Page 1

51300022501B

ABOVE & IN GROUND POOL/SPA HEAT PUMP HEATERS

INSTALLATION & OPERATIONS MANUAL

FOR YOUR SAFETY

This Heat Pump is listed by ETL as complying

with the latest edition of the UL Standard for

safety for electrical heat pumps,

air-conditioners and dehumidifiers UL 60335

and CSA C22.2 No. 60335-1 and 60335-2-40

All Heat Pumps must be installed in accordance

with all applicable National and Local codes. In

the absence of local codes, refer to the latest

edition of the National Electric Code (NEC) in the

United States and the Canadian Electric Code

(CEC) in Canada.

FOR YOUR SAFETY:

This product must be installed and serviced by

authorized personnel, qualified in pool/spa heater

installation. Improper installation and/or

operation can cause death, serious injury

and/or property damage.

CONTENTS Pg.

GETTING STARTED 2

INSTALLATION 9

LOCATING THE HEATER 9

WATER PIPING 11

ELECTRICAL CONNECTIONS 14

CHECK-OUT & START-UP 15

CONTROL SETUP 15

MAINTENANCE & SERVICE 17

WATER CHEMISTRY 17

WINTERIZATION 18

COMPONENT SERVICE 18

TROUBLESHOOTING 19

PARTS 22

SAVE THESE INSTRUCTIONS

USE ONLY GENUINE REPLACEMENT PARTS 1

Page 2

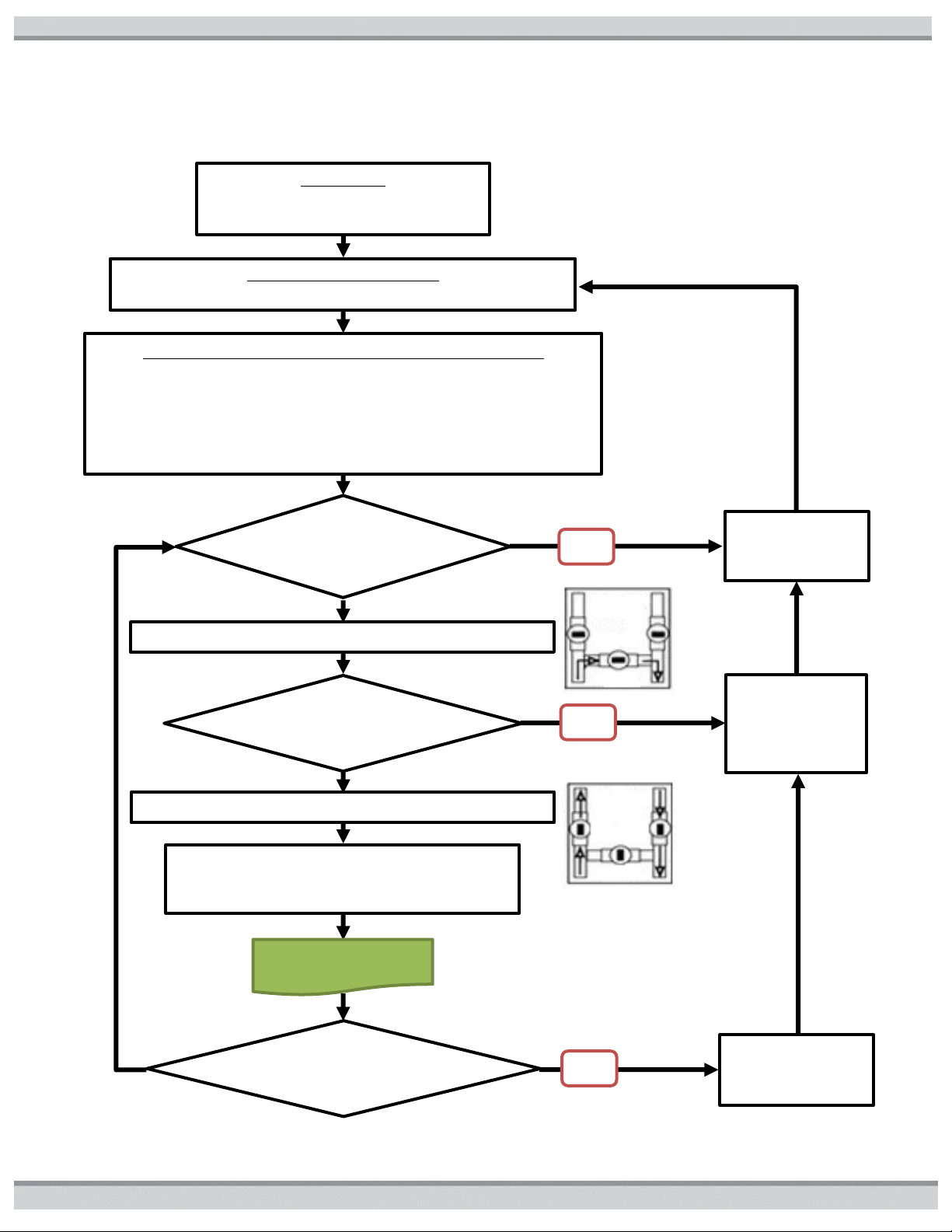

INSTALLATION

Verify that product installation was performed

to local codes and according to this manual.

IS POOL/SPA IN

CHEMICAL BALANCE?

INITIAL USE OR SPRING STARTUP

Check all pool / spa water piping. Do not connect product to water piping.

BYPASS TO CLOSED POSITION, WATER DIRECTED TO PRODUCT

TURN ON ELECTRIC POWER AND GAS AS REQUIRED.

START PRODUCT. PROGRAM REQUIRED WATER

TEMPERATURE ON PRODUCT CONTROL PANEL.

IMPORTANT FOR POOL USER HEALTH AND PRODUCT PERFORMANCE

Verify Chlorine or Bromine level every 2-3 days

Verify PH level every week

Verify Alkalinity level every 3-4 weeks (2 weeks if using an Automatic

Chlorine or Bromine Feeder)

Verify Water Hardness and Total Dissolved Solids (TDS) every month (it is

recommended that a pool professional perform this testing)

IS HEATING/COOLING

NEEDED WITHIN 1 WEEK?

SET BYPASS TO

OPEN POSITION,

WATER DIVERTED

FROM PRODUCT

CONNECT WATER PIPING TO PRODUCT, BYPASS TO OPEN POSITION

IS HEATING/COOLING

NEEDED FOR REST OF YEAR?

DISCONNECT

WATER PIPING TO

PRODUCT

TURN OFF ELECTRIC

POWER AND GAS AS

REQUIRED

NO

NO

NO

51300022501B

GETTING STARTED

WHAT TO EXPECT WHEN OPERATING YOUR POOL HEATER

This flow chart provides guidance to protect pool users and product by maintaining good water quality.

