ARI HP50HA2, HP70HA2 Installation Manual

51300022501B

ABOVE & IN GROUND POOL/SPA HEAT PUMP HEATERS

INSTALLATION & OPERATIONS MANUAL

FOR YOUR SAFETY

This Heat Pump is listed by ETL as complying

with the latest edition of the UL Standard for

safety for electrical heat pumps,

air-conditioners and dehumidifiers UL 60335

and CSA C22.2 No. 60335-1 and 60335-2-40

All Heat Pumps must be installed in accordance

with all applicable National and Local codes. In

the absence of local codes, refer to the latest

edition of the National Electric Code (NEC) in the

United States and the Canadian Electric Code

(CEC) in Canada.

FOR YOUR SAFETY:

This product must be installed and serviced by

authorized personnel, qualified in pool/spa heater

installation. Improper installation and/or

operation can cause death, serious injury

and/or property damage.

CONTENTS Pg.

GETTING STARTED 2

INSTALLATION 9

LOCATING THE HEATER 9

WATER PIPING 11

ELECTRICAL CONNECTIONS 14

CHECK-OUT & START-UP 15

CONTROL SETUP 15

MAINTENANCE & SERVICE 17

WATER CHEMISTRY 17

WINTERIZATION 18

COMPONENT SERVICE 18

TROUBLESHOOTING 19

PARTS 22

SAVE THESE INSTRUCTIONS

USE ONLY GENUINE REPLACEMENT PARTS 1

INSTALLATION

Verify that product installation was performed

to local codes and according to this manual.

