Page 1

D-060 PN 16

D-060-C PN 16

D-062 PN 25

D-065 PN 40

Combination Air Valve for High Flow

D060.WTR.CAT.ENG05

Water Supply

Description

e D-060 series Combination Air Valve has the features of both an

air release valve and an air & vacuum valve.

e air release component is designed to automatically release small

pockets of air to the atmosphere as they accumulate along a pipeline

or piping system when it is full and operating under pressure.

e air & vacuum component is designed to automatically

discharge or admit large volumes of air during the lling or draining

of a pipeline or piping system. is valve will open to relieve

negative pressures whenever water column separation occurs.

Applications

- Municipal and industrial water conveyance systems.

D-060-C, D-062, D-065 - additional applications

- Water pipelines vulnerable to vandalism and/or water theft.

- Water systems found in remote areas.

- Water systems with pressure demands of 25 & 40 bar (D-062 &

D-065 respectively).

Operation

e air & vacuum component, with the large orice, discharges

air at high ow rates during the lling of the system and admits air

into the system at high ow rates during its drainage and at water

column separation.

High velocity air will not blow the oat shut. Water will lift the

oat which seals the valve.

At any time during system operation, should internal pressure of the

system fall below atmospheric pressure, air will enter the system.

e smooth discharge of air reduces pressure surges and other

destructive phenomena.

e intake of air in response to negative pressure protects the system

from destructive vacuum conditions and prevents damage caused

by water column separation. Air entry is essential to eciently drain

the system.

e air release component releases entrapped air in pressurized

systems.

Without air valves, pockets of accumulated air may cause the

following hydraulic disturbances:

- Restriction of eective ow due to a reduction of the ow area. In

extreme cases this will cause complete ow stoppage.

- Obstruction of ecient hydraulic transmission due to air ow

disturbances.

- Acceleration of cavitation damages.

- Increase in pressure transients and surges.

- Internal corrosion of pipes, ttings and accessories.

- Dangerous high-energy bursts of compressed air.

- Inaccuracies in ow metering.

As the system starts to ll, the combination air valve functions

according to the following stages:

1. Air in the pipeline is discharged by the valve.

2. Liquid enters the air & vacuum component, lifting the oat to its

sealing position.

3. Liquid enters the air release component of the valve, lifting the

oat and pushing the rolling seal to its sealing position.

4. Entrapped air, accumulating at peaks and along the system, rises

to the top of the air release valve, displacing the liquid in the valve's

body.

5. e oat drops, unsealing the rolling seal. e air release orice

opens and the accumulated air is released.

6. Liquid replaces the air released from the valve, buoying up the

oat and pushing the rolling seal back to its sealing position.

When internal pressure falls below atmospheric pressure

(negative pressure):

1. e oats will drop down, immediately opening the air &

vacuum and air release orices.

2. Air will enter the system.

Main Features

- Working pressure range:

D-060 0.2 - 16 bar

D-060-C 0.2 - 16 bar

D-062 0.2 - 25 bar

D-065 0.2 - 40 bar

- Testing pressure for the air valve is 1.5 times its working pressure.

- Maximum working temperature: 60°C.

- Maximum intermittent temperature: 90°C.

- All main ow cross-sections are equal or greater than the nominal

port area.

Page 2

D-060

- Aerodynamic design enables high ow rates of air both at intake

and at discharge.

- Reliable operation reduces water hammer incidents.

- Dynamic design allows for high capacity air discharge while

preventing premature closure.

- Special orice seat design: bronze and E.P.D.M. rubber, assures

long-term maintenance-free operation.

- Screen protected outlet.

- e upper screen is protected with a protective cover.

Air Release Component

- Body made of high strength materials.

- All operating parts are made of specially selected corrosionresistant polymer materials.

- Large size air release orice:

• Dramatically reduces the possibility of obstruction by debris.

• Releases air at high ow rates.