ENJOY YOUR POOL/SPA

PRODUCT

OPEN

POOL/SPA

PRODUCT

CLOSED

POOL/SPA

2 USE ONLY GENUINE REPLACEMENT PARTS

Page 3

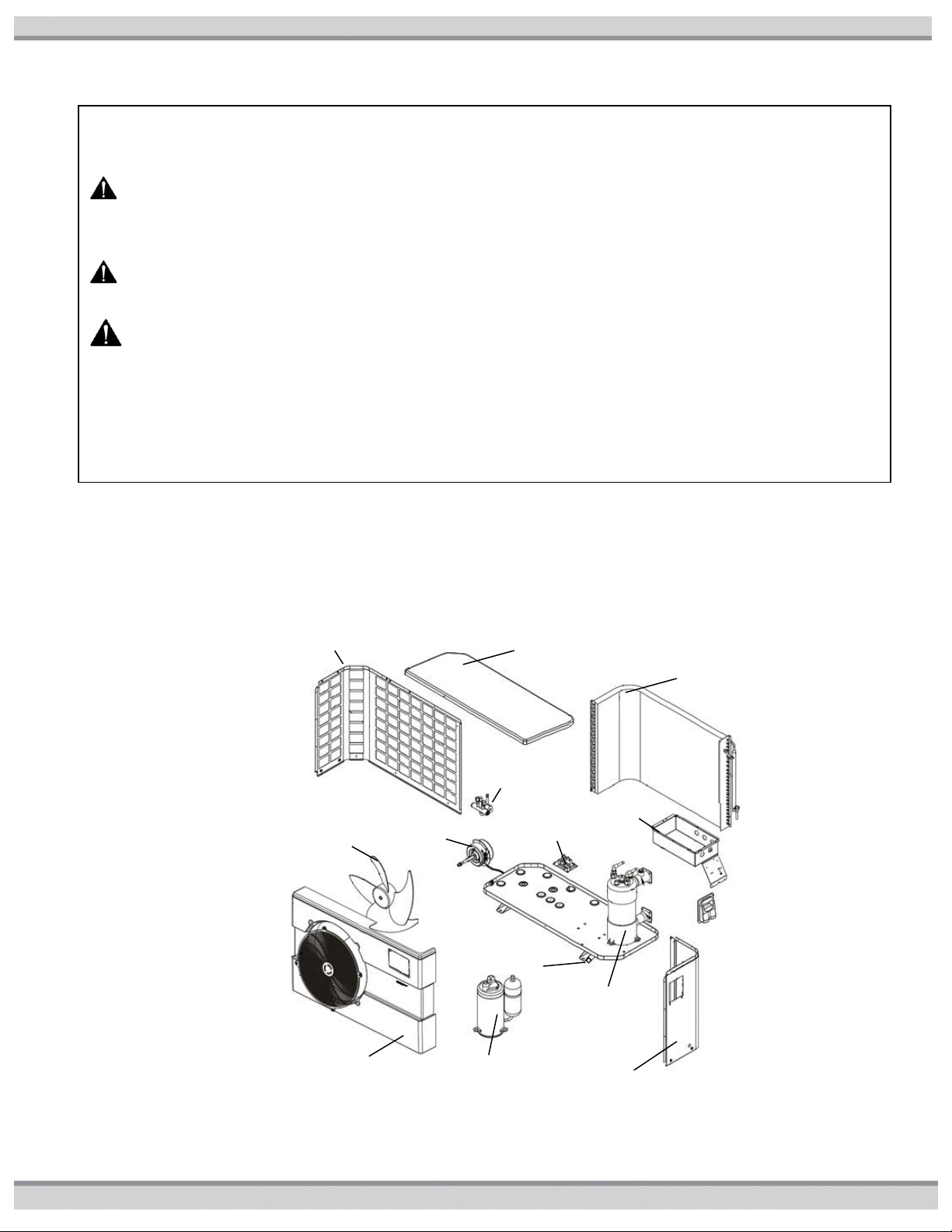

Top Panel

Coil Guard

Evaporator

Reversing

Control

Box

Front Panel

Fan

Fan

Motor

Condenser

Compressor

Service Panel

Control

Board

Bonding

Lug

51300022501B

PLEASE READ BEFORE PROCEEDING

Basic safety precautions should always be followed, including the following:

Failure to follow instructions can cause death and/or severe injury.

This is the safety-alert symbol. When you see this symbol on your equipment

or in this manual, look for one of the following signal words and be alert to the

potential for personal injury.

WARNING warns about hazards that could cause death and/or severe

injury or major property damage and if ignored presents a potential hazard.

CAUTION warns about hazards that could cause minor or moderate

personal injury and/or property damage and if ignored presents a potential

hazard. It can also make consumers aware of actions that are unpredictable

and unsafe.

NOTICE indicates special instructions that are important but not related to

hazards.

See product rating plate for manufactures information.

HEATER CONSTRUCTION

Figure1: Names of heat pump heater components

USE ONLY GENUINE REPLACEMENT PARTS 3

Page 4

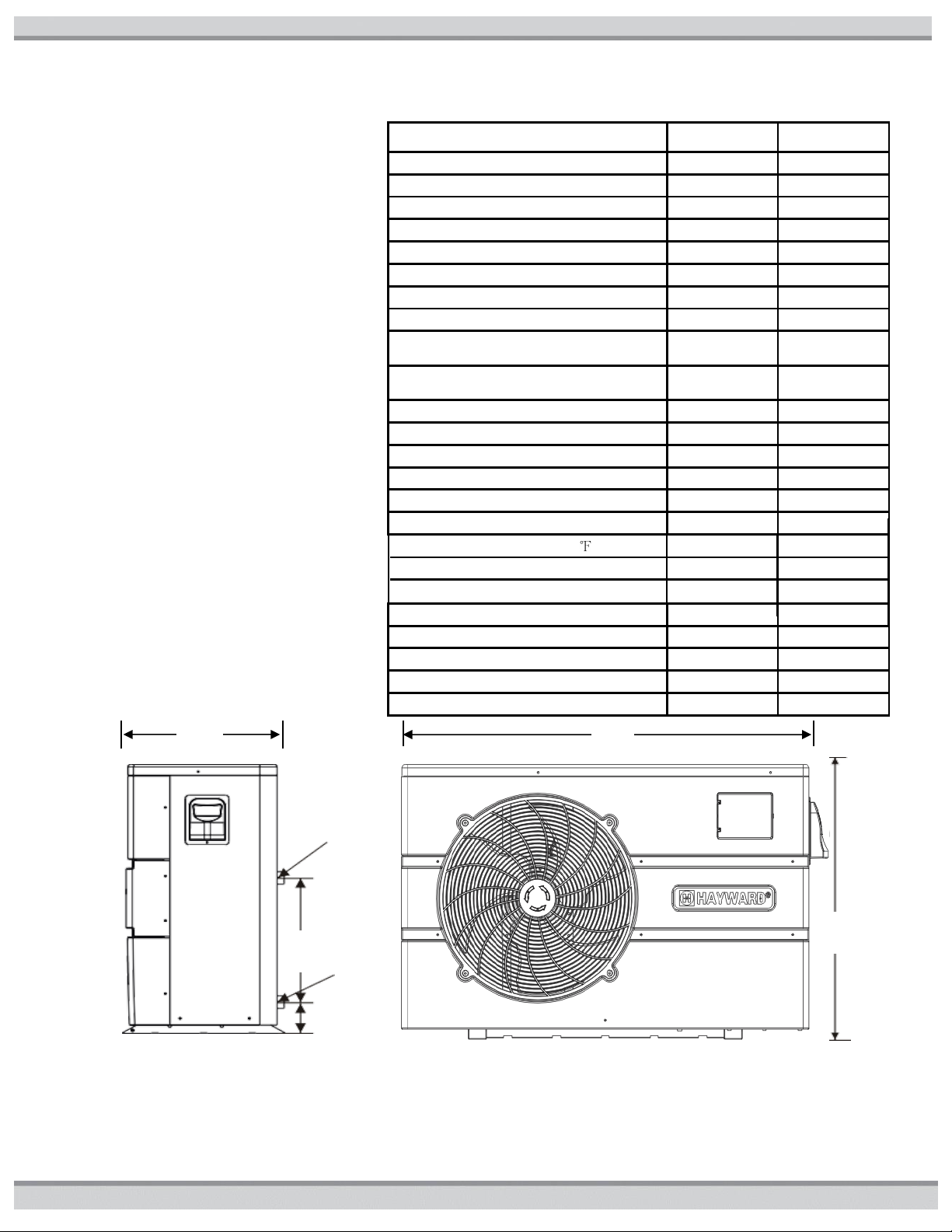

Models

HP50HA2

HP70HA2

Voltage/Phase/Hz

208-230/1/60

208-230/1/60

Capacity (btu/h) 80A-80RH-80W

47,100

73,780

Power Input, KW (80A-80RH-80W)

2.3

3.9

COP 80A-80RH-80W

6.0

5.6

Capacity (btu/h) 80A-63RH-80W

44,200

69,190

COP 80A-63RH-80W

5.8

5.4

Capacity (btu/h) 50A-63RH-80W

28,800

47,830

COP 50A-63RH-80W

4.0

4.1

Compressor/Fan Motor/System

RLA (amp)

14.5/0.5/15

19.5/0.8/20.5

Compressor/Fan Motor/System

LRA (amp)

60

70

Min. Circuit Ampacity (amp)

22

30

35

45

35 45

20.3

31.2

16

25

25

38

1.5” & barb

2” TriStar

10.4

15.7

44.5x18.5x31.1

48.0x19.3x34.6

152

230

185

270

44.9x18.9x36.3

48.4x19.7x39.8

H

Outlet

Inlet

Y

4in

L

W

51300022501B

Features:

Titanium heat exchanger

withstands the harshest water

conditions

Quiet/Reliable R410A Compressor

Digital Electronic Control with

o Easy to read display;

o Auto mode for automatic

heating and cooling operation

o Display of diagnostic codes

UV resistant cabinet for long life

Defrost function to manage

evaporator coil frosting for low

ambient temperature operation

High (590PSI) and low (80PSI)

refrigerant pressure switches

monitoring extreme operation

Corrosion resistant evaporator

fins

Table1: SPECIFICATIONS

Recommended Breaker Size (amp)

Max Fuse Breaker Size (amp)

Recommended water flow (gpm)

Minimum water flow (gpm)

Maximum water flow (gpm)

Operating water temperature( )

Min/Max. operating water pressure(PSI)

Water Connector (dia. in)

Connection Height Y (in)

Unit size L x W x H (in)

Weight (lbs)

Shipping Weight (lbs)

Shipping size L x W x H (in)