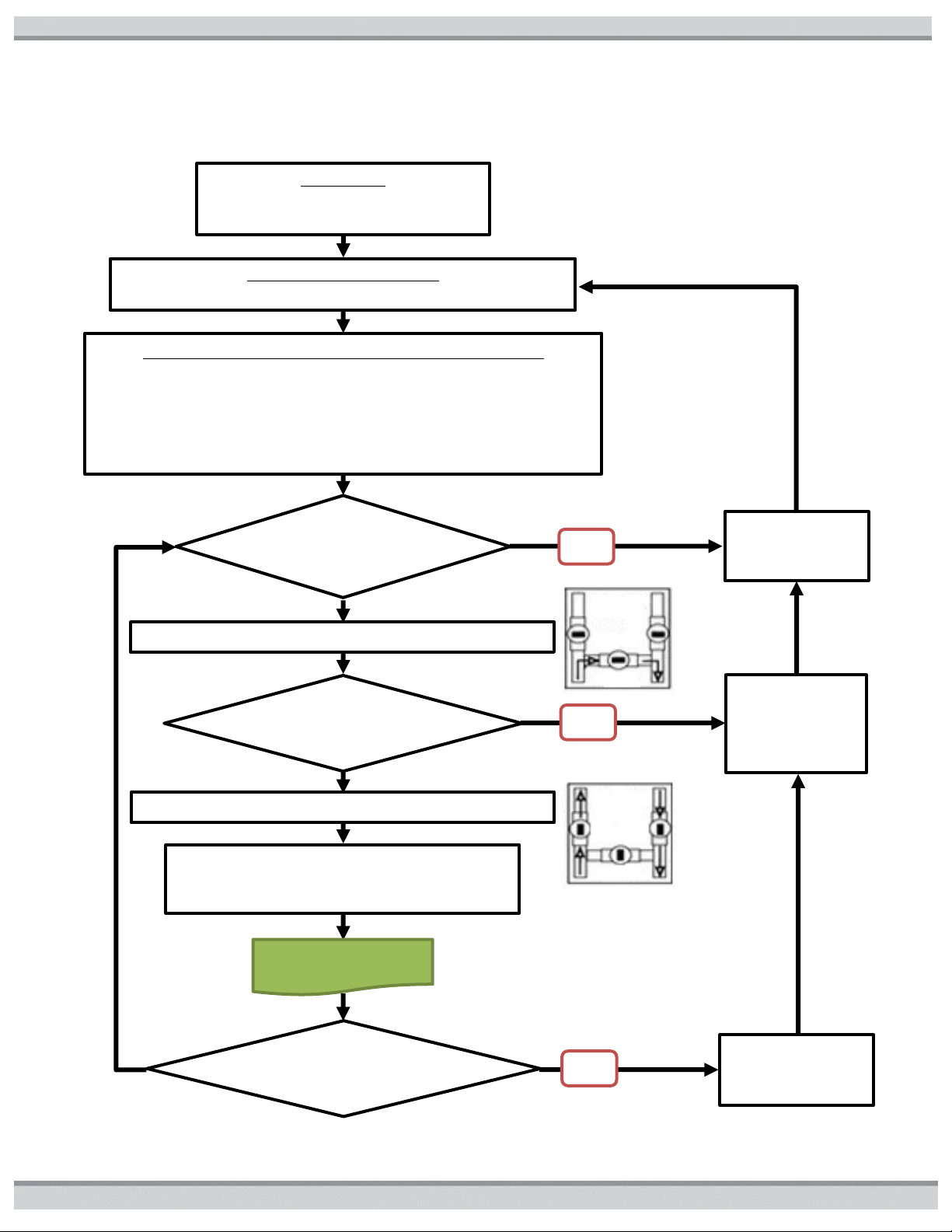

IS POOL/SPA IN

CHEMICAL BALANCE?

INITIAL USE OR SPRING STARTUP

Check all pool / spa water piping. Do not connect product to water piping.

BYPASS TO CLOSED POSITION, WATER DIRECTED TO PRODUCT

TURN ON ELECTRIC POWER AND GAS AS REQUIRED.

START PRODUCT. PROGRAM REQUIRED WATER

TEMPERATURE ON PRODUCT CONTROL PANEL.

IMPORTANT FOR POOL USER HEALTH AND PRODUCT PERFORMANCE

Verify Chlorine or Bromine level every 2-3 days

Verify PH level every week

Verify Alkalinity level every 3-4 weeks (2 weeks if using an Automatic

Chlorine or Bromine Feeder)

Verify Water Hardness and Total Dissolved Solids (TDS) every month (it is

recommended that a pool professional perform this testing)

IS HEATING/COOLING

NEEDED WITHIN 1 WEEK?

SET BYPASS TO

OPEN POSITION,

WATER DIVERTED

FROM PRODUCT

CONNECT WATER PIPING TO PRODUCT, BYPASS TO OPEN POSITION

IS HEATING/COOLING

NEEDED FOR REST OF YEAR?

DISCONNECT

WATER PIPING TO

PRODUCT

TURN OFF ELECTRIC

POWER AND GAS AS

REQUIRED

NO

NO

NO

51300022501B

GETTING STARTED

WHAT TO EXPECT WHEN OPERATING YOUR POOL HEATER

This flow chart provides guidance to protect pool users and product by maintaining good water quality.

