Page 1

Service Manual

ARGUS 60 M & ARGUS 100 M

Docking Station

Made in Switzerland

ARGUS Medical AG, CH-3627 Heimberg / Switzerland

System V4

(member of the CODAN group)

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 1 / 22

Page 2

TABLE OF CONTENTS

1. INTRODUCTION ...........................................................................................................3

1.1. General .................................................................................................................3

2. DOCKING configuration..............................................................................................4

2.1. General .................................................................................................................4

2.2. Index list of the docking configuration (with ARGUS service) ...............................4

3. MASTER & SLAVE (cascade)......................................................................................5

3.1. General .................................................................................................................5

4. ARGUS service.............................................................................................................6

4.1. General .................................................................................................................6

4.2. ARGUS service – Configuration............................................................................7

4.3. ARGUS service - Docking history .........................................................................9

5. SOFTWARE UPDATES ..............................................................................................10

5.1. General ...............................................................................................................10

5.2. Requirements for a software update ...................................................................10

5.3. Software update procedure.................................................................................10

5.4. Upgrade of a docking station from 1.x to V4 .......................................................11

5.5. Minor Firmware Update with V4..........................................................................12

5.6. Major Firmware Update with V4 ..........................................................................13

6. BARCODE READER AND LABEL DATA..................................................................14

6.1. General ...............................................................................................................14

6.2. Label layout.........................................................................................................14

6.3. Barcode format....................................................................................................14

7. Serial communication of the DOCKING...................................................................15

7.1. General ...............................................................................................................15

7.2. Serial communication protocol V4.......................................................................15

7.3. Monitoring ...........................................................................................................15

7.4. Remoting.............................................................................................................15

8. MAINTENANCE AND FAULT FINDING .....................................................................16

8.1. General ...............................................................................................................16

8.2. Fault code ...........................................................................................................16

9. REPLACEMENT OF PARTS.......................................................................................17

9.1. General ...............................................................................................................17

9.2. Disassembling of the docking station ..................................................................17

9.3. Spare parts..........................................................................................................17

10. WIRING DIAGRAM .....................................................................................................19

11. BLOCK SCHEMATIC..................................................................................................20

12. SAFETY STANDARD CHECK.................................................................................... 21

13. REPAIR ORDER FORM..............................................................................................22

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 2 / 22

Page 3

1. INTRODUCTION

1.1. General

IMPORTANT!

This service manual is intended for the exclusive use of authorized persons who

have been trained by ARGUS Medical AG in the maintenance and repair of the

ARGUS 60 M & ARGUS 100 M docking station.

The service manual is meant to be used together with the ‘User Manual’.

IMPORTANT!

ARGUS Medical AG shall not assume any responsibility for any manipulations which

have been carried out on the ARGUS 60 M or ARGUS 100 M docking station by a

non-authorized person.

IMPORTANT!

System V4: The ARGUS 60 M & ARGUS 100 M docking station with software version

4.30 only supports new ARGUS pump firmware versions beginning with v4.30.

IMPORTANT!

The reading of the barcode (medicament name and infusion data's on a syringe or a

fluid bag) and the data transfer to the pump are fail save.

The data transfer from the ARGUS 60 M & 100 M docking station to a PC is fail safe

only if the third party software and the PC hardware fulfills EN60601-1-1/-2/-4 itself.

Please contact ARGUS for details & permission to connect.

CAUTION!

The ARGUS 60 M & ARGUS 100 M docking station may only be used with spare

parts, accessories, pumps recommended by ARGUS Medical AG. The functional

safety of the docking station is not guaranteed if non approved materials are used.

The safety of the patient may be endangered.

This manual contains the latest data available. It is subject to further modifications in

accordance with technical improvements.

INTRODUCTION

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 3 / 22

Page 4

DOCKING configuration

2. DOCKING CONFIGURATION

2.1. General

CAUTION!

The configuration possibilities with the “ARGUS service” PC utility tool constitute a

modification of the docking station and may only be carried out by authorized persons!

CAUTION!

After changing the configuration a functional check has to be performed!

