Page 1

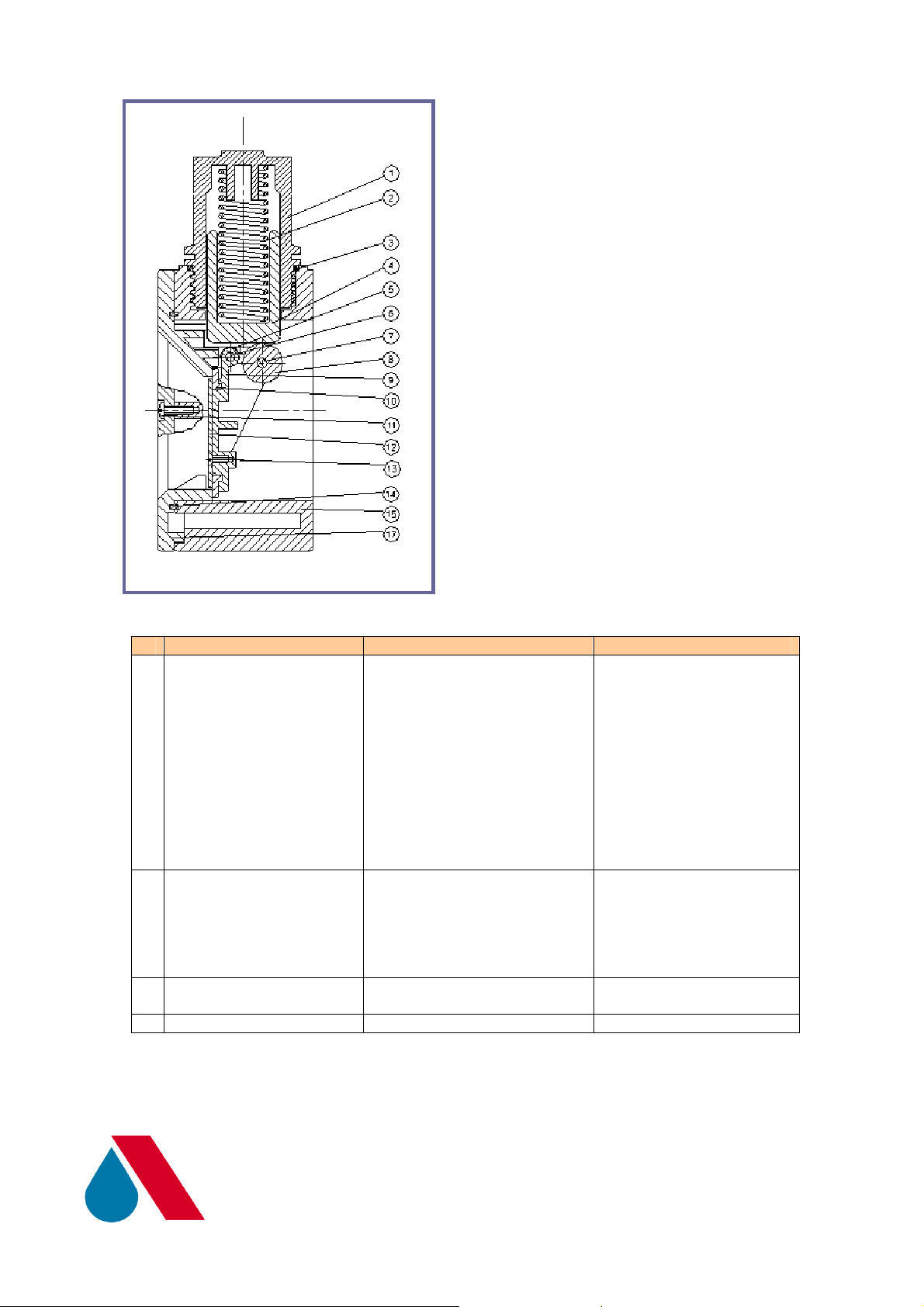

CHECK VALVE MODEL NR-020 , NR-010

MAINTENANCE INSTRUCTIONS

GENERAL INSTRUCTIONS

1. Routine service is an integral part of the

standard procedure for maintenance of a

water supply system.

2. Recommended routine maintenance–

once or twice a year, according to the

quality and kinds of the fluids in the system.

A. Installation

The valve can be installed either horizontally or vertically,

while the flow is toward the upper part.

Shut-off valve – in order to allow maintenance and removal

of the valve, it is recommended to install a shut-off valve will

before the inlet and / or after the outlet of the valve,

according to the pipeline configuration.

For easy maintenance, the valve will be installed with the

spring and piston unit (1) upward oriented.

B. Periodic Maintenance:

1. Check the flanges tightening bolts twice a year and

2. When the check valve is close under backpressure, check

retighten if needed

.

the reverse flow leakage by external hearing.

Page 2

Symptom Cause Corrective action

1 The disc doesn’t closes 1) Interference between the

disc motion and an adjacent

shut-off valve (butterfly)

2) Body deformation due to

over tightening of the

positioning bolts.

2 Swelling of the Rubber seal

disc

3 Leakage from the indicator

rode O-Ring

In the majority of cases, the

swelling is caused by the

presence of dissolved Chlorine in

the water principally near the

chlorinator in swimming pools or

treatment stations.

Erosion or chemical attack Change the spring chamber

1) Separate the two devices,

far enough, to avoid any

physical contact between

the NR-020 disc and the

shut-off valve.

2) Check the tightening

moment of the retaining

bolts to a reasoning level

allowing sealing at the

flanges.

The use of N-020 in water

with more than

4-6 ppm chlorine dissolved is

not recommended.

assembly.

A.R.I FLOW CONTROL ACCESSORIES

KIBBUTZ KFAR CHARUV 12932 WWW.ARIVALVES.COM

TEL. 972-4-6761988 FAX. 972-4-6763402 E.MAIL: ari@ari.co.il

Loading...

Loading...