Page 1

MAINTENANCE INSTRUCTIONS

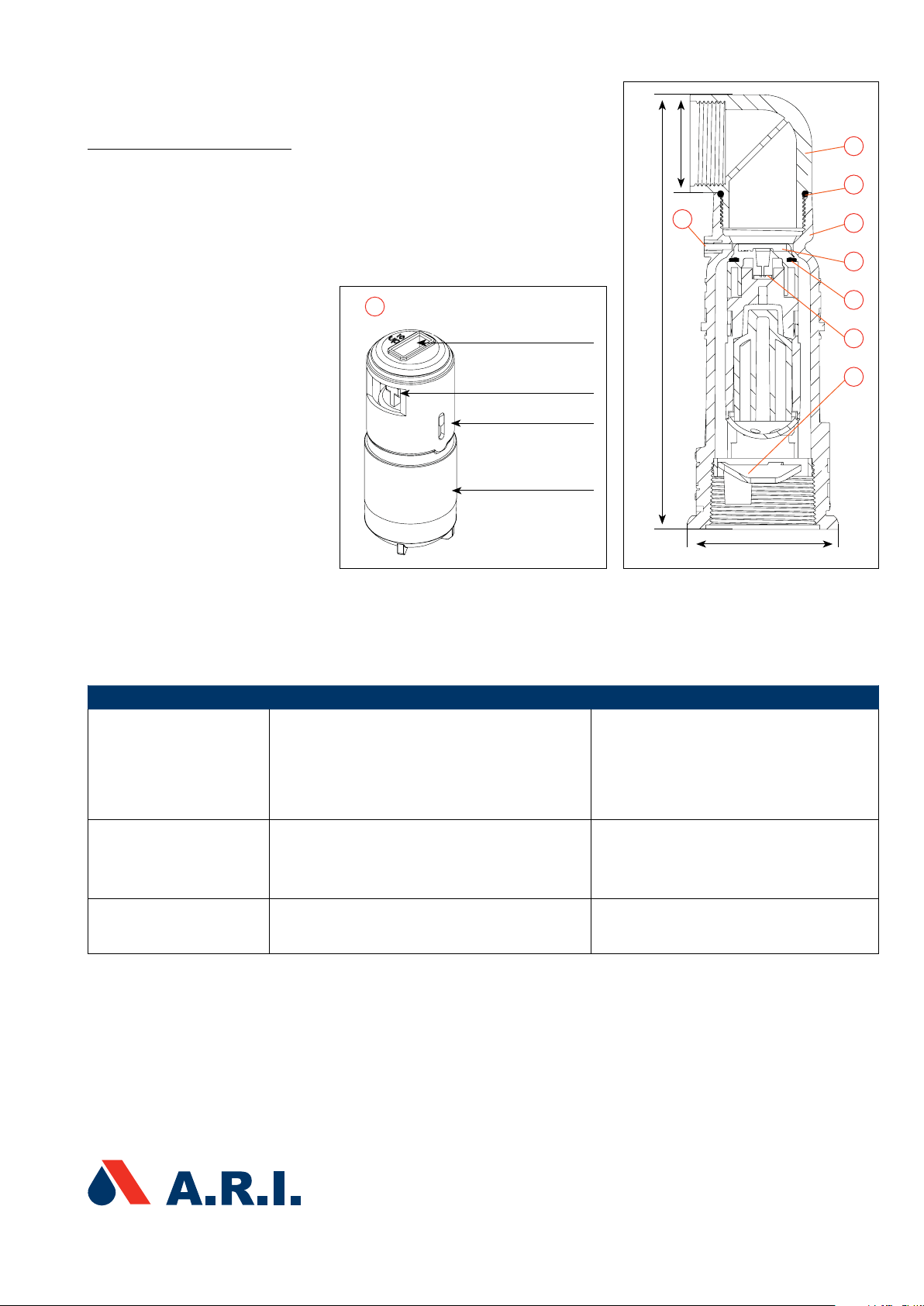

COMBINATION AIR VALVE

BARAK, MODEL D-43 2”

INSTALLATION

1. The D-43 combination air valve should be installed vertically on a riser on the

crown of the pipeline.

2. An inlet isolating valve should be installed underneath the D-43 air valve.

PERIODIC MAINTENANCE

- Routine service is an integral part of the standard procedure for maintenance

of a water supply system.

- Recommended routine maintenance - at least once a year, according to the type

and quality of the liquids in the system.

PROCEDURE (Fig. 1, 2)

1. Shut the Isolating Valve under the air valve before servicing.

2. WARNING – Slowly turn the valve Body (3) counterclockwise to release

internal pressure from the air valve. Continue turning to remove the air valve

from the service valve.

3. Wash the threaded area of the air valve Body under running water to remove

accumulated debris from the threaded area of the lower air valve Body.

4. Manually unscrew the Float Lock (5) and remove it from the air valve Body.

5. Remove the Float and Seal Assembly (4) by sliding it out from the air valve

Body.

6. Wash the Float and Seal Assembly thoroughly under running water, paying

special attention to the Air Release Orice (Fig.2), the Air Release Rolling Seal

(4b) and the Air & Vacuum Seal (4a).

7. Visually examine the Air Release Rolling Seal and the Air & Vacuum Seal for

any cracks or tears. If found, replace the entire Float and Seal Assembly unit. **

8. Manually verify free and unhindered movement between the Upper

Component and the Lower Component of the Float and Seal Assembly

(Fig. 2). Clean the slots of any debris that might cause interference.

9. Manually unscrew and remove the Discharge Outlet (1) from the air valve Body.

Thoroughly wash the Discharge Outlet and the air valve Body under running

water. Remove all debris from the Discharge Outlet screen.

10. Manually screw the Discharge Outlet tightly into the air valve Body.

11. Slide the Float and Seal Assembly into the air valve body, Upper Component

side rst (Fig. 2).

12. Manually screw the Float Lock into the air valve Body tightly till the end.

13. Wash the threaded area of the Service Valve.

14. Manually screw the D-43 Air Valve on the Isolating Valve and turn tightly till

the end.

15. Slowly open the Isolating Valve.

** The Float and Seal Assembly unit can easily be replaced in the eld.

The old Float and Seal Assembly unit should be recycled in an approved

Recycle Container for plastic materials.

Page 2

PARTS LIST

Fig. 1

No. Part

1. Discharge Outlet

2. O-Ring

3. Body

4. Float and Seal Assembly

4a. Air & Vacuum Seal

4b. Air Release Rolling Seal

5. Float Lock

6. Upper Drain Outlet

Fig. 2

4

Float and Seal Assembly

Air & Vacuum Seal

Air Release Rolling Seal

Upper Component

Lower Component

C

6

B

A

1

2

3

4

4a

4b

5

TROUBLESHOOTING GUIDE

PROBLEM REASON SOLUTION

Discharge Outlet Leak a. Debris caught in the Rolling Seal

b. Debris caught between the Air & Vacuum

Seal and the Body.

c. Torn or cracked Rolling Seal and/or Air &

Vacuum Seal.

Discharge Outlet Broken Air valve was hit or mishandled. Unscrew and replace.

Upper Drain Outlet Upper Drain Outlet plugged with debris and

won't drain the accumulated water.

Perform:

PERIODIC MAINTENANCE

Clean the hole with a pin and clean running

water or a burst of air.

A.R.I. FLOW CONTROL ACCESSORIES Ltd.

www.arivalves.com ari@ari.co.il Tel: 972-4-6761899

MAINTENANCE INSTRUCTIONS D-43

EnM-D43-2-12

Loading...

Loading...