Page 1

AUTOMATIC AIR VALVE

MODEL SG-10

M

A

I

N

T

E

N

A

N

C

E

I

N

S

T

R

U

C

T

I

O

N

S

M

A

I

N

T

E

N

A

N

C

E

I

N

S

T

R

U

C

T

M

A

I

N

T

E

N

A

N

C

E

I

N

S

T

R

U

C

T

I

I

GENERAL INSTRUCTIONS

1. Routine service is an integral part of the standard

procedure of maintenance of a water supply system.

2. Recommended routine maintenance – ones or twice a year,

according to the quality and kinds of the fluids in the system.

PROCEDURE:

1. Close the service valve under the air valve base before the servicing.

2. Turn, release and remove the valve body (1) from the base.

3. Pull down on the clamping stem (3) and remove it from the body.

4. Rem

5. Check the integrity of the rolling seal (2) by rinsing it with water. Replace the

6. Check and wash the body (1) and the float (4) with clean water.

7. Return the float(4) and rolling seal (2) assembly by inserting the free end of the

8. While holding the float in this manner, insert the clamping stem(3) into the same

9. Push both the float and stem downward into the valve body until both are sitting

10. Holding the clamping stem (3) with the thumb, turn the body upside down and

11. Screw the body back into the valve base(6).

12. Do not forget to open the service valve after the servicing.

ove the float(4) and rolling seal (2) assembly.

rolling seal in case it is torn.

rolling seal into the groove in the body and inserting the float into the two rails on

the sides of the body.

groove as the rolling seal , making sure that the angled extended end of the stem is

inserted first into the groove.

flush with the body.

check to see that the float (4) and seal (2) assembly are held attached to the body(1).

O

O

N

N

S

S

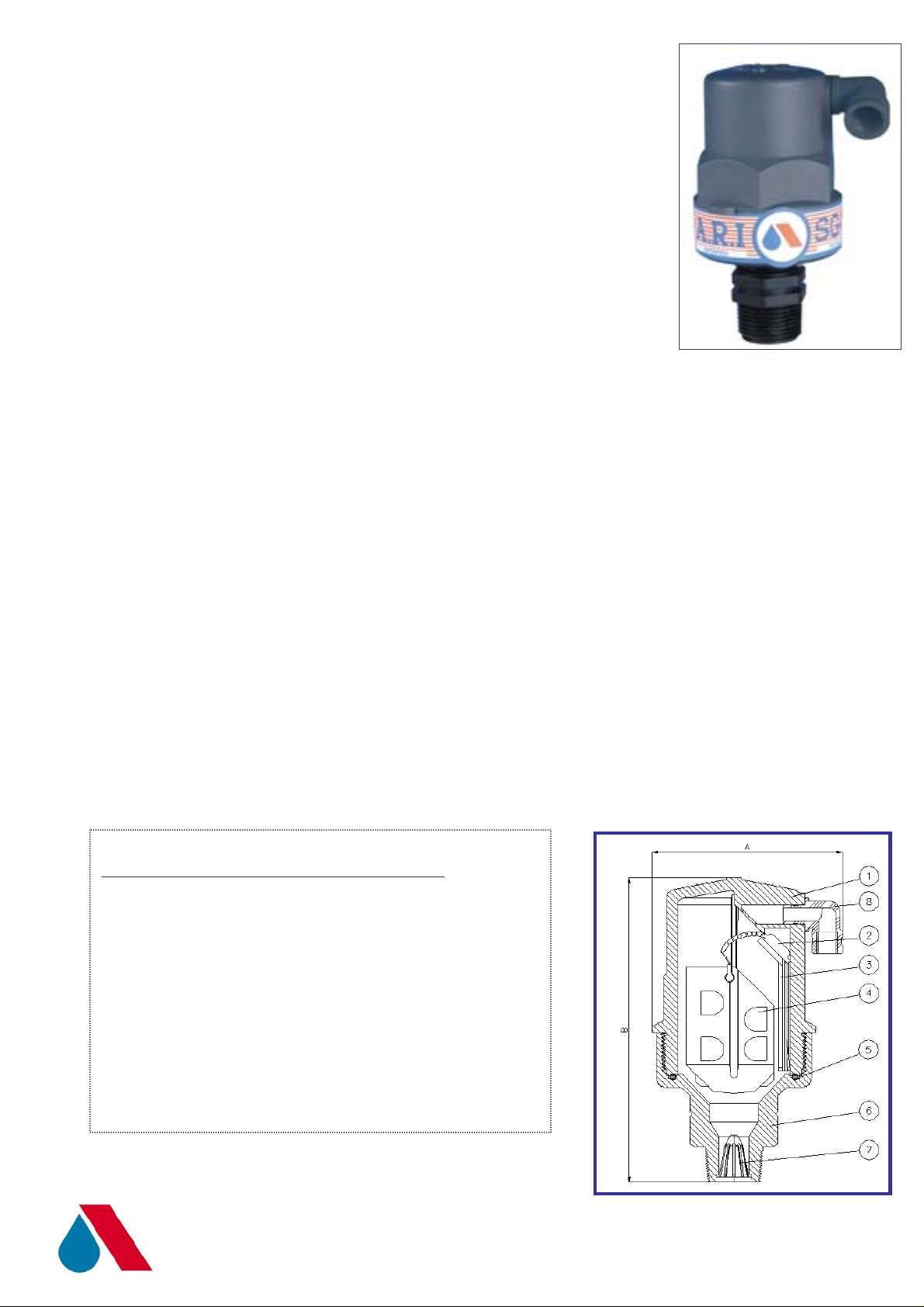

PARTS SPECIFICATIONS

NO. DESCRIPTION MATERIALS_____

1 BODY REINFORCED NYLON

2 ROLLING SEAL RUBBER EPDM

3 CLAMPING STEM REINFORCED NYLON

4 FLOAT FOAMED

POLYPROPYLENE

5 O-RING BUNA-N

6 BASE REINFORCED NYLON

/BRASS

7 FILTER REINFORCED NYLON

A.R.I FLOW CONTROL ACCESSORIES

WWW.ARIVALVES.COM

Loading...

Loading...