ENJOY YOUR POOL/SPA

PRODUCT

OPEN

POOL/SPA

PRODUCT

CLOSED

POOL/SPA

2 USE ONLY GENUINE REPLACEMENT PARTS

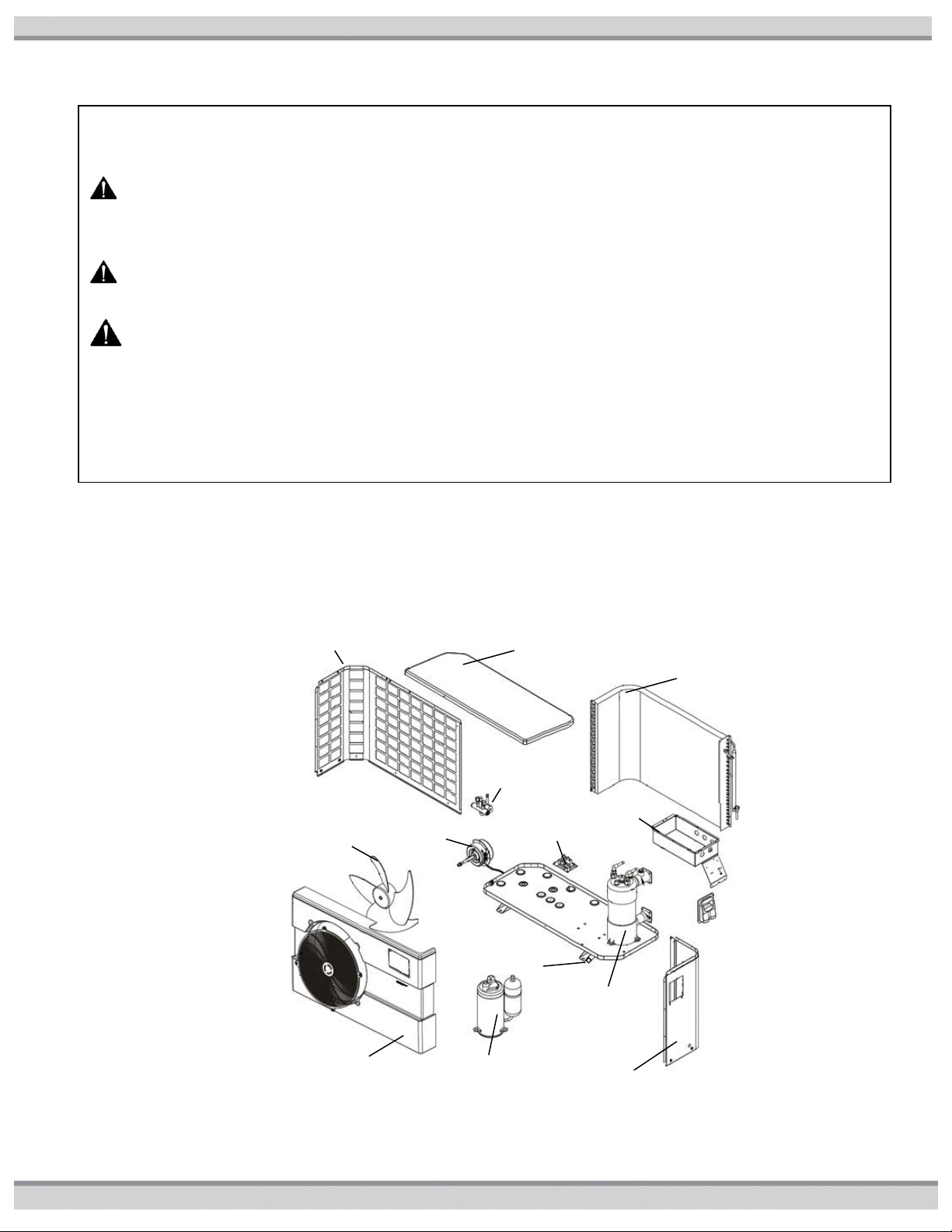

Top Panel

Coil Guard

Evaporator

Reversing

Control

Box

Front Panel

Fan

Fan

Motor

Condenser

Compressor

Service Panel

Control

Board

Bonding

Lug

51300022501B

PLEASE READ BEFORE PROCEEDING

Basic safety precautions should always be followed, including the following:

Failure to follow instructions can cause death and/or severe injury.

This is the safety-alert symbol. When you see this symbol on your equipment

or in this manual, look for one of the following signal words and be alert to the

potential for personal injury.

WARNING warns about hazards that could cause death and/or severe

injury or major property damage and if ignored presents a potential hazard.

CAUTION warns about hazards that could cause minor or moderate

personal injury and/or property damage and if ignored presents a potential

hazard. It can also make consumers aware of actions that are unpredictable

and unsafe.

NOTICE indicates special instructions that are important but not related to

hazards.

See product rating plate for manufactures information.

HEATER CONSTRUCTION

Figure1: Names of heat pump heater components

USE ONLY GENUINE REPLACEMENT PARTS 3

Models

HP50HA2

HP70HA2

Voltage/Phase/Hz

208-230/1/60

208-230/1/60

Capacity (btu/h) 80A-80RH-80W

47,100

73,780

Power Input, KW (80A-80RH-80W)

2.3

3.9

COP 80A-80RH-80W

6.0

5.6

Capacity (btu/h) 80A-63RH-80W

44,200

69,190

COP 80A-63RH-80W

5.8

5.4

Capacity (btu/h) 50A-63RH-80W

28,800

47,830

COP 50A-63RH-80W

4.0

4.1

Compressor/Fan Motor/System

RLA (amp)

14.5/0.5/15

19.5/0.8/20.5

Compressor/Fan Motor/System

LRA (amp)

60

70

Min. Circuit Ampacity (amp)

22

30

35

45

35 45

20.3

31.2

16

25

25

38

1.5” & barb

2” TriStar

10.4

15.7

44.5x18.5x31.1

48.0x19.3x34.6

152

230

185

270

44.9x18.9x36.3

48.4x19.7x39.8

H

Outlet

Inlet

Y

4in

L

W

51300022501B

Features:

