Page 1

Service Manual for Volumetric Infusion Pump

green stream

ARGUS 707

Made in Switzerland

0120

®

ARGUS Medical AG, CH-3627 Heimberg / Switzerland

(A member of the CODAN group)

Page 2

INTRODUCTION

Table of contents

1. INTRODUCTION........................................................................................................................................................ 3

1.1. General ................................................................................................................................................ 3

2. PUMP CONFIGURATIONS...................................................................................................................................... 3

2.1. General ................................................................................................................................................ 3

2.2. Interrogation mode .............................................................................................................................. 4

2.3. Configuration mode............................................................................................................................. 5

2.4. First activation of a configuration PIN Code ...................................................................................... 7

2.5. Changing an existing pin code ............................................................................................................ 7

2.6. Address list of the pump configuration ............................................................................................... 8

2.7. Special configuration options.............................................................................................................10

3. CONFIGURATION AND HISTORY PRINTOUT ............................................................................................... 11

3.1. Introduction ........................................................................................................................................11

3.2. Settings of the terminal program ........................................................................................................11

3.3. Configuration printout........................................................................................................................12

3.4. History printout ..................................................................................................................................14

4. SOFTWARE UPDATES ...........................................................................................................................................16

4.1. General ...............................................................................................................................................16

4.2. Requirements for a software update ...................................................................................................16

4.3. Safety aspects .....................................................................................................................................16

5. MAINTENANCE .......................................................................................................................................................17

5.1. General ...............................................................................................................................................17

5.2. Recalibration ......................................................................................................................................17

5.3. Pressure calibration ............................................................................................................................17

5.4. Pressure control measurement............................................................................................................23

5.5. Volume calibration.............................................................................................................................24

5.6. Pump specifications............................................................................................................................25

5.7. Fault codes..........................................................................................................................................26

6. REPLACEMENT OF PARTS.................................................................................................................................. 27

6.1. General ...............................................................................................................................................27

6.2. Disassembling of the ARGUS 707.....................................................................................................27

6.3. Replacements of parts ........................................................................................................................31

6.4. Spare parts ..........................................................................................................................................32

7. SAFETY STANDARD CHECK............................................................................................................................... 36

8. WIRING DIAGRAMM ............................................................................................................................................. 37

9. BLOC SCHEMATIC................................................................................................................................................. 37

10. APPENDIX .................................................................................................................................................................38

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 17.02.04 AS 2 / 38

Page 3

1. INTRODUCTION

1.1. General

IMPORTANT!

This service manual is intended for the exclusive use of authorized persons who have been

trained by ARGUS Medical AG in the maintenance and repair of the ARGUS 707 infusion

pump.

The service manual is meant to be used together with the user manual.

IMPORTANT!

ARGUS Medical AG shall not assume any responsibility for any manipulations which

have been carried out on the ARGUS 707 infusion pump by a non-authorized person.

This manual contains the latest data available. It is subject to further modifications in accordance with technical improvements.

2. PUMP CONFIGURATIONS

INTRODUCTION

2.1. General

CAUTION!

The configuration possibilities constitute a modification of the pump and may only be

carried out by authorized persons!

CAUTION!

After changing the configuration a function check and a control measurement has to

be performed!

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 3 / 38

Page 4

PUMP CONFIGURATIONS

7

PRo

g

5.2

0

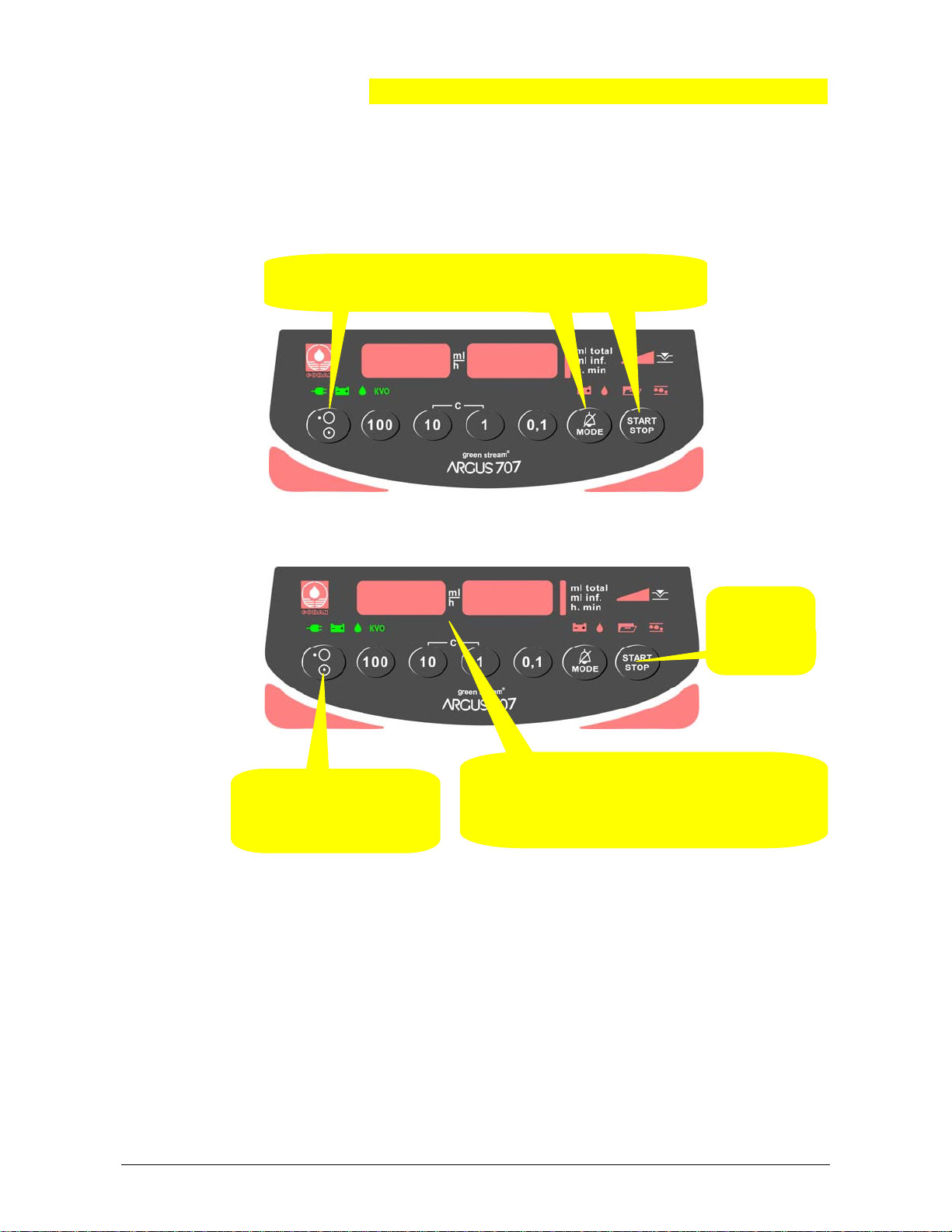

2.2. Interrogation mode

With the interrogation mode you can read the present configuration of the pump without

the possibility to modify any configurations.

Flashing decimal points indicate which display is ready to accept an input by the keys 100,

10 & 1.

In the interrogation mode the left hand display shows the address and the right hand display shows the according value configured at this address. Please refer to chapter 2.6

where the meanings of the addresses are explained.

To modify any configuration data you have to go into the configuration mode.

1. To enter into the interrogation mode, switch the pump on

while keeping the keys “MODE” and START/STOP” pressed.

70

. .

4. To quit the interrogation

mode press the

“ON/OFF” key at least 2

seconds.

.

3. Enter the requested address (see chapter 2.6), e.g.

52.

The programmed value of the address 52 appears

in the right hand display.

