A.R.I. D-040 Installation Manual

D-040.IOM.ENG01

Installation, Operation & Maintenance

COMBINATION AIR VALVE

MODEL D-040

The following is a step by step narrated description of the A.R.I. D-040 Combination Air Valve installation, operation and maintenance processes.

The D-040 series Combination Air Valve has the features of both an air release valve and an air & vacuum valve. The air release component is designed to automatically release small pockets of air to the atmosphere as they accumulate along a pipeline or piping system when it is full and operating under pressure. Please consult A.R.I. for the pressure and temperature specifications table for this model and for other products designed for hazardous liquids systems.

2 |

IOM D-040 |

|

|

TABLE OF CONTENTS |

|

|

1. SAFETY INSTRUCTIONS..................................................................................................................................... |

3 |

|

2. INSTALLATION .................................................................................................................................................. |

6 |

|

3. OPERATION ...................................................................................................................................................... |

9 |

|

4. TROUBLE SHOOTING ........................................................................................................................................ |

9 |

|

5. PERIODIC MAINTENANCE.............................................................................................................................. |

10 |

|

5.1. Preparation............................................................................................................................................. |

10 |

|

5.2. First Stage Maintenance......................................................................................................................... |

10 |

|

5.3. Second Stage Maintenance.................................................................................................................... |

13 |

|

6. ASSEMBLY BOM TABLE AND DRAWING......................................................................................................... |

19 |

|

7. A.R.I. LIMITED WARRANTY............................................................................................................................. |

20 |

Disclaimer

This document is an Installation, Operation and Maintenance (IOM) manual for A.R.I. Flow Control Accessories Ltd. (A.R.I.) products. The information enclosed herein contains restricted, privileged, proprietary and confidential information, intended only for usage by authorized A.R.I. technicians. If you are not a qualified technician, you must not take any action in reliance upon this document, unless otherwise permitted in writing by A.R.I.

A.R.I. has made every effort to ensure that this document is accurate; A.R.I. disclaims liability for any inaccuracies or omissions that may have occurred.

All the procedures, drawings, pictures and/or any other information provided in this document are presented as general information only; they can be altered, removed or changed without A.R.I.'s prior written approval. A.R.I. makes no commitment to update or keep the information in this document current and/or up-to- date, and reserves the right to make improvements, alterations and/or modifications to this document and/or to the products described in this document, at any time without providing any notice with respect thereto. Nothing in this Disclaimer derogates in any way whatsoever from the confidential nature of any document enclosed hereto, including for avoidance of doubt, any mistake or clerical error or other error. None of the procedures provided in this Disclaimer and/or in any document enclosed hereto may be used in any form or by any means without the prior written consent from A.R.I. If you received this Disclaimer and/or in any document enclosed hereto in error or by mistake or if this Disclaimer and/or in any document enclosed hereto is not intended for you, please notify A.R.I. in writing immediately.

A.R.I. assumes that all users understand the risks involved within this Disclaimer and/or in any document enclosed hereto.

A.R.I. accepts/assumes no liability whatsoever, whether caused by: accessing and/or relying upon this Disclaimer and/or in any document enclosed hereto including without limitation any links, procedures or materials.

A.R.I. shall NOT assume any liability for any costs, direct or indirect, including loss of income, loss of profits and/or goodwill, legal actions and/or damages of any kind whatsoever including any, damages accidents, equipment damage or bodily injury resulting from and/or related to any of the following:

•product has not been duly installed and thereafter maintained in strict compliance with its designated Maintenance Instructions and/or any other installation and operation manuals provided by A.R.I. for the product and/or applicable ordinances and/or codes;

•Repairs made in and to the products by personnel not authorized by A.R.I.

•Maintenance or repairs using parts or components other than those specified by A.R.I. and in their original condition.

•Operating the products in ways other than the operating procedures described in the manuals provided by A.R.I., or resulting from not following the cautionary remarks and warnings in the product manual.

•Improper storage, workplace conditions and environmental conditions which do not conform to those stated in the Product manual.

•Fires, earthquakes, floods, lightning, natural disasters, or acts of God.

A.R.I. does not warrant and hereby disclaims any express or implied warranties that the product will work properly in environments and applications other than its original design purpose, and makes no warranty and representation, either implied or expressed, with respect to the quality, performance, merchantability, or fitness for any other particular purpose.

