Page 1

A.R.I.

A.R.I.

Flow Control Accessories Ltd.

Kfar-Charuv 12932 Israel

Tel. 972-4-6761988 Fax. 972-4-6763402 www.arivalves.com

Backflow Preventer DC-500 -Double Check Valve

Approved under : USA : NSF61 (Drinking water), ASSE 1015, AWWA C510, Approved by the Foundation for Cross Connection Control and Hydraulic Research at the

University of Southern California, Listed for Uniform Plumbing Code. Australia : AS4020 (Drinking water), Watermark AS2845.1. France : ACS.

0302AusM-DC500-10

Installation

A. The DC-500 must be installed in an accessible

location to facilitate periodic field-testing and

maintenance.

A. Flush all upstream piping thoroughly to remove

foreign matter prior to installing the device.

C. The device may be installed either vertically (for

upward flow) or horizontally. It is recommended that

the horizontal configuration be chosen for ease of

testing and maintenance. A clearance between the lower

most portion of the device and flood grade or floor

should be provided for ease of maintenance.

D. Assemble the components before positioning into

permanent pipe installation.

E. A “Y” strainer can be installed just upstream of the

DC-500 assembly to eliminate any debris from entering

the device and fouling the check valves.

F. After installing the assembly and with downstream

or shut-off valve #2 closed, pressurize the device and

bleed air through test cock #1, #2, #3. Then open

shut-off valve #2.

Installation Tips

(a) Recommendation: Do not install in areas subjected

to freezing for a long period of time.

(b) The product must be protected from excessive

pressure increases. Pressure increases can be caused by

thermal expansion or water hammer. These excessive

pressure situations must be eliminated to protect the

valve and system from possible damage.

(c) Do not use any pipe glue, oil grease or solvent on

any parts unless instructed to do so.

(d) Do not force parts. Parts should fit together freely.

Maintenance Instructions

A. Disassembly – DC-500.

1. Close shut-off valve #2, then close shut-off valve

#1.

2. Bleed pressure from the assembly by opening test

cock #1, #2, #3.

3. Remove the cover bolts and lift the cover.

4. Remove the retainer.

5. Extract the check valves.

Note: all the disassembled parts may now be cleaned

and reassembled or, depending on their condition,

discarded and replaced with a new assembly from the

repair kit. O-rings should be cleaned or replaced as

necessary and lightly greased with the NSF approved

silicon based grease.

B. Assembly – DC-500.

1. Install the check valves. The valves must be securely

in place.

2. Install the retainer.

3. Put on the cover and close the bolts.

CAUTION:

Secure the screws with a recommended torque of

2.5 Kg/m. for models DN 15/20/25

9 Kg/m. for models DN 32/40/50

Page 2

TROUBLE SHOOTING GUIDE

Symptom Cause

Check valve fails to hold 6.8 kPa.

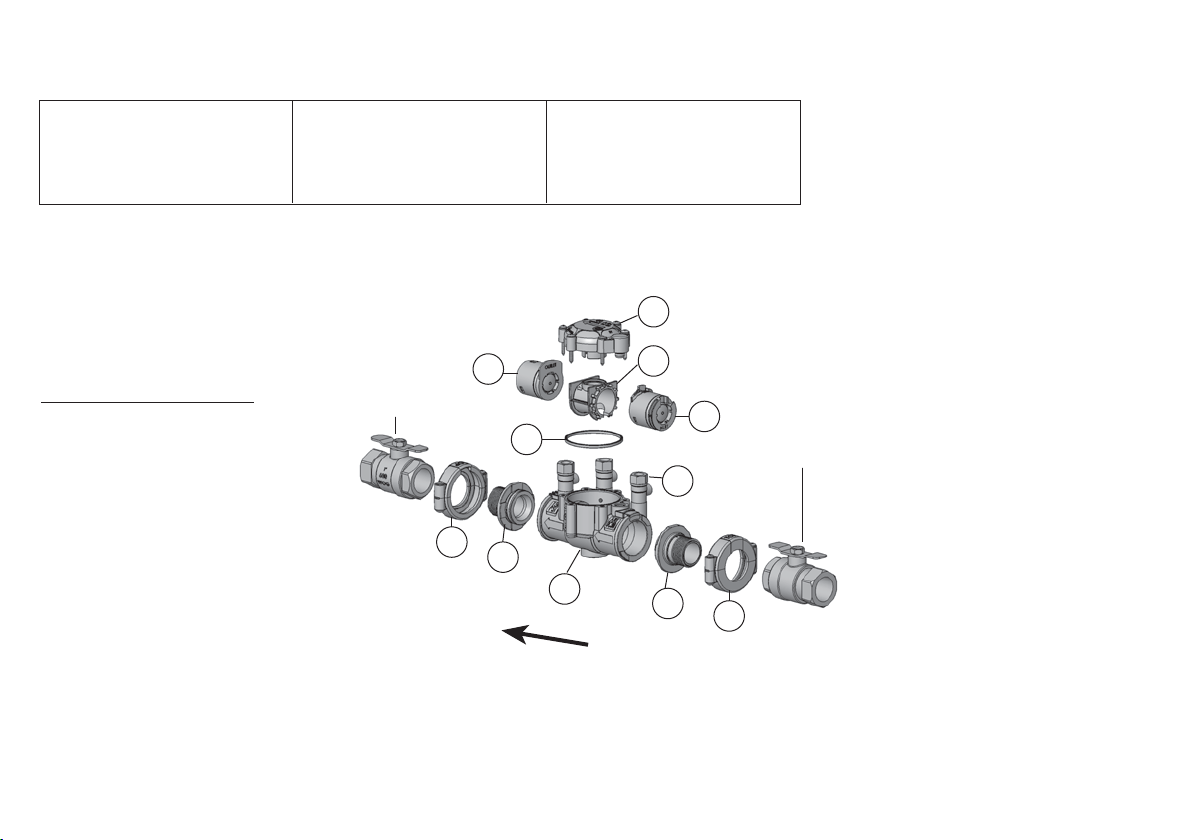

PARTS LIST

No. Part

1. Cover Ass.

2. Retainer

3. Outlet Check valve Ass.

4. Inlet Check valve Ass.

5. Body Seal

6. Test Cocks (#1, #2, #3)

7. Body ass.

8. Clamp Ass.

9. Adaptor Ass.

a. Outlet shut-off valve not closed

completely.

b. Outlet check valve fouled with

debris.

down stream

shut-off valve #2

3

9

8

Corrective Action

a. Close outlet shut-off valve or

inspect for possible through leakage

b. Inspect and clean the seat and seal

of outlet check valve.

1

2

4

5

#2

#3

#1

6

7

8

up stream

shut-off valve #1

9

Loading...

Loading...