Page 1

9^i1ens

Series

Sno-Thro®

Repair

Manuai

Ÿ/tS^

Ariens

Page 2

A Message To Ariens Repair Manuai User

Your Ariens Dealer will be happy to supply any

service or advice which may be required to

keep your Ariens equipment operating at peak

efficieny. He stocks genuine Ariens parts and

lubricants; manufactured with the same preci

sion and skill as the original equipment. His

factory trained staff is kept well informed on

the best methods of servicing Ariens equip

ment and is ready and able to serve you. If

engine repair or service are required, they can

be obtained from an Ariens dealer or from an

authorized engine manufacturer’s service

center. If service is required, be prepared to

supply the service person with the Model and

Serial Numbers of the equipment and engine,

as well as a full description of the problem

encountered.

The information contained herein is intended

for use by Ariens Dealers’ trained servicemen

and serves as a supplement to and reminder of

training sessions conducted by Ariens Com

pany. Before you attempt any repair, adjust

ment or maintenance project be certain that

you have read and fully understand the instruc

tions in your Owner’s Manual. Understand and

follow each Danger, Warning, Caution and all

instructions exactly as given. Also be sure that

you have Parts Manuals, all tools, replacement

parts and other materials required to complete

the project.

IMPORTANT: All fittings, measurements, tor

que recommendations and instructions are

significant and approximations or substitu

tions must be avoided. Improper repair,

maintenance and/or adjustments or service at

tempted by anyone other than an authorized

Ariens Service Dealer could void future warran

ty claims, and damage unit and/or result in in

jury to operator and/or bystanders.

4

Page 3

Introduction

How To Use Your Service Manual

I

The Ariens Service manual is arranged for

quick, easy reference and is divided into

numerical sections. Each section is then divid

ed into sub-sections. To use this manual pro

ceed as follows:

Refer to the index to determine section within

Which desired information will be contained

and proceed to front of that section for its

Table of Contents.

Locate subject desired. Page number is listed

across from subject and consists of section

number and page number.

NOTE: Read all information for servicing a part

or system before repair work is started to avoid

needless disassembly.

Preparation For Service

Proper preparation is very important for effi

cient service work. A clean work area at the

start of each job will allow you to perform the

repair as easily and quickly as possible, and

I

reduce incidences of misplaced tools and

parts. A sno-thro that is excessively dirty

should be cleaned before work starts. Cleaning

will occasionally uncover trouble sources.

Tools, instruments and parts needed for the

job should be gathered before work is started.

Interrupting a job to locate tools or parts is a

needless delay.

Service Buiietins

In addition to the information contained in this

Ariens Service Manual, Ariens Service

Bulletins are issued to Ariens Dealers from

time to time, which cover interim engineering

changes and supplementary information. Ser

vice Bulletins should be consulted to complete

information on models covered by this manual.

Replacement Parts

When replacement parts are required, use only

genuine Ariens parts. Failure to do so may

result in product malfunction and possible in

jury to operator and/or bystander.

NOTE: All references to “Left”, “Right”,

“Front” and “Back” are given from operators

position.

NOTE: The descriptions and specifications

contained in this manual were in effect at the

time the manual was approved for printing.

Ariens company reserves the right to discon

tinue models without notice and without incur

ring obligation. The equipment identified as

either standard or optional and the various il

lustrations may not all be applicable to your

unit. If you have questions, always check with

your Ariens dealer.

»

©Ariens 1987

RM-932

Part No. 000128A

Printed in U.S.A. 11-87

Page 4

Safety Alert Symbol And Notations

The following safety notations are used

throughout this manual to call attention to

special information or operating procedures.

Understand the message in each notation and

be alert to unsafe conditions and the possibili

ty of personal injury.

NOTE: A NOTE points out general reference in

formation regarding proper operation and

maintenance practices.

A

A

CAUTION: A CAUTION identifies safe

operating practices or indicates unsafe

conditions that could result in personal

injury.

WARNING: A WARNING describes a con

dition where failure to follow the instruc

tions could result in severe personai

injury.

i

IMPORTANT: An IMPORTANT statement in

dicates specific procedures or information

that is required to prevent damage to the

machine or its attachments.

This safety alert symbol is used to at

A

Before test operating or making repair or ad

justments to the unit, read and understand the

operating and safety instructions in the

Owner’s Manual.

Disengage power to attachment, stop engine,

remove key and wait for moving parts to stop

before performing any repair or maintenance

adjustment procedures. DO NOT make any ad

justment or perform any maintenance or repair

procedures while engine is running unless

specifically instructed to do so in this manual.

DO NOT touch tractor or attachment parts

which might be hot from operation. Before at

tempting to maintain, adjust or service, allow

such parts to cool.

Open doors if engine is run in garage, exhaust

fumes are dangerous. DO NOT run engine in an

enclosed area.

Do repair work in a well-lighted, ventilated

area.

To prevent accidental starting, disconnect wire

to spark plug(s) and position wire away from

plug.

Always wear safety goggles when cleaning or

making repairs to parts or machine.

tract your attention! PERSONAL SAFETY

IS INVOLVED! When you see this symboi

- BECOME ALERT — HEED ITS

MESSAGE.

A

Safety Precautions

DANGER: A DANGER designates a con

A

dition where failure to follow instruc

tions or heed warning will most likely

result in serious injury or death.

A

Gasoline is highly flammable and its vapors

are explosive. Handle with care. Use an approv

ed fuel container. DO NOT smoke or allow

open flame (match, pilot light, etc.) or sparks

near equipment or fuel container when refuel

ing or servicing fuel system.

Use non-flammable solvent to clean parts - DO

NOT use gasoline.

Use only Ariens original replacement parts

when making repairs.

After all repair procedures are performed,

make sure that unit is in good operating condi

tion and all safety devices and shields are in

place and in good working condition. Be sure

all fasteners are tight, all adjustments are cor

rect and all tools are removed.

DO NOT change engine governor setting or

over speed engine.

Never store equipment with fuel in tank inside

a building where fuel fumes may reach an open

flame or spark. Allow engine to cool before

storing in any enclosure.

Page 5

Index

Section

Specifications

Handlebars and Clutch

Controls.....................................

Speed Selector and Wheels .

Belt Drive...................................

Friction Wheel...........................

Auger/Impeller -

Discharge Chute

...........................

.......................

Gear Case

Engine and Headlight...............

Attachments

..................................

..............................

Page 6

Specifications

Length

Height ........................................................

Clearing Width....................

Shipping Weight......................................... 97 ibs. to 160 ibs.

WheeiSize

Engine, Horsepower

Fuel

Governed R.P.M

Discharge Distance

AirCieaner................................................... Required with Summer Attachment

Engine Oii................................................... 10W30, 5W30 Winter - 30W Summer

Spark Piug Gap

Drive ........................................................... Auger or Friction Wheei

Forward Speed........................................... 4 Forward on Wheei Driven

.................................

..................................................

..................................

.............................................................

.........................................

...................................

................

.......................

.......................

.........................

49 to 60 inches

39 to 40 inches

20” to 24”

(8”x13/4”) (4.10/3.50-4)

2.7 to 5 H.P., 120 Voit AC Eiectric

Unleaded - 1 Quart to 2 Quart Tanks

3600 (4500 Elect. Model)

3’ to 25’

RJ 17 LM Champion-.030

Variable on Auger Propelled

Reverse Speed

Eiectric Start Avaiiable

Headlight Avaiiable ..................................

Auger R.P.M................................................ 100

Chute Turning Angle

Auger Diameter

Impeiier Diameter

Auger Impelier Housing

Frame

.........................................................

...........................................

..............................

.................................

..........

...............................

............................

...........................

.........

1 Reverse on Wheel Driven

Yes (Except Eiectric Modei)

Yes (Except Eiectric Model)

220°

11”

10”

18 GA. (2-1-2 Modeis)

16 GA. (Standard Modeis)

16 GA. (2-1-2 Modeis)

14 GA. (Standard Modeis)

Page 7

Handlebar and Clutch Controls

Table of Contents

Page

2.1 Introduction.....................................................................................................■ ■ 2-6

2.2 Attachment Clutch.............................................................................................2-6

2.3 Attachment Clutch Adjustment.........................................................................2-6

2.4 Wheel Drive Clutch ...........................................................................................

2.5 Wheel Drive Clutch Adjustment........................................................................2-7

2.6 Handlebar and Key Switch................................................................................2-8

2.7 Lower Handlebar................................................................................................2-8

2.8 Handlebar Height Adjustment

..........................................................................