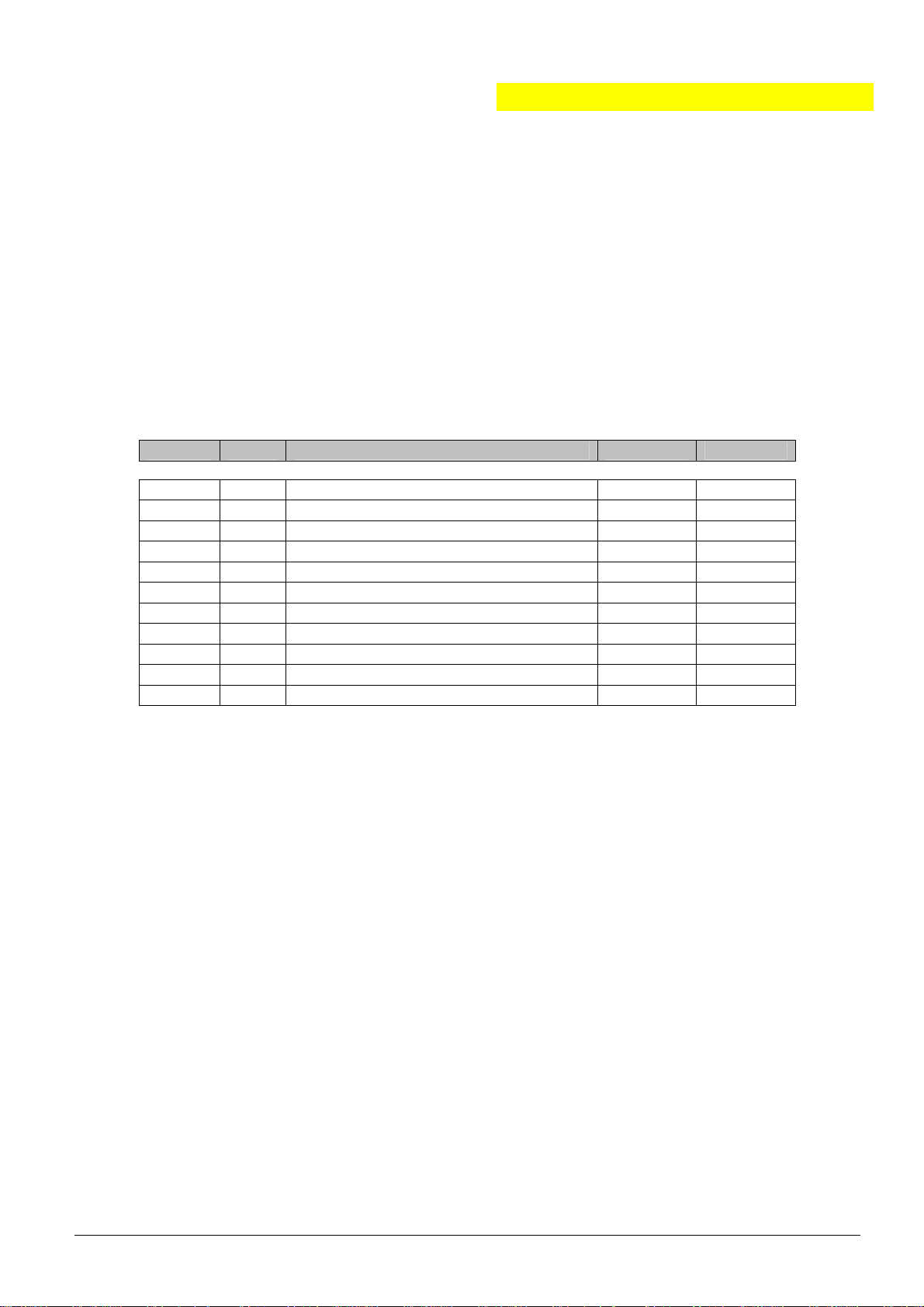

2.2. Index list of the docking configuration (with ARGUS service)

Index PC Default Function Unit Range

1 No Cascaded docking station - No / Yes

2 No Cascaded docking station, MASTER - No / Yes

3 No Barcode connected - No / Yes

4 No This is an ARGUS 60 M docking station - No / Yes

5 No Static nurse alarm relay - No / Yes

6 5 Buzzer alarm volume volume 1 - 5

7 - Customer department info text text 16 chars

8 Yes Current controlling alarm - No / Yes

440 0 Configuration PIN (visible after login) - -

396 0 ARGUS docking station serial number

nnn T yww

Using the ARGUS service tool, the complete and detailed docking configuration

can be done.

nnn T yww

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 4 / 22

Page 5

MASTER & SLAVE (cascade)

