Page 1

MAINTENANCE INSTRUCTIONS

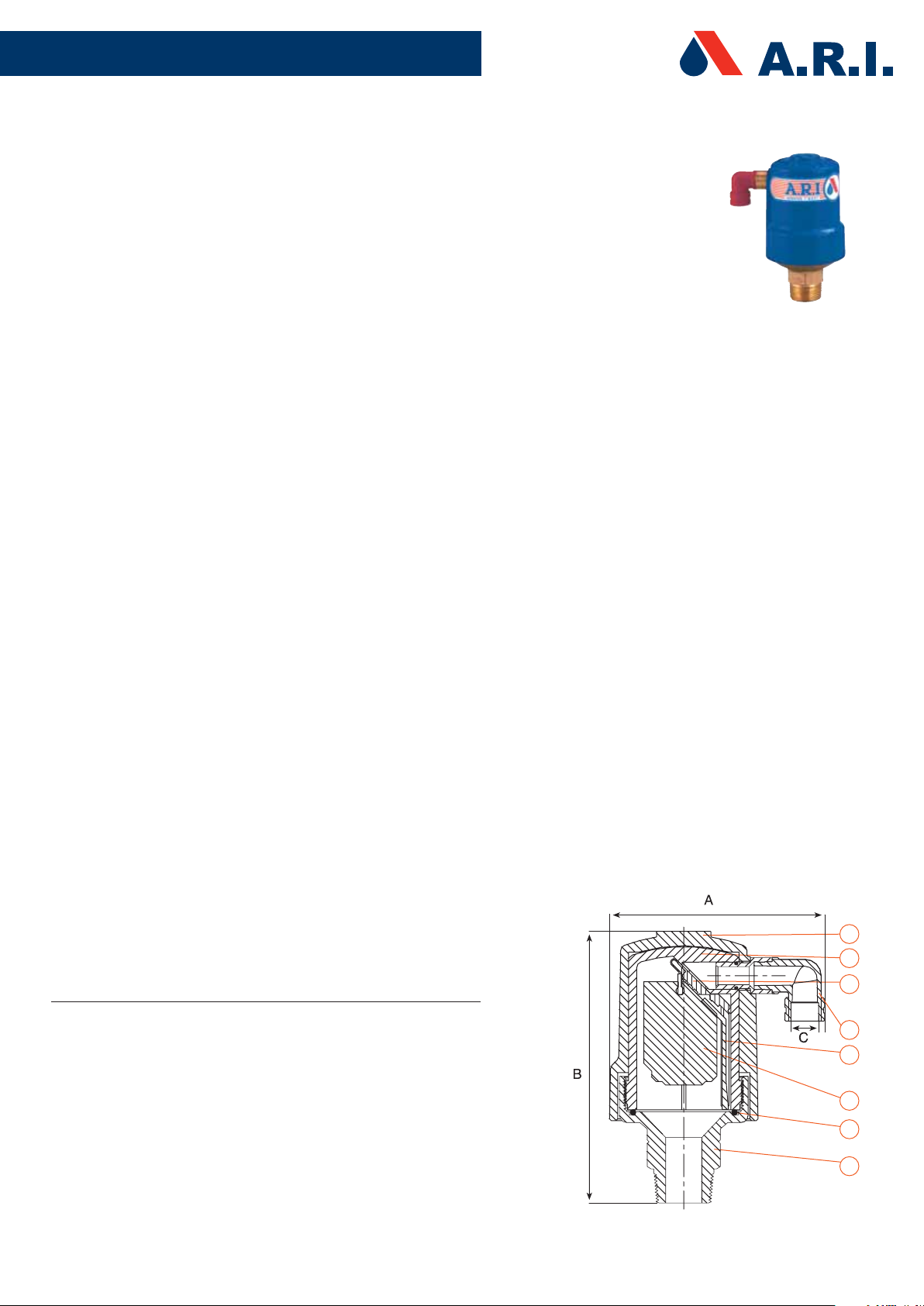

COMBINATION AIR VALVE

BARAK, MODEL D-040-C 1”

GENERAL INSTRUCTIONS

- Routine service is an integral part of the standard

procedure for maintenance of a water supply system.

