Page 1

NOTICE:

This device complies with Part 15 of the FCC Rules.

Operation shall be subject to the following two

conditions:

(1) This device may not cause harmful interface, and

(2) This device must accept any interface received,

including interface that may cause undesirable

operation.

This equipment has been tested and complied with

the limits for a Class a digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to

provide a reasonable protection against harmful

interface when the equipment is operated under a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause harmful interface to

radio communications. Operation of this equipment in

a residential area is likely to cause harmful interface in

which case the user will be required to correct the

interface at his own expenses.

Note: All brands and trademarks shall belong to their

respective owner.

Note: Specification is subject to changes without

notice.

Page 2

Using the ArgoxScan AS-8020CL

The ArgoxScan can automatically scan barcode at a distance.

Simply aim and pull the trigger. Code scanning is performed

along the center of the light bar emitted from the reading

window. This bar must cover the entire code (see “How to

Scan” in page 9).

Successful scanning shall be obtained by tilting the scanner

with respect to the barcode to avoid direct reflections that

impair the reading performance.

Recommended Steps

When the required settings have been configured, all settings

are stored in non- volatile memory of scanner and cradle

after reading EXIT Label. Recommended steps are as

follows.

1) Host interface will be automatically detected. User does

not need to set host interface for the cradle.

2) Set interface to optimize protocol of cradle with your

host in interface section.

3) Set system control of scanner, such as specific

adjustments double confirm, indicator and scanning

mode which you prefer usage in system control section.

4) Set code options of scanner for your usage in code

option section. You must make sure to enable the

symbology first, then Min./Max. code length, code ID

checksum and truncate digits are also converted.

5) Set string format of the scanner, such as preamble,

postamble Prefix, suffix, code ID and code name

transmission for your application in string format

section.

Note: If still not work properly. Please contact your dealer for

further information.

Page 3

警告: 電池若未妥善處理, 可能會導致爆炸。

請勿拆卸電池, 或用火銷毀電池。 請將電池放置於兒童拿不

到的地方。 請使用專用充電器充電, 並請依照當地政府或法

律規定妥善處理廢棄電池。

CAUTION: EXPLOSION HAZARD

Do not disassemble, short circuit, heat the battery or dispose

of in fire. Store battery pack in a proper place. Do not expose

to temperature above 60℃/140℉. Use specified charger

only. Please dispose of the used batteries following the rules

or laws issued by the local government.

Page 4

Page 5

CONTENTS

Chapter 1 Introduction

Installation…………………………………………… 1

How To Scan………………………………………… 13

Troubleshooting……………………………………… 14

Wireless Connection………………………………… 16

Battery Charging…………………………………… 19

Wireless Features…………………………………… 22

Auto Update……………………………………… 23

Deep Sleep Mode……………………………… 25

Wireless Connectivity…………………………… 26

Inquiry Beep control…………………………… 28

Cradle Beep Loudness Control………………… 30

Additional Features……………………………… 32

Default Setting.……………………………………… 33

Specification………………………………………… 34

Indications of AS-8020CL…………………………… 37

Imager…………………………………………… 37

Cradle…………………………………………… 38

Programming the AS-8020CL……………………… 39

Chapter 2 Parameter Setting

Interface………………………………………………… 41

Interface Selection.………………………………… 41

Keyboard wedge.…………………………………… 42

RS-232.……………………………………………… 47

Pin Assignments.…………………………………… 51

System Control……………………………………… 53

Scan………………………………………………… 53

Indication. …………………………………………… 57

Code Option…………………………………………… 59

UPCA.………………………………………………… 59

UPCE ………………………………………………… 63

EAN-13.……………………………………………… 67

EAN-8 ………………………………………………… 71

Page 6

Code 39 ……………………………………………… 75

Interleaved 2 of 5 …………………………………… 79

Industrial 2 of 5 ……………………………………… 81

Matrix 2 of 5 Eur …………………………………… 83

Codabar ……………………………………………… 85

Code-128 …………………………………………… 89

Code-93 ……………………………………………… 93

Code-11.……………………………………………… 95

MSI/Plessey.………………………………………… 97

UK/Plessey.………………………………………… 99

Telepen.……………………………………………… 101

Standard 2 of 5 ……………………………………… 103

China Post …………………………………………… 105

Italian pharmacode (Code 32)..…………………… 107

Code-16K…………………………………………… 109

PDF-417……………………………………………… 111

EAN UCC Composite……………………………… 113

RSS-14.……………………………………………… 115

RSS-Limited………………………………………… 117

RSS-Expanded……………………………………… 119

Micro-PDF…………………………………………… 121

String Format…………………………………………… 123

String Setting / Transmission (Prefix/Suffix)……… 123

String Setting / Transmission

(Preamble/Postamble)……………………………… 125

String Setting / Transmission

(Insert Group Characters)………………………… 127

String Setting / Transmission (Others)…………… 131

Appendix………………………………………………… 133

Test Chart.…………………………………………… 133

ASCII Code Table …………………………………… 136

Parameter Setting List.……………………………… 137

Page 7

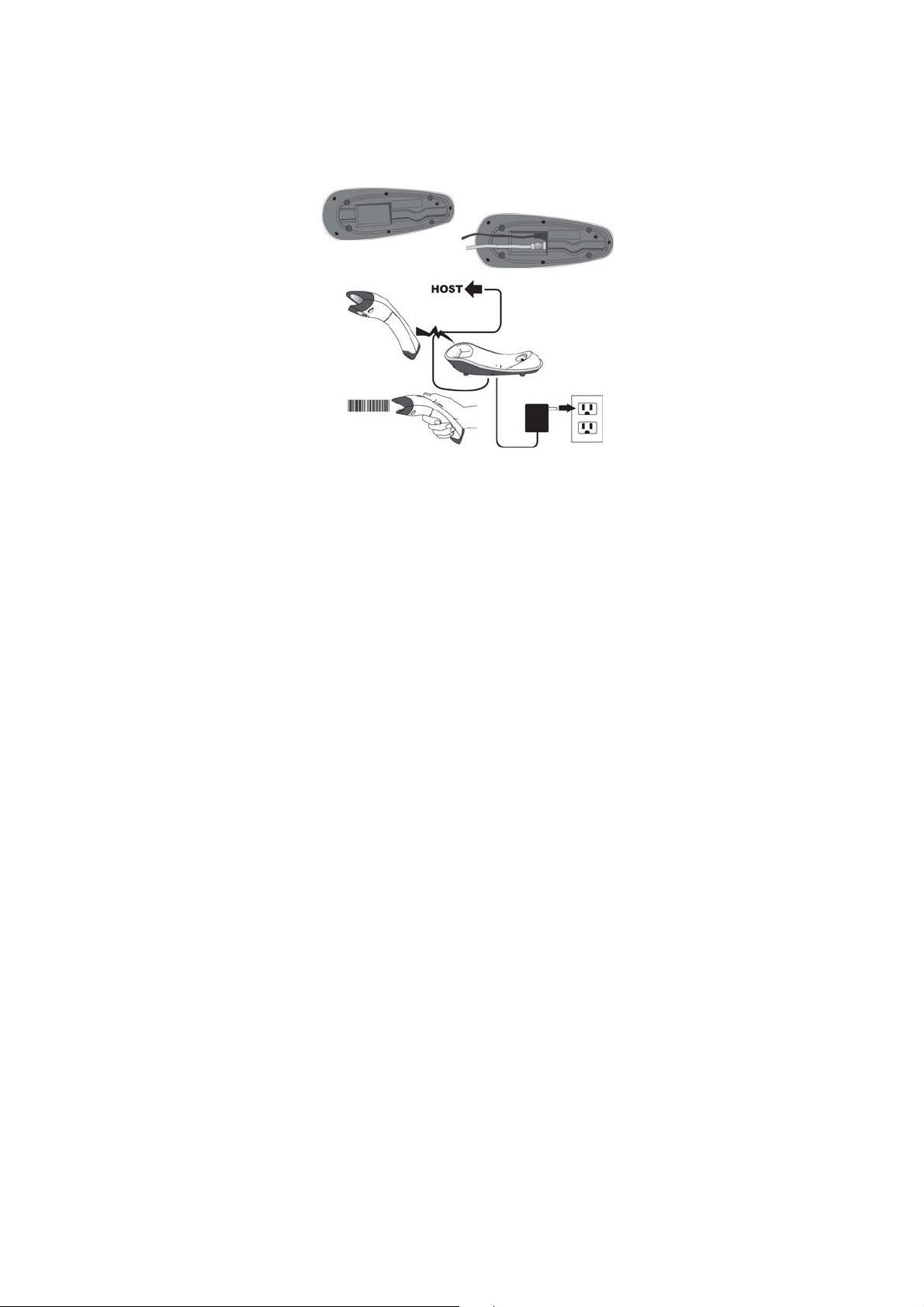

Installation

The AS-8020CL Wireless Imager is easy to install and use.

Please see the following figure showing the steps to perform

the installation.

* Note: Turn off the host computer before installation.

1. Connect the interface (I/F) cable to the cradle.

2. Connect the power cord to the cradle.

3. Route the I/F cable and power cord through the notch.

4. Connect the I/F cable to the host computer

communication port.

5. Connect the AC adapter to the wall outlet.

6. Place the imager in the cradle and verify the charge

LED is flashing. Charge the battery for at least 8 hours

before the first use.

7. To verify operation, please link the imager with cradle

first (Refer to “Wireless Connection” in page 12). Point

the imager at the barcode and pull the trigger. The

imager should emit a beep indicating that the barcode

has been scanned and transmitted to the cradle

successfully.

1

Page 8

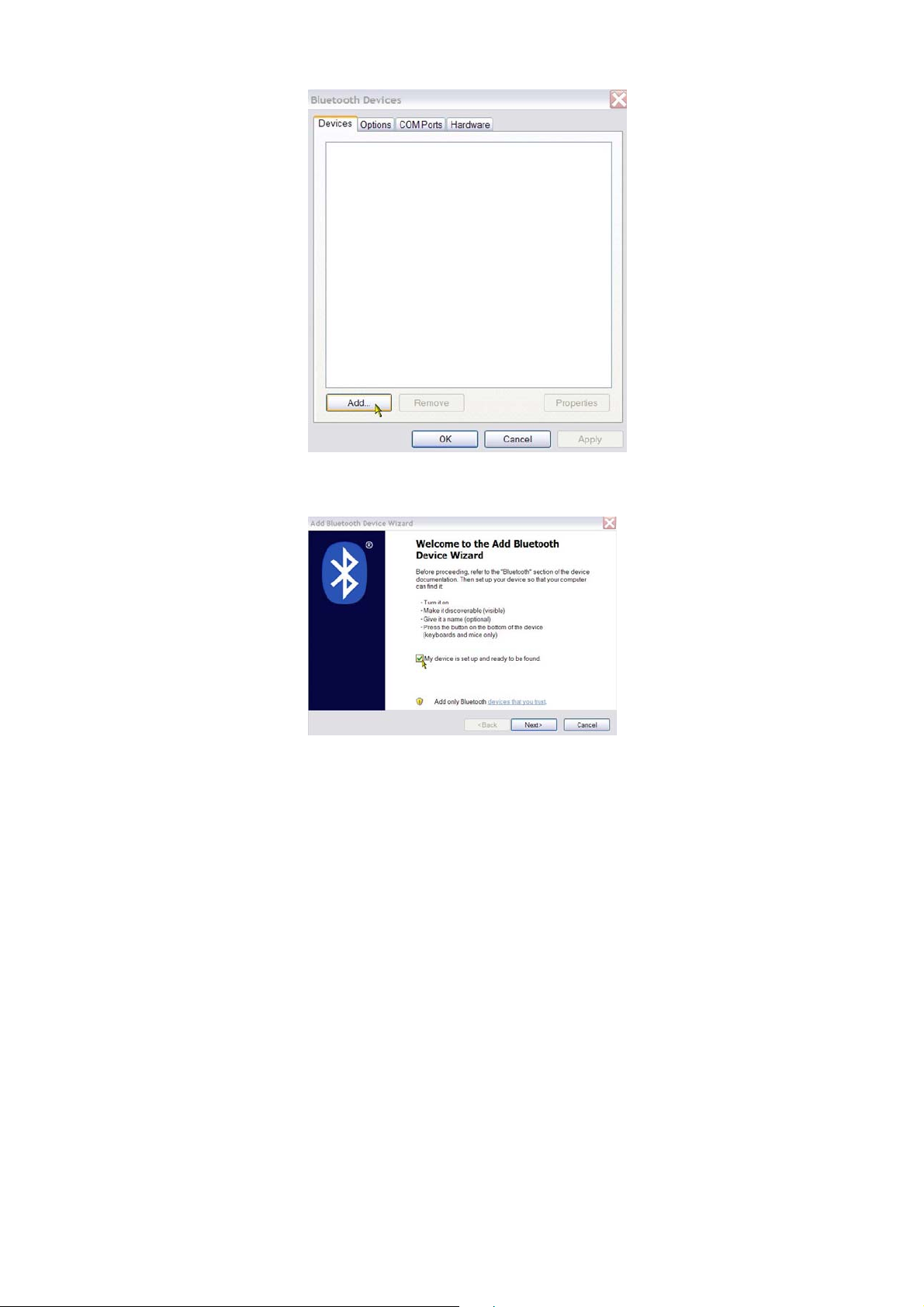

Connecting AS-8020CL to PC with USB Dongle

AS-8020CL is allowed to connect with PC via USB dongle.

