Argo-masz POM3, POM2 User Manual

_________________________________

Instruction manual

Warranty certificate

Parts catalogue

SMALL ROTARY PLOUGH

POM2 POM3

AGRO-MASZ

Paweł Nowak

Strzelce Małe 78

97-515 Masłowice

Tel. +48 44 787 49 24

Fax. +48 44 787 12 02

Address: agro-masz.eu |

Language version: ENGLISH |

|

Document No: IO.POM.17.8 |

|

Created: AUGUST 2017 |

2Copying and making excerpts only on written consent of AGRO-MASZ Paweł Nowak.

Dear Customers!

Taking the opportunity to thank you for your interest in our offer and for the purchase made, we would like to ensure that the trust placed in us becomes the motivation for the whole team for further and more intensive work to improve the machines belonging to the ever increasing range of products offered by AGRO-MASZ.

In order to ensure the fullest presentation of the capabilities of our product, we created an instruction manual, which will clearly guide you step-by-step through the essential aspects of the technical construction of the machine and protect against adverse effects caused by incorrect operation.

Detailed knowledge of the provisions set forth in this instruction manual, which remains the basic piece of equipment of every machine, is necessary for its safe use for many years.

The instruction manual should be kept in a safe place and used properly throughout the entire period of the operation of the machine.

If it is lost or damaged, pleases order a new copy.

The new instruction manual can be ordered from the dealer of AGRO-MASZ- brand the machines or directly from the manufacturer.

It is also important to note that the instruction manual should be made available to the other user in case of sale or lending of the machine.

Every machine manufactured by AGRO-MASZ is also provided with a warranty certificate and parts catalogue, in which all elements of equipment of the machine are presented.

It should be kept in mind that the use of original spare parts only will ensure the proper functionality and long service lifetime of our product. The use of non-original and duplicated parts adversely affects its parameters.

We have put every effort to present you an easy-to-operate, solid and reliable product, with the belief that our cooperation with you will also be lasting and, as a result, it will allow us to develop together new solutions in order to facilitate and increase the level of productivity in agriculture.

Thank you for choosing our product and wish all joy in your work.

3

4

I.EC DECLARATION OF CONFORMITY FOR THE MACHINE

Manufacturer

AGRO-MASZ Paweł Nowak

Strzelce Małe 78

97-515 Masłowice

Machine

Name: |

Rotary plough. |

Type/ Model: |

………………… |

Factory number: |

………………… |

Year of manufacture: |

………………… |

Application: |

bed free ploughing of medium and large depth. |

The manufacturer hereby declares that the machine, to which the declaration relates, meets:

-all relevant provisions and regulations of Directive 2006/42/EC of the

EUROPEAN PARLIAMENT and of the COUNCIL of 17 May 2006 on the machinery, and amending Directive 95/16/EC (Official Journal of the European Union L157 of 09.06.2006, page 24) and Ordinance of the

Minister of Economy of 21 October 2008 on essential requirements for the machinery (Journal of Laws, No 199, item 1228);

-requirements of harmonized standards:

•EN ISO 4254-1:2016;

•EN ISO 12100: 2012;

•EN ISO 13857: 2010; - other standards:

•ISO 3600: 1998;

•ISO 11684: 1998;

- Regulation of the Minister of Economy of 31 December 2002 on technical conditions applicable to vehicles and scope of the necessary equipment.

This Declaration shall become invalid if the machine is changed or redesigned without the written consent of the manufacturer.

Name, address of person authorized to prepare the technical documentation:

