Page 1

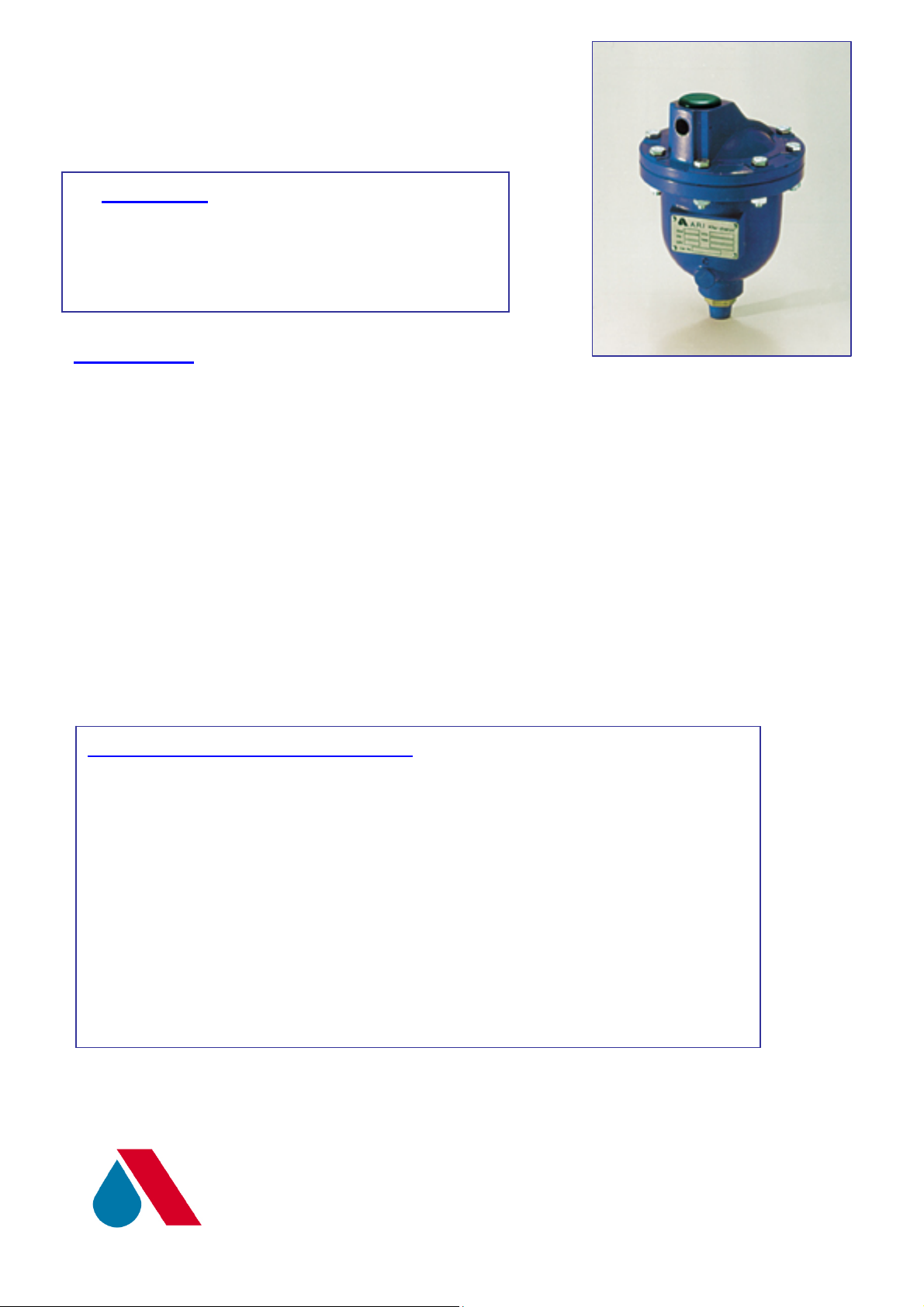

Installation and Maintenance of

A.R.I.’s S-014,S-016

Automatic Air Release Valves

A. Installation

A.1 The air valve will be mounted on a riser,

connected to the top of the pipe.

A.2 An isolating valve will be installed below the air

B. Operation

The S-014 ,S-016 Automatic Air Release valve, releases entrapped air from peaks of pressurized

systems where the valve should be installed.

Pockets of accumulated air may cause the following destructive phenomena:

*. Impediment of effective flow and hydraulic conductivity of the system, along with a throttling effect

as would a partially closed valve. In extreme cases this will cause complete flow stoppage.

*. Accelerate cavitation damages.

*. High pressure surges.

*. Accelerate corrosion of metal parts.

*. Danger of a high-energy burst of compressed air.

*. Inaccuracies in flow metering.

C. Basic, Periodic, Maintenance

B.1 Shut the isolating valve below the air valve.

