Page 1

Handeling , Installation , Operation and

Maintenance instructions for

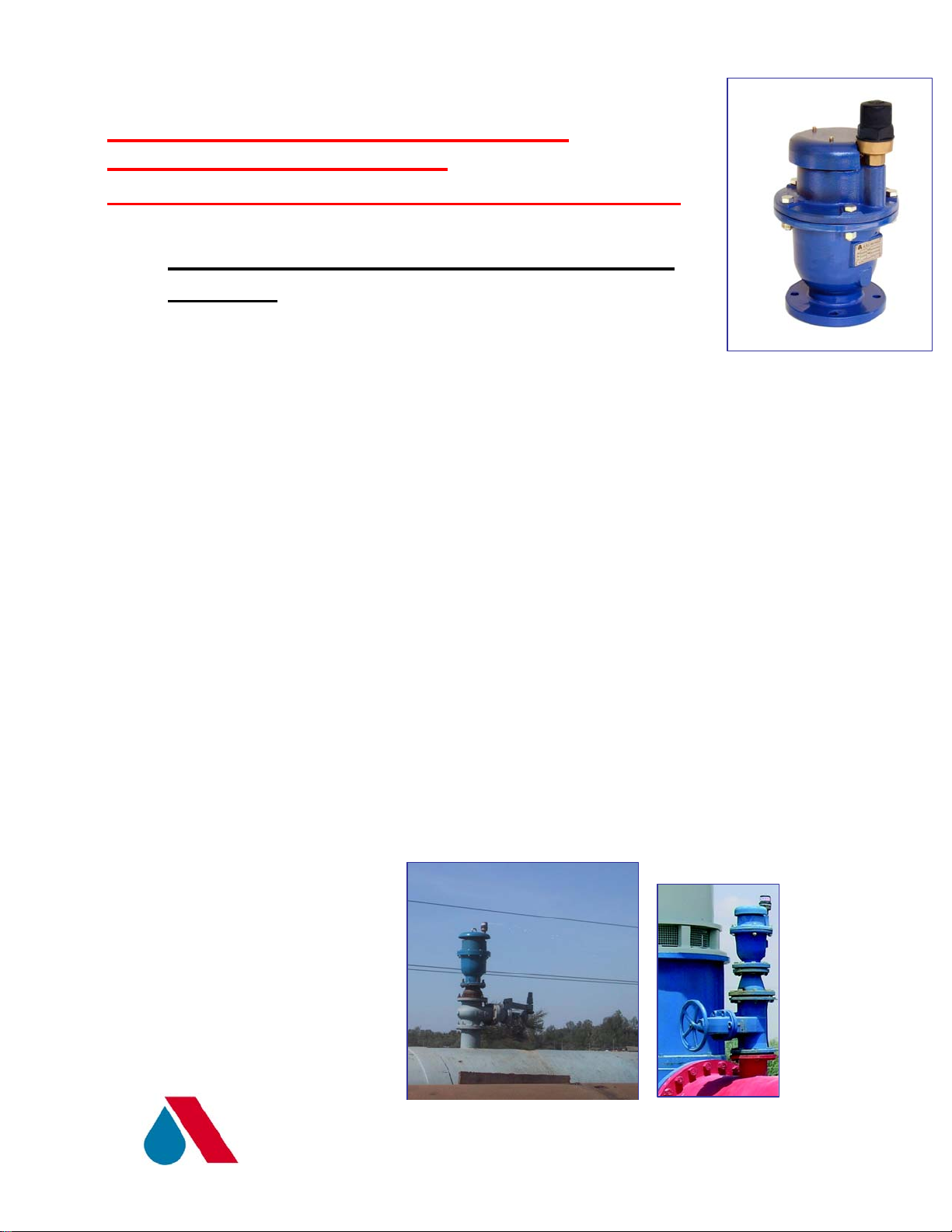

D-060 HF NS Combination Air Valves Non

Slam

A. Installing and Operating the D060 HF-NS

Air valve

B.1. The air valve will be mounted on a riser, connected to the top

of the pipe.