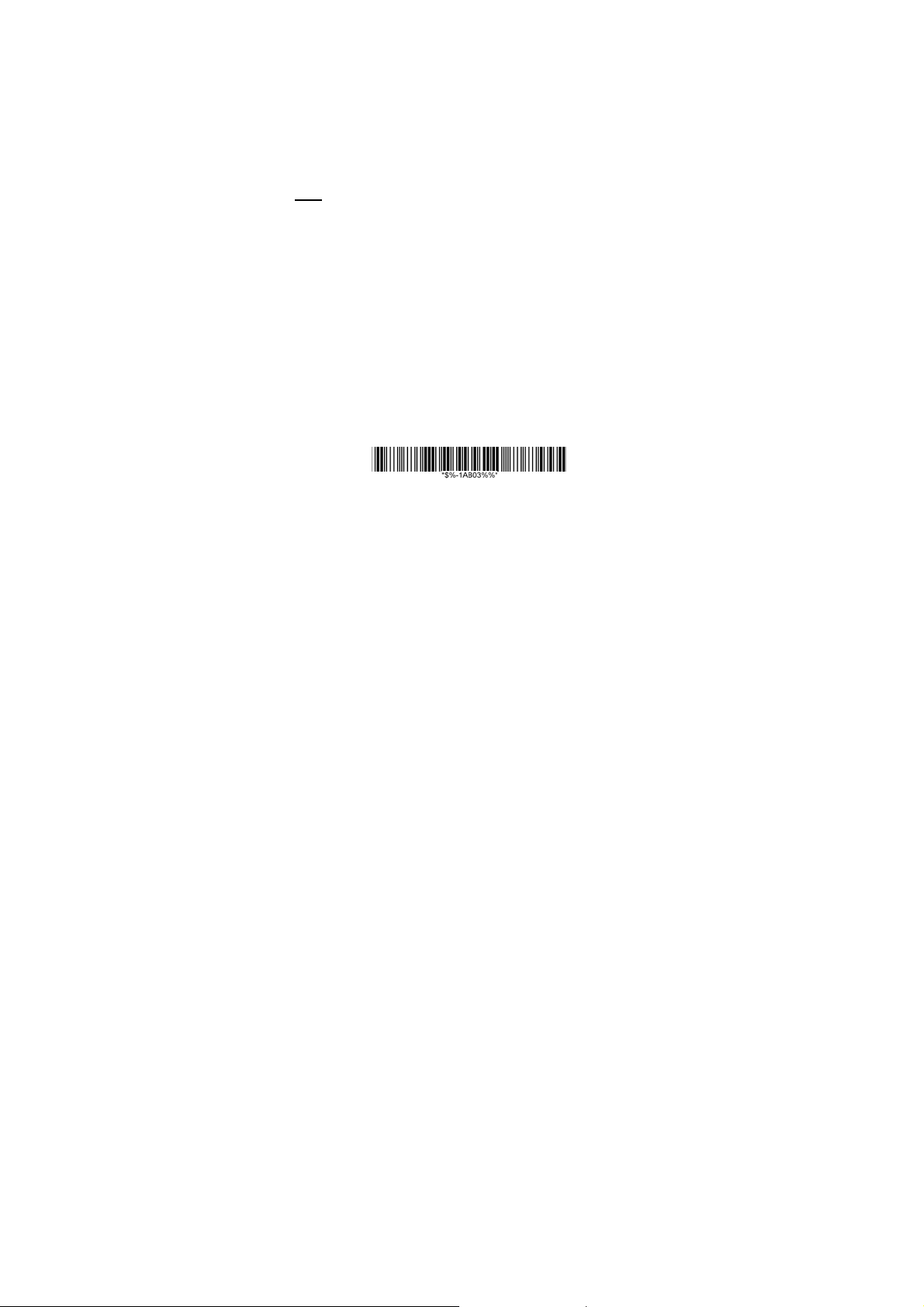

1. .Scan the following barcodes to set scanner to Bluetooth

connection mode, with PIN code as 0000 or refer to the

manual page 23

code assigned to the target Bluetooth device

rd

to set any four-to-six character PIN

Cradle/Dongle connection auto detection – The imager

can be linked to either a cradle or other Bluetooth

enabled devices.

Set PIN code to 0000

2. After well-connecting Bluetooth dongle to PC, find the

blue-tooth sign on Taskbar; double-click on it to bring out

the Bluetooth Devices prompt.

After well-connecting USB dongle to PC, find the blue-tooth

sign on Taskbar; double-click on it to bring out the

Bluetooth Devices prompt. (Or go to Control Panel –

Bluetooth Device…)

2

Page 9

Within the prompt, click “Add”.

3. Check the option, “My device is set up and ready to be

found” and click” Next”.

3

Page 10

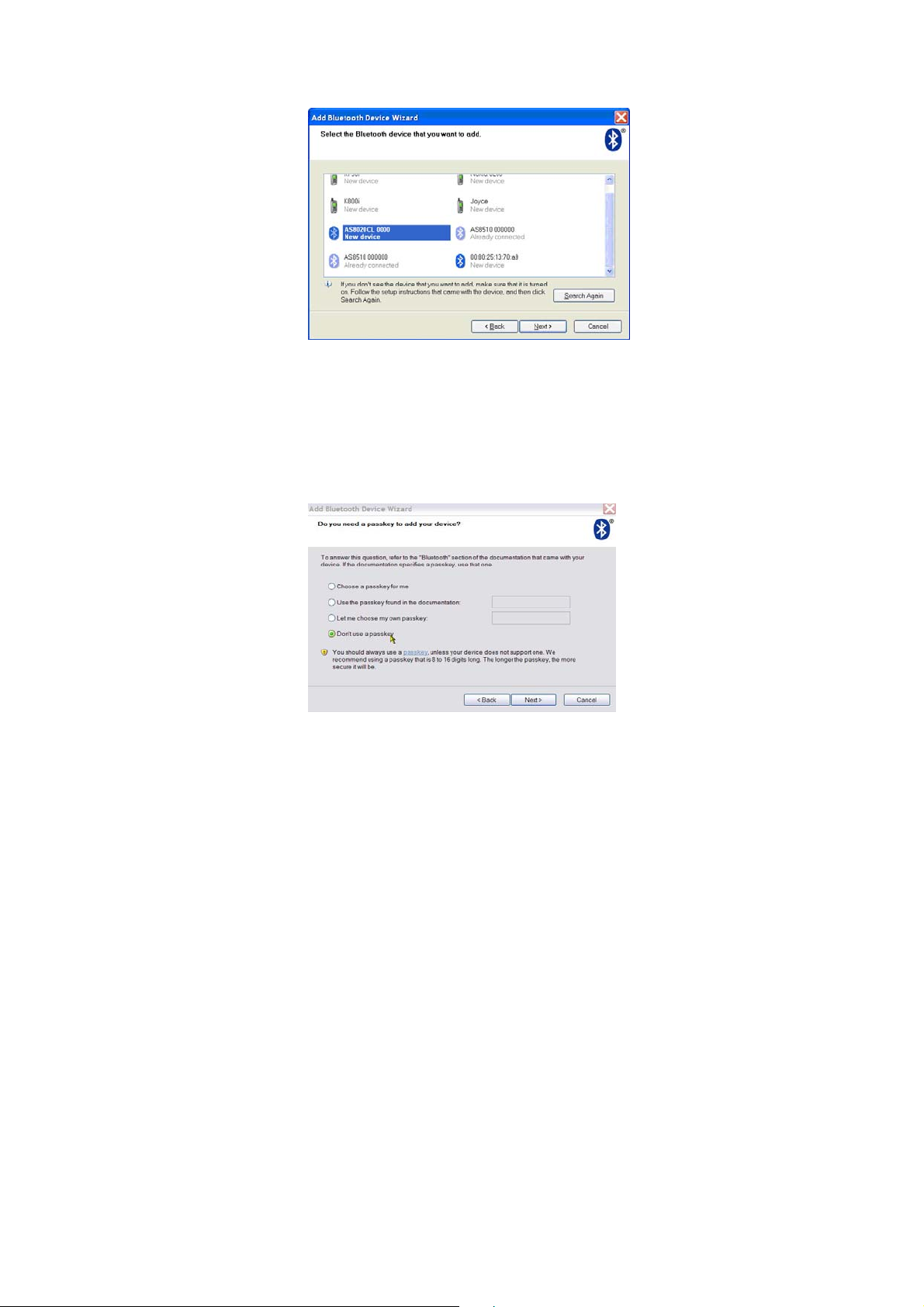

4. Select “AS-8020CL” among the Bluetooth devices found;

click “Next”.