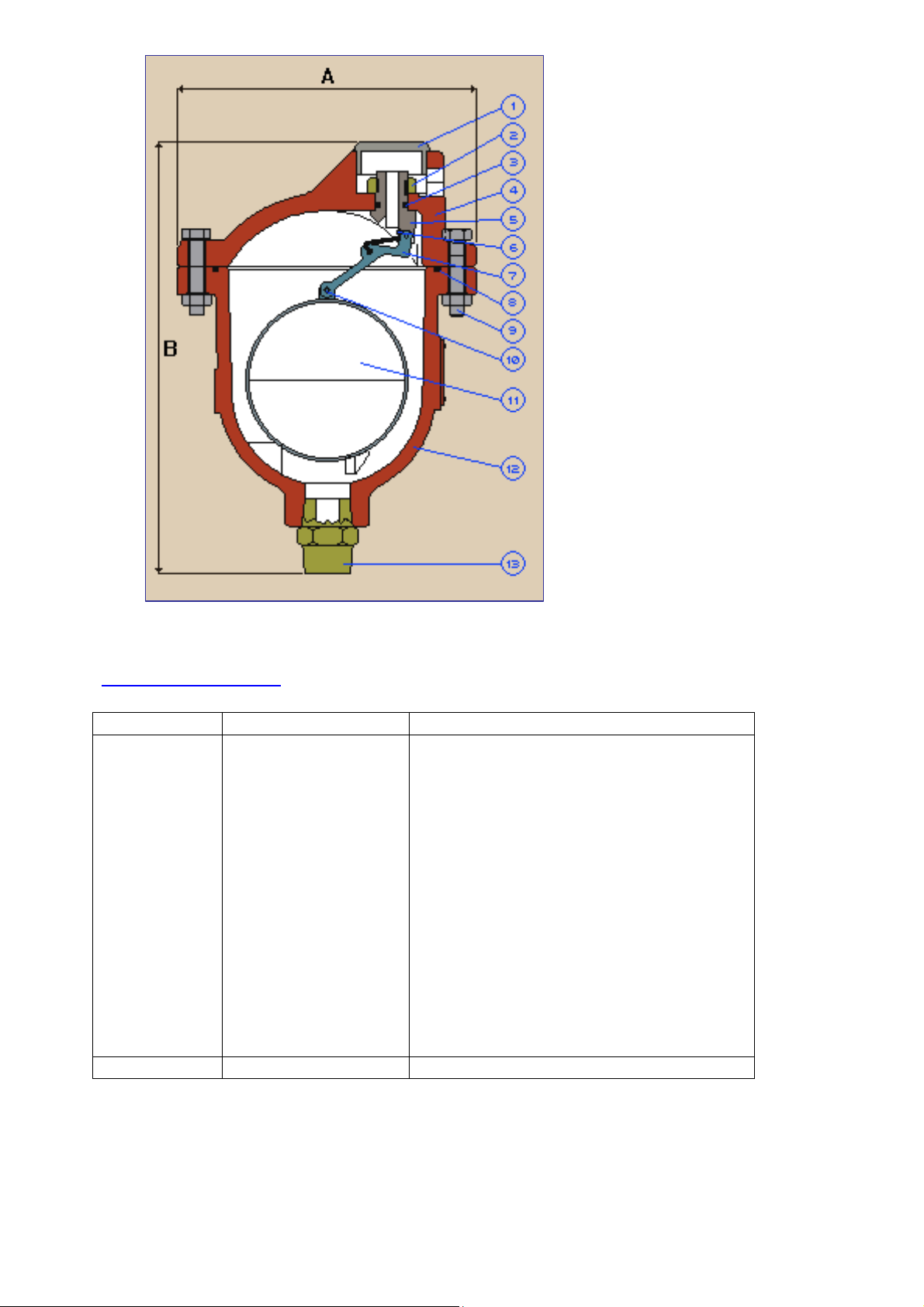

B.2 Unscrew the cover’s bolts of the automatic air valve (9) slowly,to release

accumulated pressure .

B.3 Remove the cover of the automatic a.r.v. (4) , clean the orifice (5) with flowing

water and with thin copper wire .

Wash the inside of the body(12), the float(11), and the Rolling Seal (6), with

clean water .

B.4 Check to make sure the Rolling Seal is unharmed (not torn or cracked) .

B.5 Reinstall in reverse order and fasten and tighten all bolts. Make sure to re-

assemble all the components correctly.

B.6 Open the isolating valve beneath the air valve.

A.R.I

Tel. 972-4- 6761980 Fax.972-4- 6763402

FLOW CONTROL ACCESSORIES

Page 2

D. Troubleshooting

PROBLEM CAUSE SOLUTION

Leak From the

Small Orifice

a. Dirt particles stuck

in the orifice

a. Shut the isolating valve, wait a

minute, and open it again, very fast.

If leaking continues, go to b. b. Rolling Seal torn

b. Shut the isolating valve, Unscrew

the cover bolts of the automatic air

valve, slowly, to release

accumulated pressure. Remove the

plastic cover with a screwdriver and

clean the orifice with flowing water

and with a thin copper wire. Wash

the inside of the body, the float, and

the Rolling), with clean water

c. Check to make sure the Rolling Seal

is unharmed (not torn or cracked).

Replace the Rolling Seal if needed.

Loading...

Loading...