48.2/104

43.5/435

48.2/104

43.5/435

4 USE ONLY GENUINE REPLACEMENT PARTS

Page 5

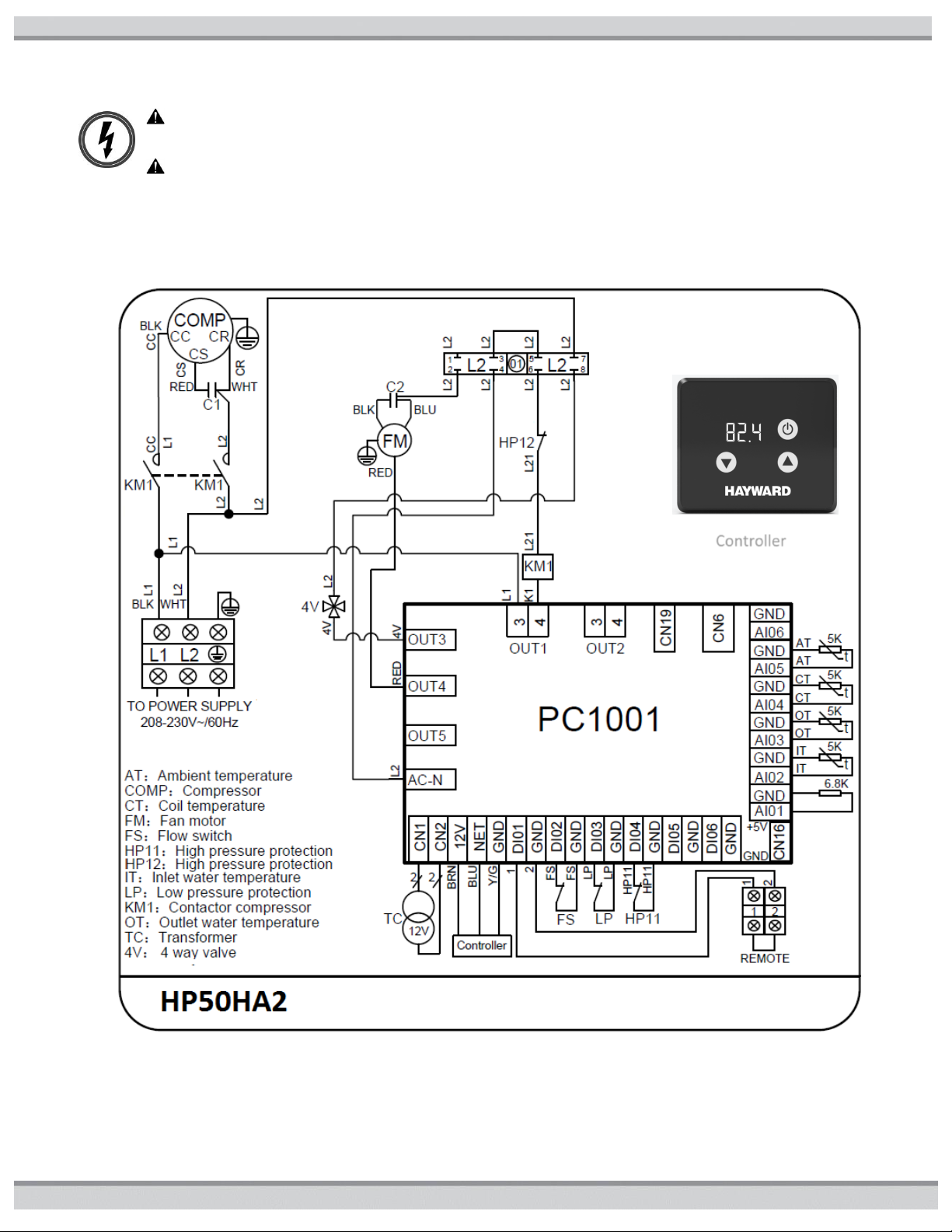

Wiring Connection Diagram

WARNING – Risk of Electric Shock Before working on any electrical equipment, turn off power supply to the

equipment.

WARNING – Risk of Electric Shock. All electrical wiring MUST conform to applicable local codes, regulations,

and the National Electric Code (NEC). Hazardous voltage can cause death, shock, burn, and/or serious property

damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide

a properly located electrical receptacle. To reduce the risk of electric shock replace damaged wiring immediately.

Locate conduit to prevent abuse from lawn mowers, hedge trimmers and other equipment. Do NOT ground to a gas

supply line.

Figure2a Single Phase Wiring Diagram HP50HA2

51300022501B

Controller

USE ONLY GENUINE REPLACEMENT PARTS 5

Page 6

CERTIFICATION CODES AND STANDARDS

USA CANADA

DESIGN CERTIFIED

ETL/ITS

ETL/ITS

DESIGN COMPLIANT

INSTALLATION COMPLIANT ELECTRIC

ANSI/NFPA 70

NEC

CSA C22.1 – Canadian

Electrical Code, Part I

51300022501B

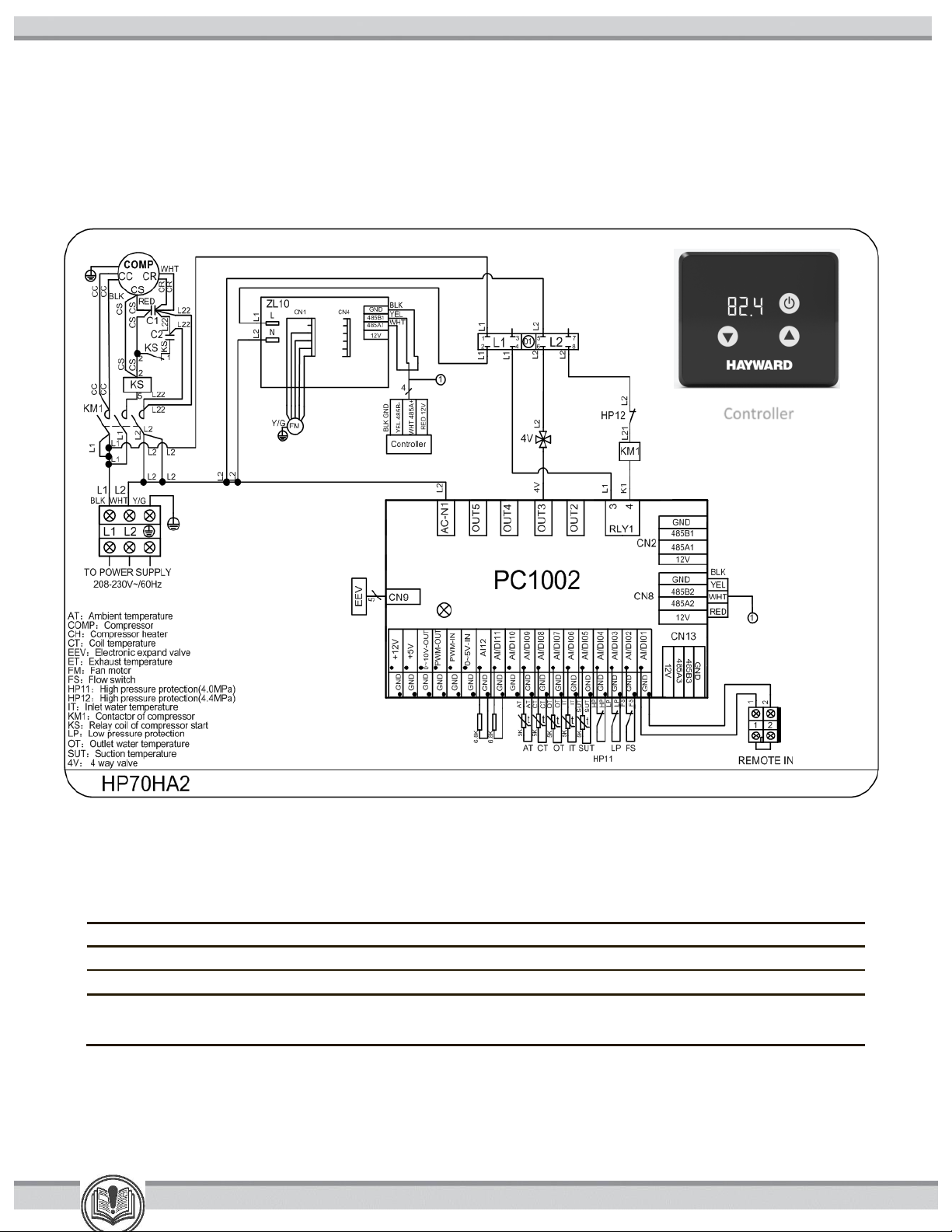

Figure2b Single Phase Wiring Diagram HP70HA2

Controller

CONFORMANCE WITH CODES: The heater shall be installed in accordance with all local and state codes and with

the requirements of the authority having jurisdiction of the installing site. The heater installation must conform to the

latest edition of the above listed installation codes.

SAFETY INFORMATION

6 USE ONLY GENUINE REPLACEMENT PARTS

Table2: CERTIFICATION AND COMPLIANCE

UL 60335-1 and UL 60335-2-40

C22.2 No. 60335-1 and 60335-2-40

Page 7

51300022501B

WARNING – Read, Understand, and Follow all Instructions in this manual and on the equipment.

Failure to follow instructions can cause death, severe injury and/or serious property damage.

WARNING – Suction Entrapment Hazard. Suction in suction outlets and/or suction outlet covers which are,

damaged, broken, cracked, missing, or unsecured can cause death and/or severe injury due to the following

entrapment hazards:

Hair Entrapment- Hair can become entangled in suction outlet cover.

Limb Entrapment- A limb inserted into an opening of a suction outlet sump or suction outlet cover that is damaged,

broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of the limb.

Body Suction Entrapment- A negative pressure applied to a large portion of the body or limbs can result in an

entrapment.

Evisceration/ Disembowelment - A negative pressure applied directly to the intestines through an unprotected

suction outlet sump or suction outlet cover which is, damaged, broken, cracked, missing, or unsecured can result

in evisceration/ disembowelment.

Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, finger, toe or knuckle to be caught

in an opening of a suction outlet cover resulting in mechanical entrapment.

