Page 1

MAINTENANCE INSTRUCTIONS

COMBINATION AIR VALVE

MODEL D-070-P

GENERAL

1. The periodic maintenance of the air valve is an integral part in the proper

regimen of water pipeline maintenance.

2. The air valve should be maintained at least once a year in accordance with the

quality of the water and the types of uid composition in the system.

INSTALLATION

Before installing the Model D-070-P air valve, make sure to ush and drain the

pipeline of all dirt and solids that may be in the line.

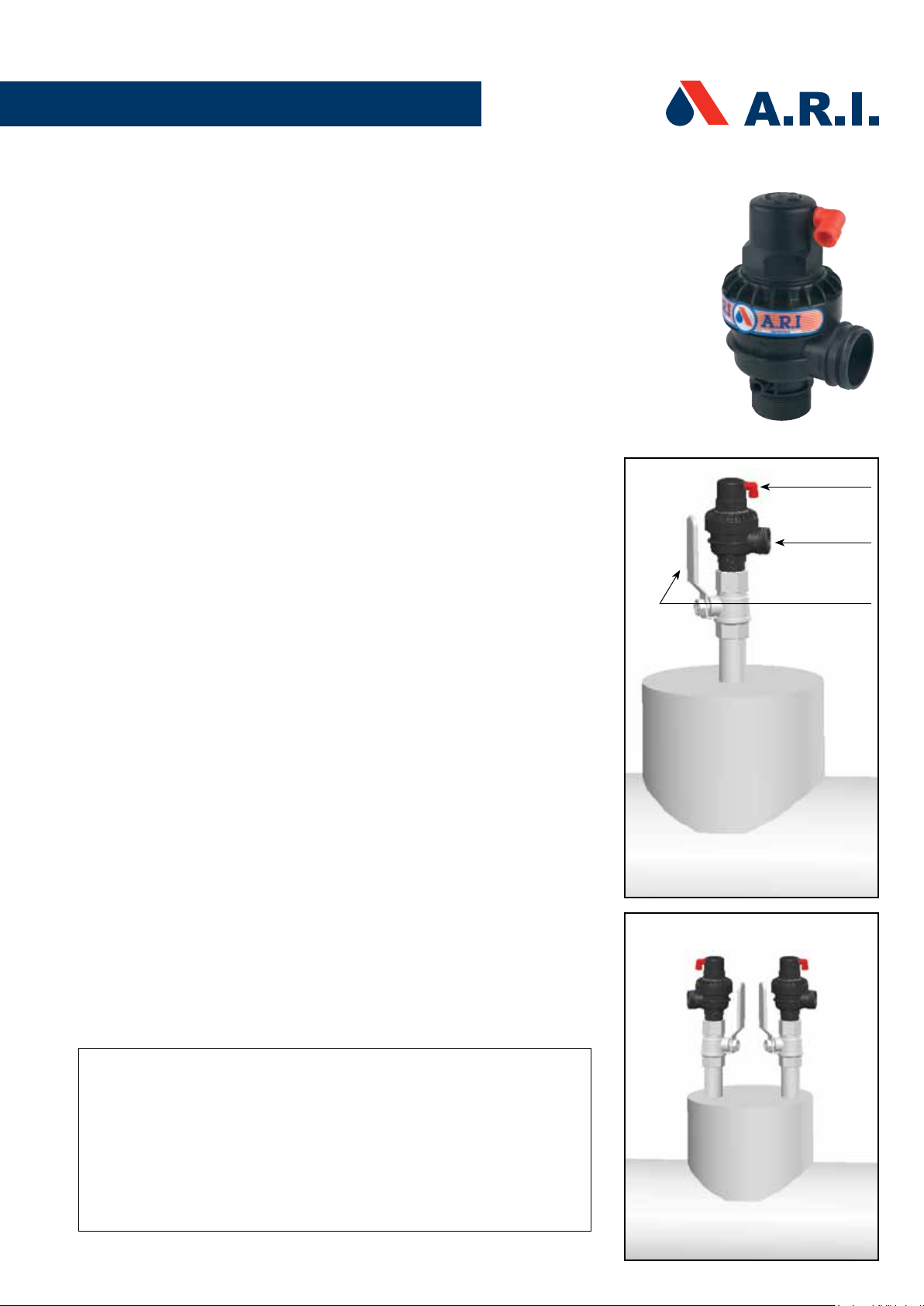

Installation of an isolating valve: An isolating valve will be installed under each

air valve to enable the performance of periodic maintenance.

Installation of a riser: It is recommended to install the Model D-070-P air valve

on top of a riser (see Fig.1). Diameter of the riser should be at least one-half the

diameter of the pipeline.

Manifold: When the valve is installed on a manifold, the air valves should be

installed only on a welded manifold. They should be installed in a manner that the

drainage port openings should face in opposite directions (see Fig.2).

DRAIN PORT

1. Drainage angle: It is recommended installing a drainage angle at the drain

port (#1) exit; the diameter of the drainage angle should be at least the

diameter of the drain port.

2. Maintain an open drain port: Do not seal or block the opening of the valve

drain port (#1).

3. Warning on emission of water: The normal operation of the valve includes

water emissions under pressure. Ensure that the drain port (#1) is not

directed toward electrical elements (pumps) or people.

4. Caution: Do not put hands or objects into the drainage port (#1).

5. Drainage Pipe: Drainage pipes, at least 2" in diameter with a maximum

length of 9m, can be connected to the drainage angle to direct the emission

water. The end of the drainage pipe should remain completely open and

unobstructed. Do not connect a drainage pipe to the upper drainage port

(#2).