2. Press the

“START/

STOP”

key.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 4 / 38

Page 5

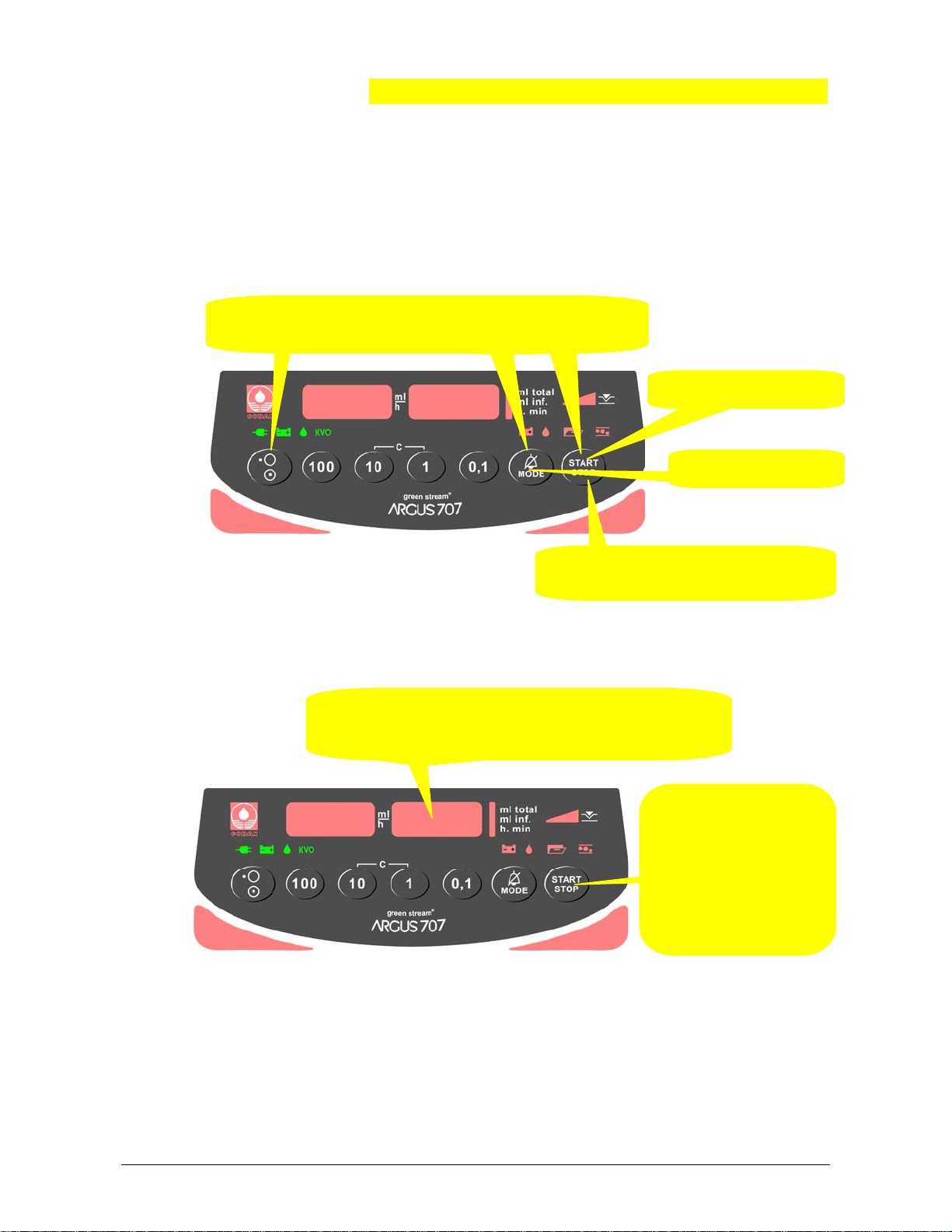

2.3. Configuration mode

-

7

g

The configuration mode alows you to modify the pump configuration manually. Please

refer to chapter 2.6 where the meaning of the configuration adresses are explained.

2.3.1. Step 1

1. To enter into the configuration mode, switch the pump on

while keeping the keys “MODE” and START/STOP” pressed.

PUMP CONFIGURATIONS

70

pro

2. Press key “START”.

3. Press key “MODE”.

4. Press key “START” again. The

3.

display will show “Cod ----“.

Pre

2.3.2. Step 2

If the PIN code was accepted the pump will show the display of chapter 2.3.1 again, but

you have now access to all writeable addresses in the list of chapter 2.6.

Select therefore any address in the left display (see next side):

5. Enter the PIN Code. If no PIN code was configured before,

default PIN 0 will be active. For PIN 0 press the key “10”

while keeping the key “1” pressed.

Cod

---

6. Press key “START” to

acknowledge the entered PIN code.

If the PIN was not

accepted, the display

will change back to

step 2.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 5 / 38

Page 6

PUMP CONFIGURATIONS

0

0.

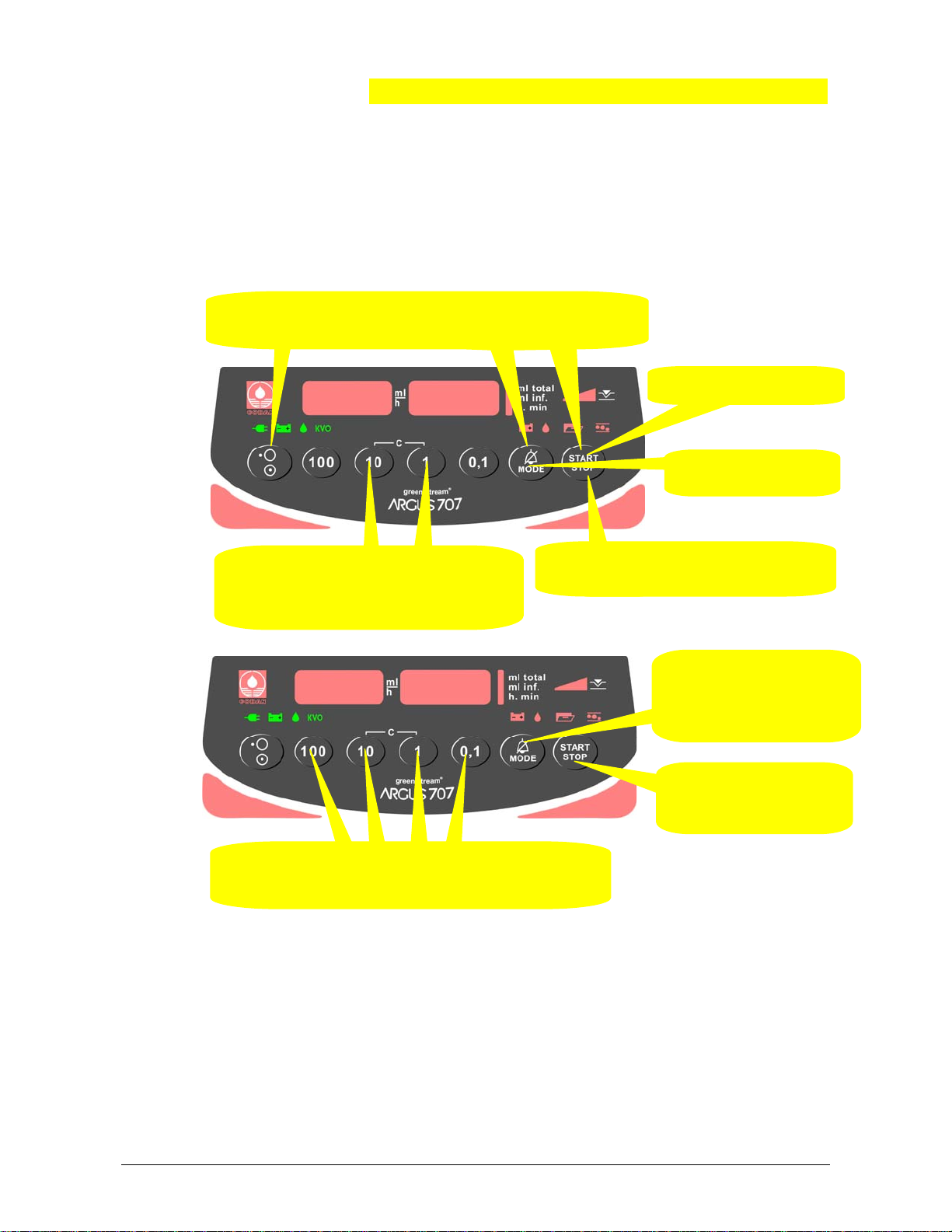

2.3.3. Step 3

8. Enter now the value on the right hand

Important remark:

Invalid values entered will be corrected automatically by the pump to the maxima or

minima value allowed for the according address!

display. The range of the value is given

by the table in chapter 2.6.

1

10. To quit the configuration mode press the

“ON/OFF” key at least 2 seconds.

Changes in configuration become active, if the

pump is switched on normally again.

7. After entering an address e.g. 10 press the key “MODE”. The

flashing decimal points will change to the right hand display.

. . .

9. Press key “START” to

acknowledge the value

entered.

The flashing decimal

points change back to

the left hand display.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 6 / 38

Page 7

PUMP CONFIGURATIONS

g

7

g

0

0

2.4. First activation of a configuration PIN Code

The activation of a PIN code allows you to protect the configuration from unauthorized

persons.

To activate the PIN code, enter the configuration mode as described in the previous

chapter. For this use the default PIN code “0”:

After you switch the pump OFF and ON again you can enter the configuration mode only,

if you enter the correct PIN code in display of chapter 2.3.2.

Please note: The interrogation mode can always be accessed without the PIN.

1. To enter into the configuration mode, switch the pump on

while keeping the keys “MODE” and START/STOP” pressed.

70

5. Enter the default PIN Code “0”. To do

this press the key “10” while keeping the

key “1” pressed. Press “START” key to

acknowled

e the entered PIN code.

pro

. . .