WARNING - To Reduce the risk of Entrapment Hazards:

o When outlets are small enough to be blocked by a person, a minimum of two functioning suction outlets per pump

must be installed. Suction outlets in the same plane (i.e. floor or wall), must be installed a minimum of three feet

(3’) [1 meter] apart, as measured from near point to near point.

o Dual suction fittings shall be placed in such locations and distances to avoid “dual blockage” by a user.

o Dual suction fittings shall not be located on seating areas or on the backrest for such seating areas.

o The maximum system flow rate shall not exceed the flow rating of as listed on Table 1.

o Never use Pool or Spa if any suction outlet component is damaged, broken, cracked, missing, or not securely

attached.

o Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately.

o In addition two or more suction outlets per pump installed in accordance with latest ASME, APSP Standards and

CPSC guidelines, follow all National, State, and Local codes applicable.

o Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

WARNING – Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa from the

suction outlets can result in an increase potential for suction entrapment as described above.

WARNING – Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper and other

material can result in an increase potential for suction entrapment as described above.

WARNING – Suction outlet components have a finite life, the cover/grate should be inspected frequently and

replaced at least every seven years or if found to be damaged, broken, cracked, missing, or not securely attached.

CAUTION – Components such as the filtration system, pumps and heater must be positioned so as to prevent their

being used as means of access to the pool by young children. To reduce risk of injury, do not permit children to use or

climb on this product. Closely supervise children at all times. Components such as the filtration system, pumps, and heaters

must be positioned to prevent children from using them as a means of access to the pool.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

WARNING – Hazardous Pressure. Pool and spa water heating and circulation systems operate under

hazardous pressure during start up, normal operation, and after pump shut off. Stand clear of circulation system

equipment during pump start up. Failure to follow safety and operation instructions could result in violent

separation of the pump housing and cover, and/or filter housing and clamp due to pressure in the system, which

could cause death, severe personal injury and/or property damage, Before servicing pool and spa water

circulation system, all system and pump controls must be in off position and filter manual air relief valve must be

in open position. Before starting system pump, all system valves must be set in a position to allow system water

to return back to the pool. Do not change filter control valve position while system pump is running. Before

starting system pump, fully open filter manual air relief valve. Do not close filter manual air relief valve until a

steady stream of water (not air or air and water) is discharged.

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent

separation of pump and/or filter components. Strainer cover must be properly secured to pump housing with

strainer cover lock ring. Before servicing pool and spa circulation system, filters manual air relief valve must be in

open position. Do not operate pool and spa circulation system if a system component is not assembled properly,

damaged, or missing. Do not operate pool and spa circulation system unless filter manual air relief valve body is

in locked position in filter upper body. Never operate or test the circulation system at more than 50 PSI. Do

not purge the system with compressed air. Purging the system with compressed air can cause components to

explode, with risk of severe injury or death to anyone nearby. Use only a low pressure (below 5 PSI), high

volume blower when air purging the pump, filter, or piping.

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local

USE ONLY GENUINE REPLACEMENT PARTS 7

codes, regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death

Page 8

51300022501B

or serious property damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit

to electric supply. Provide a properly located electrical receptacle. Before working on any electrical equipment,

turn off power supply to the equipment. To reduce the risk of electric shock replace damaged wiring immediately.

Locate conduit to prevent abuse from lawn mowers, hedge trimmers and other equipment. Do NOT ground to a

gas supply line.

WARNING – Risk of Electric Shock. Failure to ground all electrical equipment can cause serious or fatal electrical shock

hazard. Electrical ground all electrical equipment before connecting to electrical power supply.

WARNING – Risk of Electric Shock. Failure to bond all electrical equipment to pool structure will increase risk for

electrocution and could result in injury or death. To reduce the risk of electric shock, see installation instructions and consult a

professional electrician on how to bond all electrical equipment. Also, contact a licensed electrician for information on local

electrical codes for bonding requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to

reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) [No. 6 AWG (13.3 mm2) for Canada] solid copper bonding wire to the

pressure wire connector provided on the electrical equipment and to all metal parts of swimming pool, spa, or hot tub, and metal

piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub.

IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other general

wiring procedures.

CAUTION – These heaters are intended for use with permanently-installed pools and may be used with hot tubs and spas if

so marked. Do not use with storable pools. A permanently-installed pool is constructed in or on the ground or in a building

such that it cannot be readily disassembled for storage. A storable pool is constructed so that it is capable of being readily

disassembled for storage and reassembled to its original integrity.

WARNING – Risk of Hyperthermia. To avoid hyperthermia the following “Safety Rules for Hot Tubs” are recommended by

the U.S. Consumer Product Safety Commission.

1. Spa or hot tub water temperatures should never exceed 104°F [40°C]. A temperature of 100°F [38°C] is considered

safe for a healthy adult. Special caution is suggested for young children. Prolonged immersion in hot water can

induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub use can cause drowsiness, which could lead to

unconsciousness and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 100°F [38°C] can cause fetal damage during the first three

months of pregnancy (resulting in the birth of a brain-damaged or deformed child). Pregnant women should adhere to

the 100°F [38°C] maximum rule.

4. Before entering the spa or hot tub, users should check the water temperature with an accurate thermometer; spa or

hot tub thermostats may err in regulating water temperatures by as much as 4°F (2.2°C).

5. Persons taking medications, which induce drowsiness, such as tranquilizers, antihistamines or anticoagulants, should

not use spas or hot tubs.

6. If the pool/spa is used for therapy, it should be done with the advice of a physician. Always stir pool/ spa water before

entering the pool/spa to mix in any hot surface layer of water that might exceed healthful temperature limits and cause

injury. Do not tamper with controls, because scalding can result if safety controls are not in proper working order.

7. Persons with a medical history of heart disease, circulatory problems, diabetes or blood pressure problems should

obtain a physician’s advice before using spas or hot tubs.

8. Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above normal body

temperature of 98.6°F [37°C]. The symptoms of Hyperthermia include: drowsiness, lethargy, dizziness, fainting,

and an increase in the internal temperature of the body.

The effects of Hyperthermia include:

Unawareness of impending danger.

Failure to perceive heat.

Failure to recognize the need to leave the spa.

Physical inability to exit the spa.

Fetal damage in pregnant women.

Unconsciousness resulting in danger of drowning.

8 USE ONLY GENUINE REPLACEMENT PARTS

Page 9

51300022501B

INSTALLATION

This manual contains instructions for installation, operation, maintenance, troubleshooting, and parts lists for the proper operation of

the swimming pool heaters. Manufacturer strongly recommends that the installer read the manual before installing the swimming

pool heater. If after reviewing the manual any questions remain unanswered, contact the factory or local representative. Following

heater installation, the installer should leave all manuals with the consumer for future reference.

NOTICE: The installation instructions are intended for the use of a qualified technician, specifically trained and experienced in

the installation of this type of heating equipment. Some states or provinces require that installer be licensed. If this is the case in

the state or province where heater is located, the contractor must be properly certified.

SPRINKLER HEADS: The heater is designed to handle the wettest weather conditions that are typical of rain and high

humidity. Sprinkler heads force high-pressure water into the unit from the side at an odd angle. Make sure there are no sprinkler

heads near the heater that will spray on or into the unit. Many sprinkler systems are connected to a well system, whose water is

high in minerals, Sulphur, salt and other aggressive contaminates, that will leave a buildup on the unit and electronics causing

corrosion and shortens life.

NOTICE: Damage from sprinkler interaction is not covered under the warranty agreement. Make sure that sprinklers are

placed at a sufficient distance away so that normal wind will not carry the mist to the heat pump.

NOTICE: If located in an oceanfront area, the heat pump should be placed out of direct spray of sand and salt. This will clog,

damage, and corrode the unit. You may also consider protecting the unit by creating a physical barrier outside of the minimum

clearances between the unit and the prevailing beachfront wind. Damage caused by sand or salt spray is not covered by the

warranty.

THE USE OF A POOL COVER IS RECOMMENDED. A pool cover reduces heat loss, conserves chemicals, lowers the

load on filter systems and may provide a valuable safety feature

EQUIPMENT INSPECTION: On receipt of the heater, inspect the heater carton(s) for damage. If any carton(s) is damaged,

note it when signing for it. Remove the heater from the carton(s) inspect it and advise the carrier of any damages at once.

NOTICE: Do not drop the heater from a pickup truck tailgate to the ground. This may damage the heater.

NOTICE: The heat pump must not be tipped or transported on its side as evaporator “oil logging” may occur.

MATERIALS NEEDED FOR INSTALLATION

Installer is responsible for providing all external to unit electrical supplies. Extra hardware items may also be required for anchoring.

Additional plumbing items needed:

For in ground installations: 2 inch PVC pipe Schedule 40 and 2 inch fittings and components as follows:

2 inch Isolation Valves qty(3)

2 inch Check Valve qty(1)

2 x 2 x 2 PVC Tee’s qty(2)

2 x 1 1/2 PVC Adapter qty(2) as required

For above ground installations: 1 1/2inch PVC pipe Schedule 40 or 1 1/2 in clear vinyl tubing. The HP50HA2 comes with the

required barb adapter for tubing connection. Included barbed plastic condensation drain fitting is for use on underside of unit base.

This fitting is designed to accept 3/4” clear vinyl tubing and should be run to a suitable drain.