B.2. An isolating valve will be installed below the airvalve.

B.3. Flush the system before installing the air valve to avoid any

dirt or sharp objects getting into the air valve.

B.4. Lift the air valve from the lifting ring by a hoke place

it carfuly on the rubber seal over the shut-off valve.

B.5. Use washers below each bolt & nut that connects the air

valve’s flange to the shut-off valve below.

B.6. The bolts and nuts should be tighten simultanicly (one

Against the other (opposite to him).

The closure tightness of bolts and nuts shall be according

to the standard (Torque) for the bolts and nuts dimention

is used .

Please use ring ranch keys (to be operated by hand) for

closing and opening all bolts of the air valve (inclu. The bolts

at the flage).

A.R.I FLOW CONTROL ACCESSORIES LTD

Page 2

B. Maintening the D060 HF-NS Ai

r valve

.Maintening the Automatic air valve. 1.C

C.1.1. Shutoff the isolating valve below the air valve

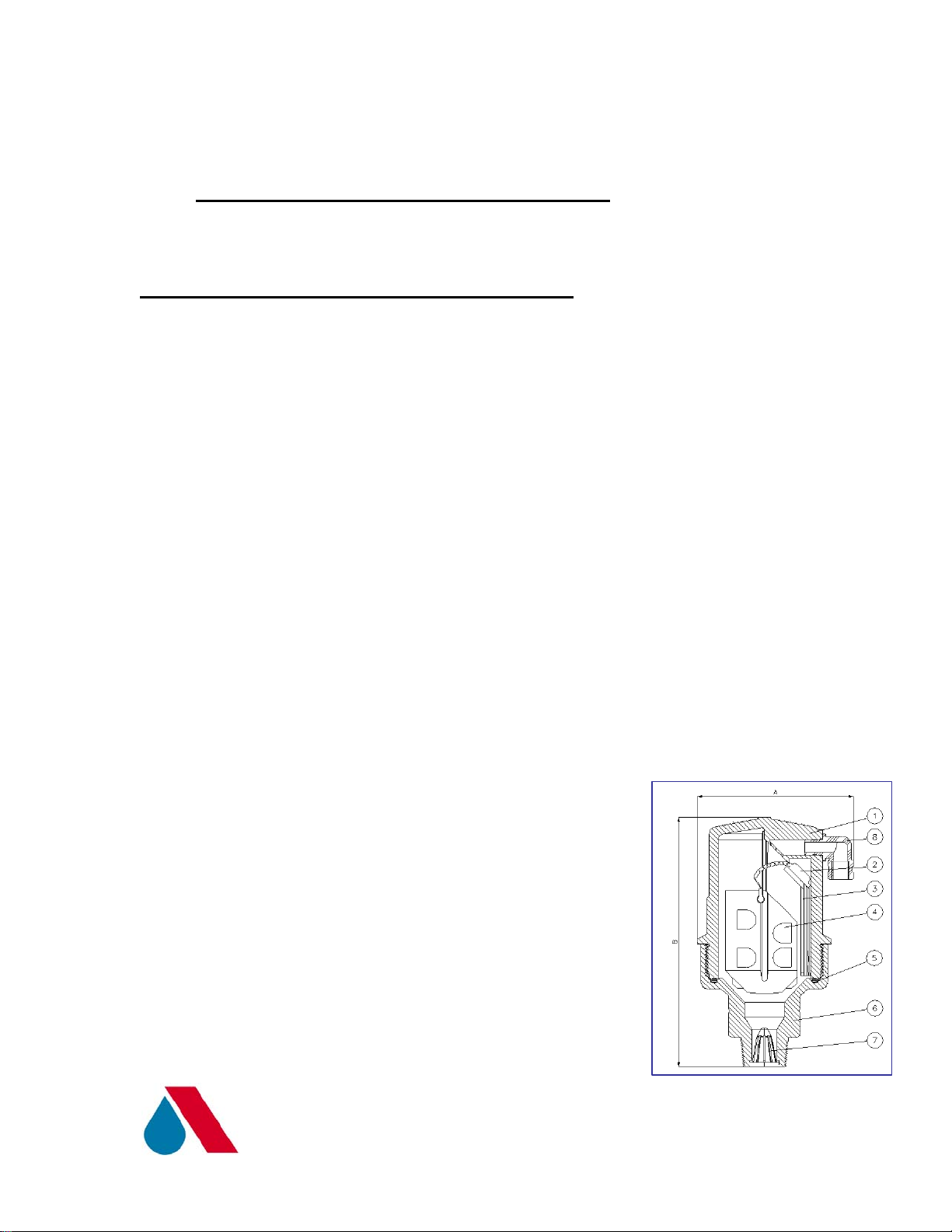

C.1.2. Unscrew the body (1)of the Automatic air valve

(No.22

drawing no. 5292-00-02) from the Base (make sure

that the base will not rotate!).

C.1.3. Remove the Clamping Stem (3)and the float (4)from

the automatiic component and wash the inside

of the body, the Clamping Stem, the float, and

the Rolling Seal (2),with clean water.

C.1.4.

Check to make sure that the Rolling Seal is unharmed

(not torn or cracked) and is located precisely in the

middle of its groove in the float.

.

C.1.5. Reassemble the air valve in the opposite order:

First insert half the lengh of the roaling seal tail

into the track (grrove) in the body, then push

the rest of the way to the end of the groove ,

using the clamp.Make sure that the

roalling seal is set and hold inits place.

A.R.I FLOW CONTROL ACCESSORIES LTD

Page 3

.Maintening the Kinetic air valve2 .C

C.2.1. Unscrew the bolts (8) that connect the valve cover (2)

to its body (1).

C.2.2. Clean the internals of the following parts part :

the body including the groove of the Oring , the screen,

the float and the cover with clean water in order to remove

coarse grime or accumulated scale.