Titanium heat exchanger

withstands the harshest water

conditions

Quiet/Reliable R410A Compressor

Digital Electronic Control with

o Easy to read display;

o Auto mode for automatic

heating and cooling operation

o Display of diagnostic codes

UV resistant cabinet for long life

Defrost function to manage

evaporator coil frosting for low

ambient temperature operation

High (590PSI) and low (80PSI)

refrigerant pressure switches

monitoring extreme operation

Corrosion resistant evaporator

fins

Table1: SPECIFICATIONS

Recommended Breaker Size (amp)

Max Fuse Breaker Size (amp)

Recommended water flow (gpm)

Minimum water flow (gpm)

Maximum water flow (gpm)

Operating water temperature( )

Min/Max. operating water pressure(PSI)

Water Connector (dia. in)

Connection Height Y (in)

Unit size L x W x H (in)

Weight (lbs)

Shipping Weight (lbs)

Shipping size L x W x H (in)

48.2/104

43.5/435

48.2/104

43.5/435

4 USE ONLY GENUINE REPLACEMENT PARTS

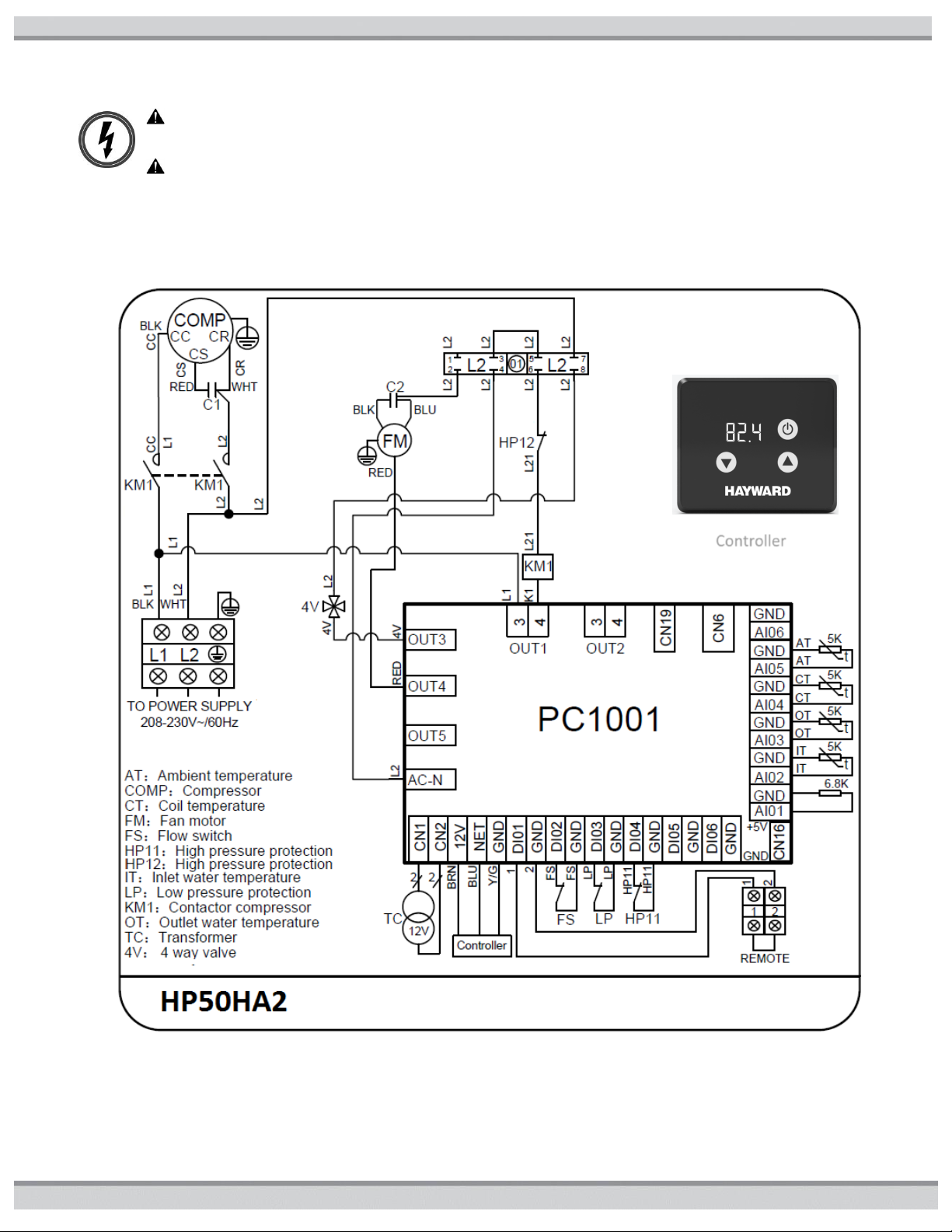

Wiring Connection Diagram

WARNING – Risk of Electric Shock Before working on any electrical equipment, turn off power supply to the

equipment.

WARNING – Risk of Electric Shock. All electrical wiring MUST conform to applicable local codes, regulations,

and the National Electric Code (NEC). Hazardous voltage can cause death, shock, burn, and/or serious property

damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide

a properly located electrical receptacle. To reduce the risk of electric shock replace damaged wiring immediately.

Locate conduit to prevent abuse from lawn mowers, hedge trimmers and other equipment. Do NOT ground to a gas

supply line.