Except as provided herein and to the full extent permitted by law, A.R.I. shall not be responsible and/or liable for direct, special, incidental or consequential damages or loss resulting from any breach of the above or under any other legal theory.

This document does not replace any certified drawing, procedure or information provided by A.R.I. in reference to a specific customer, site or project. All rights reserved.

3 IOM D-040

1. SAFETY INSTRUCTIONS

General

1.A.R.I. products always operate as components in a larger system. It is essential for the system designers, installers, operators and maintenance personnel to comply with all the relevant safety standards.

2.Installation, operation or maintenance of the product should be done only by qualified workers, technicians and/or contractors using only good engineering practices, complying with and observing all conventional safety instructions in order to minimize risk and/or danger and/or hazard to workers, the public or to property in the vicinity in accordance with all relevant local standards.

3.Extra safety considerations should be taken with hot and hazardous liquids or in hazardous environments' applications to avoid bodily/physical harm and damage to public or private property.

4.All individuals installing operating and/or handling the products including all workers should at all times adhere with the occupational safety and health (OSH) instructions and wear safety helmets, goggles, gloves, and any other personal safety equipment required by the local standards and regulations.

5.Use only appropriate standard tools and equipment operated by qualified operators when installing, operating and maintaining the product.

6.Prior to installation, operation, maintenance or any other type of action carried out on the product, read carefully the safety, installation and operation instructions of the product.

7.Please note:

oPressurized fluid and/or gas may be discharged from the product without prior warning. Make sure that the product's outlet port is not directed toward electrical elements (pumps) or people.

oThe pressurized fluid and/or gas that can be discharged from the product may create high noise levels. Take this into consideration when installing the product in areas sensitive to noise.

8.Always open and close valves slowly and gradually.

9.Please note that the maximum working pressure indicated at the product’s specifications table doesn't include pressure changes caused by water hammer and pressure surge effects. Use the product only according to its designated pressure rate specifications.

10.Use the product only for its intended use as designed by A.R.I. Any misuse of the product may lead to undesired damages and may affect your warranty coverage. Please consult with A.R.I. prior to any nonstandard use of this product and make no change or modification to the product without a prior written consent to be provided by A.R.I. at A.R.I.'s sole discretion.

11.Please note that A.R.I. shall NOT assume any liability with respect to any damage losses and/or expenses caused to any person and/or property whatsoever unless the product has been duly installed and thereafter maintained in strict compliance with its designated maintenance Instructions and/or any other installation and operation manuals provided by A.R.I. for the product and/or applicable ordinances and/or codes.

Handling

1.Shipping and handling the product must be done in a safe and stable manner and in accordance with the relevant standards and regulations.

2.For lifting and positioning the product, use only approved lifting equipment operated by authorized employees and contractors.

3.Prior to the installation visually verify that the product was not damaged during shipment to the installation site.

4 IOM D-040

Installation

1.Install the product according to the detailed Installation Instructions provided with it by A.R.I. and according to the description given in this manual.

2.The user should install a manual Isolation Valve under the product's inlet port.

3.In all installation sites the user should enable good visibility and verify that the work and auxiliary equipment used are done in accordance with the relevant local authorized standards. Extra safety considerations should be taken on hazardous environment sites.

4.Check and re-tighten the bolts connecting the product to the pipeline during commissioning and before operating the product for the first time.

Commissioning and operation

1.Read carefully the operation instructions prior to any attempt to operate the product.

2.Observe the safety stickers on the product and never perform any operation contradicting the instructions given.

3.In order to achieve maximum performance and smooth operation of the product it is crucial to perform the startup and first operation procedures exactly as described in this manual.

4.In cases where formal commissioning procedure is required it should be done by an authorized A.R.I. technician prior to the first operation of the product.

Maintenance

Before any maintenance or nonstandard operation please read the following:

1.Servicing the product should be done only by qualified technicians for this type of work.

2.Make sure that you know the exact type of the system fluid. Act accordingly and comply with all the relevant standards and regulations set for handling this type of fluid.

3.Before disconnecting the product from the system and before releasing the residual pressure do NOT:

o loosen or unscrew the product bolts; o remove any protection cover;

oopen any service port

4.Before any maintenance or nonstandard operation, shut the Isolation Valve and release the residual pressure:

A.For air valves with pressure release outlet, slowly open the pressure release plug or the ball valve and make sure that all pressure is released. Please note that some air release valves, especially the waste water models, may contain significant volume of compressed gas with accumulated energy!