7. Enter now the new PIN Code (max. 4 digit number).

Please remember this code, it will never be visible

again!

2. Press key “START”.

3. Press key “MODE”.

4. Press key “START” again. The

3.

display will show “Cod ----“.

Pre

6. Press the “MODE” key.

The flashing decimal

points will change to the

right hand display

8. Press key “START” to

acknowledge to new

PIN.

2.5. Changing an existing pin code

Enter the configuration mode (see chapter 2.3), select address 0 and enter the new pin

code.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 7 / 38

Page 8

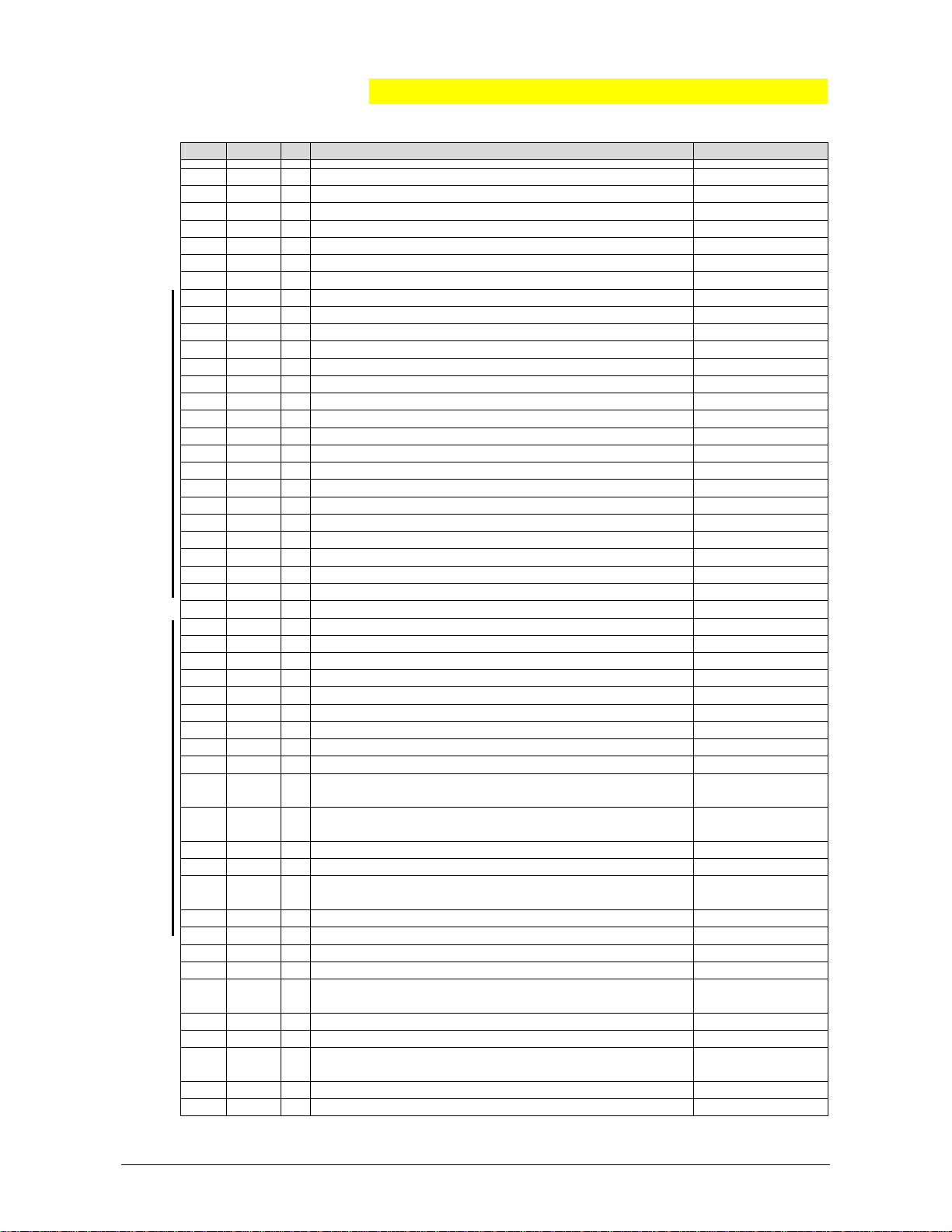

2.6. Address list of the pump configuration

Add.: Address Def.: Default value of the manufacturer

P: Protection grade (W = Write enabled)

Add. Def. P Function Range

0 0 W PIN code active 0=No; 1=Yes

1 1 W Run indication by running decimal point 0=No; 1=Yes

2 0 W Key [ON/OFF] only at STOP valid 0=No; 1=Yes

3 0 W Rate change only at STOP valid 0=No; 1=Yes

4 0 W Key [STOP] delayed (time at #361) 0=No; 1=Yes

5

6 0 W Static alarm (staff alerting system) 0=No; 1=Yes

7 0 W Display elapsed time in run mode (#8=0) 0=No; 1=Yes

8 0 W Select remaining time (#7=1) 0=No; 1=Yes

9

10 0 W Operation without drop detector 0=No; 1=Yes

11 1 W Recall "ml/h" (rate) at next power on 0=No; 1=Yes

12 0 W Recall "ml total" (end volume) at next power on 0 = N o ; 1=Yes

13 0 W Recall "ml inf." (volume inf.) at next power on 0 = N o ; 1=Yes

14 0 W SBS Step by step function 0=No; 1=Yes

15 0 W Display VTBI (Volume To Be Infused) 0=No; 1=Yes

16

17 1 W KVO (KOR, mode see (#60) 0=No; 1=Yes

18 0 W Drop alarm only if bottle empty

(#10=0, => 'trA' as default)