Figure2a Single Phase Wiring Diagram HP50HA2

51300022501B

Controller

USE ONLY GENUINE REPLACEMENT PARTS 5

CERTIFICATION CODES AND STANDARDS

USA CANADA

DESIGN CERTIFIED

ETL/ITS

ETL/ITS

DESIGN COMPLIANT

INSTALLATION COMPLIANT ELECTRIC

ANSI/NFPA 70

NEC

CSA C22.1 – Canadian

Electrical Code, Part I

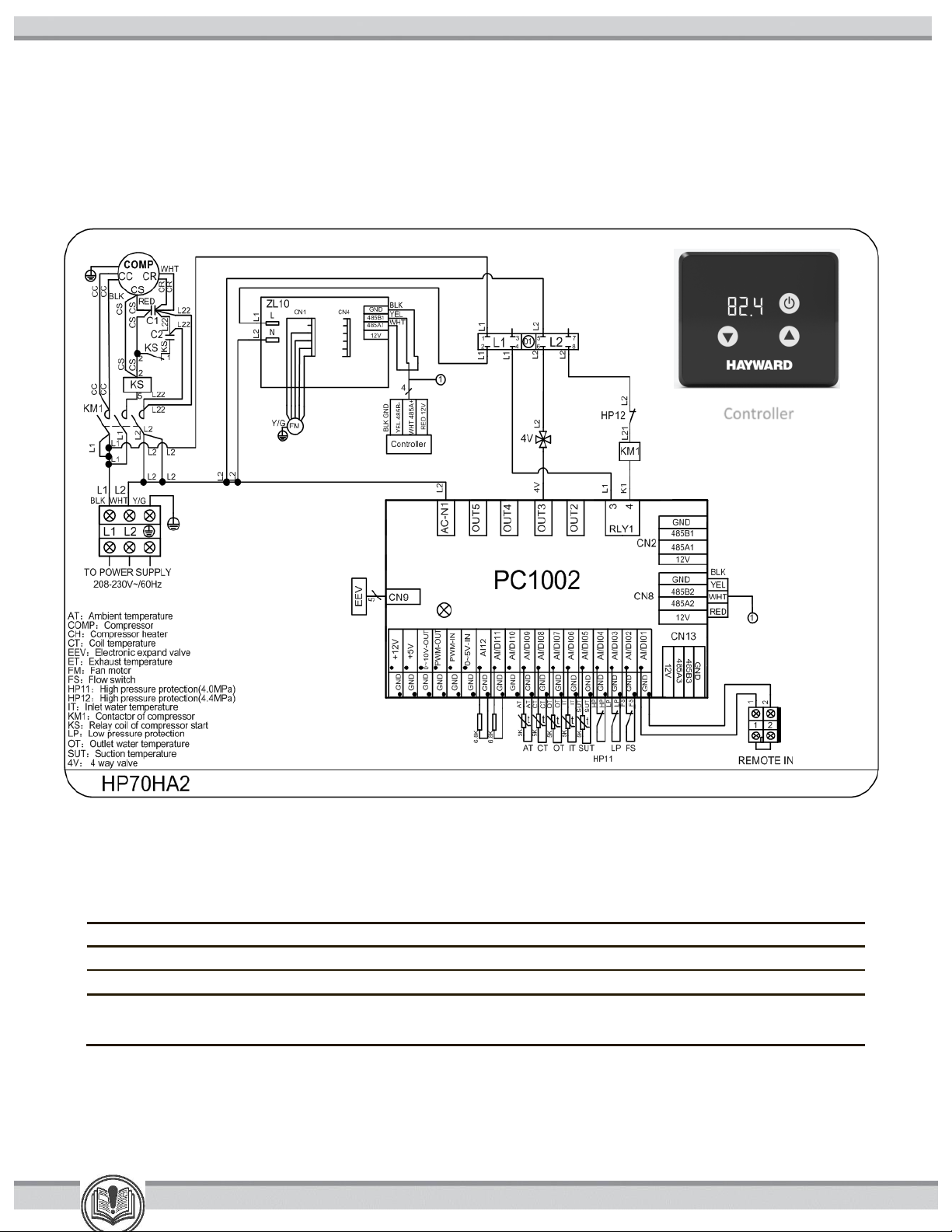

51300022501B

Figure2b Single Phase Wiring Diagram HP70HA2

Controller

CONFORMANCE WITH CODES: The heater shall be installed in accordance with all local and state codes and with

the requirements of the authority having jurisdiction of the installing site. The heater installation must conform to the

latest edition of the above listed installation codes.

SAFETY INFORMATION

6 USE ONLY GENUINE REPLACEMENT PARTS

Table2: CERTIFICATION AND COMPLIANCE

UL 60335-1 and UL 60335-2-40

C22.2 No. 60335-1 and 60335-2-40

51300022501B

WARNING – Read, Understand, and Follow all Instructions in this manual and on the equipment.

Failure to follow instructions can cause death, severe injury and/or serious property damage.

WARNING – Suction Entrapment Hazard. Suction in suction outlets and/or suction outlet covers which are,

damaged, broken, cracked, missing, or unsecured can cause death and/or severe injury due to the following

entrapment hazards:

Hair Entrapment- Hair can become entangled in suction outlet cover.

Limb Entrapment- A limb inserted into an opening of a suction outlet sump or suction outlet cover that is damaged,

broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of the limb.

Body Suction Entrapment- A negative pressure applied to a large portion of the body or limbs can result in an

entrapment.

Evisceration/ Disembowelment - A negative pressure applied directly to the intestines through an unprotected

suction outlet sump or suction outlet cover which is, damaged, broken, cracked, missing, or unsecured can result