2-7

2-8

List of Illustrations

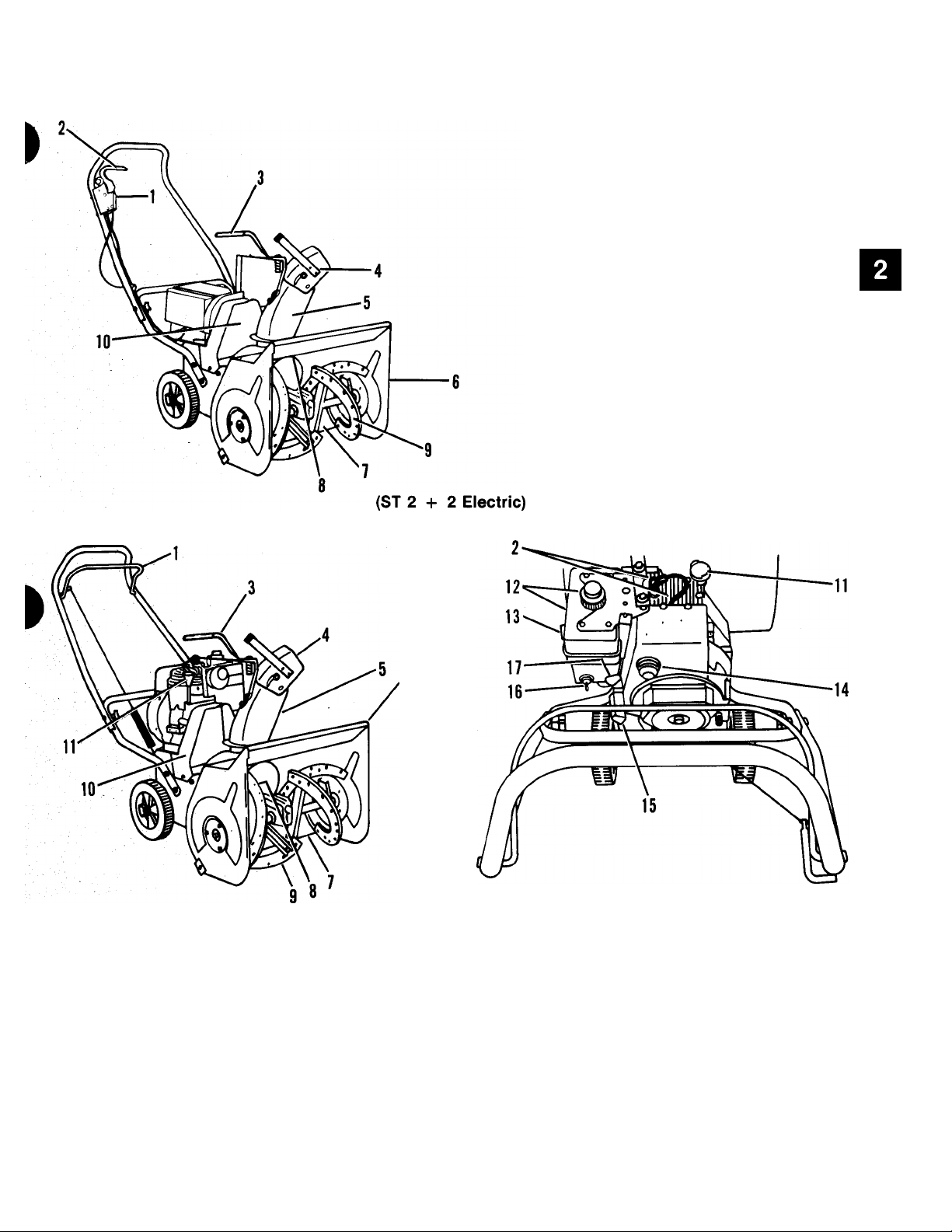

2-1: Controls and Features (Wheel Driven Models)................................................2-2

2-2: Controls and Features (Auger/lmpeller Driven Models)

2-3: Handlebars and Clutch Controls.......................................................................2-4

2-4: Attachment Clutch Adjustment.........................................................................2-6

.................................

2-3

2-5: Wheel Drive Clutch Adjustment (Inside Frame)

2'<6: Wheel Drive Clutch Adjustment.................................................................... 2-7

2-7: Wheel Clutch Adjustment (Models with Straps)..............................................2-8

2-1

..............................................

2-7

Page 8

Handlebars and Clutch Controls

1. Chute Deflector

2. Discharge Chute

3. Auger/Impeller Housing

4. Auger

5. Impeller

6. Scraper Blade

7. Runner(s)

8. Belt Guard

9. Fuel Tank and Cap

10. Speed Selector

Figure 2-1: Controls and Features (Wheel Driven Models)

2-2

11. Attachment Clutch Lever

12. Key Switch

13. Wheel Drive Clutch Lever

14. Oil Fill and Dipstick

15. Choke

16. Throttie

17. Spark Plug and Wire

18. Primer Buib

19. Rewind Starter

20. Chute Crank/Handie

Page 9

Handlebars and Clutch Controls

1. Switch Key

2. Switch Controi

3. Chute Controi Lever

4. Deflector

5. Discharge Chute

6. Auger/Impeller Housing

7. Scraper Blade

8. Impeller

9. Auger

10. Belt Guard

1. Attachment Clutch Bail

2. Spark Plug and Wire

3. Chute Control Lever

Chute Deflector

4.

5. Discharge Chute

Auger/Impeller Housing

6.

7. Scraper Blade

Impeller

8.

9. Auger

(ST 2 + 2 Gasoline)

Figure 2-2: Controls and Features (Auger/Impeller Driven Models)

10. Belt Guard

11.

Oil Fill and Dipstick

12. Fuel Tank and Cap

13.

Choke

14. Primer Bulb

15. Recoil Start

16. Engine Ignition (Key Switch)

17. Throttle

2-3

Page 10

Handlebars and Clutch Controls

i

i

Figure 2-3: Handlebars and Clutch Controls

2-4

Page 11

Handlebars and Clutch Controls

ITEM

NO.

»

1

2

3

4

5

6

7

8

9

10

11 Key Set

12

13

14

15

16

17

18

19

20

21

22

23

ITEM

DESCRIPTION

Clutch Spring

Chain and Connector

Cap Screw, 1/4-20 X 1/2

Attachment Clutch Lever

Lock Nut, 1/4-20

Tapping Screw, #12-14 X 1-1/2 29

Pin

Push Nut 31

Handle Pivot

Nut, 5/8-32

Lock Washer, 5/8

Key Switch Assembly 36

Grip

Handlebar 38

Flange Whiziock Nut, 5/16-18 39

Carriage Bolt, 5/16-18 X 1-1/2

Cable

Cover 42

Traction Clutch Lever

Hook Rod

Adjustment Strap

Flange Whiziock Screw, 5/16-18 X 5/8

NO.

DESCRIPTION

24

25

26

27

28

30

32

33

34

35

37

40

41

43

44

45

46

47

Washer, 3/8

Lower Handlebar

Carriage Bolt, 5/8-16 X 1/2

Handlebar Panel

Clamp

Shorting Wire

Taptite, 1/4-20 X 3/8

Tapping Screw, #8-15 X 3/8

Remote Stop Terminal

Traction Clutch Rod

Washer, 5/16

Lock Washer, 5/16

Cap Screw, 5/16-18 X 3/4

Cap Screw, 5/16-18 X 1-1/2

Bail

Machine Screw, 10-24 x 1-1/2

Tie

Curved Head Boit

Washer, .312/.343 x .625 x .062

Washer, .370/.390 x .875 x .083

Extension Spring, 5-1/4

Control Box

Knob

Quadrant Doubler

»

2-5

Page 12

Handlebars and Clutch Controls

2.1 Introduction

WARNING: Remove wire from spark

A

When unit is tipped to perform service pro

cedures in this section, remove enough fuei so

that no spiilage wiil occur, block securely, and

remove bottom cover.

A

plug before attempting any repair or

adjustment procedures.

WARNING: Gasoline is highly flam

mable and its vapors are explosive.

Handle with care.

2.2 Attachment Clutch

On models with spring and chain, remove push

nuts, screws and pin holding clutch handle and

handle pivot to upper handlebar. Remove pivot

and disconnect clutch handle from chain and

connector.

Assemble using reverse procedure and adjust

according to instructions in Attachment

Clutch Adjustment Section.

2.3 Attachment Clutch Adjustment

On models with spring and chain, adjust by

connecting spring to a chain link so chain is

snug, but so that attachment idler drops away

from attachment belt with Clutch Handle all

the way away from handlebar.

On models with adjustment strap, select and

mark a hold in adjustment strap that will pro

vide a slight amount of slack in cable with At

tachment Clutch all the way away from

handlebar. Unhook spring, place cable end

through hole selected above and while lifting

up on attachment clutch arm, connect spring.

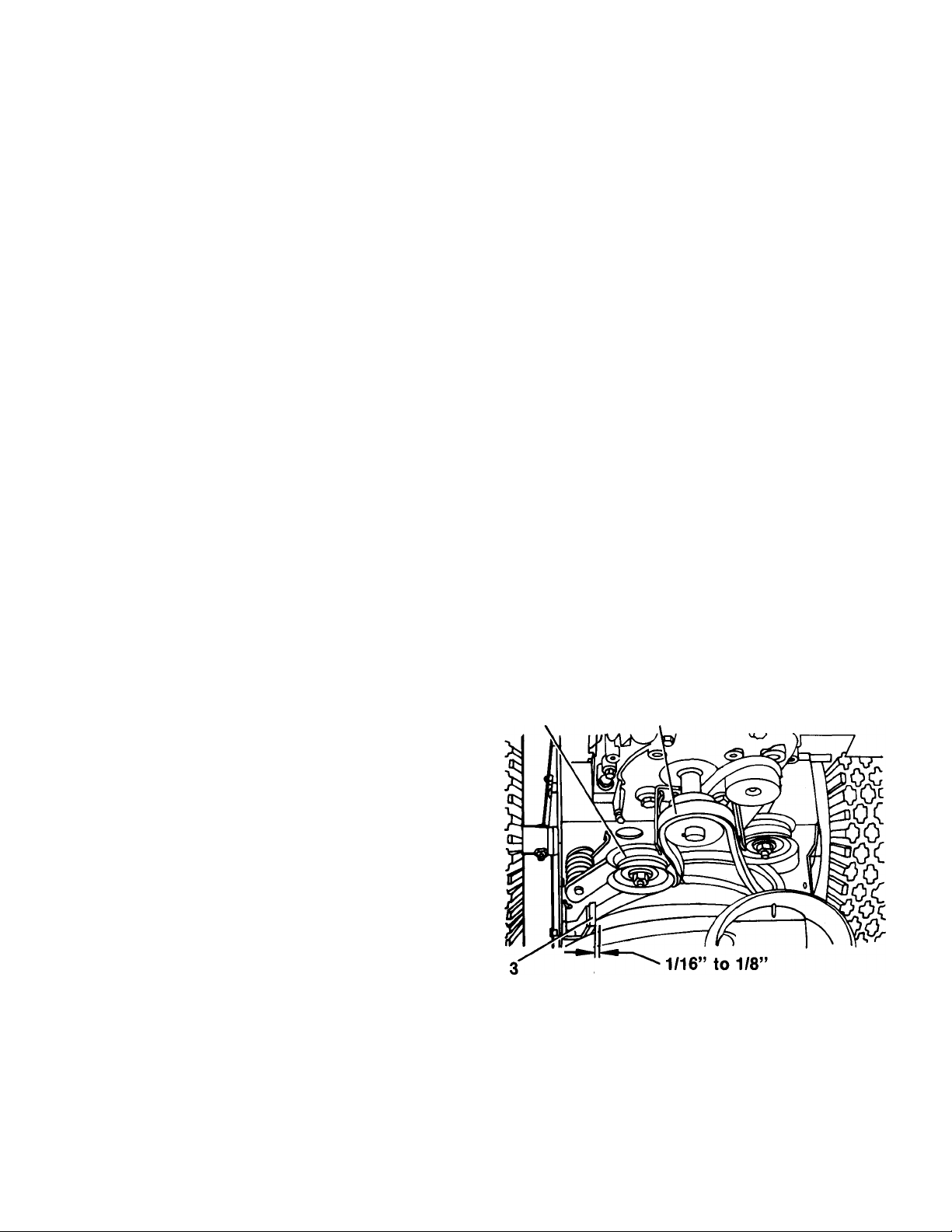

WARNING: When clutch is engaged,

A

impeller brake disengages. If brake is

not 1/16” to 1/8” from belt when

disengaged, refer to Attachment

Clutch/Impeller Brake Section.

i

Disconnect chain and clutch spring from lever.