5. Select “Don’t use a passkey” and click “Next”. The

Bluetooth connection will start to install the Bluetooth

device for AS-8020CL:

4

Page 11

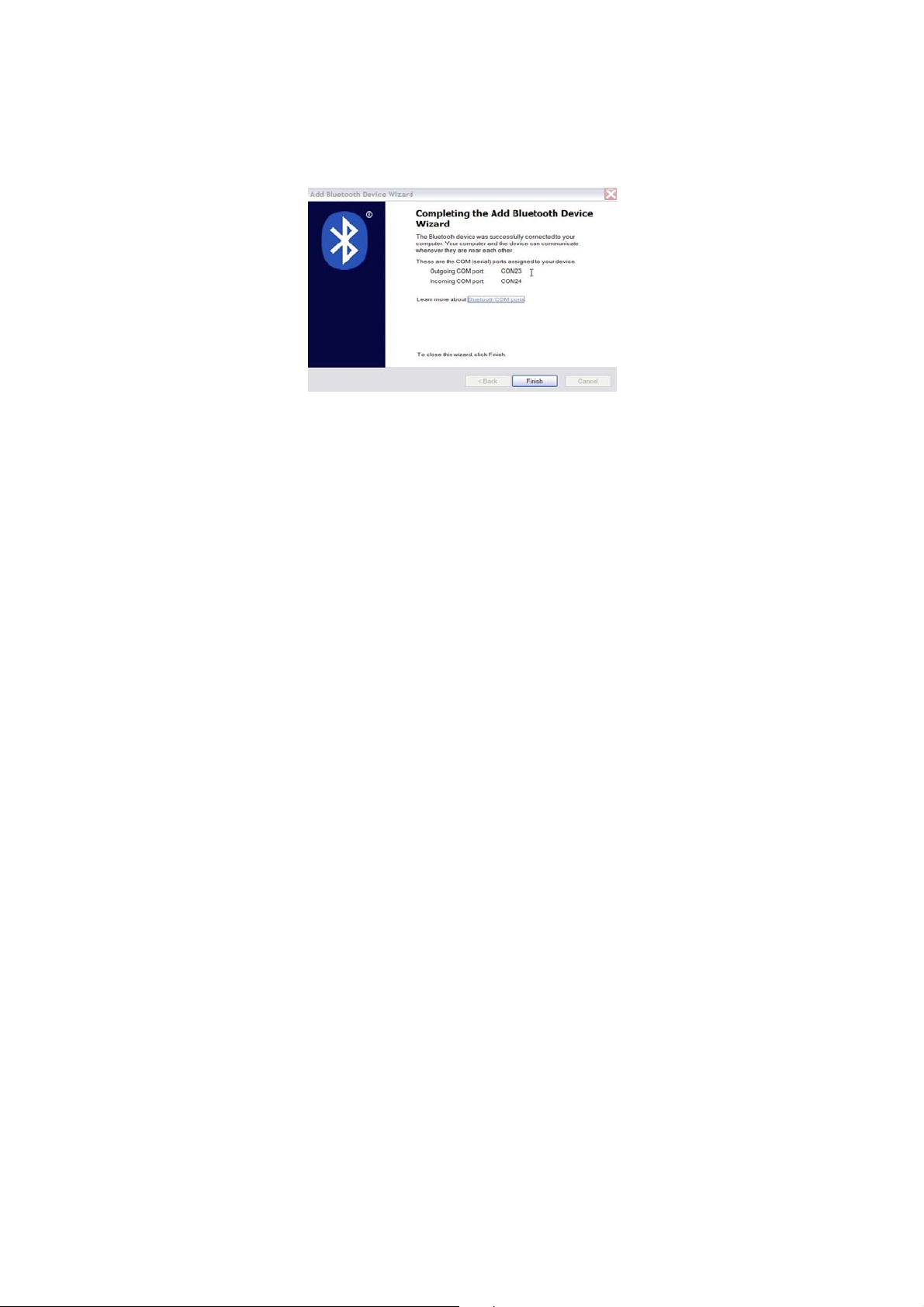

6. As it prompts, “Completing the Bluetooth Device Wizard”,

find which COM ports is assigned. The following

example lists COM23 as the Outgoing port, and COM24

as Incoming port; your actual COM ports will depend on

what’s assigned on your PC. Click “Finish”.

5

Page 12

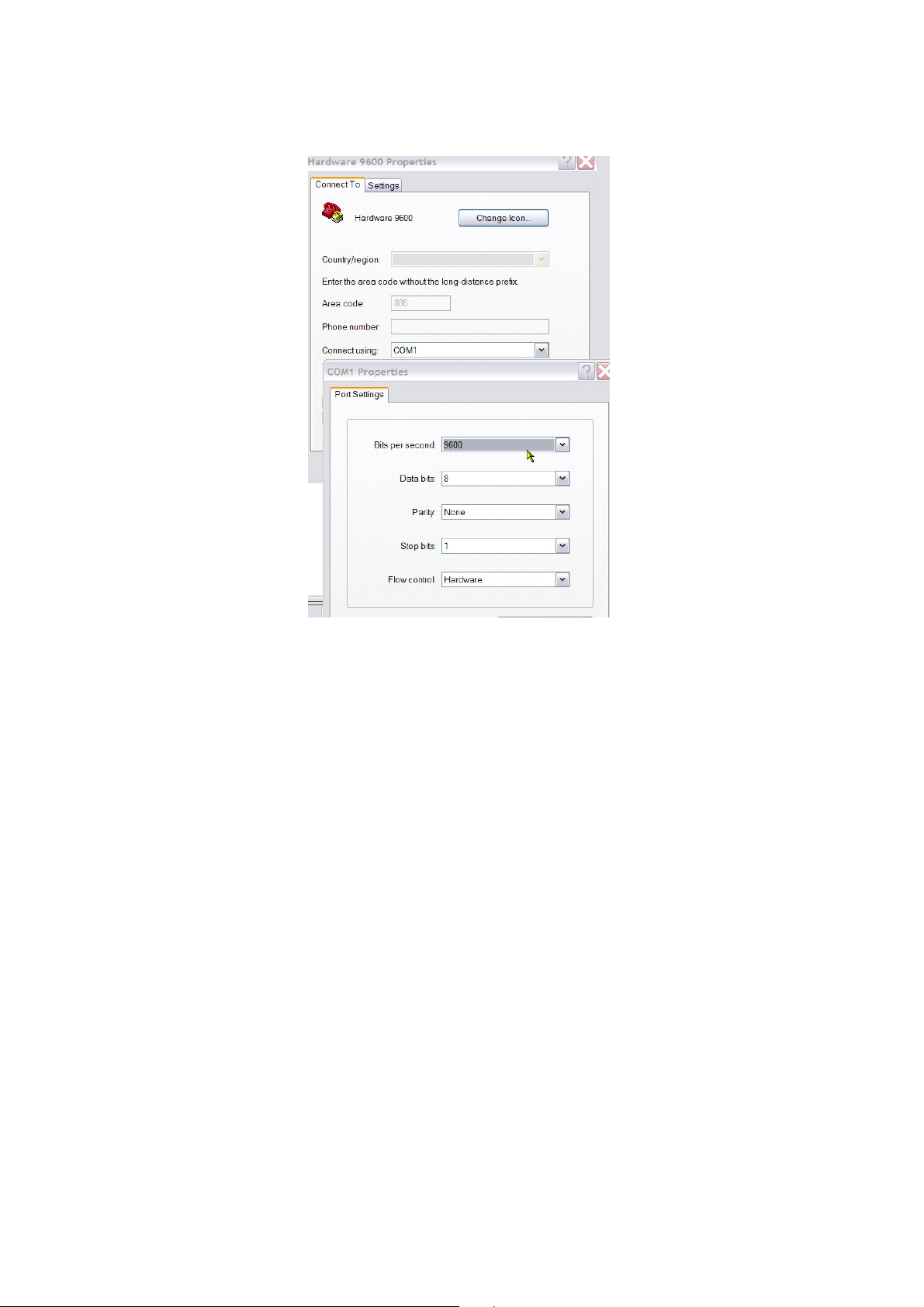

7. Open HyperTerminal. Set COM1’s Baud Rate as 9600

to communicate with AS-8020CL (whose default baud

rate is 9600):

6

Page 13

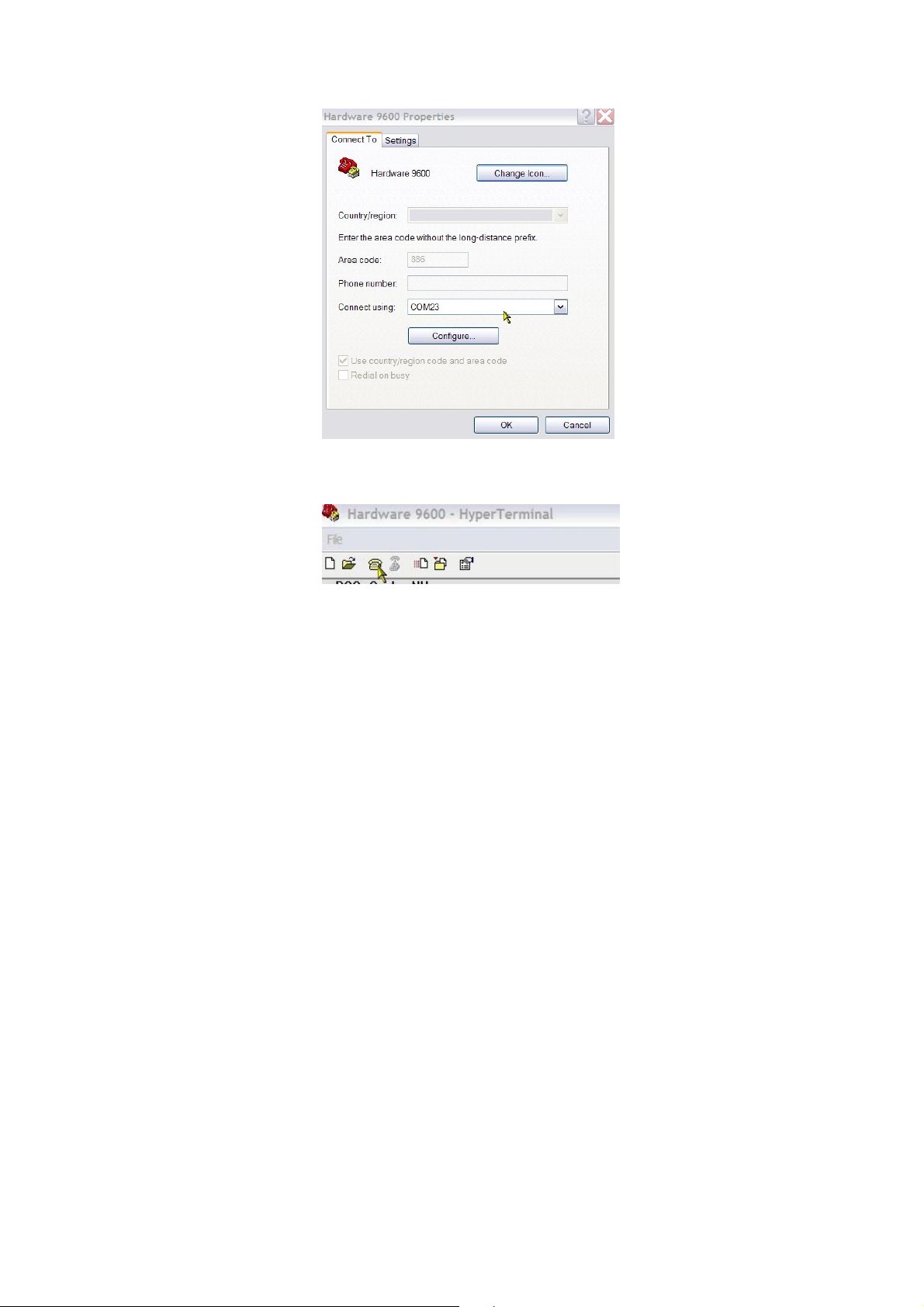

8. Select COM23 (depending on your Outgoing COM port)

to connect. Click “OK”.

9. Click on “Dial”.

7

Page 14

10. The system will show a message on Taskbar asking to

click on the Bluetooth sign on taskbar.