- Recommended routine maintenance– once or twice a year, according to the

quality and type of the uids in the system.

PROCEDURE

1. Close the service valve under the valve base before servicing.

2. Unscrew and remove the metal shell assembly (1-6) from the base (8) by turning

the metal shell (2) counterclockwise with the aid of a belt wrench.

3. Remove the clamping stem (5) from inside the valve body (1) and carefully

pull out the oat (6) with the attached rolling seal (3).

4. Check the soundness of the rolling seal (3) by washing it with water and

examining it. Note: Replace the rolling seal (3) in case it is torn.

5. Wash the body (1) and the oat (6) with clean water and examine for damage.

Note: Replace the oat (6) if it is damaged.

6. Clean the discharge elbow (4) to remove insects and debris.

7. Return the oat (6) with the attached rolling seal (3) to its original position in

the valve body (1) and lock them into place with the clamping stem (5).

8. Return the metal shell assembly (1-6) to the base (8) and close by turning it

clockwise. Note: First make sure the O-ring (7) is seated properly in the base of

the valve (8).

9. Remember to open the service valve after the servicing.

PARTS SPECIFICATION

NO. DESCRIPTION MATERIAL

1. Metal Shell Cast Iron

2. Valve Body Reinforced Nylon

3. Rolling Seal E.P.D.M.

4. Discharge Elbow Polypropylene

5. Clamping Stem Reinforced Nylon

6. Float Foamed Polypropylene

7. O-Ring BUNA-N

8. Base Brass

1

2

3

4

5

6

7

8

Page 2

TROUBLESHOOTING

SYMPTOM

Outlet thread size needed in

order to attach a drainage

hose.

Built-in plastic screen is not

accepted by health

department.

Plastic body and/or base not

acceptable.

CAUSE

Valve was hit or mishandled.Right angle outlet is broken.

End user needs to connect a

drainage pipe from the valve

outlet in order to drain

excess water.

is is an above ground

installation.

A change in product spec.

A change in designer

preference.

CORRECTIVE ACTION

Easy to replace: gently pry o the outlet with

screwdriver Pressure insert the new right angle

using a plastic hammer.

Replacement part can be ordered from A.R.I.

Note: e part is not mandatory for the function

of the valve.

D-040 has 3/8” female thread.

2” D040 has 1¼” female thread.

End of pipe must be left open in order for valve to

function.

ARI oers an approved 316 stainless screen that

threads into the 2" valve.

GSM in California has made one for the 1” valve.

Oer the cast iron or stainless steel body.

Also oer the bronze or stainless steel base.

Valve spits water.

Valve is continuously

leaking.

is is normal at start up

and during pressure test.

Could be debris in the

sealing mechanism.

Line pressure issues

(inadequate pressure)

or debris lodged in seal or

o-rings.

Plastic threads stripped.Valve leaks from threads.

Open the valve. Clean and check integrity of the

sealing mechanism and O-ring seals.

Check line pressure. It needs at least 3 psi to seal

tight.

Is the valve on a booster pump? Can be installation

issue if valve is level with the water level in a tank there is no pressure to seal.

Open valve and clean sealing mechanism, check

the rolling seal and o-rings for wear or tear.

Replace if necessary.

Check for cross-threading.

Replace bottom of valve or oer the cast metal

base.

A.R.I FLOW CONTROL ACCESSORIES Ltd.

Kfar Charuv 12932 Israel Tel. 972-4-6761803 Fax. 972-4-6763402

WWW.ARIVALVES.COM ari@ari.co.il

MAINTENANCE INSTRUCTIONS D-040-C 1”

EnM-D040C1-10

Page 3

MAINTENANCE INSTRUCTIONS

COMBINATION AIR VALVE

BARAK, MODEL D-040-C 2”

GENERAL INSTRUCTIONS

- Routine service is an integral part of the standard procedure for maintenance of a

water supply system.