• One size orice for a wide pressure range (up to 40 bar), achieved

by the rolling seal mechanism.

Valve Selection

Size Range: 1”- 10”

2" – 8" (D-065 only)

D-060, rated for 16 bar.

D-060-C, vandalism protected by a metal shell covering the air

release component, rated for 16 bar.

D-062, vandalism protected by a metal shell covering the air release

component, rated for 25 bar.

D-065, rated for 40 bar.

- ese valves are manufactured with anged ends to meet any

requested standard.

- e 1", 2” valves are also available with a threaded BSP or NPT

connection.

- Valve coating: Fusion bonded epoxy coating according to the

standard DIN 30677-2.

- Other coatings are available upon request.

- e air release component and the air & vacuum component are

available as separate units.

Note

For best suitability, it is recommended to send the uid chemical

properties along with the valve request.

Upon ordering, please specify: model, size, working pressure, thread

and ange standard and type of liquid.

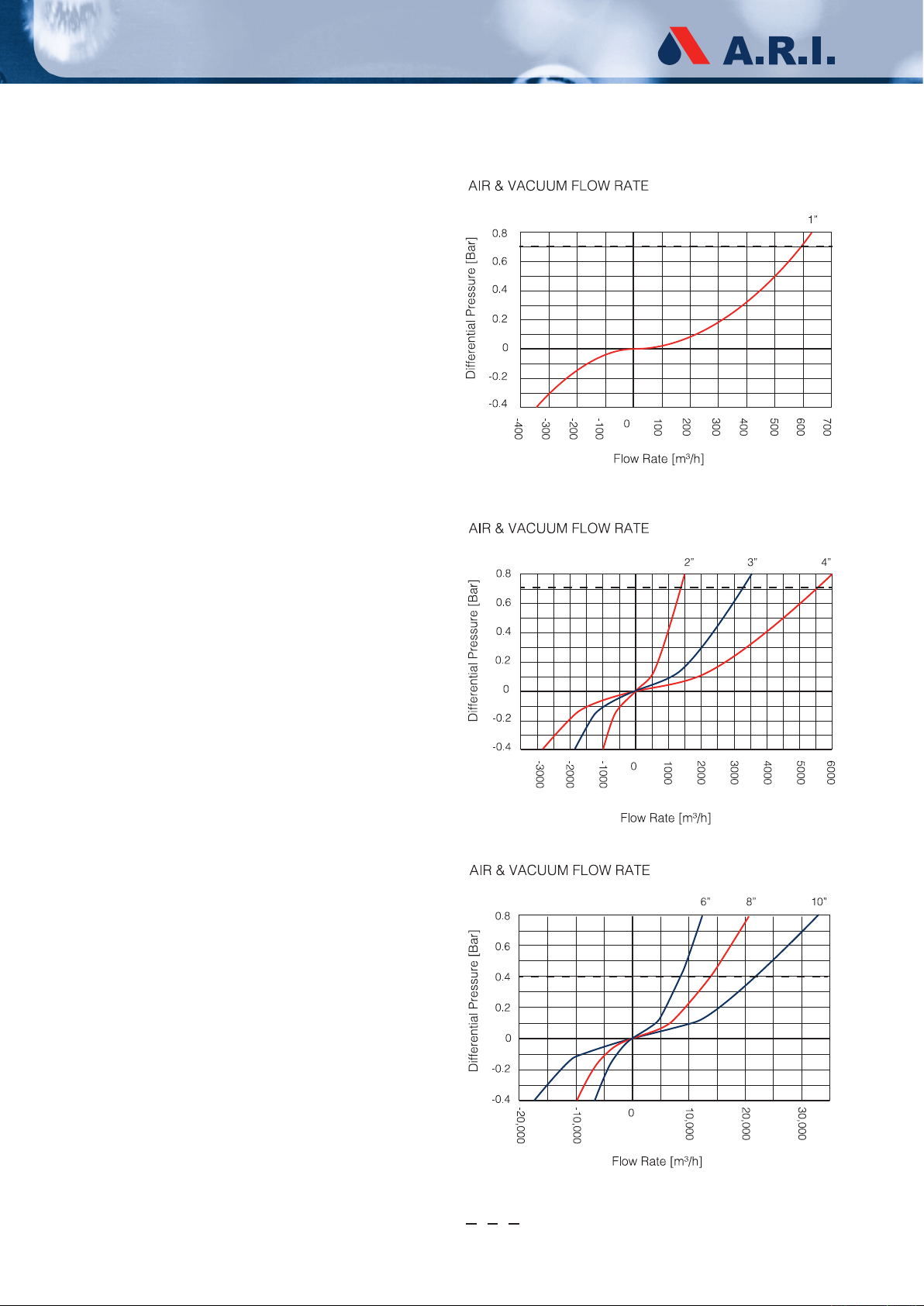

Max. recommended design air discharge

Page 3

D-060

D-060 1"

1

2

D

C

B

3

4

5

6

7

8

9

10

11

12

13

14

15

A

1" PARTS LIST AND SPECIFICATION

No. Part Material

1. Body Reinforced Nylon

2. Discharge Outlet Polypropylene

3. Rolling Seal EPDM

4. Clamping Stem Reinforced Nylon

5. Float Foamed Polypropylene

6. O-Ring BUNA-N

7. Base Reinforced Nylon

8. Strainer Nylon

9. Cover Ductile Iron

10. Orice Seat Bronze

11. Orice Seal EPDM

12. Bolt, Nut & Washer Steel, Zinc Cobalt Coated