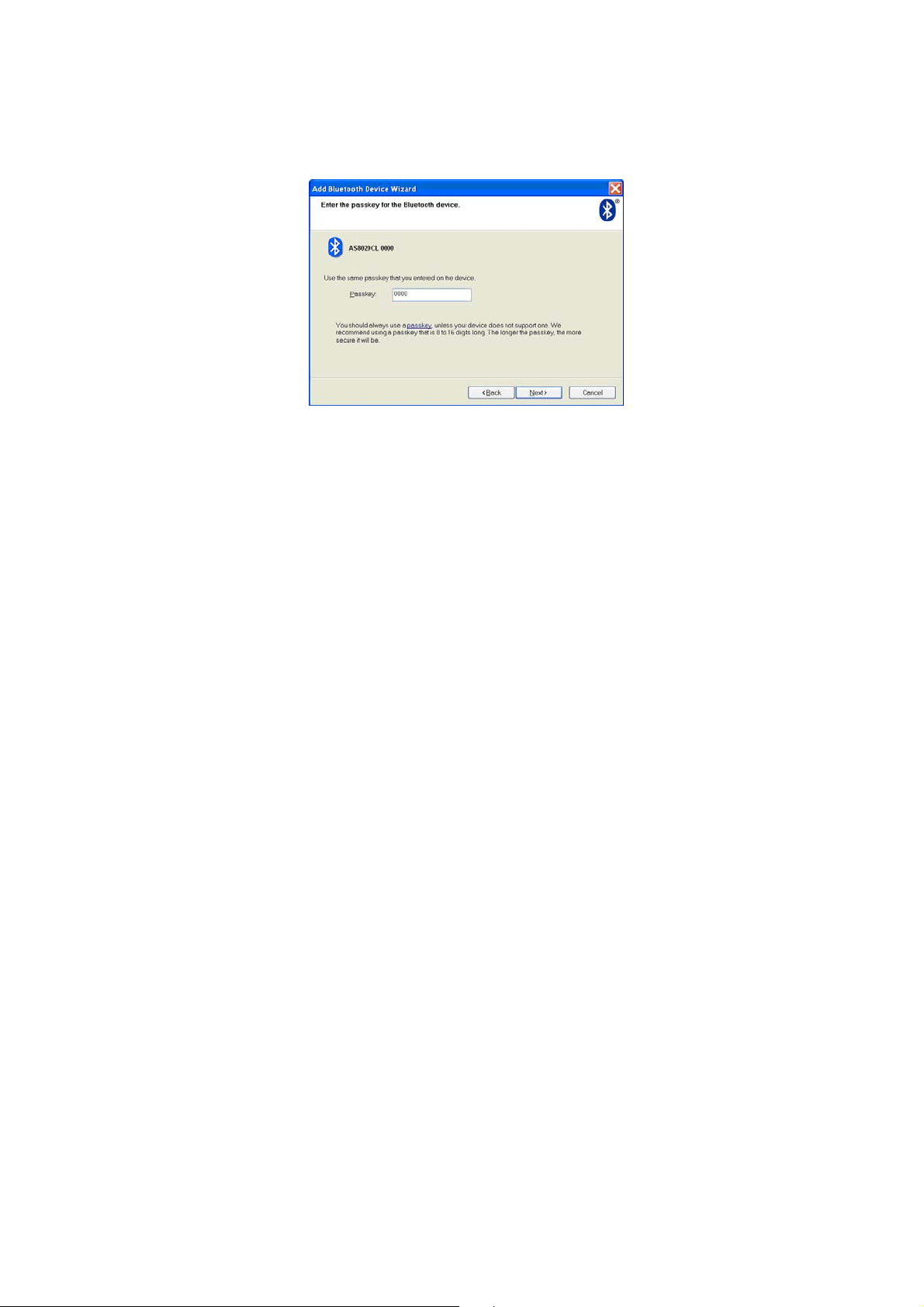

After clicking on it, the wizard will prompt as below; enter

0000 (AS-8020CL default PIN code) within the Passkey field;

click “Next”.

Now the installation and setups have been completed, you

may start to scan barcodes to transmit data to

HyperTerminal on PC.

8

Page 15

Connecting AS-8020CL to Smart Device via HID Protocol

without A Cradle (Firmware requested 3.03 or above )

AS-8020CL Bluetooth HID provides the ability to connect

other Bluetooth devices, for example smart phones, tablet

PCs, iPod, iPhone, iPad,… which require HID protocol to

pair with.(*)

Connecting with Apple iOS devices (iPod, iPhone,

iPad)

1. Make sure the battery in the AS-8020CL is fully

charged.

2. Scan “iOS HID” barcode:

3. Power on your Apple device and run “Settings”.

Go to “General” – “Bluetooth” and turn the

Bluetooth On. Then the Bluetooth device

searching will start.

4. Your Apple device will find Argox Cordless

Scanner “AS8020CL XXXXXXXXX” under the

status of “Not Paired”.

5. Click the found device and you will hear three

beeps after certain connecting time. The status

will be changed to “Connected”. Now your

Argox Cordless Scanner successfully connects

with your Apple device.

9

Page 16

6. Simply click the “Notes” in desktop of Apple

device and create a “New Note”. Tap on the

New Note and see the cursor showed on the

screen. Use your Argox Cordless Scanner to

scan a barcode and the data will show on the

Note.

Note: Apple iOS devices will allow only one input device

working at the same time. So when you connect an

Argox Cordless Scanner with your Apple device, the

Apple Virtual Keyboard will be invalid automatically. To

have the Apple Virtual Keyboard be available again, your

will need to abolish the connection between Argox

Cordless Scanner and Apple Device by scan “Unlink”

barcode.

Connecting with Android devices (mobile phone,

tablet PC)

1. Make sure the battery in the AS-8020CL is fully

charged.

2. Scan “PC HID” barcode:

3. Power on your Android device and run

“Settings”. Turn the Bluetooth On. Click

“Bluetooth” and then the Bluetooth device

searching will start

4. Your Android device will find Argox Cordless

Scanner or “AS8020CL XXXXXXXXX” under

the “Available devices”.

.

10

Page 17

5. Click the found device and you will hear three

beeps after certain connecting time. The status

will be changed to “Connected to input device”.

Now your Argox Cordless Scanner successfully

connects with your Android device.

6. Simply click the “Mini Diary” in desktop of

Android device. Click “Tap to add text” and see

the cursor showed on the screen. Use your

Argox Cordless Scanner to scan a barcode and

the data will show on the Mini Diary.

Note: Android system will allow both the connected

input device and the Android Virtual Keyboard working

at the same time. So when you connect an Argox

Cordless Scanner with your Android device, the Android

Virtual Keyboard will be still available for your input. You

don’t need to abolish the connection between Argox

Cordless Scanner and Android Device.

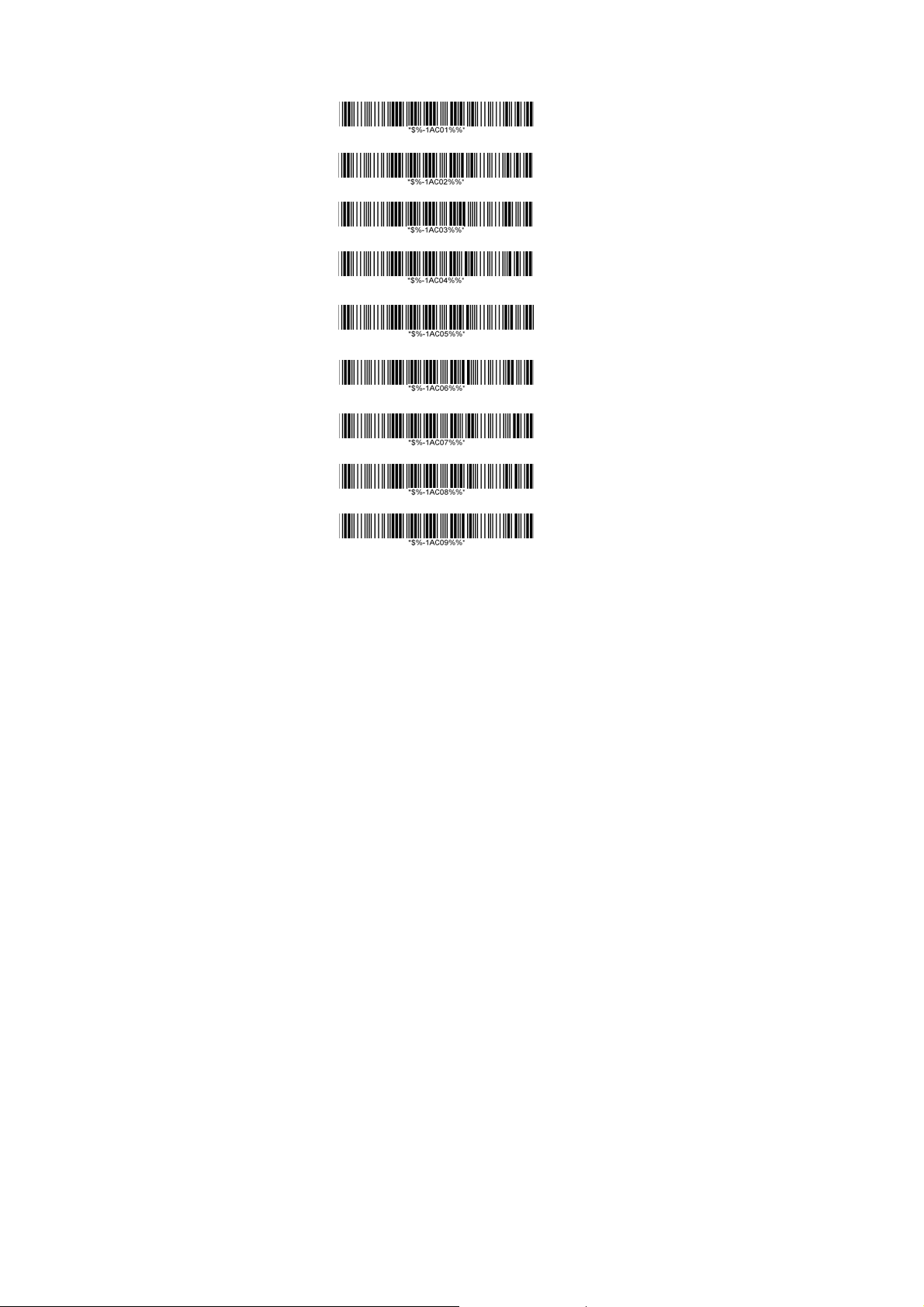

More Parameter Settings with Bluetooth HID

Cradle Connection only.

Dongle connect to PC via serial port and PIN code

input is necessary for each connect.

Dongle connect to PC via serial port and PIN code

input is necessary for the first connect only.

Turn off HID re-connect from scanner to PC.

11

Page 18

HID re-connect duration from scanner to PC

(1AC01~1AC09 – 10sec ~ 90sec).

12

Page 19

How to Scan

1. The imager must be pointed at slight angle to the

barcode so that the light reflected off the barcode can

be seen by the imager. Do not hold the imager

perpendicular to the barcode.

2. The scan line must cross the entire barcode. The

imager can not read the barcode data without seeing

the entire barcode.

13

Page 20

Troubleshooting

If the imager can not operate properly, the following checks

should be performed:

1. The cradle uses an external power supply and the

external power supply has failed, the imager will not

operate. Change the power supply with a known good

power supply and reset the imager.

2. Verify the interface cable is securely connected to the

host computer. Consult your technical support

personnel or refer to your host system manual to verify

the proper connection for the imager.

14

Page 21

3. Verify the interface cable is securely connected to the

cradle.

4. Check that the barcodes are of sufficient quality to be

recognized by the imager. Wrinkled, smudged, or torn

labels will cause the imager to not read at all. Scan a

known good label to check the imager’s read operation.

5. Ensure that the cradle’s interface type is compatible

with the host computer by consulting your host system

manual.

15

Page 22

Wireless Connection

Linking the imager with the cradle

Follow these instructions to link the two devices:

1. Connect power to the cradle. The radio LED (marked

with a light symbol) will blink amber and the cradle will

beep.

2. To ensure the cradle is unlinked from any other imager,

check if the cradle send inquiry beep or not (see Inquiry

Beep Control in page 24

3. Read the link label on the bottom of the cradle with the

imager. The imager will sound a good read beep and

the LED will flash amber.

4. Re-place the imager in the cradle to continue the

charge.

Once an imager is linked to a cradle, they will remain linked

until specific action is taken to unlink them (see Unlinking).

They will remain linked if the cradle is unplugged, if the

battery is removed from the imager or if the entire charge is

used up, and if the imager is taken out of range of the cradle.

Under normal operation, scanning of the link label will only be

required once in the life of the product.

th

).

