Page 1

Installation and Maintenance of

S-015 Automatic Air Release Valve

A. Installation

A.1 The air valve will be mounted on a riser,

A.2 A shut-off valve will be installed below the air

connected to the top of the pipe.

valve

.

B. Operation

The S-015 Automatic Air Release Valve releases entrapped air from

peaks and along pressurized systems where the valve should be installed.

Pockets of accumulated air may cause the f ollowing destructive phenomena:

* Impediment of effective flow and hydraulic conductivity of the system, along with a throttling

effect

as would a partially closed valve. In extreme cases this will cause complete flow stoppage.

* Accelerate cavitation damages.

* High pressure surges.

* Accelerate corrosion of metal parts.

* Danger of a high-energy burst of compressed air.

* Inaccuracies in flow metering.

C

.

Basic Periodic Maintenance

C.1 Close the shut-off valve below the air valve.

C.2 Unscrew the Cover

accumulated pressure .

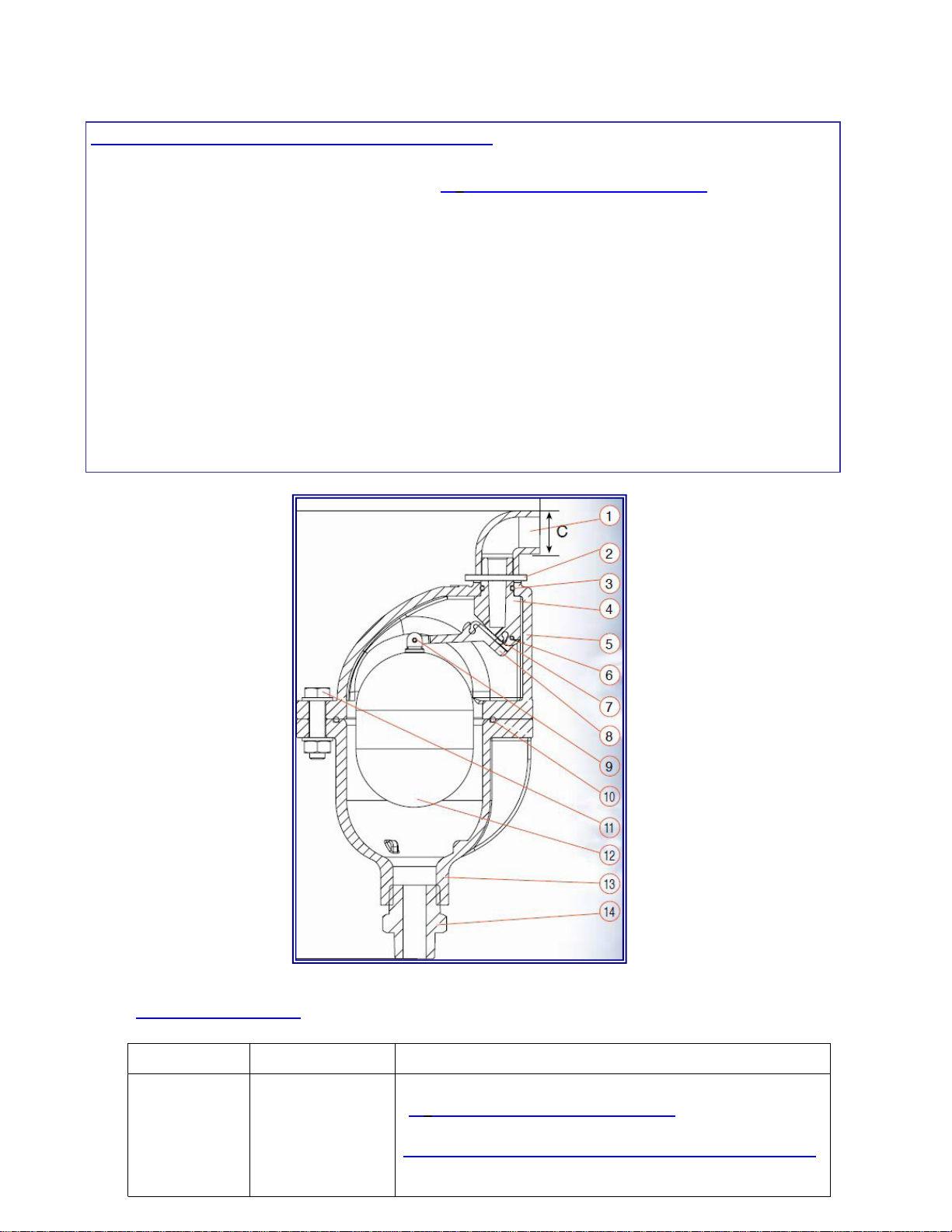

C.3 Remove the Cover (2) of the automatic a.r.v., clean the Orifice (5) with flowing

water or a burst of pressurized air.

C.4 Wash the inside of the Body (1), the Float (3), and the Rolling Seal (7)

with clean wa ter.

C.5 Check to make sure the Rolling Seal is unharmed (not torn or cracked) .

If it needs to be replaced, see below, Instructions for Replacing the Rolling Seal.

C.6 Reinstall in reverse order and fasten and tighten all bolts. Make sure to re-asse mble

all the components correctly.

C.7 Open the shutoff valve beneath the air valve.

A.R.I

Tel

B

olts (8-10) of the automatic air release valve slowly,to release

FLOW CONTROL ACCESSORIES

.

972-4- 6761980 Fax.972-4- 6763402

Page 2

D. Instructions for Replacing the Rolling Seal

D.1 Perform steps C.1 thru C.3 found above in C. Basic Periodic Maintenance

D.2 Unscre w and remove the Discharge Outlet (1).

D.3 Remove the Rollpin (2) with the aid of a han d punch, small ham mer and pliers.

D.4 Press down on the threaded end of the Orifice an d Float Assembly (4)(6)(7)(8)(12) that extends

out from the top the Cover (5), remove and place it on a flat surface for the next step.

D.5 Remove th e damaged Rolling Seal (7) by extracting it from both en ds of the Lever (8).

D.6 Replace with a new Rolling Seal by inserti ng each end of the seal into eac h slot in the Lever (8).

D.7 Rein sert the Oricice and Float Assembly into the Cover by pushing the threaded end of

the assembl y up through the bottom hole in the Cover.

D.8 Aligned the holes in the threaded end with the slots in the Cover.

D.9 Insert the Rollpin into the hole with the aid of a hand punch and small hammer.

D.10 Make sure the ends of the Rollpin sit inside the slots of the Cover.

D.11 Place the Cover with the attached assembly onto the Body (5).

D.12 Insert t h e 4 Bolts and Washers (11) into the Cover holes and tighten the Nuts (11).

E. Troubleshooting

PROBLEM CAUSE SOLUTION

Leak From

S

mall Orifice

the

a

. Dirt particles

b. Rolling Seal

stuck in

orifice

torn

the

c.

Perform the steps in:

C. Basic Periodic Maintenance

d. Perform the steps in:

D. Instructions for Replacing the Rolling Seal

Loading...

Loading...