19 1 W Buzzer at start 0=No; 1=Yes

20 0 W Menu 'CLr' (Clear "ml inf.") (#15=0) 0=No; 1=Yes

21

22 0 W Menu 'trA' (Transport)(#10=0) 0=No; 1=Yes

23 1 W Menu 'PrL' (Pressure alarm limit) 0=No; 1=Yes

24 1 W Menu 'CAP' (Battery Capacity) 0=No; 1=Yes

25 0 W Menu 'SEt Fill' 0=No; 1=Yes

26

27 0 W Menu 'dLo' (Data-lock) 0=No; 1=Yes

28 0 W Menu 'Stb' (Stand-by) 0=No; 1=Yes

29 0 W Menu 'MEd' (Medication-no.) 0=No; 1=Yes

30 0 W Menu 'tM ' (Timer alarm) 0=No; 1=Yes

32 0 W Menu 'boL ' (Release Bolus) 0=No; 1=Yes

33 0 W Menu 'boLr' (Bolus rate)(#32=1) 0=No; 1=Yes

34 0 W Menu 'tot ' (Bolus total)(#32=1) 0=No; 1=Yes

38 0 W BOLUS application automatic (#32=1,#34=1) 0=No; 1=Yes

40 0 W Demo mode (menus addr. 20..34 and 7 enabled) 0=No; 1=Yes

41 0 W Clear "ml/h" after infusion completed 0=No; 1=Yes

42 0 W Clear "ml total" after inf. completed (#41=1) 0=No; 1=Yes

43 0 W Air volume accumulated, see #350 and 351 0=No; 1=Yes

44 1 W Automatic pressure release after occlusion 0=No; 1=Yes

45 1 W Pressure display (bar graph) 0=No; 1=Yes

46 0 W Pressure display with indicator (#45=1) 0=No; 1=Yes

47 0 W Standby- and battery pre alarm low volume 0=No; 1=Yes

48 0 W Flashing numeric display at alarm 0=No; 1=Yes

49 0 W Alarm acknowledge only with key [MODE] 0=No; 1=Yes

PUMP CONFIGURATIONS

0=No; 1=Yes

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 8 / 38

Page 9

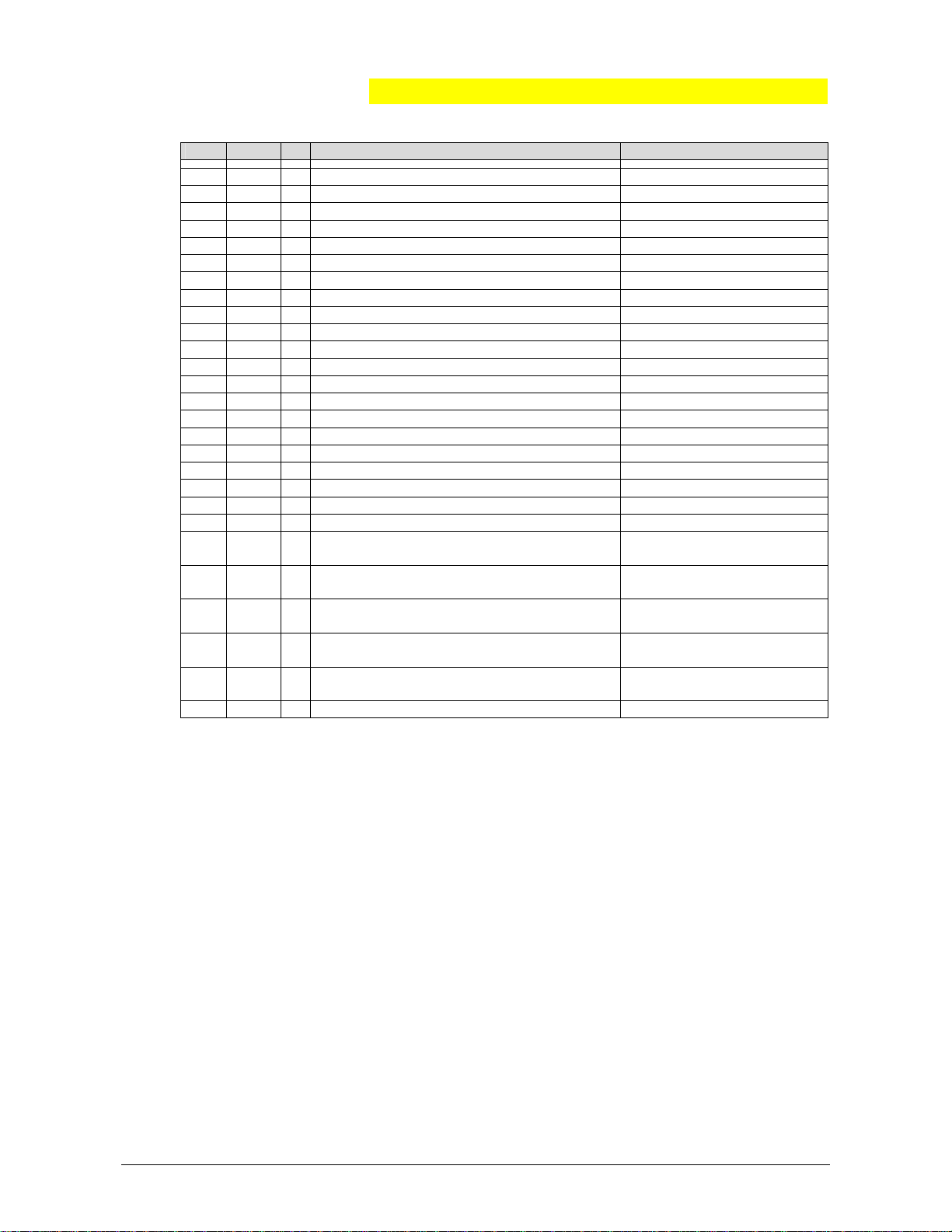

PUMP CONFIGURATIONS

Add. Def. P Function Range

50 0 W Start with >= 1bar downstream pressure allowed 0=No; 1=Yes

55 0 W Set default serial interface to RJ-45 connector 0=No; 1=Yes

60 0 W KVO only after infusion completed 0=No; 1=Yes

101 1 Set 1 enabled (always enabled) 0=No; 1=Yes

201 1091 W

202 1071 W

203 1061 W

204 1051 W

205 1031 W

206 1023 W

207 1014 W

208 1006 W

209 999 W

210 988 W

IV-Set 1 definitions IV-Set 1 parameters

211 974 W

212 967 W

213 947 W

214 939 W

215 917 W

216 900 W

217 1000 W

306 0 Infused sum in ml (xxxxyyyy) [xxxx.... ml]

307 0 Infused sum in ml (xxxxyyyy) [....yyyy ml]

308 0 Operating time in min (xxxxyyyy) [xxxx.... min]

309 0 Operating time in min (xxxxyyyy) [....yyyy min]

310 9999 W

311 999 W Prime rate in ml/h (1...999)

312 1200 W Max. bolus rate in ml/h (1...1200)

313 10 W Max. bolus total in ml (1...999)

314 10 W Upstream occlusion sensitivity

316 7 W Downstream pressure limit "PrL" default

317 250 W Air bubble size [microliters] (50...1000)

318 20 W Drop-rate window center in [drops/ml] (10...65)

319 1000 W Correction factor ((actual/nominal)*1000)

350 20 W Air summation volume, n * 50 [microliters] (2...40)

351 4 W Air summation time, n * 8 [min] (8..64)

361 500 W Key [ON/OFF] delay

362 8 W Display brightness (2...15)

363 10 W Buzzer alarm volume (5...10)

368 300 W Battery discharge time incl. 15min pre-

369 5 W Automatic Menu fall back delay time in [s] (5...30)

Max. rate in (1/10)ml/h

(0...60, 60 is highest sensitivity)

value

refer to chapter 5.5

(additional key [STOP] if #4=1)

alarm in [min]

(1...9999)

(0...60)

(1...10)

(850...1150)

(0...3000)

(45...300)

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 9 / 38

Page 10

PUMP CONFIGURATIONS

Add. Def. P Function Range

370 0 W Clock seconds (0...59)

371 0 W Clock minutes (0...59)

372 0 W Clock hours (0...23)

374 0 W Clock days (1...31)

375 0 W Clock months (1...12)

376 0 W Clock years (2000...2099)

380 0 Last failure number (F-XX) Refer to chapter 5.7

381 0 Last infusion rate at failure

382 0 .

383 0 .

384 0 .

385 0 .

386 0 .

387 0 .

388 0 Oldest failure number (F-XX)

389 0 Oldest infusion rate at failure

390 0 W Last service date (yyww, year and week)

391 0 2. last service date (yyww, year and week)

392 0 3. last service date (yyww, year and week)

393 0 W Service interval in months

(0 = disabled)

394 0 W Service interval in hours of

operation (0 = disabled)

395 0 W Own address for SCI

(0 = no address)

396 xxx W Serial number of the pump

(xxxx yyyy)

397 8yyy W Serial number of the pump

(xxxx yyyy)

399 707 Data xxxx -> clears protection key

(0...24)

(0...9999)

(0...127)

[xxxx....]

[....yyyy]

2.7. Special configuration options

1. Configuration of a reminder alarm for the safety standard check:

If a safety standard check reminder alarm is configured, the pump will display

“CtrL” after power up when the time has come to perform a standard safety check.

To configure a reminder alarm please follow next steps:

First the service interval has to be entered either in months or in hours of operation,

or both (address 393, 394).

Next the last service date has to be entered on address 390. Any value higher than 0

entered at the address 393 and/or 394 will release the reminder alarm after the service interval has elapsed (check also the correct settings of the internal clock).

2. PC configuration tool “AConfig”:

With this additional software the pump may be configured from a PC over the serial

port. This software may be available from your local distributor or ARGUS Medical AG.

Caution: AConfig may only be used with software versions greater or equal to

1.01.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 10 / 38

Page 11

CONFIGURATION AND HISTORY PRINTOUT

3. CONFIGURATION AND HISTORY PRINTOUT

3.1. Introduction

CAUTION!

The infusion pump has to be disconnected from the patient before and while the serial

interface cable is connected to the pump.

The connection of the ARGUS 707 over the serial interface RS 232 can be done by connecting the interface cable no.10.093 to the serial interface outlet of the serial COM port of

a PC.

A data transfer between ARGUS 707 and a PC can be done without any additional software running on the PC.