Mirosław Nowak, Strzelce Małe 78, 97-515 Masłowice

Strzelce Małe, 05.01.2015 |

Paweł Nowak – owner |

|

(full name, signature of person |

|

authorised to prepare the |

|

declaration) |

5

THE MACHINE

II.THE MACHINE IDENTIFICATION

2.1. Name

Mounted rotary plough

2.2. Model symbol

POM2 – Small rotary plough, 2-furrow

POM3 – Small rotary plough, 3-furrow

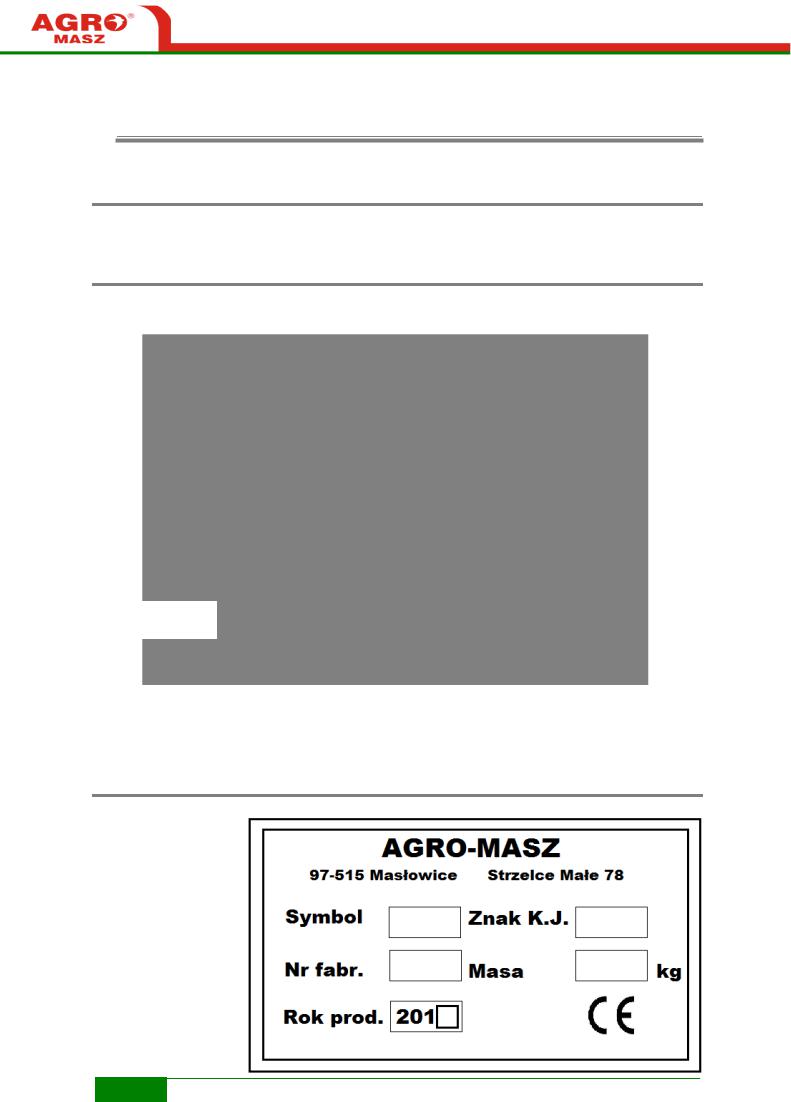

Data plate

Identification data can be found on data plate attached to the machine's frame by the three-point linkage.

2.3. Data plate

Symbol |

Certification mark |

Factory number |

Mass |

Year of manufacture |

|

6

7

THE MACHINE

The purchaser (the user) of the machine should confirm to have acquainted with warranty terms and information included in the Instruction Manual with his/her signature.

When the machine is being sold, the seller (dealer) should enter below the machine's symbol, factory number and year of manufacture in accordance with the data plate and include own data.

Machine symbol ................................................................

Factory number |

................................................................ |

Year of manufacture |

................................................................ |

Date of sale |

................................................................ |

Seller |

Address…………………………………….. |

|

Tel. / Fax…………………………………….. |

Purchaser (User) |

Address ...................................................... |

Tel. / Fax……………………………………..

NOTE! Remember the name and symbol of your machine. Always use this name and symbol in contact with the seller or the manufacturer.

NOTE! Remember the name and symbol of your machine. Always use this name and symbol in contact with the seller or the manufacturer.

2.4. Manufacturer data

AGRO-MASZ Paweł Nowak |

Export |

Spare parts |

|||||

Strzelce Małe 78 |

Tel. +48 605 724 854 |

Tel. + 48 603 728 099 |

|||||

97-515 Masłowice |

export@agro-masz.eu |

kamil.slusarczyk@agro-masz.eu |

|||||

Tel. +48 44 787 49 24 |

|

|

|

||||

Fax. +48 44 787 12 02 |

Tel. +48 661 027 679 |

|

|

||||

kontakt@agro-masz.eu |

rafal.kornatka@agro-masz.eu |

Service |

|||||

|

|

|

|

|

Tel. +48 603 676 644 |

Tel. +48 661 076 457 |

|

Domestic sales |

serwis@agro-masz.eu |

||||||

mariusz.gleda@agro-masz.eu |

|

|

|||||

Tel. +48 601 365 272 |

|

|

|

||||

inga@agro-masz.eu |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TABLE OF |

III. |

TABLE OF CONTENTS |

|

|

DEAR CUSTOMERS!........................................................................................................................... |

3 |

||

I. |

EC DECLARATION OF CONFORMITY FOR THE MACHINE............................................................ |

5 |

|

MANUFACTURER .............................................................................................................................. |

5 |

||

MACHINE ....................................................................................................................................... |

5 |

||

II. |

|

THE MACHINE IDENTIFICATION .............................................................................................. |

6 |

2.1. NAME ..................................................................................................................................... |

6 |

||

2.2. MODEL SYMBOL ........................................................................................................................ |

6 |

||

2.3. DATA PLATE.............................................................................................................................. |

6 |

||

2.4. MANUFACTURER DATA................................................................................................................ |

8 |

||

III. |

|

TABLE OF CONTENTS............................................................................................................. |

9 |

IV. |

|

INITIAL EXPLANATIONS....................................................................................................... |

11 |

4.1. DIRECTIONS IN THE INSTRUCTION MANUAL ..................................................................................... |