16

Page 23

Unlinking

There are three ways to unlink an imager from a cradle:

Force imager to disconnect and sleep

1. Scan the “Force imager to disconnect and sleep”

barcode – Reading the unlink barcode above while the

imager is in range of the cradle will break the link

between the two devices and allow another imager to

link to the cradle. It will also have the imager in Deep

Sleep Mode. If the barcode is read when the imager is

out of range of its linked cradle, the imager will unlink,

but the cradle will remain linked to the imager and will

not allow another imager to be linked to it. In this case,

you may perform the item 2 below to link another

imager.

2. Scan the Link Label and put on the original cradle –

If the cradle is linked with an imager and the original pair

was stopped by out of range of the cradle or out of

battery of the imager, scan the link label of the cradle

with a new imager and then put on the cradle, the cradle

will drop the original pair and establish a new link with

the new imager.

3. Scan the Link Label on an alternate cradle –

Scanning the link label on a cradle will drop the link

between the original pair and establish a link between

the imager and new cradle. If the new link is performed

within range of the old cradle, it is free to establish a link

to the next imager that reads its link label. If it is done

outside of the range of the old cradle, it retains its old

link and will not allow a new imager to link to it until a

new imager scan the link label and put on the cradle.

17

Page 24

4. Push the “Reset” button on the bottom of cradle – If

the cradle is linked with an imager and in range,

pushing the “Reset” button (for about 2 seconds) on the

bottom of cradle will drop the link between the devices.

If the button is pushed while the imager is out of range,

the cradle will unlink and make itself available to other

imagers. The scanner will not drop its link with the

cradle automatically, but can be linked to any other

cradle by reading its link label.

* Note: If just push the button with a short time (less than one

second), a “Paging” feature will be performed to page the

imager which was linked with the cradle.

18

Page 25

Battery Charging

The imager contains a 1000mAh Lithium-Ion rechargeable

battery. A full charged battery will provide up to 55,000 scans

over a 15 hours period. Actual charge life on the imager will

depend on the configuration of how the imager is configured

via the programmable feature in this manual; in particular,

Deep Sleep Mode settings can impact battery life.

When the imager is placed in the cradle, the battery will

automatically charge. While charging is taking place, the

charging LED (marked with a battery symbol) will blink green.

When the battery is fully charged, the charging LED will stay

on a solid green.

If there is an error in charging either with a failure in the

charging circuit or with a failure of the battery, the charging

LED will flash red. When this happens, the battery needs to

be replaced.

19

Page 26

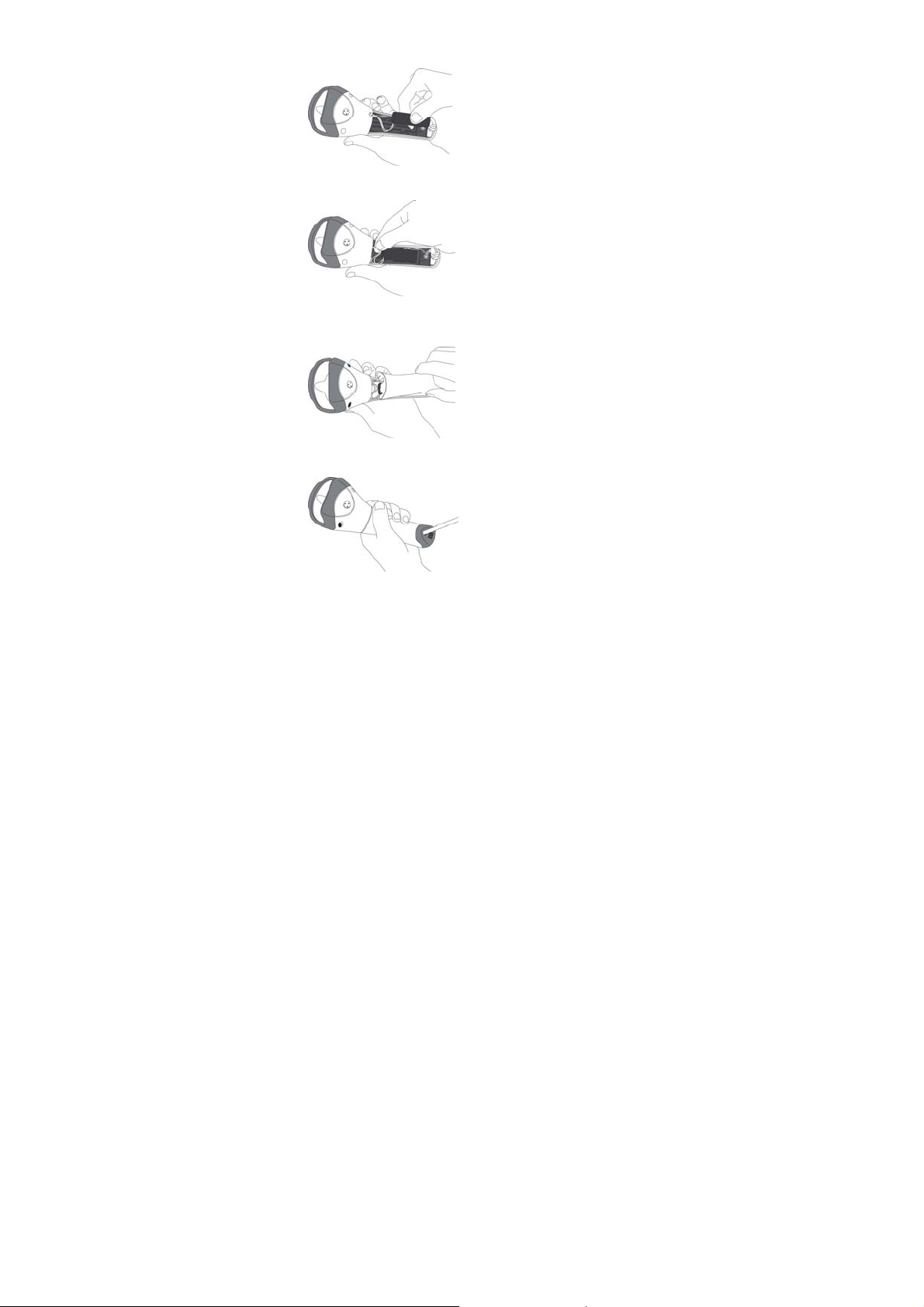

How to Change the Battery

In case the contained battery inside the imager needs to be

replaced, please follow the procedures below:

1. Loosen the screw at the

bottom of the imager.

2. Take off the battery cover

out of the imager.

3. Disconnect the battery

cable connector from the

main board.

4. Remove the used battery

from the battery container.

5. Use a new battery pack

and replace the used one.

20

Page 27

Note: DO NOT touch the PCBA inside the imager when

replacing the battery. Improper operation may damage the

imager.

6. Place the new battery into

the battery container.

7. Connect the battery cable

connector to the main board.

8. Put the battery cover back

to the imager handle.

9. Fasten the screw to the

imager.

21

Page 28

Wireless Features

The AS-8020CL Wireless model includes an imager and a

cradle. When the imager and cradle are linked together, the

imager will read and decode barcodes and transmit them via

a Wireless radio to the cradle. The cradle will then transmit

the barcode data to the host computer over the host cable.

The host interfaces available from the cradle are RS-232,

Keyboard wedge, and USB as a normal corded imager.

22

Page 29

Auto Update

When this feature is enabled, an imager and its linked cradle

can automatically ensure they stay in sync with regard to

firmware and/or configuration. This is accomplished by the

linked imager and cradle comparing firmware version number

and configuration file check sum. If either is different, the

cradle will automatically update the imager with its

firmware/configuration.

If the units are linked, any changes made to the cradle’s

configuration through the scan utility software will

automatically be sent to the imager at the completion of the

programming session. By the same token, any changes

made to the linked imager’s configuration will be transmitted

to the cradle at the end of the programming session.

The following options are available for Auto Update:

Enable configuration and firmware auto update –

Allows both configuration and firmware updating

(Default).

Enable configuration auto update only – Allows

only configuration updating.

23

Page 30

Enable firmware auto update only – Allows only

firmware updating.

Disable auto update – No automatic updates will be

performed.

24

Page 31

Deep Sleep Mode

The WIRELESS imager can be placed into Deep Sleep

Mode after this programmed duration (since the units’ last

scanning activity). Press its trigger to wake the imager form

this mode.

Disable Deep Sleep Mode (Default)

Duration 10 minutes - Force imager into deep sleep

mode if there is no barcode read in 10 minutes.

Duration 30 minutes - Force imager into deep sleep

mode if there is no barcode read in 30 minutes.

Duration 60 minutes - Force imager into deep sleep

mode if there is no barcode read in 60 minutes.

Duration 90 minutes - Force imager into deep sleep

mode if there is no barcode read in 90 minutes.

25

Page 32

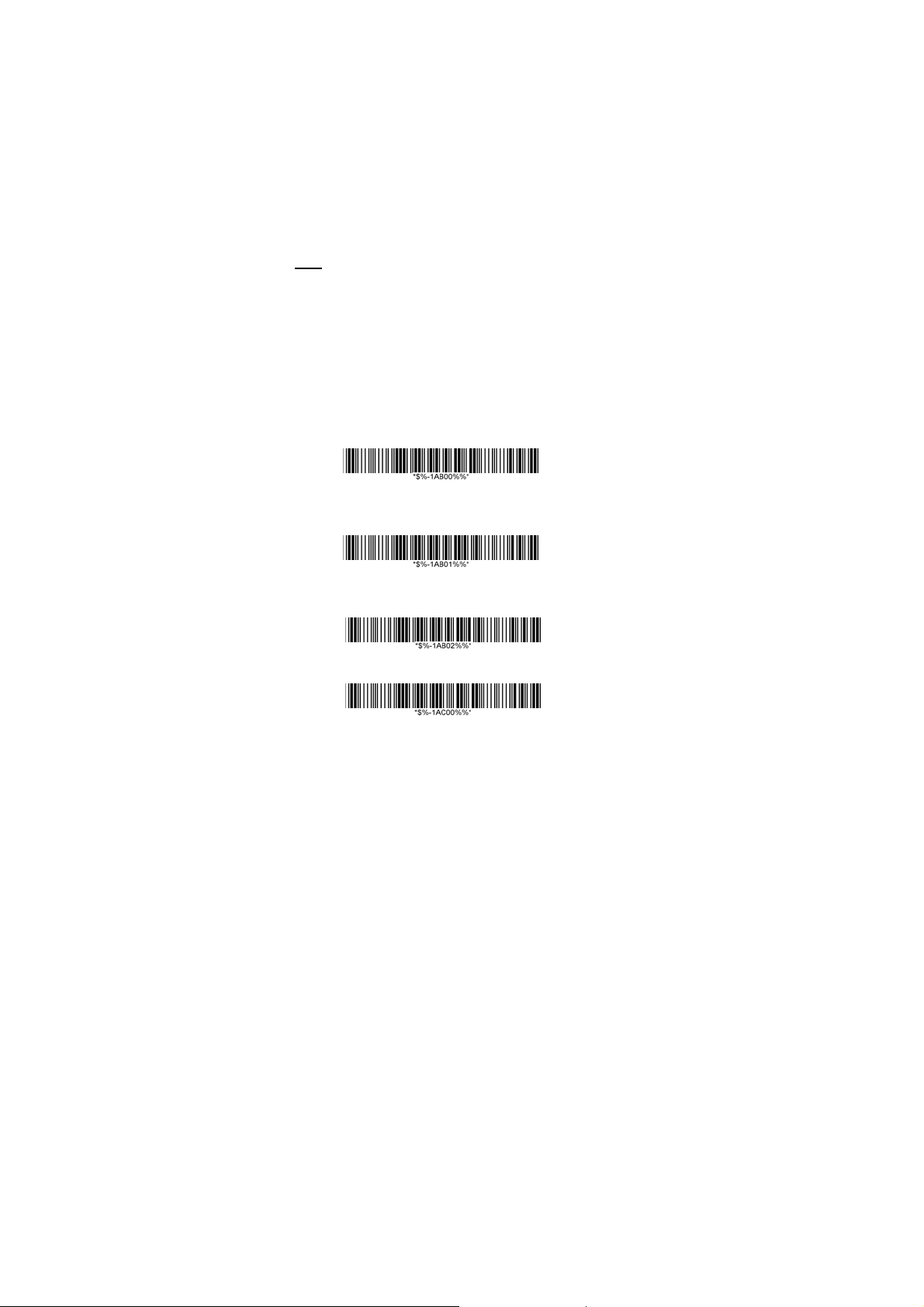

Wireless Connectivity

The AS-8020CL can be linked to any Bluetooth (BT) enabled

device which can accept such a connection with other

devices. To implement this feature, user should set the

imager to “Cradle/Dongle connection auto detection” first.