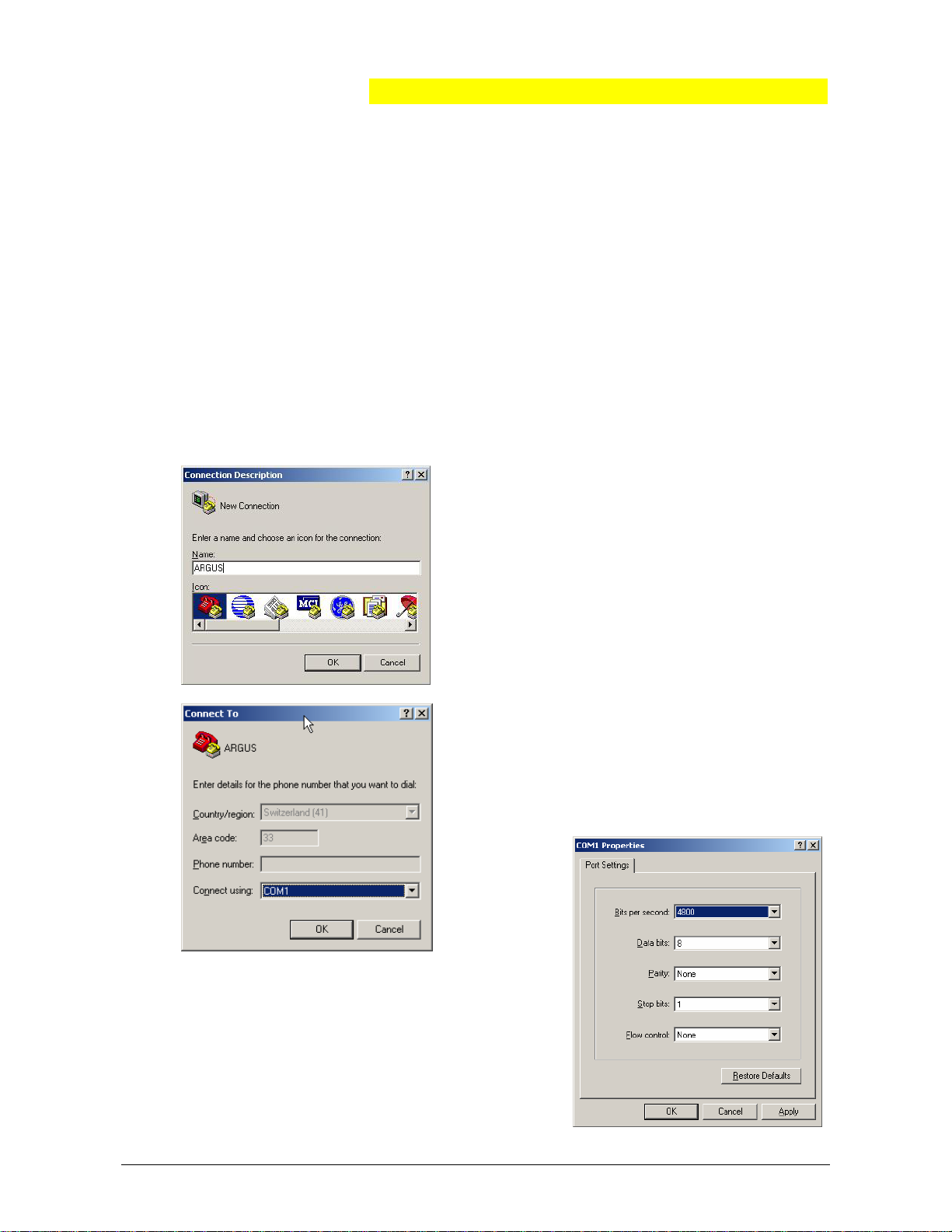

3.2. Settings of the terminal program

3.2.1. RS232 connection settings of the terminal program

Open the terminal program on the PC, e.g.

HyperTerminal, which has been included in every

Microsoft

Windows Operating System.

In the “Connection Description” menu, type for e.g.

“ARGUS” and click OK.

Please make sure that the correct COM port of the PC

has been selected.

Make the appropriate changes on the “COM Properties” menu according to the right hand picture:

Click OK, then a connection to the pump should now

be established.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 11 / 38

Page 12

CONFIGURATION AND HISTORY PRINTOUT

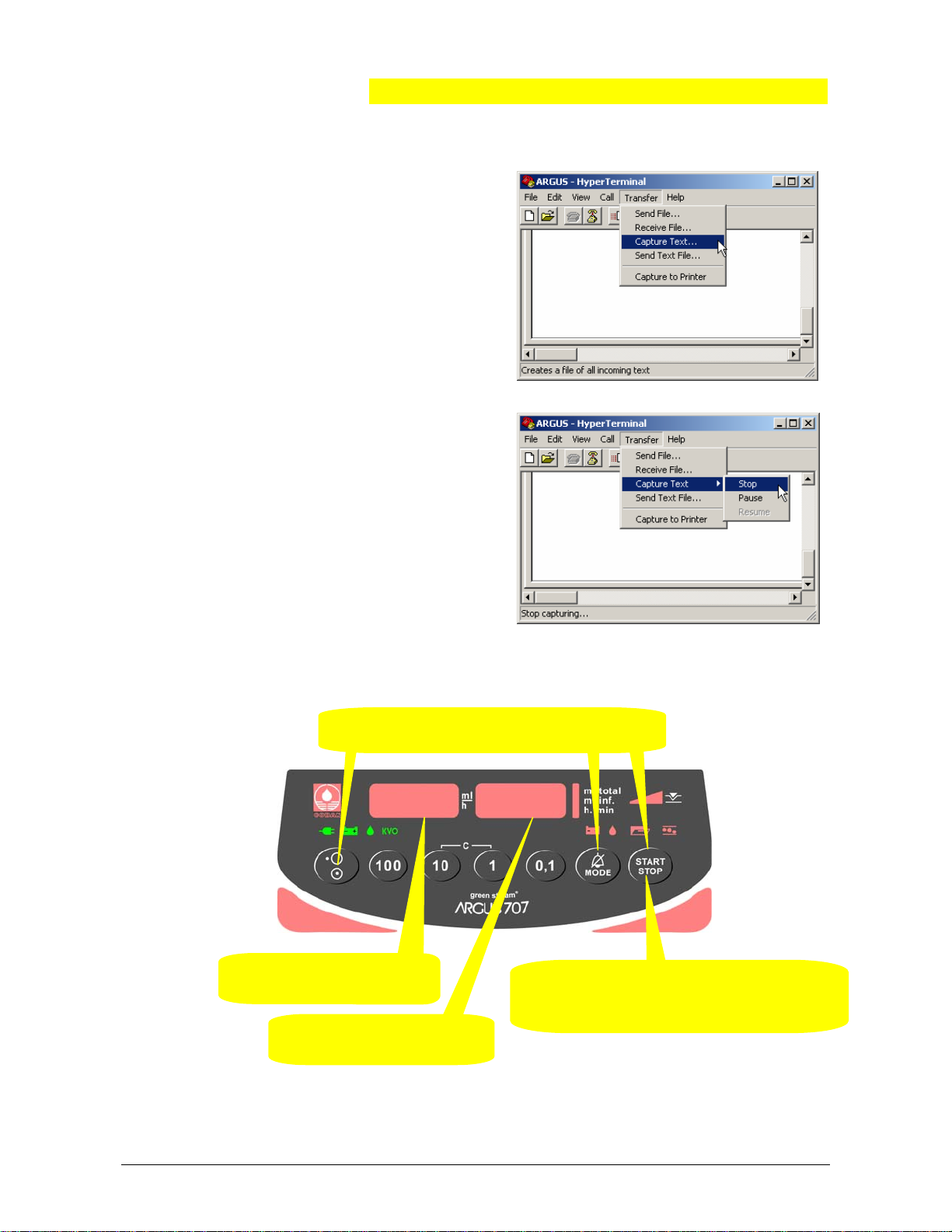

(

6

3.2.2. Capturing text from the pump transmitted

If you intent to print out the configuration

or the history events transmitted from the

pump, you should capture the text transmitted by the pump into a text file. To do this

please select “Capture Text” in the hyper

terminal’s menu.

A “File box” will open; type a descriptive

name for the file, and then click “Start”.

The terminal program starts to capture each

text received over the serial interface.

Stop the capturing after you did the required pump settings.

To do this select “Stop” in the menu “Capture Text” of the terminal program. You

will then have a text file including the data

transmitted by the pump.

3.3. Configuration printout

Connect the ARGUS 707 to your PC (see chap. 3.1) and setup the terminal program (see

chap. 3.2). Start to capture text on the PC side before you switch the pump on.

By saving the transmitted configuration text, you may print it using any text program.

See the following example of a configuration printout:

2. Select address 399 in the

left hand display.

3. Enter value 3456 in the

1. Enter into the configuration mode

see chapter2.3).

.3.9.9.

right hand display.

345

4. Press the “START/STOP” key. The pump

will now transfer the actual pump

configuration as text.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 12 / 38

Page 13

CONFIGURATION AND HISTORY PRINTOUT

3.3.1. Configuration printout example

/***** Configuration *****/ Sat 17-Jan-2004 19:00:09

Pump type : ARGUS707

Inventory number : 005 8 407

Software release : V1.00 (031218-75C2)

Infused sum : 861ml

Operating time : 15h18min

Last service date :