NOTICE: Pipe fittings such as reducers, tees, and elbows cause pressure to drop as water flows through them. Plan the

plumbing layout carefully, using as few fittings as possible to connect your heat pump. See pad plumbing layout in the WATER

PIPING section for further direction.

LOCATING THE HEAT PUMP:

The installation location of the heat pump is very important for its efficient operation. The heat pump will perform more efficiently

when placed in direct sunlight with ample air intake and the avoidance of air re-circulation. Locate the pool heater in an area where

its condensation will not result in damage to the area adjacent to the heater or a nearby structure.

NOTICE: DO NOT install the heat pump in a fully enclosed space (i.e. garage, shed etc.). Such an installation will void its

warranty

All criteria given in the following sections reflect minimum clearances. However, each installation must also be evaluated on

prevailing local conditions such as proximity and height of walls and public access areas.

USE ONLY GENUINE REPLACEMENT PARTS 9

Page 10

Table3: Installation Required Clearances

Heater Panel

Outdoor Clearance

Top 20

Front (control) 98

Back (coil)

12

Rest of Perimeter 30

98in

30in

Air Flow

Air Flow

Free

from

run off

20in

98in

30in

12in

Air

Flow

51300022501B

OUTDOOR INSTALLATION AND SERVICE CLEARANCES The heater must be installed outdoors such that the installation and

service clearances shown in Table3 and Figure3 are maintained. Additional installation requirements are as listed;

1. Level surface for proper draining.

2. Suitable electrical supply line. See rating plate on the heat pump units for electrical specifications. A junction box is not needed

at the heat pump; connections are made inside the heat pump electrical compartment. Minimum wire size to be selected per

NEC based on unit MCA.

3. Electric disconnect switch that will interrupt all power to the unit. This switch MUST be within line of sight of the heat pump

4. Do not install in a location where growing shrubs may in time obstruct a heater’s air flow areas (sides or top).

5. Do not install the heater where water spray from ground level can contact the heater. The water could damage coil or reach the

controls causing electrical damage.

6. Do not install under a deck.

7. Do not install within 24in of any outdoor HVAC equipment.

8. Do not install where water may run-off a roof into the heater. A gutter may be needed to protect the heater.

CAUTION: Make sure the heat pump is not located where large amounts of water may run-off from the roof into the unit.

Sharp sloping roofs without gutters will allow massive amounts of rainwater, mixed with debris from the roof to be forced

through the unit. Failure to follow the instructions may result in property damage and a voided warranty.

1. A minimum of 24in [610mm] of clearance on all sides.

2. If the heat pump is to be installed under a vertical

overhang, the unit must have a minimum of 20in.

[500mm] of clearance from the top of the heat pump to

the bottom of the cover or overhang.

3. Install the heat pump a minimum of 60in. [1.5m] from the

inside wall of the pool, spa, solid fence, or permanent

barrier. (not shown in Figure3)

Canadian installations require a minimum of 120 in. [3 m]

of clearance from pool water.

Figure3: Outdoor Minimum Clearances

EQUIPMENT PAD: Place the heat pump on a level surface such as concrete or a fabricated slab (pad). This allows proper

drainage of condensation and rainwater from the base of the unit. If possible, the pad should be placed at the same level or slightly

higher than the filter system equipment pad.

FLOORING: This heater may be installed on either non-combustible flooring or combustible flooring that does not reduce the

bottom clearance of the heater. Ultralite™ or equivalent concrete-over-foam HVAC pads are acceptable.

10 USE ONLY GENUINE REPLACEMENT PARTS

Page 11

51300022501B

DRAINAGE AND CONDENSATION: Condensation will be produced by the evaporator coil when the unit is heating water

and drain at a steady rate, usually three to five gallons per hour, depending upon ambient air temperature and humidity. The more

humid the conditions, the more condensation will be produced. Use the supplied condensate drain to route the condensate away

from the unit and dispose appropriately. It is easy to mistake the condensation for a water leak inside the unit. A way to verify that

the water is condensation is to shut off the unit and keep the pool pump running. If the water stops running out of the base pan, it is

condensation collecting around the unit. A quicker way is to check the water for CHLORINE. If there is no chlorine present in the

water around the unit, then it’s condensation.

ANCHORING: The heater is equipped for installation of anchoring screws when required by local codes. Follow all

relevant Local, State and National requirements regarding wind load anchoring. When anchoring is required to secure the

heat pump to concrete pad, use the specified hardware shown in the figure4. To complete the installation use the

following;

Concrete tapping screws (FIELD SUPPLIED; Tapcons® stainless steel, qty (4), size to be ¼in diameter with a

minimum length of 1-1/2in)

Fender washers (FIELD SUPPLIED; stainless steel, qty (4), size to be 1-1/2in)

Figure4: Equipment Pad and Anchoring

WATER PIPING

General: The heater is for use with pool and spa/hot tub water furnished by municipal water distribution systems only. The use of

mineral water, seawater (PPM>5000), or other non-potable waters will invalidate the warranty. These heat pumps are designed for

nominal water flows through the condenser. See specifications for minimum and maximum flow requirements to ensure sufficient

heat removal and water erosion of heat exchanger tubing. The minimum flow rate is to be calculated or measured with the in-floor

cleaning system in use, if the pool is so equipped, as well as any other jets or other demands on the water flow. Flow rates above

specified maximum will create excessive pressure drop through the condenser and require unnecessarily high pumping energy.

Bypass valve setting may be accomplished by temporarily installing a flow meter on the outlet line of the heater. Then adjust the

manual bypass valve until the flowrate through the heater is within the flow rate range specified. Once the manual bypass valve is

set, note the position and remove the valve handle to prevent accidental adjustment. Failure to install an External Bypass Assembly

with flow rates above the specified maximum will void the warranty. Do not install any restriction in the water pipe between the

heater outlet and the pool with the exception of; three-way switching valve, in-line chlorinator and/or chlorinator check valve as

shown in figure5 below.

AUTOMATIC CHLORINATORS AND CHEMICAL FEEDERS: If used, a chlorinator must be installed downstream

from the heater in the pool return line and at a lower elevation than the heater as shown in Figure5. Install a separate positive seal

corrosion resistant check valve between the heater outlet and the chlorinator to prevent highly concentrated sanitizer from back

siphoning into the heater. Back siphoning may occur when the pump is shut off and a pressure differential is created.

USE ONLY GENUINE REPLACEMENT PARTS 11

Page 12

51300022501B

Figure5: Pad Plumbing Layout

CAUTION: Improperly adjusted manual bypass valves will result in damage to the heater if the flow rates are not

maintained under all operating conditions as specified in listed SPECIFICATION. The heat exchanger will fail and this damage

will not be covered under the manufacturer’s warranty.

CAUTION: The heat pump must be protected from back siphoning of water. If there is any chance of back siphoning,

provide a check valve between the pool and the filter pump inlet. Failure to follow the instructions may result in property damage

due to flooding.

CAUTION: Automatic erosion type chlorinators, if used, must be installed downstream (between the heat pump and the

pool) of the heat pump, and a check valve (or Hartford Loop) installed in a manner that will not allow the raw chlorine to drain

back to the heat pump when the water pump is off. Failure to follow the instructions may result in property damage.

CAUTION: Do not pour chemicals directly into the skimmer. It could result in damage to your system and heat pump.

Arrangement of pool system components other than as illustrated in figure5 can affect the operation of the heat pump’s water

pressure switch. Location of the heat pump above or below the elevation of the pool water surface can also affect operation of the

switch. In general, the pressure switch can be adjusted to accommodate this effect if the heat pump water connections are no more

than six (6) feet [1,8 m] below the pool water surface or no more than fifteen (15) feet [4,6 m] above it. See instructions for pressure

switch adjustment in the START-UP section of this manual. If the heat pump is installed outside of this range, an external pressure

switch may need to be installed in the plumbing upstream of the heat pump.

NOTICE: Be advised, that when pool equipment is located below the pool surface, a leak at this lower level can result in

large-scale water loss or flooding. Manufacturer is not responsible for water loss or damage it causes

.

UNIONS: The heater is equipped with two

detachable union connectors, (2 union nuts and 2

gaskets) included with the heat pump. These

fittings must be installed on the heat pump water

inlet and outlet to facilitate servicing and winterizing

the unit. (See figure6). Heat sinks, heat tapes,

firemen switches, and check valves are not required

on the heater. However, if there is any chance of

“back-siphoning” of hot water when the pump stops

running, it is suggested that a check valve be used

on the heater outlet pipe down stream of bypass

system

Figure6: In Ground Included Union Connectors

12 USE ONLY GENUINE REPLACEMENT PARTS

Page 13

51300022501B

INSTALLATION ABOVE

POOL/SPA SURFACE: If the heater is

installed less than three (3) feet above the

surface of the pool/spa water, install eyeball

fittings or directional flow fittings on the end

of the return water line to the pool/spa to

create adequate back pressure at the heater

to operate the pressure safety switch when

the pump is running. If the heater is installed

more than three (3) feet above the surface of

the pool/spa water, install a loop as shown in

Figure7 to prevent drainage of water in the

heater during a filter change. For installation

above or below the pool/spa surface, refer to

START UP section for proper pressure

switch setup.

TYPICAL POOL ARRANGEMENT:

Figure8 illustrates a typical pool piping

diagram and layout for the pool equipment.