And then set the PIN code to 0000 assigned to the target

Bluetooth device. In this case, the PIN code of the Bluetooth

enabled device should be set to 0000 to be identical with

your imager.

Cradle connection only – The imager can be used

only with cradle (Default).

Cradle/Dongle connection auto detection – The

imager can be linked to either a cradle or other

Bluetooth enabled devices.

Set PIN code to 0000

Note: The imager only support “Serial Port Profile” under

“Dongle connection”

26

Page 33

Wireless Connectivity (continued)

User is also allowed to set any four- to six-character PIN

code assigned to the target Bluetooth device using the

setting procedures below:

STATE CODE

Cradle/Dongle

connection auto

detection

Program

Begin PIN setting

PIN no.

(Set 4~6 character)

End PIN setting

27

Page 34

Inquiry Beep Control

When the cradle is not linked to an imager, the Radio LED

will blink amber and the cradle will beep. This beep can be

disabled or reconfigured to sound for different durations by

using the following programming barcodes.

Disable inquiry beep

Inquiry beep continuously (Default)

Inquiry beep every 10 seconds

Inquiry beep every 20 seconds

Inquiry beep every 30 seconds

Inquiry beep every 40 seconds

28

Page 35

Inquiry beep every 50 seconds

Inquiry beep every 60 seconds

Inquiry beep every 70 seconds

29

Page 36

Cradle Beep Loudness Control

The beep loudness of cradle can be defined with the

following levels.

Cradle beep off

Level 1

Level 2

Level 3 (Default)

Level 4

Level 5

30

Page 37

Level 6

Level 7

31

Page 38

Additional Features

Here list three additional features of AS-8020CL wireless

imager for the convenience of use to users.

Download firmware from the cradle

Download configuration parameters from the

cradle

Force cradle to reset the configuration – This

feature will also force imager to reset the configuration

to factory default.

Note: To meet the regulation of air transportation, the

wireless imager should disconnect with the cradle during

shipment. All AS-8020CL wireless imagers are suggested to

scan the following command before packaging into boxes

and ship to customers.

Force imager to disconnect and sleep

32

Page 39

Default setting

V

For each barcode shown as below:

Code Type

UPC-A V V V A

UPC-E V V V E

EAN-13 V V V F

EAN-8 V V V FF

Code-39 V *

Interleaved

2 of 5

Industrial

2 of 5

Matrix 2 of 5 B

Codabar %

Code-128 V V #

Code-93 V two digits &

Code-11 V One digit O

MSI/Plessey V @

UK/Plessey V @

Telepen S

Standard 2 of 5 V V i

China Post t

Italian

Pharmacode.

Code-16K - -

PDF417 V - -

EAN UCC

Composite

Databar

(RSS-14)

Databar

(RSS-Limited)

Databar

(RSS-Expanded)

Micro-PDF - - U

Read

Enable

Checksum

erification

Enable

V i

- - i

p

- - RC

R4

RL

RX

Checksum

Transmission

Enable

Code

ID

33

Page 40

Specification

ArgoScan AS-8020CL

Specification Model AS-8020CL

Operational

Light Source 630 nm Visible Red LED

Optical System 2048 pixel CCD

(Charge-coupled device)

Depth of Scan Field 0~270mm (CODE 39, PSC=90%,

20mil)

0~180mm for 13mil

0~60mm for 5mil

5mm~50mm for 4mil

Scan Speed 300 scans/sec

Resolution

Print Contrast 30% or more

Scanning Angle Front: 60° Rear: 60° Yaw: 70°

Decode Capability Auto-discriminates all standard

Beeper Operation 7 tones or no beep

Indicator on imager Green & Red led

Mechanical

Length 187 mm

Width-handle 35 mm

Width-head 75 mm

0.1mm (4mil)

barcodes and some 2D symbologies

including PDF-417 and RSS code;

Other symbologies can be ordered

Code39, PCS=90%

optionally

34

Page 41

Depth-handle 33 mm

Depth-head 44 mm

Weight Less than 200g (with a battery)

Case material ABS (over molded at contact points)

Cushion material Double injection

Cradle interface RS232, Keyboard wedge, USB

Electrical

Input Voltage

(Cradle)

Power - Operating

(Cradle)

Power – Standby

(Cradle)

Current – Operating

(Cradle)

Current – Standby

(Cradle)

Charge Current

(Cradle)

Input Voltage

(Imager)

Power - Operating

(Imager)

Power – Standby

(Imager)

Current – Operating

(Imager)

Current – Standby

(Imager)

5 VDC ± 10% VDC

500 mW

350 mW

100 mA

70 mA

600mA

3.4V ~ 4.2V

925 mW

59 mW

250 mA

16 mA

35

Page 42

Current – Sleep

(Imager)

Light Level Up to 45000 Lux

Shock (Imager) 1.5m drop onto concrete

Shock (Cradle) 90cm drop onto concrete

Contaminants Seals to resist airborne particulate

Ventilation None required

Programming

Programming

method

Program upgrade Enabled by built-in flash memory

Programmable

characteristics

Manual (Reading special barcode)

Code type selection, check digit

selection Decoding option Decoding

option Transmitted character delay,

Header selection, trailer selection,

message suffix, good read beep tone

and volume, scanner trigger selection

Keyboard emulation type

(intermessage delay, keyboard type

and keyboard language)

Serial interface type (ACK/NAK,

Xon/Xoff, RTS/CTS, good read LED

control, start/stop bits)

Remark. Current are marked as RMS (Root mean square)

2 mA

contaminants (IP42)

36

Page 43

Indications of AS-8020CL

Imager:

Status

Link

established

Hardware

fail

Program

download

Program

checksum

fail

LED

Data

transmitting

Data trans.

Fail

Data trans.

OK

Low battery

(<3.2V)

(Trigger is

pressed)

Green

ON for

200msec

Red LED

LED

Blink

once

Flash

Flash

Flash

ON

Flash

ON for

300msec

Good beep

37

Orange

LED

A special

High freq.

300msec

Error beep

Beeper

beep

Beep for

Page 44

Cradle:

Status

Inquiry Blink

Connecting Blink

Link

established

Hardware fail Flash

Data receiving

RF

status

LED

Battery

LED

from the

scanner

Barcode data

proof or

transmitted

Data send to

the host Fail

Program

download

Program

checksum Fail

Idle

Charging Blink

Battery full ON

Battery/charger

Fail

Green

LED

ON

Flash

Red

Orange

LED

Flash

Blink

ON for

0.5sec

LED

Beeper

Beeps

once a

second

Good

beep

Error

beep

38

Page 45

Programming the AS-8020CL

To program the AS-8020CL, you must scan a series of

programming barcode in the correct order. Fold out the back

cover of this manual. You will see a table of alphanumeric

barcodes, which are used to program the various options

presented.

To program each option, you must:

1. Scan the Program barcode on the parameter setting part.

2. Enter the option mode by scanning the Option Bar Code

(also on the Parameter setting part).

3. To the right of the option barcode, the necessary

alphanumeric inputs are listed. Scan these alphanumeric

entries from the back fold out page. To confirm above

steps, you must scan the Finish barcode on the back fold

out page.

4. Once you have finished programming. Scan the Exit

barcode, listed on the lower right hand corner of each

parameter setting part.

39

Page 46

Option Bar Code Option Alphanumeric Entry

Program

Program Barcode

Interface

selection

Option Barcode

Keyboard Wedge

RS-232

Wand emulation

USB

Keyboard/RS-232

Auto detection

Reserved

Exit Barcode

00*

01

02

03

04

05

Exit

Back Fold Out

Finish barcode

40

Page 47

Interface Selection

This cradle comes in one model and supports interfaces such

as keyboard wedge, RS232 serial wedge, and USB interface.

In most of the cases, simply selecting an appropriate cable

with a device code will work for a specific interface.

Interface selection: You can change factory interface

default for other type interface. By plugging different cables,

setting right interface, then the cradle will be changed to

another interface. However, you must make sure which cable

you need.

Keyboard/RS232/UBS Auto detection: By setting this

function, it will automatically select the Keyboard wedge or

RS-232 or UBS interface for user.

Option Bar Code Option Alphanumeric

Program

Entry

Interface selection

Note:*-Default

Keyboard Wedge

RS-232

USB

Keyboard

/RS232/USB

Auto detection

41

00

01

03

04

*

Exit

Page 48

Keyboard wedge

As a keyboard interface, the cradle supports most of the

popular PCs and IBM terminals. The installation of the wedge

is a fairly simple process without any changes of software or

hardware.

Keyboard Type: Select keyboard type connector of your

host computer. Cradle must be selected to the appropriate

host interface cable converter.

Option Bar Code Option Alphanumeric

Program

Entry

Keyboard type

IBM AT, PS/2

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

42

00

01

02

03

04

05

06

*

Exit

Page 49

Keyboard wedge

Keyboard Layout: The selecting of keyboard layout

supports many country languages other than USA keyboard

layout. First you need to confirm country language that you

desire. In DOS, using command “keyb” to select the

desirable keyboard layout or in WINDOWS entry “Control”

then pops “Keyboard” to select country at “language” item.

For details, please refer to your DOS or WINDOWS user’s

manual.

Keyboard Speed: By selecting, you can change output

speed of data transmission to match with host computer.

Generally, set 00 or 01 in working high speed. If some output

characters of barcode have been lost, you may need to set

05 or 06 to match your host keyboard speed.

Function Key: Set Enable, imager can output code as

pressing function-key in your application program while the

barcode datas contain ASCII value between 01

Refer to ASCII table.

Numeric Key: The Keypad has to be selected if your

application program is only keypad numeric code acceptable.

So, cradle will output code as press numeric keypad when it

read numeric digit. (The keypad is in the right side of

keyboard, and Num Lock control key is also on.) If

Alt+Keypad is selected, the data characters will be

transmitted as “Alt” + numbers. For example, when sending

character “A”, the actual sending will be “Alt”+65. It is also

useful when using non-English OS and keyboard layout.

Option Bar Code Option Alphanumeric

Program

16 to 1F16.

43

Entry

Page 50

Keyboard layout

USA

Belgium

Danish

France

00

01

02

03

*

Keyboard speed

Function key

Alpha/Numeric key

Germany

Italian

Portuguese

Spanish

Swedish

Switzerland

UK

Latin American

Japanese

0-8

0 : high clock rate

8 : low clock rate

Disable

Enable

Alphabetic key

Numeric keypad

(Num lock state

04

05

06

07

08

09

10

11

12

00-08

03

00

01

00

01

*

*

*

only)

Alt+Keypad

44

02

Exit

Page 51

Keyboard wedge

Caps Lock: By selecting Caps lock”ON” or Caps lock”OFF”,

imager can get Caps Lock status.

Power-on simulation: All of the PCs check the keyboard

status during power-on selftest. It is recommended to Enable

function if you are working without keyboard installation. It

simulates keyboard timing and pass keyboard present status

to the PC during power-on.

Inter-character delay: This delay is inserted after each data

characters transmitted. If the transmission speed is too high,

the system may not be able to receive all characters. Adjust it

and try out suited delay to make system work properly.

Block transmission delay: It is a delay timer between

barcode data output. The feature is used to transfer

continually with shorter barcode data or multi-field scanning.