11 |

||

4.2. USER FEEDBACK ....................................................................................................................... |

11 |

||

4.3. RECOMMENDATIONS AND DESCRIPTIONS ....................................................................................... |

13 |

||

4.4. INTENDED USE ......................................................................................................................... |

13 |

||

V. |

|

SAFETY NOTES..................................................................................................................... |

14 |

THE MENTIONED SAFETY REGULATIONS REFER TO THE PLOUGH. NOTWITHSTANDING, OBSERVE THE GENERAL SAFETY |

|||

AND ACCIDENT PREVENTION RULES AS WELL AS ROAD TRAFFIC REGULATIONS................................................. |

14 |

||

5.1. GENERAL SAFETY RULES ............................................................................................................. |

14 |

||

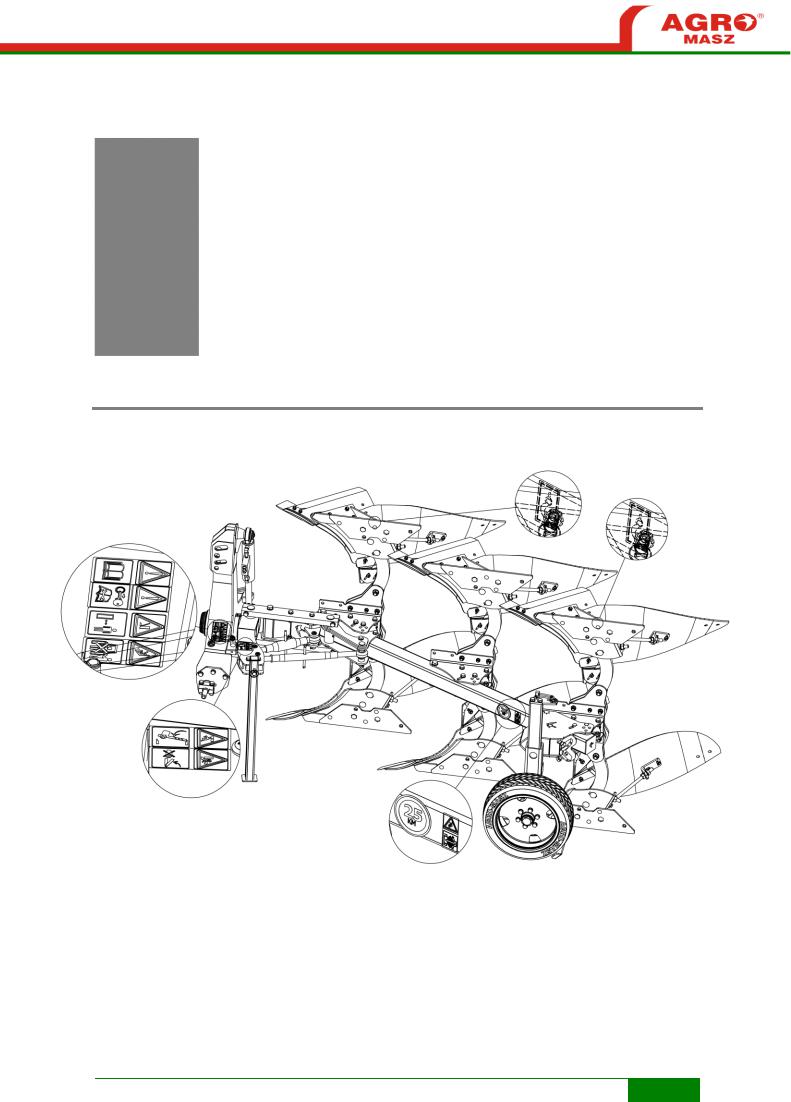

5.2. WARNING PICTOGRAMS PLACED ON THE PLOUGH............................................................................. |

16 |

||

5.3. LOCATION OF WARNING LABELS ON THE MACHINE ............................................................................ |

19 |

||

5.4. OTHER RISKS........................................................................................................................... |

20 |

||

5.4.1. WIRING SYSTEM............................................................................................................................... |

20 |

||

5.4.2. HYDRAULIC SYSTEM .......................................................................................................................... |

20 |

||

5.4.3. RESIDUAL ENERGY ............................................................................................................................ |

21 |

||

5.4.4. FOREIGN BODIES .............................................................................................................................. |

21 |

||

5.4.5. OTHER OBSTACLES............................................................................................................................ |

21 |

||

5.5. OPERATOR’S OBLIGATIONS AND TRAINING...................................................................................... |

22 |

||

5.5.1. OPERATOR’S OBLIGATIONS ................................................................................................................ |

22 |

||

5.5.2. PERSONNEL TRAINING....................................................................................................................... |

22 |

||

5.5.3. PERSONAL PROTECTIVE EQUIPMENT.................................................................................................... |

23 |

||

5.6. RISK ZONES............................................................................................................................. |

