARTER, AND THE ENGINE

MIGHT ACCIDENTALLY START RESULTING IN INJURY. THE

SPARK PLUG WIRE MUST BE DISCONNECTED DURING THIS

PROCEDURE.

The traction drive belt and the blower drive belt are both accessi

ble by tipping apart the blower housing and tractor as follows:

1. Remove the nut and lockwashers holding the worm clevis

on the bracket. Remove the chute crank by sliding it back

in the bracket and out of the way.

ENGINE SHEAVE

(BLOWER)

AHACHMENT

IDLER

TRACTION SHEAVE

^ ii J

BRAKE SHOE J

ENGINE SHEAVE

(TRACTION)

2. Remove the two screws securing the belt guard to the trac

tor. Remove belt guard.

3. Remove the top screws and loosen the lower screws on

each side that secures the blower housing to the frame. As

the blower housing and tractor are tipped apart, roll the

blower belt off the engine sheave between the sheave and

belt finger. This can be easily done by pulling the recoil

starter rope to rotate the engine sheave. See “CAUTION”

note,this section. With the blower belt disconnected, the

blower housing may then be tipped from the frame.

REPLACEMENT OF TRACTION DRIVE BELT — FIGURES

3 & 9

CAUTION: SINCE REPLACING THE BELTS WILL INVOLVE TURN

ING THE ENGINE OVER WITH THE STARTER, AND THE ENGINE

MIGHT ACCIDENTALLY START RESULTING IN INJURY, THE

SPARK PLUG WIRE MUST BE DISCONNECTED DURING THIS

PROCEDURE.

With the blower and tractor tipped apart, pull the idler away from

the traction drive belt and remove belt from around the traction

sheave and engine sheave. Install the new belt on the engine

sheave and traction sheave. Then reposition the idler back into

position on the outside of the traction drive belt.

FIGURE 8

BRAKE SHOE

FIGURE 9

With the belts in position and the idler in place, check the belt

alignment. The engine sheave and the tractor sheave must align

with one another. If the sheaves are not properly aligned, loosen

the setscrews on the engine sheave and align the sheaves.

Retighten the setscrews.

- 8

Page 9

ADJUSTMENTS/ MAINTENANCE

REPLACEMENT OF THE BLOWER DRIVE BELT —

FIGURES 8 & 9

CAUTION: SINCE REPLACING THE BELTS WILL INVOLVE TURN

ING THE ENGINE OVER WITH THE STARTER, AND THE ENGINE

MIGHT ACCIDENTALLY START RESULTING IN INJURY, THE

SPARK PLUG WIRE MUST BE DISCONNECTED DURING THIS

PROCEDURE.

The blower drive belt is on the sheave on the blower housing.

Remove and install the new belt on the sheave. Hold it in position

on the sheave as the blower is tipped into position on the tractor.

Be sure the brake shoe seats on the belt as the units are tipped

together. Once assembled, roll the blower drive belt on to the

engine sheave and position the idler on the outside of the belt.

Align blower engine sheave and blower sheave (on blower hous

ing) with attachment idler. If sheaves are not properly aligned,

loosen setscrews on the blower engine sheave and blower

sheave (on blower housing) and align with attachment idler.

Retighten setscrews. Readjust Attachment Clutch per instruc

tions on page 6.

REPLACEMENT OF BLOWER HOUSING t- FIGURES 8 &

9

CAUTION: SINCE REPLACING THE BELTS WILL INVOLVE TURN

ING THE ENGINE OVER WITH THE STARTER, AND THE ENGINE

MIGHT ACCIDENTALLY START RESULTING IN INJURY, THE

SPARK PLUG WIRE MUST BE DISCONNECTED DURING THIS

PROCEDURE.

1. Tip the blower and tractor together. Hold the blower drive

belt up as the units are tipped together. Be sure the

blower brake shoe seats on the blower sheave. Secure

with the two cap screws into the frame.

2. Roll the blower belt on to the engine sheave. Pull the recoil

starter rope to turn the engine sheave and roll the belt into

place under the belt finger.

3. Check the belt finger spacing. There should be 1/8 inch

clearance between the belt finger and belt with the attach

ment clutch engaged. Readjust the belt finger if required.

4. Check the sheave alignment with the blower belt in place.

Readjust as required to align the sheaves. It may be

necessary to tip the blower housing away from the tractor

to gain access to the blower sheave. Replace blower hous

ing by reversing the instructions found in “BELT

REPLACEMENT — GENERAL” section on page 8.

