Page 1

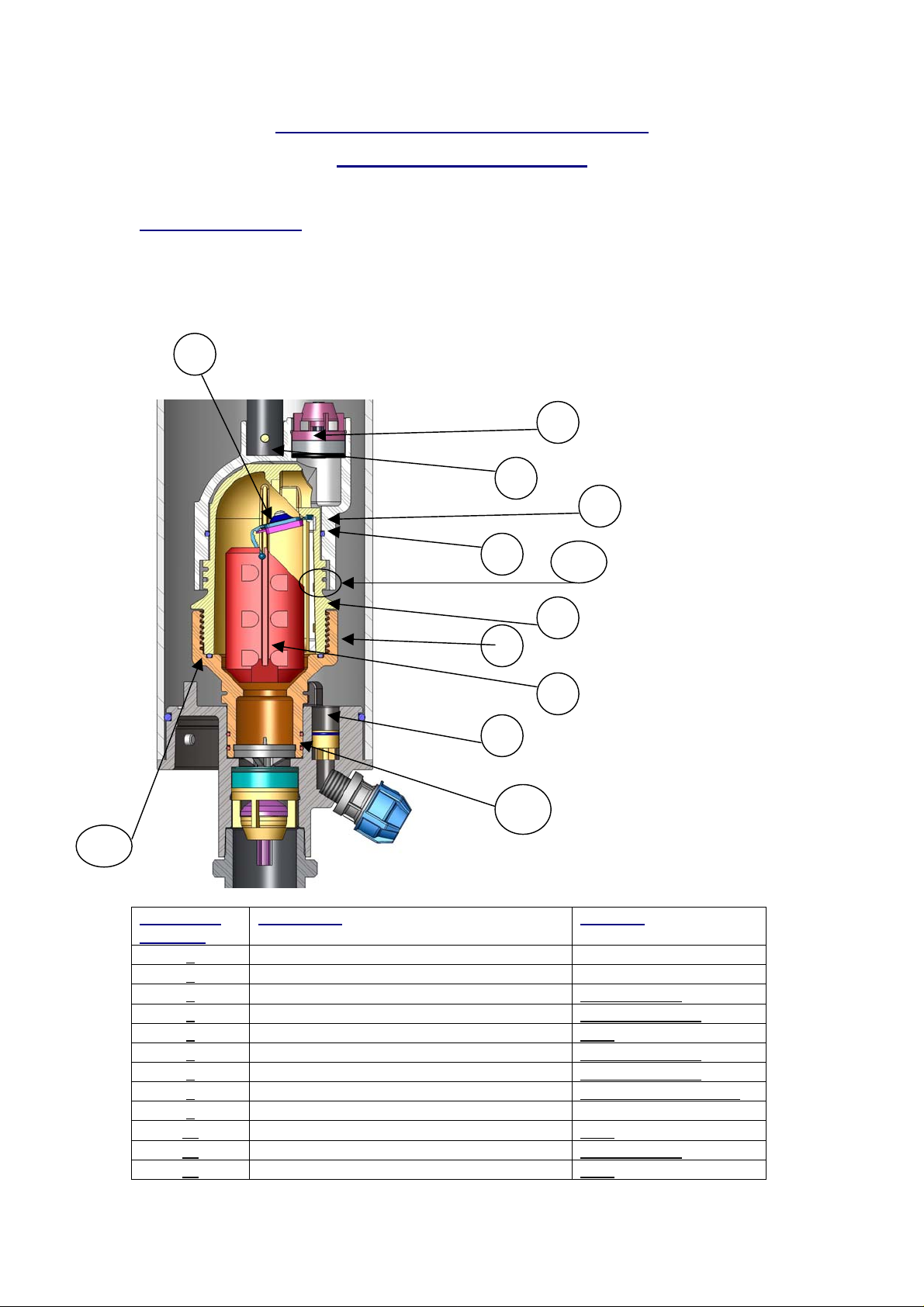

Underground Air Valve system D-090-P.

Maintenance Instructions.

1. Part one- General.

1. Routine service is an integral part of the standard procedure of a water supply

system. The recommended routine maintenance period is once or twice a year

depending on the water quality requirement of the individual system.

1

2

3

4

12

5

11

6

7

8

9

10

Number in

Drawing

1 Seal Assembly.

2 One-way valve ( Vacuum Only ).

3 Shaft. Stainless steel.

4 Outer Cover. Reinforced Nylon.

5 “O” ring. NBR.

6 Body. Reinforced Nylon.

7 Base. Reinforced Nylon.

8 Float. Foamed Polypropylene.

9 Entrance to Drain Valve.

10 Base “O” rings. NBR.

11 Lock Pin. Stainless steel.

12 “O” ring. NBR.

Discription

Material

1

Page 2

2. Procedure For Maintenance of the Barak.

a) Gently remove the Outer cover (4) from the valve body (6) after

removing the Lock Pin (11).

b) Unscrew the Base (7) from the Body (6).

c) Check that the seal assembly (1) is not damaged and is free from debris and

wash with clean water. If the assembly is damaged or worn, replace it.

d) Wash the Valve Body (6) and the Float (8) with clean water and check both

for damage.

e) Wash the base (7) with clean water and check for damage.

f) Check that the entrance to the drain valve (9) is free from dirt or other

obstructions. Clean if necessary.

g) Reassemble the parts carefully in reverse order paying attention to the

condition of the all “O” rings (5) , (10) and (12) replacing if necessary. It is

recommended to lightly apply a thin film of a silicone based grease to the “O”

rings on reassembly.

Nick Levi- Technical Administrator R&D Department – A.R.I. Water Accessories, Kfar Charuv, Israel.

2

Loading...

Loading...