Also shown is implementation of an optional

Gas or Solar heater system for additional

capacity. Other pool heaters, such as gasfired or solar-powered devices must be

installed in a parallel circuit and operated

independently (only one at a time) for your

warranty to be valid.

NOTICE - Because of the intense

heat that can be generated by gas and

solar units, isolating it with a shut-off

valve and a check valve when gas or

solar heater is in operation protects the

heat pump. Failure to follow the

instructions may result in property

damage.

Notes:

1. Isolate the heat pump from hot

water flow of heating devices such as

gas or solar heater.

2. Install bypass loop for heat pump

unit.

Figure9 illustrates a multiple heater

installation for very large pools with and

without a manual bypass valve.

1. Maintain 4-6ft [1,2-1,8 m] clearance

between the units, 2ft [0,6 m] around

perimeter, and at least 6ft [1,8 m] over

them. Refer to LOCATING THE

HEATER section for more details.

2. Install bypass loops for each unit.

3. Install union style fittings from the heat

pump CONSUMER KIT adjacent to the

unit to facilitate easy service procedures

Figure7: Heater Installation Above Pool

Figure8: Typical Plumbing to Pool

Figure9: Multiple Heater System

USE ONLY GENUINE REPLACEMENT PARTS 13

Page 14

51300022501B

ELECTRICAL CONNECTIONS:

GENERAL INFORMATION: An external supply of power is required to operate the pool heater system. Review

SPECIFICATIONS for this heater in the GETTING STARTED section to properly size field power connections. All wiring

connections to the heater must be made in accordance with the latest edition of the National Electrical Code ANSI/NFPA 70, unless

local code requirements specify otherwise. In Canada, follow CSA C22.1 Canadian Electrical Code, Part 1. The heater must be

electrically grounded and bonded in accordance with local codes or, in the absence of local codes, with National Electrical Code,

ANSI/NFPA 70. Wiring connections must be made as shown in the wiring diagram found inside the heater cabinet, and a copy is

provided for convenience in the GETTING STARTED section at the beginning of the manual. The heater must also have an

independent ground and bond connections. There is a ground lug inside the control box adjacent to the power connections and a

bonding lug on the side of the heater. Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding

lug to reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) solid copper bonding wire to the grounding lug provided on the

heat pump and to all metal parts of swimming pool or spa, and to all electrical equipment, metal piping (except gas piping), and

conduit within 5 ft. (1.5 m) of inside walls of swimming pool or spa. IMPORTANT - Reference NEC codes for all wiring standards

including, but not limited to, grounding, bonding and other general wiring procedures.

WARNING: Risk of Electric Shock Review all safety information provided in the GETTING STARTED section

of this manual prior to servicing. Always disconnect power circuit before connecting the heat pump, or working on

the heat pump. This equipment contains wiring that carries high voltage. Contact with these wires could result in

death or personal injury and/or may also cause property damage.

WARNING: All electrical wiring MUST be in conformance with all applicable local codes, regulations and the

National Electric Code (NEC), in particular NEC Article 680: Swimming Pools, Fountains & Similar Installations

and Article 440: Air-Conditioning & Refrigeration Equipment.

NOTICE: Manufacturer does not recommend the use of ground fault protective devices in conjunction with heat

pumps. Most service calls regarding tripping of ground fault devices, are found to be “nuisance” calls. GFCI

nuisance trips are not covered under warranty.

NOTICE: If voltage drops below 208V, this may damage the heat pump and void the warranty. Take proper

steps to ensure correct voltage at the heat pump during operation

ELECTRICAL CONNECTIONS: Turn OFF source power

to the heat pump before working on electrical connections. Any

unused openings must be plugged and all wiring secured for

proper strain relief. The power connections are to be made on

the contactor terminals located in the control box (see Figure11

Power Connections).

A damaged cord be replaced with

one supplied by the unit manufacture and not repaired

Use supply wires suitable for -7~43 °C

Figure11: Power Connections

Figure12: Remote Control

If the unit is controlled with remote on/off connection with

remote temperature control;

For heating, set mode to Heat set thermostat to 104°F

For cooling, set mode to Cool set thermostat to 65°F.

The remote on/off can then activate the unit as needed for

remote temperature control.

NOTICE: Pump must be running for unit to operate with

remote control connection.

All remote wiring must be run in a conduit separate from

incoming power. Use 22 AWG wire for runs less than 30 feet.

Use 20 AWG wire for runs over 30 feet. The maximum

allowable run is 200 feet.

REMOTE CONTROL CONNECTION: The heater is

equipped for remote control via an independent 2-wire

connection. (See Figure12 for remote in connection). The unit is

factory shipped with the jumper in place. The jumper can be

replaced with a remote switch to activate the unit. It is

recommended the unit be placed in Auto mode if only a remote

switch closure is used. Temperature is set at the unit controller.

14 USE ONLY GENUINE REPLACEMENT PARTS

Page 15

51300022501B

CHECK-OUT & START-UP

GENERAL: After completing the installation connections to the pool heater, follow the procedures outlined below to ensure that

the pool heater is functioning properly. Before proceeding, MAKE CERTAIN there are no water leaks in any plumbing connections

or piping and water flow is within the proper flow rate ranges. The heater is equipped with a control system that automatically

monitors the water temperature set points and safety devices. As water conditioning is needed, it turns on the compressor to start

the appropriate transfer of heat to the water. Figure13 provides a summary of heater components and their locations in the system.

Check that the pump is operating and the system is filled with water prior to starting the heater.

Figure13: Location of Components (heating operation flow shown)

The heat pump takes heat from the environment and uses it to heat the pool water. During heat pump operation, high temperature,

high-pressure sub cooled liquid Refrigerant (A) is throttled by Metering Device (TXV) and turned into low temperature, low-pressure

saturated liquid (B). The two-phase Refrigerant flows through the Air Coil (Evaporator), where the liquid refrigerant evaporates into

vapor by absorbing heat from the surrounding air. At the outlet of the Air Coil (Evaporator) it becomes a low temperature, lowpressure superheated vapor (C). The Compressor receives this flow at the suction line (D), and compresses it into a high

temperature, high pressure superheated vapor, which is discharged from the Compressor (E) and flows through the reversing valve

into the Water Heat Exchanger (Condenser). The heat carried by the flow is then released to the pool water. At the same time, the

high temperature, high-pressure superheated vapor is then condensed back to high-pressure sub cooled liquid (A), which

completes the cycle. The water, which is being forced through the Water Heat Exchanger (Condenser) by the pool pump, is thus

heated as it passes through.

HEAT PUMP PROTECTION FEATURES: These heat pumps are equipped with safeguards that will stop heater operation

to protect the unit in case of the following events:

• Excessively high refrigerant pressure

• Excessively high water temperature

• Loss of refrigerant

• Evaporator Freeze-up

• Low Ambient Temperature

CONTROL SETUP

This pool heater is equipped with a digital thermostat which allows the user to select the desired water temperature. The heater will

then function automatically to maintain the desired temperature. The heater has 3 modes of operation:

1. HEATING: in this mode, the heater will automatically function to manage a minimum water temperature setting.

2. COOLING: in this mode, the heater will automatically function to manage a maximum water temperature setting.

3. AUTO: In this mode the heat pump will automatically respond to either a call for heating or cooling as described above.

USER INTERFACE PANEL AND INPUTS: The

control displays temperatures, mode selections,

diagnostic codes and accepts user inputs via the three

buttons of the user panel.

ON/OFF Button Press the key to activate the

unit. The will also cancel the present selection

when making adjustments.

LED Display When power is supplied to the unit,

the display will either show sensor temperature (in

degrees F or C), operation mode or the diagnostic code.

Up / Down Arrow Buttons Raises or lowers the

temperature set point or toggles the selection.

Figure14: User Interface Panel

USE ONLY GENUINE REPLACEMENT PARTS 15

Page 16

Press the key 0.5s

Present return

water temperature

Cooling mode

Heating mode

Auto mode

Press & hold and keys

Press the key

Press the

or key,

current set pt

flashes

Press the or

key to adjust

set pt temp.

Press the

key 2s to

temporarily

display outlet

temp.

Example:

Water Inlet

Temp. Sensor

malfunction

To switch between Fahrenheit and Celsius,

Press and hold the and keys for 7s

and display units will be converted

51300022501B

Turn Unit ON/OFF: When the unit is off, press the key to turn the unit ON; when the unit is on, press the key to turn the

unit OFF. Pressing the key will also cancel the any selection when making a change or adjustment.

Mode Setting: When unit is operating press and hold and to display the current mode, then press or to cycle through

the mode selections. Pressing will cancel the change and return operation to the original temperature display mode. To save

the new mode, do not press a key for 5s and the displayed value will be saved and operation will return to temperature display

mode.

Press the key

Setting/Displaying Temperatures: When unit is operating, press either or and the current temperature set point flashes.

Then press either or to increase or decrease the temperature set point. Pressing will cancel the change and return

operation to the original temperature display mode. To save the new temperature set point, do not press a key for 5s and the

displayed value will be saved and operation will return to temperature display mode. To view the outlet temperature while in the

temperature display mode press and hold for 2s. The outlet temperature is temporarily displayed, and then the display is

returned to temperature display mode.