STORAGE

A

WARNING: NEVER STORE PRODUCT IN AN ENCLOSED AREA

WHERE FUEL FUMES MAY REACH AN OPEN FLAME, SPARK,

OR PILOT OF FURNACE, ETC. DRAIN FUEL OUTDOORS, AWAY

FROM OPEN FLAME, AND USE ONLY AN APPROVED FUEL CON

TAINER.

ENGINE

Refer to Engine Manufacturer's Instructions supplied with the

product.

5. Replace the belt guard and chute crank assemblies. Read

just the chute crank as described in “CHUTE CRANK AD

JUSTMENT” section. Replace the spark plug wire.

GENERAL

Store Sno-Thro in a cool, dry place.

Inspect Sno-Thro for visible signs of wear, breakage or damage.

Order any parts required and make necessary repairs to avoid

delays when beginning use again.

Lubricate Sno-Thro as described in “LUBRICATION” section of

this manual.

Clean the Sno-Thro thoroughly. Touch up all unpainted and ex

posed areas with paint to avoid rust.

Page 10

LUBRICATION

ENGINE

Fill Crankcase with oil as recommended in Engine

Manufacturer’s Instructions supplied with the product. Check oil

level before each use and change oil regularly according to

Engine Manufacturer’s Instructions.

SNO-THRO TRACTION DRIVE - FIGURE 10

At the start of each operating season, grease the hex shaft as in

dicated in Figure 10. Put a few drops of oil on the Speed Selector

linkage and other linkage points. Lubricate the bushings on the

axle as indicated in Figure 10.

NOTE: BEFORE LUBRICATING THE BUSHINGS ON AXLE

(BETWEEN THE WHEEL AND FRAME) BE SURE TO CLEAN

THE INNER SURFACES OF THE BUSHINGS. REMOVE THE

CAP SCREW (1) AND LOCKNUT (2). REMOVE WHEEL (3)

FROM AXLE. CLEAN INSIDE OF BUSHING (4) AND ADD OIL

TO INNER BUSHING SURFACE. REPLACE WHEEL.

shear bolt holes, turn rakes on shaft several times and replace^

shear bolts. See Figure 11 A.

On models equipped with zerk fittings on the rake shaft it will be

necessary to re-grease the rake shaft zerk fittings provided each

time a shear bolt is replaced and/or at the end of the season. Be

sure to rotate the rakes on the shaft several times after applying

grease. See Figure 11B.

Oil the Discharge Chute with several drops of oil See Figure 12.

Rotate the Discharge Chute after applying oil to spread oil over

the Discharge Chute gear teeth to prevent rust and provide

smooth operation.

CLEAN & OIL

FIGURE 10

SNO-THRO UNIT - FIGURES 11 & 12

The blower gear case is lubricated with Ariens Liquid Grease

(Part No. 000070). This grease will not flow at lower

temperatures, it is therefore difficult to check the lubricant level.

Best method for checking is to place the unit in a warm location

overnight. This allows the grease to flow to level. Check the

lubrication by removing the filler plug on the side of the gear

case just above the left auger shaft. Lubrication should be even

with the hole with the machine sitting level, it may be necessary

to insert a wire into the hole to check level. The unit will not be

damaged by over lubricating.

NOTE: OIL CAN (PUMP-TYPE) MAY BE USED TO LUBRICATE

WITH ARIENS LIQUID GREASE.

Some models are equipped with zerk fittings on the rake shaft.

See Figure 11B. For those models that do not have zerk fittings,

oil rake shaft periodically or each time a shear bolt is replaced. At

the end of the season, remove shear bolts, oil rake shaft through

-10-

Page 11

SNO-THRO SERVICE GUIDE

PROBLEM POSSIBLE CAUSE CORRECTION

r^-

Difficult starting, engine runs poorly.

Engine stalls or Iqoses power. 1. Choke is on after engine is

Excessive vibration.

Sno-Thro will not move. -

Sno-Thro will not discharge snow.

1.

Defective spark plug.

2.

Engine-is not getting fuel. 2. Fill fuel tank; check and clean

warm.

2. Impeller is blocked.

Water in fuel.

3.

1. Loose hardware securing

components.

Damage to unit.

2.

1. Traction Clutch is not adjusted

correctly.

2. Loose or damaged drive belt. 2.

1. Attachment Clutch is not

adjusted correctly.