23 |

||

5.7. RESIDUAL RISK......................................................................................................................... |

24 |

||

5.7.1. DESCRIPTION OF RESIDUAL RISK .......................................................................................................... |

24 |

||

5.7.2. RESIDUAL RISK ASSESSMENT............................................................................................................... |

24 |

||

5.8. STABILITY OF TRACTOR - PLOUGH ASSEMBLY ................................................................................... |

25 |

||

|

|

|

9 |

VI. |

GENERAL INFORMATION .................................................................................................... |

27 |

|||

6.1. TECHNICAL DATA FOR POM PLOUGHS........................................................................................... |

27 |

||||

6.2. CONSTRUCTION OF PLOUGH........................................................................................................ |

28 |

||||

6.3. CONSTRUCTIONAL CHANGES ....................................................................................................... |

28 |

||||

VII. |

MAINTENANCE AND SERVICE............................................................................................. |

29 |

|||

7.1. PREPARATION OF THE TRACTOR TO WORK WITH THE PLOUGH.............................................................. |

29 |

||||

7.1.1. TYRES............................................................................................................................................. |

29 |

||||

7.1.2. WHEEL TRACK ................................................................................................................................. |

29 |

||||

7.1.3. THREE-POINT LINKAGE ...................................................................................................................... |

30 |

||||

7.1.4. HYDRAULIC SYSTEM .......................................................................................................................... |

30 |

||||

7.1.5. FRONT AXLE LOAD ............................................................................................................................ |

31 |

||||

7.2. PREPARATION OF THE PLOUGH .................................................................................................... |

31 |

||||

7.2.1. MOUNTING THE PLOUGH ON THE TRACTOR .......................................................................................... |

32 |

||||

7.3. START OF PLOUGHING ............................................................................................................... |

33 |

||||

7.3.1. UPPER ATTACHMENT POINT ............................................................................................................... |

33 |

||||

7.3.2. SPINDLES (BOTTLE SCREWS) ............................................................................................................... |

33 |

||||

7.3.3. BODIES........................................................................................................................................... |

34 |

||||

7.3.4. MOULDBOARDS............................................................................................................................... |

35 |

||||

7.3.5. SUPPORT WHEEL .............................................................................................................................. |

35 |

||||

7.3.6. ADJUSTMENT OF VERTICAL TILT........................................................................................................... |

37 |

||||

7.3.7. ADJUSTMENT OF HORIZONTAL TILT...................................................................................................... |

37 |

||||

7.4. PLOUGH ROTATION................................................................................................................... |

38 |

||||

7.5. SAFETY DEVICES ....................................................................................................................... |

39 |

||||

VIII. |

TRANSPORT...................................................................................................................... |

41 |

|||

8.1. DELIVERY AND UNLOADING......................................................................................................... |

41 |

||||

8.2. TRANSPORT – DRIVING ON PUBLIC ROADS ...................................................................................... |

42 |

||||

8.2.1. SPEED ............................................................................................................................................ |

42 |

||||

IX. |

MAINTENANCE ................................................................................................................... |

43 |

|||

9.1. LUBRICATION .......................................................................................................................... |

43 |

||||

9.2. BOLT TIGHTENING .................................................................................................................... |

45 |

||||

9.3. INSTRUCTIONS FOR PROPER OPERATION......................................................................................... |

46 |

||||

9.4. DETACHMENT OF PLOUGH .......................................................................................................... |

51 |

||||

9.5. STORAGE ............................................................................................................................... |

52 |

||||

9.6. REPLACEMENT OF PARTS ............................................................................................................ |

52 |

||||

9.7. DEFECTS AND THEIR ELIMINATION ................................................................................................ |

53 |

||||

9.8. ENVIRONMENTAL PROTECTION .................................................................................................... |

55 |

||||

9.9. NOISE AND VIBRATIONS ............................................................................................................. |

55 |

||||

X. |

WARRANTY CERTIFICATE ..................................................................................................... |

58 |

|||

10.1. WARRANTY TERMS ................................................................................................................. |

58 |

||||

10.2. WARRANTY TABLE .................................................................................................................. |

59 |

||||

10.3. LIST OF SERVICE WORKS ........................................................................................................... |

59 |

||||

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

XI. PARTS CATALOGUE............................................................................................................. |

61 |

INITIAL EXPLANATIONS

IV. INITIAL EXPLANATIONS

When you receive the machine, please make sure that there are no transport damages, and the machine is complete!

To avoid any misunderstanding, a complaint should be filed immediately. This instruction manual is delivered to the user of the machine at the point of sale. Getting familiar with its provisions and guidelines gives the operator an opportunity to conduct the safe and trouble-free operation of the machine. Failure to observe the provisions of the instruction manual can lead to an accident or the machine breakdown. This may result in the loss of the guarantee and warranty rights.

The instruction manual is provided with the parts catalogue, which is to enable the user to identify the parts and to purchase them in case of possible damage to the machine.