00=0 50=0 100=0 150=0 200=0000 250=0000 300=0000 350=0020

01=1 51=0 101=1 151=0 201=1091 251=0000 301=0000 351=0004

02=0 52=0 102=0 152=0 202=1071 252=0000 302=0000 352=0000

03=0 53=0 103=0 153=0 203=1061 253=0000 303=0000 353=0000

04=0 54=0 104=0 154=0 204=1051 254=0000 304=0000 354=0000

05=0 55=0 105=0 155=0 205=1031 255=0000 305=0000 355=0000

06=0 56=0 106=0 156=0 206=1023 256=0000 306=0000 356=0000

07=0 57=0 107=0 157=0 207=1014 257=0000 307=8611 357=0000

08=0 58=0 108=0 158=0 208=1006 258=0000 308=0001 358=0000

09=0 59=0 109=0 159=0 209=0999 259=0000 309=2918 359=0000

10=0 60=0 110=0 160=0 210=0988 260=0000 310=9999 360=0000

11=1 61=0 111=0 161=0 211=0974 261=0000 311=0999 361=0500

12=0 62=0 112=0 162=0 212=0967 262=0000 312=1200 362=0008

13=0 63=0 113=0 163=0 213=0947 263=0000 313=0010 363=0010

14=0 64=0 114=0 164=0 214=0939 264=0000 314=0010 364=0000

15=0 65=0 115=0 165=0 215=0917 265=0000 315=0000 365=0000

16=0 66=0 116=0 166=0 216=0900 266=0000 316=0007 366=0000

17=1 67=0 117=0 167=0 217=1000 267=0000 317=0250 367=0000

18=0 68=0 118=0 168=0 218=0000 268=0000 318=0020 368=0300

19=1 69=0 119=0 169=0 219=0000 269=0000 319=1000 369=0005

20=0 70=0 120=0 170=0 220=0000 270=0000 320=0000 370=0012

21=0 71=0 121=0 171=0 221=0000 271=0000 321=0000 371=0000

22=0 72=0 122=0 172=0 222=0000 272=0000 322=0000 372=0019

23=1 73=0 123=0 173=0 223=0000 273=0000 323=0000 373=0000

24=1 74=0 124=0 174=0 224=0000 274=0000 324=0000 374=0026

25=0 75=0 125=0 175=0 225=0000 275=0000 325=0000 375=0007

26=0 76=0 126=0 176=0 226=0000 276=0000 326=0000 376=2003

27=0 77=0 127=0 177=0 227=0000 277=0000 327=0000 377=0000

28=0 78=0 128=0 178=0 228=0000 278=0000 328=0000 378=0000

29=0 79=0 129=0 179=0 229=0000 279=0000 329=0000 379=0000

30=0 80=0 130=0 180=0 230=0000 280=0000 330=0000 380=0000

31=0 81=0 131=0 181=0 231=0000 281=0000 331=0000 381=0000

32=0 82=0 132=0 182=0 232=0000 282=0000 332=0000 382=0000

33=0 83=0 133=0 183=0 233=0000 283=0000 333=0000 383=0000

34=0 84=0 134=0 184=0 234=0000 284=0000 334=0000 384=0000

35=0 85=0 135=0 185=0 235=0000 285=0000 335=0000 385=0000

36=0 86=0 136=0 186=0 236=0000 286=0000 336=0000 386=0000

37=0 87=0 137=0 187=0 237=0000 287=0000 337=0000 387=0000

38=0 88=0 138=0 188=0 238=0000 288=0000 338=0000 388=0000

39=0 89=0 139=0 189=0 239=0000 289=0000 339=0000 389=0000

40=0 90=0 140=0 190=0 240=0000 290=0000 340=0000 390=0000

41=0 91=0 141=0 191=0 241=0000 291=0000 341=0000 391=0000

42=0 92=0 142=0 192=0 242=0000 292=0000 342=0000 392=0000

43=0 93=0 143=0 193=0 243=0000 293=0000 343=0000 393=0000

44=1 94=0 144=0 194=0 244=0000 294=0000 344=0000 394=0000

45=1 95=0 145=0 195=0 245=0000 295=0000 345=0000 395=0000

46=0 96=0 146=0 196=0 246=0000 296=0000 346=0000 396=0000

47=0 97=0 147=0 197=0 247=0000 297=0000 347=0000 397=0000

48=0 98=0 148=0 198=0 248=0000 298=0000 348=0000 398=0000

49=0 99=0 149=0 199=0 249=0000 299=0000 349=0000 399=0707

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 13 / 38

Page 14

CONFIGURATION AND HISTORY PRINTOUT

n

t

3.4. History printout

3.4.1. General

Connect the ARGUS 707 to your PC (see chap. 3.1) and setup the terminal program (see

chap. 3.2). Start to capture text on the PC side before you switch the pump on.

1. Switch the pump on while keeping the key “100” pressed

Pr

HIS

3.4.2. History header

At the top of the history, a header will appear showing the device type, the software release

and if configured, the inventory number and the last service date.

It shows also the pump internal real time at the moment of the printout.

Please note that there may be one hour summer or winter time deviation!

3.4.3. History events

Each registered event starts with a message line. Please refer to the complete list mentioned in chapter 3.4.5 which shows the possible messages generated by the user’s handling on the pump or by the pump itself.

Each event has a time stamp on the right side of the second line.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 14 / 38

Page 15

CONFIGURATION AND HISTORY PRINTOUT

3.4.4. History printout example

/***** History *****/ Tue 20-Jan-2004 19:40:30

Pump type : ARGUS707

Inventory number : 005 8 407

Software release : V1.00 (031218-75C2)

Infused sum : 388ml

Operating time : 24h44min

Last service date :

Pump off

Rate = 0040.0ml/h Inf-Set = 1 Tue 20-Jan-2004 18:29:22

Total = 0000.0ml PrLimit = 0700mbar

Infsum = 0000.0ml Status = 0x0000

Pump on

Rate = 0040.0ml/h Inf-Set = 1 Tue 20-Jan-2003 18:27:18

Total = 0000.0ml PrLimit = 0700mbar

Infsum = 0000.0ml Status = 0x0000

3.4.5. History messages

Possible messages appearing in the first line of each history event:

No information available

Battery defective

Battery low pre alarm

Battery low, pump stop

Bolus start

Bolus stop

External power off

External power on

Downstream occlusion, pump stop

PrLimit change

Pump has detected failure

Pump off

Pump on

Pump start

Pump stop (KVO)

Rate change

Enter setup mode

No drops, pump stop

Not enough drops, pump stop

Too many drops, pump stop

Door open, pump stop

Inf-Set change

Timer alarm, pump stop (KVO)

Total volume reached, pump stop (KVO)

Data lock off

Data lock on

Infsum cleared

Transport off

Transport on

Air bubble, pump stop

Bolus total reached

Exit setup mode

PC configuration done

PC configuration failure

Pump start, ext. changed parameters

Upstream occlusion, pump stop

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 15 / 38

Page 16

4. SOFTWARE UPDATES

4.1. General

This chapter describes the procedure to perform a software update on the ARGUS 707 infusion pump. To check the installed software release in your ARGUS 707 press the

"MODE" key while switching on the pump.

Please refer to your local distributor or ARGUS Medical AG to determine the latest software release able to run on your device hardware.

4.2. Requirements for a software update

To update an ARGUS Medical device, the following items are needed:

- A PC with Microsoft Windows.

- RS 232 serial interface cable (part no. 10.093), connected to the PC.

- Software file "AMFlasher" and corresponding user instruction (pdf-file) on your PC.

- Data file "A707_xxx.txt" including the pump software which can be downloaded with

the "AMFlasher" software.

The file name "A707_xxx.txt" contains the software release (xxx) version of the pump

software release.

Those items are available from your local distributor or from ARGUS Medical.

SOFTWARE UPDATES

4.3. Safety aspects

Be aware of the following points:

• For medical device traceability your local distributor or ARGUS Medical AG

needs to be informed about every device updates (serial number) you performed!

• Do not make any software updates when the device is used and/or connected to a

patient!

CAUTION!

A standard safety check (see appendix) has to be performed after every software update!

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 17.02.04 AS 16 / 38

Page 17

5. MAINTENANCE

5.1. General

CAUTION!

Only authorized persons who have been trained by ARGUS Medical AG or by the local

distributor are allowed to service the ARGUS 707 infusion pump. In case of repair request,

send the unit to the local distributor with a report outlining the exact nature of the failure.

More information is available from:

CAUTION!

The safety standard check has to be performed at least every 24 month or after

10'000 hours of operation. The check has to be done in accordance to the chapter 7.

No special maintenance of the ARGUS 707 infusion pump is necessary. There are no

wear and tear parts.

5.2. Recalibration

MAINTENANCE

ARGUS Medical AG

CH-3627 Heimberg / Switzerland

E-mail: info@argusmedical.com

5.2.1. General

Unless otherwise specified by the customer, the ARGUS 707 has been calibrated by the

manufacturer with the CODAN L86 infusion set. If a different infusion set is used (see

recommended list in the appendix of the user manual), a recalibration is required.

CAUTION!

A recalibration with a different IV-set always requires a recalibration of both pressure sensors and a volumetric calibration!

CAUTION!

It is mandatory to execute first the calibration procedure of the pressure sensors and

afterwards the volume calibration.

5.3. Pressure calibration

5.3.1. General

The volumetric infusion pump ARGUS 707 contains two pressure sensors:

- One upstream sensor, bottle side (left input)

- One downstream sensor, patient side (right output).

CAUTION!

A pressure calibration becomes necessary if the pressure control measurement

was not accurate enough, a new IV-set configured or a pressure sensor replaced or the main board is replaced.

Needed equipment: - a manometer with a resolution of 0,05 bar.

- a 3-way stop cock

- the chosen IV-set (refer to the list

including the recommended IV-set in the user manual)

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 17 / 38

Page 18

C

.