1.

Replace spark plug, check

connections of plug wire.

fuel line.

1.

Turn Choke Lever to “OFF”.

2. Turn off Sno-Thro, remove

obstruction.

3. Follow Engine Instructions to drairtank and refill.

1.

Do not run unit. Stop and tighten

all hardware, check for damage.

2. See your Ariens dealer.

1.

Adjust Clutch, see “ADJUST-

MENTS-MAINTENANCE” Section of

Owner's Manual.

Replace belt - see “ADJUSTMENTS

-MAINTENANCE” section.

1.

Adjust Clutch, see “ADJUST-

MENTS-MAINTENANCE” section

of Owner's Manual.

Blower drive belt is loose

2.

or damaged.

Broken shear bolt.

■ 3.

A

4. Chute or auger is clogged. 4.

r'-

2.

Replace belt - see “ADJUSTMENTS

-MAINTENANCE” section.

3. Replace with Ariens shear bolt see “ADJUSTMENTS-MAINTE-

NANCE” section.

Turn off Sno-Thro, remove clog.

-11 -

Page 12

BASIC CONSUMER-USER SERVICE COMPONENTS

NOTE: FOR ENGINE LUBRICATION AND PARTS SUCH AS AIR

CLEANER AND SPARK PLUGS REFER TO ENGINE ENSTRUC-

TIONS MANUAL SUPPLIED WITH UNIT. CONTACT ENGINE

MANUFACTURER’S DEALER FOR REPLACEMENTS.

SHIFT HANDLE

032071

KEY SET

013157

CHUTE CONTROL CRANK

022081

SHEARBOLT

& NUT

532005

RI6HTRAKE

532014 - 20”

532016 - 24”

LEFT RAKE

532015 • 20”

532017 • 24”

RUNNER

010165

CLUTCH SPRING

083008

PARTS OR SERVICE MANUALS

Basic Consumer-User Service Components are Il

lustrated on tMs page and are described in the text

of this manual. These components are most com

monly used for consumer repair.

Should a complete parts list and/or a repair manual

less engine be required order under the following

part numbers.

Parts Manual

SPRING

083171

SHEAVE

073103

BLOWER

DRIVE

BELT

072114

TRACTION OPTIONAL ACCESSORIES*:

Repair Manual

Please Request From; AriensSorvice

For engine parts Hst and repair instructions, contact

the engine manufacturer’s dealer.

Electric Starter, 722006

Slicer Bar, 710997

Homeowner’s Kit, 732003

Tire Chains, 732001 for Model 932001;

732002 for Models 932004, 6

Part No. PM-32-82

Part No. RM932-1982

655 West Ryan Street

n, Wl 54110

OPTIONAL ATTACHMENTS*:

Rotary Brush - 24”: 832001 (RB24)

Rotary Tiller, 832004 (RT20)

‘Available at Extra Cost

Page 13

ASSEMBLY & PRE-SERVICE

WARNING: FAILURE TO FOLLOW ALL INSTRUCTIONS FOR

ASSEMBLY AND PRE-SERVICE COULD RESULT IN PERSONAL

INJURY AND/OR DAMAGE TO THE SNO-THRO. CHECK AND

TEST THE FUNCTION OF ALL CONTROLS BEFORE STARTING

ENGINE AND BE SURE TO FILL ENGINE WITH OIL.

WARNING: ALL ASSEMBLY AND ADJUSTMENT PROCEDURES

ARE TO BE MADE WITH ENGINE STOPPED AND SPARK PLUG

WIRE DISCONNECTED.

NOTE: MAKE SURE ALL SAFETY DEVICES AND GUARDS ARE IN

POSITION AND OPERATING PROPERLY. READ THE OWNER’S

MANUAL AND ITS INSTRUCTIONS FOR SAFE OPERATION

BEFORE USING UNIT.

GENERAL

The unit is shipped with tractor and snow head assembled. The

handlebars are assembled but must be installed, along with the

clutch rods and chute crank.

HANDLEBAR INSTALLATION - FIGURE 13

The handlebars are attached to the holes in the side of the frame.

Install a cap screw (59022, 3/4” long), a flat washer (64123)

and lockwasher (63003) in the lower holes on each side of the

^^handle and attach to the frame. Do not tighten. Insert a cap

^ icrew (59069,1-1 /4” long), a washer (64123) and lockwasher

t63003) through each of the upper holes in the handlebars. Hold

the handlebars up in a comfortable position and tighten all hard

ware. The handlebars are adjustable for customer use.