Before any use, check the machine and tractor, with which it is coupled, for work and transport safety.

The operator is responsible for his/her safety and the safety of persons that come into contact with the plough throughout the period of use, operation and storage.

Before using the plough, get acquainted with the instruction manual. Special attention should be paid to the danger warning signs and safety marks placed on the plough. They indicate important information relating to the risk specified in the instruction manual.

4.1. Directions in the instruction manual

The terms: “the left side" or “the right side" used in the instruction manual mean the sides on the left and right hand of the observer facing the direction of the machine travel, respectively.

REMEMBER! The AGRO-MASZ company assumes no responsibility for damage caused by any failure to observe the instruction manual.

In case of any concern or doubt about maintenance and operation, consult the authorised seller or manufacturer’s sales department.

The seller is obliged to fill in the address of the contractor of the warranty service in the warranty certificate.

The company is developing its products and therefore reserves the right to introduce constructional and technological changes and modifications in the equipment.

4.2. User feedback

AGRO-MASZ will be grateful for sending any comments on the use and operation of the machine and on this instruction manual. Instruction manuals are regularly updated, but it is your feedback that enables us to jointly create a user-friendly instruction manual.

Office: AGRO-MASZ Paweł Nowak Tel. +48 44 787 49 24

Fax. +48 44 787 12 02 kontakt@agro-masz.eu

11

12

INITIAL EXPLANATIONS

4.3. Recommendations and descriptions

The recommendations, referred to as: WARNING, ATTENTION,

REMEMBER, are used in order to underline the importance of information.

WARNING! This indicates a possibility of danger, which if not avoided, can lead to cutting or heavier injuries to personnel operating the machine.

ATTENTION! This is used when there is a risk of damage to the machine.

REMEMBER! This is used with complementary information.

This symbol warns about the risk. Information included in the instruction manual and marked by this symbol is particularly important for user of the machine.

Descriptions to figures and diagrams are given next to or near them.

Procedures to be carried out by the machine's operator are given as enumeration:

•Operation 1

•Operation 2 …

Service operations included herein, marked with this symbol should be carried out by a specialized service.

Service operations included herein, marked with this symbol should be carried out by a specialized service.

4.4. Intended use

Mounted rotary ploughs with POM are designed for bed free ploughing of medium and large depth on flat fields and fields with maximum inclination of 8,5o, using left and right bodies alternatively. Ploughs POM2, POM3 are suitable for cooperation with tractors of 40 to 80 HP power. The plough is fitted with safety devices of bodies by means of shear bolts and is intended only for works in agriculture for cultivation of non-stony fields.

Plough should be used, operated and repaired only by personnel familiar with its construction, operation and safety procedures.

The scope of the use compliant with its purpose also includes:

•Observance of provisions of the instruction manual (widely understood regulations related to operation, maintenance, service, settings, repairs and performance),

•Observance of safety regulations, in particular, warning pictograms located on the machine and legal provisions of the country where the machine is operated,

•Use of original spare parts only,

•Observance of maximum permissible loads of the machine (also the recommendations of the manufacturer of the tractor, with which the machine is aggregated).

Any use of the machine other than the above, as recommended by the manufacturer, shall be considered as a misuse.

REMEMBER! Any arbitrary modifications introduced to the machine without consent of the manufacturer shall exempt the manufacturer from the responsibility for machine damages, personal injuries and other material losses.

13

SAFETY

V.SAFETY NOTES

REMEMBER! Before operation and use of the (tractor + plough) assembly, get acquainted with this instruction manual, the construction of the plough and its sub-assemblies, their functions, ranges and adjustment method, paying special attention to information on the work safety. During work it is too late for that!

REMEMBER! Before operation and use of the (tractor + plough) assembly, get acquainted with this instruction manual, the construction of the plough and its sub-assemblies, their functions, ranges and adjustment method, paying special attention to information on the work safety. During work it is too late for that!

The mentioned safety regulations refer to the plough. Notwithstanding, observe the general safety and accident prevention rules as well as road traffic regulations.

WARNING! Observance of the safety rules related to the use included in this instruction manual will allow avoiding personal accidents, damage or premature wear of the machine.

WARNING! Observance of the safety rules related to the use included in this instruction manual will allow avoiding personal accidents, damage or premature wear of the machine.

5.1. General safety rules

The below-mentioned safety regulations refer to the plough aggregated with the tractor. Notwithstanding, always observe general occupational health and safety rules and road traffic regulations.

•In addition to the recommendations included in this instruction manual, follow general occupational health and safety rules as well!

•Observe warning symbols placed on the machine. Their observance is for your own safety!

•The machine can be used only by adults who hold adequate qualifications to drive tractors, and are familiar with instruction manuals of both the plough, and the tractor.

•Use of the machine by minors, and children in particular, is forbidden.

•Before any start, check if the condition of the plough and tractor ensures traffic and work safety.