5.3.2. Enter the pressure calibration mode

(

3.9.9

4

2. Select address 399 in this display.

Press then key “MODE”.

1. Enter into the configuration mode

see chapter 2.3).

123

.

3. Enter value 1234 in this

display.

MAINTENANCE

4. Press the “START/STOP” key, the

pump starts to running at a constant

rate of 200 ml/h. The display

shows “CAL. door”.

5.3.3. Calibrating the offset of both sensors

Remove any IV-set inserted in the pump!

1. Open the

door.

Remark:

By pressing the key "1" the actual value of the offset voltage in mV is displayed,

for the upstream sensor in the left hand display, for the downstream sensor in the

right hand display. Return to the original state by pressing the key "1" again.

2. Press the “START / STOP”

key to store both values for the

up- and downstream sensor,

this will be acknowledged by a

sound.

3. Press the “MODE” key to go to the next

calibration step. The display shows “roll

LAM”

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 18 / 38

Page 19

5.3.4. Calibrating the upstream sensor part 1 (left side)

1. Insert a new IV-set filled with water, place the roller

clamp on the upstream side near the pump and close

the door. Open the roller clamp and let the pump

running for 5 seconds at least.

5. Open the roller clamp for the

next step!

Remark:

By pressing the key "1" the pump display changes to “xxxx Pr S” where the left

display shows the actual upstream pressure sensor signal in mV.

Return to the original state by pressing the key "1" again.

MAINTENANCE

2. Close the

roller

clamp and

wait 10

seconds.

3. Press the

"START /

STOP" key to

store the

value for an

upstream occlusion. This

will be acknowledged

by a sound.

4. Press key

"MODE" to

enter the next

calibration

procedure.

The display

shows

“CAL. 0.4b”.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 19 / 38

Page 20

5.3.5. Calibrating the downstream sensor (right side).

1. Simulate a downstream occlusion by the 3-way

stop cock.

The pump must generate a pressure of at least 1.4

bar. Otherwise there might be a mechanical problem (pressure plate, door hinge, peristaltic, etc.).

Release the pressure again.

4. Press the "MODE" key.

The display shows “CAL.

1.4b”. Follow the instructions on the next side.

3. Press the "START / STOP" key

when a pressure of 0.4 bar has been

reached. The stored value will be

acknowledged by a sound.

Remark:

By pressing the key "1" the pump display changes to “Pr S xxxx” where the right

display shows the actual downstream pressure sensor signal in mV.

Return to the original state by pressing the key "1" again.

MAINTENANCE

2. Restart a

pressure

build-up.

Check for

the pressure

gauge display which

must increase.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 20 / 38

Page 21

MAINTENANCE

5. When the

occlusion pressure reaches

1.4 bar press

the "START /

STOP" key.

The stored

value will be

acknowledged

by a sound.

4. Press the "MODE" key. The display shows

“CAL. -0.4b”. The pump starts to deliver backwards

and the pressure in the system decreases.

Remark:

By pressing the key "1" the pump display changes to “Pr S xxxx” where the right

display shows the actual downstream pressure sensor signal in mV.

Return to the original state by pressing the key "1" again.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 21 / 38

Page 22

5.3.6. Calibrating the upstream sensor part 2 (left side)

Close the door.

1. Close the roller clamp and install

the tube in the reverse direction.

3. Restart a

pressure

build-up.

4. Check for the pressure gauge display which must increase.

Press the "START / STOP" key when a pressure of 0.4 bar has been reached.

Press key “MODE”, the display shows “CAL. –1.4b”.

Repeat this point at a pressure of 1.4 bar.

5. Switch the pump off and insert the IV-set in the normal direction!

Now, perform a pressure control measurement according to chapter "

Pressure control measurement".

Remark(s):

- By pressing the key "1" the pump display changes to “xxxx Pr S” where the

left display shows the actual downstream pressure sensor signal in mV.

Return to the original state by pressing the key "1" again.

- The procedure for the upstream sensor calibration part 2 is equal to the proce-

dure for the downstream sensor, but with inverse delivery direction.

MAINTENANCE

2. Open the roller clamp.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 22 / 38

Page 23

5.4. Pressure control measurement

5.4.1. Downstream control measurement

Start an infusion at an infusion rate of 250 ml/h according to the user manual.

Insert a pressure gauge on the downstream (patient) side which monitors the pressure in the tube.

Simulate an downstream occlusion.

The pump must stop and the alarm must be activated at the default pressure limit of

700 mbar ±100 mbar, except a different default pressure limit has been configured.

If the result of this control measurement does not fulfil the stated requirement, a

pressure calibration according to chapter "Pressure calibration" has to be done.

5.4.2. Upstream control measurement

Start an infusion at an infusion rate of 250 ml/h with the roller clamp on the upstream side near to the pump.

Simulate an upstream occlusion by closing the roller clamp. To avoid the drop

alarm release, simulate falling drops on the drop detector.

The pump must stop after several seconds and an upstream alarm (right hand LED

in the pressure bar graph) must be activated.

If the result of this control measurement does not fulfil the stated requirement, a

pressure calibration according to chapter "Pressure calibration" has to be done.

MAINTENANCE

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 23 / 38

Page 24

5.5. Volume calibration

⋅

5.5.1. General

There are two ways to calibrate the volume delivered by the ARGUS707 volumetric pump, select one:

• By entering the correction factor

• With the internal calibration program of the pump

Needed equipment: - balance with a resolution of 0,1g at least

5.5.2. Volume calibration by entering the correction factor

1. Insert a new IV-set (only recommended IV-sets may be used, see appendix in

the user manual) in the pump and perform a “warm up” infusion of 10 ml at an

infusion rate of 999.9 m/h!

2. Infuse now a volume of 15 ml of water in a measuring cup on a zeroed balance

at an infusion rate of 250 ml/h.

MAINTENANCE

3. Determine the weight of the delivered water.

4. Enter the configuration mode as described in chapter 2.3.

5. Go to address #319 and read the present correction factor.

6. Calculate the new correction factor as follows:

factor correction New

=

15

*

water)delivered ofweight (factor)(Present

e.g.:

*

Pre-set volume of point 2.)

Present correction factor: 1020

Weight of delivered water [g]: 14.9

New correction factor: 1013

7. Enter the new correction factor at address #319 (e.g. 1013) in the right hand

display and save it by pressing key “START”; then switch the pump off.

8. Perform a control measurement according to the steps 2 & 3 above. Repeat the

calibration procedure if necessary.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 24 / 38

Page 25

MAINTENANCE

5.5.3. Volume calibration with the pump integrated calibration program

Needed equipment: - balance with a resolution of 0,1g at least

1. Insert a new IV-set (only recommended IV-sets may be used, see appendix in

the user manual) in the pump (filled with water) and connect the infusion line

to a measuring cup on a balance.

2. Enter the configuration mode as described in chapter in chapter 2.3.

Enter the value "123" at address 399. This will force the pump to enter the

calibration mode which will be displayed as "bAL tArA".

3. Press the key “START/STOP”. The pump delivers a volume of 5 ml at an infusion rate of 250 ml/h (“tArA” is flashing).

4. When “tArA” stops flashing, reset the balance to 0.

5. Press the key “START/STOP”. The pump will display “tM 215” (infusion delivery time is 215 seconds). It should now deliver a volume of 15 ml at an infusion rate of 250 ml/h.

6. After the delivery time has elapsed, the pump stops and shows “baL.” “12.75”

in the displays.

Enter now the value of the balance, e.g. 14.90 g. This value must be within the

range of 12.75 – 17.25. Otherwise switch the pump off and restart the volume

calibration.

7. Press the key “START/STOP” to acknowledge the entered value.

8. The pump displays the new correction factor, e.g. 1013.

9. Press the key “START/STOP” to store the new correction factor acknowledged

10. Switch the pump off. Do not remove the infusion set!

11. Perform a control measurement with an infusion rate of 250 ml/h and an infu-

5.6. Pump specifications

Please refer to the user manual for the specifications (chapter 8).

by a buzzer sound. The pump display changes back to “bAL tArA” again.

sion total of 15 ml. Repeat the calibration procedure if necessary.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 25 / 38

Page 26

MAINTENANCE

)

5.7. Fault codes

A technical failure will be signalled by the pump with a continuous alarm display and a

continuous sound. During this state, the fault code which causes the pump to fail can be

displayed by pressing the key “MODE”.

IF the pump was switched OFF after a detected failure, the fault code will be stored in the

configuration of the pump, please refer to chapter 2.6 (Addresses 380-389).