WIRING HARNESS - FIGURE 13

BELT

COVER

KEY SWITCH

ON PANEL

FLANGE

WHIZLOCK

SCREW

TO

FRAME

AHACHMENT

CLUTCH HANDLE

CHAIN

SPRING

TO ENGINE

MAGNETO

TAPPING

SCREW

CLAMP

KEY

SWITCH

TRACTION

CLUTCH ROD

WIRE HARNESS

1-1/4” CAP SCREW

IN UPPER HOLE

3/4” CAP SCREW

IN LOWER HOLE

BOnOM

COVER

TRACTION

CLUTCH

HANDLE

-(BENT

END OF

CLUTCH

ROD

GOES

HERE)

1/8” T0Í

3/16’

FIGURE 13A

The wiring harness is supplied attached to the engine. Run this

harness from the engine, up the left handlebar, to the key

switch. Connect wire to terminals on the key switch; wires can

be attached to either terminal. Secure the wiring harness to the

left handlebar with clamp (69099).

TRACTION CLUTCH ROD - FIGURE 13

The traction clutch rod is shipped loose in the carton. To install

the rod, place the Speed Selector in third speed; insert the bent

end of the clutch rod into the hole in the clutch handle on the left

handlebar. See Figure 13A. Insert the straight end of the clutch

rod into the hole in the rod adapter in the clutch bracket at the

left rear of the frame. See Figure 13B. Hold the clutch handle all

the way down; raise the clutch bracket up to 1/16 inch of the

frame; now tighten the rod in place with the setscrew in the rod

adapter.

This adjustment can be checked by tipping Sno-Thro onto blower

housing and removing bottom cover. To remove bottom cover,

^^remove the two screws on each side of cover that mount it to the

ame. With the clutch handle fully depressed the clearance bet

ween the roll pin and the bracket should be 1/8 inch to 3/16

inch. See Figure 13A. Loosen the setscrew and readjust if re

quired.

- 13

Page 14

ASSEMBLY & PRE-SERVICE

a. Remove belt cover located in front of engine.

b. Check alignment of blower engine sheave and blower

sheave with attachment Idler. If sheaves are not aligned

properly loosen the setscrews on the blower engine

sheave and blower sheave, then align them with the

blower idler. Retighten setscrews. See Figure 14.

c. Insert a 3/16” thickness shim (use a 1” wide flat

stock) between the brake shoe and the attachment

drive belt on the blower sheave. See Figure 14.

d. With the 3/16” shim installed, adjust the attachment

Idler in the slot toward blower drive belt until it is just

snug against belt. See. Figure 14. Remove shim. Ad

justment should be re-checked after completion of at

tachment clutch assembly.

e. Check and, if necessary, adjust the belt fingers so

there is approximately 1/16” clearance between at

tachment drive belt and belt fingers when attachment

clutch is engaged. See Figure 14.

f. Check attachment clutch handle function. There should

be total travel of handle down and up (to point of con

tact of handle center on handlebar) and free movement

of the handle.

AHACHMENT

CLUTCH

ROD SPRIHG

©

m

AHACHMENT CLUTCH LEVER

FIGURE 1SB

g. Attachment clutch rod spring ® should be Installed by

hooking the end of the rod spring up through the hole in

the Attachment Clutch Lever on the right rear of SnoThro frame. See Figure 15B. Connect the spring end of

the attachment clutch rod spring to a link in the chain

® on the attachment clutch handle as shown in Figure

15A. With the handle in the disengaged (up) position

select a link that will allow the spring to stay slack (not

extended) and will extend the spring a minimum of

3/8” length when the handle is engaged (down posi

tion). When clutch is disengaged the brake shoe must

engage the attachment drive belt on the blower sheave.

h. Check function of attachment clutch. The blower at-^

tachment must stop running within five (5) second!.

-14-

Page 15

ASSEMBLY & PRE-SERVICE

ATTACHMENT CLUTCH - CONTINUED

after attachment clutch handle is disengaged (up posi

tion). If this is not achieved, check blower idler adjust

ment according to paragraph "d" (attachment drive

belt tension may be too tight) and belt finger adjust

ment (paragraph "e"). Reinstall belt cover.

CAUTION: PROPER FUNCTION OF ATTACHMENT CLUTCH CAN

BE ASSURED ONLY WHEN THE PREVIOUS STEPS IN “ATTACH

MENT CLUTCH” SECTION HAVE BEEN PERFORMED.