13. O-Ring BUNA-N

14. Body Ductile Iron

15. Float Polycarbonate / Stainless Steel

Page 4

D-060

DIMENSIONS AND WEIGHTS

Nominal Dimensions mm Connections Weight Orice Area mm

Size A B C D Kg. A / V Auto.

1” (25mm)

1” (25mm)

Nominal Dimensions mm Connection Weight Orice Area mm

readed 158 303 1½” Female 1/8” Female 4.4 506.7 12

Flanged 158 303 1½” Female 1/8” Female 5.4 506.7 12

2

Size A B D Kg. A / V Auto.

2” (50mm)

2” (50mm)

3” (80mm) 249 387 1/8”

4” (100mm) 286 431 1/8”

6” (150mm) 375 588 1/8”

8” (200mm) 463 630 1/8”

10” (250mm) 586 788 1/8”

readed 215 323 1/8” Female 9.7 - 10 1960 12

Flanged 215 336 1/8” Female 10.7 - 11 1960 12

Female 17 - 18 5030 12

Female 23.6 - 25 7850 12

Female 73.5 - 78 17662 12

Female 108.6 - 117 31400 12

Female 137.7 - 150 49087 12

2"-10" PARTS LIST AND SPECIFICATION

No. Part Material

1. Body Reinforced Nylon

2. Air Release Outlet Polypropylene

3. Rolling Seal EPDM

4. Clamping Stem Reinforced Nylon

5. Float Foamed Polypropylene

6. O-Ring BUNA-N

7. Base Brass

8. Strainer Nylon

9. Domed Nut & Washer Stainless Steel 304

10. Screen Cover 2”-4” Ductile Iron

6”-10” Polyethylene / Ductile Iron

11. readed Rod Stainless Steel 304

12. Screen Stainless Steel 304

13. Cover Ductile Iron

9

10

11

12

13

14

B

15

16

17

18

14. Bolt, Nut & Washer Steel, Zinc Cobalt Coated

15. Orice Seat Bronze

19

16. Orice Seal EPDM

17. O-Ring BUNA-N

18. Float Polycarbonate / Stainless Steel

19. Body Ductile Iron

2

1

2

3

C

4

5

6

7

8

A

Loading...

Loading...