3. MASTER & SLAVE (CASCADE)

3.1. General

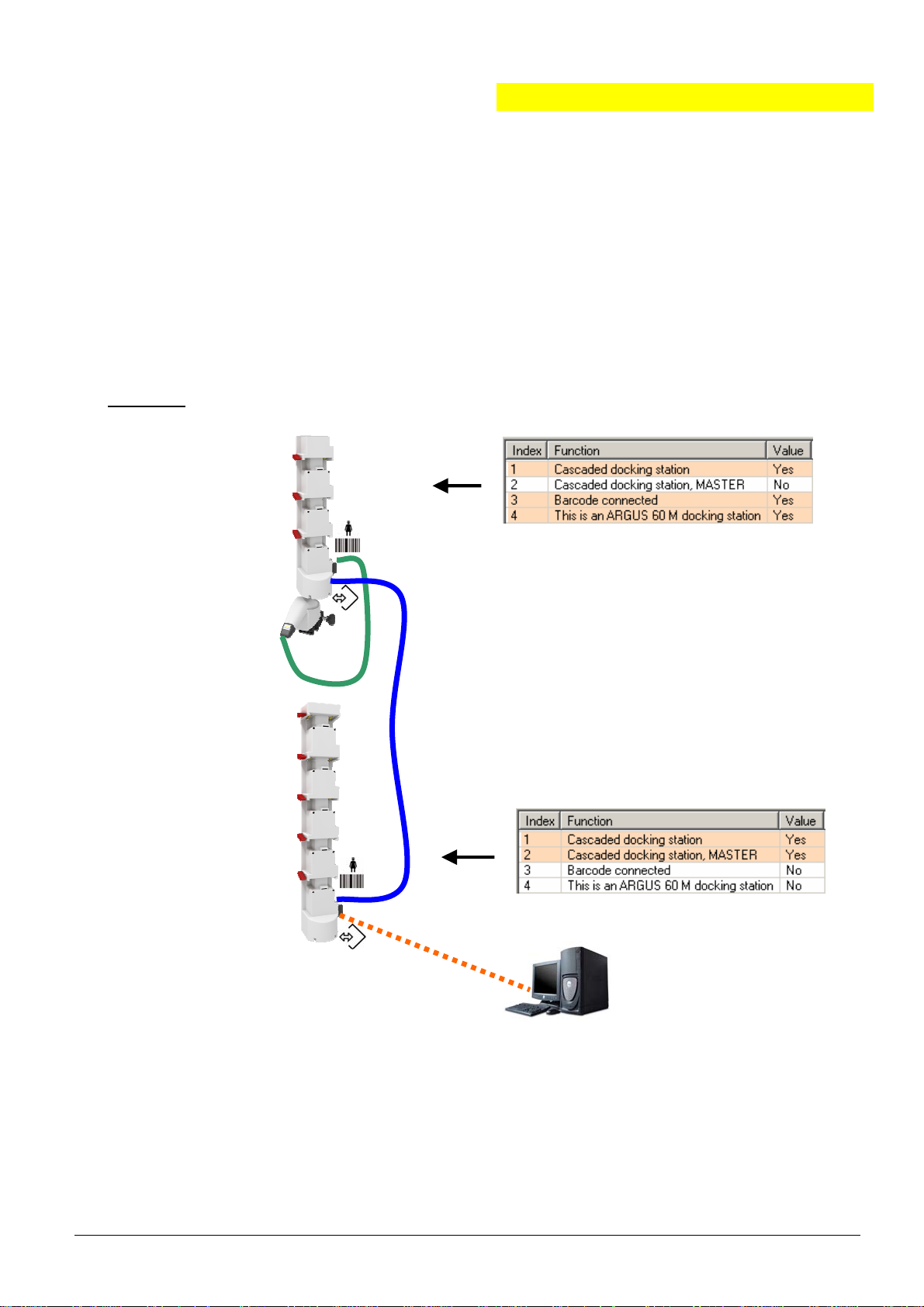

The system V4 firmware allows to cascade two docking stations (both either ARGUS 60 M

or ARGUS 100 M). Thus many more combinations of pumps are possible and a single barcode reader can be used to operate both docking stations.

With the ARGUS service configuration indexes # 1+2+3+4 you define a

logical communication sequence:

(Personal Computer optional) → Master docking → Slave docking → (Barcode-Reader optional)

Example:

(e.g. ARGUS 60 M)

Slave

Barcode-

reader

Cascade

cable

(12.046)

(e.g. ARGUS 100 M)