Check parts for wear or replacement.

Assemble using reverse procedure and adjust

according to instructions in Attachment

Clutch Adjustment Section.

On models with adjustment strap, remove

push nuts and pin holding clutch lever to

handlebar. Remove lever and disconnect

clutch cable from adjustment strap.

Disconnect adjustment strap and clutch

spring from attachment clutch arm.

On models with bails, remove bail from

handlebar by removing push nuts.

Check parts for wear or replacement.

1. Attachment Belt Idler

2. Attactment Drive Belt

3. Brake Shoe

Figure 2-4: Attachment Clutch Adjustment

2-6

Page 13

Handlebars and Clutch Controls

^ 2.4 Wheel Drive Clutch

On models with traction rod and rod adapter,

remove push nut, tapping screws and pin

hoiding handle pivot and wheei drive clutch

handle to handlebar. Remove handle pivot and

wheel drive clutch handle.

Remove set screw in rod adapter and remove

traction clutch rod.

On models with adjustment strap, remove

push nut and pin holding clutch lever to

handlebar and remove cable from clutch lever.

Remove hook rod from traction clutch arm and

adjustment strap.

Check parts for wear or replacement.

For assembly and adjustment procedure see

Wheel Drive Clutch Adjustment Section.

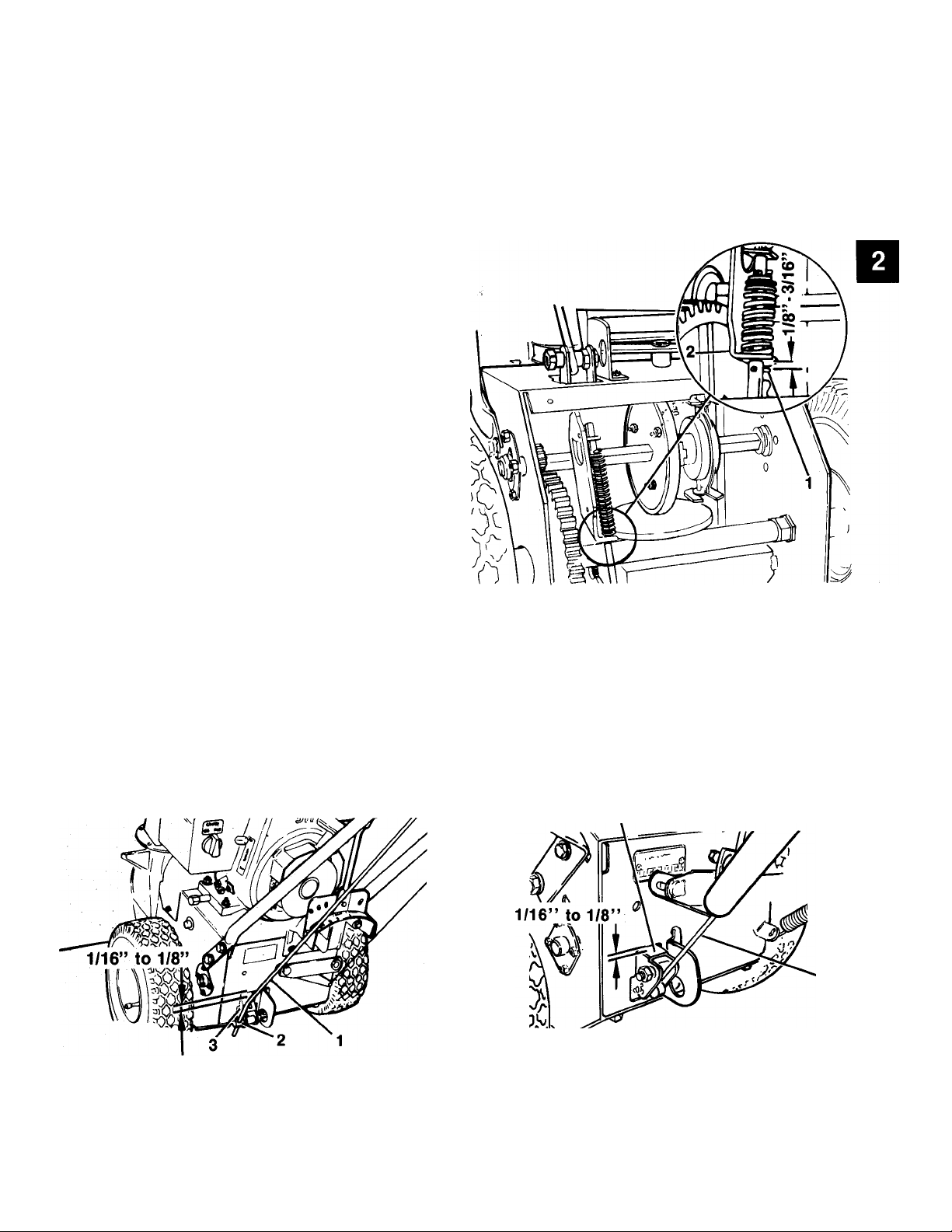

Check for proper adjustment by measuring

distance between roll pin and bracket on trac

tion rod. Distance must be 1/8 - 3/16” with

clutch engaged.

2.5 Wheel Drive Clutch Adjustment

Adjust wheel drive clutch to compensate for

wear of friction wheel when slippage occurs.

On models with rod adapter, adjust by loosen

ing set screw in rod adapter, pushing clutch

handle down on handle grip, and shifting

speed selector to third gear. Raise rod adapter

so top of bracket clears top of slot in frame by

1/16” to 1/8” and tighten set screw.

1.

Roll Pin

2.

Bracket

Figure 2-5: Wheel Drive Ciutch Adjustment

(inside Frame)

1. Traction Clutch Rod 1. Hook Rod

2. Rod Adapter 2. Bracket

3. Bracket

Figure 2-6: Wheel Drive Ciutch Adjustment

2-7

Page 14

Handlebars and Clutch Controls

Oh models with adjustment strap, adjust by

selecting and marking a hole in adjustment

strap that will provide a slight amount of slack

in cable. Unhook hook rod, place cable end

through hole selected above and while lifting

up on traction clutch arm connect hook arm to

traction clutch arm.

IMPORTANT: With Wheel drive clutch engag

ed, clutch bracket should be within 1/16” to

1/8” from top of slot in frame on adjustment

strap and rod adapter models.

Check parts for wear or replacement.

Assemble using reverse procedure.

2.7 Lower Handlebar

Remove hardware attaching lower handlebar

to each side of frame and remove lower

handlebar from'frame.

Check parts for wear or replacement.

Assemble using reverse procedure.

2.8 Handlebar Height Adjustment

CAUTION: On models with adjustable

A

handlebars, whenever handlebar

height is changed. Attachment and

Wheel Drive Clutches, as well as

Speed Selector on models with Speed

Selector on Handlebar Panel, must be

adjusted to insure proper operation of

machine.

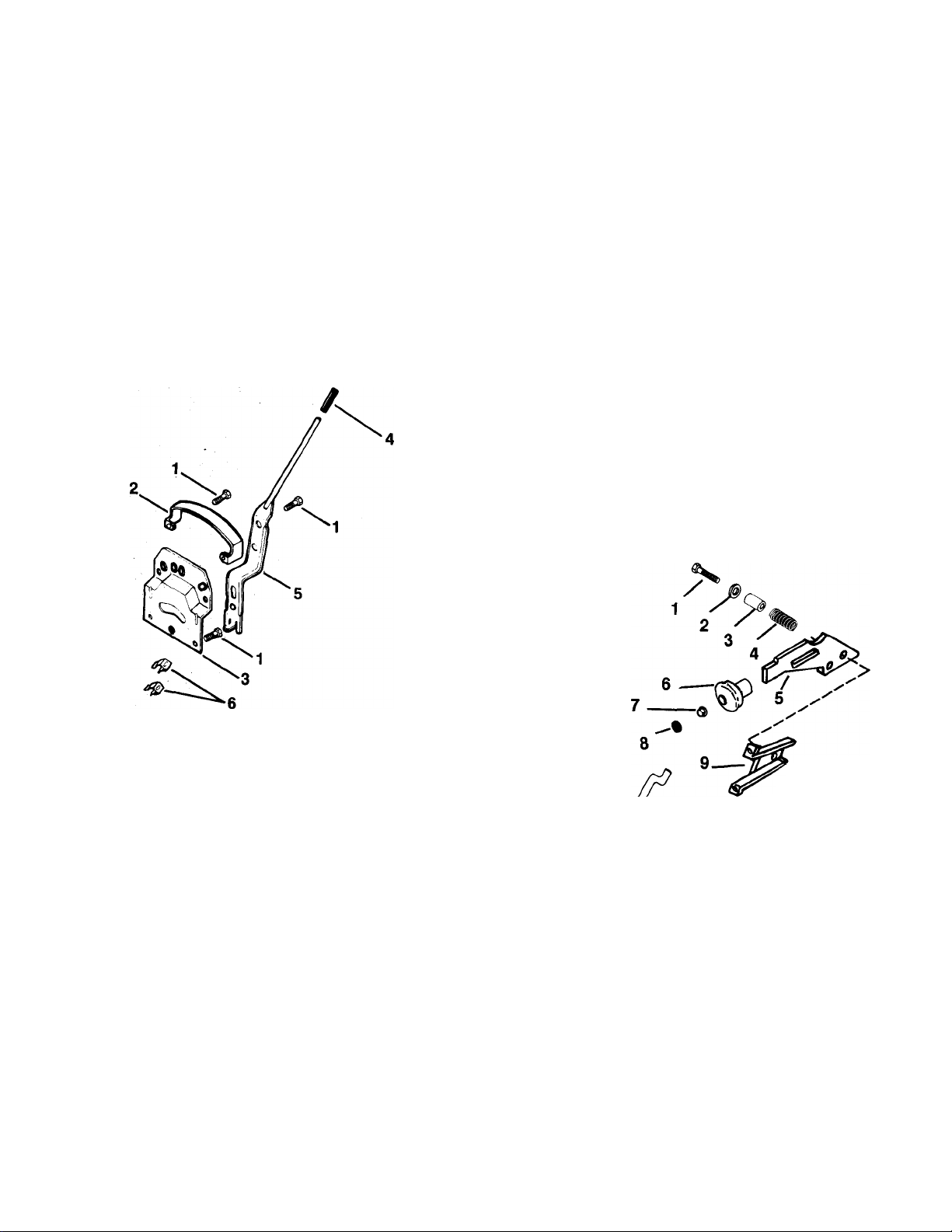

1. Cable End

2. Adjustment Strap

3. Hook Rod

4. Traction Clutch Arm

Figure 2-7: Wheel Clutch Adjustment

(Models with straps)

2.6 Handlebar and Key Switch

Disconnect wires to key switch (unplug cable

from motor on electric model).