45

Page 52

Option Bar Code Option Alphanumeric

Program

Entry

Caps lock

Power-on simulation

Inter-character delay

Block transmission

delay

Caps lock”ON”

Caps lock”OFF”

Disable

Enable

00-99 (msec) 00-99

00-99 (10 msec) 00-99

00

*

01

00

*

01

02

*

10

*

Exit

46

Page 53

RS-232

CTS: Clear To Send (Hardware Signal)

RTS: Request To Send (Hardware Signal)

Xon: Transmit On (ASCII Code 11

Xoff: Transmit Off (ASCII Code13

Flow control:

None-The communication only uses TxD and RxD signals

without regard for any hardware or software handshaking

protocol.

RTS/CTS-If the cradle wants to send the barcode data to

host computer, it will issue the RTS signal first, wait for the

CTS signal from the host computer, and then perform the

normal data communication. If there is no replied CTS signal

from the host computer after the timeout (Response Delay)

duration, the imager will issue a 5 warning beeps.

Xon/Xoff- When the host computer is unable to accept data,

it sends a Xoff code to inform the cradle to suspend data

transmission, and Xon to continue.

ACK/NAK- When the ACK/NAK protocol is used, the cradle

waits for an ACK (acknowledge) or (not acknowledge) from

the host computer after data transmission, and will resend in

response to a NAK.

Inter-character delay: It is delay time between data

character’s data output. It is also same as Inter-char. delay of

keyboard wedge.

Block transmission delay: It is a delay time between

barcode data output. It is also same as Block transmission

delay of keyboard wedge.

Response delay: This delay is used for serial

communication of the cradle to waiting for handshaking

acknowledgment from the host computer.

16)

16)

47

Page 54

Option Bar Code Option Alphanumeric

Program

Entry

Flow control

Inter-character delay

Block transmission

delay

Response delay

None

RTS/CTS

Xon/Xoff

ACK/NAK

RTS/CTS bracket

mode

00-99 (msec)

00-99 (10 msec)

00-99 (100 msec)

48

00

01

02

03

04

00-99

00

00-99

00

00-99

20

*

*

*

*

Exit

Page 55

Option Bar Code Option Alphanumeric

Program

Entry

Baud rate

Parity

Data bit

Stop bit

300 BPS

600 BPS

1200 BPS

2400 BPS

4800 BPS

9600 BPS

19200 BPS

38400 BPS

None

Odd

Even

8 bits

7 bits

One bit

Two bits

00

01

02

03

04

05

*

06

07

00

*

01

02

*

00

01

00

*

01

Exit

49

Page 56

50

Page 57

Pin Assignments

10-pin

AS Series 10-pin RJ-45 Connector

Pin RS-232 Keyboard

1 I/F I/F

2 NA NC

3 TXD NC

4 NC CLK / PC

5 GND DATA / PC

6 CTS DATA / KB

7 RXD NC

8 RTS CLK / KB

9 GND GND

10 NC GND

1

2

3

4

5

6

7

8

9

10

51

Page 58

Keyboard Wedge PS/2 Connector (To Host Side):

Pin Mini-DIN 6P Male Mini-DIN 6P Female

1 DATA / PC DATA / KB

2 NC NC

3 GND GND

4 VCC (+5V) NA

5 CLK / PC CLK / KB

6 NC NC

4

2

1

3

Mini-DIN 6P Male Connector

RS-232 DB-9F Connector (To Host Side):

Pin Definition

1 NC

2 TXD

3 RXD

4 NC

5 GND

6 NC

7 CTS

8 RTS

9 NC

Mini-DIN 6P Female Connector

6

5

4

6 2

5

1

3

5

9

4

8

3

7

2

6

1

52

Page 59

Scan

Scanning mode:

Good-read off-The trigger button must be pressed to

activate scanning. The light source of imager stops scanning

when there is a successful reading or no code is decoded

after the Stand-by duration elapsed.

Momentary-The trigger button acts as a switch. Press button

to activate scanning and release button to stop scanning.

Alternate-The trigger button acts as a toggle switch. Press

button to activate or stop scanning.

Timeou t off-The trigger button must be pressed to activate

scanning, and imager stops scanning when no code is

decoded after the Stand-by duration elapsed.

Continue-Imager always keeps reading, and it does not

matter when trigger button is pressed or duration is elapsed.

Test only-For test of scan performance only. It is improper to

be utilized to check the accuracy of transmitted data.

Double read timeout: The imager will require a several

times successful decoding to confirm the data when enabled.

The more confirming times required, the more inhibitive

miss-reading code will be shown. The Multi field scan Enable

function won’t be able to work if set Double confirm.

Double confirm: If the barcode has been scanned twice,

then only the first barcode will be accepted.

Supplement Check Counter: It will be more reliable to read

the barcode with extension (supplement) like UPCE/A or

EAN-8/13, but slow down the decoding speed when this

counter is set more.

53

Page 60

Option Bar Code Option Alphanumeric

Program

Entry

Scanning mode

Stand-by duration

Double read timeout

Double confirm

Supplement Check

Good-read off

Momentary

Alternate

Timeout off

Continue

Test only

01-99 (second) 00-99

01-99 (10 msec) 01-99

00-09

(00: no double

confirm)

00-64

(verifications)

00

01

02

03

04

05

06

50*

00-09

00

00-64

30

*

*

*

*

Counter

54

Exit

Page 61

Scan

Global min./max. code length: These are to define the min/

max readable code length of all symbologies. Code length

less than min. code length or more than max. code length will

not be read. In popular, you can set the same value for both

min. and max. reading length to force the fixed length

barcode decoded. The values of setting have no effect on

certain symbologies with fixed length. You can specify the

settings for individual barcode by the min/max code length

setting of each barcode.

Notes 1): Please set the min/max length if you have special

demand for individual barcode.

2): Include the Check sum digits if you want to set

Global min/max code length.

Inverted image scan: Set Enabled the imager will scan both

black/white barcode with white/black background.

55

Page 62

Option Bar Code Option Alphanumeric

Program

00-99 00-99

Entry

Global min. code length

Global max. code length

Inverted image scan

04

*

00-99 00-99

*

99

Disable

Enable

00

01

*

Exit

56

Page 63

Indication

Power on alert: After power-on the cradle it will generate an

alert signal to indicate a successful self-test.

LED indication: After each successful reading, the LED

above the imager will light up to indicate a good barcode

reading.

Beeper indication: After each successful reading, the

imager will beep buzzer to indicate a good barcode reading,

and its Beep loudness, Beep tone freq. and Beep tone

duration are adjustable.

Beep loudness/Beep tone freq./Beep tone duration: You

can adjust Beep Loudness, Beep tone and Beep duration for

a good reading upon favorite usage.

Exit

57

Page 64

Option Bar Code Option Alphanumeric

Program

Entry

Disable

Enable

Power on alert

Disable

Enable

LED indication

Disable

Enable

Beeper indication

00-07

(00 - off)

Beep loudness

00-99 (100Hz) 00-99

Beep tone freq.

00-99 (10 msec) 00-99

Beep tone duration

00

01

00

01

00

01*

00-07

07

26

08*

*

*

*

*

Exit

58

Page 65

UPCA

Format

Leading

Zero

Read: Enable or disable the read function.

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Truncate leading/ending: The leading or ending digits of

barcode data characters can be truncated when these values

are set to non-zero. It will beep instead of reading anything

when the truncate value is more than the barcode data digits

or the value of Truncate Leading is overlapped with that of

the Ending. The maximum value of truncate digits is 15.

Code ID setting: Code ID setting is a character used to

represent the symbol upon a succeeding reading. A Code ID

setting is prefixed to the data begin or end transmitted if the

feature is selected. If you want application to transmit Code

ID, you must set Code ID transmission to Enable first. Refer

to Code ID transmission.

Data Digits

(11 Digits)

Check

Digit

59

Page 66

Option Bar Code Option Alphanumeric

Program

Entry

Read

Check-sum transmission

Truncate leading

Truncate ending

Code ID setting

Disable

Enable

Disable

Enable

0-15 00-15

0-15 00-15

00-ffH ASCII

code

00

01

*

00

*

01

00*

00

*

00-ffH

< A >

*

Exit

60

Page 67

UPCA

Insertion group number selection: The imager offers max.

two insertion groups for one symbology. By setting one or two

digits to indicate which insertion group you want to insert.

You may refer to Character insertion. The function is to insert

specific characters as a group into transmitted data of

selected symbologies. Enable the group insertion by

selecting the group number.

Example: Group 2 → set 02 or 20.

Group 1 and 4 → set 14 or 41.

Notes 1): Group number set to “0” means that no group

insertion required.

2): Details about the Insert Group settings please refer

to page 123

table.

Supplement digits: The Supplement digits barcode is the

supplemental 2 or 5 characters for WPC code.

Format

Leading

Zero

Truncation / Expansion: The leading “0” digits of UPCA

data characters can be truncated when the function is

enabled.

rd

~126th , and page 132nd ASCII code

Data Digits

(11 Digits)

Check

Digit

Supplement Digits

2 or 5 or

UCC / EAN 128

61

Page 68

Option Bar Code Option Alphanumeric

Program

Entry

00-44 00-44

Insert group number

selection

Supplement digits

Truncation/

Expansion

The

None

2 digits

5 digits

2,5 digits

UCC/EAN 128

2, UCC/EAN 128

5, UCC/EAN 128

All

None

Truncate leading

zero

Expand to EAN13

62

00

00*

01

02

03

04

05

06

07

00

01

02

*

*

Exit

Page 69

UPCE

Read: Format

Leading

Zero

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code ID setting: Refer to Code ID setting of UPCA.

Option Bar Code Option Alphanumeric

Data Digits (6

Program

Digits)

Check

Digits

Entry

Read

Check-sum

transmission

Truncate leading

Disable

Enable

Disable

Enable

0-15 00-15

63

00

01

00

01

00

*

*

*

Page 70

Truncate ending

0-15 00-15

00

*

Code ID setting

00-ffH ASCII

code

00-ffH

< E >

*

Exit

64

Page 71

UPCE

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Supplement digits:

Format

Leading

Zero

Expansion: The expansion function is used only for UPCE

and EAN-8 code reading. It extends to 13-digits with “0” digits

when the feature is enabled.

Example: Barcode “0123654”

Output: “0012360000057”

UPCE-1: Enable imager to read UPCE with leading digit 1.

Option Bar Code Option Alphanumeri

Data Digits

(6 Digits)

Program

00-44 00-44

Check

Digit

Supplement Digits

UCC/EAN 128

2 or 5 or

c Entry

th

Insert group number

selection

65

00*

Page 72

Supplement digits

None

2 digits

5 digits

00

*

01

02

Truncation/Expansion

Expansion

UPCE-1

2,5 digits

UCC/EAN 128

2, UCC/EAN 128

5, UCC/EAN 128

All

None

Truncate leading

zero

Expand to EAN13

Expand to UPCA

Disable

Enable

Disable

Enable

03

04

05

06

07

00

*

01

02

03

*

00

01

00

*

01

Exit

66

Page 73

EAN-13

Read: Format

Data Digits (12 Digits) Check Digits

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Truncate leading zero: Refer to Truncation / Expansion of

UPCA.

The

Option Bar Code Option Alphanumeric

Program

Entry

Read

Check-sum

transmission

Truncate leading

Disable

Enable

Disable

Enable

0-15 00-15

67

00

01*

00

01

*

00*

Page 74

0-15 00-15

Truncate ending

00

*

Exit

68

Page 75

EAN-13

Code ID setting: Refer to page 57

selection of UPCA.

Insertion group number selection: Refer to Insertion group

selection of UPCA.

Supplement digits:

Format

Data Digits

(12 Digits)

ISBN/ISSN: The ISBN (International Standard Book Number)

and ISSN (International Standard Serial Number) are two

kinds of barcode for book and magazines. The ISBN is 10

digits with leading “978” and the ISSN is 8 digits with leading

“977” of the “EAN-13” symbology.