Master

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 5 / 22

Page 6

4. ARGUS SERVICE

4.1. General

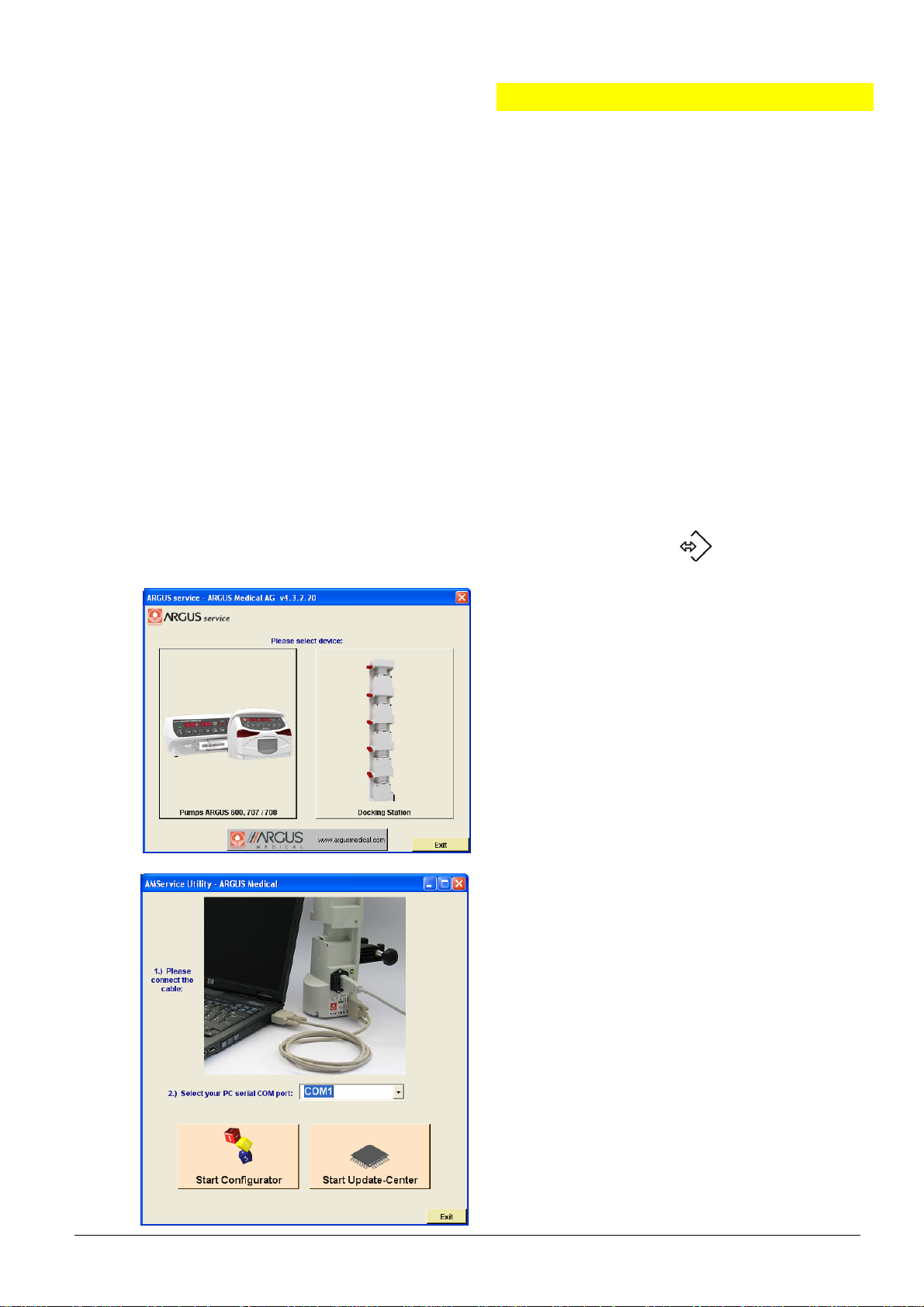

The new ARGUS service utility is a highly user friendly PC software which can config-

ure and upgrade ARGUS devices over PC serial COM port. With this Windows based

software you can also set pump clock, change PIN code, read and print out history

and easily replicate pump configurations, and so on. The modern and clearly structured design of this self-describing PC-tool allows a very easy and rapid modification

of the ARGUS 600 Syringe pump, the ARGUS 707 / 708 Volumetric infusion pump

and the ARGUS 60 M / 100 M docking station. This software may be available from

your local distributor or directly from ARGUS Medical.

REMARK:

“ARGUS service” may only be used with V4 software versions greater or equal to 4.30.

CAUTION!

The docking station has to be disconnected from the pumps before and while the serial interface cable is connected to the docking station.

Connect a straight RS-232 cable from the docking data interface to the serial interface (COM port) of your PC.

ARGUS service

Start the ARGUS service

Press the ‘Docking Station’ button.

Select “Start Configurator” (see next chapter)

or “Start Update-Center” (see chapter 5.5.).