Remove key switch nut and lock washer and

remove key switch from upper handlebar panel

or heater box.

Remove handlebar panel from handlebar by

removing machine screws or upper handlebar

and panel by removing carriage bolts.

On 2-I-2 models, separate lower and upper

handlebar by removing curved head bolt, ad

justing knob, lock washer and washer connect

ing upper and lower handlebar on each side.

On models with adjustable handlebars, the

standard Speed Selector rod that comes with

Sno-Thro allows for handlebar height adjust

ment for the average user (from low to about

mid height range). For those who wish to

operate unit with handlebar adjusted up to it’s

maximum height, a longer Speed Selector rod

(Part Number 032245) is available.

Lower handlebar mounting holes are slotted to

provide variable handlebar height. To adjust,

loosen handlebar mounting hardware, select a

safe comfortable operating height, and tighten

hardware. Torque to 150 inch pounds.

NOTE: A 63023 pyramid style lock washer is

recommended in place of the flat washer to

lock handlebar at a selected height especially

for hard usage.

On 2 -I- 2 Models with adjustable handlebars,

adjust by disconnecting clutch cable and

removing upper handlebar from lower

handlebar.

Remove hardware that attaches lower

handlebar to frame, turn lower handlebar over

(side to side), and secure with hardware just

removed. Secure upper handlebar to lower

handlebar and attachment clutch cable.

1

2-8

Page 15

Speed Selector and Wheels

Table of Contents

Page

3.2 Speed Selector Removal................................................................................... 3-2

3.2 Speed Selector Adjustment (Models with Speed Selector mounted to

handlebar panel)............................................................................................ 3-2

3.3 Wheel Assembly............................................................................................... 3-3

List of Illustrations

Page

3*1: Speed Selector and Wheels..............................................................................3-1

3-2: Speed Selector (Models with Speed Selector)

3-3: Speed Selector (Models with Speed Selector on handlebar panel).............3-2

3-4: Speed Selector Adjustment...............................................................................3-3

3-5: Speed Selector

3-6: Wheel...................................................................................................................3-3

.........

.........................................................................................3-3

............................................

3-2

Page 16

Speed Selector and Wheels

2

3

4

5

1. Speed Selector

2. Shift Retainer

3. Quadrant

4. Friction Wheel

Figure 3-1: Speed Selector and Wheels

5. Drive Plate

6. Shift Fork

7. Shift Rod

8. Handlebar Panel

3-1

Page 17

Speed Selector and Wheels

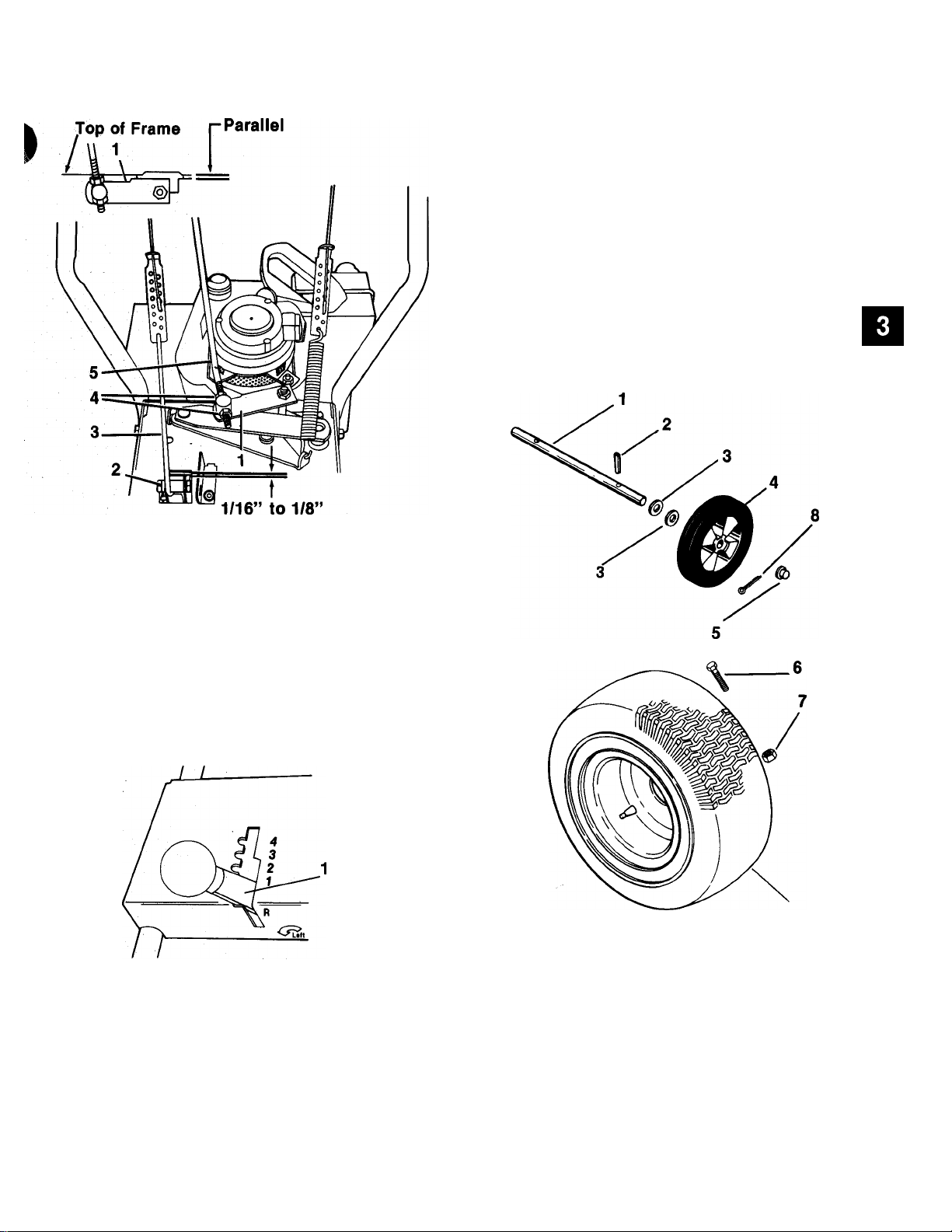

3.1 Speed Selector Removal

On models with lower speed selector, remove

two taptites securing shift handie retainer to

quadrant and remove retainer.

Remove taptite securing speed selector to

quadrant. Remove taptites securing quadrant

to frame and remove speed selector and

quadrant from frame.

Inspect parts for wear or replacement

assemble using reverse procedure.

and

3.2 Speed Selector Adjustment (Models with Speed Selector mounted to handlebar panel)

NOTE: Refer to Handlebars and Clutch Con

trols Section for handlebar height adjustment

procedure.

On models with adjustabie handlebars, after

adjusting handlebar height (from about mid to

low standard setting), loosen nuts on Speed

Selector rod at rod adapter enough to allow

Speed Selector to be positioned in first (1)

speed slot. Position Speed Selector arm

parallel with top of frame and tighten nuts to

lock rod in position.

To achieve maximum safe operating height of

handlebar utilizing standard rod, place Speed

Selector in first (1) speed, position lower nut to

end of rod (with threads fuliy engaged) and

lock rod in position with top nut. Raise

handlebar until Speed Selector arm is parallel

to top of frame and secure handlebar.

1. Taptite

2. Speed Selector Retainer

3. Quadrant

4. Grip

5. Speed Selector

6. Retainer and Nut

Figure 3-2: Speed Selector

(Models with lower speed selector)

On models with Speed Seiector on handlebar

panel, remove nut, bolt, washer, spring and

spacer attaching Speed Selector to handlebar

panel and remove Speed Selector. Remove

gear selector rod from Speed Selector.

Remove lower nut from bottom of Speed

Selector rod and remove rod from rod adapter.

Inspect parts for wear or replacement.

1. Cap Screw

2. Washer

3. Spacer

/\ii

12

13

^ 12

14

Figure 3-3: Speed Selector

(Models with Speed Selector on handlebar

panel)

3-2

4. Compression Spring

5. Speed Selector

6. Grip

7. Push Nut

8. Hole Plug

9. Shift Pivot

10. Lock Nut

11. Shift Rod

12. Lock Nut

13. Swivel

14. Cap

10

Page 18

Speed Selector and Wheels

3.3 Wheel Assembly

Remove cap or cap screw and lock nut secur

ing wheel onto axle and remove wheel from

axle.

Check parts for wear or replacement.

Assemble using reverse procedure.

1. Speed Selector Arm

2. Traction Clutch Arm

3. Hook Rod

4. Speed Selector Rod Nuts

5. Speed Selector Rod

Figure 3-4: Speed Selector Adjustment

1. First Speed Slot

1.

Axie

2.

Roii Pin

Washer

3.

4.

Wheei

5. Cap

6. Cap Screw

7. Lock Nut

8. Cotter Pin

Figure 3-5: Speed Selector

Figure 3-6: Wheei

3-3

Page 19

Belt Drive

Table of Contents

Page

4.1 Introduction....................................................................................................... 4-6

4.2 Attachment Drive Belt....................................................................................... 4-6

4.3 Traction Drive Belt.............................................................................................4-6

4.4 Attachment Clutch/lmpeller Brake....................................................................4-7

List of Illustrations

Page

4-1: Belt Drive System

4-2: Belt Drive Exploded View (Wheei Driven iViodeis)...........................................4-2

4-3: Beit Drive (Auger Driven Modeis)......................................................................4-4

4-4: Drive Beit (Auger Propeiied Modeis)

4-5: Drive Belts (Wheel Drive Modeis)......................................................................4-6

............

...................................................................................4-1

.................................................................

4-6

Page 20

Belt Drive

Wheel Driven Models

1. Attachment Drive Pulley

2. Attachment Belt

3. Attachment Idler

4. Attachment Pulley

Figure 4-1: Belt Drive System

5. Traction Drive Pulley

6. Idler Arm

7. Traction Drive Pulley

8. Traction Idler

4-1

Page 21

Belt Drive

Figure 4-2: Belt Drive (Wheel Driven Models)

4-2

Page 22

Belt Drive

ITiM

NO.