•The tractor cooperating with the plough must be equipped with ballast weights of the front axle. Balance of the tractor with the machine mounted, its manoeuvrability and braking capacity must be maintained. Observe the maximum permissible load per axle and transport dimensions.

•Stay of any personnel on the machine during work and transport is forbidden. Before operation, make sure that nearby the machine there are no bystanders. Pay special attention to children.

•Lever for the tractor hydraulic sections should be operated only from the driver’s seat.

•Exercise particular caution when the machine is being connected to and disconnected from the tractor. Turn the tractor's engine off, remove the ignition key, and engage the hand brake.

•When the plough is aggregated with the tractor, raised or lowered on the tractor’s hydraulic lift and turned on the headlands, check if there are no bystanders, children in particular, nearby the tractor + plough assembly.

•It is forbidden to approach the plough while it is being lifted and lowered, and turned.

14

SAFETY

•Do not stand between the tractor and the plough while the engine is working.

•When connecting hoses to tractor's hydraulic system make sure the hydraulic system is depressurized. Check position of control levers for the tractor's hydraulic system.

•Appliances controlled by the hydraulic sections can be activated only when there are no personnel within the operation area of the machine. There are crushing and cutting places on the parts activated with the use of the other force than their own (e.g. hydraulic system).

•Rotate the plough once the plough is lifted on the tractor's three-point linkage.

•Raise, lower, tune and start the assembly slowly, without sharp jerks.

•It is forbidden to reverse the tractor and make turns with the lowered plough in the working position.

•While making turns, take the far protruding elements into account, do not use the brakes independent of the tractor.

•Check air pressure in the tractor’s tyres.

•Connect the machine to the tractor as described herein.

•The machine can be connected only to tractors of adequate power and equipped with category 3 rear three-point linkage (in accordance with ISO 730-1:1996). Also remember to choose the tractor's class correctly to ensure its manoeuvrability.

•In order to maintain proper tractor's manoeuvrability, the machine should be connected to the tractor equipped with a set of front axle ballast weights. Pressure of the tractor's front axle with the mounted plough must be at least 20% of the tractor's weight.

•Balance of the tractor with the machine mounted, its manoeuvrability and braking capacity must be maintained. Observe the maximum permissible load per axle and transport dimensions.

•Do not operate the plough on slopes greater than 8.5°.

•Use special, dedicated pins and cotter pins to secure connections between the machine and the tractor. It is forbidden to use any substitute means, such as bolts, rods, wires etc., as these can be sheared or fall out during work or transport, and thus cause an accident or damage to the machine. Diameter of the pins must be compliant with the machine's three-point linkage category.

•All maintenance, repair and adjustment works should be carried out only when the machine is lowered and the tractor's engine is turned off. Remove the ignition key! It is forbidden to remain under the raised plough due to risk of being crushed by machine elements.

•It is forbidden to replace working elements of the machine without proper protection against shifting of the tractor-machine assembly and falling of the machine.

•During repairs requiring the machine to be lifted use stable and strong supports protecting the machine against falling. Do not use supports made of materials that can be easily damaged (e.g. hollow tiles, bricks).

•If working units are clogged during operation, clean the machine by lifting / lowering it few times on the tractor linkage.

•It is forbidden to leave the tractor with the machine mounted on slopes or other sloping areas without protecting it against uncontrolled rolling. Take care while working on the slopes.

•For operation wear working clothes and protective gloves.

•Never leave the tractor with the engine operating. Before leaving the driver’s seat, lower the machine, turn the tractor's engine off, remove the ignition key, and engage the hand brake.

•Do not work with the machine which is defective or incomplete. Also inspect the hydraulic system. The cylinder, hydraulic hoses and connections must be tight. Replace worn or defective parts immediately.

•Due to material wear and tear, flexible hydraulic hoses should be replaced periodically, every 4 years from the date of their manufacture. The date of manufacture, i.e. year and week number, is indicated on hydraulic hoses.

15

SAFETY

•Exercise particular caution when driving on public roads, observe the relevant road traffic rules and regulations. For the time of transport on the public roads, install the following on the plough: warning signs painted in white and red stripes, with lamps: front – white position, rear – red position and red round reflective (warning signs can be ordered at the machine's manufacturer on additional charge or purchased at a point of sale of agricultural machinery) and a warning triangle for slow moving vehicles.

•For transport on public roads protect the plough against rotation by means of a mechanical lock.

•Speed during machine transport should be adjusted to the condition of the road surface.

•During transport, drive the tractor as close to the right side of the road as possible.

•During manoeuvres on roads pay attention to the space around the machine. Exercise particular caution when passing and overtaking, and on curves (the machine is firmly connected to the tractor).

•During transport and work, it is forbidden to stand on the plough or load it with additional ballast weights.

•Detach the plough from the tractor when the plough is supported on right bodies on a firm and level ground, and protected with a lock, with the engine turned off.

•During breaks in operation, the plough should be stored in a place that is inaccessible to unauthorised personnel and animals.

•Pay particular attention when dismantling and use drawings provided in the spare parts catalogue.