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 6 / 22

Page 7

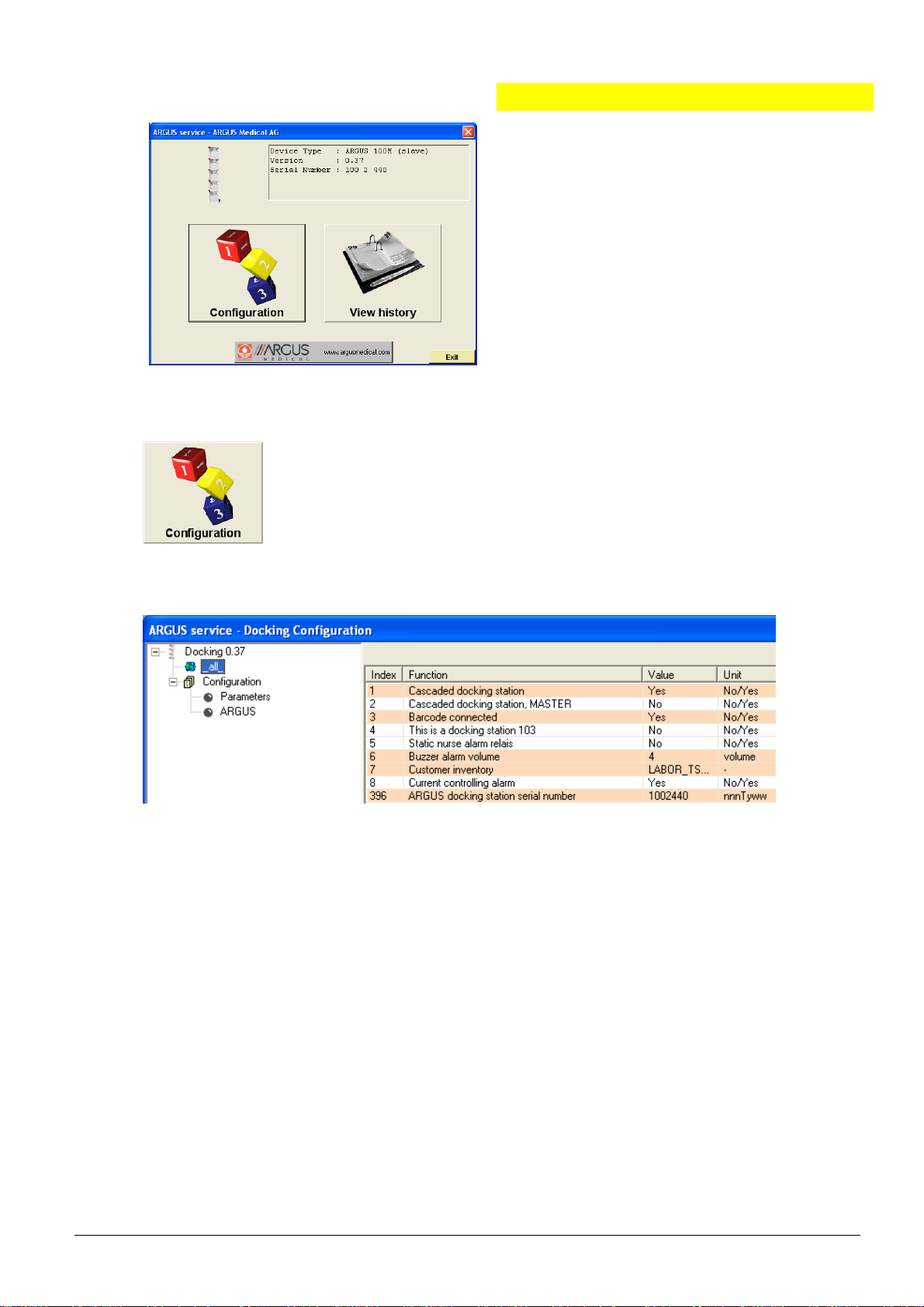

4.2. ARGUS service – Configuration

Important remark:

After each configuration change,

a functional check has to be done!

ARGUS service

Select the next step by pressing one of the

buttons (“Configuration” or “View history”).

4.2.1. Docking configuration

All configuration possibilities (indexes) mentioned in chapter 2.2 can be modified

herein in its own tree structure as shown above.

All indexes which are different from the ARGUS firmware default are highlighted.

CAUTION!

Every pump used with the ARGUS 60 M or ARGUS 100 M docking station has to be

preconfigured with its corresponding serial number label!

Index #396 in the configuration of each pump must be programmed with the corresponding serial number. Please refer to the pumps respective service manual to

change these indexes if necessary. In the case of an invalid serial number, the docking station will generate an alarm and the pump can not be programmed via barcode.

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 7 / 22

Page 8

ARGUS service

4.2.2. How to edit a configuration

The following procedure describes how to edit a docking configuration:

1. Press the green “Edit” button.

2. The software will ask for the docking PIN code as next. The button “Edit” changes

its colour and will be renamed into “Download”.

3. If you want to import a configuration from a file press the “Import” button, otherwise

skip this point (note: import does overwrite all settings including PIN and serial).

4. Select “Configuration” in the structure tree in the left upper frame.

5. Select the index group you want to modify by selecting the according structure tree

and the according index.

6. Modify the according index (within the given restrictions shown).

Each value (number) must be acknowledged by the green “Enter” button.

Go through point 5 & 6 for all further indexes you want to modify.

7. Press the “Download” button if you want to save the modified configuration on the

docking station. Otherwise you can save the modified configuration into a file by

pressing the “Save” button.

8. Make a functional check on each docking station you have configured.

Important remark!

If a configuration has been edited (performed point 1 and 2) once do not disconnect

the docking station! Otherwise the docking station will remain in the PC-configuration

mode.

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 8 / 22

Page 9

4.3. ARGUS service - Docking history

Each registered event has its own date & time stamp. An event is

registered on each docking status change. Please refer to the com-

plete list mentioned in chapter 4.3.1 below.

4.3.1. History messages

Possible messages appearing in the description of each history event:

"No information available" “Pump(s) docked in or out of docking station"

"Power up on docking station" "Pump(s) on docking station has/have failure"

"Power off on docking station" "Pump 1 programmed by barcode"

"Enter PC configuration mode" "Pump 2 programmed by barcode"

"Logon in PC configuration mode" "Pump 3 programmed by barcode"

"Logoff in PC configuration mode" "Pump 4 programmed by barcode"

"Docking has detected failure F-XX" "Pump 5 programmed by barcode"

"Host communication on serial port" "Pump(s) on docking station has/have an alarm"

"Pump(s) on docking has/have invalid serial number"

ARGUS service

4.3.2. History printout example

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 9 / 22

Page 10

5. SOFTWARE UPDATES

5.1. General

This chapter describes the procedure to perform software (firmware) updates on the

ARGUS 60 M and/or 100 M docking station.