I

H Belt Cover

2 Taptite, 1/4-20 X 3/8

3

4

5

6

7 V-Belt (Attachment Drive)

8

9

10

11 Woodruff Key, 1/8 X 5/8

12 Camshaft Pulley

13

14

15

16 Roll Pin; 5/32 X 7/8

17 Washer, 1/2

18

19

20

DESCRIPTiON

Belt Finger

Washer, 5/16

Lock Washer, 5/16

Cap Screw, 5/16-24 X 3/4

Straight Key, 3/16 X 3/16 X 1”

Engine Pulley

Set Screw, 5/16-18 X 3/8

V-Belt (Traction Drive)

Lock Washer, 5/16

Extension Spring

Flanged Bushing

Cover

Lever

ITEM

NO. DESCRIPTION

21 Clutch Lever

22

23

24

25

26

27

28

29 Spacer Bushing

30 Lock Nut, 5/16-18

31

32 Idler

33

34 Idler Arm

35

36

37

38

39

40 Engine

Lock Nut, 5/16-18

Hub

Pulley

Flange Whiziock Nut, 5/16-18

Extension Spring

Cap Screw, 5/16-18 X 5/8

Washer, 5/16

Washer, 5/16

Shoulder Spacer

Carriage Bolt, 5/16-18 X 1-1/4

Oval Rivet

Brake Lining

Brake Clutch Arm W/Lining

Torsion Spring

I

V

4-3

Page 23

Belt Drive

Figure 4>3: Belt Drive (Auger Driven Models)

4-4

Page 24

Belt Drive

i

ITEM

NO. DESCRIPTION

1

2

3

4

5

6

7

■ 8

9

10

11 :

12

13

14

15

Belt Cover

Taptite, 1/4-20 X 3/8

Taptite, 3/8-16 X 1

, Engine/Motor

Push Nut

Washer, .526/.546 x 1.062 x .095

Frame

Center Lock Nut, 1/4-20

Arm

Flange Bushing

Cap Screw, 1/4-20 x 5/8

Oval Rivet

Brake Lining

Washer, .370/,390 x .875 x .083

Two Way Lock Nut, 5/16-18 x 1-3/8

ITEM

NO.

16

17

18

19 Clutch Arm w/Lining

20

21

22

23

24

25

26 V-Belt

27

28 Belt Finger

29 Cap Screw, 5/16-24 x 3/4

30

DESCRIPTION

Carriage Bolt, 5/16-18 x 1-3/8

idler

Bearing Spacer

Torsion Spring

Spacer

Extension Spring

Straight Key, 3/16 X 1 X 3/16

Motor/Engine Pulley

Set Screw, 5/16-18 x 3/8

Lock Washer, 5/16 ID

Washer, .328 x .875 x 7 GA.

4-5

Page 25

Belt Drive

4.1 Introduction

WARNING: Remove wire from spark plug

A

When unit is tipped onto housing, remove

enough fuel so that no spillage will occur,

block securely and remove bottom cover.

A

NOTE: Auger/Impeller Housing and frame must

be tipped apart to perform repairs in this sec

tion. Refer to Auger/Impeller Section of this

manual.

A

before attempting any repair or adjust

ment procedures.

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

CAUTION: After new belts have been

installed, Clutches must be adjusted

per instructions in Handiebars and

Ciutch Controls Section to insure pro

per function.

4.2 Attachment Drive Belt

Remove attachment drive belt from pulley

(hold brake away from belt).

Place attachment drive belt on auger/impeller

pulley, and while holding brake out of way, tip

unit together. Assemble unit in reverse order.

NOTE: Make sure pulleys align. If alignment is

necessary, loosen attachment pulley set

screws, reposition pulley and tighten set

screws.

WARNING: When clutch is engaged, im

peller brake disengages. If brake is not

1/16 to 1/8” from belt when disengaged,

A

refer to Attachment Clutch/Impeller

Brake Section.

4.3 Traction Drive Beit

Pull idler away from belt and remove belt from

idler pulley, engine and drive pulley (it may be

necessary to turn engine pulley using rewind

starter).

NOTE: To gain clearance, engage traction

clutch and pull back attachment idler arm

clevis pin.

Replace traction drive belt in reverse order

making sure pulleys align. If alignment is

necessary, loosen engine pulley set screws,

reposition pulley and tighten set screws.

Check alignment of attachment drive pulley

and align according to above instructions if

necessary.

I

1

1. Engine Puiiey

2. Attachment Puiiey

3. Attachment Drive Beit

4. Attachment Brake

Figure 4-4: Drive Beit (Auger PropeNed Modeis)

1. Attachment Brake

2. Attachment Pulley

3. Attachment Drive Belt

4. Attachment Idler

Figure 4-5: Drive Belts (Wheel Driven Models)

4-6

Engine Attachment

Pulley

Engine Drive Pulley

Drive Belt

Traction Idler

1

Page 26

Belt Drive

4.4 Attachment Clutch/Impeller Brake

WARNING: With improper use, injury

A

Figure 6-4: Attachment Clutch and Impeller

may result if attachment clutch lever is

released and brake DOES NOT STOP

auger/impeller within 5 seconds.

1. Spring Extension

2. Brake Shoe

3. Attachment Drive Beit

Brake

To check and/or adjust impeller brake, tip unit

forward onto auger/impeller housing. Remove

bottom cover by removing rear and loosening

front cap screws.

Measure distance between impeller brake

shoe and belt with attachment clutch engaged.

When attachment clutch is disengaged, brake

must contact belt.

If impeller brake shoe is not 1/16 to 1/8 inch

from belt, disengage clutch (release bail),

loosen attachment idler nut, reposition idler to

compensate for belt length, and tighten nut.

Adjust attachment clutch cable with clutch

disengaged. Pull clutch chain taught and con

nect chain link to spring. Spring should extend

approximately 3/8” with clutch engaged. With

ciutch disengaged, clutch arm should fall to its

maximum down position.

V"‘

4-7

Page 27

Friction Wheel Drive

Table of Contents

Page

5.1 Introduction........................................................................................................5-4

5.2 Friction Wheei Removal

5.3 Drive Plate Removal...........................................................................................5-4

5.4 Clutch Fork Removal.........................................................................................5-4

5.5 Friction Wheel Drive..........................................................................................5-6

....................................................................................

5-4

List of Illustrations

Page

5-1: Friction Wheei System.......................................................................................5-1

5-2: Friction Wheei Expioded View...........................................................................5-2

5-3: Friction Wheei.....................................................................................................5*4

5-4: Reduction Drive System

5'5: Reduction Drive (Expioded View)......................................................................5-6

....................................................................................

5-5

Page 28

Friction Wheei Drive

.4

-5

1. Hex Shaft

2. Bearing Flange

3. Shift Fork

4. Friction Wheel

5. Drive Plate

6. Clutch Fork

7. Drive Pulley

Figure 5-1: Friction Wheel System

8. Drive Belt

9. Idler Arm

10. Spring

11. Axle Shaft

12. Gear

13. Pinion Gear

14. Traction Clutch Assembly

5-1

Page 29

Friction Wheel Drive

Figure 5-2: Friction Wheei

5-2

Page 30

Friction Wheel Drive

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12 Friction Wheel Hub

13

14

15

16

17

18

19

20

21

OESCRIPTION

Compression Spring 22

Shifting Fork 23

Flanged Bushing

Washer, 1/2

Cap Screw, 5/16-18 x 1-1/2

Washer, 5/16

Lock Nut, #10-24 28

Bushing Flange 29

Bearing Flange

Washer, 1/2 31

Lock Nut, 1/4-20

Friction Wheel

Cap Screw, 1/4-20 X 1/2

Roll Pin, 1/8 X 7/8

Pinion -

Carriage Bolt, #10-24 x 3/8

Snap Ring, External

Cap Screw, 1/4-20 x 1-3/4

Clevis Pin

Cotter Pin, 3/32 X 3/4

ITEM

NO.

24 Hairpin, 3/32 X 1-3/16

25

26

27

30

32

33

34 Woodruff Key, 3/16 x 3/4

35 Washer, 5/8

36

37

38

39

40

41 Hex Shaft

42 Spacer

DESCRIPTION

Cap Screw, 5/16-18 x 3/4

Traction Clutch Assembly

Clutch Fork

Set Screw, 5/16-18 x 3/8

Rod Adapter

Lock Nut, 5/16-18

Bracket

Cotter Pin, 1/8 X 1”

Cap

Spacer

Extension Spring

Flange Bushing, Long

Drive Plate

Hex Shaft

Lock Nut, 3/8-16

Flange Bushing

-n

5-3

Page 31

Friction Wheei Drive

5.1 Introduction

WARNING: Remove wire from spark plug

A

When unit is tipped onto housing, remove

enough fuel so that no spillage will occur,

block securely and remove bottom cover.

A

before attempting any repair or adjust

ment procedures.

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

Remove three cap screws securing friction

wheel to hub and remove friction wheel.

Secure new friction wheel onto hub with three

cap screws and torque cap screws to 8-10 foot

pounds.

Assemble using reverse procedure.

NOTE: Position friction wheel hub in forks. Be

sure washers are in place on bearing flange

pins. Slide hex shaft to left and into left bear

ing with flat washers in position. Pinion gear

must mesh with large gear.

5.3 Drive Plate Removal

Remove auger/impeller housing and bottom

cover according to instructions in Auger/-

Impeller Section.

Remove attachment drive belt according to in

structions in Belt Drive Section and remove ex

tension springs from idlers.

1. Friction Wheel

2. Cap Screw

3. Bearing Flange Screws

4. Clutch Fork

5. Extension Spring

6. Frame

Figure 5-3: Friction Wheel

5.2 Friction Wheel Removal

Tip unit onto housing and remove bottom

cover by removing four Cap screws.

Remove bearing flange screws on right hand

side of frame and remove bearing flange.

Remove hairpin cotter from traction clutch rod,

pull rod from clutch fork arm and tip up and out

of way.

Slide friction wheel assembly and hex shaft to

right until left end of hex shaft comes free of

left bearing. Slip assembly back to left and pull

forward out of frame.

Remove drive plate return spring and bearing

flange from frame opposite axle gear, and

remove friction wheel.

Remove set screws from attachment pulley

hub and remove attachment pulley and hub.

Remove drive plate assembly, and remove fric

tion plate and bearing flange from assembly by

removing snap ring.

NOTE: Apply Loctite Anti-Sieze to hex end of

shaft before placing friction plate back onto

assembly.

Assemble using reverse procedure.

5.4 Clutch Fork Removal

Remove friction wheel assembly according to

instructions in Friction Wheel Removal Sec

tion and remove axle.

Remove cap from outside of frame and cotter

pin from clutch fork rod. Remove clutch fork.

Inspect parts for wear or replacement and

assemble using reverse procedure.