•When loading, lifting devices (e.g. forklift truck, overhead crane) can be operated only by personnel with proper qualifications. Elements of the frame (marked on the machine) should be used as fixing points.

5.2.Warning pictograms placed on the plough

The warning labels informing of permanent or periodical hazards are placed by the manufacturer on the machine in easily visible locations. Do not remove them from the machine. These labels should be replaced if worn, damaged or illegible for other reasons.

Warning pictograms can be ordered at the manufacturer of the machine.

Each warning sign consists of two vertically arranged fields (black figures on a yellow background).

1 – figure on a warning triangle background presents a risk (e.g. 1 – risk of rolling of the machine and crushing of the body),

2 – figure presents a way of behaviour to avoid the risk (e.g. 2 – to avoid the risk, secure the wheels of the machine with wedges).

16

SAFETY

The below section presents graphically warning signs, shows their location on the machine, explains what type of risk they indicate and the way to keep safety and avoid hazard.

Additionally, each sign bears a number, which refers to the number of a warning pictogram included in the parts catalogue, which facilitates identification of a label if damaged.

A. Risk due to non-observance of the provisions of the instruction manual!

This risk can result in serious injuries of the operator and bystanders.

Before using the machine, get acquainted with the instruction manual and safety regulations included there.

B. Risk due to uncontrolled rolling of the machine and tractor!

This risk can result in serious injuries, even fatal, to operator of the machine.

Before maintenance or repair works, turn off the tractor's engine and remove the ignition key!

C. Risk of crushing of the limbs by working elements of the machine or cutting by sharp edges!

This risk can result in serious injuries leading to loss of a limb, in extreme cases.

Keep a safe distance from the machine! Exercise particular caution when replacing the working elements!

17

SAFETY

D. Risk of crushing of the body within the three-point linkage operating area!

This risk can result in crushing of chest or other part of the body, or even death of the operator.

It is forbidden to stay between the machine and tractor when fixing the machine and starting the lifting device!

E. Risk of crushing of the hand or fingers by the moving parts of the machine!

This risk can result in serious injuries leading to the loss of fingers, a hand, or even the whole arm.

Never reach into the area of moving elements of machine (e.g. cylinders, plough rotation points, release area of plough bodies), especially during work of the machine or when the tractor's engine is turned on, or the hydraulic installation is being started!

F. Risk of crushing of the whole body due to the machine swing while turning!

This risk can result in serious bodily injuries, including fatal injuries.

Do not stay within the swing area of the machine during work and transport! Keep a safe distance from the plough when it is being swung!

G. Risk of crushing of the whole body due to movement of an unprotected subassembly of the machine!

This risk may cause serious injuries.

When detaching the plough from the tractor, remember to unfold the support foot and secure it with cotter!

18

SAFETY

H. Marking of a place to fasten loading slings!

These are suggested places to maintain the safe loading / unloading of the machine and its balance while it is hanging on ropes, belts or chains.

Always take the weight of the lifted machine into account!

5.3. Location of warning labels on the machine

19

SAFETY

5.4. Other risks

In addition to the risks defined in the section 5.2. and presented in the form of warning pictograms placed on the machine, the other risks described by manufacturer in this section can also appear during operation.

5.4.1.Wiring system

•Electrical devices, such as lighting system, are powered by 12V current.

•Too high or too low voltage can cause malfunction of an electronic device or cause its damage!

•Use of non-original elements of electrical and electronic devices and improper fuses can result in a breakdown!

•Take special care when installing electrically operated devices. Improper connection to the tractor's battery, in extreme cases, can result in a fire or explosion of the battery!

•When removing the electrical and electronic devices from the machine, protect their elements (plugs, cables, etc.) properly against moisture and atmospheric agents.

5.4.2.Hydraulic system

•Hydraulic system works under high pressure!

•Hydraulic hoses of the machine can be connected to the tractor only when hydraulic systems, of both the machine mounted and the tractor, are under pressure-free conditions.

•Hydraulic hoses of the machine should be connected to hydraulic connectors of the tractor, paying attention to their correct arrangement! Improper connection can result in a breakdown of the mounted machine or the tractor!

•Hoses of the hydraulic system should be controlled regularly for tightness and damages.

•Damaged hoses should be replaced immediately only with original hoses, as recommended by the machine's manufacturer!

•Period of use (as intended) of hydraulic hoses should not be longer than 4 years.

•Do not work with the machine, in which hydraulic system is not tight! There is a risk of a serious breakdown!

•There is a risk of being cut by the machine elements, which are moved by means of the hydraulic system.

•During work and operation of the machine, there is a risk of cutting a skin of face, hand, and in particular eyes caused by oil splashing!

•It is forbidden to seal hydraulic hoses manually!

•In case of skin burns or oil penetration into the body, seek medical attention immediately!

•When checking the condition of the hydraulic hoses, use appropriate equipment and protective clothing. It is recommended to check the condition of hydraulic hoses by a specialized service point on a yearly basis.