To check the currently installed software release in your docking station:

• With versions 1.x (pre-V4), you can either read out the history or enquiry the dock-

ing station’s status over the serial interface (see older manuals).

• With versions 4.x (V4), you can use the ARGUS service tool.

Please refer to your local distributor or ARGUS Medical AG to determine the latest

software release available to run on your device hardware.

The ARGUS 60 M & 100 M contains a flash memory which can be updated easily via

the serial interface of a PC. This flash memory is divided in 2 sectors:

- User Program sector - Boot loader sector

The User Program sector contains the program which runs when the device is

switched on normally. The Boot loader sector contains a supportive program which

runs only when updating the flash memory.

SOFTWARE UPDATES

5.2. Requirements for a software update

To update an ARGUS Medical device, the following items are needed:

• PC with Microsoft

®

Windows™ 2000/XP or newer, the Microsoft .NET Framework

2.0 must be installed!

• PC configuration tool “ARGUS service”

• A straight RS-232 serial interface cable (REF 12.041), connected to the

data interface (lower plug)

• Latest firmware (‘user program’), either as a file (A100_Vxxx.txt),

(“xxx” is the placeholder for the firmware version) or embedded inside ARGUS ser-

vice (this embedded version might be older, ask for a newer ARGUS service).

Those items are available from your local distributor or from ARGUS Medical AG.

5.3. Software update procedure

5.3.1. General

Please carefully check the software presently installed on the docking. If you have a

firmware lower than version 4.xx please follow chapter 5.4 to upgrade the firmware.

NOTE!

The user program performs an internal ROM-Test during the self test phase of the

docking station. If an error occurred during the update process the device will enter the

fail safe state (for fault codes please refer to chapter 8.2 ).

Please contact your local distributor or ARGUS Medical AG to determine the latest

software release able to run on your device hardware.

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 10 / 22

Page 11

5.3.2. Safety aspects

Be aware of the following points:

• Never make any software updates while the device is used and/or connected to a

patient!

• For medical device traceability your local distributor or ARGUS Medical AG needs

to be informed about every device updates (serial number) you performed!

• Connect the docking station to the mains supply.

• Do not disconnect the data cable during the software update process!

CAUTION!

A standard safety check (see chap.12) has to be performed after a software update!

5.4. Upgrade of a docking station from 1.x to V4

With the “Update center” it’s also possible to upgrade the docking firmware to V4.

Use a crossed serial interface cable (or a null-modem adapter REF 12.050), con-

nected to the barcode interface (upper plug).

1. Launch the ARGUS service “Update center”

2. Press “Upgrade to bootloader V4” and follow

Use a straight RS-232 serial interface cable (REF 12.041), connected to the data inter-

face (lower plug)

3. Press “Update the docking firmware”.

4. Select the appropriate firmware source.

5. The new firmware will be installed.

Important:

• All previous settings are lost during this upgrade procedure!

Thus you will have to reconfigure them with ARGUS service.

• Finally, perform a standard safety check (see chapter 12 ).

SOFTWARE UPDATES

(see chapter 4.1).

the instructions displayed on the PC. The bootloader will be upgraded.

Follow the instructions displayed on the PC.

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 11 / 22

Page 12

SOFTWARE UPDATES

5.5. Minor Firmware Update with V4

A minor update is a newer firmware version where only the lowest digit changes.

For example: minor update = 4.30 to 4.33 (major update = 4.30 to 4.40)

1. Launch the ARGUS service “Update center”

(see chapter 4.1):

2. Press "Update the docking firmware".

Follow the instructions displayed on the PC.

3. Select the appropriate firmware source.

4. The new firmware will be installed.

Important:

• All your settings will be preserved.

• Finally, perform a standard safety check (see chapter 12 ).

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 12 / 22

Page 13

SOFTWARE UPDATES

5.6. Major Firmware Update with V4

A major update is a newer firmware version where upper digit changes.

For example: major update = 4.30 to 4.40 (minor update = 4.30 to 4.33)

1. Launch the ARGUS service “Configurator”

(see chapter 4.1):

2. Use the ‘Save’ button to store

your full configuration in a file on disk.

3. Launch the ARGUS service “Update center”

(see chapter 4.1):

4. Press "Update the docking firmware".

Follow the instructions displayed on the PC.

5. Select the appropriate firmware source.

6. The new firmware will be installed.

7. Launch the “Configurator” again

(some warnings will be shown)

8. Click ‘Edit’ and enter PIN (default = 0)

9. Click ‘Import’ and select the file you saved in

step 2.

10. Review all your settings for correctness.

11. Download, then quit ARGUSservice.

Important:

• Finally, perform a standard safety check (see chapter 12 ).