5-4

Page 32

Friction Wheel Drive

ITEM

NO. DESCRIPTION

1

2

3

4

5

6 Bushing Flange

7

Roll Pin, 1/8 X 7/8

Hex Shaft

Pinion 10

Washer, 1/2 11

Flanged Bushing

Carriage Bolt, #10-24 x 3/8

Figure 5-5: Reduction Drive (Expioded View)

5.5 Friction Wheei Drive

Remove friction drive assembly according to

instructions in Friction Drive Section.

Remove cap screw and lock nut securing

reduction gear to axle shaft and remove axle

ITEM

N0.

8

9

12

13

DESCRIPTION

Lock Nut, 1/4-20

Gear

Cap Screw

Axle Shaft

Flanged Bushing

Lock Nut, #10-24

and gear from frame.

Inspect parts for wear or replacement.

Assemble using reverse procedure.

5-5

Page 33

Auger/Impeller - Discharge Chute

Table of Contents

Page

6.1 Introduction.............................................................................................................6-5

6.2 Auger/Impeller Housing.........................................................................................6-5

6.3 Auger/impeiler Removal.........................................................................................6-5

6.4 Attachment Clutch/Impeller Brake........................................................................6-5

6.5 Scraper Blade..........................................................................................................6-6

6.6 Auger Rubber..........................................................................................................6-6

6.6 Shear Bolt Replacement........................................................................................ 6-7

6.8 Runners...................................................................................................................6-7

6.9 Discharge Chute Removai.....................................................................................6-7

6.10 Discharge Chute Adjustment (Models without crank)

6.11 Chute Crank Adjustment (Models with crank mounted to ieft

handlebar)...........................................................................................................6-9

6.12 Chute Crank Adjustment (Models with crank through handiebar

panel)...................................................................................................................6-9

....................................

List of Illustrations

6-1

6-2

6-3

6-4

6-5

6-6

Auger/Impeller System....................................................................................6-1

Discharge Chute Exploded View

Auger/impeiler Housing...................................................................................6-4

Attachment Clutch and Impeller Brake

Shear Bolts and Scraper Blade.......................................................................6-6

Auger Rubber Replacement............................................................................6-6

....................................................................

..........................................................

6-8

Page

6-2

6-5

6-7

6-8

6-9

6-10: Discharge Chute (Modeis with crank mounted to left handlebar)

6-11: Discharge Chute Adjustment (Models with crank mounted to left

Runners.............................................................................................................6-7

Discharge Chute (Modeis with crank through handiebar panei)

Discharge Chute Gears...................................................................................6-8

handlebar.................................................................................................................6-9

................

................

6-8

6-8

Page 34

Auger/Impeller-Discharge Chute

8 9 10 1

1. Crank Rod (Handle)

2. Impeller

3. Gear Case

4. Scraper Blade

5. Runner

6. Auger/Impeller Housing

7. Auger

8. Discharge Chute

Figure 6-1: Auger/impelier System

6-1

9. Worm Gear

10. Worm Cievis

11. Chute Deflector

12. Gear Cover

Page 35

Auger/Impeller - Discharge Chute

%\

w

Figure 6-2: Discharge Chute (Expioded View)

6-2

Page 36

Auger/lmpeller - Discharge Chute

I

ITEM

KO.

1

1

3

4

5 Gear Bracket

6

7

8

9

10

11

12

13

14

15

16

17

18

19 Washer, 5/16

20

21

22

23

24 Cap Screw, 5/16-18 X 1/2

25

26

27 Machine Screw, 1/4-20 X 3/4

28 Lock Nut, 1/4-20

29

30 , Grip

DESCRIPTION

Taptite, 1/4-20 X 3/8

Gear Cover

Push Nut

Taptite, 1/4-20 X 3/8

Washer or Bushing 36 Carriage Bolt, 1/4-20 X 1-1/4

Hair Pin

Chute Pinion Gear

Cap Screw, 1/4-20 X 1-1/2

Lock Washer, 1/4

Washer, .312/.343 X .875 X .062

Cap Screw, 5/16-18 X 5/8

Chute Strap

Spacer

Washer, .312/.343 X .875 X .062

Lock Washer, 5/16 ID

Cap Screw, 5/16-24 X 3/4

Lock Nut, 5/16-18

Wave Washer

Plastic Washer

Deflector

Carriage Bolt, 5/16-18 X 3/4

Discharge Chute

Tapping Screw, 8-32 X 3/8

Chute Control Bracket

ITEM

NO. DESCRIPTION

31

32

33

34 Roll Pin, 1/8 X 3/4

35 Worm Gear

37

38

39 Lock Washer 3/8

40 Nut, 5/16-18

42

43 Chute Control Strap

44 Flange Whiziock Nut, 1/4-20

45

46 Hex Nut, 1/4-20

47

48

49 Compression Spring

50

51

52

53 Chute Gear

54

55

56

57 Nut, 1/4-20

58 Chute Handle

59 Carriage Bolt, 3/8-16 X 2

60

61

Cap

Carriage Bolt, 1/4-20 X 1-1/4

Chute Control Crank

Worm Clevis

Lock Washer, 5/16

Carriage Bolt, 1/4-20 X 5/8

Washer, 1/4

Lock Nut, 3/8-16

Washer, 3/8

Friction Plate

Friction Washer

Gear Strap

Carriage Bolt, 3/8-16 X 2-1/4

Washer, 1/4

Lock Washer, 1/4

Lock Washer, 5/16

Lock Nut, 5/16-18

6-3

Page 37

Auger/Impeller • Discharge Chute

ITEM

NO.

1

2

3

4

5

6

7 Cap Screw, 5/16-18 x 5/8

8

9

10 Lock Nut, 3/8-16

11

12

13

14

16

DESCRIPTION

Auger/Impeller Housing

Flange Whiziock Screw, 5/16-18 x 1/2

Washer, 3/4

Bearing Flange w/BushIng

Flange Whiziock Nut, 1/4-20 21

Lock Washer, 5/16

Washer, 5/16

Flange Bushing

Washer, 3/8

Runner

Rib Neck Bolt, 1/4-20 x 1/2

Carriage Bolt, 3/8-16 x 3/4

Flange Whiziock Nut, 1/4-20

Center Lock Nut, 1/4-20

Figure 6-3: Auger/Impeller Housing (Exploded View)

ITEM

N0.

17

18

19

20

22

23

24 Auger

25

26

27 Carriage Bolt

28

29 Hub

30 Flange Whiziock Nut, 5/16-18

31 Pulley

32 Set Screw

6-4

DESCRIPTION

Scraper Blade and Scraper Support

Lock Nut # 10-24

Auger Rubber w/Hardware

Machine Screw, #10-24 x 5/8

Washer, 3/16

Spin Drive Zerk Fitting

Washer, 17/64

Center Lock Nut, 1/4-20

Shear Bolt

Rib Neck Bolt, 5/16-18 x 3/4

Page 38

Auger/Impeller - Discharge Chute

6.1 Introduction

WARNING: Stop engine, remove key,

A

When unit is tipped onto housing, remove

enough fuel so that no spillage will occur,

block securely and remove bottom cover.

A

wait for moving parts to stop and remove

wire from spark plug before leaving

operator’s position and attempting to

maintain or inspect auger.

WARNING: Remove wire from spark plug

before attempting any repair or adjust

ment procedures.

WARNING: Gasoline is highiy flammabie

and its vapors are explosive. Handie with

care.

6.2 Auger/Impeller Housing

Remove pulley from auger/impeller assembly

and pull gear case and auger/impeller

assembly free of housing.

Remove shear bolts and remove augers from

shaft.

Check parts for wear or replacement.

Assemble using reverse procedure.

NOTE: Make sure pulleys align. If alignment is

necessary, loosen attachment pulley set

screws, reposition pulleys and tighten set

screws.

6.4 Attachment Clutch/Impeller Brake

WARNING: With improper use, injury

A

may result if attachment clutch lever is

released and brake DOES NOT STOP

auger/impeller within 5 seconds.

Remove nut and lockwashers holding worm

clevis to housing and position crank out of

way.

On auger propelled models, remove nut secur

ing chute bracket to engine/motor, and remove

chute.

On models with flat gear, remove hardware

securing chute bracket to engine and remove

hair pin securing chute rod to pinion gear.

Remove chute rod and lift discharge chute off

augeryimpeller housing.

Remove two screws securing belt guard to

tractor arid remove belt guard.

Remove top screws and loosen lower screws

that secure impeller housing to frame on each

side and tip tractor and impeller housing apart.

Assemble using reverse procedure.

6.3 Auger/Impeller Removal

Remove (3) nuts holding bearing flange to

housing on each side, remove cap screw,

lockwasher and washer on each side holding

auger shaft, and remove bearing flange with

bushing.

1. Spring Extension - 3/8”

2. Brake Shoe

3. Attachment Drive Belt

Figure 6-4: Attachment Clutch and Impeller

Brake

To check and/or adjust impeller brake, tip unit

forward onto auger/impeller housing. Remove

bottom cover by removing rear and loosening

front cap screws.

Measure distance between impeller brake

shoe and belt with attachment clutch engaged.

When attachment clutch is disengaged, brake

must contact belt.

If impeller brake shoe is not 1/16 to 1/8 inch

from belt, disengage clutch (release bail),

loosen attachment idler nut, reposition idler to

compensate for belt length, and tighten nut.

6-5

Page 39

Auger/Impeller - Discharge Chute

Adjust attachment clutch cable with clutch

disengaged. Pull clutch chain taught and con

nect chain link to spring. Spring should extend

approximately 3/8” with clutch engaged. With

clutch disengaged, clutch arm should fall to its

maximum down position.

6.5 Scraper Blade

IMPORTANT: If blade wears too far, auger/im-

peller housing may be damaged.

Scraper blade on models with runners is ad

justable to compensate for wear.

To adjust scraper blade, tip unit back onto

handlebar, support housing, and loosen nuts

retaining blade. With runners adjusted to their

full up position, reposition scraper blade down,

flush with runners, and tighten lock nuts.

6.6 Auger Rubber

On 2 -I- 2 models, the rubber edges on auger

will wear and require replacement after a

period of use. Two replacement kits are

available.

The first procedure replaces both the right and

left augers requiring the removal of the augers

and impeller from the auger/impeller housing.

Then removing augers from auger shafts, plac

ing new augers onto auger shafts and reas

sembling unit.

3 1

Shear Bolt

Scraper Blade

Auger

Figure 6-5: Shear Bolts and Scraper Blade

On 2 + 2 models, scraper blade is adjustable

to compensate for wear and to control traction.