The possible fault codes registered in the configuration are listed in the table below:

Fault

Code

F_21 ROM test

F_22 ROM check (Runtime)

F_23 RAM test/check

F_24 XRAM test/check

F_25 CPU test

F_26 Invalid function menu

F_27 EEPROM data invalid

F_28 RTC data invalid, no RTC etc

F_29 Stepper motor power test (delayed 5s)

F_32 5Volt supply out of range

F_33 24Volt supply out of range (delayed 5s)

F_37 Downstream pressure sensor test failed (always > 4.7V, delayed 5s

F_38 Upstream pressure sensor test failed (always > 4.7V, delayed 5s)

F_39 Downstream pressure sensor test failed (dynamical test failed)

F_40 Upstream pressure sensor test failed (dynamical test failed)

F_44 Address invalid for config-eeprom

F_45 Address invalid for history-eeprom

F_46 Frequency from uC or RTC out of range

F_47 Display-print not present

F_48 Key(s) too long active

F_49 Sensor-print not present

F_50 AIL (Air in line) detector test failed

F_51 Movement test failed (Home-Pulse < (Hall / Home))

F_52 Movement test failed (Home-Pulse > (Hall / Home))

F_53 More than one rotation at 'STOP' without 'KVO'

F_54 Infused sum <> Calculated sum (Rotations)

F_55 Frequency calculation

F_57 Rotation (SW overflow)

F_58 Volsum control

Failure

We recommend replacing the main board in case a fault code is not included in this list

above.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 26 / 38

Page 27

6. REPLACEMENT OF PARTS

6.1. General

CAUTION!

The ARGUS 707 may only be used with accessories and spare parts which have been

approved by ARGUS Medical AG for safe technical use.

CAUTION!

If a door, a housing, a pressure sensor or a main board is replaced, a full calibration

(pressure sensors and volume calibration) is required.

6.2. Disassembling of the ARGUS 707

CAUTION!

Disconnect the mains cable from the power outlet before opening the housing!

Observe the antistatic protection rules when disassembling the ARGUS 707 (the use

of an antistatic table mat and a grounded clip are recommended).

6.2.1. Disassembly of the case

1. Remove the four screws on the back side.

REPLACEMENT OF PARTS

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 27 / 38

Page 28

REPLACEMENT OF PARTS

b

2. Separate the front and the back side.

3. Disconnect the battery, the supply

and the docking interface connection.

6.2.2. Removing the pump door

1. Gently press this hinge stopper

ackwards.

2. Pull the shaft towards the centre.

Repeat point 1 and 2 for the other

side of the door and then remove the

door.

6.2.3. Disassembling the pump unit

1. Unscrew these screws.

Remove the pump unit.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 28 / 38

Page 29

REPLACEMENT OF PARTS

6.2.4. Assembling the pump

1. Use the screw with a washer at

these places (torque 1.0 Nm)!

2. Use the screw without a

washer at these places

(torque 1.0 Nm)!

3. Reinstall the door. Make sure

that a washer has been installed on each side!

4. Make sure that this part

touches nowhere, otherwise noises may be

generated!

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 29 / 38

Page 30

7. Use the short screw at these

places (torque 1.1 Nm)!

7. Use the long screw at these

places (torque 1.1 Nm)!

REPLACEMENT OF PARTS

5. Reconnect the back

side with the front side

(battery, power &

docking interface)!

6. Make sure that both

cables are correctly

placed in the notch before the main board is

inserted!

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 30 / 38

Page 31

Mind the torque for the screws listed below:

Combination clamp 1.0 Nm

Transformer 1.0 Nm

All other screws not mentioned

in this chapter: 0.6 Nm

6.3. Replacements of parts

CAUTION!

The ARGUS 707 may only be used with accessories and spare parts which have been

approved by ARGUS Medical AG for safe technical use.

For the part numbers of replacement parts consult the following chapter.

REPLACEMENT OF PARTS

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 31 / 38

Page 32

6.4. Spare parts

10.093 Interface cable docking

10.087 Combination clamp

pumps

10.121 Pressure sensor

A707

REPLACEMENT OF PARTS

10.089 External drop detector

10.120 Display board A707

10.122 Air detector A707

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 32 / 38

Page 33

REPLACEMENT OF PARTS

10.123 Stop flow A707

10.124 Main board A707

10.125 Sensor board A707 10.126 Pump unit A707

10.127 Door complete A707

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 33 / 38

Page 34

REPLACEMENT OF PARTS

10.128 Casing back plane A707

230VAC complete

10.136 Casing back plane A707

10.129 Casing forepart (without door)

complete

10.137 Casing forepart

12.011 Interface cable 8pol/2m

& 12.012 Interface adapter

12.042 Cable staff alert 2m

10.119 Battery NiMHd 12V/1500mAh A707 11.221 Sealing A707

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 34 / 38

Page 35

p

m

REPLACEMENT OF PARTS

Part no. 11.222 Front panel A707

12.035 Pressure gauge

with sto

cock

10.135 Edge board complete A707

11.005 Bottle holder 45 cm

11.043 Bottle holder 60 c

Part no. Description Part no. Description

11.237 Identification plate A707 11.244 Short instruction Czech

11.238 Label flow direction 11.245 Short instruction Portuguese

11.239 Short instruction German 11.246 Short instruction Spanish

11.240 Short instruction English 11.247 Short instruction Italian

11.241 Short instruction French

11.242 Short instruction Danish

11.243 Short instruction Dutch

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 35 / 38

Page 36

SAFETY STANDARD CHECK

7. SAFETY STANDARD CHECK

The safety check should be done at least every 10’000 running hours or every 24 months.

Refer to the form in the appendix of this manual.

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 36 / 38

Page 37

8. WIRING DIAGRAMM

WIRING DIAGRAMM

9. BLOC SCHEMATIC

1

1

8

3

2

Nurse-call

RS-232

Motor

Motor

Driver

Switcher

AC Main

AC

DC

Ext. DC

Ni-Cd

Akku 12V

Buzzer

Alarm

Relay

RS232

Reset +

Watchdog

Power Switch Test

DC

DC

DC

DC

Pressure Sensor (in)

Pressure Sensor (out)

+ 24V

(Motor +

Buzzer)

+5V

(Logic)

Controller

On/Off

2

IC

512 Hz

KVO

0,1

1

10

100

Latch

EEPROM

RTC

Li-Batt.

3 Volt

Air Bubble Detector

Drop Detector

Door Control

Motion Control

Mode

Display

Driver

FLASH

Start/Stop

Pressure

ml total

ml inf.

h. min

DOOR

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 37 / 38

Page 38

APPENDIX

10. APPENDIX

Safety standard check (SSC)

ARGUS 707 ARGUS Medical AG

Serial-no.: ……………………………….………….. Inventory-no:.……………………..……………….

Hospital: ………………..……………………………………………………………………..

Department: ………………..……………………………………………………………………..

Customer: ………………..……………………………………………………………………..

The SSC has to be performed at least every 24 months or after 10'000 hours of operation. The check has to be

done in accordance to the user- and service manuals.

Visual check for damage, cleanness and completeness - Housing, labels, accessories, connectors, power

1

Test the function of the stop flow clamp - Proper movement of the clamp

2

Keep "MODE" pressed while switching on the pump - Display pump type and software release

3

Connect/Disconnect the pump to the mains - The indicator “external supply” lights up

4

Test the drop detector by simulating drops - Check the green “drop” indicator

5

Test the door switch, open and close the door - Door open the “door” indicator lights up

6

Open the door and remove any IV-set - Indicator “air bubble” lights up

7

Install a water filled IV-set, close the door - Indicator “air bubble” turns off

8

Set rate to 333.3 m/h, press "START", disconnect the

9

drop detector

Press "MODE" - The acoustical alarm mutes

10

Check the external connector “nurse call” - Relay contact switches (see chapter 9)

11

Calibration of the pressure sensors

12

IV-set type used:

Codan……… Other……………..………………….

Volume calibration - See chapter 5.5 of the service manual

13

Charge the battery while the pump is running 16

14

hours, at a rate of 30.0 ml/h

Battery check at a rate of 30 ml/h.

15

Run the battery test until the pump switches

off automatically

Printout the pump history (refer to chapter 3.4) - Check the battery run time by checking the latest

16

Electrical test according to EN60601-1

17

(all measurements made with a power cable 2.5 m)

Charge the battery after this test!

18

The pump has passed the SSC and is safe for use

cable, etc.

- Display of 2, 4, 7, F., in numeric display

- Display of all operation- and alarm indicators

- Door close the “door” indicator turns off

- The red indicator “drop” lights up (delayed)

- The acoustical alarm turns on

- See chapter 5.3 and 5.4 of the service manual

- The indicator “external supply” must light

- The green indicator “battery” lights up during this

test

history entries, > 4h 30min

- Check the pump internal time and date

- Measurements attached

Date: ………………..……………………………………………………………………..

Name: ………………..……………………………………………………………………..

Signature: ………………..……………………………………………………………………..

14.164.A_A707en.SM.V1.01.doc ARGUS Medical AG 10.02.04 AS 38 / 38

Loading...

Loading...