in evisceration/ disembowelment.

Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, finger, toe or knuckle to be caught

in an opening of a suction outlet cover resulting in mechanical entrapment.

WARNING - To Reduce the risk of Entrapment Hazards:

o When outlets are small enough to be blocked by a person, a minimum of two functioning suction outlets per pump

must be installed. Suction outlets in the same plane (i.e. floor or wall), must be installed a minimum of three feet

(3’) [1 meter] apart, as measured from near point to near point.

o Dual suction fittings shall be placed in such locations and distances to avoid “dual blockage” by a user.

o Dual suction fittings shall not be located on seating areas or on the backrest for such seating areas.

o The maximum system flow rate shall not exceed the flow rating of as listed on Table 1.

o Never use Pool or Spa if any suction outlet component is damaged, broken, cracked, missing, or not securely

attached.

o Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately.

o In addition two or more suction outlets per pump installed in accordance with latest ASME, APSP Standards and

CPSC guidelines, follow all National, State, and Local codes applicable.

o Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

WARNING – Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa from the

suction outlets can result in an increase potential for suction entrapment as described above.

WARNING – Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper and other

material can result in an increase potential for suction entrapment as described above.

WARNING – Suction outlet components have a finite life, the cover/grate should be inspected frequently and

replaced at least every seven years or if found to be damaged, broken, cracked, missing, or not securely attached.