C.2.3. Check that the nozzle seal (4) is in a good shap , means

that is not torn and/or not cracked.

C.2..4. In case that the nozzle seal is in a bad condition, please

Remove the nozzle seat + seal (3+4) witout harming

the coating, than clean carefuly the cover seat

of the reamined glue, rub into the seat Epoxy glue and

push the nozzle seat and seal into the its place in the cover.

Wait for minimum 24 hours for the glue to get dried

completely.

C.2.5. Reassemble the air valve in the opposite order:

insert the float, than place the Oring in the groove,

place the cover on the body, insert the botls ,

the washers and the screw the nuts and the washers on

the nuts.

C.2..6. The bolts and nuts should be tighten simultanicly

(one against the other opposite to him).

The closure tightness of bolts and nuts shall be according

to the standard (Torque) for the bolts and nuts dimention

is used .

Please use ring ranch keys (to be operated by hand) for

closing and opening all bolts of the air valve.

A.R.I FLOW CONTROL ACCESSORIES LTD

Page 4

.Shock element-Maintening the Anti3 .C

C.3..1. Please check (through the cover) that the flap (18) moves

Freely without any distturb in the falp house (17).

C.3.2. In case that the flap does not move freely in the flap house,

Please act as follows:

C.3.3. Unsrew the four domed nuts (12) , take of the screen

Cover (6) and the screen (7).

C.3.4. Unscrew the nuts (13) of the four threaded rods.

C.3..5.Take of the ring K060NS.

C.3.6. Pull out the flap of the house.

C.3.7. Clean the flap house and the flap in order to remove

coarse grime or accumulated scale.

C.3.8. Reassemble the Anti- Shock element in the opposite order:

insert the flap into the flap house, than place the ring

K060HF-NS through the threade rods , screw the nuts

on the four threade rods and close it tightly. Place the

screen over the K060HF-NS ring , than screw the nuts

on the four threade rods .

Place the screen cover over the nuts , add the four

domed nuts over the screen cover and close it tightly

to the screen cover.

A.R.I FLOW CONTROL ACCESSORIES LTD

Loading...

Loading...