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 13 / 22

Page 14

6. BARCODE READER AND LABEL DATA

6.1. General

The barcode reader "ScanPlus 1800 VT" (Intermec) including a gender changer may

be ordered from ARGUS (REF 90.150). It should be connected to the appropriate plug

of the ARGUS 60 M or ARGUS 100 M docking station marked with the sign:

CAUTION!

The barcode reader "ScanPlus 1800 VT" has been preconfigured and tested by

ARGUS for the use with the ARGUS 60 M and/or ARGUS 100 M docking station v4.30

6.2. Label layout

ARGUS Medical recommends to use its own Excel tool named “Medication Barcode

Labels” to generate these barcode labels and bar-coded prescription sheets.

A medication barcode label holds the following relevant information:

1. The Medication concentration in the programmed unit

2. The dose (ml total) in ml

3. The dose in the programmed unit

4. The infusion rate in ml/h

5. The medication name

6. The initial rate in the

programmed unit

7. The patient name

8. The patient weight in kg

9. A software version and an ARGUS check number

BARCODE READER AND LABEL DATA

6.3. Barcode format

The used barcode standard corresponds to code 3 of 9 including check digit.

The barcode format is:

* T Rate

1E3

Rate

1E2

Rate

1E1

Rate

1E0

Rate

1E-1

Dose

1E3

Dose

1E2

Dose

1E1

Dose

1E0

Dose

1E-1

Med.

HEX

High

digit

Med.

HEX

low

digit

CD *

T = Pump Type: “S” for syringe pump, “V” for volumetric pump

Med. = Medication number in HEX format (see pump service manual for details)

CD = Modulo 43 checksum digit.

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 14 / 22

Page 15

Serial communication of the DOCKING

7. SERIAL COMMUNICATION OF THE DOCKING

7.1. General

The ARGUS 60 & 100 M docking station has one serial interface on board, which is

connected to the RS232 data connector.

Important remark!

This RS232 connector is galvanic isolated, but the docking slots for the pumps are

non-isolated interfaces. So if a pump is docked into the docking station, the software

switches automatically to the docking interface and the docking station builds the

separation device (galvanic isolation) then.

7.2. Serial communication protocol V4

The following characteristics are basics for all the ARGUS devices (volumetric pumps,

syringe pumps and docking stations with V4.xx):

• Full-duplex RS232, currently 4800 baud for single pumps,

9600 baud for docking stations (also on master/slave-link).

• Simple master (host/PC) – slave (device) communication (host does polling).

• The host has to repeat the request if there is no valid response.

• Uses a checksum (CRC-8).

• Binary data transmission, thus no ASCII/text parsing.

• Fast & direct communication with pumps on ARGUS docking station.

• Specified timeouts during remote mode.

A Programmer’s Kit with documentation is available on request from ARGUS.

7.3. Monitoring

The interface protocol of software release V4 is intended to be used in combination

with a PDMS (Patient Data Management System). For visualization and documentation purposes, the status of each docked-in pump and the status of the docking station

itself can be requested through the serial interface.

CAUTION!

Those PC transmitted data are not intended to be used for diagnostic or remote controlling of the pumps or other devices.

7.4. Remoting

Future extensions will allow remote controlling of the pumps. This requires written

permission from ARGUS Medical.

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 15 / 22

Page 16

8. MAINTENANCE AND FAULT FINDING

8.1. General

CAUTION!

Only authorized persons who have been trained by ARGUS Medical AG or by the local

distributor are allowed to service the ARGUS 60 M and/or ARGUS 100 M docking sta-

tion. In case of repair request, send the unit with the filled out “repair order form” (see

chapter 13 ) to the local distributor. Further information is available from:

ARGUS Medical AG

CH-3627 Heimberg / Switzerland

E-mail: info@argusmedical.com

CAUTION!

The safety standard check (SSC) has to be performed at least every 24 month or after

10'000 hrs of operation. The check has to be done in accordance to the chapter 12 .

No special maintenance of the ARGUS 60 M & ARGUS 100 M docking station is necessary. There are no wear and tear parts.

MAINTENANCE AND FAULT FINDING

8.2. Fault code

The fault code in case of a technical failure is displayed in the history file, refer to

chapter 4.3 . The possible fault codes registered in the history event log file are listed

in the table below:

Fault Failure:

Code:

00..Internal hardware and software issues

20 Internal hardware and software issues

21 ROM test

22 ROM check (Runtime)

23 RAM test/check

24 XRAM test/check

25 CPU test

27 EEPROM data invalid

28 Switcher for RS232 power supply test failed

32 5 Volt supply out of range

33 20 Volt supply out of range

34 Power supply voltage control out of range (VIN)

41 Pump1 supply: no comm. at powerup/dock-in

42 Pump2 supply: no comm. at powerup/dock-in

43 Pump3 supply: no comm. at powerup/dock-in

44 Pump4 supply: no comm. at powerup/dock-in

45 Pump5 supply: no comm. at powerup/dock-in

50 Address invalid for history-eeprom

51 Pump1 supply: communic.lost while docked

52 Pump2 supply: communic.lost while docked

53 Pump3 supply: communic.lost while docked

54 Pump4 supply: communic.lost while docked

55 Pump5 supply: communic.lost while docked

Exceptionally a fault code not listed above may appear. In this case we recommend

changing the main board.