CAUTION – Components such as the filtration system, pumps and heater must be positioned so as to prevent their

being used as means of access to the pool by young children. To reduce risk of injury, do not permit children to use or

climb on this product. Closely supervise children at all times. Components such as the filtration system, pumps, and heaters

must be positioned to prevent children from using them as a means of access to the pool.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

WARNING – Hazardous Pressure. Pool and spa water heating and circulation systems operate under

hazardous pressure during start up, normal operation, and after pump shut off. Stand clear of circulation system

equipment during pump start up. Failure to follow safety and operation instructions could result in violent

separation of the pump housing and cover, and/or filter housing and clamp due to pressure in the system, which

could cause death, severe personal injury and/or property damage, Before servicing pool and spa water

circulation system, all system and pump controls must be in off position and filter manual air relief valve must be

in open position. Before starting system pump, all system valves must be set in a position to allow system water

to return back to the pool. Do not change filter control valve position while system pump is running. Before

starting system pump, fully open filter manual air relief valve. Do not close filter manual air relief valve until a

steady stream of water (not air or air and water) is discharged.

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent

separation of pump and/or filter components. Strainer cover must be properly secured to pump housing with

strainer cover lock ring. Before servicing pool and spa circulation system, filters manual air relief valve must be in

open position. Do not operate pool and spa circulation system if a system component is not assembled properly,

damaged, or missing. Do not operate pool and spa circulation system unless filter manual air relief valve body is

in locked position in filter upper body. Never operate or test the circulation system at more than 50 PSI. Do

not purge the system with compressed air. Purging the system with compressed air can cause components to

explode, with risk of severe injury or death to anyone nearby. Use only a low pressure (below 5 PSI), high

volume blower when air purging the pump, filter, or piping.

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local

USE ONLY GENUINE REPLACEMENT PARTS 7

codes, regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death

51300022501B

or serious property damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit

to electric supply. Provide a properly located electrical receptacle. Before working on any electrical equipment,

turn off power supply to the equipment. To reduce the risk of electric shock replace damaged wiring immediately.

Locate conduit to prevent abuse from lawn mowers, hedge trimmers and other equipment. Do NOT ground to a

gas supply line.

WARNING – Risk of Electric Shock. Failure to ground all electrical equipment can cause serious or fatal electrical shock

hazard. Electrical ground all electrical equipment before connecting to electrical power supply.

WARNING – Risk of Electric Shock. Failure to bond all electrical equipment to pool structure will increase risk for

electrocution and could result in injury or death. To reduce the risk of electric shock, see installation instructions and consult a

professional electrician on how to bond all electrical equipment. Also, contact a licensed electrician for information on local

electrical codes for bonding requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to

reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) [No. 6 AWG (13.3 mm2) for Canada] solid copper bonding wire to the

pressure wire connector provided on the electrical equipment and to all metal parts of swimming pool, spa, or hot tub, and metal

piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub.

IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other general

wiring procedures.

CAUTION – These heaters are intended for use with permanently-installed pools and may be used with hot tubs and spas if

so marked. Do not use with storable pools. A permanently-installed pool is constructed in or on the ground or in a building

such that it cannot be readily disassembled for storage. A storable pool is constructed so that it is capable of being readily

disassembled for storage and reassembled to its original integrity.

WARNING – Risk of Hyperthermia. To avoid hyperthermia the following “Safety Rules for Hot Tubs” are recommended by

the U.S. Consumer Product Safety Commission.

1. Spa or hot tub water temperatures should never exceed 104°F [40°C]. A temperature of 100°F [38°C] is considered

safe for a healthy adult. Special caution is suggested for young children. Prolonged immersion in hot water can

induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub use can cause drowsiness, which could lead to

unconsciousness and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 100°F [38°C] can cause fetal damage during the first three

months of pregnancy (resulting in the birth of a brain-damaged or deformed child). Pregnant women should adhere to

the 100°F [38°C] maximum rule.

4. Before entering the spa or hot tub, users should check the water temperature with an accurate thermometer; spa or

hot tub thermostats may err in regulating water temperatures by as much as 4°F (2.2°C).

5. Persons taking medications, which induce drowsiness, such as tranquilizers, antihistamines or anticoagulants, should

not use spas or hot tubs.

6. If the pool/spa is used for therapy, it should be done with the advice of a physician. Always stir pool/ spa water before

entering the pool/spa to mix in any hot surface layer of water that might exceed healthful temperature limits and cause

injury. Do not tamper with controls, because scalding can result if safety controls are not in proper working order.

7. Persons with a medical history of heart disease, circulatory problems, diabetes or blood pressure problems should

obtain a physician’s advice before using spas or hot tubs.

8. Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above normal body

temperature of 98.6°F [37°C]. The symptoms of Hyperthermia include: drowsiness, lethargy, dizziness, fainting,

and an increase in the internal temperature of the body.

