Page 1

M

A

I

N

T

E

N

A

N

C

E

I

N

S

T

M

A

I

N

T

E

N

A

N

C

E

I

M

A

I

N

T

E

N

A

N

C

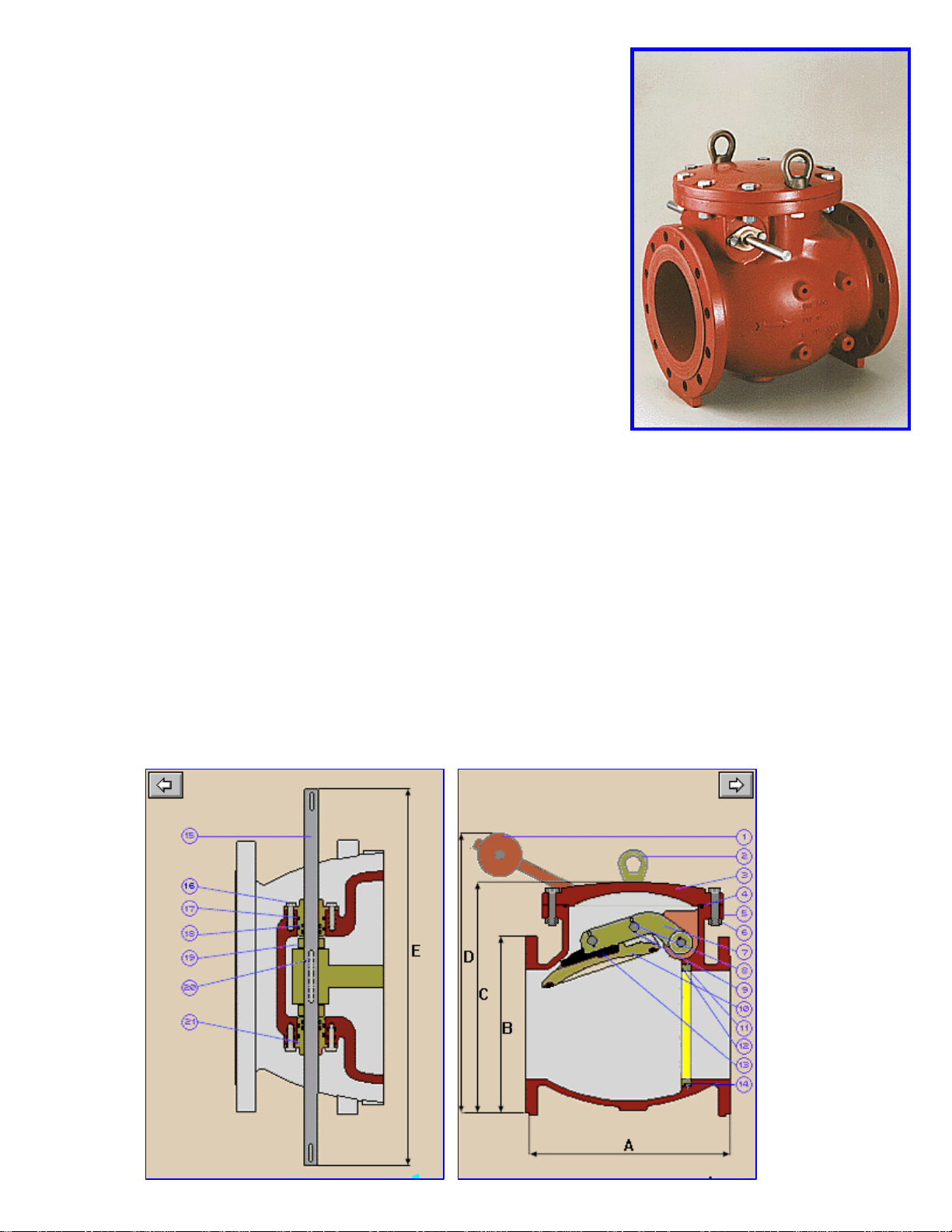

CHECK VALVE WITH LID

E

N

I

N

S

S

T

T

R

R

R

U

U

U

C

C

C

T

T

T

I

I

I

O

O

O

N

N

N

S

S

S

MODEL “EREZ” NR-040

GENERAL INSTRUCTIONS

1. Routine service is an integral part of the standard

procedure for maintenance of a water supply system.

2. Recommended routine maintenance– once or

twice a year, according to the quality and kinds

of the fluids in the system.