- Recommended routine maintenance– once or twice a year, according to the quality

and type of the uids in the system.

PROCEDURE

1. Close the service valve under the valve base before servicing.

2. Loosen and remove the four bolts and nuts (9).

3. Remove the metal shell (2) and enclosed valve body (1).

4. Remove the clamping stem (5) from the valve body (1) and carefully pull out the

oat (6) with the attached rolling seal assembly (3).

5. Check the soundness of the rolling seal assembly (3) by washing it with water

and examining it. Note: Replace the seal assembly (3) in case it is torn.

6. Wash the body (1) and the oat (6) with clean water and examine for

damage. Note: Replace the oat (6) if it is damaged.

7. Clean the drainage elbow (4) to remove insects and debris.

8. Return the oat (6) with the attached rolling seal assembly (3) to its original

position in the valve body (1) and lock them into place with the clamping stem (5).

9. Place the metal shell (2) and enclosed valve body (1) on the base (8).

Note: First make sure the O-ring (7) is seated properly in the base of the valve (8).

10. Attach by inserting and tightening the four bolts and nuts (9).

11. Remember to open the service valve after the servicing.

PARTS SPECIFICATION

NO. DESCRIPTION MATERIAL

1. Metal Shell Cast Iron

2. Valve Body Reinforced Nylon

3. Rolling Seal Assembly

4. Drainage Elbow Polypropylene

5. Clamping Stem Reinforced Nylon

6. Float Foamed Polypropylene

7. O-Ring BUNA-N

8. Base Brass

9. Bolt & Nut Cast Iron

2 1

43

5

6

7

8

9

Page 4

TROUBLESHOOTING

SYMPTOM

Outlet thread size needed in

order to attach a drainage

hose.

Built-in plastic screen is not

accepted by health

department.

Plastic body and/or base not

acceptable.

CAUSE

Valve was hit or mishandled.Right angle outlet is broken.

End user needs to connect a

drainage pipe from the valve

outlet in order to drain

excess water.

is is an above ground

installation.

A change in product spec.

A change in designer

preference.

CORRECTIVE ACTION

Easy to replace: gently pry o the outlet with

screwdriver Pressure insert the new right angle

using a plastic hammer.

Replacement part can be ordered from A.R.I.

Note: e part is not mandatory for the function

of the valve.

D-040 has 3/8” female thread.

2” D040 has 1¼” female thread.

End of pipe must be left open in order for valve to

function.

ARI oers an approved 316 stainless screen that

threads into the 2" valve.

GSM in California has made one for the 1” valve.

Oer the cast iron or stainless steel body.

Also oer the bronze or stainless steel base.

Valve spits water.

Valve is continuously

leaking.

is is normal at start up

and during pressure test.

Could be debris in the

sealing mechanism.

Line pressure issues

(inadequate pressure)

or debris lodged in seal or

o-rings.

Plastic threads stripped.Valve leaks from threads.

Open the valve. Clean and check integrity of the

sealing mechanism and O-ring seals.

Check line pressure. It needs at least 3 psi to seal

tight.

Is the valve on a booster pump? Can be installation

issue if valve is level with the water level in a tank there is no pressure to seal.

Open valve and clean sealing mechanism, check

the rolling seal and o-rings for wear or tear.

Replace if necessary.

Check for cross-threading.

Replace bottom of valve or oer the cast metal

base.

A.R.I FLOW CONTROL ACCESSORIES Ltd.

Kfar Charuv 12932 Israel Tel. 972-4-6761803 Fax. 972-4-6763402

WWW.ARIVALVES.COM ari@ari.co.il

MAINTENANCE INSTRUCTIONS D-040-C 2”

EnM-D040C2-10

Loading...

Loading...