Example: Barcode “9789572222720” - Output: “9572222724”

Example: Barcode “9771019248004” - Output: “10192484”

Check

Digits

th

Insertion group number

Supplement Digits

2 or 5 or

UCC / EAN 128

Program

Option Bar Code Option Alphanumeric

Entry

Code ID setting

Insert group number

selection

00-ffH ASCII

code

00-44 00-44

69

00-ffH

< F >*

00

*

Page 76

Supplement digits

None

2 digits

5 digits

2,5 digits

00

*

01

02

03

ISBN/ISSN

conversion

ISBN ID setting

UCC/EAN 128

2, UCC/EAN 128

5, UCC/EAN 128

All

Disable

Enable

00-ffH ASCII

code

04

05

06

07

00

*

01

00-ffH

< I >

*

Exit

70

Page 77

EAN-8

Read: Format

Data Digits

(7 Digits)

Check-sum transmission: By setting Enable, checks sum

will be transmitted.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code ID setting: Refer to Code ID setting of UPCA.

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Option Bar Code Option Alphanumeric

Program

Check

Digits

Entry

th

Read

Check-sum

transmission

Truncate leading

Disable

Enable

Disable

Enable

0-15 00-15

71

00

01*

00

01

*

00*

Page 78

0-15 00-15

Truncate ending

00-ffH ASCII

code

Code ID setting

00-44 00-44

Insert group number

selection

00

*

00-ffH, 00-ffH

*

< FF >

00

*

Exit

72

Page 79

EAN-8

Supplement digits: Format

Data Digits

(7 Digits)

Truncation / Expansion: Refer to Truncate Leading zero of

UPCE.

Expansion: Refer to Expansion of UPCE.

Check

Digits

Supplement Digits

2 or 5 or

UCC/EAN 128

Option Bar Code Option Alphanumeric

Program

Entry

Supplement digits

Truncation /

Expansion

None

2 digits

5 digits

2,5 digits

UCC/EAN 128

2, UCC/EAN 128

5, UCC/EAN 128

All

None

Truncate leading

zero

Expand to EAN13

73

00

*

01

02

03

04

05

06

07

00

*

01

02

Page 80

Expansion

Disable

Enable

00

*

01

Exit

74

Page 81

Code 39

Read: Format

Start

Data Digits

“★”

( Variable)

Check-sum verification: The checksum of Code-39 is

optional and made as the sum module 43 of the numerical

value of the data digits.

Check-sum transmission: By setting Enable, checksum

will be transmitted.

Max./Min. code length: Each symbology has own Max./Min.

Code Length. They can be set to qualify data entry. If their

Max./Min. Code Length is zero, the Global Min./Max. Code

Length is in effect. The length is defined as to the actual

barcode data length to be sent. Label with length exceeds

these limits will be rejected. Make sure that the Minimum

length setting is no greater than the Maximum length setting,

or otherwise all the labels of the symbology will not be

readable. In particular, you can see the same value for both

Minimum and Maximum reading length to force the fixed

length barcode decoded.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Option Bar Code Option Alphanumeric

Program

Checksum

(Optional)

End

“★”

Entry

Read

Disable

Enable

75

00

01*

Page 82

Check-sum

verification

Disable

Enable

00

*

01

Check-sum

transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00-ffH ASCII

code

76

00

*

01

*

00

00*

00

*

*

00

00-ffH

<*>

Exit

Page 83

Code 39

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Format: The Full ASCII Code-39 is an enhanced set of

Code-39 that is the data with total of 128 characters to

represent Full ASCII code. It is combined one of the digits +,

%, $ and/ with one of the alpha digits (A to Z).

Append: This function allows several symbols to be

concatenates and be treat as one single data entry. The

imager will not transmit the embedded appending code

(space for Code-39). If Enable and other symbols were read

again with the appended code, then codes will be transmitted

without Code ID, Preamble and Prefix. When a symbol was

decoded without the appended code, the data will be

transmitted without Code ID and Prefix, but the Postamble

Suffix codes are appended. This function is used when the

first number of code 39 is a space. Example: □123456.

Start/end transmission: The start and end characters of

Code-39 are“★”. Y ou can transmit all data digit s including two

“★”.

Option Bar Code Option Alphanumeric

Program

th

Insert group number

selection

Entry

00-44 00-44

00

*

77

Page 84

Format

Standard

Full ASCII

00

01

*

Disable

Enable

Append

Disable

Enable

Start/end

transmission

00

01

00

01

*

*

Exit

78

Page 85

Interleaved 2 of 5

Read: Format

Data Digits

(Variable)

Check-sum verification: The checksum is made as the sum

module 10 of the numerical values of all data digits.

Check-sum transmission: By setting Enable, checksum

will be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code ID setting: Refer to Code ID setting of UPCA.

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Option Bar Code Option Alphanumeric

Program

Checksum

(Optional)

th

Entry

Read

Check-sum

verification

Disable

Enable

Disable

Enable

79

00

01*

00

*

01

Page 86

Check-sum

transmission

Disable

Enable

00-64 00-64

00

*

01

Max. code leading

Min. code leading

Truncate leading

Truncate ending

Code ID setting

Insert group number

00*

00-64 00-64

00

*

0-15 00-15

*

00

0-15 00-15

00*

00-ffH ASCII

code

00-44 00-44

00-ffH

< i >

*

00

*

selection

80

Exit

Page 87

Industrial 2 of 5

Read: Format

Data Digits

(Variable)

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Option Bar Code Option Alphanumeric

Program

Checksum

(Optional)

th

Entry

Read

Max. code length

Min. code length

Disable

Enable

00-64 00-64

00-64 00-64

81

00

01

00

00

*

*

*

Page 88

0-15 00-15

Truncate leading

Truncate ending

Code ID setting

Insert group number

selection

0-15 00-15

00-ffH ASCII

code

00-44 00-44

82

00

*

*

00

00-ffH

< i >*

00

*

Exit

Page 89

Matrix 2 of 5 Eur

Read: Format

Data Digits

(Variable)

Checksum Verification: The checksum is made as the sum

module 10 of the numerical values of all data digits.

Checksum Transmission: By setting Enable, checksum will

be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code ID setting: Refer to Code ID setting of UPCA.

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Option Bar Code Option Alphanumeric

Program

Checksum

(Optional)

Entry

th

Read

Checksum

Verification

Disable

Enable

Disable

Enable

83

00

01

00

01

*

*

Page 90

Checksum

Transmission

Disable

Enable

00-64 00-64

00

*

01

Max. code length

Min. code length

Truncate leading

Truncate ending

Code ID setting

Insert group number

00*

00-64 00-64

00

*

0-15 00-15

*

00

0-15 00-15

00*

00-ffH ASCII

code

00-44 00- 44

00-ffH

< B >

00

*

*

selection

84

Exit

Page 91

Codabar

Read: Format

Start Data Digits (Variable) Checksum (Optional) End

Checksum Verification: The checksum is made as the sum

module 16 of the numerical values of all data digits.

Checksum Transmission: By setting Enable, checksum will

be transmitted.

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Option Bar Code Option Alphanumeric

Program

Entry

Read

Checksum

Verification

Disable

Enable

Disable

Enable

85

00

01

00

01

*

*

Page 92

Checksum

Transmission

Max. code length

Min. code length

Truncate leading

Truncate ending

Disable

Enable

00-64 00-64

00-64 00-64

0-15 00-15

0-15 00-15

00

01

00

00

00

00

*

*

*

*

*

Code ID setting

00-ffH ASCII

code

86

00-ffH

< % >

*

Exit

Page 93

Codabar

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Start/End type: The Codabar has four pairs of Start/End

pattern; you may select one pair to match your application.

Start/End Transmission: Refer to Start/End Transmission of

Code 39.

Option Bar Code Option Alphanumeric

Insert group

selection

Program

00-44 00-44

00

Entry

*

th

Start/End type

Start/End

transmission

ABCD/ABCD

abcd/abcd

ABCD/TN*E

Abcd/tn*e

Disable

Enable

87

00

01

02

03

00

01

*

*

Exit

Page 94

Code-128

Read: Format

Data Digits

(Variable)

Checksum Verification: The checksum is made as the sum

module 103 of all data digits.

Checksum Transmission: By setting Enable, checksum will

be transmitted.

Option Bar Code Option Alphanumeric

Program

Checksum

(Optional)

Entry

Read

Checksum

Verification

Checksum

Transmission

Disable

Enable

Disable

Enable

Disable

Enable

88

00

01

00

01

00

01

*

*

*

Exit

Page 95

Code-128

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code ID setting: Refer to Code ID setting of UPCA.

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Format: The Code-128 can be translated to UCC/EAN-128

format if it starts with FNC1 character. The first FNC1 will

be translated to “]C1”,and next to be a field separator code as

<GS>(1D

]C1 Data <GS> Data Checksum

Append / FNC4 control: When Append function is enabled,

it won't show the data immediately if imager read the barcode

includes FNC2 code. It will show all data until it read the

barcode, which doesn't have FNC2 code. When FNC4 is

enabled, the imager will send the data with FNC4 code. If the

FNC4 is ignore, the imager will send the data without FNC4

code.

16).

Program

Option Bar Code Option Alphanumeric

th

Max. code length

Min. code length

00-64 00-64

00-64 00-64

89

00

00

Entry

*

*

Page 96

Truncate leading

Truncate ending

0-15 00-15

0-15 00-15

00

00

*

*

Code ID setting

Insert group number

selection

Format

Append / FNC4 control

00-ffH ASCII

code

00-44 00-44

Standard

UCC/EAN-128

Disable/Enable

Enable/Enable

Disable/Ignore

Enable/Ignore

00-ffH

< # >

00

00

01

00

01

02

03

*

*

*

*

Exit

90

Page 97

Code-128

ISBT enable: This feature is commonly used in a blood bank

for identification.

ISBT concatenation timeout: This feature is to setup the

timeout duration of ISBT concatenation.

Field separator code: This feature is only used for

UCC/EAN-128 format. This Field separator code means you

can reassign second or after a FNC1 for your usage. The

default of ASCII code is <GS>(1D

UCC/ EAN 128 ID setting: Refer to Code ID setting of

UPCA.

16).

Option Bar Code Option Alphanumeric

Program

Entry

ISBT enable

Field separator code

UCC/EAN-128

ID setting

Disable

Enable normal

00-ffH ASCII

code

00-ffH ASCII

code

91

00

*

01

00-ffH

1DH

00-ffH

< # >

*

*

Exit

Page 98

Code-93

Read: Format

Data Digits

(Variable)

Checksum Verification: The checksum is made as the sum

module 47 of the numerical values of all data digits.

Checksum Transmission: By setting Enable, checksum

will be transmitted.

Option Bar Code Option Alphanumeric

Program

Checksum1

(Optional)

Checksum2

(Optional)

Entry

Read

Checksum

Verification

Checksum

Transmission

Disable

Enable

Disable

Enable

(two digits)

Disable

Enable

92

00

01

00

01

00

01

*

*

*

Exit

Page 99

Code-93

Max./Min. code length: Refer to Max./Min. code length of

Code-39.

Truncate leading/ending: Refer to Truncate leading/ending

of UPCA.

Code Id setting: Refer to Code ID setting of UPCA.

Insertion group number selection: Refer to page 57

Insertion group number selection of UPCA.

Option Bar Code Option Alphanumeric

Max. code length

Program

00-64 00-64

00-64 00-64

00

Entry

*

th

Min. code length

Truncate leading

Truncate ending

*

0-15 00-15

0-15 00-15

93

00

00

00

*

*

Page 100

00-ffH ASCII

00-ffH

Code ID setting

Insert group number

selection

code

00-44 00-44

< & >

00

*

*

Exit

94

Loading...

Loading...