B.For air valves without a pressure release outlet, slowly unscrew the flange bolts until all the pressure is released from the valve.

5.Make sure the air valve is empty of all liquid prior to commencing maintenance.

6.Remove the product from the line only after ensuring that internal pressure has been released.

7.Place warning signs around the work area as required by the local standards and procedures.

8.Inspect the product safety stickers and replace any damaged or faded sticker.

9.Manual cleaning of the product and/or its components using high water pressure or steam should be performed in accordance with its specific cleaning instructions, the local standards and regulations and without endangering the operator or the vicinity

10.Manual cleaning of product and/or its components using acid or other chemical agents should be performed in accordance with the specific cleaning instructions, the relevant safety instructions for using that chemical as given by its supplier, the local standards and regulations and without endangering the operator or his vicinity.

11.For products used in potable water systems if it is required to disinfect the product, do so according to the local water authority standards and regulations before putting the product into service.

5 IOM D-040

Before returning to regular operation

1.Reassemble any protective covers or protection mechanisms removed during service or maintenance operations.

2.Make sure that all the tools, ladders, lifting devices, etc. used during the maintenance procedures are taken away from the product area and stored.

3.Remove grease and oily material residues in order to avoid slipping.

4.In order to return the product to regular operation, follow the First Start-up Operation instructions as detailed in your user manual.

6 IOM D-040

2. INSTALLATION

Important: Before performing any work on the air valve make sure that all workers on site are familiar with the safety instructions and the relevant local and general safety instructions and work regulations.

2.1. Installation Recommendations

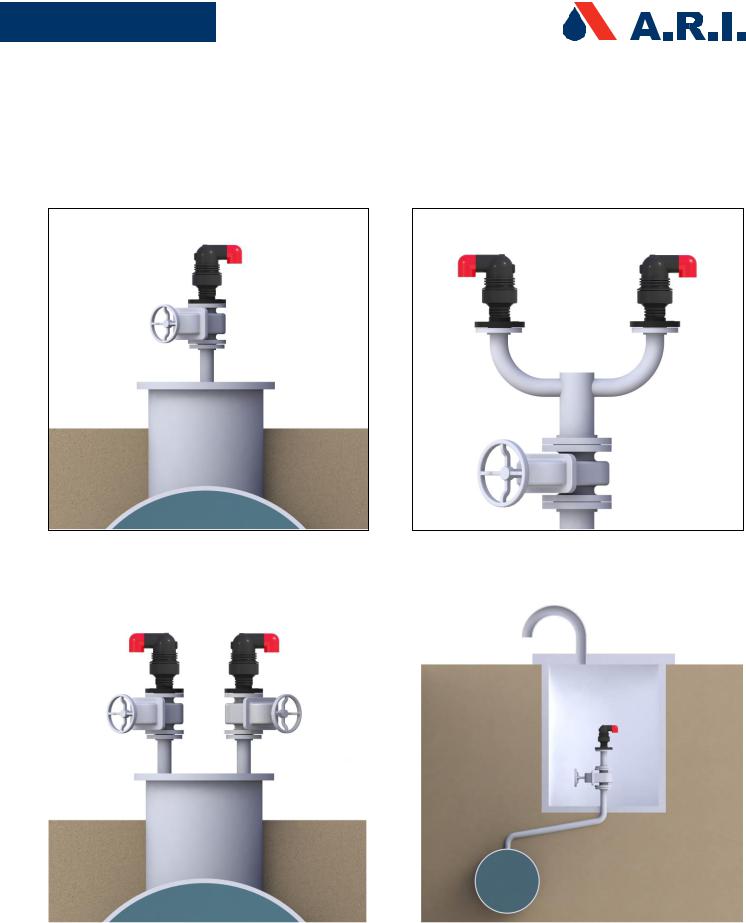

Single Air Valve on an Isolating Valve at 45° to Air Valve outlet |

Two Air Valves on a shared Isolating Valve. Air Valves outlets |

|

|

face outward and the Isolating Valve at 45° to Air Valve outlets |

|

|

|

|

|

|

|

Two Air Valves on an Air Trap with separate Isolating Valves. Air Valve outlets face outward and the Isolating Valves at 45° to Air Valve outlets

Underground Installations

Underground installations require a venting pipe from the manhole

Use an angular installation to bypass an obstacle directly above the pipeline.

Loading...

Loading...