Best operation occurs if scraper blade edge

leaves a fine dusting of snow with auger tracks

(auger propels unit). Adjust scraper blade

equally its full length if machine does not

scrape cleanly or if machine does not drive for

ward properly.

To adjust scraper blade, tip unit back and rest

unit on handlebar. Loosen nuts on carriage

bolts along scraper support. If unit does not

scrape cleanly, move scraper blade forward. If

unit does not drive forward and scraper blade

drags, move scraper blade to the rear.

I

1. Drill {Va” or larger)

2. Auger

3. Rubber Edge

4. Access Hole

Figure 6-6: Auger Rubber Replacement

The second procedure replaces the rubber

edges and requires the drilling off of rivets

holding old rubber edge to segment by means

of a 1/4” diameter or larger drill bit. (An access

hole is provided on sides of auger/impeller

housing for access to outer rivets.) Then posi

tioning new rubber edge on segment and se

curing with bolts, flat washers and lock nuts.

NOTE: Be sure scraper support is fully engaged

in groove of scraper blade. Tighten hardware

and test unit. Repeat adjustment as required

until proper operation is obtained.

NOTE: After repiacement of auger rubber

edges, adjust scraper biade per instruction in

Adjustments Section.

6-6

Page 40

Auger/Impeller - Discharge Chute

6.7 Shear Bolt Replacement

IMPORTANT: Use only Ariens Shear Bolts for

replacement. Use of any other type of shear

bolt may result In severe damage to unit.

Occasionally an object may enter auger/

impeller housing and jam auger, breaking

shear bolts which secure auger to shaft. This

allows auger to turn freely on shaft, preventing

damage to gear drive.

To replace shear bolt, slide auger outward and

align hole in shaft with hole in auger (holes in

shaft for shear bolts line up). Drive new shear

bolt through hole (if old shear bolt was broken,

this will drive remaining part from shaft), and

secure with nut.

6.8 Runners

CAUTION: Adjust auger/impeller hous

ing height to clear gravel or crushed

A

rock surfaces.

Position Sno-Thro on a flat, level surface. Ad

just runners by inserting a spacer of desired

thickness under center of scraper blade,

loosen hardware, slide runners to flat surface

and tighten hardware.

Note: Above method keeps housing level by ad

justing runners equally. Uneven runners make

machine difficult to steer and result in uneven

clearing.

6.9 Discharge Chute Removal

On models with discharge chute crank rod

going through handlebar panel, remove hair

pin from discharge chute crank rod and slide

rod out through handlebar panel. Remove hard

ware attaching bracket to engine/motor and lift

discharge chute off auger/impeller housing.

Remove gear cover by removing two taptites

on cover.

Remove flat gear by removing nut securing car

riage bolt to center of flat gear.

Runners should be adjusted as conditions re

quire. Raising or lowering runners controls

distance scraper blade is held above surface

being cleared. When operating machine on

gravel surface, lower runners so that housing

will not pick up gravel. On concrete, blacktop,

or packed down snow surfaces, raise runners

so scraper blade scrapes clean. To reduce

tendency of housing to ride up over heavy, wet,

or hard-packed snow, remove runners and in

stall with narrow edge down.

1. Runner

2. Adjusting Hardware

3. Auger Housing

Figure 6-7: Runners

Remove pinion gear by removing push nut that

secures pinion gear to gear bracket and slide

pinion gear out of gear bracket.

1. Hair Pin

2. Mounting Hardware

3. Discharge Chute Crank Rod

4. Brace

5. Gear Cover

6. Spacer

7. Taptites

Figure 6-8: Discharge Chute (Models with

crank through handlebar panel)

6-7

Page 41

Auger/Impeller - Discharge Chute

On models with discharge chute crank rod

mounted to left handlebar, remove nut and

bolt securing worm clevis to bracket. Remove

bolt securing crank clamp to handlebar,

remove retainer clips at bottom of discharge

chute, and remove discharge chute from

auger/impeller housing.

Inspect parts for wear or replacement and

assemble in reverse order (apply oil to

discharge base). Adjust according to instruc

tions in Chute Crank Adjustment Section.

1. Taptite

2. Gear Cover

Discharge Chute Crank Rod

3.

Push Nut

4.

Gear Bracket

5.

Washer

6.

7. Plastic Bushing

Figure 6-9: Discharge Chute Gears

NOTE: When installing pinion gear with 5/8”

diameter hub, do not use plastic bushing.

To assemble, position discharge chute over

opening on auger/impeller housing and secure

by fastening brace to engine with mounting

hardware (spacer goes under brace at front,

washers and lock washers go under head of

cap screws on top of brace).

Place discharge chute crank rod through grom

met in handlebar panel and into gear on

discharge chute. (Rod has two holes. Select

hole that provides best operator comfort and

secure with hair pin.)

To adjust tension, tighten nut that secures flat

gear flush with end of bolt, then tighten or

loosen the nut to set the desired tension.

To adjust amount of friction between flat gear

and pinion gear, loosen bolt that secures chute

control strap to discharge chute, adjust chute

control strap up or down (hole in chute control

strap is slotted) and tighten bolt.

11. Carriage Bolt

12. Hair Pin

1. Discharge Chute

2. Mounting Clips

Figure 6-10: Discharge Chute (Models with

crank mounted to left handelbar)

On models without cranks, remove mounting

clips from discharge chute by removing bolts

securing mounting clips to auger/impeller

housing and remove discharge chute.

On 2 -f 2 models, remove capscrews securing

bracket to engine/motor and lift chute off

auger/impeller housing.

Inspect parts for wear or replacement.

Assemble using reverse procedure.

6.10 Discharge Chute Adjustment

(Models without crank)

Position discharge chute over opening on

auger/impeller housing and secure chute

handle to bracket. Tighten nut until it is flush

with end of bolt.

Swivel discharge chute from side to side to

see that it moves freely.

If discharge chute is not seated with proper

tension on bracket, loosen cap screws secur

ing bracket to engine/motor, adjust bracket to

desired tension and tighten cap screws.

«

6-8

Page 42

Auger/Impeller - Discharge Chute

6.11 Chute Crank Adjustment

(Models with crank mounted to

I

left handlebar)

Loosen nut securing worm clevig to bracket.

Position worm gear with siight ciearance be

tween worm gear and discharge chute gear

teeth, and tighten nut on bracket.

Lubricate discharge chute gear teeth and

lower base of discharge chute with oil and

move chute from side to side to see that it

moves freely.

6.12 Chute Crank Adjustment

(Models with crank through

handlebar panel)

The two brackets that attach flat gear to

discharge chute are slotted for adjustment.

Adjust so that pinion gear and flat gear mesh

together smoothly and tighten hardware.

1. Discharge Chute Gear Teeth

2. Worm Clevis

3. Nut

4. Discharge Chute

5. Worm Gear

Figure 6-11: Discharge Chute Adjustment

(Models with crank mounted to left

handlebar)

6-9

Page 43

Table of Oontenti^,^

m

' v^чÄ-»i*^Ш>ílìïáí^ " ' ï 'iS

im AMwmbiy

:/ 7;:'

7 “ .4 ■ '

/ ,4

Л

I ,'í':rv‘ »tiifl

i i

/

H

i. %.vw-

'•/4^

^4'',’-.

..........

? i . - ^

............

1*,^

^...V

.........................................

'î . . • . . l . A • • .....

7-3

...................

' '

X ■ . , . , ,4 ,

is7*'r'"' ':вт:ч: lev í" '\/í '

?-,-7

!S ;

.■; ì

,7 :

si ' ■'

:í у ^ . .

А ;■',;

' '

v.,4'

/lg¡* itti ,’*.■■•■' ■■

■'■ '--П îl \

/

.'AfA :Л7Г1 '

.'k'v Í yVf i.«:

у 'J :. 'yiÿ'ki

,, W'. .;¥■'!, A,,

/' ^ ■

./V r ■ ... ;. y A. : ^

,-7í7

■■/ -

V '‘'..i

^ '’- \ '■ ■ ' ';’'

4

“-Ч ‘‘'

" ' Г.. ’ 7лршт ШЁт^шштт

■■ ' ‘ * r-j шпе гэн, -

' V5'¥

Vi

€ . ^<

A

> ’ ‘ '^

P. i- A-

mm,

. C '

i-r-v.,« ■*'A ‘

■:. 7s'

í 7i"> .“J.'". .‘ i. S 77.v-r;

"1 ■..•-•

¥<Ï7- À'tri ‘K77.7fdr.í.№7, \fv; 'V7'‘V ^4:,: rjl,:':. ^v;;1fi ^

7 ' »saO tfmB :77'

',4i

'7 •

-------

4 7^

Ч

..A.

..............................

''■ Ч

■' •''Г. \ ’

s’*

'',\í

-

r'

Ж-^фт^-

^ v4- •

'■i'»

'V 4‘'"i'-4-

«-Л. '7'V

{■7,

;■■ . ■ ■ ■ 1 ■ ■ ■ ' .' .

in 4 Г4-П;-у

'■

-

4U -' í ' A '

%) ^

■’ 4 'vji

V ‘ ' ,,' l'v. V >;nS!

íl'V •; V, sv uí"'il ijvvnvÄA; v77

77 :;••?¥;■ V vjn 7 I, ¡'A> m.:.

fvvvy H'. 75tCÍ Sí7l7 лЬ^ШлГ

, ■-

- \Jr:^

7‘ ?

a' 'í/***

rá.

A-i

' I -

■ , ’'í'4í>

y

r' y

ft г

4 , t II

m ^

'..

Л=,

"•

I!'

4.v«S..v7, ,,

Па,.;

■ M

Page 44

Gear Case

Figure 7-1: Gear Case

7-2

Page 45

Gear Case

ITEM

N0.

t

1

2

3 0-Ring 3/4 I.D.

4 Roll Pin 1/4 X 1-1/4

5

6 Radial Bearing 3/4 ID X 1-3/4 OD

7 Center Lock Nut 1/4-20

8

9 Set Screw 5/16-18 X 3/8 (932015)

10 Pulley 1-1/4 X 7

11

12

13 Woodruff Key 3/16 X 7/8 X 3/8

14

15

16 Thrust Collar

17 L.H. Gear Case Half 34

7.1 Introduction

ITEM

DESCRIPTION

Groove Pin 3/16 X 1-1/4

Flanged Bushing 3/4 X 1” X 3/4

Bearing Flange 22

Rib Neck Bolt 5/16-18 X 3/4

Flange Whiziock Nut 5/16-18

Hub

Bearing Flange 31

Impeller 32

N0.