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 16 / 22

Page 17

9. REPLACEMENT OF PARTS

9.1. General

CAUTION!

The ARGUS 60 M & 100 M docking station may only be used with accessories and

spare parts which have been approved by ARGUS Medical AG for safe technical use.

9.2. Disassembling of the docking station

CAUTION!

Disconnect the mains cable from the power outlet before opening the housing!

Observe the antistatic protection rules when disassembling the ARGUS 60 M or

ARGUS 100 M docking station (the use of an antistatic table mat and a grounded clip

are recommended).

9.3. Spare parts

REPLACEMENT OF PARTS

10.169 Cover for ARGUS 60 M

11.297 Casing for ARGUS 60 M

11.215 Casing for ARGUS 100 M

10.114 Cover for ARGUS 100 M

12.041 RS232 Interface cable

(docking - PC)

12.046 RS232 Cascade cable

(docking - docking)

12.043 Gender Changer m/m

(docking - Barcode-Reader)

12.050 Null Modem Adapter

10.096 Voltage regulator

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 17 / 22

Page 18

10.087 Combination clamp

10.115 Main board 60&100M

10.095 Extended board (100M only)

10.116 Flat cable set 60&100M

REPLACEMENT OF PARTS

10.097 Transformer 230V

10.130 Barcode holder with clamp

11.214 Transformer holder

11.218 Coil spring

11.216 Handle with axle

11.220 Centring fixation

11.217 Locking device

12.008 Mains plug with filter

90.041 Rail set (25x10mm)

90.042 Rail set (35x 8mm)

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 18 / 22

Page 19

10. WIRING DIAGRAM

100 M

only

Main-Board_2

(30.022.A)

WIRING DIAGRAM

X13

Docking place 5

Voltage regulator

20V

Operation LED

X12

X15

10

3

3

X16

X03

X14

X11

X10

Docking place 4

Docking place 3

Docking place 2

Main-Board_1

(30.020.A)

Traf o

AC Main

2

2

X01

10

Barcode Reader

Nurse Call

X05

X06

10

Interface

RS 232

X07

X08

X09

Docking place 1

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 19 / 22

Page 20

11. BLOCK SCHEMATIC

BLOCK SCHEMATIC

AC Main

Nurse-call

AC

DC

RS232

RS232

DC

Alarm

Relay

DC

+ 20V

(Docking-

places)

Controller

2

I C

Buzzer

Operation/

Alarm LED

Reset/

Watchdog

Latch

EEPROM

FLASH

DC

+ 5V

DC

(Logic)

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 20 / 22

Page 21

p

y

SAFETY STANDARD CHECK

12. SAFETY STANDARD CHECK

Safety standard check ARGUS 60 M & ARGUS 100 M ARGUS Medical AG

Serial-No.:

Hospital/Dept/Customer:

The safety standard check has to be performed at least every 24 months or after 10000 hours of operation.

The check has to be done in accord ance to the o p eration an d service manu al.

1 V isu al check for damage, cleanness and comp leteness: - H o u sing, lab els, accessories, conn ectors, cables, etc..?

2 P lu g in th e mains o f the do cking station - The green LED on the dockin g station ligh ts up ?

3 Ch eck each do cking p o sition with a

- Docking buzzer sounds twice, ok?

4 Ch eck the external con n ection s: - C o mp uter interface ?

5 Electrical test according to EN 6 06 01-1: - Measurements attached?

Do not install an

All measurements made with a 2.5 m power cord

6 The do ckin g station h as passed the safety standard check and is safe for use.

Date: Name: Signature:

pump!

ump: - Mechanical locking and unlocking ok ?

- After dockin g the p u mp, its green p o wer LED lights u p ?

- LE D o n d o cking station flashes oran ge-red, o k?

- B arco de read er interface ?

- S taff alerting system ?

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 21 / 22

Page 22

13. REPAIR ORDER FORM

ARGUS Medical AG / Heimberg Switzerland

REPAIR ORDER FORM

Purchase order / Proforma invoice number:

Customer name and address:

Name of contact person: Tel. number:

REPAIR ORDER FORM

Device:

Detailed failure or problem description:

Expected work / repair to be done:

Warranty repair

A414 ARGUS 60 P / 100 P

A400 ARGUS 60 M / 100 M

A404 ARGUS 600 S

A200 ARGUS 707 V

A300 ARGUS 708 V Serial Number:

Accessory:

Repair

Replacement

Serial Number / Production code:

Other Description:

Date:

Signature:

14.227._A60_A100 M en.SM.V4.3X ARGUS 28.03.06 / PJ 22 / 22

Loading...

Loading...