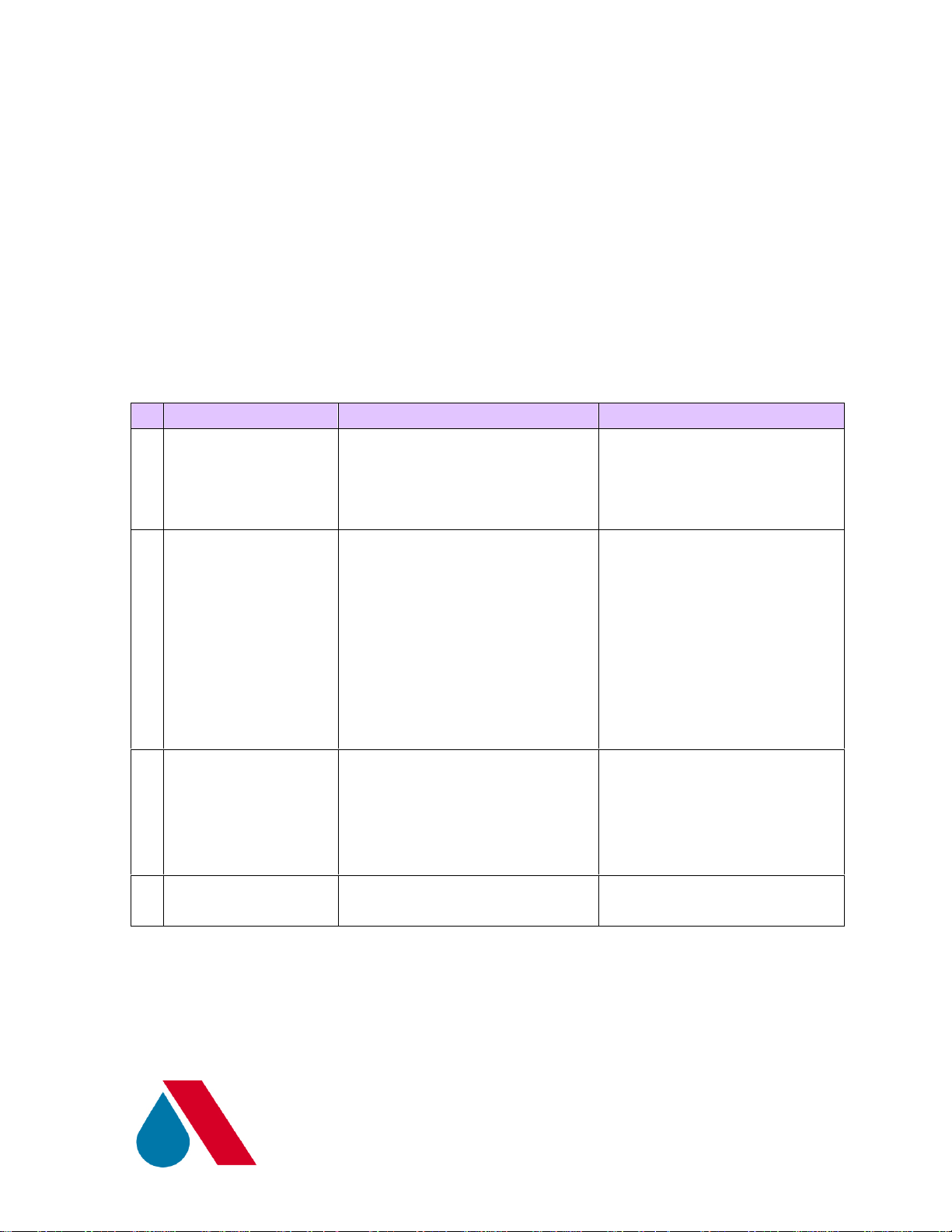

A. Installation

The valve can be installed either horizontally or

vertically , while the flow is toward the upper part.

The counter weight assembly (1 ) will be installed

so the arm turns down at a 45

valve closes.

Shut-off valve – in order to allow maintenance and

removal of the valve, a shut-off valve will be

installed before the inlet and / or after the outlet of

the valve, according to the conditions in the

pipeline.

It is recommended drainage valves before and after

the valve in order to release the pressure and to

drain the line.

Stainless Steel shaft (15) – it is forbidden to weld

or to coat the shaft.

0

angle when the

Page 2

B. Periodic Maintenance

1. Greasing of the bolt and key of the counter weight.

2. Greasing the bolts of the valve’s cover (lid) .

3. Brush painting of the surface area of the valve body.

4. In case the valve is installed in waste water system , open the valve’s

cover and wash the internal part from dirt, solids and debris

Symptom Cause Corrective action

1 Leakage from the

shaft O-Ring

2 The seats no

properly sealed

(reverse flow

occurring)

1) O-ring Elastomer

deterioration.

2) Shaft Erosion at

O-rings contact

1)Hard solid stuck on the

seats

2) Elastomer deterioration.

1) Change the

O-rings plugs.

2) Replace the complete

shaft.

1) Open the upper lid and

clean both the two

seats. If needed,

replace the body seat.

2) Replace the rubber-

lined disc.

3) Exaggerated clearance

between the internal parts

3) Change the complete

disc and arm assembly

due to Erosion

3 The micro switch

is out of function

The micro switch roller is

no more in contact with the

actuator came

Check the tightening of

the came retaining bolt on

the shaft. Carefully fix the

came in the right position

for correct indication.

4 Leakage from the

upper cover

Defective O-ring seal Change the lid O-ring

seal

A.R.I FLOW CONTROL ACCESSORIES

KIBBUTZ KFAR CHARUV 12932 WWW.ARIVALVES.COM

TEL. 972-4-6761988 FAX. 972-4-6763402 E.MAIL: ari@ari.co.il

Loading...

Loading...