CHUTE CONTROL CRANK — FIGURE 16

The chute control crank is shipped fully assembled and In place

in the bracket. Install as follows: Bolt the crank clamp in place

on the left handlebar. See Figure 16.

Position the worm clevis on the bracket on the blower housing.

Place external tooth lockwasher between worm clevis and

bracket. Adjust in slot so that there is a little clearance between

worm and gear teeth on blower collar.

Secure the worm clevis with the carriage bolt (already in place on

the clevis). Use a lockwasher (63023) and a 5/16-18 nut

(65015) under the bracket. See Figure 16.

Rotate the discharge chute through its full travel to see that it

turns easily. Readjust the position of the worm clevis, if re

quired. Oil discharge chute, see Figure 17B.

DEFLECTOR - FIGURE 17

The deflector is shipped in place on the discharge chute but

must be raised into operating position. Remove the locking hard

ware from the discharge chute. Raise the deflector up into posi

tion. Re-install the hardware as shown In Figure 17A. Adjust the

nut to apply sufficient tension so the deflector can be easily

moved by hand but will still hold position when blowing snow.

BLOWER GEAR CASE

The blower gear case is factory lubricated and should require no

lubrication by the dealer.

The blower gear case Is lubricated with Ariens Liquid Grease

(Part No. 000070). This grease will not flow at lower

temperatures. It is therefore difficult to check the lubricant level.

Best method for checking is to place the unit in a warm location

overnight. This aliows the grease to flow to level. Check the

lubrication by removing the filler plug on the side of the gear

case just above the left auger shaft. Lubrication shouid be even

with the hoie with the machine sitting level. It may be necessary

to Insert a wire into the hoie to check levei. The unit will not be

damaged by over lubricating.

-15

Fill crankcase with oil as recommended in Engine

Manufacturer’s Instructions supplied with the product. Check oil

level before each use and change oil regularly according to

Engine Manufacturer’s Instructions.

Page 16

ASSEMBLY & PRE-SERVICE

TIRE PRESSURE

Models 932004 and 932006 are equipped with pneumatic tires.

Adjust pressure to 12 to 20 PSI before operating. Tire pressure

of 20 PSI is recommended for use with tire chains.

REGISTRATION

Fill out pre-warranty registration card and mail to Ariens Com

pany. Warranty will only be registered under the model and

serial number found on the serial number label (also stamped in

to the frame of the unit). Add serial numbers in serial number

recording area of this manual.

DELIVERY

Using the Owner’s Manual as a guide, instruct the customer as

follows:

1. Instruct the customer on the operation of the Sno-Thro.

Emphasize safety and discuss the safety information in the

Owner’s Manual.

2. Advise customer to change oil in the engine crankcase

after the first two hours of operation.

3. Explain how to perform the recommended lubrication and^

periodic service.

4. Explain maintenance and adjustment instructions.

5. Demonstrate how to mount and dismount attachments.

6. Make certain the customer has his Owner’s Manual and

Engine Instructions.

7. Explain Ariens Warranty Policy. Fill out and return Ariens

Warranty Registration Card.

SERIAL NUMBER — SNO-THRO

(PLATE LOCATED ON REAR OF FRAME)

SERIAL NUMBER — ENGINE

(STAMPED INTO TOP OF ENGINE ABOVE RECOIL START)

A message to the Ariens customer...

Welcome to the world of Ariens equipment. We are pleased that you have selected Ariens and sincerely believe you have pur

chased the best equipment available. The care you give your new Ariens equipment will greatly determine the satisfaction and ser

vice life you will obtain from it. Use this manual and the engine manual supplied, as your guide. By observing the instructions and

suggestions in these manuals, your Ariens equipment will serve you well for many years.

Your Ariens dealer will be happy to supply any service or advice which may be required to keep your Ariens equipment operating at

peak efficiency. He stocks genuine Ariens parts and lubricants; manufactured with the same precision and skill as the original

equipment. His factory trained staff is kept well informed on the best methods of servicing Ariens equipment and is ready and able

to serve you. If engine repairs or services are required, they can be obtained from an Ariens dealer or from an authorized engine

manufacturer’s service station. If service is required, be prepared to supply the service person with the Model Number and Serial

Number of the equipment and the engine, as well as a full description of the problem encountered.

-16-

Loading...

Loading...