DESCRIPTION

18

19

20

21

23

24

25

26

27

28

29

30

33

Impeller Shaft and Worm Gear Set

Carriage Bolt 1/4-20 X 1-1/4

Seal 3/4 I.D.

Washer .805/.842 X 1.469 X .134

Flange Whiziock Nut 1/4-20

Flanged Bushing 1/2 X 3/4 X 3/4

Taptite 3/8-16 X 1/2

Carriage Bolt 1/4-20 X 7/8

Taptite #10-24 X 3/4

Washer .750/.760 X 1.400 X .062

Woodruff Key 3/16 X 5/8 X 1/4

Gasket

R.H. Gear Case Half

Auger Shaft

Gear Case Assembly

8 Cz. Tube Ariens Liquid Grease

Grease Fill

Remove impeller shaft from gearcase and slide

front flanged bushing off front of impeller

shaft.

WARNING: Remove wire from spark plug

before attempting any repair or adjust

ment procedures.

When unit is tipped onto housing, remove

enough fuel so that no spillage will occur,

block securely and remove bottom cover.

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

A

care.

Remove Auger/Impeller and gearcase from

housing according to instructions in

Auger/Impeller Section to perform the follow

ing procedures.

7.2 Gear Case

Remove six (6) bolts holding right and left gear-

case halves together and remove halves from

rake shaft.

Remove seals from outsides of gearcase

halves with screwdriver, and remove bushings

from outside in with bearing driver.

Slide 0-Ring and rear flanged bushing off rear

of impeller shaft.

Drive groove pin out of thrust collar and

remove thrust collar from rear of impeller shaft

(drive pin in direction of least resistance).

Remove washers located on each side of

bronze gear. Slide bronze gear off rake shaft

and remove woodruff key from rake shaft.

Inspect all parts and replace if necessary.

Place all parts back on impeller shaft and rake

shaft in reverse order.

Insert assembled rake shaft into left gearcase

half and fill gearcase with 2 oz. of Ariens Liquid

Grease, Part No. 000072.

Insert assembled impeller shaft into left gearcase half, making sure flanged bushings are

seated correctly.

Replace gearcase gasket and slide right gearcase half onto rake shaft. Turn input shaft

clockwise until gearcase halves fit snugly

together. Secure with six (6) bolts.

When properly assembled, input shaft should

turn freely.

7-3

Page 46

Engine and Headlight

Table of Contents

Page

8.1 Introduction....................................................................................................... 8-3

8.2 Engine Oil.......................................................................................................... 8-3

8.3 Engine Cooling.................................................................................................. 8-3

8.4 Engine Oil Recommendations..........................................................................8-3

8.5 Headlight............................................................................................................ 8-3

8.6 Engine Air Cleaner.............................................................................................8-4

8.7 Headlight Assembly...........................................................................................8-4

8.8 Add-On Alternator............................................................................................. 8-4

8.9 Sparkplugs..........................................................................................................8-4

List of Illustrations

Page

8-1: Engine Components......................................

8-2: Alternator/Headlight............................................................................................8-2

.....................................................

8-1

Page 47

Engine and Headlight

1. Primer Bulb

2. Choke

3. Throttle

4. Key Switch

5. Oil Fill Spout

6. Rewind Starter

7. Gas Cap

8. Spark Plug

Figure 8-1: Engine Components

8-1

Page 48

Engine and Headlight

Models 724039, 40, 41

12

Fits 932001 S/N 043801 >

Fits 932004 S/N 035001 >

Fits 932006 S/N O5830l>

Fits 932007 S/N 001301 >

Fits 932015,18,19,20

ITEM

N0.

1 Alternator Shaft 3”

2

3

4

5

6

7 Cap Screw, 1/4-20 x 1-3/4

8

9

10

DESCRIPTION

(Tec. 590613) (932000 Series)

Centering Tub, 2.7 to 5 HP (Tec. 590610)

Alternator (Tec. 611077)

Self-Tapping Screw (Tec. 650868)

Lighting Connector (Tec. 611078)

Headlight Bracket

(932019, 20)

Cap Screw, 1/4-20 x 1-1/4

(93 2001 ,4,6 ,7,15 ,18)

Lock Nut, 1/4-20

Washer, 1/4

Conduit Clamp

Figure 8-2: Alternator/Headlight

ITEM

N0.

11 Headight Assembly (724039)

12 Headlight

13

14 Switch Boot (724039)

15 U-Bracket

16

17

18 Carriage Boit, 5/16-18 x 1”

19

20

21

DESCRIPTION

Headlight Assembly (724040, 41)

Push Button Switch (724039)

Lock Washer 5/16

Cap Screw, 5/16-18 x 2-1/2

Lock Washer, 5/16

Nut, 5/16-18

Flange Whiziock Nut, 5/16-18

(Consists of items 12 thru 21)

8-2

Page 49

Engine and Headlight

8.1 Introduction

r

WARNING: Stop engine, remove key,

A

A

wait for moving parts to stop and remove

wire from spark plug (keep wire away

from spark plug to prevent accidental

starting) before attempting any lubrica

tion or maintenance procedures.

CAUTION: DO NOT touch engine or SnoThro drive parts which are hot from

operation. Allow such parts to cool

before servicihg unit.

8.2 Engine Oil

Checking

The engine crankcase oil should be checked

daily or every 5 hours of operation. Oil level

MUST be maintained in safe operating range

on dipstick at all times or engine damage will

result

r

To check oil, park sno-thro on a flat, level sur

face, stop engine, and wipe all debris from

around dipstick cap. Remove dipstick and wipe

oil off. Screw dipstick assembly firmly but

slowly until cap bottoms on tube. Remove

dipstick and observe oil level.

Drain crankcase by removing oil drain plug.

When oil has drained, replace plug and refill

engine with new oil of proper grade (per engine

manufacturer’s instructions). Recheck oil level

with dipstick.

8.3 Engine Cooling

The engine is air cooled. Air must circulate

freely around engine from air intake screen,

over cooling fins on cylinder head and block to

prevent overheating.

Every 100 operating hours or yearly (more often

if conditions require) remove blower housing

and clean cooling fins. Also clean external sur

faces of your engine of dust, dirt and oil

deposits which can contribute to improper

cooling.

IMPORTANT: DO NOT operate engine with

cooling shrouds removed. This will cause

overheating and engine damage.

Fill crankcase with oil as recommended below.

Refer also to Engine manufacturer’s instruc

tions supplied with the product. Check oil level

before each use and change oil regularly ac

cording to Engine Manufacturer’s instructions.

8.4 Engine Oil Recommendations

If oil is low, add clean, fresh oil of same type

and viscosity as is in engine to bring oil level to

Full (F) mark (per engine manufacturers in

structions).

IMPORTANT: DO NOT overfill. Level must not

exceed full (F) mark. Changing Oil

Changing Oil

IMPORTANT: Change oil after first 5 hours of

operation. Thereafter change oil every 25 hours

of operation (more often in dusty, dirty condi

tions). See engine manufacturer’s instructions

for proper type, viscosity and amount required.

NOTE: Run engine just prior to changing oil. Oil

will flow more freely and carry away more con

tamination when warm.

Summer:

(Above 32 F)

Winter

(Below 32 F)

SAE 30W or Substitutes:

10W30

SAE 5W20, 5W30 or

Substitute:

SAE low

8.5 Headlight

To replace lamp, remove metal ring or remove

lamp from rubber housing.

CAUTION: When handling glass lamp,

A

Disconnect electrical plug and assemble new

lamp in reverse order.

8-3

breakage may occur.

Page 50

Engine and Headlight

NOTE: Be sure headlight assembly is grounded

at headlight bracket for single wire models and

at terminal on two wire models.

8.6 Engine Air Cieaner

IMPORTANT: When using tractor with summer

attachment, install air cleaner and clean ele

ment every 25 hours of operation (more often

under dusty, dirty conditions).

8.7 Keadiight Assembly

Install headlight bracket (level with floor) on

right handlebar with hardware provided.

NOTE: Two washers go between bracket and

handlebar at top hole.

Assemble headlight, bracket and U-bracket

with hardware provided and install onto

headlight bracket.

NOTE: Remove quadrant mounting hardware

(on Models 932001, 4,6,7) for additional

clearance when mounting alternator. Secure

quadrant when assembled.

Install Alternator shaft over crank shaft nut

(tap hex with pipe or light drift until it contacts

flywheel washer) and place centering tube on

to alternator shaft.

NOTE: Three inch alternator shaft and short

centering tube are for 932000 Series. Alter

nator shaft must extend approximately 5/8”

beyond top of starter. If not, incorrect shaft

has been installed.

Center rewind starter (using centering tube)

and secure with keps nuts removed earlier.

Remove centering tube and position alternator

onto alternator shaft with lighting connector

receptical to right (as viewed from operator’s

position).

Secure alternator to rewind starter with (3) self

tapping screws.

Position headlight wire harness behind name

plate along handlebar and plug into alternator

connector. Secure harness to handlebar with

clips.

8.8 Add-On Alternator

Remove rewind starter keps nuts and starter

from engine. (Note location of rewind starter

handle).

Remove pushout plug from top center of re

wind starter.

On die cast recoils, remove center hole cast

material with Va inch drill.

Rotate pulley to expose 3 punch-outs, place

starter on back-up surface and remove pun-

chouts with 1/8” punch.

IMPORTANT: DO NOT exceed 15 inch pounds

seating torque (after threads are formed), to

prevent screws from contacting pulley or

distorting alternator.

Insert lighting connector into connector recep

tical.

8.9 Spark Plugs

Spark plugs should be cleaned or replaced (if

necessary) and gap reset to .030” every 100

hours of operation or yearly whichever comes

first.

To clean, remove spark plug from engine, scrape

electrodes (DO NOT wire brush or sand blast).

NOTE: Sparking can occur if wire terminals do

not fit firmly on spark plugs. Reform terminals if

necessary.

8-4

Page 51

Attachments

Table of Contents

Page

9.1 Air Cleaner Installation....................................................................................9-1

9.2 Tiller Installation...............................................................................................9-5

9.3 Tiller Lubrication..............................................................................................9-5

9.4 Tine Adjustment...............................................................................................9-5

9.5 Rotary Brush Installation................................................................................9-8

9.6 Rotary Brush Lubrication................................................................................9-8

9.7 Rotary Brush Adjustment

List of Illustrations

Air Cleaner Installation....................................................................................9-1

9-1

9-2

9-3

9-4

9-5

Rotary Tiller Exploded View............................................................................9-3

Tiller Lubrication..............................................................................................9-5

Tine Adjustment...............................................................................................9-5