The effects of Hyperthermia include:

Unawareness of impending danger.

Failure to perceive heat.

Failure to recognize the need to leave the spa.

Physical inability to exit the spa.

Fetal damage in pregnant women.

Unconsciousness resulting in danger of drowning.

8 USE ONLY GENUINE REPLACEMENT PARTS

51300022501B

INSTALLATION

This manual contains instructions for installation, operation, maintenance, troubleshooting, and parts lists for the proper operation of

the swimming pool heaters. Manufacturer strongly recommends that the installer read the manual before installing the swimming

pool heater. If after reviewing the manual any questions remain unanswered, contact the factory or local representative. Following

heater installation, the installer should leave all manuals with the consumer for future reference.

NOTICE: The installation instructions are intended for the use of a qualified technician, specifically trained and experienced in

the installation of this type of heating equipment. Some states or provinces require that installer be licensed. If this is the case in

the state or province where heater is located, the contractor must be properly certified.

SPRINKLER HEADS: The heater is designed to handle the wettest weather conditions that are typical of rain and high

humidity. Sprinkler heads force high-pressure water into the unit from the side at an odd angle. Make sure there are no sprinkler

heads near the heater that will spray on or into the unit. Many sprinkler systems are connected to a well system, whose water is

high in minerals, Sulphur, salt and other aggressive contaminates, that will leave a buildup on the unit and electronics causing

corrosion and shortens life.

NOTICE: Damage from sprinkler interaction is not covered under the warranty agreement. Make sure that sprinklers are

placed at a sufficient distance away so that normal wind will not carry the mist to the heat pump.

NOTICE: If located in an oceanfront area, the heat pump should be placed out of direct spray of sand and salt. This will clog,

damage, and corrode the unit. You may also consider protecting the unit by creating a physical barrier outside of the minimum

clearances between the unit and the prevailing beachfront wind. Damage caused by sand or salt spray is not covered by the

warranty.

THE USE OF A POOL COVER IS RECOMMENDED. A pool cover reduces heat loss, conserves chemicals, lowers the

load on filter systems and may provide a valuable safety feature

EQUIPMENT INSPECTION: On receipt of the heater, inspect the heater carton(s) for damage. If any carton(s) is damaged,

note it when signing for it. Remove the heater from the carton(s) inspect it and advise the carrier of any damages at once.

NOTICE: Do not drop the heater from a pickup truck tailgate to the ground. This may damage the heater.

NOTICE: The heat pump must not be tipped or transported on its side as evaporator “oil logging” may occur.

MATERIALS NEEDED FOR INSTALLATION

Installer is responsible for providing all external to unit electrical supplies. Extra hardware items may also be required for anchoring.

Additional plumbing items needed:

For in ground installations: 2 inch PVC pipe Schedule 40 and 2 inch fittings and components as follows:

2 inch Isolation Valves qty(3)

2 inch Check Valve qty(1)

2 x 2 x 2 PVC Tee’s qty(2)

2 x 1 1/2 PVC Adapter qty(2) as required

For above ground installations: 1 1/2inch PVC pipe Schedule 40 or 1 1/2 in clear vinyl tubing. The HP50HA2 comes with the

required barb adapter for tubing connection. Included barbed plastic condensation drain fitting is for use on underside of unit base.

This fitting is designed to accept 3/4” clear vinyl tubing and should be run to a suitable drain.

NOTICE: Pipe fittings such as reducers, tees, and elbows cause pressure to drop as water flows through them. Plan the

plumbing layout carefully, using as few fittings as possible to connect your heat pump. See pad plumbing layout in the WATER

PIPING section for further direction.

LOCATING THE HEAT PUMP:

The installation location of the heat pump is very important for its efficient operation. The heat pump will perform more efficiently

when placed in direct sunlight with ample air intake and the avoidance of air re-circulation. Locate the pool heater in an area where

its condensation will not result in damage to the area adjacent to the heater or a nearby structure.

NOTICE: DO NOT install the heat pump in a fully enclosed space (i.e. garage, shed etc.). Such an installation will void its

warranty

All criteria given in the following sections reflect minimum clearances. However, each installation must also be evaluated on

prevailing local conditions such as proximity and height of walls and public access areas.

USE ONLY GENUINE REPLACEMENT PARTS 9

Loading...

Loading...