Keyboard Lock: To avoid unintended operations, the controller keys may be locked after parameter setting. At the main interface,

press and hold the key for 5s. After beep, the keys are locked. Repeat to unlock keys. When the unit is displaying error codes,

the key lock is unlocked automatically to allow immediate cycling through codes.

Error and Operation Codes: If multiple error or operation codes are available for display, Press the or key to cycle through

codes. See Display Code Index for descriptions.

16 USE ONLY GENUINE REPLACEMENT PARTS

Page 17

Table4: Water Chemistry

Chemical

Recommended

Level

Effect of Low Levels

Effect of High Levels

Chlorine

1 - 3 ppm

hazy water, algae growth,

bacteria causing infections

swimmer irritation, bleaching of

clothes/hair, corrosive to heat

exchanger

Bromine

2 - 4 ppm

pH

7.4 - 7.6

corrosive to heat exchanger,

swimmer irritation

cloudy water, scaling of heat

exchanger, reduced sanitizer

effectiveness

Total Alkalinity

80 - 120 ppm

corrosive to heat exchanger,

large fluctuations in pH

scaling of heat exchanger

Calcium

Hardness

200 - 400 ppm

corrosive to heat exchanger

scaling of heat exchanger

Salt

2700 - 5000 ppm

poor salt chlorinator performance

corrosive to heat exchanger

51300022501B

TWO-SPEED PUMP: In a few cases the flow from a two-speed pump is below the minimum required to operate the water flow

switch on the heater. In these cases the pump must be run at high speed to operate the heater. If the pump and piping arrangement

are such that the required minimum flow cannot be obtained, do not attempt to operate the heater. Correct the installation.

NOTICE: Heater installation, checkout, and start-up should now be completed. BE SURE to leave this manual with the pool

owner.

MAINTENANCE & SERVICE

PERIODIC INSPECTION: The heater is designed and built for long performance life when installed and operated according to the

manufacturer’s directions. Regular inspection by qualified service personnel is recommended to keep the heater working properly.

The following inspection points are suggested to help maximize heater life.

1. Periodically check the fan discharge area. The fan discharge must never be obstructed in any way and minimum clearances

must be observed. Remember that shrubs grow and in time may obstruct

2. Keep the entire pool heater area clean and free of all debris, corrosive materials, and other flammable vapors and liquids.

Remove any leaves or paper from around the heater.

3. Do not store chlorine, other pool chemicals, or other corrosives in the vicinity of the heater.

4. Do not use the heater if any part has been under water. Contact a qualified service technician to inspect the entire heater and

replace any part of the control system that was under water. If heater has been totally submerged in water it must be removed

and the entire heater must be replaced.

5. An inspection program is a good preventative maintenance measure. Keep this manual in a safe place for future reference for

yourself as well as for a service technician to consult when inspecting or servicing the heater. Additional inspection procedures

to be performed by a qualified service technician.

WATER CHEMISTRY:

WARNING: WATER CHEMISTRY. Failure to maintain proper water chemistry may cause premature heat exchanger

damage or failure

The heat exchanger in your pool heater is made from the highest quality of materials. The titanium condenser is a premium material

and the processes used to manufacture the heat exchanger are state of the art in pool heater design and manufacture. However, it

remains vital that the heat exchanger be protected from damaging or corrosive chemicals, insufficient water flow or improperly

balanced water chemistry. Heat exchanger damage or failure resulting from improper flow, improperly balanced pool water or the

improper addition of sanitizer into the water is NOT covered under the terms of the warranty. The following factors are critical to

heat exchanger protection. Follow these guidelines to help prevent pre-mature damage or failure to your heater and heat

exchanger.

1. WATER FLOW THROUGH HEATER Water must be flowing through the heater at the minimum rated flow rate during operation.

Check that the pump is operating and the system is filled with water and purged of all air prior to starting the heater. The

minimum rated flow rates are listed in the specifications section. Some installations may require an adjustment to the water

pressure switch for proper low-flow protection. Test your system and if necessary, adjust the water pressure switch as described

in WATER TESTING SECTION OF MANUAL.

USE ONLY GENUINE REPLACEMENT PARTS 17

Page 18

51300022501B

2. WATER CHEMISTRY The chemistry balance and mineral content of swimming pool and spa water changes rapidly due to the

addition of sanitizing chemicals, user loads, exposed rain, runoff and the amount of sun - to name a few. Improper chemistry

(See Table4) balance and mineral content can cause scaling and deposits to form on pool walls, in the filtration system, in the

heat exchanger tubes and additionally can promote corrosive action to all metals in the water path. Changing spa water regularly

and maintaining the correct chemical balance in your pool/spa will keep the pool/spa safe and sanitary, and will help the heat

exchanger longevity. Use a 4-way pool/spa water test kit to check your water frequently (at least weekly). Use the following

guidelines to help maintain proper water chemistry:

3. SKIMMER CHLORINATION Placing chlorine or bromine Tablets directly into the skimmer may result in high chemical

concentrations flowing through the heater. DO NOT place chlorine or bromine Tablets in the skimmer.

4. CHLORINATOR INSTALLATION Chlorinators must be installed downstream of the heater, and a check valve must be installed

between the heater and chlorinator to prevent high chemical concentrations from back flowing into the heater. Make sure your

piping arrangement meets the chlorinator installation requirements shown on page 26.

5. USE BYPASS Until water chemistry is properly balanced, so that corrosive and potentially damaging water will not flow through

the heater and therefore the heat exchanger. Close the bypass valve once the water is properly balanced.

WARNING BYPASS. Failure to close the bypass valve when attempting to operate the heater will result in extensive damage

to the heat exchanger

Ensure water flow through the heater is restored before operating the heater. A bypass feature is also advantageous for service

needs and for the ability to remove the heater from the water path when not heating.

WINTERIZATION:

In moderate climates, the heater can continue to operate during short-term cold spells. Do not use the heater to maintain the water

temperature just above freezing or for freeze protection. Care must be taken to avoid freeze-up in the heater. When it is used during

freezing weather, the pump must run continuously. The heater is not warranted against freeze-ups. In regions where freezing

temperatures are encountered, all water must be drained from the heater when it is out of service, to prevent damage to the heater

and piping. Draining the heat exchanger is recommended as part of the season’s shutdown procedures.

NOTICE: A heater damaged by freezing is not covered under the manufactures warranty.

DRAINING THE HEAT EXCHANGER: This procedure applies to installations where the heater is located higher than the pool water

level. If itis necessary to drain a pool heater located below the pool water level, you must either partially drain the pool, or isolate the

pool heater from the pool using valves, then perform draining the heat exchanger.

1. Set the heater to OFF mode using the keypad.

2. Turn the electricity to the heater OFF at the circuit breaker panel.

3. Be sure the circulating pump is OFF.

4. If no drain plug is provided, open lower inlet water union and allow all water to drain from the heater.

5. Re-install the drain plug or reattach the water union.

SPRING START-UP: This procedure should be performed annually to ready your heater for the upcoming season. In addition to

the steps outlined below, it is recommended that a PERIODIC INSPECTION also be performed.

1. Inspect and clean the heater, being sure the heater is free of leaves and debris prior to startup.

2. Properly attached inlet and outlet piping and confirm the drain valve is closed.

3. Turn the filtration system pump ON and allow the system to run long enough to purge all the air from the lines.

4. Turn the electricity to the heater ON at the circuit breaker panel.

5. Set the heater to H mode and adjust the set point to the desired temperature setting.

6. If operating difficulties are encountered, contact a qualified service company for assistance.

COMPONENT SERVICE

NOTICE: Only qualified service technicians, with appropriate test equipment, should be allowed to service the heater. For

conditions where refrigerant must be managed, an EPA certified technician is required. All of the components that comprise the

system have an effect on heater operation. Before proceeding with heater related troubleshooting tips, be certain that the pump

is operating correctly, the filters and strainers are not blocked, the valves in the piping are properly positioned, and the time

clocks are properly set.

WARNING: EXPLOSION HAZARD Do not attempt to repair broken or faulty components of this heater. Do

not modify the heater or its components in any manner. To do so may result in a malfunction that could result in

death, personal injury, or property damage. Check with the pool owner to see if any part of the heater has been

under water. Replace any electrically operated component that has been under water.

WARNING: Risk of Electric Shock Review all safety information provided in the GETTING STARTED

section of this manual prior to servicing. Always disconnect power circuit before connecting the heat pump, or

working on the heat pump. This equipment contains wiring that carries high voltage. Contact with these wires

could result in death or personal injury and/or may also cause property damage.

18 USE ONLY GENUINE REPLACEMENT PARTS

Page 19

51300022501B

TROUBLESHOOTING

ERROR and OPERATION CODES: See Table 5: Display Code Index.

TROUBLESHOOTING: See Table 6: Troubleshooting Lookup Chart.

AUTOMATIC RESET TIME: The heater will automatically reset when an error condition is corrected and resume operation.

NOTICE: These instructions are intended for the use of qualified personnel trained and experienced in the installation

and servicing of this type of heating equipment and its related system components. Some states may require installation

and service personnel to be licensed. Persons not qualified should not attempt to repair this equipment according to these

instructions. These instructions and procedures are not for the use of “do-it-yourself” consumers.

NOTICE: As a preliminary check, make sure that all wire connections are clean and tight and that all wiring conforms to

the wiring diagram.