Drain Port #2

Drain Port #1

Isolating valve

Fig. 1

WARNING

Perform the following operations prior to maintenance or removal of the air

valve from the pipeline:

1. Shut the isolating valve (Fig.1) on the riser below the air valve.

2. Slowly open the Locking Ring (6) until water and air start to be released. Wait

until all the water and air cease to be released before continuing

3. Continue to open the Locking Ring (6) slowly; making sure that the pressure

has been released from inside the air valve prior to maintenance/removal

from the pipeline.

Fig. 2

Page 2

PERIODIC MAINTENANCE

The purpose of periodic maintenance: check integrity of the seals and clean the

sealing areas.

The frequency of maintenance will be determined by the condition of the water

system – weekly, monthly, quarterly etc.

The maintenance of the Dynamic Air Valve is performed for 2 separate parts:

MAINTENANCE OF THE OPERATING VALVE

1. Shut the isolating valve on the riser below the air valve.

2. Unscrew the Operating Valve Body (2).

3. Remove the Clamping Stem (4) and the Operating Assembly (5). Wash the

inside of the Body , the Clamping Stem , the Operating Assembly , the

Rolling Seal (3), and the O-ring (7) with clean water.

4. Gently wash and clean the sealing area inside the valve body.

5. Check the O-Ring visually for any defects. Replace if needed.

6. Check and make sure that the Rolling Seal is intact (not torn or cracked)

and is positioned precisely in the middle of its groove in the Operating

Assembly. Replace if needed.

7. The disc at the bottom of the Operating Assembly (Fig. 4) should be loose

and move freely. Do not tighten the holding screw.

8. Reassemble the Operating Valve after maintenance.

MAINTENANCE OF THE DYNAMIC VALVE BODY

9. Unscrew and remove the Locking Ring (6) together with the attached

Operating Valve. Remove the Air & Vacuum Sealing Assembly (9) from the

Body (11).

10. Wash the Body and the Locking Ring in clean water in order to remove

coarse grime or accumulated scale.

11. Wash the Air & Vacuum Sealing Assembly and check the rubber parts for

any tears. Replace the entire unit if needed.

Do not open screws of the assembly under any circumstances.

12. Make sure that the drill hole is clean and the passage is open (Figure 5).

13. Make sure that there is no dirt or debris around the sealing area of the

dynamic valve body.

14. Replace the assembly in the body, reassemble in reverse order, then fasten

and tighten the Locking Ring.

15. Open the isolating valve beneath the air valve, making sure that there are

no leaks.

1

2

3

4

5

6

7

8

9

10

11

Fig. 3

Disc

Fig. 4 Operating Assembly

Sealing Assembly Drill Hole

FIg. 5

Air & Vacuum Sealing Assembly

Page 3

No. Part

1. Discharge Outlet

2. Operating Valve Body

3. Rolling Seal

4. Clamping Stem

5. Operating Assembly

6. Locking Ring

7. O-Ring

8. Base Adaptor

9. Air & Vacuum Sealing Ass.

10. Supporting Ring

11. Body

TROUBLESHOOTING GUIDE

PROBLEM REASON SOLUTION

1

2

3

4

5

6

7

8

9

10

11

Fig. 3

1.

Leaking from the

Drain Port #2

(Fig 1).

2.1.

Leaking from the

Drain Port #1

(Fig 1).

2.2.

Leaking from the

Drain Port #1

(Fig 1).

Debris or scale

build-up on the

rolling seal (5).

Debris or

unwanted object

caught in the air

& vacuum sealing

assembly. (11)

Torn sealing

assembly or

diaphragm. (11)

1. Shut off the isolating valve on the riser below the air valve.

2. Unscrew the operating valve body. (2).

3. Remove the clamping stem (4) and the operating assembly (5). Wash the

inside of the body, the clamping stem, the operating assembly, the rolling

seal (3), and the O-ring (7) with clean water.

4. Gently wash and clean the sealing area inside the valve body.

5. Check the O-ring visually for any defects. Replace if needed.

6. Check and make sure that the rolling seal (3) is intact (not torn or cracked)

and is positioned precisely in the middle of its groove in the operating

assembly. Replace if needed. The disc at the bottom of the operating

assembly (5) should be loose and move freely.

Do not tighten the holding screw.

7. Reassemble the Operating Valve after maintenance.

1. Shut off the isolating valve on the riser below the air valve.

2. Unscrew and remove the locking ring (6)together with the attached

operating valve.

3. Remove the air & vacuum sealing assembly (9) from the body (11).

4. Wash the body (14) and the locking ring in clean water in order to remove

coarse grime or accumulated scale.

5. Wash the air & vacuum sealing assembly (9) and check the rubber parts for

any tears.

6. Make sure that the drill hole (Fig. 5) is clean and the passage is open.

7. Make sure the air & vacuum assembly seal is intact and not torn.

8. Replace the whole air & vacuum assembly if any of the above parts are torn

or damaged.

9. Do not open screws of the assembly under any circumstances.

10. Make sure that there is no dirt or debris around the sealing area of the

dynamic valve body.

11. Replace the assembly in the body, reassemble in reverse order, then fasten

and tighten the locking ring.

12. Open the isolating valve beneath the air valve, making sure that there are no

leaks.

A.R.I. FLOW CONTROL ACCESSORIES Ltd.

www.arivalves.com ari@ari.co.il Tel: 972-4-6761899

MAINTENANCE INSTRUCTIONS D-070-P

EnM-D070-P-11

Loading...

Loading...