20

SAFETY

•It is forbidden to lock hydraulic system controls in the tractor.

•Before any works on the hydraulic system:

o Lower the mounted machine,

o Remove pressure from the hydraulic system,

o Turn the tractor's engine off and engage the parking brake, o Remove the ignition key.

5.4.3. Residual energy

WARNING! During operation of the machine keep in mind that there is residual electric, pneumatic and mechanical energy on the machine!

WARNING! During operation of the machine keep in mind that there is residual electric, pneumatic and mechanical energy on the machine!

Electric current for powering road lights, high-pressure oil in the hydraulic system intended to power such sub-assemblies as rotation cylinder, ruling cylinder and mechanical energy accumulated in the elastic parts constitute a hazard to an inattentive operator and unauthorised personnel!

The machine's operator must be careful during work and all service and maintenance actions carried out on the machine!

5.4.4. Foreign bodies

During operation of the machine there is a risk that the personnel remaining nearby will be injured by stones, lumps of the soil or other foreign bodies unexpectedly thrown by the machine and its sub-assemblies.

WARNING! During work no person is allowed to remain within the danger zone or move near the machine, until the tractor's engine is turned on!

WARNING! During work no person is allowed to remain within the danger zone or move near the machine, until the tractor's engine is turned on!

5.4.5. Other obstacles

During field works there is a risk of burning or electric shock after contact with overhead power lines or as a result of getting too near to high voltage lines.

WARNING! Observe national regulations regarding a safe distance, within which the live overhead power lines can be approached to!

WARNING! Observe national regulations regarding a safe distance, within which the live overhead power lines can be approached to!

21

SAFETY

5.5.Operator’s obligations and training

5.5.1.Operator’s obligations

The operator must:

•get acquainted with the instruction manual attached to the machine, in particular become familiar with the safety regulations related to work, repair and maintenance,

•take care that the instruction manual is always stored in a place ensuring its maintenance in good condition and to make sure it is always available during work,

•be equipped with proper protective clothes, in accordance with the description included in 5.5.3.,

•get acquainted with the legal regulations, applicable in a specific country, relating to the occupational safety, accident prevention and environmental protection,

•operate the machine according to the manufacturer’s recommendations,

•use only original spare parts and do not make any modifications of the machine without a written consent of the manufacturer.

The machine should be always stored and transported protected in order to avoid accidents caused by contact of the children or bystanders with the machine, untrained in their use!

5.5.2.Personnel training

The machine can be operated, to the same extent as the operator (owner), only by personnel who are authorized and trained by the owner.

The authorized personnel (e.g. an employee) must:

•hold a driving licence compliant with requirements of regulations applicable in a specific country,

•get acquainted with the instruction manual attached to the machine,

•observe general occupational health and safety rules,

•undergo training provided by the owner in regulations relating to work safety (machine installation, operation and maintenance),

•get acquainted with construction and function of the machine.

The above-mentioned provisions are also applicable to any further owner of the machine, when it is sold on the secondary market.

22

SAFETY

5.5.3. Personal Protective Equipment

Before any service works operator of the machine must be equipped with:

•protective gloves protecting against sharp edges of the machine elements and against a direct contact with oils and lubricants,

•clothing which do not constrain movements but, at the same time, are tight to such extent not to be caught by any of the machine subassembly,

•protective goggles, hearing protectors and breathing protection mask, if necessary (when strong wind is encountered during operation or the tractor is not provided with a cab).

5.6.Risk zones

According to a general definition, a danger zone includes surroundings of the machine, within which people can be caught. Places of risk are as follows:

•an area between the tractor and mounted machine,

•immediate vicinity of the machine's moving elements (rotation cylinders, ruling cylinders, springs),

•flat surfaces, such as frame,

•places within plough raising / lowering and rotating areas.

In such surroundings a person can come in contact with:

•foreign bodies ejected by the machine,

•mounted machine due to its unexpected lowering,

•the tractor-plough assembly due to its rolling or shifting when operating and changes in its while turning or reversing, rotating,

•mounted machine due to its working elements, changing their position, driven by mechanical, electric or hydraulic power.

When operating the machine there is a risk that parts of the body of people present nearby will be injured! This risk can be permanent or periodically variable. Pay attention to lumps of soil, stones and other foreign bodies ejected by working elements of the machine in motion, and keep a safe distance!

During operation no person is allowed to remain within reach of the tractormachine assembly, i.e. no person can be present neither directly in front of, behind nor by the machine! It is also forbidden to move nearby and stand on the machine during work.

People cannot stay within the risk area until:

•the tractor's engine and control units for the plough's working elements are off (hydraulic system for rotation control, etc.),

•both the tractor and machine mounted, and its sub-assemblies are protected against rolling and unintended motion.

WARNING! Keep a safe distance!

WARNING! Keep a safe distance!

The risk area varies during work when the machine is running!

23

Loading...

Loading...