INTERNAL WIRING: If the heater display is blank after the electrical has been installed, refer to Troubleshooting Lookup Chart

to determine the cause. Note, the cable between the display board and the control board is keyed to ensure correct connection.

USE ONLY GENUINE REPLACEMENT PARTS 19

Page 20

Table 5: Display Code Index

Display

Malfunction

Possible Cause

Information

(blank)

No power to heat pump

Tripped circuit breaker/

no power supply

Check breaker and ensure that the unit is

properly installed.

Faulty electrical

component

Call for service.

Unit will not turn on

Display module failure

Call for service.

E01

High Pressure Switch,

circuit open.

Low water flow

Check water flow to heat pump. Ensure pool

pump is on.

Clean your filter

Make sure all valves are fully open and

bypass valve is closed

Turn off fountains, etc.

High water temp

Check pool temp. confirm within allowable

limits for heating and cooling.

Call for service.

E02

Low Pressure Switch,

circuit open.

Remove debris and other items restricting air

flow to heat exchanger

Wait for outside temperature to reach 50°F.

Call for service.

E03

Flow Switch circuit open

Check water flow to heat pump. Ensure pool

pump is on.

Make sure all valves are fully open and

bypass valve is closed

Clean your filter

E06

Unit water temperature

rise to great

Low water flow

Call for service

E07

Freeze up during

cooling mode

Low water flow

Call for service

E08

Communication failure

No communication

between display and

controller

Call for service or check connection points of

display and controller

E19

Primary anti-freezing

protection heating mode

Ambient temperature too

low for operation

Call for service

E29

Primary anti-freezing

protection heating mode

Ambient temperature too

low for operation

Call for service

P01

Inlet temperature sensor

failure

Sensor short circuit, open

circuit or not connected

Call for service or replace sensor

P02

Outlet temperature

sensor failure

Sensor short circuit, open

circuit or not connected

Call for service or replace sensor

P04

Ambient temperature

sensor failure

Sensor short circuit, open

circuit or not connected

Call for service or replace sensor

P05

Pipe temperature sensor

failure

Sensor short circuit, open

circuit or not connected

Call for service or replace sensor

P07

Evaporator temperature

sensor failure

Sensor short circuit, open

circuit or not connected

Call for service or replace sensor

51300022501B

Air flow obstruction

Low Ambient

Temperature cutoff

Unit low on refrigerant

Low or no water flow or

remote on/off in use

WARNING: To avoid possible outer jacket damage or injury: (1) no materials should be stored against the jacket and

(2) care should be taken to avoid unnecessary contact (especially by children) with the jacket.

20 USE ONLY GENUINE REPLACEMENT PARTS

Page 21

Table 6: Troubleshooting Lookup Chart

Problem

Possible Cause

Possible Solution(s)

Unit is not

operating.

No power to unit

Make sure power is on.

Breaker is tripped

Check the breaker / see note above

Thermostat not turned up

high enough

Turn thermostat up until unit comes on

3 minute compressor delay

timer still running

Be sure the delay has passed

Low water flow

Make sure filter is clean

Make sure filter pump is on

Unhook cleaning devices

Outside temperature too low

Fan not functioning

Heat pump is

running but

Display LEDs do

not come on.

System Component failure.

Heat pump runs

continually

Thermostat set too high for

ambient temperature

Evaporator is dirty.

Clean by running tap water over the coil without

additional nozzle attachment. Do not use

pressurized water as it can damage the coil and

void warranty.

Electrical component failure

Turn off pump. If the unit is still running after 3

minutes, turn off the power to the unit and call for

service.

Heat pump is

cycling (on / off

too quickly)

Bad bypass valve or

improper water flow

Ensure water flow is sufficient (is the filter pump

running continually?) If heat pump continues to

cycle, turn unit off to prevent compressor

damage.

Low refrigerant, low ambient

temp, or high humidity with

low ambient temp

Check evaporator coil for severe frost. Turn unit

off to prevent compressor damage.

If heat pump continues to cycle, turn unit off to

prevent compressor damage. Call for service.

Water is coming

from bottom of unit

Condensation

This is normal and there is no reason to be

concerned

Possible water leak

Turn the unit off for several hours, but leave the

filter pump running continuously. If water

quantity decreases, then it is only condensation.

Otherwise there is a possible leak.

51300022501B

Check outside ambient temperature or wait for

warmer temperatures to operate. (refer to

Operating section)

Call for service.

Call for service.

Turn thermostat down

USE ONLY GENUINE REPLACEMENT PARTS 21

Page 22

51300022501B

PARTS

Figure16a: Service Parts Exploded View HP50HA2

22 USE ONLY GENUINE REPLACEMENT PARTS

Page 23

Item No.

Part No.

Description

1

HPX20000-110041

Compressor

2

HPX2002-8881

Steel sleeve 3

User Interface

4

HPX3400-2203

Drainage Adapter

5

HPX32008-220053

Logo Mounting Plate

6

HPX2000-1460

Tee

7

HPX20000-230596

Hayward Logo

8

HPX80900662

Front Panel

9

HPX32008-220052

Front Trim

10

HPX80300003

Fan

11

HPX20000-220188

Fan guard

12

HPX80200144

Fan motor

13

HPX32008-210069

Front Cover

14

HPX32012-210742

Motor bracket

15

HPX32012-210737

Top Cover

16

HPX32012-210740

Control Top Cover

17

HPX32012-210736

Coil Guard

18

HPX2001-1418

Four-way valve

19

HPX2000-3505

Compressor capacitor

20

HPX32008-220054

Top Panel

21

HPX2002-1443

Variable diameter

22

HPX20000-390231

Five-connector

23

HPX2000-3909

Two-connector

24

HPX20000-370006

Power transformer

25

HPX2004-1446

Filter

26

HPX80600627

Evaporator heat exchanger

27

HPX2000-3501

Fan capacitor

28

HPX2000-3603

Pressure switch (0.30MPa/0.15MPa)

29

HPX20000-360005

Water flow switch

30

HPX32012-210739

Electrical box

31

HPX2001-3605

Pressure switch (3.2 MPa / 4.4 Mpa)

32

HPX2000-3242

Water outlet sensor

33

HPX32009-220029

Terminal box

34

HPX2000-3242

Water inlet sensor

35

HPX80600622

Titanium tubular exchanger

36

Tee

37

HPX32012-210735

Right-side plate

38

Needle Valve

39

HPX20000-360059

Pressure switch (3.2 MPa / 4.0 Mpa)

40

HPX32012-210738

Median septum

41

HPX95005-310145

PC1001

42

HPX32012-210741

Chassis

HPX304030-00000002

HPX20000-140150

HPX72200268

Figure16b: Service Parts HP50HA2

USE ONLY GENUINE REPLACEMENT PARTS 23

Page 24

51300022501B

PARTS

Figure16a: Service Parts Exploded View HP70HA2

24 USE ONLY GENUINE REPLACEMENT PARTS

Page 25

Item No.

Part No.

Description

1

HPX20000-110429-

Compressor

2

HPX80707301

Chassis

3

HPX32009-210634

Motor bracket

4

HPX95005-310598

User Interface

5

HPX20000-270004-

Fan

6

Fan guard

7

HPX80900640

Front Panel

8

HPX80600667

Evaporator heat exchanger

9

HPX20000-140150

Needle Valve

10

HPX2000-3909

Two-connector

11

HPX20000-360297

Relay

12

HPX32017-220002

Front frame decoration 1

13

HPX2000-3603

Pressure switch (0.30MPa/0.15MPa)

14

HPX20000-360059

Pressure switch (3.2 MPa / 4.0 Mpa)

15

HPX2001-3605

Pressure switch (3.2 MPa / 4.4 Mpa)

16

HPX20000-360005

Water flow switch

17

HPX32009-210631

Median septum

18

HPX32017-210010

Rear panel

19

HPX20000-330132

Fan motor

20

HPX32009-210633

Electrical box

21

HPX32009-210635

Control Top Cover

22

HPX32017-220004

Top Panel

23

HPX72200052

DC speed control module

24

HPX2004-1444

Filter

25

HPX32009-210630

Right-side plate

26

Drainage Adapter

27

HPX2001-1491

Four-way valve

28

HPX2000-1460

Tee

29

HPX32009-220029

Terminal box

30

HPX2000-3524

Compressor capacitor 1

31

HPX2000-3510

Compressor capacitor 2

32

HPX20000-390237

Three-connector

33

HPX72200101

PC1002

34

HPX20000-140237

Electronic expansion valve

35

HPX20000-360226

Ac contactor

36

Titanium tubular exchanger

37

HPX2000-3242

Water inlet temperature sensor

38

Water outlet temperature sensor

39

HPX32009-210219

Support panel

40

HPX32017-220003

Front frame decoration 2

41

HPX20000-230596

Hayward Logo

HPX80600624

HPX20000-220169

HPX2000-3242

HPX3400-2203

51300022501B

Figure16b: Service Parts HP70HA2

USE ONLY GENUINE REPLACEMENT PARTS 25

Page 26

51300022501B

26

USE ONLY GENUINE REPLACEMENT PARTS

Page 27

51300022501B

USE ONLY GENUINE REPLACEMENT PARTS 27

Page 28

51300022501B

USE ONLY GENUINE REPLACEMENT PARTS

28

Loading...

Loading...